IEC 60794-1-22:2012

(Main)Optical fibre cables - Part 1-22: Generic specification - Basic optical cable test procedures - Environmental tests methods

Optical fibre cables - Part 1-22: Generic specification - Basic optical cable test procedures - Environmental tests methods

IEC 60794-1-22:2012(E) applies to optical fibre cables for use with telecommunication equipment and devices employing similar techniques, and to cables having a combination of both optical fibres and electrical conductors. The object of this standard is to define test procedures to be used in establishing uniform requirements for the environmental performance. This edition of IEC 60794-1-22 cancels and replaces the environmental tests part of the second edition of IEC 60794-1-2 published in 2003. It constitutes a technical revision. It has been decided to split the second edition of IEC 60794-1-2 into six new documents. A list of all the parts in the IEC 60794 series, published under the general title optical fibre cables, can be found on the IEC website, www.iec.ch

General Information

- Status

- Published

- Publication Date

- 11-Jun-2012

- Technical Committee

- SC 86A - Fibres and cables

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 05-Oct-2017

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60794-1-22:2012 - "Optical fibre cables – Part 1-22: Generic specification – Basic optical cable test procedures – Environmental test methods" - defines standardized environmental test procedures for optical fibre cables used with telecommunications equipment, including cables that combine optical fibres and electrical conductors. This edition replaces the environmental tests portion of IEC 60794-1-2 (2003) and is part of the wider IEC 60794 series. The standard’s objective is to provide uniform methods to assess environmental performance so manufacturers, test laboratories and specifiers can compare and qualify cable designs reliably.

Key topics and technical scope

The document specifies test objects, sampling, apparatus, procedures, requirements, and the details to be specified and reported for each method. Major environmental test methods include:

- Method F1 – Temperature cycling (initial measurements, pre‑conditioning, conditioning, recovery)

- Method F5 – Water penetration (variants F5A, F5B, F5C for swellable materials)

- Method F7 – Nuclear radiation (effects on fibres and materials)

- Method F8 – Pneumatic resistance

- Method F9 – Ageing (accelerated thermal/oxidative ageing procedures)

- Method F10 – Underwater hydrostatic pressure

- Method F11 – Sheath shrinkage (for patch cords)

- Method F12 – Temperature cycling for patch cords

- Method F13 – Microduct pressure‑withstand

- Method F14 – UV resistance

- Method F15 – External freezing

- Normative annexes such as colour permanence and numerous figures/tables supporting setup and reporting

Note: several tests from earlier editions (e.g., F2, F3, F4, F6) are marked as deleted in this edition.

Practical applications and users

Who uses IEC 60794-1-22:2012:

- Cable manufacturers validating environmental robustness of new designs

- Independent test laboratories performing type and acceptance testing

- Telecommunications operators and system integrators specifying cables for field conditions

- Procurement teams / QA departments ensuring contractual test criteria are met

- Standards writers and certification bodies harmonizing requirements

Typical use cases:

- Qualifying cables for outdoor, underground, ducted, microduct and submarine installations

- Verifying water‑blocking and hydrostatic performance for flooded/underwater routes

- Assessing UV exposure, freeze/thaw tolerance, and long‑term ageing for lifecycle planning

- Ensuring patch cord materials resist sheath shrinkage and temperature cycling

Related standards

- IEC 60794 series (other Parts cover mechanical tests, optical measurements, installation)

- The standard references and cross‑points to IEC publications; official documents and updates are available on the IEC website (www.iec.ch).

