IEC TS 62668-2:2014

(Main)Process management for avionics - Counterfeit prevention - Part 2: Managing electronic components from non-franchised sources

Process management for avionics - Counterfeit prevention - Part 2: Managing electronic components from non-franchised sources

IEC TS 62668-2:2014(en) defines requirements for avoiding the use of counterfeit, recycled and fraudulent components when these components are purchased outside of franchised distributor networks for use in the aerospace, defence and high performance (ADHP) industries. This practice is used, as derogation, only when there are no reasonable or practical alternatives. Although developed for the ADHP industry, this document may be used by other high-performance and high-reliability industries, at their discretion.

This publication is to be read in conjunction with IEC TS 62239-1:2012 and IEC TS 62668-1:2014

General Information

- Status

- Published

- Publication Date

- 08-Jul-2014

- Technical Committee

- TC 107 - Process management for avionics

- Drafting Committee

- WG 3 - TC 107/WG 3

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 09-Aug-2016

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62668-2:2014 - Process management for avionics - Counterfeit prevention - Part 2: Managing electronic components from non-franchised sources provides requirements and guidance for avoiding counterfeit, recycled and fraudulent electronic components when parts are procured outside franchised distributor networks. Intended primarily for the aerospace, defence and high-performance (ADHP) industries, the Technical Specification defines a controlled “derogation” process to be used only when franchised procurement is impractical or unavailable. The document complements IEC TS 62239-1:2012 and IEC TS 62668-1:2014.

Key topics and technical requirements

The standard focuses on practical supply‑chain controls and risk mitigation for non-franchised sourcing. Major topics include:

- Scope and definitions - clear terms for brokers, aftermarket sources, COTS, counterfeit, etc.

- Risk taxonomy - identification of procurement risks: quality, industrial, reliability, financial and legal risks associated with non-franchised distributors.

- Derogation process - stepwise requirements when using non-franchised sources, including:

- notification to OEM,

- analysis of alternative solutions,

- maintenance of an approved non‑franchised distributor list,

- distributor consultation and verification,

- procurement risk analysis and order authorization,

- incoming inspection, testing and quarantine procedures,

- records, traceability and storage/handling during manufacturing.

- Incoming processing and testing - guidance on inspection, test levels and revalidation of suspect stock (annexes include example test lists).

- Tools and supporting material - flowcharts, sample test matrices and reference to iNEMI counterfeit-calculator tools for risk assessment.

Applications and users

IEC TS 62668-2 is designed for organizations that require high reliability and traceability of electronic components, including:

- avionics and aerospace OEMs and subcontractors

- defence contractors and system integrators

- procurement and supply‑chain managers evaluating non‑franchised suppliers

- quality, assurance and counterfeit prevention teams

- repair and maintenance organizations dealing with obsolete parts

Use cases include controlled sourcing of hard‑to‑find or obsolete components, supplier audits, incoming inspection procedures, and formal approvals for single‑source procurements when franchised distribution is not an option.

Related standards

- IEC TS 62668-1:2014 - Counterfeit prevention Part 1: Avoiding use of counterfeit, fraudulent and recycled electronic components

- IEC TS 62239-1:2012 - Management plan for electronic components

- AS/EN/JISQ 9100 & AS/EN/JISQ 9120 - Quality management for aviation, space and defence organizations and distributors

Keywords: IEC TS 62668-2:2014, counterfeit prevention, avionics, non-franchised distributors, electronic components, aerospace, defence, ADHP, procurement risk, incoming inspection.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

IEC TS 62668-2:2014 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Process management for avionics - Counterfeit prevention - Part 2: Managing electronic components from non-franchised sources". This standard covers: IEC TS 62668-2:2014(en) defines requirements for avoiding the use of counterfeit, recycled and fraudulent components when these components are purchased outside of franchised distributor networks for use in the aerospace, defence and high performance (ADHP) industries. This practice is used, as derogation, only when there are no reasonable or practical alternatives. Although developed for the ADHP industry, this document may be used by other high-performance and high-reliability industries, at their discretion. This publication is to be read in conjunction with IEC TS 62239-1:2012 and IEC TS 62668-1:2014

