IEC 60794-1-22:2017

(Main)Optical fibre cables - Part 1-22: Generic specification - Basic optical cable test procedures - Environmental test methods

Optical fibre cables - Part 1-22: Generic specification - Basic optical cable test procedures - Environmental test methods

IEC 60794-1-22:2017 defines test procedures to be used in establishing uniform requirements for the environmental performance of:

- optical fibre cables for use with telecommunication equipment and devices employing similar techniques, and

- cables having a combination of both optical fibres and electrical conductors.

Throughout this document, the wording "optical cable" can also include optical fibre units, microduct fibre units, etc. See IEC 60794-1-2 for a reference guide to test methods of all types and for general requirements and definitions. This second edition cancels and replaces the first edition published in 2012. It constitutes a technical revision. This second edition includes the following significant technical changes with respect to the previous edition:

- new test method designation F16 – Compound flow (drip) [E14 in IEC 60794-1-21];

- new test method F17 – Cable shrinkage test (fibre protrusion);

- new test method F18 – Mid-span temperature cycling test.

Keywords: optical fibre cables for use with telecommunication equipment

Câbles à fibres optiques - Partie 1-22: Spécification générique - Procédures fondamentales d’essais des câbles optiques – Méthodes d’essais d’environnement

IEC 60794-1-22:2017 définit les modes opératoires d’essai ŕ utiliser pour définir des exigences harmonisées pour les performances environnementales

- des câbles à fibres optiques destinés à ętre utilisés avec les équipements et dispositifs de télécommunications employant des techniques similaires, et

- des câbles combinant fibres optiques et conducteurs électriques.

Dans la présente norme, le terme «câble optique» peut également englober les unités de fibres optiques, les unités de fibres en microconduit, etc. Se reporter à l’IEC 60794-1-2 comme guide de référence des méthodes d’essai de tous types, et pour consulter les exigences générales et les définitions. Cette deuxième édition annule et remplace la première édition parue en 2012. Cette édition constitue une révision technique. Cette deuxième édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) nouvelle désignation de la méthode d’essai F16 – Ecoulement (égouttement) des matériaux

de remplissage [E14 dans l'IEC 60794-1-21],

b) nouvelle méthode d’essai F17 – Essai de rétraction du câble (excroissance des fibres),

c) nouvelle méthode d’essai F18 – Essai de cycles de température à mi-portée.

Mots clés: des câbles à fibres optiques destinés à ętre utilisés avec les équipements et dispositifs de télécommunication

General Information

- Status

- Published

- Publication Date

- 04-Oct-2017

- Technical Committee

- SC 86A - Fibres and cables

- Current Stage

- PPUB - Publication issued

- Start Date

- 05-Oct-2017

- Completion Date

- 03-Nov-2017

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

IEC 60794-1-22:2017 - Optical fibre cables - Environmental test methods

Overview

IEC 60794-1-22:2017 specifies basic environmental test procedures for establishing uniform requirements for the environmental performance of optical fibre cables. It applies to optical fibre cables for use with telecommunication equipment as well as cables combining optical fibres and electrical conductors. The term “optical cable” in the document also covers optical fibre units and microduct fibre units. This is the second edition (2017), a technical revision that supersedes the 2012 edition.

Key Topics

The standard provides standardized test methods and reporting details for environmental stresses affecting optical cables. Major technical topics include:

- Temperature effects

- Method F1 - Temperature cycling

- Method F12 - Temperature cycling for cables intended for patch cords

- Method F18 - Mid-span temperature cycling test for exposed buffer tubes (new)

- Water and pressure resistance

- Method F5 - Water penetration (multiple variants)

- Method F10 - Underwater cable resistance to hydrostatic pressure

- Method F13 - Microduct pressure withstand

- Mechanical and material behaviour in environment

- Method F11 - Sheath shrinkage (patch cords)

- Method F17 - Cable shrinkage test (fibre protrusion) (new)

- Method F15 - Cable external freezing test

- Durability and degradation

- Method F9 - Ageing

- Method F14 - Cable UV resistance test

- Method F16 - Compound flow (drip) (new)

- Special environmental exposures

- Method F7 - Nuclear radiation

- Method F8 - Pneumatic resistance

The document also indicates some previously listed tests were deleted and refers users to IEC 60794-1-2 for a reference guide to all test methods, definitions, and general requirements.

Applications

IEC 60794-1-22:2017 is used to:

- Define environmental test requirements in product specifications and tender documents for telecommunication fibre cables

- Guide manufacturers and test laboratories in validating cable environmental performance (temperature cycling, water ingress, UV, ageing)

- Support network operators, procurement teams, and system integrators when assessing suitability of cables for outdoor, aerial, submarine, microduct, or indoor patch-cord applications

- Inform R&D teams and materials suppliers about environmental failure modes (shrinkage, fibre protrusion, compound flow)

Typical users: cable designers, qualification/test engineers, certification bodies, procurement and standards compliance teams.

Related Standards

- IEC 60794-1-2 - Reference guide to test methods, general requirements and definitions for optical fibre cables

- Other parts of IEC 60794 series cover mechanical and performance tests; consult the IEC catalogue for cross-references.

Keywords: optical fibre cables for use with telecommunication equipment, environmental test methods, IEC 60794-1-22, optical cable testing, cable environmental performance.

IEC 60794-1-22:2017 - Optical fibre cables - Part 1-22: Generic specification - Basic optical cable test procedures - Environmental test methods Released:10/5/2017 Isbn:9782832248645

REDLINE IEC 60794-1-22:2017 - Optical fibre cables - Part 1-22: Generic specification - Basic optical cable test procedures - Environmental test methods Released:10/5/2017 Isbn:9782832249260

IEC 60794-1-22:2017 - Optical fibre cables - Part 1-22: Generic specification - Basic optical cable test procedures - Environmental test methods

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 60794-1-22:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Optical fibre cables - Part 1-22: Generic specification - Basic optical cable test procedures - Environmental test methods". This standard covers: IEC 60794-1-22:2017 defines test procedures to be used in establishing uniform requirements for the environmental performance of: - optical fibre cables for use with telecommunication equipment and devices employing similar techniques, and - cables having a combination of both optical fibres and electrical conductors. Throughout this document, the wording "optical cable" can also include optical fibre units, microduct fibre units, etc. See IEC 60794-1-2 for a reference guide to test methods of all types and for general requirements and definitions. This second edition cancels and replaces the first edition published in 2012. It constitutes a technical revision. This second edition includes the following significant technical changes with respect to the previous edition: - new test method designation F16 – Compound flow (drip) [E14 in IEC 60794-1-21]; - new test method F17 – Cable shrinkage test (fibre protrusion); - new test method F18 – Mid-span temperature cycling test. Keywords: optical fibre cables for use with telecommunication equipment

