IEC 60297-3-108:2014

(Main)Mechanical structures for electronic equipment - Dimensions of mechanical structures of the 482,6 mm (19 in) series - Part 3-108: Dimensions of R-type subracks and plug-in units

Mechanical structures for electronic equipment - Dimensions of mechanical structures of the 482,6 mm (19 in) series - Part 3-108: Dimensions of R-type subracks and plug-in units

IEC 60297-3-108:2014 provides dimensions and features for R-type subracks and plug-in units, i.e. ruggedized variants of the mechanical structures of the 482,6 mm (19 in) series, with enhanced vibration and shock resistance and/or improved EMC performance, for use in more harsh environment. This leads to a subrack standard which is externally compatible with IEC 60297-3-100 but internally largely incompatible with IEC 60297-3-101. R-type subracks, chassis integrated subracks and plug-in units incorporate dimensions and features which provide for a higher level of ruggedness, compared with IEC 60297-3-101 (test set-up and load definitions are selected from IEC 61587-1 and IEC 61587-5). Key words: R-Type, Subracks, Plug-in unit

Structures mécaniques pour équipements électroniques - Dimensions des structures mécaniques de la série 482,6 mm (19 pouces) - Partie 3-108: Dimensions des bacs de type R et des blocs enfichables

IEC 60297-3-108:2014 donne les dimensions et caractéristiques des bacs de type R et des blocs enfichables, c'est-à-dire des variantes renforcées des structures mécaniques de la série 482,6 mm (19 pouces), avec une augmentation de la résistance aux vibrations et aux chocs et/ou une amélioration des performances CEM, pour utilisation dans un environnement plus sévère. Ceci donne lieu à une norme sur les bacs, qui est compatible d'un point de vue externe avec l'IEC 60297-3-100, mais largement incompatible d'un point de vue interne avec l'IEC 60297-3-101. Les bacs de type R, les bacs intégrés au châssis et les blocs enfichables comportent des dimensions et des caractéristiques qui fournissent un niveau plus élevé de robustesse, par rapport à l'IEC 60297-3-101 (les définitions relatives au montage d'essai et à la charge sont choisies dans l'IEC 61587-1 et l'IEC 61587-5). Mots-clés: type R, bacs, bloc enfichable

General Information

- Status

- Published

- Publication Date

- 08-Sep-2014

- Technical Committee

- SC 48D - Mechanical structures for electrical and electronic equipment

- Drafting Committee

- WG 4 - TC 48/SC 48D/WG 4

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-Sep-2014

- Completion Date

- 31-Aug-2014

Overview

IEC 60297-3-108:2014 is an international standard developed by the International Electrotechnical Commission (IEC) focusing on mechanical structures for electronic equipment within the 482.6 mm (19 in) series. This part specifically addresses the dimensions and features of R-type subracks and plug-in units. Characterized as ruggedized variants, R-type mechanical structures offer enhanced vibration and shock resistance alongside improved electromagnetic compatibility (EMC) performance, designed for use in harsh environments.

This standard guides manufacturers and designers in producing subracks and plug-in units that maintain external compatibility with IEC 60297-3-100 but feature internal designs optimized for robustness rather than compatibility with IEC 60297-3-101. It defines critical mechanical details-such as dimensions, mounting provisions, and electromagnetic shielding-that facilitate building durable and reliable electronic equipment enclosures.

Key Topics

R-Type Subrack Dimensions

The standard specifies precise dimensions for RA- and RB-type subracks, including front and rear mounting parameters, allowing for sturdy construction with optimized height apertures for top and bottom load bearing members.Plug-in Unit Compatibility and Features

Detailed dimensions and features enable alignment pins and secure fastening of plug-in units, promoting ease of insertion/extraction and secure mounting.Mounting Flanges and Chassis Integration

Introduces design provisions such as recessable mounting flanges to accommodate heavy subracks with optimal center of gravity placement. It also includes chassis integrated subracks emphasizing improved thermal management.Ruggedness and Environmental Resistance

The subracks are designed following test setups and load definitions from IEC 61587-1 and IEC 61587-5, ensuring superior vibration and shock resistance for use under challenging operational conditions.Electromagnetic Shielding

Incorporates guidelines for electromagnetic shielding provisions and mounting flanges to enhance EMC performance in demanding environments.

