IEC TS 62647-22:2013

(Main)Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 22: Technical guidelines

Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 22: Technical guidelines

IEC/TS 62647-22:2013(E) is intended for use as technical guidance by aerospace, defence, and high performance (ADHP) electronic applications and systems suppliers, e.g., original equipment manufacturers (OEMs) and system maintenance facilities, in developing and implementing designs and processes to ensure the continued performance, quality, reliability, safety, airworthiness, configuration control, affordability, maintainability, and supportability of high performance aerospace systems both during and after the transition to Pb-free electronics. The guidelines may be used by the OEMs and maintenance facilities to implement the methodologies they use to ensure the performance, reliability, airworthiness, safety, and certifiability of their products, in accordance with IEC/TS 62647-1:2012. This document also contains lessons learned from previous experience with Pb-free aerospace electronic systems.

General Information

- Status

- Published

- Publication Date

- 24-Sep-2013

- Technical Committee

- TC 107 - Process management for avionics

- Drafting Committee

- WG 1 - TC 107/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 25-Sep-2013

- Completion Date

- 31-Dec-2013

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62647-22:2013 - Process management for avionics: Technical guidelines - provides practical guidance for aerospace, defence and high‑performance (ADHP) electronic systems transitioning to lead‑free (Pb‑free) solder. It supplements IEC/TS 62647‑1:2012 by describing design, manufacturing, testing and maintenance practices to preserve reliability, airworthiness, safety and maintainability of avionics equipment during and after Pb‑free conversion. The document also captures lessons learned from prior Pb‑free aerospace implementations.

Key topics and technical scope

This technical specification addresses the full system lifecycle with emphasis on process management and risk reduction for Pb‑free avionics electronics. Major topics include:

- General Pb‑free solder alloy behavior (temperature effects, thermal cycling, stress relaxation)

- System level service environments (steady and cyclic temperatures, vibration, shock, humidity, salt spray and cooling‑air quality)

- High‑performance electronics testing (thermal cycling, vibration, shock, combined environments)

- Solder joint reliability and mixed metallurgy (Pb‑free/tin‑lead interactions, bismuth effects, modeling)

- Piece parts and PCB/PWB considerations (terminal finishes, plated through‑holes, copper dissolution, laminate CTE, surface finishes)

- Assembly and manufacturing practices (process coupons, fluxes, cleaning, inspection)

- Module assembly and conformal coatings

- Rework, repair and depot maintenance (area‑array rework, mixed‑alloy profiles, cleaning)

- Generic life testing, similarity analysis and qualification

The standard includes informative annexes, risk tables (e.g., finish compatibility, whisker risk), and process recommendations without prescribing a single mandatory method.

Practical applications

IEC TS 62647‑22 is used to:

- Develop Pb‑free design rules and process controls for avionics PCBs and modules

- Define qualification and acceptance testing for Pb‑free assemblies (thermal, vibration, shock)

- Guide maintenance, depot repair and configuration control during Pb‑free transitions

- Assess mixed‑metallurgy risks (BGA, SMT, through‑hole) and select compatible finishes and fluxes

- Inform conformity and airworthiness evidence for OEMs and MROs

Who should use this standard

- OEM design and manufacturing engineers in aerospace and defence

- System integrators, maintenance, repair and overhaul (MRO) facilities

- Reliability, qualification and quality assurance teams working with Pb‑free electronics

- Procurement and certification personnel evaluating parts and processes for avionics

Related standards

- IEC/TS 62647‑1:2012 (process management framework for Pb‑free avionics)

- Applicable IPC, JEDEC and aerospace wiring/airworthiness standards for complementary guidance

IEC TS 62647‑22 is a practical, application‑focused resource to manage the technical and reliability risks of switching to Pb‑free solder in high‑performance aerospace and defence electronic systems.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

IEC TS 62647-22:2013 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Process management for avionics - Aerospace and defence electronic systems containing lead-free solder - Part 22: Technical guidelines". This standard covers: IEC/TS 62647-22:2013(E) is intended for use as technical guidance by aerospace, defence, and high performance (ADHP) electronic applications and systems suppliers, e.g., original equipment manufacturers (OEMs) and system maintenance facilities, in developing and implementing designs and processes to ensure the continued performance, quality, reliability, safety, airworthiness, configuration control, affordability, maintainability, and supportability of high performance aerospace systems both during and after the transition to Pb-free electronics. The guidelines may be used by the OEMs and maintenance facilities to implement the methodologies they use to ensure the performance, reliability, airworthiness, safety, and certifiability of their products, in accordance with IEC/TS 62647-1:2012. This document also contains lessons learned from previous experience with Pb-free aerospace electronic systems.