IEC TS 62668-2:2014(en) defines requirements for avoiding the use of counterfeit, recycled and fraudulent components when these components are purchased outside of franchised distributor networks for use in the aerospace, defence and high performance (ADHP) industries. This practice is used, as derogation, only when there are no reasonable or practical alternatives. Although developed for the ADHP industry, this document may be used by other high-performance and high-reliability industries, at their discretion. This publication is to be read in conjunction with IEC TS 62239-1:2012 and IEC TS 62668-1:2014

IEC TS 62668-2:2014 is classified under the following ICS (International Classification for Standards) categories: 03.100.50 - Production. Production management; 31.020 - Electronic components in general; 49.060 - Aerospace electric equipment and systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62668-2:2014 has the following relationships with other standards: It is inter standard links to IEC TS 62668-2:2016, IEC 62668-2:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62668-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62668-2 ®

Edition 1.0 2014-07

TECHNICAL

SPECIFICATION

colour

inside

Process management for avionics – Counterfeit prevention –

Part 2: Managing electronic components from non-franchised sources

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TS 62668-2 ®

Edition 1.0 2014-07

TECHNICAL

SPECIFICATION

colour

inside

Process management for avionics – Counterfeit prevention –

Part 2: Managing electronic components from non-franchised sources

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

W

ICS 03.100.50; 31.020; 49.060 ISBN 978-2-8322-1680-4

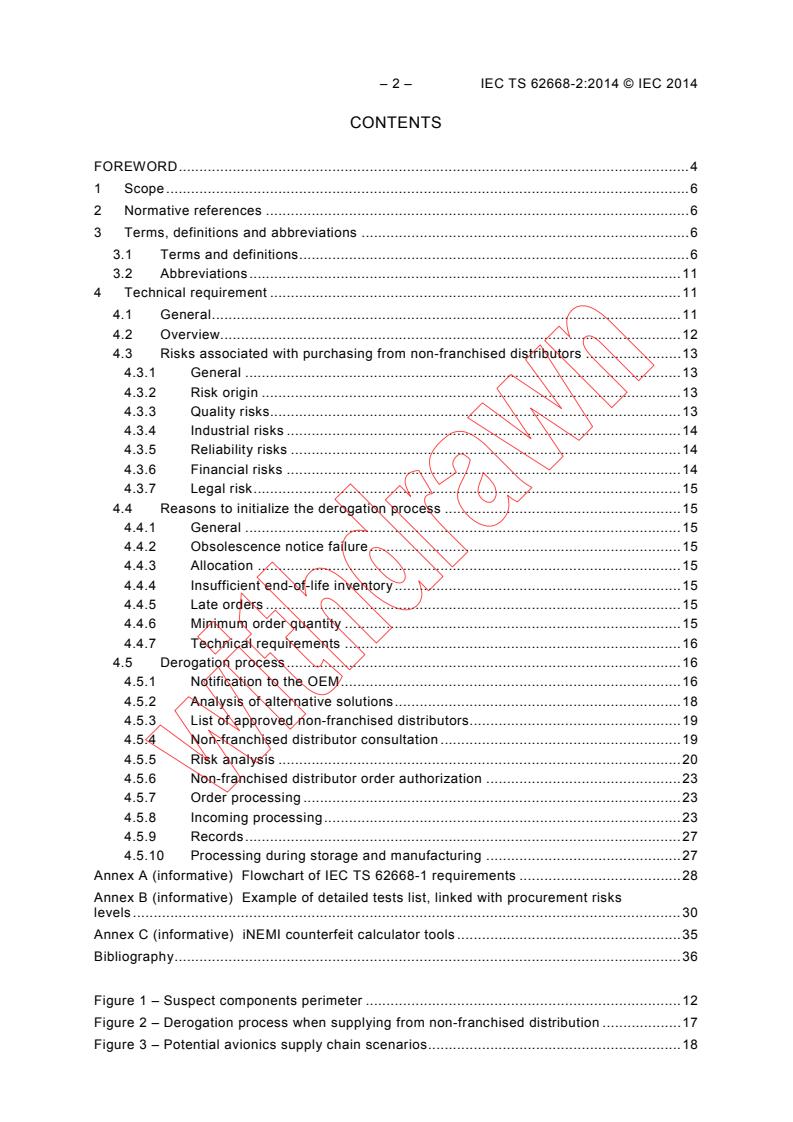

– 2 – IEC TS 62668-2:2014 © IEC 2014

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and abbreviations . 6

3.1 Terms and definitions . 6

3.2 Abbreviations . 11

4 Technical requirement . 11

4.1 General . 11

4.2 Overview. 12

4.3 Risks associated with purchasing from non-franchised distributors . 13

4.3.1 General . 13

4.3.2 Risk origin . 13

4.3.3 Quality risks. 13

4.3.4 Industrial risks . 14

4.3.5 Reliability risks . 14

4.3.6 Financial risks . 14

4.3.7 Legal risk . 15

4.4 Reasons to initialize the derogation process . 15

4.4.1 General . 15

4.4.2 Obsolescence notice failure . 15

4.4.3 Allocation . 15

4.4.4 Insufficient end-of-life inventory . 15

4.4.5 Late orders . 15

4.4.6 Minimum order quantity . 15

4.4.7 Technical requirements . 16

4.5 Derogation process . 16

4.5.1 Notification to the OEM . 16

4.5.2 Analysis of alternative solutions . 18

4.5.3 List of approved non-franchised distributors. 19

4.5.4 Non-franchised distributor consultation . 19

4.5.5 Risk analysis . 20

4.5.6 Non-franchised distributor order authorization . 23

4.5.7 Order processing . 23

4.5.8 Incoming processing . 23

4.5.9 Records . 27

4.5.10 Processing during storage and manufacturing . 27

Annex A (informative) Flowchart of IEC TS 62668-1 requirements . 28

Annex B (informative) Example of detailed tests list, linked with procurement risks

levels . 30

Annex C (informative) iNEMI counterfeit calculator tools . 35

Bibliography . 36

Figure 1 – Suspect components perimeter . 12

Figure 2 – Derogation process when supplying from non-franchised distribution . 17