Using IEC 60794-1-22:2012 helps ensure consistent, repeatable environmental testing for optical fibre cables so stakeholders can specify, compare and qualify products with confidence.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 60794-1-22:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Optical fibre cables - Part 1-22: Generic specification - Basic optical cable test procedures - Environmental tests methods". This standard covers: IEC 60794-1-22:2012(E) applies to optical fibre cables for use with telecommunication equipment and devices employing similar techniques, and to cables having a combination of both optical fibres and electrical conductors. The object of this standard is to define test procedures to be used in establishing uniform requirements for the environmental performance. This edition of IEC 60794-1-22 cancels and replaces the environmental tests part of the second edition of IEC 60794-1-2 published in 2003. It constitutes a technical revision. It has been decided to split the second edition of IEC 60794-1-2 into six new documents. A list of all the parts in the IEC 60794 series, published under the general title optical fibre cables, can be found on the IEC website, www.iec.ch

IEC 60794-1-22:2012(E) applies to optical fibre cables for use with telecommunication equipment and devices employing similar techniques, and to cables having a combination of both optical fibres and electrical conductors. The object of this standard is to define test procedures to be used in establishing uniform requirements for the environmental performance. This edition of IEC 60794-1-22 cancels and replaces the environmental tests part of the second edition of IEC 60794-1-2 published in 2003. It constitutes a technical revision. It has been decided to split the second edition of IEC 60794-1-2 into six new documents. A list of all the parts in the IEC 60794 series, published under the general title optical fibre cables, can be found on the IEC website, www.iec.ch

IEC 60794-1-22:2012 is classified under the following ICS (International Classification for Standards) categories: 33.180.10 - Fibres and cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60794-1-22:2012 has the following relationships with other standards: It is inter standard links to IEC 60794-1-22:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60794-1-22:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60794-1-22 ®