IEC/TS 62647-22:2013(E) is intended for use as technical guidance by aerospace, defence, and high performance (ADHP) electronic applications and systems suppliers, e.g., original equipment manufacturers (OEMs) and system maintenance facilities, in developing and implementing designs and processes to ensure the continued performance, quality, reliability, safety, airworthiness, configuration control, affordability, maintainability, and supportability of high performance aerospace systems both during and after the transition to Pb-free electronics. The guidelines may be used by the OEMs and maintenance facilities to implement the methodologies they use to ensure the performance, reliability, airworthiness, safety, and certifiability of their products, in accordance with IEC/TS 62647-1:2012. This document also contains lessons learned from previous experience with Pb-free aerospace electronic systems.

IEC TS 62647-22:2013 is classified under the following ICS (International Classification for Standards) categories: 03.100.50 - Production. Production management; 31.020 - Electronic components in general; 49.060 - Aerospace electric equipment and systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62647-22:2013 has the following relationships with other standards: It is inter standard links to IEC PAS 62647-22:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62647-22:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TS 62647-22 ®

Edition 1.0 2013-09

TECHNICAL

SPECIFICATION

Process management for avionics – Aerospace and defence electronic systems

containing lead-free solder –

Part 22: Technical guidelines

IEC/TS 62647-22:2013(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

IEC/TS 62647-22 ®

Edition 1.0 2013-09

TECHNICAL

SPECIFICATION

Process management for avionics – Aerospace and defence electronic systems

containing lead-free solder –

Part 22: Technical guidelines

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

XB

ICS 03.100.50; 31.020; 49.060 ISBN 978-2-8322-1112-0

– 2 – TS 62647-22 IEC:2013(E)