Applications

IEC 60297-3-108:2014 is highly relevant for industries requiring robust electronic equipment housing solutions, including:

Telecommunications and Networking

Ruggedized subracks for outdoor or industrial telecom equipment exposed to vibration and electromagnetic interference.Military and Aerospace Electronics

Systems requiring high shock and vibration resistance, along with reliable modular components for maintainability.Industrial Automation and Control Systems

Equipment deployed in harsh factory floors or field environments demanding shielding against EMI and mechanical endurance.Transportation and Railways

Electronic units and control modules subjected to dynamic mechanical stresses necessitating sturdy enclosure standards.Energy and Power Electronics

Subrack solutions optimized for thermal management and EMC compliance in power generation and distribution systems.

Related Standards

To ensure comprehensive compliance and compatibility, IEC 60297-3-108:2014 should be considered alongside relevant related standards:

IEC 60297-3-100

Defines mechanical structures for 19-inch series subracks with general mechanical dimensions.IEC 60297-3-101

Details the mechanical structure dimensions for plug-in units with standard, less rugged configurations than the R-type.IEC 61587-1 and IEC 61587-5

Specify mechanical load tests, vibration, and shock requirements critical for validating ruggedness in line with this subrack standard.IEC 60917 Series

Covers mechanical structures and assembly methods in electronic equipment enclosures, complementing the specifications for thermal and EMC performance.

By adhering to IEC 60297-3-108:2014, manufacturers ensure their R-type subracks and plug-in units meet stringent durability, mechanical, and electromagnetic requirements emerging from demanding industrial and environmental conditions. This standard facilitates interoperability, safety, and longevity in electronic equipment mechanical design.

Frequently Asked Questions

IEC 60297-3-108:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Mechanical structures for electronic equipment - Dimensions of mechanical structures of the 482,6 mm (19 in) series - Part 3-108: Dimensions of R-type subracks and plug-in units". This standard covers: IEC 60297-3-108:2014 provides dimensions and features for R-type subracks and plug-in units, i.e. ruggedized variants of the mechanical structures of the 482,6 mm (19 in) series, with enhanced vibration and shock resistance and/or improved EMC performance, for use in more harsh environment. This leads to a subrack standard which is externally compatible with IEC 60297-3-100 but internally largely incompatible with IEC 60297-3-101. R-type subracks, chassis integrated subracks and plug-in units incorporate dimensions and features which provide for a higher level of ruggedness, compared with IEC 60297-3-101 (test set-up and load definitions are selected from IEC 61587-1 and IEC 61587-5). Key words: R-Type, Subracks, Plug-in unit

IEC 60297-3-108:2014 provides dimensions and features for R-type subracks and plug-in units, i.e. ruggedized variants of the mechanical structures of the 482,6 mm (19 in) series, with enhanced vibration and shock resistance and/or improved EMC performance, for use in more harsh environment. This leads to a subrack standard which is externally compatible with IEC 60297-3-100 but internally largely incompatible with IEC 60297-3-101. R-type subracks, chassis integrated subracks and plug-in units incorporate dimensions and features which provide for a higher level of ruggedness, compared with IEC 60297-3-101 (test set-up and load definitions are selected from IEC 61587-1 and IEC 61587-5). Key words: R-Type, Subracks, Plug-in unit

IEC 60297-3-108:2014 is classified under the following ICS (International Classification for Standards) categories: 31.240 - Mechanical structures for electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60297-3-108:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60297-3-108 ®