IEC 60794-1-22:2017 defines test procedures to be used in establishing uniform requirements for the environmental performance of: - optical fibre cables for use with telecommunication equipment and devices employing similar techniques, and - cables having a combination of both optical fibres and electrical conductors. Throughout this document, the wording "optical cable" can also include optical fibre units, microduct fibre units, etc. See IEC 60794-1-2 for a reference guide to test methods of all types and for general requirements and definitions. This second edition cancels and replaces the first edition published in 2012. It constitutes a technical revision. This second edition includes the following significant technical changes with respect to the previous edition: - new test method designation F16 – Compound flow (drip) [E14 in IEC 60794-1-21]; - new test method F17 – Cable shrinkage test (fibre protrusion); - new test method F18 – Mid-span temperature cycling test. Keywords: optical fibre cables for use with telecommunication equipment

IEC 60794-1-22:2017 is classified under the following ICS (International Classification for Standards) categories: 33.180.10 - Fibres and cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60794-1-22:2017 has the following relationships with other standards: It is inter standard links to IEC 60794-1-217:2024, IEC 60794-1-218:2025, IEC 60794-1-201:2024, IEC 60794-1-209:2024, IEC 60794-1-216:2025, IEC 60794-1-214:2025, IEC 60794-1-207:2025, IEC 60794-1-213:2024, IEC 60794-1-211:2021, IEC 60794-1-212:2024, IEC 60794-1-208:2025, IEC 60794-1-22:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60794-1-22:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60794-1-22 ®

Edition 2.0 2017-10

INTERNATIONAL

STANDARD

colour

inside

Optical fibre cables –

Part 1-22: Generic specification – Basic optical cable test procedures –

Environmental test methods

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 60794-1-22 ®

Edition 2.0 2017-10

INTERNATIONAL

STANDARD

colour

inside

Optical fibre cables –

Part 1-22: Generic specification – Basic optical cable test procedures –

Environmental test methods

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 33.180.10 ISBN 978-2-8322-4864-5

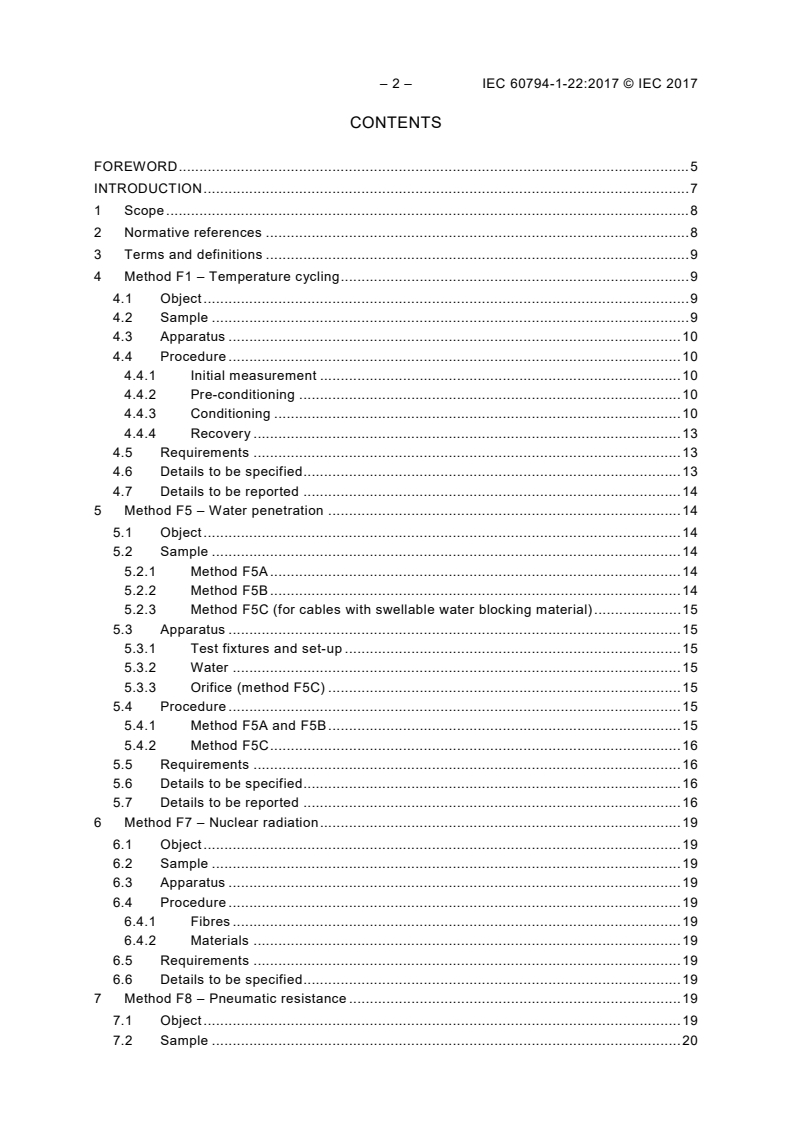

– 2 – IEC 60794-1-22:2017 © IEC 2017

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Method F1 – Temperature cycling . 9