Figure 3 – Potential avionics supply chain scenarios . 18

Table 1 – Typical procurement risk scenarios and guidance for procurement risk

assessment . 20

Table 2 – Typical testing . 25

Table B.1 − Example of detailed revalidation testing of suspect stock . 30

– 4 – IEC TS 62668-2:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PROCESS MANAGEMENT FOR AVIONICS –

COUNTERFEIT PREVENTION –

Part 2: Managing electronic components

from non-franchised sources

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when:

• The required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• The subject is still under technical development or where, for any other reason, there is

the future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC/TS 62668-2, which is a technical specification, has been prepared by IEC technical

committee 107: Process management for avionics.

IEC/TS 62668-2 adapts and modifies the GIFAS 5052/2008 document that has served as a

basis for the elaboration of this technical specification.

This technical specification is to be used in conjunction with IEC/TS 62239-1 and

IEC/TS 62688-1.

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

107/228/DTS 107/236/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62668 series, published under the general title Process

management for avionics – Counterfeit prevention, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC TS 62668-2:2014 © IEC 2014

PROCESS MANAGEMENT FOR AVIONICS –

COUNTERFEIT PREVENTION –

Part 2: Managing electronic components

from non-franchised sources

1 Scope

The avionics industry has a responsibility to ensure that all flight equipment produced has a

predicted product life which correlates to the predicted repair and service life to ensure the

public is not endangered. Typically an OEM calculates a mean time between failure (MTBF)

and possibly a mean time to failure (MTTF) prediction. These calculations assume all

components are new, or considered as “unused”, at the point of introduction into flight use

and that no useful component life and/or any “unsafe” component conditions have been used.

This part of IEC 62668, which is a technical specification, defines requirements for avoiding

the use of counterfeit, recycled and fraudulent components when these components are

purchased outside of franchised distributor networks for use in the aerospace, defence and

high performance (ADHP) industries. This practice is used, as derogation, only when there are

no reasonable or practical alternatives.

Although developed for the ADHP industry, this document may be used by other high-

performance and high-reliability industries, at their discretion.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC TS 62239-1, Process management for avionics – Management plan – Part 1: Preparation

and maintenance of an electronic components management plan

IEC TS 62668-1:2014, Process management for avionics – Counterfeit prevention – Part 1:

Avoiding the use of counterfeit, fraudulent and recycled electronic components

AS/EN/JISQ 9100, Quality Management Systems – Requirements for Aviation, Space and

Defense Organizations

AS/EN/JISQ 9120, Quality Management Systems – Requirements for Aviation, Space and

Defense Distributors

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms, definitions and abbreviations apply.