Edition 1.0 2014-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Mechanical structures for electronic equipment – Dimensions of mechanical

structures of the 482,6 mm (19 in) series –

Part 3-108: Dimensions of R-type subracks and plug-in units

Structures mécaniques pour équipements électroniques – Dimensions des

structures mécaniques de la série 482,6 mm (19 pouces) –

Partie 3-108: Dimensions des bacs de type R et des blocs enfichables

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60297-3-108 ®

Edition 1.0 2014-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Mechanical structures for electronic equipment – Dimensions of mechanical

structures of the 482,6 mm (19 in) series –

Part 3-108: Dimensions of R-type subracks and plug-in units

Structures mécaniques pour équipements électroniques – Dimensions des

structures mécaniques de la série 482,6 mm (19 pouces) –

Partie 3-108: Dimensions des bacs de type R et des blocs enfichables

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX U

ICS 31.240 ISBN 978-2-8322-1790-0

– 2 – IEC 60297-3-108:2014 © IEC 2014

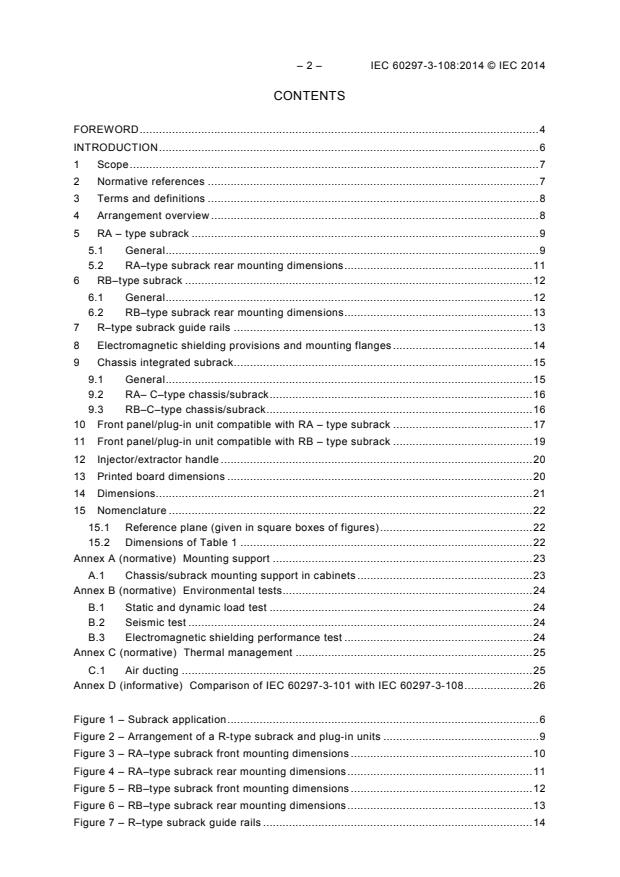

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Arrangement overview . 8

5 RA – type subrack . 9

5.1 General . 9

5.2 RA–type subrack rear mounting dimensions . 11

6 RB–type subrack . 12

6.1 General . 12

6.2 RB–type subrack rear mounting dimensions . 13

7 R–type subrack guide rails . 13

8 Electromagnetic shielding provisions and mounting flanges . 14

9 Chassis integrated subrack . 15

9.1 General . 15

9.2 RA– C–type chassis/subrack . 16

9.3 RB–C–type chassis/subrack . 16

10 Front panel/plug-in unit compatible with RA – type subrack . 17

11 Front panel/plug-in unit compatible with RB – type subrack . 19

12 Injector/extractor handle . 20

13 Printed board dimensions . 20

14 Dimensions. 21

15 Nomenclature . 22

15.1 Reference plane (given in square boxes of figures) . 22

15.2 Dimensions of Table 1 . 22

Annex A (normative) Mounting support . 23

A.1 Chassis/subrack mounting support in cabinets . 23

Annex B (normative) Environmental tests. 24

B.1 Static and dynamic load test . 24

B.2 Seismic test . 24

B.3 Electromagnetic shielding performance test . 24

Annex C (normative) Thermal management . 25

C.1 Air ducting . 25

Annex D (informative) Comparison of IEC 60297-3-101 with IEC 60297-3-108 . 26

Figure 1 – Subrack application . 6

Figure 2 – Arrangement of a R-type subrack and plug-in units . 9

Figure 3 – RA–type subrack front mounting dimensions . 10

Figure 4 – RA–type subrack rear mounting dimensions . 11

Figure 5 – RB–type subrack front mounting dimensions . 12

Figure 6 – RB–type subrack rear mounting dimensions . 13

Figure 7 – R–type subrack guide rails . 14

Figure 8 – R–type subrack front attachment plane and mounting flanges . 15

Figure 9 – RA – C type chassis/subrack . 16

Figure 10 – RB–C – type chassis/subrack . 17

Figure 11 – Front panel/ plug-in unit compatible with RA – type subrack . 18

Figure 12 – Front panel/ plug-in unit compatible with RB – type subrack . 19

Figure 13 – Injector/extractor handle . 20

Figure 14 – Printed board dimensions . 21

Figure A.1 – Subrack/chassis mounting support . 23

Figure C.1 – Thermal management example . 25

Table 1 – Dimensions . 21

Table D.1 – Comparison of dimensions and features . 26

– 4 – IEC 60297-3-108:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MECHANICAL STRUCTURES