4.1 Object . 9

4.2 Sample . 9

4.3 Apparatus . 10

4.4 Procedure . 10

4.4.1 Initial measurement . 10

4.4.2 Pre-conditioning . 10

4.4.3 Conditioning . 10

4.4.4 Recovery . 13

4.5 Requirements . 13

4.6 Details to be specified . 13

4.7 Details to be reported . 14

5 Method F5 – Water penetration . 14

5.1 Object . 14

5.2 Sample . 14

5.2.1 Method F5A . 14

5.2.2 Method F5B . 14

5.2.3 Method F5C (for cables with swellable water blocking material) . 15

5.3 Apparatus . 15

5.3.1 Test fixtures and set-up . 15

5.3.2 Water . 15

5.3.3 Orifice (method F5C) . 15

5.4 Procedure . 15

5.4.1 Method F5A and F5B . 15

5.4.2 Method F5C . 16

5.5 Requirements . 16

5.6 Details to be specified . 16

5.7 Details to be reported . 16

6 Method F7 – Nuclear radiation . 19

6.1 Object . 19

6.2 Sample . 19

6.3 Apparatus . 19

6.4 Procedure . 19

6.4.1 Fibres . 19

6.4.2 Materials . 19

6.5 Requirements . 19

6.6 Details to be specified . 19

7 Method F8 – Pneumatic resistance . 19

7.1 Object . 19

7.2 Sample . 20

7.3 Apparatus . 20

7.4 Procedure . 20

7.5 Requirement . 20

7.6 Details to be specified . 20

8 Method F9 – Ageing . 21

8.1 Object . 21

8.2 Sample . 21

8.3 Apparatus . 21

8.4 Procedure . 21

8.5 Requirement . 21

8.6 Details to be specified . 21

9 Method F10 – Underwater cable resistance to hydrostatic pressure . 22

9.1 Object . 22

9.2 Sample . 22

9.3 Apparatus . 22

9.4 Procedure . 22

9.5 Requirements . 22

9.6 Details to be specified . 22

10 Method F11 – Sheath shrinkage (cables intended for patch cords) . 22

10.1 Object . 22

10.2 Sample . 23

10.3 Apparatus . 23

10.4 Procedure . 23

10.5 Requirements . 24

10.6 Details to be specified . 24

10.7 Details to be reported . 24

11 Method F12 – Temperature cycling of cables to be terminated with connectors . 24

11.1 Object . 24

11.2 Sample . 24

11.3 Apparatus . 24

11.4 Procedure . 25

11.5 Requirements . 25

11.6 Details to be specified . 25

12 Method F13 – Microduct pressure withstand . 25

12.1 Object . 25

12.2 Sample . 26

12.3 Apparatus . 26

12.4 Procedure . 26

12.5 Requirements . 26

12.6 Details to be specified . 26

13 Method F14 – Cable UV resistance test . 26

13.1 Object . 26

13.2 Sample . 27

13.3 Apparatus . 27

13.4 Procedure . 27

13.4.1 General . 27

13.4.2 Conditioning for outdoor cables (weatherometer test) . 27

13.4.3 Conditioning for indoor cables (QUV test) . 28

– 4 – IEC 60794-1-22:2017 © IEC 2017

13.5 Requirements . 28

13.6 Details to be specified . 28

14 Method F15 – Cable external freezing test . 28

14.1 Object . 28

14.2 Sample . 28

14.3 Apparatus . 28

14.4 Procedure . 28

14.5 Requirements . 29

14.6 Details to be specified . 29

15 Method F16 – Compound flow (drip) . 29

15.1 Object . 29

15.2 Sample . 29

15.3 Apparatus . 30

15.4 Procedure . 30

15.5 Requirements . 31

15.6 Details to be specified . 31

16 Method F17 – Cable shrinkage test (fibre protrusion) . 31

16.1 Object . 31

16.2 Sample . 31

16.3 Apparatus . 31

16.4 Conditioning . 31

16.5 Requirements . 33

16.6 Details to be specified . 33

16.7 Details to be reported . 33

17 Method F18 – Mid-span temperature cycling test for exposed buffer tubes . 34

17.1 Object . 34

17.2 Sample . 34

17.3 Apparatus . 34

17.4 Procedure . 34

17.5 Requirements . 35

17.6 Details to be specified . 35

Annex A (normative) Colour permanence . 36

Bibliography . 37

Figure 1 – Initial cycle(s) procedure . 12

Figure 2 – Final cycle procedure . 13

Figure 3 – Test arrangement for method F5A . 17

Figure 4 – Test arrangement for method F5B . 17

Figure 5 – Test arrangement for method F5C: pre-soaked sample . 17

Figure 6 – Test arrangement for method F5C: pre-soak procedure . 18

Figure 7 – Test arrangement for method F5C: orifice . 18

Figure 8 – Test arrangement for method F5C: longer sample . 18

Figure 9 – Preparation of the cable ends. 32

Figure 10 – Fibre protrusion measurement . 33

Table 1 – Minimum soak time t . 12

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL FIBRE CABLES –

Part 1-22: Generic specification –

Basic optical cable test procedures –

Environmental test methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60794-1-22 has been prepared by subcommittee 86A: Fibres and

cables, of IEC technical committee 86: Fibre optics.

This second edition cancels and replaces the first edition published in 2012. It constitutes a

technical revision.

This second edition includes the following significant technical changes with respect to the

previous edition:

a) new test method designation F16 – Compound flow (drip) [E14 in IEC 60794-1-21];

b) new test method F17 – Cable shrinkage test (fibre protrusion);

c) new test method F18 – Mid-span temperature cycling test.

– 6 – IEC 60794-1-22:2017 © IEC 2017

NOTE Missing numbers in the test methods sequence are intentional. They can suggest a deleted test method or

a test method that was never published.

The text of this International Standard is based on the following documents:

FDIS Report on voting

86A/1813/FDIS 86A/1827/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60794 series, published under the general title Optical fibre

cables, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

IEC 60794-1-2:2003 has been split into five new documents:

• IEC 60794-1-2, Optical fibre cables – Part 1-2: Generic specification – Basic optical cable

test procedures – General guidance

• IEC 60794-1-21, Optical fibre cables – Part 1-21: Generic specification – Basic optical

cable test procedures – Mechanical tests methods

• IEC 60794-1-22, Optical fibre cables – Part 1-22: Generic specification – Basic optical

cable test procedures – Environmental tests methods

• IEC 60794-1-23, Optical fibre cables – Part 1-23: Generic specification – Basic optical

cable test procedures – Cable elements tests methods

• IEC 60794-1-24, Optical fibre cables – Part 1-24: Generic specification – Basic optical

cable test procedures – Electrical tests methods

– 8 – IEC 60794-1-22:2017 © IEC 2017

OPTICAL FIBRE CABLES –

Part 1-22: Generic specification –

Basic optical cable test procedures –

Environmental test methods

1 Scope

This part of IEC 60794 defines test procedures to be used in establishing uniform

requirements for the environmental performance of

• optical fibre cables for use with telecommunication equipment and devices employing

similar techniques, and

• cables having a combination of both optical fibres and electrical conductors.

Throughout this document, the wording "optical cable" can also include optical fibre units,

microduct fibre units, etc.

See IEC 60794-1-2 for a reference guide to test methods of all types and for general

requirements and definitions.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60304, Standard colours for insulation for low-frequency cables and wires

IEC 60544-1, Electrical insulating materials – Determination of the effects of ionizing radiation

– Part 1: Radiation interaction and dosimetry

IEC 60793-1-40, Optical fibres – Part 1-40: Measurement methods and test procedures –

Attenuation

IEC 60793-1-46, Optical fibres – Part 1-46: Measurement methods and test procedures –

Monitoring of changes in optical transmittance

IEC 60793-1-54, Optical fibres – Part 1-54: Measurement methods and test procedures –

Gamma irradiation

IEC 60794-1-1, Optical fibre cables – Part 1-1: Generic specification – General

IEC 60811-503, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 503: Mechanical tests – Shrinkage test for sheaths

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 4892-3, Plastics – Methods of exposure to laboratory light sources – Part 3: Fluorescent

UV lamps

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Method F1 – Temperature cycling

4.1 Object

This measuring method applies to optical fibre cables, which are tested by temperature

cycling in order to determine the stability behaviour of the attenuation of cables submitted to

temperature changes. This method can also be used for evaluation of buffer tubes or other

elements independent of a cable construction, as defined by a detail specification.

Changes in the attenuation of optical fibre cables, which can occur with changing

temperature, are generally the result of buckling or tensioning of the fibres resulting from

differences between their thermal expansion coefficient and the coefficients of the cable

strength and sheath members. Test conditions for temperature-dependent measurements

shall simulate the worst conditions.

This test can be used either for monitoring cable behaviour in the temperature range, which

can occur during storage, transportation and usage, or to check, in a selected temperature

range (usually wider than that required for the above-mentioned case), the stability behaviour

of the attenuation connected to a substantially microbend-free situation of the fibre within the

cable structure.

NOTE 1 Method F12 is a specialized subset of this method, specifically addressing cables for use in patch cords.