3.1.1

aftermarket source

reseller which may or may not be under contract with the original component manufacturer

(OCM) or is sometimes a component “re-manufacturer”, under contract with the OCM

Note 1 to entry: The reseller accumulates inventories of encapsulated or non-encapsulated components (wafer

and/or die) whose end of life date has been published by the OCM. These components are then resold at a profit to

fill a need within the market for components that have become obsolete.

[SOURCE: IEC TS 62668-1:2014, 3.1.1]

3.1.2

broker

individual or corporate organization that serves as an intermediary between buyer and seller

Note 1 to entry: In the electronic component sector a broker specifically seeks to supply obsolete or hard to find

components in order to turn a profit. To do so it may accumulate an inventory of components considered to be of

strategic value or may rely on inventories accumulated by another. The broker operates within a worldwide

component exchange network.

[SOURCE: IEC TS 62668-1:2014, 3.1.2]

3.1.3

COTS

commercial off-the-shelf products

one or more pieces, mechanical or electrical, developed for multiple commercial consumers,

whose design and/or configuration is controlled by the supplier’s specification or industry

standard

Note 1 to entry: They can include electronic components, subassemblies, or top level assemblies. COTS

subassemblies include circuit card assemblies, power supplies, hard drives, and memory modules. Top-level COTS

assemblies include a fully integrated rack of equipment such as raid arrays, file servers to individual switches,

routers, personal computers, or similar equipment.

[SOURCE: IEC TS 62668-1:2014, 3.1.3]

3.1.4

counterfeit, verb

action of simulating, reproducing or modifying a material, good or its packaging without

authorization

Note 1 to entry: It is the practice of producing products which are imitations or are fake goods or services. This

activity infringes the intellectual property rights of the original manufacturer and is an illegal act. Counterfeiting

generally relates to willful trademark infringement.

[SOURCE: IEC TS 62668-1:2014, 3.1.4]

3.1.5

counterfeited component

material good imitating or copying an authentic material, good which may be covered by the

protection of one or more registered or confidential intellectual property rights

Note 1 to entry: A counterfeited component is one whose identity or pedigree has been altered or misrepresented

by its supplier.

Identity = original manufacturer, part number, date code, lot number, testing, inspection, documentation or warranty

etc.

Pedigree = origin, ownership history, storage, handling, physical condition, previous use etc.

[SOURCE: IEC TS 62668-1:2014, 3.1.5]

3.1.6

customer device specification

device specification written by a user and agreed by the supplier

– 8 – IEC TS 62668-2:2014 © IEC 2014

[SOURCE: IEC/TS 62668-1:2014, 3.1.6]

3.1.7

customer

user

original equipment manufacturer (OEM) which purchases electronic components, including

integrated circuits and/or semiconductor devices compliant with this technical specification,

and uses them to design, produce, and maintain systems

[SOURCE: IEC TS 62668-1:2014, 3.1.7]

3.1.8

data sheet

document prepared by the manufacturer that describes the electrical, mechanical, and

environmental characteristics of the component

[SOURCE: IEC TS 62668-1:2014, 3.1.8]

3.1.9

franchised distributor or agent

individual or corporate organisation that is legally independent from the franchiser (in this

case the electronic component manufacturer or OCM) and agrees under contract to distribute

products using the franchiser’s name and sales network

Note 1 to entry: Distribution activities are carried out in accordance with standards set and controlled by the

franchiser. Shipments against orders placed can be dispatched either direct from the OCM or the franchised

distributor or agent. In other words, the franchised distributor enters into contractual agreements with one or more

electronic component manufacturers to distribute and sell the said components. Distribution agreements may be

stipulated according to the following criteria: geographical area, type of clientele (avionics for example), maximum

manufacturing lot size. Components sourced through this route are protected by the OCM’s warranty and supplied

with full traceability.

[SOURCE: IEC TS 62668-1:2014, 3.1.9]

3.1.10

fraudulent component

electronic component produced or distributed either in violation of regional or local law or

regulation, or with the intent to deceive the customer

Note 1 to entry: This includes but is not limited to the following which are examples of components which are

fraudulently sold as new ones to a customer:

(1) a stolen component;

(2) a component scrapped by the original component manufacturer (OCM) or by any user;

(3) a recycled component, becomes a fraudulent recycled component ,when it is a disassembled component

resold as a new component (see Figure 1), where typically there is evidence of prior use and rework (e.g.

solder, re-plating or lead re-attachment activity) on the component package terminations;

(4) a counterfeit component, a copy, an imitation, a full or partial substitute of brands;

(5) fraudulent designs, models , patents, software or copyright sold as being new and authentic, For example:

a component whose production and distribution are not controlled by the original manufacturer;

(6) unlicensed copies of a design;

(7) a disguised component (remarking of the original manufacturer’s name, reference date/code or other

identifiers etc.),which may be a counterfeit component; see Figure 1;

(8) a component without an internal silicon die or with a substituted silicon die which is not the original

manufacturer’s silicon die.