FOR ELECTRONIC EQUIPMENT –

DIMENSIONS OF MECHANICAL STRUCTURES

OF THE 482,6 mm (19 in) SERIES –

Part 3-108: Dimensions of R-type subracks and plug-in units

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60297-3-108 has been prepared by subcommittee 48D:

Mechanical structures for electronic equipment, of IEC technical committee 48: Electrical

connectors and mechanical structures for electrical and electronic equipment.

The text of this standard is based on the following documents:

FDIS Report on voting

48D/565/FDIS 48D/570/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 60297 series, under the general title Mechanical structures for

electronic equipment – Dimensions of mechanical structures of the 482,6 mm (19 in) series

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60297-3-108:2014 © IEC 2014

INTRODUCTION

The purpose of this standard is to establish alternative dimensions and features for subracks

and associated plug-in units, compared with IEC 60297-3-101. These alternatives allow more

sturdy designs for the load bearing members of the subrack. In addition, the plug-in units are

with alignment pins and fastened with M3 screws. Chassis integrated subracks are also part

of this standard.

The main differing dimensions/features compared with IEC 60297-3-101 are:

a) The subrack height aperture is decreased in order to increase the dimension for the top

and bottom members (most critical load bearing parts).

b) Incorporated alignment between the subrack and the plug-in units. Injecting and extracting

provisions for plug-in units.

c) The mounting flanges of the subracks are recessable. This feature meets the mounting

requirements of heavy subracks and allows the positioning to the centre of gravity.

d) Chassis integrated subracks for optimized thermal management features.

e) Comparison of dimensions and features with IEC 60297-3-101 is shown in appendix D,

Table D.1. For an application image of the subrack based on this standard see Figure 1.

IEC 60297-3-101

Conventional form factor

and normal weight, for small to medium

volume applications, e.g. general industrial

computing and data processing

IEC 60297-3-107 IEC 60297-3-108

Small form factor and light weight, Heavy weight and large form

for large volume applications, e.g. factor, for large volume

embedded systems, applications, e.g. cloud-

mobile/ubiquitous computing computing servers, telecom

systems servers

Embedded system Full scaled 19 in system Heavy duty 19 in system

Subrack and plug-in unit system weight factor

IEC

Figure 1 – Subrack application

Subrack and plug-in unit

mechanical complexity factor

Low High

MECHANICAL STRUCTURES

FOR ELECTRONIC EQUIPMENT –

DIMENSIONS OF MECHANICAL STRUCTURES

OF THE 482,6 mm (19 in) SERIES –

Part 3-108: Dimensions of R-type subracks and plug-in units

1 Scope

This part of IEC 60297 provides dimensions and features for R-type subracks and plug-in

units, i.e. ruggedized variants of the mechanical structures of the 482,6 mm (19 in) series,

with enhanced vibration and shock resistance and/or improved EMC performance, for use in

more harsh environment. This leads to a subrack standard which is externally compatible with

IEC 60297-3-100 but internally largely incompatible with IEC 60297-3-101. R-type subracks,

chassis integrated subracks and plug-in units incorporate dimensions and features which

provide for a higher level of ruggedness, compared with IEC 60297-3-101 (test set-up and

load definitions are selected from IEC 61587-1 and IEC 61587-5).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60297-3-100, Mechanical structures for electronic equipment – Dimensions of mechanical

structures of the 482,6 mm (19 in) series – Part 3-100: Basic dimensions of front panels,

subracks, chassis, racks and cabinets

IEC 60297-3-101, Mechanical structures for electronic equipment – Dimensions of mechanical

structures of the 482,6 mm (19 in) series – Part 3-101: Subracks and associated plug-in units

