IEC 61800-7-203:2007

(Main)Adjustable speed electrical power drive systems - Part 7-203: Generic interface and use of profiles for power drive systems - Profile type 3 specification

Adjustable speed electrical power drive systems - Part 7-203: Generic interface and use of profiles for power drive systems - Profile type 3 specification

IEC 61800-7-203:2007 specifies profiles for Power Drive Systems (PDS) and their mapping to existing communication systems by use of a generic interface model as well as specifies profile type 3 for Power Drive Systems (PDS). Profile type 3 can be mapped onto different communication network technologies.

Entraînements électriques de puissance à vitesse variable - Partie 7-203: Interface générique et utilisation de profils pour les entraînements électriques de puissance - Spécification du profil de type 3

La CEI 61800-7-203:2007 spécifie les profils dédiés aux entraînements électriques de puissance (PDS) et leur mise en correspondance avec les systèmes de communication existants grâce à un modèle d'interface générique ainsi que le profil de type 3 dédié aux entraînements électriques de puissance (PDS). Le profil de type 3 peut être mis en correspondance sur différentes technologies de réseaux de communication.

General Information

- Status

- Published

- Publication Date

- 26-Nov-2007

- Technical Committee

- SC 22G - Adjustable speed electric power drive systems (PDS)

- Drafting Committee

- WG 10 - TC 22/SC 22G/WG 10

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 20-Nov-2015

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61800-7-203:2007 defines a generic interface and profile type 3 for Adjustable speed electrical power drive systems (Power Drive Systems, PDS). The standard specifies how PDS profiles map to existing communication systems using a generic interface model. Profile type 3 is intended to be adaptable - it can be mapped onto different communication network technologies, enabling interoperable drive integration in automation and process systems.

Key Topics

- Generic interface model for Power Drive Systems, including the Base Model and Drive Model

- Profile type 3 specification (PROFIdrive-related concepts present in the document)

- Data types and profile-specific formats (normalised values, fixed-point values, bit sequences, time constants)

- Parameter model: global/local parameter handling, access methods and parameter definitions

- Application models and application classes (multiple classes defining functional scope and I/O)

- Drive control application process: axis type Drive Object architecture, control/status words, operating modes and state machines

- Motion and position control: setpoint channels, homing, traversing tasks, position feedback interfaces and sensor mapping

- Dynamic Servo Control (DSC) and position control circuits

- Diagnostics and fault handling: warnings, messages, fault buffers, acknowledgement procedures

- Integration for process technology incl. VIK‑NAMUR style commands and state diagrams

- Mapping to communication networks - how profile type 3 can be applied across different fieldbus and industrial Ethernet technologies

Applications

IEC 61800-7-203 is practical for:

- System integrators designing multi-vendor drive systems that require interoperability across networks

- Drive manufacturers implementing a standardized interface profile (Profile type 3) so their devices can be integrated into higher-level automation

- Control engineers specifying motion control, position feedback and servo loops within machine and process automation

- Automation architects mapping PDS profiles onto fieldbus or industrial Ethernet for deterministic control and diagnostics

Benefits include consistent parameter access, standardized operating modes and state machines, reliable diagnostics and simpler multi-axis/multi-drive integration.

Who uses this standard

- Drive and inverter manufacturers

- Machine builders and OEMs

- Control and automation engineers

- System integrators and procurement specialists focused on industrial communication and motion control

Related Standards

- Other parts of the IEC 61800-7 series (generic interfaces and profiles for power drive systems)

- Fieldbus and industrial Ethernet specifications (for mapping Profile type 3 to specific network technologies)

- PROFIdrive-related profiles and documentation where PROFIdrive terminology and structures are used

Keywords: IEC 61800-7-203, Profile type 3, Power Drive Systems, PDS, generic interface, adjustable speed drives, PROFIdrive, drive integration, motion control, position feedback, industrial communication.

IEC 61800-7-203:2007 - Adjustable speed electrical power drive systems - Part 7-203: Generic interface and use of profiles for power drive systems - Profile type 3 specification Released:11/27/2007 Isbn:2831893771

IEC 61800-7-203:2007 - Adjustable speed electrical power drive systems - Part 7-203: Generic interface and use of profiles for power drive systems - Profile type 3 specification Released:11/27/2007 Isbn:9782832207109

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 61800-7-203:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Adjustable speed electrical power drive systems - Part 7-203: Generic interface and use of profiles for power drive systems - Profile type 3 specification". This standard covers: IEC 61800-7-203:2007 specifies profiles for Power Drive Systems (PDS) and their mapping to existing communication systems by use of a generic interface model as well as specifies profile type 3 for Power Drive Systems (PDS). Profile type 3 can be mapped onto different communication network technologies.

IEC 61800-7-203:2007 specifies profiles for Power Drive Systems (PDS) and their mapping to existing communication systems by use of a generic interface model as well as specifies profile type 3 for Power Drive Systems (PDS). Profile type 3 can be mapped onto different communication network technologies.

IEC 61800-7-203:2007 is classified under the following ICS (International Classification for Standards) categories: 29.200 - Rectifiers. Convertors. Stabilized power supply; 35.100.05 - Multilayer applications. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61800-7-203:2007 has the following relationships with other standards: It is inter standard links to IEC 61800-7-203:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61800-7-203:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61800-7-203

Edition 1.0 2007-11

INTERNATIONAL

STANDARD

Adjustable speed electrical power drive systems –

Part 7-203: Generic interface and use of profiles for power drive systems –

Profile type 3 specification

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61800-7-203

Edition 1.0 2007-11

INTERNATIONAL

STANDARD

Adjustable speed electrical power drive systems –

Part 7-203: Generic interface and use of profiles for power drive systems –

Profile type 3 specification

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

XH

ICS 29.200; 35.100.05 ISBN 2-8318-9377-1

– 2 – 61800-7-203 © IEC:2007(E)