Edition 1.0 2012-06

INTERNATIONAL

STANDARD

colour

inside

Optical fibre cables –

Part 1-22: Generic specification – Basic optical cable test procedures –

Environmental test methods

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

IEC 60794-1-22 ®

Edition 1.0 2012-06

INTERNATIONAL

STANDARD

colour

inside

Optical fibre cables –

Part 1-22: Generic specification – Basic optical cable test procedures –

Environmental test methods

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

U

ICS 33.180.10 ISBN 978-2-83220-131-2

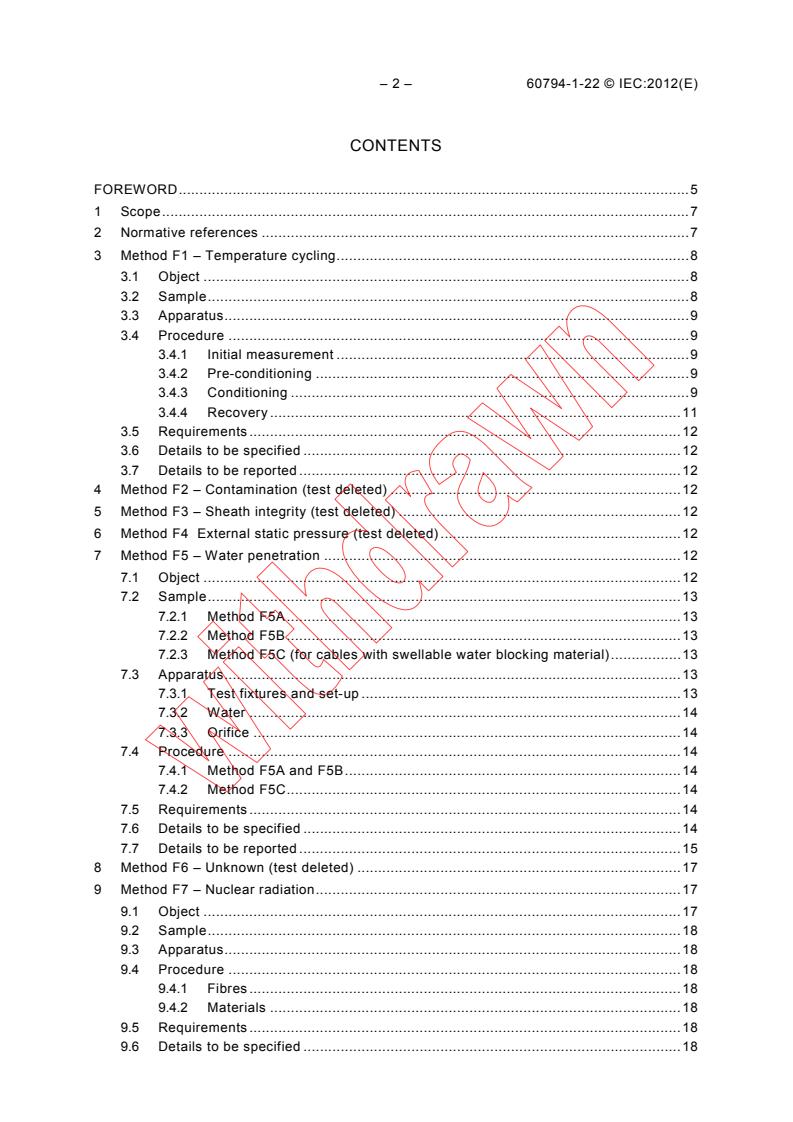

– 2 – 60794-1-22 © IEC:2012(E)

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Method F1 – Temperature cycling . 8

3.1 Object . 8

3.2 Sample . 8

3.3 Apparatus . 9

3.4 Procedure . 9

3.4.1 Initial measurement . 9

3.4.2 Pre-conditioning . 9

3.4.3 Conditioning . 9

3.4.4 Recovery . 11

3.5 Requirements . 12

3.6 Details to be specified . 12

3.7 Details to be reported . 12

4 Method F2 – Contamination (test deleted) . 12

5 Method F3 – Sheath integrity (test deleted) . 12

6 Method F4 External static pressure (test deleted) . 12

7 Method F5 – Water penetration . 12

7.1 Object . 12

7.2 Sample . 13

7.2.1 Method F5A . 13

7.2.2 Method F5B . 13

7.2.3 Method F5C (for cables with swellable water blocking material) . 13

7.3 Apparatus . 13

7.3.1 Test fixtures and set-up . 13

7.3.2 Water . 14

7.3.3 Orifice . 14

7.4 Procedure . 14

7.4.1 Method F5A and F5B . 14

7.4.2 Method F5C . 14

7.5 Requirements . 14

7.6 Details to be specified . 14

7.7 Details to be reported . 15

8 Method F6 – Unknown (test deleted) . 17

9 Method F7 – Nuclear radiation . 17

9.1 Object . 17

9.2 Sample . 18

9.3 Apparatus . 18

9.4 Procedure . 18

9.4.1 Fibres . 18

9.4.2 Materials . 18

9.5 Requirements . 18

9.6 Details to be specified . 18

60794-1-22 © IEC:2012(E) – 3 –

10 Method F8 – Pneumatic resistance . 18

10.1 Object . 18

10.2 Sample . 18

10.3 Apparatus . 18

10.4 Procedure . 18

10.5 Requirement . 19

10.6 Details to be specified . 19

11 Method F9 – Ageing . 19

11.1 Object . 19

11.2 Sample . 19

11.3 Apparatus . 19

11.4 Procedure . 20

11.5 Requirement . 20

11.6 Details to be specified . 20

12 Method F10 – Underwater cable resistance to hydrostatic pressure . 20

12.1 Object . 20

12.2 Sample . 20

12.3 Apparatus . 20

12.4 Procedure . 20

12.5 Requirements . 21

12.6 Details to be specified . 21

13 Method F11 – Sheath shrinkage (cables intended for patch cords) . 21

13.1 Object . 21

13.2 General . 21

13.3 Apparatus . 21

13.4 Conditioning . 21

13.5 Sampling . 21

13.6 Procedure . 22

13.7 Requirements . 22

13.8 Details to be specified . 22

13.9 Details to be reported . 23

14 Method F12 – Temperature cycling of cables used for patch cords . 23

14.1 Object . 23

14.2 Apparatus . 23

14.3 Sample . 23

14.4 Procedure . 23

14.5 Requirements . 23

14.6 Details to be specified . 24

15 Method F13 – Microduct pressure-withstand . 24

15.1 Object . 24

15.2 General . 24

15.3 Samples . 24

15.4 Test equipment . 24

15.5 Procedure . 24

15.6 Requirements . 25

15.7 Details to be specified . 25

16 Method F14 – Cable UV resistance test . 25

16.1 Object . 25

– 4 – 60794-1-22 © IEC:2012(E)