IEC 60297-3-105, Mechanical structures for electronic equipment – Dimensions of mechanical

structures of the 482,6 mm (19 in) series – Part 3-105: Dimensions and design aspects for 1U

high chassis

IEC 61587-1, Mechanical structures for electronic equipment – Tests for IEC 60917 and

IEC 60297 series – Part 1: Environmental requirements, test set-up and safety aspects for

cabinets, racks, subracks and chassis under indoor conditions

IEC 61587-3, Mechanical structures for electronic equipment – Tests for IEC 60917 and

IEC60297 – Part 3: Electromagnetic shielding performance tests for cabinets and subracks

IEC 61587-5, Mechanical structures for electronic equipment – Tests for IEC 60917 and

IEC 60297 – Part 5: Seismic tests for chassis, subracks, and plug-in units

IEC TS 62610-2, Mechanical structures for electronic equipment – Thermal management for

cabinets in accordance with IEC 60297 and IEC 60917 series – Part 2: Design guide: Method

for determination of forced air-cooling structure

– 8 – IEC 60297-3-108:2014 © IEC 2014

3 Terms and definitions

For the purposes of this document the following terms and definitions apply.

3.1

R–type subrack and plug–in unit

ruggedized subrack and plug-in unit, with enhanced shock and vibration resistance, with or

without EMC provisions compared with subrack/plug-in units according to IEC 60297-3-101

3.2

chassis integrated subrack

subrack integrated within the envelope of a chassis

4 Arrangement overview

Figure 2 illustrates the typical arrangement of a R-type subrack with the associated plug-in

units.

Optional, additional

receptacle for

Injector/extractor handle

Mounting flange with

mounting dimensions

according to

IEC 60297-3-101

Mandatory receptacle

for injector/extractor

handle

Front panel

Plug-in unit with

injector/extractor handle

IEC

Figure 2 – Arrangement of a R-type subrack and plug-in units

5 RA – type subrack

5.1 General

Figure 3 illustrates the RA-type subrack, defined by the dimension of the first printed board

position in relation to the first pitch line (see detail A). The deflection of the load bearing

members of max. 0,2 mm is permitted.

– 10 – IEC 60297-3-108:2014 © IEC 2014

Dimensions in millimetres,

Front view

tolerances are non-cumulative

≥ 431,80

C D

84 x 5,08 = 426,72

5,08

B

A

G

G

G

A

≤ 449,0 (including fixing hardware)

Detail A

J

Ø4,0 ± 0,1 x 3,2 ± 0,1 receptacle holes

1)

(4,27) 9,7 ± 0,2

for front panel alignment pins

on lower and upper horizontal member

First printed

I

board position

A

G

H

A

M3

6,35 ± 0,1

(see A – A)

1)

1)

Cross-section

13,97 ± 0,1

20,32 ± 0,1

≥ 2, 54

A - A

First pitch line

E

A

2)

1,5 ± 0,2 M3

Min 2,0

R 1,5

Max 1,5

9,5 ± 0,2

IEC

Key

1 If this dimension needs to be increased increments of 5,08mm shall be used, based on the dimension

4,07 mm as in IEC 60297-3-101.

2 May be applied by press-in nuts.

Figure 3 – RA–type subrack front mounting dimensions

n x U

H 6

5,5 + 0/-0,5

H 5

0,2 D

H 6

0,2 G

H 1

5.2 RA–type subrack rear mounting dimensions

Figure 4 illustrates the rear mounting dimensions with the possible mounting holes for

backplanes.

Dimensions in millimetres,

tolerances are non-cumulative

Rear view

84 x 5,08 = 426,72

First pitch line

82 x 5,08 = 416,56

5,08

B

M3 threaded holes

shall be applied for

backplane mounting

C

D

≥ 2,54

First possible backplane

B

mounting position M3

J

(4,27)

B

A

Cross-section B - B

0,2 E

F

E

D 1

IEC

Figure 4 – RA–type subrack rear mounting dimensions

n x U

H 6

H 1

n x U

H 6

– 12 – IEC 60297-3-108:2014 © IEC 2014

6 RB–type subrack

6.1 General

Figure 5 illustrates the subrack RB-type, defined by the dimension of the first printed board

position in relation to the first pitch line (see Detail B). The deflection of the load bearing

members of max. 0,2 mm is permitted.