NOTE 2 The ageing test, F9, uses method F1 as its pre- and post-test temperature cycle. Often these tests are

done together.

NOTE 3 The cable shrinkage test, F17, uses method F1 as temperature cycling. These tests can be done

together.

4.2 Sample

The sample shall be a factory length or a sample of sufficient length as indicated in the detail

specification but, nevertheless, of length appropriate to achieve the desired accuracy of

attenuation measurements. The sample is additionally defined as the cable sample as

deployed for testing.

In order to gain reproducible values, the cable sample shall be brought into the climatic

chamber in a manner such that the deployment does not affect the measurement. Such

methods could be a loose coil or on a reel with large diameter coils, cushioned reels with a

soft layer or a zero tension facility device.

The ability of the fibre(s) to accommodate differential expansion and contraction (e.g. by

slipping within the cable) could be influenced by the bending radius of the cable. Sample

conditioning should, therefore, be realized as close as possible to normal usage conditions.

The bend diameter of the cable sample shall not violate the minimum bend diameter of the

cable, tube or other unit as specified by the detail specification.

– 10 – IEC 60794-1-22:2017 © IEC 2017

Potential problems are due to an actual difference between the expansion coefficients of the

test sample and of the holder (e.g. reel, basket, plate) which can induce, during thermal

cycles, a significant effect on the test result if "no effect" conditions are not completely

fulfilled. The intent is to simulate the installed condition, in which the cable is generally

straight for the majority of its length.

Parameters of influence are mainly the details of conditioning, the type and materials of the

holder, and the diameter of the sample coil or reel.

General recommendations include the following.

a) The winding diameter shall be large enough to keep the ability of the fibre to

accommodate differential expansion and contraction. A winding diameter substantially

greater than the value selected for cable delivery can be necessary.

b) Any risk of cable expansion (or contraction) limitation created by conditioning shall be

suppressed. In particular, special care should be taken to avoid residual tension on the

cable during the test. For example, a tight winding on a drum is not recommended as it

can limit cable contraction at low temperature. On the other hand, a tight multilayer

winding can limit expansion at high temperature.

c) The use of loose winding is recommended with large diameter coils and cushioned reels

with a soft layer or zero tension facility device.

d) The number of fibres tested shall conform to IEC 60794-1-1.

e) The fixed cable ends as well as connection to the equipment shall be outside of the

temperature chamber to avoid negative influences.

When necessary, in order to limit the length of the cable under test, it is permissible to

concatenate several fibres of the cable and to measure the concatenated fibres. The number

of connections shall be limited and they should be located outside the climatic chamber.

4.3 Apparatus

The apparatus shall consist of the following.

a) An appropriate attenuation measuring apparatus for the determination of attenuation

change (see the test methods of IEC 60793-1-40 and 60793-1-46).

b) a climatic chamber of a suitable size to accommodate the sample and whose temperature

shall be controllable to remain within ±3 °C of the specified testing temperature. One

example of a suitable chamber is given in Clause 8 of IEC 60068-2-14:2009.

c) A temperature sensing device to measure the temperature of the sample, when applicable.

Samples with a large thermal mass can require measurement to verify temperature

stability rather than utilizing a specified exposure period, t (see Table 1).

4.4 Procedure

4.4.1 Initial measurement

The sample shall be visually inspected and a basic value for attenuation at the initial

temperature shall be determined.

4.4.2 Pre-conditioning

Pre-conditioning conditions shall be agreed between customer and supplier.

4.4.3 Conditioning

Figure 1 and Figure 2 show graphically the initial cycle(s) and the final cycle. Together, they

illustrate the temperature cycle sequence to be used. If only one high and low temperature is

specified, use Figure 1; for cycles with multiple high and/or low temperature steps,

use Figure 2.

NOTE The language of the conditioning procedure is written in reference to Figure 1, for clarity. If Figure 2, with

multiple low and/or high temperatures, is used, the appropriate steps are repeated for each temperature. That is,

steps (2) to (4) would be repeated for each additional low temperature and/or steps (5) to (7) would be repeated for

each high temperature.

1) The sample at ambient temperature shall be introduced into the climatic chamber which is

also at that temperature.

2) The temperature in the chamber shall then be lowered to the appropriate low temperature

T at a rate of cooling not to exceed 60 ºC per hour, unless otherwise specified.

A2

NOTE The initial cycles use the temperature extremes, T and T , regardless of whether the cycle

A2 B2

Figure 1 or Figure 2 is being used.

3) After temperature stability in the chamber has been reached, the sample shall be exposed

to the low temperature conditions for the appropriate period t (see (4), below).

4) A minimum soak time is given in Table 1; however, the soak time, t , shall be sufficient to

bring the complete cable to equilibrium with the specified temperature.

5) The temperature in the chamber shall then be raised to the appropriate high temperature

T at a rate of heating not to exceed 60 ºC per hour, unless otherwise specified.

B2

6) After temperature stability in the chamber has been reached, the sample shall be exposed

to the high temperature conditions for the appropriate period t .

7) The temperature in the chamber shall then be lowered to the value of the ambient

temperature at the appropriate rate of cooling. This procedure constitutes one cycle (see

Figure 1 or Figure 2). If this is the intermediate step in a series of cycles, no soak is

required, but no measurements shall be taken.

8) Continue to the next cycle, using steps 2) through 7). The sample shall be subjected to at

least two cycles unless otherwise required by the relevant detail specification. The initial

cycle(s) shall comprise one low temperature and one high temperature, as per Figure 1.

The final cycle shall comprise one low temperature and one high temperature, as per

Figure 1, as required by the relevant detail specification. If multiple low or high

temperature steps are required, the final cycle shall comprise two or more low

temperatures and two or more high temperatures, as per Figure 2. On the last cycle, if

multiple temperatures are specified, the sample shall be held at each intermediate

temperature (T or T ) for the appropriate time t . At the end of the cycling sequence,

A1 B1 1

hold the sample at ambient temperature for the appropriate period t .

9) The attenuation shall be measured at ambient temperature at the start of the first cycle, at

at each of the specified temperature steps (T , T , T , T )

the end of the soak time t

1 A1 A2 B1 B2

in the final cycle, and at ambient temperature at the end of the final cycle. If measurement

at intermediate cycles is required by the detail specification, the measurements shall be

performed in the same manner.

10) Before removal from the chamber, the sample under test shall have reached temperature

stability at ambient temperature.

– 12 – IEC 60794-1-22:2017 © IEC 2017

Table 1 – Minimum soak time t

Minimum soak times for a given sample mass

Sample mass Minimum soak time, t

kg h

Under 0,35 0,5

0,36 to 0,7 1

0,8 to 1,5 2

1,6 to 15 4

16 to 100 8

101 to 250 12

251 to 500 14

Over 501 16

NOTE It is the responsibility of the tester to assure that the soak time is long enough to bring the cable to

equilibrium with the specified temperature.