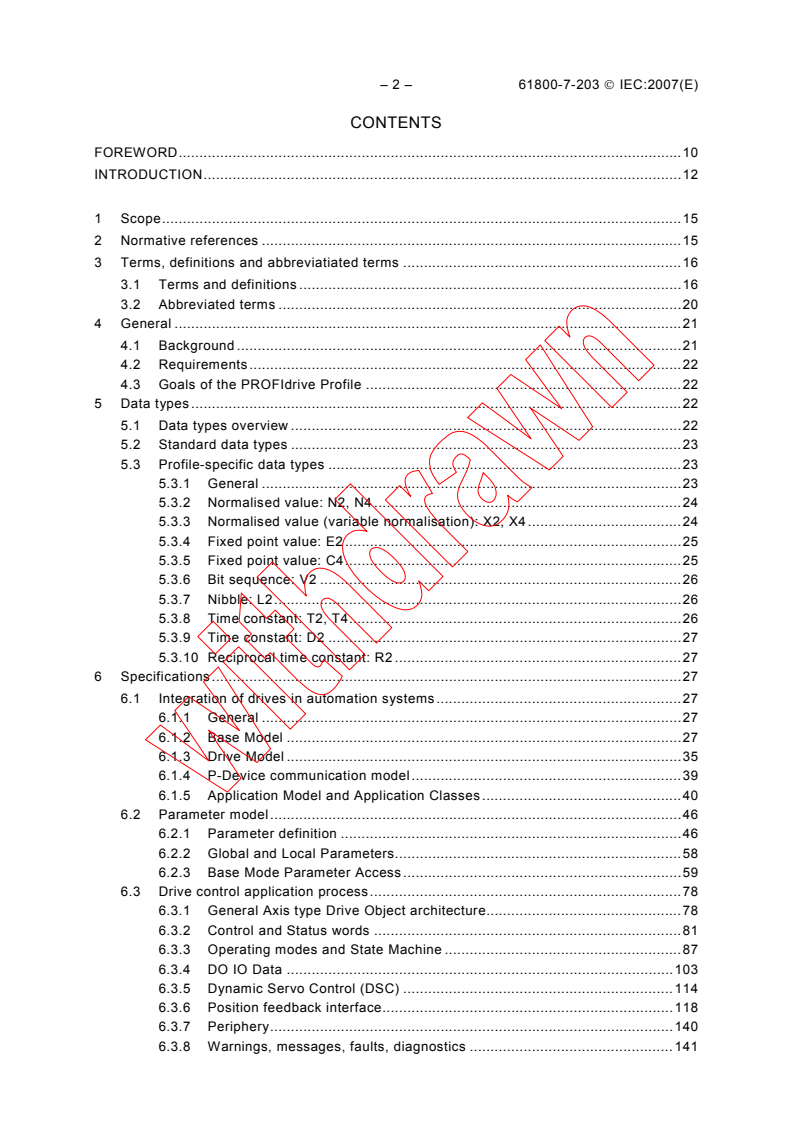

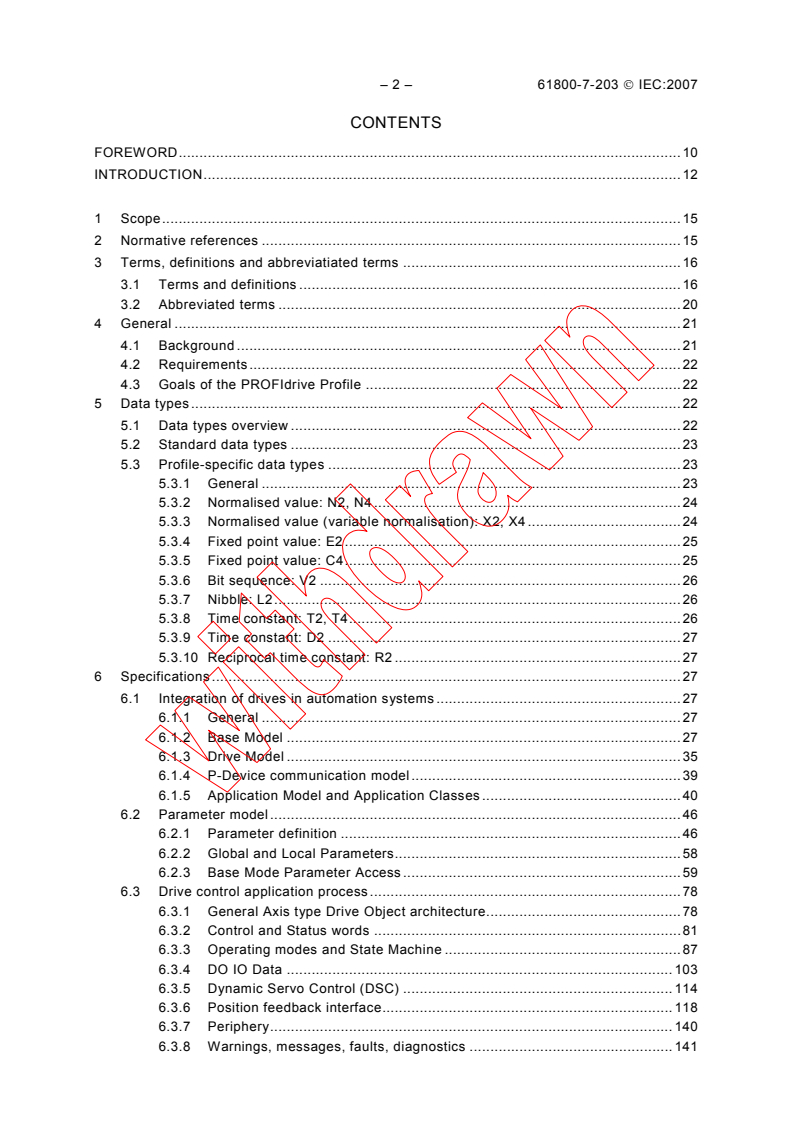

CONTENTS

FOREWORD.10

INTRODUCTION.12

1 Scope.15

2 Normative references .15

3 Terms, definitions and abbreviatiated terms .16

3.1 Terms and definitions .16

3.2 Abbreviated terms .20

4 General .21

4.1 Background .21

4.2 Requirements.22

4.3 Goals of the PROFIdrive Profile .22

5 Data types.22

5.1 Data types overview .22

5.2 Standard data types .23

5.3 Profile-specific data types .23

5.3.1 General .23

5.3.2 Normalised value: N2, N4 .24

5.3.3 Normalised value (variable normalisation): X2, X4.24

5.3.4 Fixed point value: E2 .25

5.3.5 Fixed point value: C4.25

5.3.6 Bit sequence: V2 .26

5.3.7 Nibble: L2.26

5.3.8 Time constant: T2, T4.26

5.3.9 Time constant: D2 .27

5.3.10 Reciprocal time constant: R2 .27

6 Specifications .27

6.1 Integration of drives in automation systems.27

6.1.1 General .27

6.1.2 Base Model .27

6.1.3 Drive Model .35

6.1.4 P-Device communication model.39

6.1.5 Application Model and Application Classes .40

6.2 Parameter model.46

6.2.1 Parameter definition .46

6.2.2 Global and Local Parameters.58

6.2.3 Base Mode Parameter Access.59

6.3 Drive control application process.78

6.3.1 General Axis type Drive Object architecture.78

6.3.2 Control and Status words .81

6.3.3 Operating modes and State Machine .87

6.3.4 DO IO Data .103

6.3.5 Dynamic Servo Control (DSC) .114

6.3.6 Position feedback interface.118

6.3.7 Periphery.140

6.3.8 Warnings, messages, faults, diagnostics . 141

61800-7-203 © IEC:2007(E) – 3 –

6.3.9 Identification.150

6.3.10 Drive reset (power-on reset) .153

6.3.11 Operation priority of parameters and control priority . 155

6.3.12 User data reliability.157

6.3.13 Specified DO functions for the Application Classes.161

6.4 Parameter Definition.163

6.4.1 PROFIdrive Parameter listed by Function .163

6.4.2 PROFIdrive Parameter listed by number. 167

6.5 Integration of Drives in Process Technology (VIK-NAMUR) .176

6.5.1 General .176

6.5.2 Commands and Checkback Signals .177

6.5.3 State diagrams .179

6.5.4 Inevitable line interruption and external interlock . 181

6.5.5 Standard telegram .182

Bibliography.184

Figure 1 – Structure of IEC 61800-7.14

Figure 2 – PROFIdrive Devices and there relationship .28

Figure 3 – General Communication Model of a PROFIdrive Automation System .29

Figure 4 – The PROFIdrive Device (consists of one or several Functional Objects).30

Figure 5 – Hierarchical order in the Object Model .31

Figure 6 – PROFIdrive Base Model contains the “Application Layer” and

“Communication Layer”.32

Figure 7 – Typical use case for Clock Synchronous Operation .33

Figure 8 – General Model for Clock Synchronous Operation .34

Figure 9 – Base Model State Machine.35

Figure 10 – General Drive Unit model .36

Figure 11 – General Drive Object architecture .37

Figure 12 – Principle functional model of an Axis type Drive Object .37

Figure 13 – Classes of PROFIdrive P-Devices .38

Figure 14 – Classes of PROFIdrive Drive Units.39

Figure 15 – Overview about the available Communication Services between the

PROFIdrive Devices .39

Figure 16 – Application Class 1 .41

Figure 17 – Application Class 2 .42

Figure 18 – Application Class 3 .43

Figure 19 – Application Class 4 .44

Figure 20 – Application Class 5 .45

Figure 21 – Application Class 6 .46