Dimensions in millimetres,

Front view

tolerances are non-cumulative

≥ 431,80

C

D

84 x 5,08 = 426,72

5,08

B

A

G

B

≤ 449,0 (including fixing hardware)

Detail B

J

Ø4,0 ± 0,1 x 3,2 ± 0,1 receptacle holes for front

7,16 ± 0,2

panel alignment pins

1)

(6,81)

on lower and upper horizontal member.

First printed board

position

G

C

C

Cross-section

C - C

6,35 ± 0,1

C M3 (see C – C)

1)

1)

13,97± 0,1

20,32 ± 0,1

≥ 2, 54

E

First pitch line

2)

M3

A

1,5 ± 0,2

Min 2,0

R 1,5

9,5 ± 0,2

Max 1,5

IEC

Key

1 If this dimension needs to be increased increments of 5,08 mm shall be used, based on the dimension

4,07 mm as in IEC 60297-3-101.

2 Press-in nuts may be applied.

Figure 5 – RB–type subrack front mounting dimensions

n x U

H6

5,5 + 0/-0,5

H 5

0,2 D

H 6

0,2 G

H 1

6.2 RB–type subrack rear mounting dimensions

Figure 6 illustrates the rear mounting dimensions with the possible mounting holes for

backplanes.

Dimensions in millimetres,

tolerances are non-cumulative

Rear view

84 x 5,08 = 426,72

82 x 5,08 = 416,56

First pitch line

D 5,08

M3 threaded holes

shall be applied for

backplane mounting

C

D

≥ 2,54

First possible backplane

mounting position M3

D

J

(6,81)

B

A

Cross-section D - D

0,2 E

E F

D 1

IEC

Figure 6 – RB–type subrack rear mounting dimensions

7 R–type subrack guide rails

The position of guide rails (Figure 7) is always in relation to the receptacle holes for the

alignment pin of the plug-in unit (as shown in Figures 3 and 5, Details A and B).

n x U

H 6

H 1

n x U

H 6

– 14 – IEC 60297-3-108:2014 © IEC 2014

Dimensions in millimetres,

tolerances are non-cumulative

Front view

E E

3)

Cross-section E - E

F

2,8 ± 0,1

E

≥ 30 °

First pitch line

IEC

Key

1 Dimension D 1 and D 2 depend on printed board depth and connector type.

2 Position of an optional ESD contact, connecting both sides of the printed board (ESD = Electrostatic discharge).

3 First guide rail on left.

Figure 7 – R–type subrack guide rails

8 Electromagnetic shielding provisions and mounting flanges

Figure 8 illustrates the subrack front mounting plane with the conductive areas for the

attachment of front panels and the vertical connection at the left and right side panels. The

electromagnetic shielding provisions (EMC: Electromagnetic Compatibility) at the rear of the

subrack may be resolved by backplanes and/or user defined covers. For EMC shielding

performance test see IEC 61587-3.

The mounting flanges may be recessed by n × 25 mm.

1)

D 1

1)

D 2

≥ 13 ,0

2)

10 ± 1,0

3,0 + 0/-0,2 3,0 + 0/-0,2

2)

30 ± 1

Dimensions in millimetres,

Front view

tolerances are non-cumulative

Missing dimensions, see IEC 60297-3-101

Conductive surface

F

F

482,6 ± 0,4

Top view

Cross-section F - F

First pitch line

n x 5,08

Conductive

EMC gasket

surface

C

Uncompressed

gasket

0,3 ± 0,1

min 0,5 mm

max 1,3 mm

Detail “C“

Mounting flanges may be

recessed by n x 25 mm.

IEC

Figure 8 – R–type subrack front attachment plane and mounting flanges

9 Chassis integrated subrack

9.1 General

Chassis integrated subracks are common for electronic equipment where air ducting, cooling

devices or space for cabling are incorporated into one mechanical unit.