T

B2

Time (t)

t

T

A2

t

1 cycle

IEC

Figure 1 – Initial cycle(s) procedure

Temperature in the chamber

T

B2

T

B1

Time (t)

T

A1

t t

1 1

T

A2

t t

1 1

1 cycle

IEC

Figure 2 – Final cycle procedure

4.4.4 Recovery

If the ambient temperature is not the standard atmospheric condition to be used for testing

after removal from the chamber, the sample shall be allowed to attain temperature stability at

this latter condition.

The relevant detail specification can call for a specific recovery period for a given type of

sample.

4.5 Requirements

The acceptance criteria for the test shall be as stated in the detail specification. Typical failure

modes include loss of optical continuity, degradation of optical transmittance or physical

damage to the cable. Unless otherwise specified, the change in attenuation shall be

calculated with respect to the attenuation value attained at ambient conditions prior to the

start of the temperature cycling test (4.4.1).

4.6 Details to be specified

The detail specification shall include the following:

a) cable sample length;

b) number of fibres tested if different from 4.2;

c) length of the fibre under test;

d) type of connection between concatenated fibres (optional);

e) temperature limits:

i) T and T (Figure 1), or

A2 B2

ii) T , T , T and T (Figure 2);

A1 A2 B1 B2

f) number of cycles;

g) humidity levels at each temperature extreme (if specified);

Temperature in the chamber

– 14 – IEC 60794-1-22:2017 © IEC 2017

h) maximum change of attenuation (see 4.5) at a specified wavelength as a function of

temperature cycling.

4.7 Details to be reported

Type of winding:

a) coil, reel, other (to be stated, in case of a cushioned reel, the type of cushioning and

material used);

b) winding diameter;

c) single or multilayer;

d) winding tension and zero tension facility device (if any).

Soaking time, t , if different, as specified in Table 1.

5 Method F5 – Water penetration

5.1 Object

This test applies to continuously water-blocked cables. The purpose is to determine the ability

of a cable to block water migration along a specified length.

• F5A evaluates radial ingress of water due to sheath damage.

• F5B evaluates longitudinal ingress of water down the entire cable cross-section designed

to be water-blocked, from an undefined water exposure at a cable end.

• F5C also evaluates longitudinal ingress of water from cable end and is applicable for

cables with swellable water blocking material.

Compliance shall be checked on samples of cable using one of the three following methods

(F5A, F5B or F5C), as stated in the detail specification. Method F5A tests for water migration

between the outer interstices of the optical core and the outer sheath, whereas methods F5B

and F5C test for water migration over the entire cross-section designed to be water-blocked.

Method F5C includes a precondition step, a restricted-flow apparatus, or longer sample to

simulate gradual water exposure at a location along the length of a cable or at a cable end.

Multiple sheath designs, for example armoured cables, are not necessarily designed to be

water blocked. If so, then remove the outer layers before application of the seals.

5.2 Sample

5.2.1 Method F5A

A circumferential portion of sheath and wrapping 25 mm wide shall be removed 3 m from one

end of a sample length of cable and a watertight sleeve shall be applied over the exposed

core so as to bridge the gap in the sheath and allow a 1 m height of water to be applied.

The opposite end of the sample shall be capped to block any water leakage in that direction.

The sample shall be long enough to include the test end length, the length of removed sheath,

and length sufficient to cap the opposite end. Generally, 3,1 m should be sufficient.

5.2.2 Method F5B

A cable sample that shall not exceed 3 m is used.

A watertight seal shall be applied to one end of the sample to allow a 1 m height of water to

be applied.

NOTE 1 If the armour in armoured cables is not designed to be water-blocked, the armour can be removed at the

end before the application of the seal.

NOTE 2 Water pressure can force the fibre and filling compound out of the core tubes of filled cables. Such an

occurrence would be a “test void” result. Therefore, the core can require that the fibres be restrained at the exit

end – as with a screen or cloth covering. Since the filled tubes exhibit robust water blocking ability, testing can

focus on the water penetration characteristics of the rest of the cable. In this case, it is suggested that the core

tube(s) be plugged at either end to avoid this problem.

5.2.3 Method F5C (for cables with swellable water blocking material)

A cable sample, which shall not exceed 3 m, is used for pre-soak or orifice procedure. Unless

one of these procedures is selected, a longer cable sample, which shall not exceed 40 m, can

be used.

A watertight seal shall be applied to one end of the sample to allow a 1 m height of water to

be applied.

NOTE 1 If the armour in armoured cables is not designed to

...

IEC 60794-1-22 ®

Edition 2.0 2017-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Optical fibre cables –

Part 1-22: Generic specification – Basic optical cable test procedures –

Environmental test methods

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 60794-1-22 ®

Edition 2.0 2017-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Optical fibre cables –

Part 1-22: Generic specification – Basic optical cable test procedures –

Environmental test methods

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 33.180.10 ISBN 978-2-8322-4926-0

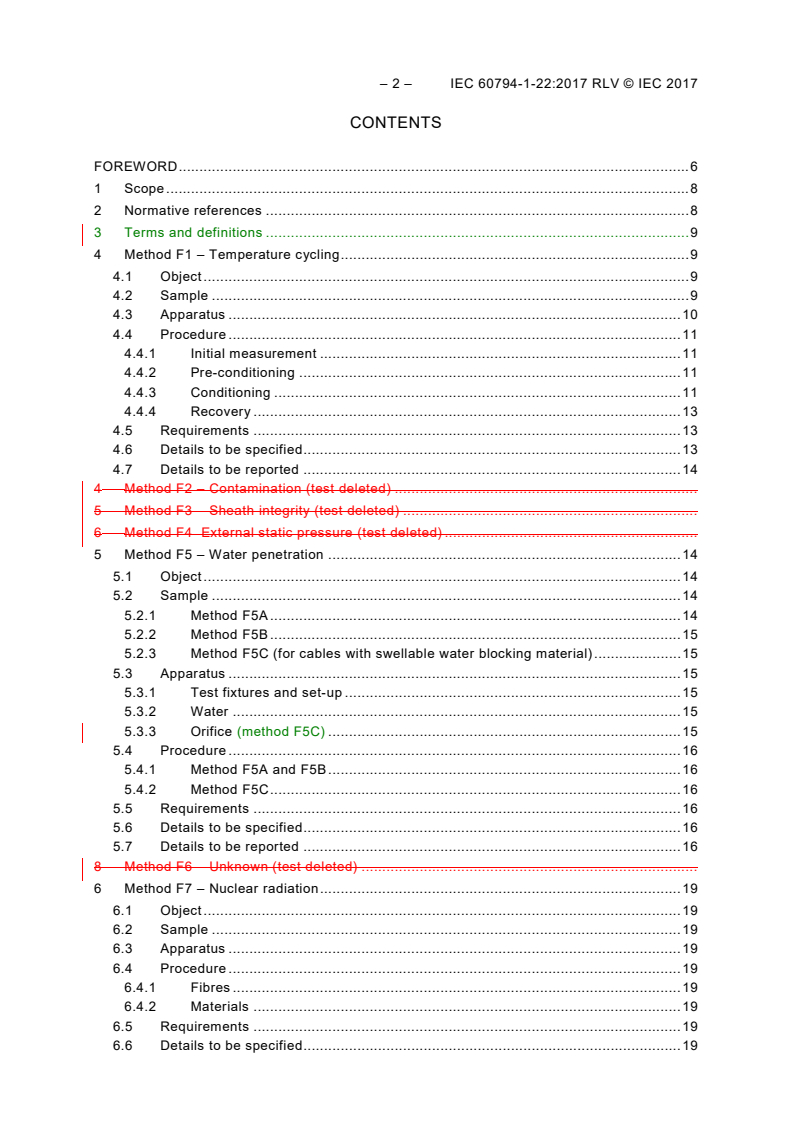

– 2 – IEC 60794-1-22:2017 RLV © IEC 2017

CONTENTS

FOREWORD . 6

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Method F1 – Temperature cycling . 9