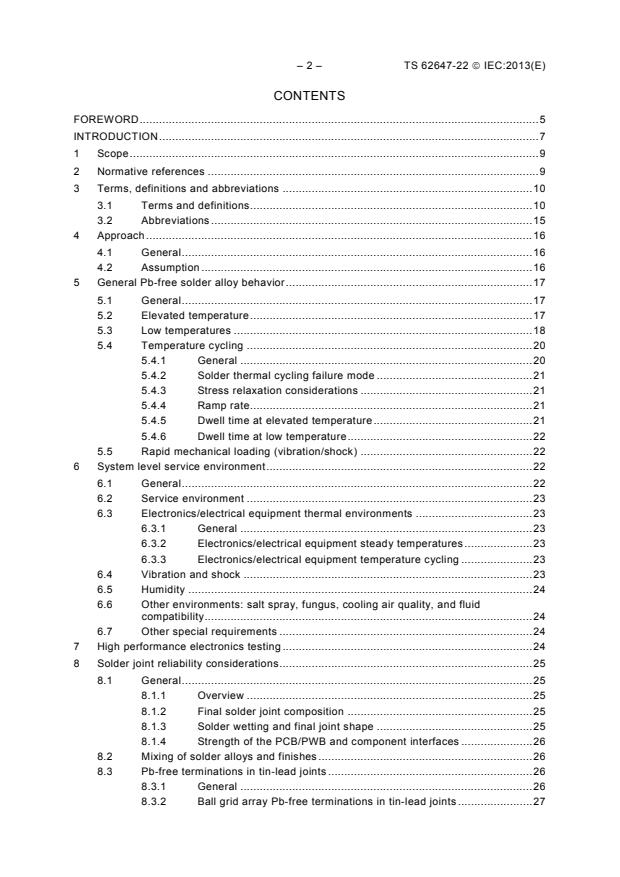

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 9

2 Normative references . 9

3 Terms, definitions and abbreviations . 10

3.1 Terms and definitions . 10

3.2 Abbreviations . 15

4 Approach . 16

4.1 General . 16

4.2 Assumption . 16

5 General Pb-free solder alloy behavior . 17

5.1 General . 17

5.2 Elevated temperature . 17

5.3 Low temperatures . 18

5.4 Temperature cycling . 20

5.4.1 General . 20

5.4.2 Solder thermal cycling failure mode . 21

5.4.3 Stress relaxation considerations . 21

5.4.4 Ramp rate . 21

5.4.5 Dwell time at elevated temperature . 21

5.4.6 Dwell time at low temperature . 22

5.5 Rapid mechanical loading (vibration/shock) . 22

6 System level service environment . 22

6.1 General . 22

6.2 Service environment . 23

6.3 Electronics/electrical equipment thermal environments . 23

6.3.1 General . 23

6.3.2 Electronics/electrical equipment steady temperatures . 23

6.3.3 Electronics/electrical equipment temperature cycling . 23

6.4 Vibration and shock . 23

6.5 Humidity . 24

6.6 Other environments: salt spray, fungus, cooling air quality, and fluid

compatibility . 24

6.7 Other special requirements . 24

7 High performance electronics testing . 24

8 Solder joint reliability considerations . 25

8.1 General . 25

8.1.1 Overview . 25

8.1.2 Final solder joint composition . 25

8.1.3 Solder wetting and final joint shape . 25

8.1.4 Strength of the PCB/PWB and component interfaces . 26

8.2 Mixing of solder alloys and finishes . 26

8.3 Pb-free terminations in tin-lead joints . 26

8.3.1 General . 26

8.3.2 Ball grid array Pb-free terminations in tin-lead joints . 27

TS 62647-22 IEC:2013(E) – 3 –

8.3.3 Flat pack and chip device Pb-free terminations in tin-lead

joints . 29

8.4 Tin-lead terminations in Pb-free joints . 30

8.4.1 General . 30

8.4.2 Ball grid array tin-lead terminations in lead-free joints . 30

8.4.3 Flat pack and chip device tin-lead terminations in lead-free

joints . 30

8.5 Bismuth effects . 30

8.6 JCAA/JG-PP testing of mixed alloy combinations . 31

8.6.1 General . 31

8.6.2 Vibration . 31

8.6.3 Thermal shock testing . 32

8.6.4 Combined environments . 32

8.7 Pb-free solder and mixed metallurgy modeling . 32

9 Piece parts . 36

9.1 Materials . 36

9.2 Temperature rating . 36

9.3 Special considerations . 36

9.4 Plastic encapsulated microcircuit (PEM) moisture sensitivity level (MSL) . 36

9.5 Terminal finish . 36

9.6 Assembly stresses . 38

9.7 Hot solder dipping . 38

10 Printed circuit boards . 38

10.1 General . 38

10.2 Plated through holes . 38

10.3 Copper dissolution . 39

10.4 PCB/PWB laminate materials . 40

10.4.1 General . 40

10.4.2 Coefficient of thermal expansion . 40

10.5 Surface finish . 41

10.6 Pb-free PCB/PWB qualification . 42

10.7 PCB/PWB artwork and design considerations for Pb-free solder

applications . 42

11 Printed circuit board (PCB)/printed wiring board (PWB) assembly . 43

11.1 General . 43

11.2 PCB/PWB process indicator coupons . 43

11.3 Solder inspection criterion . 43

11.4 Fluxes, residues, cleaning and SIR issues . 43

12 Module assembly considerations . 49

12.1 Connectors and sockets . 49

12.2 Heatsinks/modules . 49

12.3 Conformal coating . 49

13 Manufacturing resources . 50

14 Aerospace wiring/cabling considerations . 50

14.1 Insulation temperature rating . 50

14.2 Cable connectors . 50

14.3 Wire terminals . 51

14.4 Splices . 51

14.5 Sleeving . 51

– 4 – TS 62647-22 IEC:2013(E)