16.2 Sample . 25

16.3 Apparatus . 25

16.4 Procedure . 25

16.5 Conditioning . 25

16.6 Requirements . 26

16.7 Details to be specified . 26

17 Method F15 – Cable external freezing test . 26

17.1 Object . 26

17.2 Sample . 26

17.3 Apparatus . 27

17.4 Procedure . 27

17.5 Requirements . 27

17.6 Details to be specified . 27

Annex A (normative) Colour permanence . 28

Figure 1 – First cycle(s) procedure . 11

Figure 2 – Last cycle procedure . 11

Figure 3 – Method F5-A . 15

Figure 4 – Method F5-B . 15

Figure 5 – Method F5C pre-soaked sample . 16

Figure 6 – Method F5C Alternative pre-soak procedure . 16

Figure 7 – Method F5C Orifice . 17

Figure 8 – Method F5C Longer sample . 17

Table 1 – Minimum soak time t . 10

60794-1-22 © IEC:2012(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OPTICAL FIBRE CABLES –

Part 1-22: Generic specification –

Basic optical cable test procedures –

Environmental test methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60794-1-22 has been prepared by subcommittee 86A: Fibres and

cables, of IEC technical committee 86: Fibre optics.

This edition of IEC 60794-1-22 cancels and replaces the environmental tests part of the

second edition of IEC 60794-1-2 published in 2003. It constitutes a technical revision.

It has been decided to split the second edition of IEC 60794-1-2 into six new documents:

– IEC 60794-1-2, Optical fibre cables – Part 1-2: Generic specification – Basic optical cable

test procedures

– IEC 60794-1-20, Optical fibre cables – Part 1-20: Generic specification – Basic optical

cable test procedures – General and definitions

– IEC 60794-1-21, Optical fibre cables – Part 1-21: Generic specification – Basic optical

cable test procedures – Mechanical tests methods

– 6 – 60794-1-22 © IEC:2012(E)

– IEC 60794-1-22, Optical fibre cables – Part 1-22: Generic specification – Basic optical

cable test procedures – Environmental tests methods

– IEC 60794-1-23, Optical fibre cables – Part 1-23: Generic specification – Basic optical

cable test procedures – Cable elements tests methods

– IEC 60794-1-24, Optical fibre cables – Part 1-24: Generic specification – Basic optical

cable test procedures – Electrical tests methods

The text of this standard is based on the following documents:

CDV Report on voting

86A/1424/CDV 86A/1445/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60794 series, published under the general title Optical fibre

cables, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

60794-1-22 © IEC:2012(E) – 7 –

OPTICAL FIBRE CABLES –

Part 1-22: Generic specification –

Basic optical cable test procedures –

Environmental test methods

1 Scope

This part of IEC 60794 applies to optical fibre cables for use with telecommunication

equipment and devices employing similar techniques, and to cables having a combination of

both optical fibres and electrical conductors.

The object of this standard is to define test procedures to be used in establishing uniform

requirements for the environmental performance.

Throughout the standard the wording “optical cable” may also include optical fibre units,

microduct fibre units, etc.

See IEC 60794-1-2 for general requirements and definitions and reference guide to test

methods of all types.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60304, Standard colours for insulation for low-frequency cables and wires

IEC 60544-1, Electrical insulating materials – Determination of the effects of ionizing radiation

– Part 1: Radiation interaction and dosimetry

IEC 60793-1-40, Optical fibres – Part 1-40: Measurement methods and test procedures –

Attenuation

IEC 60793-1-46, Optical fibres – Part 1-46: Measurement methods and test procedures –

Monitoring of changes in optical transmittance

IEC 60793-1-54, Optical fibres – Part 1-54: Measurement methods and test procedures –

Gamma irradiation

IEC 60794-1-1, Optical fibre cables – Part 1-1: Generic specification – General

IEC 60794-1-2, Optical fibre cables – Part 1-2: Generic specification – Basic optical cable test

procedures

IEC 60811-502, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 502: Mechanical tests – Shrinkage test for insulations

– 8 – 60794-1-22 © IEC:2012(E)

IEC 60811-503, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 503: Mechanical tests – Shrinkage test for sheaths

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 4892-3, Plastics – Methods of exposure to laboratory light sources – Part 3: Fluorescent

UV lamps

3 Method F1 – Temperature cycling

3.1 Object

This measuring method applies to optical fibre cables which are tested by temperature cycling

in order to determine the stability behaviour of the attenuation of cables submitted to

temperature changes.