4.1 Object . 9

4.2 Sample . 9

4.3 Apparatus . 10

4.4 Procedure . 11

4.4.1 Initial measurement . 11

4.4.2 Pre-conditioning . 11

4.4.3 Conditioning . 11

4.4.4 Recovery . 13

4.5 Requirements . 13

4.6 Details to be specified . 13

4.7 Details to be reported . 14

4 Method F2 – Contamination (test deleted) .

5 Method F3 – Sheath integrity (test deleted) .

6 Method F4 External static pressure (test deleted) .

5 Method F5 – Water penetration . 14

5.1 Object . 14

5.2 Sample . 14

5.2.1 Method F5A . 14

5.2.2 Method F5B . 15

5.2.3 Method F5C (for cables with swellable water blocking material) . 15

5.3 Apparatus . 15

5.3.1 Test fixtures and set-up . 15

5.3.2 Water . 15

5.3.3 Orifice (method F5C) . 15

5.4 Procedure . 16

5.4.1 Method F5A and F5B . 16

5.4.2 Method F5C . 16

5.5 Requirements . 16

5.6 Details to be specified . 16

5.7 Details to be reported . 16

8 Method F6 – Unknown (test deleted) .

6 Method F7 – Nuclear radiation . 19

6.1 Object . 19

6.2 Sample . 19

6.3 Apparatus . 19

6.4 Procedure . 19

6.4.1 Fibres . 19

6.4.2 Materials . 19

6.5 Requirements . 19

6.6 Details to be specified . 19

7 Method F8 – Pneumatic resistance . 20

7.1 Object . 20

7.2 Sample . 20

7.3 Apparatus . 20

7.4 Procedure . 20

7.5 Requirement . 21

7.6 Details to be specified . 21

8 Method F9 – Ageing . 21

8.1 Object . 21

8.2 Sample . 21

8.3 Apparatus . 21

8.4 Procedure . 21

8.5 Requirement . 22

8.6 Details to be specified . 22

9 Method F10 – Underwater cable resistance to hydrostatic pressure . 22

9.1 Object . 22

9.2 Sample . 22

9.3 Apparatus . 22

9.4 Procedure . 22

9.5 Requirements . 23

9.6 Details to be specified . 23

10 Method F11 – Sheath shrinkage (cables intended for patch cords) . 23

10.1 Object . 23

10.2 Sample . 23

10.3 Apparatus . 23

10.4 Procedure . 23

10.5 Requirements . 24

10.6 Details to be specified . 24

10.7 Details to be reported . 25

11 Method F12 – Temperature cycling of cables used for patch cords to be

terminated with connectors . 25

11.1 Object . 25

11.2 Sample . 25

11.3 Apparatus . 25

11.4 Procedure . 25

11.5 Requirements . 26

11.6 Details to be specified . 26

12 Method F13 – Microduct pressure withstand . 26

12.1 Object . 26

12.2 Sample . 26

12.3 Test equipment Apparatus . 26

12.4 Procedure . 27

12.5 Requirements . 27

12.6 Details to be specified . 27

13 Method F14 – Cable UV resistance test . 27

13.1 Object . 27

13.2 Sample . 27

13.3 Apparatus . 27

– 4 – IEC 60794-1-22:2017 RLV © IEC 2017

13.4 Procedure . 28

13.4.1 General . 28

13.4.2 Conditioning for outdoor cables (weatherometer test) . 28

13.4.3 Conditioning for indoor cables (QUV test) . 28

13.5 Requirements . 28

13.6 Details to be specified . 28

14 Method F15 – Cable external freezing test . 29

14.1 Object . 29

14.2 Sample . 29

14.3 Apparatus . 29

14.4 Procedure . 29

14.5 Requirements . 30

14.6 Details to be specified . 30

15 Method F16 – Compound flow (drip) . 30

15.1 Object . 30

15.2 Sample . 30

15.3 Apparatus . 31

15.4 Procedure . 31

15.5 Requirements . 31

15.6 Details to be specified . 32

16 Method F17 – Cable shrinkage test (fibre protrusion) . 32

16.1 Object . 32

16.2 Sample . 32

16.3 Apparatus . 32

16.4 Conditioning . 32

16.5 Requirements . 34

16.6 Details to be specified . 34

16.7 Details to be reported . 34

17 Method F18 – Mid-span temperature cycling test for exposed buffer tubes . 34

17.1 Object . 34

17.2 Sample . 35

17.3 Apparatus . 35

17.4 Procedure . 35

17.5 Requirements . 36

17.6 Details to be specified . 36

Annex A (normative) Colour permanence . 37

Bibliography . 38

Figure 1 – First Initial cycle(s) procedure . 12

Figure 2 – Last Final cycle procedure . 13

Figure 3 – Test arrangement for method F5A . 17

Figure 4 – Test arrangement for method F5B . 17

Figure 5 – Test arrangement for method F5C Alternative: pre-soaked sample . 17

Figure 6 – Test arrangement for method F5C: pre-soak procedure . 18

Figure 7 – Test arrangement for method F5C: orifice . 18

Figure 8 – Test arrangement for method F5C: longer sample . 18

Figure 9 – Preparation of the cable ends. 33

Figure 10 – Fibre protrusion measurement . 34

Table 1 – Minimum soak time t . 12

– 6 – IEC 60794-1-22:2017 RLV © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL FIBRE CABLES –

Part 1-22: Generic specification –

Basic optical cable test procedures –

Environmental test methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60794-1-22 has been prepared by subcommittee 86A: Fibres and

cables, of IEC technical committee 86: Fibre optics.

This second edition cancels and replaces the first edition published in 2012. It constitutes a

technical revision.

This second edition includes the following significant technical changes with respect to the

previous edition:

a) new test method designation F16 – Compound flow (drip) [E14 in IEC 60794-1-21];

b) new test method F17 – Cable shrinkage test (fibre protrusion);

c) new test method F18 – Mid-span temperature cycling test.

NOTE Missing numbers in the test methods sequence are intentional. They can suggest a deleted test method or

a test method that was never published.