5,0 ± 0,5

(n x 25)

≥ 10,0

– 16 – IEC 60297-3-108:2014 © IEC 2014

9.2 RA– C–type chassis/subrack

The RA–C type chassis/subrack, in which RA – type subrack is integrated, defines the chassis

dimensions (see Figure 9).

Dimensions in millimetres,

Front view

tolerances are non-cumulative

2)

(4,27)

First pitch line

IEC

Key

1 Chassis height reduced for the mounting of chassis supports (see Annex A).

2 First guide rail position (see Figure 2).

Figure 9 – RA – C type chassis/subrack

9.3 RB–C–type chassis/subrack

The RB–C–type chassis/subrack, in which RB–type subrack is integrated, defines the chassis

dimensions (see Figure 10). The subrack may be placed asymmetrically within the chassis

dimensions. For chassis overall dimensioning see IEC 60297-3-105 (plus n × 1U).

H 1

1)

U – (3,0 + 0,5/-0)

n x 44,45 = U

Front view

2)

(6,81)

First pitch line

IEC

Key

1 Chassis height reduced for the mounting of chassis supports (see Annex A).

2 First guide rail position (see Figure 4).

Figure 10 – RB–C – type chassis/subrack

10 Front panel/plug-in unit compatible with RA – type subrack

Figure 11 illustrates the frontpanel/plug-in unit compatible with RA–type subrack and the

position of a printed board.

H 1

1)

U – (3,0 + 0/-0,5)

n x 44,45 = U

– 18 – IEC 60297-3-108:2014 © IEC 2014

Front view

Dimensions in millimetres,

tolerances are non-cumulative

2)

G

10.82 ± 0,1

2)

2,9 ± 0,1

Cross-section H - H

Optional EMC

6,35 ± 0,1

gasket

Ø3 ± 0,05

≤ 1,0

10,0 ± 0,2

≤ 1,0

Alignment pin ≤ 13,5

max 5 fastened

≤ 0,0 unfastened 1,0 ± 0,1

H M3

H

Uncompressed gasket

min 0,5 mm

13,97 ± 0,1

max 1,3 mm

1)

(0,15) 19,72 ± 0,1 (0,67)

Pitch line

1)

20,32

G

Top view

Cross-section G - G

Connector user

defined

Printed board

component side 2

Printed board

7,0 ± 0,1

component side 1

12,5 ± 0,2

(optional)

Optional cover

M 2,5

(4,07)

9,7 ± 0,1

6,0 ± 0,1 (optional)

3)

Pitch line

13,97 ± 0,1

4,0 ± 0,1

Alternative front

1)

panel design

(0,15) 18,72 ± 0,1

IEC

Key

1 May be increased by n x 5,08 mm

2 Optional cut outs if injector/extractor handles are used

3 Retention screw float +/- 0,5 mm

Figure 11 – Front panel/ plug-in unit compatible with RA – type subrack

H 8

Conductive

H 6

surface

2) 2)

11,0 -± 0,2

11,0 -± 0,2

H5 -2,35 ± 0,2

6,0 ± 0,1

≤ 2,5

5,0 ± 0,5

H5 -8,35 ± 0,1

11 Front panel/plug-in unit compatible with RB – type subrack

Figure 12 illustrates the frontpanel/plug-in unit compatible with RB–type subrack and the

position of a printed board.

Front view Dimensions in millimetres,

tolerances are non-cumulative

2)

10,82 ± 0,1

2)

2,9 ± 0,1

Cross-section K - K

Optional EMC

6,35 ± 0,1

Ø3 ± 0,05

gasket

≤ 1,0

≤ 1,0

J 10,0 ± 0,2

Alignment pin

≤ 13,5

max 5 fastened

1,0 ± 0,1

≤ 0,0 unfastened

M3

Uncompressed gasket

K K

min 0,5

13,97 ± 0,1 max 1,3

1)

(0,15) 19,72 ± 0,1 (0,67)

Pitch line

1)

20,32

J

Cross-section J - J

Top view

Connector user

defined

Printed board

7,0 ± 0,1

component side 2

12,5 ± 0,2

Printed board

(optional)

component side 1

Optional cover

M 2,5

6,0 ± 0,1 (optional)

3)

(6,61)

7,16 ± 0,1

4,0 ± 0,1

Pitch line

13,97 ± 0,1

Alternative frontpanel

design

1)