Changes in the attenuation of optical fibre cables which may occur with changing

temperatures are generally the result of buckling or tensioning of the fibres resulting from

differences between their thermal expansion coefficient and the coefficients of the cable

strength and sheath members. Test conditions for temperature-dependent measurements

shall simulate the worst conditions.

This test can be used either for monitoring cable behaviour in the temperature range which

may occur during storage, transportation and usage or to check, in a selected temperature

range (usually wider than that required for the above-mentioned case), the stability behaviour

of the attenuation connected to a substantially microbend-free situation of the fibre within the

cable structure.

NOTE 1 Method F12 is a specialized subset of this method, specifically addressing cables for use in patchcords.

NOTE 2 The ageing test, F9, uses Method F1 as its pre- and post-test temperature cycle. Often these tests are

done together.

3.2 Sample

The sample shall be a factory length or a sample of sufficient length as indicated in the detail

specification but, nevertheless, of length appropriate to achieve the desired accuracy of

attenuation measurements.

In order to gain reproducible values, the cable sample shall be brought into the climatic

chamber in a manner such that the deployment does not affect the measurement. Such

methods could be a loose coil or on a reel with large diameter coils, cushioned reels with a

soft layer or a zero tension facility device.

The ability of the fibre(s) to accommodate differential expansion and contraction (e.g. by

slipping within the cable) could be influenced by the bending radius of the cable. Sample

conditioning should, therefore, be realized as close as possible to normal usage conditions.

The bend diameter of the cable sample shall not violate the minimum bend diameter of the

cable, tube or other unit as specified by the detail specification.

Potential problems are due to an actual difference between the expansion coefficients of the

test sample and of the holder (e.g. reel, basket, plate) which can induce, during thermal

cycles, a significant effect on the test result if "no effect" conditions are not completely

fulfilled. The intent is to simulate the installed condition, in which the cable is generally

straight for the majority of its length.

Parameters of influence are mainly the details of conditioning, the type and materials of the

holder, the diameter of the sample coil or reel.

60794-1-22 © IEC:2012(E) – 9 –

General recommendations include the following:

a) The winding diameter shall be large enough to keep the ability of the fibre to

accommodate differential expansion and contraction. A winding diameter substantially

greater than the value selected for cable delivery may be necessary.

b) Any risk of cable expansion (or contraction) limitation created by conditioning shall be

suppressed. In particular, special care should be taken to avoid residual tension on the

cable during the test. For example, a tight winding on a drum is not recommended as it

can limit cable contraction at low temperature. On the other hand, a tight multilayer

winding can limit expansion at high temperature.

c) The use of loose winding is recommended with large diameter coils and cushioned reels

with a soft layer or zero tension facility device.

d) The number of fibres tested shall conform to IEC 60794-1-1:2011, Annex B.

e) The fixed cable ends as well as connection to the equipment shall be outside of the

temperature chamber to avoid negative influences.

When necessary, in order to limit the length of the cable under test, it is permissible to

concatenate several fibres of the cable and to measure the concatenated fibres. The number

of connections shall be limited and they should be located outside the climatic chamber.

3.3 Apparatus

The apparatus consists of:

a) an appropriate attenuation measuring apparatus for the determination of attenuation

change (see the test methods of IEC 60793-1-40);

b) a climatic chamber of a suitable size to accommodate the sample and whose temperature

shall be controllable to remain within ± 3 °C of the specified testing temperature. One

example of a suitable chamber is given in Clause 8 of IEC 60068-2-14:2009: Test Nb:

Change of temperature with specified rate of change;

c) a temperature sensing device to measure the temperature of the sample, when applicable.