[SOURCE: IEC TS 62668-1:2014, 3.1.10]

3.1.11

microcircuit

component

device

electrical or electronic device that is not subject to disassembly without destruction or

impairment of design use and is a small circuit having a high equivalent circuit element

density which is considered as a single part composed of interconnected elements on or

within a single substrate to perform an electronic circuit function

Note 1 to entry: This excludes printed wiring boards / printed circuit boards, circuit card assemblies and modules

composed exclusively of discrete electronic components).

[SOURCE: IEC TS 62668-1:2014, 3.1.11]

3.1.12

non-franchised distributor

companies which do not fall under a franchised distributor or OCM

Note 1 to entry: Tthese distributors may purchase components from component manufacturers, franchised

distributors, or through other supply channels (open markets). These distributors cannot always provide the

guarantees and support provided by the franchised distributor network; components sourced through this source

are usually protected by the source’s warranty only. However, some of them are able to purchase traceable

components and/or to provide traceability paperwork and/or are able to return stock for investigation to the OCM.

[SOURCE: IEC TS 62668-1:2014, 3.1.12]

3.1.13

OCM

original component manufacturer

company specifying and manufacturing the electronic component

[SOURCE: IEC TS 62668-1:2014, 3.1.13]

3.1.14

OEM

original equipment manufacturer

manufacturer which defines the electronic subassembly that includes the electronic

components or defines the components used in an assembly and/or test specification

[SOURCE: IEC TS 62668-1:2014, 3.1.14]

3.1.15

piracy

willful copyright infringement

[SOURCE: IEC TS 62668-1:2014, 3.1.15]

3.1.16

purchasing agency

organization which groups the quantities of electronic components required by a series of

companies in order to constitute significant buying power and thereby obtain the best possible

supplier conditions for purchasing (especially as regards pricing and purchasing conditions)

as well as for assistance with management, documentation , financing etc.

3.1.17

reseller

general supplier which offers a selection of electronic components to order from a catalogue

[SOURCE: IEC TS 62668-1:2014, 3.1.16]

– 10 – IEC TS 62668-2:2014 © IEC 2014

3.1.18

recycled component

electrical component removed from its original product or assembly and available for reuse

Note 1 to entry: The component has authentic logos, trademarks and markings. However, it typically has no

output to measure the useful life remaining for its reuse. A recycled component can fail earlier than a new one

when re-assembled into another product or assembly. A recycled component may also be physically or ESD

damaged during the removal process.

[SOURCE: IEC TS 62668-1:2014, 3.1.17]

3.1.19

semiconductor

electronic component in which the characteristic distinguishing electronic conduction takes

place within a semiconductor

Note 1 to entry: This includes semiconductor diodes which are semiconductor devices having two terminals and

exhibiting a nonlinear voltage-current characteristic and transistors which are active semiconductor devices

capable of providing power amplification and having three or more terminals.

[SOURCE: IEC TS 62668-1:2014, 3.1.18]

3.1.20

subcontractor

manufacturer of electronic subassemblies, supplier manufacturingitems in compliance with

customer design data pack and drawings, and under the authority of the OEM

Note 1 to entry: This supplier may potentially procure all or part of the electronic components required to produce

a sub assembly and is often referred to as the contract electronic manufacturer (CEM) or electronics manufacturing

services (EMS).

[SOURCE: IEC TS 62668-1:2014, 3.1.19]

3.1.21

supplier

company which provides to another an electronic component which is identified by the logo or

name marked on the device

Note 1 to entry: A supplier can be an OCM, a franchised distributor or agent, a non-franchised distributor, broker,

reseller, OEM, CEM, and EMS etc.