Figure 22 – Example overview of global and local parameters of a Multi-Axis/Modular

Drive Unit .59

Figure 23 – Byte order for Words and Double words .60

Figure 24 – Data flow for Base Mode Parameter Access.67

Figure 25 – General functional elements of the PROFIdrive Axis type DO.79

Figure 26 – Functional block diagram of the PROFIdrive Axis type DO .80

– 4 – 61800-7-203 © IEC:2007(E)

Figure 27 – General state diagram for all operating modes .89

Figure 28 – General functionality of a PROFIdrive Axis DO with Application Class 1

functionality .91

Figure 29 – Speed setpoint channel for use in Application Class 1 and 4 .92

Figure 30 – General functionality of a PROFIdrive Axis DO with Application Class 4

functionality .93

Figure 31 – Reduced speed setpoint channel for use in Application Class 4 (optional).94

Figure 32 – General functionality of a PROFIdrive Axis DO with Application Class 3

functionality .95

Figure 33 – Functionality of the Motion Controller in the Program submode .96

Figure 34 – Functionality of the Motion Controller in the MDI submode .97

Figure 35 – State diagram of the positioning mode in Program-submode .99

Figure 36 – State diagram of the positioning mode in MDI-submode . 100

Figure 37 – Homing Procedure: Home Position Set.101

Figure 38 – Homing Procedure: Abortion by the controller . 101

Figure 39 – Traversing Task Active.102

Figure 40 – Change of the traversing tasks immediately .102

Figure 41 – Example for configuring a telegram . 111

Figure 42 – Structure of the position control circuit based on the velocity setpoint

interface without DSC .114

Figure 43 – Structure of the position control circuit based on the velocity setpoint

interface with DSC .115

Figure 44 – Example of the sensor interface (Sensor-1: two actual values/Sensor-2:

one actual value) .119

Figure 45 – Actual value format, example 1 .123

Figure 46 – Actual value format, example 2 .123

Figure 47 – Actual value format, example 3 .123

Figure 48 – Actual value format, example 4 .124

Figure 49 – Actual value format, example 5 .124

Figure 50 – Actual value format, example 6 .124

Figure 51 – Actual value format, example 7 .124

Figure 52 – Actual value format, example 8 .125

Figure 53 – State diagram of the position feedback interface with designations of the

states and transitions.130

Figure 54 – Acknowledgement of acknowledgeable sensor error. 135

Figure 55 – Acknowledgement of unacknowledgeable sensor error.136

Figure 56 – Timing diagram: Measurement on the fly – sequence 1 .137

Figure 57 – Timing diagram: Measurement on the fly – sequence 2 .138

Figure 58 – Timing diagram: Reference mark search .139

Figure 59 – Overview about the diagnostic mechanisms of PROFIdrive .141

Figure 60 – Working of the warning mechanism .142

Figure 61 – Overview about the fault buffer mechanism .143

Figure 62 – Fault acknowledgement for the fault buffer mechanism . 144

Figure 63 – Processing of the fault messages in the fault buffer mechanism . 145

Figure 64 – Fault buffer (subsequent system) with example .147

61800-7-203 © IEC:2007(E) – 5 –

Figure 65 – Fault number list with example .148

Figure 66 – Drive reset: Direct initiation (P972 = 1).155

Figure 67 – Example: Long term Sign-Of-Life failure of the controller. 158

Figure 68 – Example: Temporary failure of the controller LS (negative deviation) . 158