Samples with a large thermal mass may require measurement to verify temperature

stability rather than utilizing a specified exposure period, t .

3.4 Procedure

3.4.1 Initial measurement

The sample shall be visually inspected and a basic value for attenuation at the initial

temperature shall be determined.

3.4.2 Pre-conditioning

Pre-conditioning conditions shall be agreed between customer and supplier.

3.4.3 Conditioning

Figures 1 and 2 show, graphically, the initial cycle(s) and the final cycle. Together, they

illustrate the temperature cycle sequence to be used. If only one cycle is specified, use

Figure 1.

(1) The sample at ambient temperature shall be introduced into the climatic chamber which

is also at that temperature.

(2) The temperature in the chamber shall then be lowered to the appropriate low

temperature T at the appropriate rate of cooling.

A2

(3) After temperature stability in the chamber has been reached the sample shall be

exposed to the low temperature conditions for the appropriate period t .

– 10 – 60794-1-22 © IEC:2012(E)

(4) A minimum soak time is given in Table 1; however the soak time must be sufficient to

bring the complete cable to equilibrium with the specified temperature.

(5) The temperature in the chamber shall then be raised to the appropriate high

temperature T at the appropriate rate of heating.

B2

(6) After temperature stability in the chamber has been reached, the sample shall be

exposed to the high temperature conditions for the appropriate period t .

(7) The temperature in the chamber shall then be lowered to the value of the ambient

temperature at the appropriate rate of cooling. This procedure constitutes one cycle

(see Figure 1 or 2). If this is the intermediate step in a series of cycles, no soak is

required, but no measurements shall be taken.

(8) Continue to the next cycle, using steps 2) through 7). The sample shall be subjected to

at least two cycles unless otherwise required by the relevant detail specification. The

initial cycle(s) shall comprise one low temperature and one high temperature, per Figure

1. The last cycle shall comprise one or more low temperatures and one or more high

temperatures, per Figure 2, as required by the relevant detail specification. On the last

cycle, if multiple temperatures are specified, the sample shall be held at each

intermediate temperature (T or T ) for the appropriate time t . At the end of the

A1 B1 1

cycling sequence, hold the sample at ambient temperature for the appropriate period t .

(9) The attenuation shall be measured at ambient temperature at the start of the first cycle,

at the end of the soak time t at each of the specified temperature steps (T , T , T ,

1 A1 A2 B1

T ) in the last cycle, and at ambient temperature at the end of the last cycle.

B2

(10) Before removal from the chamber, the sample under test shall have reached

temperature stability at ambient temperature.

Table 1 – Minimum soak time t

Minimum soak times for a given sample mass

Sample mass Minimum soak time, t

kg h

Under 0,35 0,5

0,36 to 0,7 1

0,8 to 1,5 2

1,6 to 15 4

16 to 100 8

101 to 250 12

251 to 500 14

Over 501 16

NOTE It is the responsibility of the tester to assure that the soak time is long enough to bring the cable to

equilibrium with the specified temperature.

60794-1-22 © IEC:2012(E) – 11 –

T

B2

A

Time t

t

T

A2

t

1 cycle

IEC 1089/12

Figure 1 – First cycle(s) procedure

T

B2

T

B1

A

Temperature

in the chamber

Time t

t

t

T

A1

T

A2

t t

1 1

1 cycle

IEC 1090/12

Figure 2 – Last cycle procedure

3.4.4 Recovery

If the ambient temperature is not the standard atmospheric condition to be used for testing

after removal from the chamber, the sample shall be allowed to attain temperature stability at

this latter condition.

The relevant detail specification may call for a specific recovery period for a given type of

sample.

– 12 – 60794-1-22 © IEC:2012(E)

3.5 Requirements

The acceptance criteria for the test shall be as stated in the detail specification. Typical failure

modes include loss of optical continuity, degradation of optical transmittance or physical

damage to the cable.