[SOURCE: IEC TS 62668-1:2014, 3.1.20]

3.1.22

suspect component

electronic component which has lost supply chain traceability back to the original

manufacturer and which may have been misrepresented by the supplier or manufacturer and

may meet the definition of fraudulent or counterfeit component

Note 1 to entry: Suspect components may include but are not limited to:

(1) counterfeit components;

(2) recycled components coming from uncontrolled recycling operations carried outside of the OEM, franchised

network and OEM business where typically it has been fraudulently sold to the OEM as being in a new

unused condition.

[SOURCE: IEC TS 62668-1:2014, 3.1.21]

3.1.23

traceability

ability to have for an electronic component its full trace back to the original component

manufacturer

Note 1 to entry: This traceability means that every supplier in the supply chain is prepared to legally declare in

writing that they know and can identify their source of supply, which goes back to the original manufacturer and

can confirm that the electronic components are brand new and were handled with appropriate handling precautions

including ESD and MSL. This authenticates the electronic components being supplied are unused, brand new

components with no ESD, MSL or other damage. This ensures that the electronic components are protected by

any manufacturer’s warranties, have all of their useful life remaining and function according to the manufacturer’s

published data sheet, exhibiting the expected component life in the application for the OEM’s reliability predictions

and product warranty.

[SOURCE: IEC TS 62668-1:2014, 3.1.22]

3.1.24

untraceable

property of electronic components which have lost their traceability (see 3.1.23)

[SOURCE: IEC TS 62668-1:2014, 3.1.23]

3.2 Abbreviations

ACTF Semiconductor Industries Association Anti Counterfeit Task Force

ADHP aerospace, defence and high performance

COTS commercial off-the-shelf

CEM contract electronic manufacturer

CSAM C-mode scanning acoustic microscopy

DSCC Defence Supply Centre Columbus (see http://www.dscc.dla.mil/), now known as

DLA

DLA Defense Logistics Agency

EMS electronics manufacturing services

ERAI Electronic Reseller Association International (see http://www.erai.com)

ESD electrostatic discharges

G-19 SAE Counterfeit Electronic Parts Committee

GIDEP Government-Industry Data Exchange Program

GIFAS Groupement des Industries Françaises Aéronautiques et Spatiales (French

Aerospace Association)

HTRB high temperature reverse bias

IDEA Independent Distributors of Electronics Association

LTB last time buy

LDC lot date code

MSL moisture sensitivity level

OCM original component manufacturer

OEM original equipment manufacturer

RECS Reliable Electronic Component Supplier

SEM scanning electron microscopy

UKEA UK Electronics Alliance

4 Technical requirement

4.1 General

IEC TS 62668-1 minimises counterfeiting, recycling and fraudulent activities by providing

guidelines and requirements for maintaining intellectual property and recommends purchasing

traceable components from the OCMs or their franchised distributors (see Annex A). IEC TS

62668-1 references this part of the IEC 62668 series when purchasing components outside of

– 12 – IEC TS 62668-2:2014 © IEC 2014

the franchised distributor network in order to avoid and manage suspect components (see

3.1.22 for the definition of “suspect component” and Figure 1).

IEC

Figure 1 – Suspect components perimeter

4.2 Overview

OEM companies have numerous sourcing channels available to procure components for their

equipment. It is the original equipment manufacturer’s (OEM) responsibility to ensure that its

electronic component procurement process is robust.

The original equipment manufacturer, or subcontractor, which includes Purchasing Agents

acting on its behalf, which places orders for these components shall order directly from a

component manufacturer, the manufacturer representative or its franchised distributor. This is

the only supply system that can guarantee component compliance with specifications and

component origin (see IEC TS 62668-1).

Under exceptional circumstances, and after having exhausted all options within the franchised

system, the OEM may decide to purchase components through a non-franchised distribution

network. Purchasing through non-franchised channels is considered a derogation process for

which the OEM is fully responsible.

The OEM is responsible for ensuring that its products do not include counterfeit components.

Moreover, it guarantees that the reliability of its equipment is not affected when this

equipment includes components purchased from non-franchised sources.

The OEM shall have anti-counterfeit management plans in place, to comply with

IEC TS 62668-1.

Subclauses 4.3 to 4.5.10 apply to OEMs and their subcontractors when purchasing

components from sources of supply other than from the OCM or from franchised distributors.

However, there are the following exclusions to this specification:

1) In situations where Purchasing Agents are under contract to the OEMs to order

components on their behalf, the Purchasing Agent is considered to be ‘the OEM’ and is

not considered to be a non-franchised distributor.