Figure 69 – Example: Temporary failure of the controller LS (positive deviation; double

step) .158

Figure 70 – Example: Permanent failure of the DO LS . 159

Figure 71 – Example: Temporary failure of the DO LS (negative deviation). 160

Figure 72 – Example: Temporary failure of the DO LS (positive deviation; double step) .160

Figure 73 – Value of the DO Sign-Of-Life failure counter (axis-specific) with respect to

the transferred controller Sign-Of-Life.161

Figure 74 – Functionality and Interfaces for drive integration according to VIK-NAMUR .176

Figure 75 – Principle structure of the drive interface according to VIK-NAMUR

guideline.177

Figure 76 – Speed setpoint channel for VIK-NAMUR process technology operating

mode .180

Figure 77 – Process technology operating mode, control word 1 bit 15 and status word

1 bit 10,11,13,14.181

Figure 78 – Process technology operating mode, inevitable line interruption and

external interlock .182

Table 1 – Standard data types .23

Table 2 – Profile specific data types .23

Table 3 – N2, N4-Range of values .24

Table 4 – N2, N4-Coding .24

Table 5 – X2, X4-Range of values.25

Table 6 – X2, X4-Coding (example x=12/28) .25

Table 7 – E2-Range of values.25

Table 8 – E2-Coding .25

Table 9 – C4-Range of values.26

Table 10 – V2-Coding .26

Table 11 – L2-Coding .26

Table 12 – T2, T4-Range of values .26

Table 13 – D2-Range of values.27

Table 14 – R2-Range of values.27

Table 15 – Application Classes .40

Table 16 – Parameter definition .46

Table 17 – Parameter description elements .47

Table 18 – Parameter description element "Identifier (ID)" .48

Table 19 – Parameter description element "variable attribute“ .48

Table 20 – Variable index and conversion index for SI units .49

Table 21 – Conversion values for the conversion index (SI units).53

Table 22 – Variable index and conversion index for US units .54

Table 23 – Conversion values for the conversion index (US units) .55

– 6 – 61800-7-203 © IEC:2007(E)

Table 24 – Parameter Description Elements “IO Data Reference Value/IO Data

Normalisation“ .57

Table 25 – Text array for parameter description.57

Table 26 – Text array for the data type Boolean.58

Table 27 – Text array for data type V2 (bit sequence).58

Table 28 – Base mode parameter request.61

Table 29 – Base mode parameter response .61

Table 30 – Permissible combinations consisting of attribute, number of elements and

subindex .64

Table 31 – Coding of the fields in parameter request/parameter response of Base

Mode Parameter Access .64

Table 32 – Error numbers in Base Mode parameter responses .65

Table 33 – General State machine for the Parameter Manager Processing .67

Table 34 – Sequence 1: Parameter request .68

Table 35 – Sequence 1: Parameter response positive with data of data type Word .68

Table 36 – Sequence 1: Parameter response positive with data of data type Double

word .69

Table 37 – Sequence 1: Parameter response, negative .69

Table 38 – Sequence 2: Parameter request .69

Table 39 – Sequence 2: Parameter response, positive.69

Table 40 – Sequence 2: Parameter response, negative .70

Table 41 – Sequence 3: Parameter request .70

Table 42 – Sequence 3: Parameter response, positive.70

Table 43 – Sequence 3: Parameter response, negative .70

Table 44 – Sequence 4: Parameter request .71

Table 45 – Sequence 4: Parameter response, positive.71

Table 46 – Sequence 4: Parameter response, negative .71

Table 47 – Sequence 5: Parameter request .71

Table 48 – Sequence 5: Parameter response, positive.72

Table 49 – Sequence 5: Parameter response, negative .72

Table 50 – Sequence 6: Parameter request .72

Table 51 – Sequence 6: Parameter response (+): all partial accesses OK.73

Table 52 – Sequence 6: Parameter response (-): first and third partial access OK,

second partial access erroneous.73

Table 53 – Sequence 7: Parameter request .73

Table 54 – Sequence 7: Parameter response (+): all partial accesses OK.74

Table 55 – Sequence 7: Parameter response (-): first and third partial access OK,

second partial access erroneous.74

Table 56 – Sequence 8: Parameter request .75

Table 57 – Sequence 8: Parameter response positive with data of the data type word

(for example ID).75

Table 58 – Sequence 8: Parameter response positive with text.75

Table 59 – Sequence 8: Parameter response, negative .75

Table 60 – Sequence 9: Parameter request .76

Table 61 – Sequence 9: Parameter response, positive.76

61800-7-203 © IEC:2007(E) – 7 –

Table 62 – Sequence 9: Parameter response, negative .76

Table 63 – Sequence 10: Parameter request .77

Table 64 – Sequence 10: Parameter response, positive.77

Table 65 – Sequence 10: Parameter response, negative .77

Table 66 – Sequence 11: Request of values, description and text in one request.77

Table 67 – Sequence 11: Parameter response (+): all partial accesses OK.78

Table 68 – Overview on the assignment of the bits of control word 1 .81

Table 69 – Detailed assignment of the common control word 1 bits (STW1) for speed

control/positioning.82

Table 70 – Detailed assignment of the special control word 1 bits (STW1) for speed

control mode.83

Table 71 – Detailed assignment of the special control word 1 bits (STW1) for the

positioning mode.83

Table 72 – Overview on the assignment of the bits of control word 2 .84

Table 73 – Overview on the assignment of the bits of status word 1.84

Table 74 – Detailed assignment of the common status word 1 bits (ZSW1) for the

speed control /positioning mode.85

Table 75 – Detailed assignment of the special status word 1 bits (ZSW1) for the speed