3.6 Details to be specified

The detail specification shall include the following:

a) cable sample length;

b) number of fibres tested if different from 3.2;

c) length of the fibre under test typically 1 km minimum, unless otherwise specified;

d) type of connection between concatenated fibres (if any);

e) Temperature limits:

i) T and T (Figure 1), or

A2 B2

ii) T , T , T and T (Figure 2);

A1 A2 B1 B2

f) number of cycles;

g) humidity levels at each temperature extreme (if any);

h) change of attenuation at a specified wavelength as a function of temperature cycling.

3.7 Details to be reported

Type of winding:

a) coil, reel, other (to be stated, in case of a cushioned reel, the type of cushioning and

material used);

b) winding diameter;

c) single or multilayer;

d) winding tension and zero tension facility device (if any).

4 Method F2 – Contamination (test deleted)

5 Method F3 – Sheath integrity (test deleted)

6 Method F4 – External static pressure (test deleted)

7 Method F5 – Water penetration

7.1 Object

This test applies to continuously water-blocked cables. The purpose is to determine the ability

of a cable to block water migration along a specified length.

– F5A evaluates radial ingress of water due to sheath damage;

– F5B evaluates longitudinal ingress of water down the entire cable cross-section designed

to be water-blocked, from an undefined water exposure at a cable end;

– F5C also evaluates longitudinal ingress of water from cable end and is applicable for

cables with swellable water blocking material.

Compliance shall be checked on samples of cable using one of the three following methods

(F5A, F5B or F5C), as stated in the detail specification. Method F5A tests for water migration

between the outer interstices of the optical core and the outer sheath, whereas methods F5B

60794-1-22 © IEC:2012(E) – 13 –

and F5C test for water migration over the entire cross-section designed to be water-blocked.

Method F5C includes a precondition step, a restricted-flow apparatus, or longer sample to

simulate gradual water exposure at a location along the length of a cable or at a cable end.

NOTE Multiple sheath designs, e.g. armoured cables, are not necessarily designed to be water blocked. If so,

then remove the outer layers before application of the seals.

7.2 Sample

7.2.1 Method F5A

A circumferential portion of sheath and wrapping 25 mm wide shall be removed 3 m from one

end of a sample length of cable and a watertight sleeve shall be applied over the exposed

core so as to bridge the gap in the sheath and allow a 1 m height of water to be applied.

The opposite end of the sample shall be capped to block any water leakage in that direction.

The sample shall be long enough to include the test end length, the length of removed sheath,

and length sufficient to cap the opposite end. Generally 3,1 m should be sufficient.

7.2.2 Method F5B

A cable sample that shall not exceed 3 m is used.

A watertight seal shall be applied to one end of the sample to allow a 1 m height of water to

be applied.

NOTE 1 If the armour in armoured cables is not designed to be water-blocked, the armour may be removed at the

end before the application of the seal.

NOTE 2 Water pressure may force the fibre and filling compound out of the core tubes of filled cables. Such an

occurrence would be a “test void” result. Therefore, the core may require that the fibres be restrained at the exit

end – as with a screen or cloth covering. Since the filled tubes exhibit robust water blocking ability, testing may

focus on the water penetration characteristics of the rest of the cable. In this case, it is recommended that the core

tube(s) be plugged at either end to avoid this problem.

7.2.3 Method F5C (for cables with swellable water blocking material)

A cable sample which shall not exceed 3 m is used for pre-soak or orifice procedure. Unless

one of these procedures is selected, a longer cable sample, which shall not exceed 40 m, can

be used.

A watertight seal shall be applied to one end of the sample to allow a 1 m height of water to

be applied.

NOTE 1 If the armour in armoured cables is not designed to be water-blocked, the armour may be removed at the

end before the application of the seal.

NOTE 2 Water pressure may force the fibre and water-blocking material out of the core tubes of filled cables.

Such an occurrence would be a “test void” result. Therefore, the core may require that the fibres be restrained at

the exit end – as with a screen or cloth covering.

7.3 Apparatus

7.3.1 Test fixtures and set-up

Suitable test arrangements are shown in Figures 3 to 8 for methods F5A, F5B, and F5C,

respectively. Unless otherwise specified in the detail specification, the sample shall be

supported horizontally.