2) In situations where an approved logistics supply agency, for example the DLA in the USA,

supplies components for logistics purposes to a national defence customer and associated

OEMs, the approved logistics supply agency is not considered to be a non-franchised

distributor.

4.3 Risks associated with purchasing from non-franchised distributors

4.3.1 General

There are the following risks to consider (see 4.3.2 to 4.3.7).

Various risk assessment tools exist which the OEM may consider when assessing risks; for

example, iNEMI provided three counterfeit calculator tools (see Annex C).

4.3.2 Risk origin

Counterfeit and fraudulent products have been repeatedly identified by electronic equipment

manufacturers. Purchasing, using and reselling fraudulent components is illegal. A major

difficulty lies in recognizing these fraudulent components, as electronic components may be

counterfeited in many ways. Increased market demand encourages this illicit activity and

counterfeiters continue to improve their manufacturing processes, disguise and falsification

methods. Electronic equipment manufacturers shall consequently take increasingly strict

measures to mitigate risk. The equipment manufacturer shall take all necessary measures,

both internally and with regard to its chosen supplier, to ensure that components acquired are

OCM (original component manufacturer) produced that they have not been modified,

remarked, or previously installed in applications, nor undergone testing that might impact their

performance or reliability.

Fraud and specifically counterfeiting of electronic components has most often been detected

with components supplied by brokers. Therefore, the information that follows in this document

will refer essentially to this type of supplier which cannot generally supply traceability back to

the OCM. The electronic equipment manufacturer should remember, however, to use caution

when purchasing from any source outside of a franchised network.

4.3.3 Quality risks

4.3.3.1 General

Quality risks include the following.

4.3.3.2 Lots

There is a high risk of receiving non-homogeneous lots of components, having different

manufacturing date/codes and produced at various manufacturing sites. A large lot of

obsolete components with a single lot date code (LDC) should be considered suspect by the

purchaser (risks of refurbished/relabeled components for example).

4.3.3.3 Packaging

The origin and storage conditions of the components proposed by non-franchised distributors

are generally unknown. This presents a risk that the components proposed by a non-

franchised distributor were not stored under manufacturer-recommended conditions. This is

important for components that are sensitive to electrostatic discharges (ESDs) or moisture.

These components may also have been removed from their original packaging and handled

without the proper protective measures.

– 14 – IEC TS 62668-2:2014 © IEC 2014

4.3.3.4 Disassembled or recycled components

There is a great risk that these components were recovered from board or equipment at the

end of their life cycles or no longer in use. As component removal conditions are strictly

unknown, the integrity, performance and reliability of the components cannot be guaranteed.

4.3.3.5 Failed or scrap components

There is also the risk that the proposed components come from OCM lots rejected by a

manufacturer or customer after discovery of a manufacturing or specification non-compliance

issue.

NOTE Often EMSs dispose of surplus stock onto the open market without identifying if these were scrap parts or

good parts. Damaged components from fires, floods, earthquakes, etc., also can be sold onto the open market.

These can also be products rejected by the customer due to specific requirements not being met, such as an

unsatisfactory parameter sort.

4.3.3.6 Traceability

Purchasing through non-franchised distributors cannot often provide traceability back to the

OCM.

NOTE Moreover lack of traceability can lead to supply stolen components or components issued from

uncontrolled midnight production. Certificates of conformance can themselves be counterfeited.

4.3.4 Industrial risks

Use of components whose origin is uncertain can result in industrial risks during equipment

manufacturing and utilization:

• during production of boards, potential poor storage and handling of components supplied

by non-franchised distributors may impact these components. Oxidation, pollution, moisture,

warping or imperfect flatness of connections may cause visible or hidden faults during

board wiring;

• late detection of defective or counterfeit components during board and/or equipment

functional testing may seriously impact management of production and costs, due to

potential part scrapping or repair;

• detection of defective or counterfeit components during equipment utilization may require

retrofitting the equipment concerned, with probable serious consequences for the OCM.

4.3.5 Reliability risks

Use of components whose origin is uncertain can directly and gravely impact the operational

reliability of the equipment concerned.

4.3.6 Financial risks

4.3.6.1 Part costs

Purchasing components from a non-franchised supplier can have impacts on the purchasing

costs. The unit price of the component may be extremely high, because of market demand,

the degree of obsolescence, and the technical specification and quality levels required for

certain applications (defence applications, for example). Requests sent out to numerous

brokers can create an inflated, artificial demand for a given inventory, whose price will

subsequently rise.