15 Rework/repair . 51

15.1 General . 51

15.2 Piece part rework . 53

15.2.1 Area array rework . 53

15.2.2 Surface mount capacitor/resistor rework . 53

15.2.3 Through hole piece part rework . 53

15.3 Depot level repair. 54

15.4 Mixed solder rework temperature profiles . 54

15.5 Solder fluxes . 54

15.6 Rework/repair cleaning process . 55

15.7 Inspection requirements . 55

16 Generic life testing . 55

16.1 Thermal cycling, vibration, and shock testing . 55

16.2 Other environments . 56

16.2.1 Salt fog . 56

16.2.2 Cooling air quality . 56

16.2.3 Fluid compatibility . 56

16.2.4 Generic humidity . 56

17 Similarity analysis . 56

Annex A (informative) Equipment service environmental definition . 58

A.1 Steady temperature service environments . 58

A.2 Service cyclic temperature environments . 58

Bibliography . 59

Table 1 – Review of piece part surface finish and potential concerns . 33

Table 2 – Elements promoting and supressing tin whiskers . 34

Table 3 – Elements promoting and supressing tin pest. 35

Table 4 – Piece part lead/terminal and BGA ball metallization tin whisker and tin pest

propensity . 37

Table 5 – PCB/PWB metallization tin whisker and tin pest propensity . 42

Table 6 – Piece part terminal and BGA ball metallization solder process compatibility

risk . 44

Table 7 – PCB/PWB finish solder process compatibility risk . 46

Table 8 – Piece part terminal and BGA ball metallization reliability risk . 47

Table 9 – PCB/PWB metallization reliability risk . 48

Table 10 – Relative rigidity of IPC-CC-830 conformal coating categories . 50

Table 11 – Process temperatures of mixed alloys . 55

TS 62647-22 IEC:2013(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PROCESS MANAGEMENT FOR AVIONICS –

AEROSPACE AND DEFENCE ELECTRONIC

SYSTEMS CONTAINING LEAD-FREE SOLDER –

Part 22: Technical guidelines

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC/TS 62647-22, which is a technical specification, has been prepared by IEC technical

committee 107: Process management for avionics.

– 6 – TS 62647-22 IEC:2013(E)

The text of this technical specification is based on the following document:

IEC/PAS 62647-22 .

This technical specification cancels and replaces IEC/PAS 62647-22, published in 2011. This

edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Coherence with IEC/TS 62647-1 and IEC/TS 62647-2 definitions.

b) Reference to IEC 62647 documents when already published.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

107/205/DTS 107/218/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62647 series, published under the general title Process

management for avionics – Aerospace and defence electronic systems containing lead-free

solder, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

___________

IEC/PAS 62647-22, which served as a basis for the present document, has been derived from GEIA-HB-0005-2.

TS 62647-22 IEC:2013(E) – 7 –

INTRODUCTION

0.1 General

The global transition to lead-free (Pb-free) electronics impacts the aerospace, defence, and

high performance (ADHP) industry and other industries having high reliability applications in

various ways.

0.2 Transition to Pb-free

In addition to the perceived need to replace the tin-lead solders used as an interconnect

medium in electronic and electrical systems, the following variations to established practice

will need to be considered:

• components and printed circuit boards (PCBs)/printed wiring boards (PWBs) will need to

be able to withstand higher manufacturing process temperatures;

• printed circuit boards (PCBs)/printed wiring boards (PWBs) will need to have robust

solderable lead-free (Pb-free) surface finishes;

• manufacturing and inspection techniques are needed that yield repeatable reliability

characteristics;

• at least initially, Pb-free alloys used within the equipment should be restricted to those that

are compatible with tin-lead soldering systems;

• a maintenance strategy should be developed that will facilitate the support repair of new

and existing equipment throughout a long life time which can be higher than 20 years.

This document will establish guidelines for the use of Pb-free solder and mixed tin-lead/lead-

free alloy systems while maintaining the high reliability standards required for aerospace

electronic and electrical systems. Currently the largest volume of lead (Pb) in many of these

electronic systems is in the tin-lead eutectic (Sn-37Pb) and near eutectic alloys

(Sn-36Pb-2Ag, Sn-40Pb) used in printed circuit board/printed wiring board assemblies, wiring

harnesses and electrical systems. High-lead solder alloys are not specifically addressed in

this document; however, many of the methodologies outlined herein are applicable for their

evaluation.