control mode.86

Table 76 – Detailed assignment of the special status word 1 bits (ZSW1) for the

positioning mode.86

Table 77 – Overview on the assignment of the bits of status word 2.86

Table 78 – Structure of “Status word bit Pulses Enabled”.87

Table 79 – Definition of signal SATZANW .98

Table 80 – Definition of signal AKTSATZ .98

Table 81 – Definition of signal MDI_MOD.98

Table 82 – Signal list – assignment.103

Table 83 – Definition of standard telegram 1.105

Table 84 – Definition of standard telegram 2.105

Table 85 – Definition of standard telegram 3.105

Table 86 – Definition of standard telegram 4.106

Table 87 – Definition of standard telegram 5.106

Table 88 – Definition of standard telegram 6.107

Table 89 – Definition of standard telegram 7.107

Table 90 – Definition of standard telegram 9.107

Table 91 – Definition of standard telegram 8.108

Table 92 – Parameters for configuring a telegram.108

Table 93 – Coding of P922 .109

Table 94 – Example A/B for normalising DO IO Data, parameter values. 112

Table 95 – Example A/B for normalising DO IO Data, parameter description elements. 113

Table 96 – Example C for normalising DO IO Data, parameter values. 113

Table 97 – Example C for normalising DO IO Data, parameter description elements. 113

Table 98 – Structure of parameter 979 (sensor format) .120

Table 99 – Subindex 0 (header) of parameter 979 . 120

Table 100 – Subindex 1 (sensor type) of parameter 979 . 121

– 8 – 61800-7-203 © IEC:2007(E)

Table 101 – Subindex 2 (sensor resolution) of parameter 979. 121

Table 102 – Assigning Gx_XIST2 (sensor-x position actual value-2) . 125

Table 103 – Error codes in Gx_XIST2.126

Table 104 – Sensor control word .127

Table 105 – Sensor status word.128

Table 106 – States.131

Table 107 – Transitions .132

Table 108 – Prioritisation of Sensor Control Word. 135

Table 109 – Example for standard telegram with additional peripheral control. 140

Table 110 – Fault buffer parameters .146

Table 111 – Fault codes examples.147

Table 112 – Definition of the fault classes attribute .149

Table 113 – Definition of the PROFIdrive fault classes.149

Table 114 – Structure of parameter 964 (Drive Unit identification) . 150

Table 115 – Definition of the Profile identification number.150

Table 116 – Structure of parameter 975 (DO identification). 151

Table 117 – Structure of P975.5 .151

Table 118 – DO type class definition in P975.5 .151

Table 119 – Assignment of the bits of DO sub class 1 identification in P975.6 . 152

Table 120 – Structure of parameter 974 (Base Mode Parameter Access identification) . 153

Table 121 – PROFIdrive I&M parameter definition . 153

Table 122 – PROFIdrive parameter value definition .154

Table 123 – PROFIdrive error code definition .154

Table 124 – Specified DO functions for the Application Classes. 162

Table 125 – Parameter for “Life sign monitoring“ .163

Table 126 – Parameter for “DO IO DATA-Telegram selection and configuration“.163

Table 127 – Parameter for “Sensor interface“ .164

Table 128 – Parameter for “Fault buffer handling“ . 164

Table 129 – Parameter for “Warning mechanism“ .164

Table 130 – Parameter for “Closed loop control operating mode“. 164

Table 131 – Parameter for “Set and store of the local parameter set“. 164

Table 132 – Parameter for “Set and store complete parameter set“. 165

Table 133 – Parameter for “Drive reset“ .165

Table 134 – Parameter for “Operation priority for write parameters“. 165

Table 135 – Parameter for “DO identification and setup“. 165

Table 136 – Parameter for “Parameter set identification“ . 166

Table 137 – Parameter for “Device identification“. 166

Table 138 – Parameter for “Alternative supervisor DO IO Data control channel“ .166

Table 139 – PROFIdrive Parameter listed by number.167

Table 140 – Overview on the assignment of the bits of control word1 for the process

technology operating mode .177

Table 141 – Overview on the assignment of the bits of status word1 for the process

technology operating mode .178

61800-7-203 © IEC:2007(E) – 9 –

Table 142 – Overview on the assignment of the bits of drive status/fault word for the

process technology operating mode.179

Table 143 – Definition of standard telegram 20 .183

– 10 – 61800-7-203 © IEC:2007(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ADJUSTABLE SPEED ELECTRICAL POWER DRIVE SYSTEMS –

Part 7-203: Generic interface and use

of profiles for power drive systems –

Profile type 3 specification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The International Electrotechnical Commission (IEC) draws attention to the fact that it is

claimed that compliance with this document may involve the use of a patent concerning the

following:

Publication/ Holder Title Derwent Derwent publication

Application serial accession

number Number

EP844542 [SI] Numerical control method 1998- EP844542-A1

and control structure for 274369 27.05.1998;

controlling of movement DE59603496-G

of objects whereby speed 02.12.1999;

control is effected at a EP844542-B1

higher rate than position 27.10.1999

control

The IEC takes no position concerning the evidence, validity and scope of this patent right.

61800-7-203 © IEC:2007(E) – 11 –

The holder of this patent right has assured the IEC that he is willing to negotiate licences

under reasonable and non-discriminatory terms and conditions with applicants throughout the

world. In this respect, the statement of the holder of this patent right is registered with IEC.

Information may be obtained from

[SI] Siemens AG

Corporate Intellectual Property

Licensing & Transactions

Otto-Hahn-Ring 6

81730 Munich

Germany

Attention is drawn to the possibility that some of the elements of this document may be the

subject of patent rights other than those identified above. IEC shall not be held responsible for

identifying any or all such patent rights.

The International Standard IEC 61800-7-203 has been prepared by subcommittee SC 22G:

Adjustable speed electric drive systems incorporating semiconductor power converters, of IEC

technical committee TC 22: Power electronic systems and equipment.

The text of this standard is based on the following documents:

FDIS Report on voting

22G/184/FDIS 22G/192/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61800 series, under the general title Adjustable speed electrical

power drive systems, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. A

...