The text of this International Standard is based on the following documents:

FDIS Report on voting

86A/1813/FDIS 86A/1827/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60794 series, published under the general title Optical fibre

cables, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 8 – IEC 60794-1-22:2017 RLV © IEC 2017

OPTICAL FIBRE CABLES –

Part 1-22: Generic specification –

Basic optical cable test procedures –

Environmental test methods

1 Scope

This part of IEC 60794 applies to optical fibre cables for use with telecommunication

equipment and devices employing similar techniques, and to cables having a combination of

both optical fibres and electrical conductors.

This part of IEC 60794 defines test procedures to be used in establishing uniform

requirements for the environmental performance of

• optical fibre cables for use with telecommunication equipment and devices employing

similar techniques, and

• cables having a combination of both optical fibres and electrical conductors.

Throughout this document, the wording "optical cable” may can also include optical fibre units,

microduct fibre units, etc.

See IEC 60794-1-2 for a reference guide to test methods of all types and for general

requirements and definitions.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60304, Standard colours for insulation for low-frequency cables and wires

IEC 60544-1, Electrical insulating materials – Determination of the effects of ionizing radiation

– Part 1: Radiation interaction and dosimetry

IEC 60793-1-40, Optical fibres – Part 1-40: Measurement methods and test procedures –

Attenuation

IEC 60793-1-46, Optical fibres – Part 1-46: Measurement methods and test procedures –

Monitoring of changes in optical transmittance

IEC 60793-1-54, Optical fibres – Part 1-54: Measurement methods and test procedures –

Gamma irradiation

IEC 60794-1-1, Optical fibre cables – Part 1-1: Generic specification – General

IEC 60794-1-2, Optical fibre cables – Part 1-2: Generic specification – Basic optical cable test

procedures

IEC 60811-502, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 502: Mechanical tests – Shrinkage test for insulations

IEC 60811-503, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 503: Mechanical tests – Shrinkage test for sheaths

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 4892-3, Plastics – Methods of exposure to laboratory light sources – Part 3: Fluorescent

UV lamps

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Method F1 – Temperature cycling

4.1 Object

This measuring method applies to optical fibre cables, which are tested by temperature

cycling in order to determine the stability behaviour of the attenuation of cables submitted to

temperature changes. This method can also be used for evaluation of buffer tubes or other

elements independent of a cable construction, as defined by a detail specification.

Changes in the attenuation of optical fibre cables, which may can occur with changing

temperature, are generally the result of buckling or tensioning of the fibres resulting from

differences between their thermal expansion coefficient and the coefficients of the cable

strength and sheath members. Test conditions for temperature-dependent measurements

shall simulate the worst conditions.

This test can be used either for monitoring cable behaviour in the temperature range, which

may can occur during storage, transportation and usage, or to check, in a selected

temperature range (usually wider than that required for the above-mentioned case), the

stability behaviour of the attenuation connected to a substantially microbend-free situation of

the fibre within the cable structure.

NOTE 1 Method F12 is a specialized subset of this method, specifically addressing cables for use in patch cords.

NOTE 2 The ageing test, F9, uses method F1 as its pre- and post-test temperature cycle. Often these tests are

done together.

NOTE 3 The cable shrinkage test, F17, uses method F1 as temperature cycling. These tests can be done

together.

4.2 Sample

The sample shall be a factory length or a sample of sufficient length as indicated in the detail

specification but, nevertheless, of length appropriate to achieve the desired accuracy of

– 10 – IEC 60794-1-22:2017 RLV © IEC 2017

attenuation measurements. The sample is additionally defined as the cable sample as

deployed for testing.

In order to gain reproducible values, the cable sample shall be brought into the climatic

chamber in a manner such that the deployment does not affect the measurement. Such

methods could be a loose coil or on a reel with large diameter coils, cushioned reels with a

soft layer or a zero tension facility device.

The ability of the fibre(s) to accommodate differential expansion and contraction (e.g. by

slipping within the cable) could be influenced by the bending radius of the cable. Sample

conditioning should, therefore, be realized as close as possible to normal usage conditions.

The bend diameter of the cable sample shall not violate the minimum bend diameter of the

cable, tube or other unit as specified by the detail specification.

Potential problems are due to an actual difference between the expansion coefficients of the

test sample and of the holder (e.g. reel, basket, plate) which can induce, during thermal

cycles, a significant effect on the test result if "no effect" conditions are not completely

fulfilled. The intent is to simulate the installed condition, in which the cable is generally

straight for the majority of its length.

Parameters of influence are mainly the details of conditioning, the type and materials of the

holder, and the diameter of the sample coil or reel.

General recommendations include the following.

a) The winding diameter shall be large enough to keep the ability of the fibre to

accommodate differential expansion and contraction. A winding diameter substantially

greater than the value selected for cable delivery may can be necessary.

b) Any risk of cable expansion (or contraction) limitation created by conditioning shall be

suppressed. In particular, special care should be taken to avoid residual tension on the

cable during the test. For example, a tight winding on a drum is not recommended as it

can limit cable contraction at low temperature. On the other hand, a tight multilayer

winding can limit expansion at high temperature.

c) The use of loose winding is recommended with large diameter coils and cushioned reels

with a soft layer or zero tension facility device.

d) The number of fibres tested shall conform to IEC 60794-1-1:2011, Annex B.

e) The fixed cable ends as well as connection to the equipment shall be outside of the

temperature chamber to avoid negative influences.

When necessary, in order to limit the length of the cable under test, it is permissible to

concatenate several fibres of the cable and to measure the concatenated fibres. The number

of connections shall be limited and they should be located outside the climatic chamber.

4.3 Apparatus

The apparatus shall consists of the following.

a) An appropriate attenuation measuring apparatus for the determination of attenuation

change (see the test methods of IEC 60793-1-40 and 60793-1-46).

b) a climatic chamber of a suitable size to accommodate the sample and whose temperature

shall be controllable to remain within ±3 °C of the specified testing temperature. One

example of a suitable chamber is given in Clause 8 of IEC 60068-2-14:2009: Test Nb:

Change of temperature with specified rate of change.

c) A temperature sensing device to measure the temperature of the sample, when applicable.

Samples with a large thermal mass may can require measurement to verify temperature

stability rather than utilizing a specified exposure period, t (see Table 1).

4.4 Procedure

4.4.1 Initial measurement

The sample shall be visually inspected and a basic value for attenuation at the initial

temperature shall be determined.

4.4.2 Pre-conditioning

Pre-conditioning conditions shall be agreed between customer and supplier.

4.4.3 Conditioning

Figure 1 and Figure 2 show graphically the initial cycle(s) and the final cycle. Together, they

illustrate the temperature cycle sequence to be used. If only one cycle high and low

temperature is specified, use Figure 1; for cycles with multiple high and/or low temperature

steps, use Figure 2.

NOTE The language of the conditioning procedure is written in reference to Figure 1, for clarity. If Figure 2, with

multiple low and/or high temperatures, is used, the appropriate steps are repeated for each temperature. That is,

steps (2) to (4) would be repeated for each additional low temperature and/or steps (5) to (7) would be repeated for

each high temperature.

1) The sample at ambient temperature shall be introduced into the climatic chamber which is

also at that temperature.