A good deal of the information desired for inclusion in this technical guidelines document does

not exist. A large number of lead-free (Pb-free) investigative studies for aerospace and high

reliability electronic and electrical systems are either in progress or in the initiation stage. The

long durations associated with reliability testing necessitates a phased release of information.

The information contained herein reflects the best information available at the time of

document issuance. It is not the goal of this document to provide technical guidance without

an understanding of why that guidance has technical validity or without concurrence of the

technical community in cases where sufficient data is lacking or conflicting. The document will

be updated as new data becomes available.

Further complicating matters is the fact that no single alloy across the supply base will be

replacing the heritage tin-lead eutectic alloy and that it is not likely that qualification of one

alloy covers qualification for all other alloys. Given the usual requirement for long, high

performance electronic service lives, any lead-free (Pb-free) alloy will need to have

predictable performance when mixed with heritage tin-lead alloys. Lead-free (Pb-free) alloys

containing elements such as bismuth (Bi) or indium (In) that can form alloys having melting

points within the equipment’s operating temperature range will need to be considered very

carefully before use. Although lead-free (Pb-free) solder alloys are still undergoing some

adjustments, it appears that the Sn-Ag-Cu family of alloys will be used for surface mount

assembly and either Sn-Ag-Cu, Sn-Cu or Sn-Cu-Ni (Sn-Cu stabilized with nickel) alloys will be

– 8 – TS 62647-22 IEC:2013(E)

dominant in wave solder applications. In addition, some applications are using the Sn-Ag alloy

family [1] [2] [3].

The majority of the lead-free (Pb-free) solder alloys being considered have higher melting

temperatures than tin-lead eutectic solder. In order to make use of the lead-free (Pb-free)

solders, changes to the molding compound, die attach and printed circuit board (PCB)/printed

wiring board (PWB) insulation systems are being introduced to accommodate the 30 °C to

40 °C higher (54 °F to 72 °F higher) processing temperature. Thus, not only is the lead-free

(Pb-free) transition changing the solder alloy, but a significant portion of the electronic

packaging materials are changing as well. The higher melting point, greater creep resistance

and higher strength of the lead-free (Pb-free) alloys have driven a significant amount of study

into the thermal cycling and mechanical vibration/shock assessments of these new alloys.

The consumer electronics industry has invested considerable resources to ensure that lead-

free (Pb-free) solder will perform adequately for their products. Creep resistance of lead-free

(Pb-free) alloys can vary considerably from heritage tin-lead solders. The creep/stress

relaxation performance of the solder depends on the stress level, temperature and time for a

specific solder material and joint composition. Therefore, one needs to establish what the

acceleration factor is between a particular test condition and application. The interpretation of

the results of a head-to-head testing needs to be assessed in terms of the anticipated service

conditions with respect to these acceleration factors. Thermal preconditioning prior to thermal

cycling should be considered in the lead-free (Pb-free) solder assessment plan particularly as

it relates to changes in solder microstructure. Modeling/analysis is needed to properly

compare the tin-lead and lead-free (Pb-free) alloy performance and correct for the stress

relaxation differences obtained for the various piece parts and thermal cycling conditions.

While there is much data on near eutectic SAC (e.g., SAC305 and SAC405) Pb-free thermal

cycling, there is less information regarding lead-free (Pb-free) vibration and shock

performance. Fortunately, the vibration and shock performance data can be obtained

relatively quickly. During vibration/shock testing, the near eutectic SAC Pb-free solder

behaves more rigidly than the Sn-Pb solder transferring greater loads to the interfaces

between the solder alloy and the substrate interfaces. The increased amount of tin in Pb-free

alloys increases the intermetallic thickness when copper substrates are used. In addition,

when nickel or electroless nickel (nickel – phosphorous) substrates are used, the increased

copper in the SAC alloy can result in the formation of intermetallics on the nickel interface,

which are less robust than Sn-Cu or Sn-Ni intermetallics that are typical of tin-lead solder

joints. Mechanical test results to-date suggest that a robust assessment of lead-free (Pb-free)

alloy assembly in vibration and shock environments will need to include thermal aging for

interface and microstructural stabilization prior to any dynamic mechanical testing. Alloys

other than SAC should be assessed to determine their vibration and shock performance

characteristics.