– 14 – 60794-1-22 © IEC:2012(E)

7.3.2 Water

Water shall be potable water, either common tap water or deionized or distilled water, at the

option of the cable manufacturer.

A water soluble fluorescent dye or other suitable colouring agent may be used to aid in the

detection of water seepage at the option of the cable manufacturer. Care should be taken in

choosing a fluorescent dye that does not react with any of the cable components.

NOTE Fluorescent dyes inhibit the action of many swellable water blocking materials to some degree, which may

bias test results.

If required by the detail specification, water simulating sea water (or other) may be used for

the test. Note that special design considerations and test limits should apply to cables

designed for salt water or brackish water exposure.

7.3.3 Orifice

An orifice may be placed in the tube connecting the water source to the sample to limit the

water flow rate.

The orifice, if used, shall be 1,50 mm ± 0,25 mm diameter, and a maximum length of 30 mm

(see Figure 7).

7.4 Procedure

7.4.1 Method F5A and F5B

1 m height of water shall be applied for 24 h.

7.4.2 Method F5C

7.4.2.1 Pre-soak

One end of the sample shall be pre-soaked in a bucket of water to a depth of

100 mm ± 10 mm for 10 min. At the same end, a watertight seal shall be applied to allow a

1 m height of water to be applied.

After the pre-soak procedure, 1 m height of water shall be applied for 24 h.

7.4.2.2 Orifice

The orifice, if used, may be placed in any part of the tube connecting the water head source

to the sample.

7.4.2.3 Longer sample

1 m height of water shall be applied for 24 h (see Figure 8).

7.5 Requirements

For methods F5A, F5B and F5C, no water shall be detected at the unsealed end of the

sample. If a fluorescent dye is used, an ultraviolet light may be used for the examination.

NOTE The test procedure mentioned above is a basic compliance requirement. For process evaluation tests

samples of shorter lengths may be tested for a shorter time.

7.6 Details to be specified

The detail specification shall include the following:

a) method used – F5A, F5B, or F5C (see Figures 3 to 8);

60794-1-22 © IEC:2012(E) – 15 –

b) any alternative test length, water head, water type, or test duration;

c) alternative test lengths, preconditioning or leakage requirements if salt water is to be

used.

7.7 Details to be reported

Orifice if used:

– details of dye, if used;

– test length, if different;

– duration of test, if different.

25 mm

1 m height

of water

Cap

Sample Sample

3 m

IEC 1091/12

Figure 3 – Method F5-A

Water

Water seal

1 m Sample (3 m max.)

IEC 1092/12

Figure 4 – Method F5-B

– 16 – 60794-1-22 © IEC:2012(E)

Water

Water seal

Sample (3 m max.)

1 m

Pre-soaked portion

100 mm ± 10 mm

IEC 1093/12

Figure 5 – Method F5C pre-soaked sample

Cable-sample

Water

IEC 1094/12

Figure 6 – Method F5C Alternative pre-soak procedure

100 ± 10 mm

60794-1-22 © IEC:2012(E) – 17 –

Water

Water seal

1 m

Sample

Orifice (1,5 mm ID × 30 mm max. length)

IEC 1095/12

Figure 7 – Method F5C orifice

Water

Water seal

1 m Sample (40 m max.)

IEC 1096/12

Figure 8 – Method F5C longer sample

8 Method F6 – Unknown (test deleted)

9 Method F7 – Nuclear radiation

9.1 Object

Exposure of optical fibre cables to nuclear radiation can cause a change in the attenuation of

the fibres and a change in the physical characteristics of the materials used in the cable

construction.

The attenuation of cabled and uncabled optical fibres generally increases when exposed to

radiation, due mainly to the trapping of radiolytic electrons and holes at defect sites in the

glass. Exposure of polymeric materials to radiation generally produces degradation in

properties such as tensile strength, elongation at break and impact performance as the

material becomes brittle (although some materials can show an initial improvement at

relatively low levels of exposure due to crosslinking).

In special cases where the cable operational environment includes exposure to nu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...