2) The temperature in the chamber shall then be lowered to the appropriate low temperature

T at the appropriate a rate of cooling not to exceed 60 ºC per hour, unless otherwise

A2

specified.

NOTE The initial cycles use the temperature extremes, T and T , regardless of whether the cycle

A2 B2

Figure 1 or Figure 2 is being used.

3) After temperature stability in the chamber has been reached, the sample shall be exposed

to the low temperature conditions for the appropriate period t (see (4), below).

4) A minimum soak time is given in Table 1; however, the soak time, t , must shall be

sufficient to bring the complete cable to equilibrium with the specified temperature.

5) The temperature in the chamber shall then be raised to the appropriate high temperature

T at the appropriate a rate of heating not to exceed 60 ºC per hour, unless otherwise

B2

specified.

6) After temperature stability in the chamber has been reached, the sample shall be exposed

to the high temperature conditions for the appropriate period t .

7) The temperature in the chamber shall then be lowered to the value of the ambient

temperature at the appropriate rate of cooling. This procedure constitutes one cycle (see

Figure 1 or Figure 2). If this is the intermediate step in a series of cycles, no soak is

required, but no measurements shall be taken.

8) Continue to the next cycle, using steps 2) through 7). The sample shall be subjected to at

least two cycles unless otherwise required by the relevant detail specification. The initial

cycle(s) shall comprise one low temperature and one high temperature, as per Figure 1.

The last final cycle shall comprise one or more low temperatures and one or more high

temperatures, as per Figure 2 1, as required by the relevant detail specification. If multiple

low or high temperature steps are required, the final cycle shall comprise two or more low

temperatures and two or more high temperatures, as per Figure 2. On the last cycle, if

multiple temperatures are specified, the sample shall be held at each intermediate

or T ) for the appropriate time t . At the end of the cycling sequence,

temperature (T

A1 B1 1

hold the sample at ambient temperature for the appropriate period t .

9) The attenuation shall be measured at ambient temperature at the start of the first cycle, at

the end of the soak time t at each of the specified temperature steps (T , T , T , T )

1 A1 A2 B1 B2

in the last final cycle, and at ambient temperature at the end of the last final cycle. If

measurement at intermediate cycles is required by the detail specification, the

measurements shall be performed in the same manner.

– 12 – IEC 60794-1-22:2017 RLV © IEC 2017

10) Before removal from the chamber, the sample under test shall have reached temperature

stability at ambient temperature.

Table 1 – Minimum soak time t

Minimum soak times for a given sample mass

Sample mass Minimum soak time, t

kg h

Under 0,35 0,5

0,36 to 0,7 1

0,8 to 1,5 2

1,6 to 15 4

16 to 100 8

101 to 250 12

251 to 500 14

Over 501 16

NOTE It is the responsibility of the tester to assure that the soak time is long enough to bring the cable to

equilibrium with the specified temperature.

T

B2

Time (t)

t

T

A2

t

1 cycle

IEC

Figure 1 – First Initial cycle(s) procedure

Temperature in the chamber

T

B2

T

B1

Time (t)

T

A1

t t

1 1

T

A2

t t

1 1

1 cycle

IEC

Figure 2 – Last Final cycle procedure

4.4.4 Recovery

If the ambient temperature is not the standard atmospheric condition to be used for testing

after removal from the chamber, the sample shall be allowed to attain temperature stability at

this latter condition.

The relevant detail specification may can call for a specific recovery period for a given type of

sample.

4.5 Requirements

The acceptance criteria for the test shall be as stated in the detail specification. Typical failure

modes include loss of optical continuity, degradation of optical transmittance or physical

damage to the cable. Unless otherwise specified, the change in attenuation shall be

calculated with respect to the attenuation value attained at ambient conditions prior to the

start of the temperature cycling test (4.4.1).

4.6 Details to be specified

The detail specification shall include the following:

a) cable sample length;

b) number of fibres tested if different from 4.2;

c) length of the fibre under test typically 1 km minimum, unless otherwise specified;

d) type of connection between concatenated fibres (if any optional);

e) temperature limits:

i) T and T (Figure 1), or

A2 B2

ii) T , T , T and T (Figure 2);

A1 A2 B1 B2

f) number of cycles;

g) humidity levels at each temperature extreme (if any specified);

Temperature in the chamber

– 14 – IEC 60794-1-22:2017 RLV © IEC 2017

h) maximum change of attenuation (see 4.5) at a specified wavelength as a function of

temperature cycling.

4.7 Details to be reported

Type of winding:

a) coil, reel, other (to be stated, in case of a cushioned reel, the type of cushioning and

material used);

b) winding diameter;

c) single or multilayer;

d) winding tension and zero tension facility device (if any).

Soaking time, t , if different, as specified in Table 1.

4 Method F2 – Contamination (test deleted)

5 Method F3 – Sheath integrity (test deleted)

6 Method F4 – External static pressure (test deleted)

5 Method F5 – Water penetration

5.1 Object

This test applies to continuously water-blocked cables. The purpose is to determine the ability

of a cable to block water migration along a specified length.

• F5A evaluates radial ingress of water due to sheath damage.

• F5B evaluates longitudinal ingress of water down the entire cable cross-section designed

to be water-blocked, from an undefined water exposure at a cable end.

• F5C also evaluates longitudinal ingress of water from cable end and is applicable for

cables with swellable water blocking material.

Compliance shall be checked on samples of cable using one of the three following methods

(F5A, F5B or F5C), as stated in the detail specification. Method F5A tests for water migration

between the outer interstices of the optical core and the outer sheath, whereas methods F5B

and F5C test for water migration over the entire cross-section designed to be water-blocked.

Method F5C includes a precondition step, a restricted-flow apparatus, or longer sample to

simulate gradual water exposure at a location along the length of a cable or at a cable end.

NOTE Multiple sheath designs, for example armoured cables, are not necessarily designed to

be water blocked. If so, then remove the outer layers before application of the seals.

5.2 Sample

5.2.1 Method F5A

A circumferential portion of sheath and wrapping 25 mm wide shall be removed 3 m from one

end of a sample length of cable and a watertight sleeve shall be applied over the exposed

core so as to bridge the gap in the sheath and allow a 1 m height of water to be applied.

The opposite end of the sample shall be capped to block any water leakage in that direction.

The sample shall be long enough to include the test end length, the length of removed sheath,

and length sufficient to cap the opposite end. Generally, 3,1 m should be sufficient.

5.2.2 Method F5B

A cable sample that shall not exceed 3 m is used.

A watertight seal shall be applied to one end of the sample to allow a 1 m height of water to

be applied.

NOTE 1 If the armour i

...

IEC 60794-1-22 ®

Edition 2.0 2017-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Optical fibre cables –

Part 1-22: Generic specification – Basic optical cable test procedures –

Environmental test methods

Câbles à fibres optiques –

Partie 1-22: Spécification générique – Modes opératoires de base applicables

aux essais des câbles optiques – Méthodes d’essais d’environnement

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org