___________

Numbers in square brackets refer to the Bibliography.

TS 62647-22 IEC:2013(E) – 9 –

PROCESS MANAGEMENT FOR AVIONICS –

AEROSPACE AND DEFENCE ELECTRONIC

SYSTEMS CONTAINING LEAD-FREE SOLDER –

Part 22: Technical guidelines

1 Scope

This part of IEC 62647 is intended for use as technical guidance by aerospace, defence, and

high performance (ADHP) electronic applications and systems suppliers, e.g., original

equipment manufacturers (OEMs) and system maintenance facilities, in developing and

implementing designs and processes to ensure the continued performance, quality, reliability,

safety, airworthiness, configuration control, affordability, maintainability, and supportability of

high performance aerospace systems (subsequently referred to as ADHP) both during and

after the transition to Pb-free electronics.

The guidelines may be used by the OEMs and maintenance facilities to implement the

methodologies they use to ensure the performance, reliability, airworthiness, safety, and

certifiability of their products, in accordance with IEC/TS 62647-1:2012.

This document also contains lessons learned from previous experience with Pb-free

aerospace electronic systems. The lessons learned give specific references to solder alloys

and other materials, and their expected applicability to various operating environmental

conditions. The lessons learned are intended for guidance only; they are not guarantees of

success in any given application.

This document may be used by other high-performance and high-reliability industries, at their

discretion.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC/TS 62647-1:2012, Process management for avionics – Aerospace and defence electronic

systems containing lead-free solder – Part 1: Preparation for a lead-free control plan

IEC/TS 62647-2, Process management for avionics – Aerospace and defence electronic

systems containing lead-free solder – Part 2: Mitigation of deleterious effects of tin

IEC/TS 62647-3:–, Process management for avionics – Aerospace and defence electronic

systems containing lead-free solder – Part 3: Performance testing for systems containing

lead-free solder and finishes

GEIA-HB-0005-4, Guidelines for Performing Reliability Assessment for Lead Free Assemblies

used in Aerospace and High-Performance Electronic Applications

IPC/JEDEC JP002, Current Tin Whiskers Theory and Mitigation Practices Guideline

___________

Under consideration.

– 10 – TS 62647-22 IEC:2013(E)

IPC-1066, Marking, Symbols and Labels for Identification of Lead-Free and Other Reportable

Materials in Lead-Free Assemblies, Components and Devices

IPC-9701, Performance Test Methods and Qualification Requirements for Surface Mount

Solder Attachments

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

alloy composition

whole ingredients of an alloy whose weight is defined in percent

Note 1 to entry: For instance 63Sn-37Pb corresponds to a mixture of 63 % by weight of tin (Sn) and 37 % by

weight of lead (Pb).

3.1.2

alloy 42

nickel-iron controlled-expansion alloy containing 42 % nickel that is often used as a lead-

frame material in electronic packages

3.1.3

assemblies

electronic items that require electrical attachments, including soldering of wires or component

terminations

EXAMPLE Circuit cards and wire harnesses.

[SOURCE: IEC/TS 62647-1:2012, 3.1]

3.1.4

CAF

conductive anodic filament

copper conductive filament form between two adjacent conductors or plated vias in a printed

circuit board (PCB)/printed wiring board (PWB)

Note 1 to entry: See IPC-TM-650, method 2.6.25.

3.1.5

critical

state of an item or function, which if defective, will result in the system’s inability to retain

operational capability, meet primary objective, or affect safety

[SOURCE: IEC/TS 62647-1:2012, 3.2]

3.1.6

creep

time-dependent strain occurring under stress

3.1.7

CSAM

C-mode scanning acoustic microscopy

method for evaluating electronic packages for internal delamination using high frequency

sound waves

TS 62647-22 IEC:2013(E) – 11 –

3.1.8

CTE

coefficient of thermal expansion

degree of expansion of a material divided by the change in temperature

Note 1 to entry: PCB/PWB CTE (x-y axis) is measured in the direction in the plane of the piece part mounting

surface and is used to quantify the stresses in the solder joint arising from the differences in CTE between the

piece parts and the PCB/PWB during thermal cycling. CTE (z axis) is measured in the “thickness” direction and is

typically used to quantify plated through hole stress.