4.3.6.2 Reimbursement

Many brokers, and more generally non-franchised distributors, work exclusively with sales

agreements that contain non-cancellation clauses. In some countries once components have

been identified as counterfeit they have to be stored for the regional law enforcement bodies

and cannot be returned back into the supply chain as in those countries it is illegal to sell

counterfeit or fraudulent components.

4.3.7 Legal risk

An electronic equipment manufacturer may be held legally liable for equipment failure having

serious consequences. Sourcing components from outside the franchised network makes it

nearly impossible to hold the OCM liable for product failure during utilization. Because this

type of purchasing does not provide OCM warrantees, only the OEM is held responsible.

The OEM is considered contractually liable for the sale of equipment containing counterfeit or

suspect parts. The vendor’s extra-contractual liability (or tort liability) may also be invoked if

the sale is considered an act of negligence or carelessness.

Damage caused by failure of components integrated into equipment is covered by the

electronic equipment manufacturer’s liability insurance. If the damage results from failure of a

counterfeit or suspect component, the electronic equipment manufacturer may be held

criminally responsible. These aspects should be considered in the context of the applicable

legislation in the countries in which the various supply chain vendors operate.

4.4 Reasons to initialize the derogation process

4.4.1 General

If there are no other reasonable or practical alternatives, then the OEM or the subcontractor

shall use the following derogation process when they are considering procuring untraceable

components from a non-franchised distributor. This process shall be used in exceptional

circumstances and shall not be normal practice.

4.4.2 Obsolescence notice failure

The last time buy (LTB) has expired. No LTB date was published by the manufacturer or the

obsolescence process failed to detect the LTB.

4.4.3 Allocation

A shortage caused by high market demand. The supplier cannot provide a firm delivery date.

This situation was not detected or foreseen during the production planning.

4.4.4 Insufficient end-of-life inventory

The end-of-life inventory accumulated at the last time buy (LTB) order is not sufficient for the

current program or to fill new orders.

4.4.5 Late orders

Late-stage modifications (quantities, lead time, etc.) were made to production planning. The

standard supply period for a needed component is not compatible with the modifications

made.

4.4.6 Minimum order quantity

The minimum order quantity greatly exceeds required quantities.

– 16 – IEC TS 62668-2:2014 © IEC 2014

4.4.7 Technical requirements

Upon request of the OEM design authority when the design or manufacturing data pack

requires use of a specific version of a component (date/code, mask, production site, lead

finish, etc.) that is no longer available through franchised distributors.

4.5 Derogation process

4.5.1 Notification to the OEM

Under the circumstances described in 4.4, the subcontractor shall notify the OEM defined

authority of the unavailability of a given component with traceability through the franchised

distributor network; AS/EN/JISQ 9100 certified non-franchised distributors which can provide

traceability back to the OCM are exempt from these requirements.

Figure 2 describes the derogation process when supplying without traceability from non-

franchised distribution.

Figure 3 describes potential avionics supply chain scenarios which may exist.

IEC

Figure 2 – Derogation process when supplying from non-franchised distribution

– 18 – IEC TS 62668-2:2014 © IEC 2014

Customer e.g.

airframer

OEM

CEM for OEM

Subcontractor is the OEM Purchasing

assembly where OEM component

design authority for his Agent under

the OEM is the procurement

product sold to OEM contract to OEM

design authority

CEM for CEM procurement

Subcontractor

subcontractor who based on OEM

component

is the design approved part

procurement

authority numbers

CEM component

procurement

Use of non- Use of non- Use of non- Use of non- Use of non-

franchised franchised franchised franchised franchised

distributor distributor distributor distributor distributor

IEC

Figure 3 – Potential avionics supply chain scenarios

4.5.2 Analysis of alternative solutions

Alternative solutions shall be examined by the OEM with the subcontractor to take into

account the technical and financial impacts for each program concerned, as well as the

reasons behind the sourcing difficulty.

The following alternative solutions should take precedence, as they provide the best

guarantees with regard to component origin:

Definition maintained (no change in the bill of material):

– Production cycle rescheduled to coincide with the component supply lead time using a

franchised network.

– The individual who defined the need authorizes use of an equivalent compone

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...