IEC 61800-7-203 ®

Edition 1.0 2007-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Adjustable speed electrical power drive systems –

Part 7-203: Generic interface and use of profiles for power drive systems –

Profile type 3 specification

Entraînements électriques de puissance à vitesse variable –

Partie 7-203: Interface générique et utilisation de profils pour les entraînements

électriques de puissance – Spécification du profil de type 3

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 61800-7-203 ®

Edition 1.0 2007-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Adjustable speed electrical power drive systems –

Part 7-203: Generic interface and use of profiles for power drive systems –

Profile type 3 specification

Entraînements électriques de puissance à vitesse variable –

Partie 7-203: Interface générique et utilisation de profils pour les entraînements

électriques de puissance – Spécification du profil de type 3

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XH

CODE PRIX

ICS 29.200; 35.100.05 ISBN 978-2-83220-710-9

– 2 – 61800-7-203 IEC:2007

CONTENTS

FOREWORD . 10

INTRODUCTION . 12

1 Scope . 15

2 Normative references . 15

3 Terms, definitions and abbreviatiated terms . 16

3.1 Terms and definitions . 16

3.2 Abbreviated terms . 20

4 General . 21

4.1 Background . 21

4.2 Requirements . 22

4.3 Goals of the PROFIdrive Profile . 22

5 Data types . 22

5.1 Data types overview . 22

5.2 Standard data types . 23

5.3 Profile-specific data types . 23

5.3.1 General . 23

5.3.2 Normalised value: N2, N4 . 24

5.3.3 Normalised value (variable normalisation): X2, X4 . 24

5.3.4 Fixed point value: E2 . 25

5.3.5 Fixed point value: C4 . 25

5.3.6 Bit sequence: V2 . 26

5.3.7 Nibble: L2 . 26

5.3.8 Time constant: T2, T4 . 26

5.3.9 Time constant: D2 . 27

5.3.10 Reciprocal time constant: R2 . 27

6 Specifications . 27

6.1 Integration of drives in automation systems . 27

6.1.1 General . 27

6.1.2 Base Model . 27

6.1.3 Drive Model . 35

6.1.4 P-Device communication model . 39

6.1.5 Application Model and Application Classes . 40

6.2 Parameter model . 46

6.2.1 Parameter definition . 46

6.2.2 Global and Local Parameters . 58

6.2.3 Base Mode Parameter Access . 59

6.3 Drive control application process . 78

6.3.1 General Axis type Drive Object architecture. 78

6.3.2 Control and Status words . 81

6.3.3 Operating modes and State Machine . 87

6.3.4 DO IO Data . 103

6.3.5 Dynamic Servo Control (DSC) . 114

6.3.6 Position feedback interface . 118

6.3.7 Periphery . 140

6.3.8 Warnings, messages, faults, diagnostics . 141

61800-7-203 IEC:2007 – 3 –

6.3.9 Identification . 150

6.3.10 Drive reset (power-on reset) . 153

6.3.11 Operation priority of parameters and control priority . 155

6.3.12 User data reliability . 157

6.3.13 Specified DO functions for the Application Classes . 161

6.4 Parameter Definition . 163

6.4.1 PROFIdrive Parameter listed by Function . 163

6.4.2 PROFIdrive Parameter listed by number . 167

6.5 Integration of Drives in Process Technology (VIK-NAMUR) . 176

6.5.1 General . 176

6.5.2 Commands and Checkback Signals . 177

6.5.3 State diagrams . 179

6.5.4 Inevitable line interruption and external interlock . 181

6.5.5 Standard telegram . 182

Bibliography . 184

Figure 1 – Structure of IEC 61800-7. 14

Figure 2 – PROFIdrive Devices and there relationship . 28

Figure 3 – General Communication Model of a PROFIdrive Automation System . 29

Figure 4 – The PROFIdrive Device (consists of one or several Functional Objects) . 30

Figure 5 – Hierarchical order in the Object Model . 31

Figure 6 – PROFIdrive Base Model contains the “Application Layer” and

“Communication Layer” . 32

Figure 7 – Typical use case for Clock Synchronous Operation . 33

Figure 8 – General Model for Clock Synchronous Operation . 34

Figure 9 – Base Model State Machine . 35

Figure 10 – General Drive Unit model . 36

Figure 11 – General Drive Object architecture . 37

Figure 12 – Principle functional model of an Axis type Drive Object . 37

Figure 13 – Classes of PROFIdrive P-Devices . 38

Figure 14 – Classes of PROFIdrive Drive Units . 39

Figure 15 – Overview about the available Communication Services between the

PROFIdrive Devices . 39

Figure 16 – Application Class 1 . 41

Figure 17 – Application Class 2 . 42

Figure 18 – Application Class 3 . 43

Figure 19 – Application Class 4 . 44

Figure 20 – Application Class 5 . 45

Figure 21 – Application Class 6 . 46

Figure 22 – Example overview of global and local parameters of a Multi-Axis/Modular

Drive Unit . 59

Figure 23 – Byte order for Words and Double words . 60

Figure 24 – Data flow for Base Mode Parameter Access . 67

Figure 25 – General functional elements of the PROFIdrive Axis type DO . 79

Figure 26 – Functional block diagram of the PROFIdrive Axis type DO . 80

– 4 – 61800-7-203 IEC:2007

Figure 27 – General state diagram for all operating modes . 89

Figure 28 – General functionality of a PROFIdrive Axis DO with Application Class 1

functionality . 91

Figure 29 – Speed setpoint channel for use in Application Class 1 and 4 . 92

Figure 30 – General functionality of a PROFIdrive Axis DO with Application Class 4

functionality . 93

Figure 31 – Reduced speed setpoint channel for use in Application Class 4 (optional) . 94