3.1.9

customer

entity or organization that (a) integrates a piece part, soldered assembly, unit, or system into

a higher control level system, (b) operates the higher control level system, or (c) certifies the

system for use

EXAMPLE This may include end item users, integrators, regulatory agencies, operators, original equipment

manufacturers (OEMs), and subcontractors.

[SOURCE: IEC/TS 62647-1:2012, 3.5]

3.1.10

dicy cure

use of dicyandiamide (dicy), as a curing agent for epoxy resins

3.1.11

EM

electromigration of the PCB/PWB metallization

Note 1 to entry: Resistance to electromigration testing is typically performed between electrically biased

conductors at elevated humidity and temperature.

3.1.12

eutectic

mixture of two or more metals at a composition that has the lowest melting point, and where

the phases simultaneously crystallize from molten solution at this temperature

Note 1 to entry: A non-eutectic mixture will exhibit a pasty range during cooling where both liquid and solid

phases are present prior to reaching the mixture’s solidus temperature.

3.1.13

FR4

flame retardant laminate made from woven glass fiber material impregnated with epoxy resin

3.1.14

Fick’s law

classic diffusive mass transport model where the mass diffusion is proportional to the

concentration gradient in the material

3.1.15

fillet lifting

separation that occurs between a solder fillet and a PCB/PWB pad where the solder fillet has

the appearance that it has lifted off the PCB/PWB pad

Note 1 to entry: The fillet lifting is caused by the formation of a low melting point phase (often a ternary alloy) or

liquid phase in an alloy having a large pasty range. The thin layer of liquid present adjacent to the PCB/PWB pad

results in a layer that allows the solidified solder above it to pull off the PCB/PWB pad [38] [73].

– 12 – TS 62647-22 IEC:2013(E)

3.1.16

high performance

continued performance or performance on demand where an application (product, equipment,

electronics, system, program) down time cannot be tolerated in an end-use environment

which can be uncommonly harsh, and the application must function when required

EXAMPLE: Examples of high performance applications are life support or other critical systems.

[SOURCE: IEC/TS 62647-1:2012, 3.7]

3.1.17

incubation period

time required at cold temperature to initially form the brittle gray (α) tin

phase from the ductile white (β) tin phase

3.1.18

inoculation

practice of facilitating the white (β) tin to gray (α) tin phase

transformation by using seed particles of the gray tin phase on the white tin to reduce the

nucleation barrier energy associated with the transformation

3.1.19

ICP-MS

inductively coupled plasma mass spectrometry

type of mass spectrometry used for analysis and capable of detecting metals and non-metals

3.1.20

Kirkendall void formation

void induced in a diffusion couple between two metals that have different interdiffusion

coefficients

3.1.21

lead-free

Pb-free

less than 0,1 % by weight of lead (Pb) in accordance with reduction of hazardous substances

(RoHS) guidelines

[SOURCE: IEC/TS 62647-1:2012, 3.8]

3.1.22

MSL

moisture sensitivity level

moisture sensitivity level rating of a plastic encapsulated electronic device as it relates to

soldering

3.1.23

PCB

printed circuit board

PWB

printed wiring board

substrate using conductive pathways, tracks or signal traces etched from copper sheets

laminated, and allowing to connect electrically a set of electronic components to realize a

circuit card

[SOURCE: IEC/TS 62647-21:2013, 3.1.10]

TS 62647-22 IEC:2013(E) – 13 –

3.1.24

peritectic

in a peritectic reaction, solid phase and liquid phase react on cooling to produce a new solid

phase

3.1.25

piece part

electronic component that is not normally disassembled without destruction and is normally

attached to a printed wiring board to perform an electrical function

[SOURCE: IEC/TS 62647-1:2012, 3.14]

3.1.26

PTH

plated through hole

plated through hole used on printed circuit boards (PCBs)/printed wiring boards (PWBs) for

interconnecting between layers and for component attachment

Note 1 to entry: Plating of metal the wall of the hole allows electrical connection between internal and/or external

conductive patterns on different layers.