Figure 32 – General functionality of a PROFIdrive Axis DO with Application Class 3

functionality . 95

Figure 33 – Functionality of the Motion Controller in the Program submode . 96

Figure 34 – Functionality of the Motion Controller in the MDI submode . 97

Figure 35 – State diagram of the positioning mode in Program-submode . 99

Figure 36 – State diagram of the positioning mode in MDI-submode . 100

Figure 37 – Homing Procedure: Home Position Set . 101

Figure 38 – Homing Procedure: Abortion by the controller . 101

Figure 39 – Traversing Task Active . 102

Figure 40 – Change of the traversing tasks immediately . 102

Figure 41 – Example for configuring a telegram . 111

Figure 42 – Structure of the position control circuit based on the velocity setpoint

interface without DSC . 114

Figure 43 – Structure of the position control circuit based on the velocity setpoint

interface with DSC . 115

Figure 44 – Example of the sensor interface (Sensor-1: two actual values/Sensor-2:

one actual value) . 119

Figure 45 – Actual value format, example 1 . 123

Figure 46 – Actual value format, example 2 . 123

Figure 47 – Actual value format, example 3 . 123

Figure 48 – Actual value format, example 4 . 124

Figure 49 – Actual value format, example 5 . 124

Figure 50 – Actual value format, example 6 . 124

Figure 51 – Actual value format, example 7 . 124

Figure 52 – Actual value format, example 8 . 125

Figure 53 – State diagram of the position feedback interface with designations of the

states and transitions . 130

Figure 54 – Acknowledgement of acknowledgeable sensor error. 135

Figure 55 – Acknowledgement of unacknowledgeable sensor error . 136

Figure 56 – Timing diagram: Measurement on the fly – sequence 1 . 137

Figure 57 – Timing diagram: Measurement on the fly – sequence 2 . 138

Figure 58 – Timing diagram: Reference mark search . 139

Figure 59 – Overview about the diagnostic mechanisms of PROFIdrive . 141

Figure 60 – Working of the warning mechanism . 142

Figure 61 – Overview about the fault buffer mechanism . 143

Figure 62 – Fault acknowledgement for the fault buffer mechanism . 144

Figure 63 – Processing of the fault messages in the fault buffer mechanism . 145

Figure 64 – Fault buffer (subsequent system) with example . 147

61800-7-203 IEC:2007 – 5 –

Figure 65 – Fault number list with example . 148

Figure 66 – Drive reset: Direct initiation (P972 = 1) . 155

Figure 67 – Example: Long term Sign-Of-Life failure of the controller . 158

Figure 68 – Example: Temporary failure of the controller LS (negative deviation) . 158

Figure 69 – Example: Temporary failure of the controller LS (positive deviation; double

step) . 158

Figure 70 – Example: Permanent failure of the DO LS . 159

Figure 71 – Example: Temporary failure of the DO LS (negative deviation) . 160

Figure 72 – Example: Temporary failure of the DO LS (positive deviation; double step) . 160

Figure 73 – Value of the DO Sign-Of-Life failure counter (axis-specific) with respect to

the transferred controller Sign-Of-Life . 161

Figure 74 – Functionality and Interfaces for drive integration according to VIK-NAMUR . 176

Figure 75 – Principle structure of the drive interface according to VIK-NAMUR

guideline . 177

Figure 76 – Speed setpoint channel for VIK-NAMUR process technology operating

mode . 180

Figure 77 – Process technology operating mode, control word 1 bit 15 and status word

1 bit 10,11,13,14 . 181

Figure 78 – Process technology operating mode, inevitable line interruption and

external interlock . 182

Table 1 – Standard data types . 23

Table 2 – Profile specific data types . 23

Table 3 – N2, N4-Range of values . 24

Table 4 – N2, N4-Coding . 24

Table 5 – X2, X4-Range of values . 25

Table 6 – X2, X4-Coding (example x=12/28) . 25

Table 7 – E2-Range of values . 25

Table 8 – E2-Coding . 25

Table 9 – C4-Range of values . 26

Table 10 – V2-Coding . 26

Table 11 – L2-Coding . 26

Table 12 – T2, T4-Range of values . 26

Table 13 – D2-Range of values . 27

Table 14 – R2-Range of values . 27

Table 15 – Application Classes . 40

Table 16 – Parameter definition . 46

Table 17 – Parameter description elements . 47

Table 18 – Parameter description element "Identifier (ID)" . 48

Table 19 – Parameter description element "variable attribute“ . 48

Table 20 – Variable index and conversion index for SI units . 49

Table 21 – Conversion values for the conversion index (SI units) . 53

Table 22 – Variable index and conversion index for US units . 54

Table 23 – Conversion values for the conversion index (US units) . 55

– 6 – 61800-7-203 IEC:2007

Table 24 – Parameter Description Elements “IO Data Reference Value/IO Data

Normalisation“ . 57

Table 25 – Text array for parameter description . 57

Table 26 – Text array for the data type Boolean . 58

Table 27 – Text array for data type V2 (bit sequence) . 58

Table 28 – Base mode parameter request . 61

Table 29 – Base mode parameter response . 61

Table 30 – Permissible combinations consisting of attribute, number of elements and

subindex . 64

Table 31 – Coding of the fields in parameter request/parameter response of Base

Mode Parameter Access . 64

Table 32 – Error numbers in Base Mode parameter responses . 65

Table 33 – General State machine for the Parameter Manager Processing . 67

Table 34 – Sequence 1: Parameter request . 68

Table 35 – Sequence 1: Parameter response positive with data of data type Word . 68

Table 36 – Sequence 1: Parameter response positive with data of data type Double

word . 69

Table 37 – Sequence 1: Parameter response, negative . 69

Table 38 – Sequence 2: Parameter request . 69

Table 39 – Sequence 2: Parameter response, positive . 69

Table 40 – Sequence 2: Parameter response, negative . 70

Table 41 – Sequence 3: Parameter request . 70

Table 42 – Sequence 3: Parameter response, positive . 70

Table 43 – Sequence 3: Parameter response, negative . 70

Table 44 – Sequence 4: Parameter request . 71

Table 45 – Sequence 4: Parameter response, positive . 71

Table 46 – Sequence 4: Parameter response, negative . 71

Table 47 – Sequence 5: Parameter request . 71

Table 48 – Sequence 5: Parameter response, positive . 72

Table 49 – Sequence 5: Parameter response, negative . 72

Table 50 – Sequence 6: Parameter request . 72

Table 51 – Sequence 6: Parameter response (+): all partial accesses OK . 73

Table 52 – Sequence 6: Parameter response (-): first and third partial access OK,

second partial access erroneous . 73

Table 53 – Sequence 7: Parameter request . 73

Table 54 – Sequence 7: Parameter response (+): all partial accesses OK . 74

Table 55 – Sequence 7: Parameter response (-): first and third partial access OK,

second partial access erroneous . 74

Table 56 – Sequence 8: Parameter request . 75

Table 57 – Sequence 8: Parameter response positive with data of the data type word

(for example ID) . 75

Table 58 – Sequence 8: Parameter response positive with text . 75

Table 59 – Sequence 8: Parameter response, negative . 75

Table 60 – Sequence 9: Parameter request . 76

Table 61 – Sequence 9: Parameter response, positive . 76

61800-7-203 IEC:2007 – 7 –

Table 62 – Sequence 9: Parameter response, negative . 76

Table 63 – Sequence 10: Parameter request . 77

Table 64 – Sequence 10: Parameter response, positive . 77

Table 65 – Sequence 10: Parameter response, negative . 77

Table 66 – Sequence 11: Request of values, description and text in one request . 77

Table 67 – Sequence 11: Parameter response (+): all partial accesses OK . 78

Table 68 – Overview on the assignment of the bits of control word 1 . 81

Table 69 – Detailed assignment of the common control word 1 bits (STW1) for speed

control/positioning. 82

Table 70 – Detailed assignment of the special control word 1 bits (STW1) for speed

control mode . 83

Table 71 – Detailed assignment of the special control word 1 bits (STW1) for the

positioning mode. 83

Table 72 – Overview on the assignment of the bits of control word 2 . 84

Table 73 – Overview on the assignment of the bits of status word 1 . 84

Table 74 – Detailed assignment of the common status word 1 bits (ZSW1) for the

speed control /positioning mode . 85

Table 75 – Detailed assignment of the special status word 1 bits (ZSW1) for the speed

control mode . 86

Table 76 – Detailed assignment of the special status word 1 bits (ZSW1) for the

positioning mode. 86

Table 77 – Overview on the assignment of the bits of status word 2 . 86

Table 78 – Structure of “Status word bit Pulses Enabled” . 87

Table 79 – Definition of signal SATZANW . 98

Table 80 – Definition of signal AKTSATZ . 98

Table 81 – Definition of signal MDI_MOD. 98

Table 82 – Signal list – assignment . 103

Table 83 – Definition of standard telegram 1 . 105

Table 84 – Definition of standard telegram 2 . 105

Table 85 – Definition of standard telegram 3 . 105

Table 86 – Definition of standard telegram 4 . 106

Table 87 – Definition of standard telegram 5 . 106

Table 88 – Definition of standard telegram 6 . 107

Table 89 – Definition of standard telegram 7 . 107

Table 90 – Definition of standard telegram 9 . 107

Table 91 – Definition of standard telegram 8 . 108

Table 92 – Parameters for configuring a telegram . 108

Table 93 – Coding of P922 . 109

Table 94 – Example A/B for normalising DO IO Data, parameter values. 112

Table 95 – Example A/B for normalising DO IO Data, parameter description elements . 113

Table 96 – Example C for normalising DO IO Data, parameter values . 113

Table 97 – Example C for normalising DO IO Data, parameter description elements . 113

Table 98 – Structure of parameter 979 (sensor format) . 120

Table 99 – Subindex 0 (header) of parameter 979 . 120

Table 100 – Subindex 1 (sensor type) of parameter 979 . 121

– 8 – 61800-7-203 IEC:2007

Table 101 – Subindex 2 (sensor resolution) of parameter 979 . 121

Table 102 – Assigning Gx_XIST2 (sensor-x position actual value-2) . 125

Table 103 – Error codes in Gx_XIST2 . 126

Table 104 – Sensor control word . 127

Table 105 – Sensor status word . 128

Table 106 – States . 131

Table 107 – Transitions . 132

Table 108 – Prioritisation of Sensor Control Word . 135

Table 109 – Example for standard telegram with additional peripheral control. 140

Table 110 – Fault buffer parameters . 146

Table 111 – Fault codes examples . 147

Table 112 – Definition of the fault classes attribute . 149

Table 113 – Definition of the PROFIdrive fault classes . 149

Table 114 – Structure of parameter 964 (Drive Unit identification) . 150

Table 115 – Definition of the Profile identification number . 150

Table 116 – Structure of parameter 975 (DO identification) . 151

Table 117 – Structure of P975.5 . 151

Table 118 – DO type class definition in P975.5 . 151

Table 119 – Assignment of the bits of DO sub class 1 identification in P975.6 . 152

Table 120 – Structure of parameter 974 (Base Mode Parameter Access identification) . 153

Table 121 – PROFIdrive I&M parameter definition . 153

Table 122 – PROFIdrive parameter value definition . 154

Table 123 – PROFIdrive error code definition . 154

Table 124 – Specified DO functions for the Application Classes . 162

Table 125 – Parameter for “Life sign monitoring“ . 163

Table 126 – Parameter for “DO IO DATA-Telegram selection and configuration“ . 163

Table 127 – Parameter for “Sensor interface“ . 164

Table 128 – Parameter for “Fault buffer handling“ . 164

Table 129 – Parameter for “Warning mechanism“ . 164

Table 130 – Parameter for “Closed loop control operating mode“ . 164

Table 131 – Parameter for “Set and store of the local parameter set“. 164

Table 132 – Parameter for “Set and store complete parameter set“. 165

Table 133 – Parameter for “Drive reset“ . 165

Table 134 – Parameter for “Operation priority for write parameters“ . 165

Table 135 – Parameter for “DO identification and setup“ . 165

Table 136 – Parameter for “Parameter set identification“ . 166

Table 137 – Parameter for “Device identification“ . 166

Table 138 – Parameter for “Alternative supervisor DO IO Data control channel“ . 166

Table 139 – PROFIdrive Parameter listed by number . 167

Table 140 – Overview on the assignment of the bits of control word1 for the process

technology operating mode . 177

Table 141 – Overview on the assignment of the bits of status word1 for the process

technology operating mode . 178

61800-7-203 IEC:2007 – 9 –

Table 142 – Overview on the assignment of the bits of drive status/fault word for the

process technology operating mode . 179

Table 143 – Definition of standard telegram 20 . 183

– 10 – 61800-7-203 IEC:2007

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ADJUSTABLE SPEED ELECTRICAL POWER DRIVE SYSTEMS –

Part 7-203: Generic interface and use

of profiles for power drive systems –

Profile type 3 specification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...