3.1.27

repair

act of restoring the functional capability of a defective article in a manner that precludes

compliance of the article with applicable drawings or specifications

[SOURCE: IEC/TS 62647-1:2012, 3.17]

3.1.28

rework

action taken to return a unit (SRU/LRU/system) to a state meeting all requirements of the

engineering drawing, including both functionality and physical configuration by making repairs

Note 1 to entry: Also used to define the act of reprocessing non-complying articles, through the use of original or

equivalent processing in a manner that assures full compliance of the article with applicable drawings or

specifications.

[SOURCE: IEC/TS 62647-1:2012, 3.16]

3.1.29

SAC

family of Pb-free alloys containing tin, silver and copper used in surface mount technology or

sometimes in wave solder processes

Note 1 to entry: The alloys typically have a composition near the eutectic (95,6Sn-3,5Ag-0,9Cu).

3.1.30

SAC-L

low silver content SAC alloys that are not eutectic compositions

Note 1 to entry: These alloys have increasingly been used for BGA package interconnects.

3.1.31

SIR

surface insulation resistance

method of electrical resistance measurement used to quantify the deleterious effects of

fabrication, process or handling residues and performed on PCB/PWB

Note 1 to entry: These electrical resistance measurements are often performed after periods of humidity

exposure.

– 14 – TS 62647-22 IEC:2013(E)

3.1.32

Sn-Cu

solder or alloy refering to Pb-free alloys that are comprised of tin-copper (Sn-0,7Cu)

3.1.33

Sn-Cu-Ni

solder or alloy refering to tin-copper with nickel trace (Sn-0,7Cu-0,05Ni)

Note 1 to entry: Some formulations also include other minor additions such as germanium (Ge).

3.1.34

Sn-Pb

solder generally refering to the family of tin-lead alloys at or near the eutectic composition

with or without silver added (Sn-37Pb, Sn-40Pb, or Sn-36Pb-2Ag)

3.1.35

solder ball technology

technology for a family of components employing solder balls or bumps to make mechanical

and electrical connections between components and a printed circuit board (PCB)/printed

wiring board (PWB)

Note 1 to entry: Examples are ball grid arrays (BGA), flip chip, and chip scale interconnections.

3.1.36

soldered assembly

assembly of two or more basic parts interconnected by a solder alloy

Note 1 to entry: A lead (Pb)-based soldered assembly is one in which the solder alloys are solely lead (Pb)-

based. A lead-free soldered assembly is one in which the solder alloys are solely lead-free.

3.1.37

supplier

entity or organization that designs, manufactures, repairs, or maintains a piece part, unit, or

system

Note 1 to entry: This includes original equipment manufacturers (OEMs), repair facilities, subcontractors, and

piece part manufacturers.

[SOURCE: IEC/TS 62647-1:2012, 3.23]

3.1.38

system

one or more units that perform electrical function(s)

[SOURCE: IEC/TS 62647-1:2012, 3.24]

3.1.39

T

d

decomposition temperature of a PCB/PWB laminate

3.1.40

T

g

glass transition temperature of a PCB/PWB laminate

3.1.41

tin whisker

spontaneous crystal growth that emanates from a tin (Sn) surface and which may be

cylindrical, kinked, or twisted

TS 62647-22 IEC:2013(E) – 15 –

Note 1 to entry: Typically tin whiskers have an aspect ratio (length/width) greater than two, with shorter growths

referred to as nodules or odd-shaped eruptions (OSEs).

[SOURCE: IEC/TS 62647-1:2012, 3.26]

3.1.42

µm

unit of length measure defined to be a micro-meter or one millionth of a meter, commonly

referred to as a micron

3.1.43

unit

one or more assemblies within a chassis or higher level system to perform electrical function(s)

[SOURCE: IEC/TS 62647-1:2012, 3.27]

3.1.44

XY

paraxylylene resin conformal coating

Note 1 to entry: This is also known by the trade na

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...