18,72 ± 0,1

(0,15)

IEC

Key

1 May be increased by n x 5,08 mm

2 Optional cut outs if injector/extractor handles are used

3 Retention screw float +/- 0,5 mm

Figure 12 – Front panel/ plug-in unit compatible with RB – type subrack

H 8

Conductive

surface

H 6

2)

2)

11,0 ± 0,2 11,0 ± 0,2

H5 -2,35 ± 0,2

≤ 2,5

6,0 ± 0,1

5,0 ± 0,5

H5 -8,35 ± 0,1

– 20 – IEC 60297-3-108:2014 © IEC 2014

12 Injector/extractor handle

Figure 13 illustrates the injector/extractor handle. The max. single handle lever dimension is

due to connector forces of max. 350 N. Handle lever for higher connector forces shall be

agreed between supplier and user. The minimal travel of the handle for extraction/insertion

shall be 7,5 mm. Even if the handle may be with a self-locking function, the reliable fastening

of front panels shall be resolved by screws M3. As shown in Figure 13, the handle lever

direction may be vertical or horizontal.

Dimensions in millimetres,

tolerances are non-cumulative

Side view

Injector/extractor handle

position within the subrack

G

max 40

Alternative handle lever design,

horizontal

(2,0)

Front view

G

11,0 ± 0,5

Side view

Handle details

Max 3,0

Retention screw

2,0 ± 0,1

2,0 ± 0,1

Pivot point

Ø2,0

15,0 ± 0,2

Ø4,0

Ø4,0

(0,36) 18,0 ± 0,2

5,0 ± 0,1

Pitch line

IEC

Figure 13 – Injector/extractor handle

13 Printed board dimensions

Figure 14 illustrates the printed board dimensions.

10,0 ± 0,1

9,0 ± 0,1

max 40

6,5 ± 0,1

(13,5)

Dimensions in millimetres,

tolerances are non-cumulative

D 3

3,6 ± 0,1

6,0 ± 0,1

OptionalOpt ional holes

holes Ø 2,7

2)

1)

≥13,5

IEC

Key

1 Keep out area for frontpanel attachment and components.

2 Printed board thickness 1,4 – 2,6 mm.

Figure 14 – Printed board dimensions

14 Dimensions

Table 1 contains the dimensions of subracks and plug-in units.

Table 1 – Dimensions

Dimensions in millimetres

Height units U H1 H5 H6 H8 H10

(n × 44,45) ± 0,4 ± 0,2 ± 0,2 ± 0,2 + 0/- 0,3

3U

132,55 100,35 113,55 119,55 100,00

(133,35)

4U

177,00 144,80 158,00 164,00 144,45

(177,80)

5U

221,45 189,25 202,45 208,45 188,90

(222,25)

6U

265,90 233,70 246,90 252,90 233,35

(266,70)

7U

310,35 278,15 291,35 297,35 277,80

(311,15)

8U

354,80 322,60 335,80 341,80 322,25

(355,60)

9U

399,25 367,05 380,25 386,25 366,70

(400,05)

NOTE The dimensions H1 and H10 comply with IEC 60297-3-101.

H 10

H 10 -8,0 ± 0,1

(4,0)

Ø 2,7 ± 0,1

1)

1)

≥7,5

≥7,5

1)

≥7,5

1)

1)

≥3,5 ≥3,5

– 22 – IEC 60297-3-108:2014 © IEC 2014

15 Nomenclature

15.1 Reference plane (given in square boxes of figures)

A First pitch line

B Last pitch line

C Left side plate

D Right side plate

E Front attachment plane

F Rear attachment plane

G Subrack height aperture

H Position of receptacle holes for M3

I Position of alignment pin receptacle hole

J Guide rail reference line for printed boards and two part connectors

15.2 Dimensions of Table 1

Height

U: Coordination height unit of 44,45 mm (1,75 in). See IEC 60297-3-100.

H1: Subrack heights (equal to dimension E of IEC 60297-3-100).

H5: Subrack vertical aperture for plug-in units

H6: Mounting centre distance for front plug-in units and panels, front and rear.

H8: Plug-in unit panel height.

H10: Printed board height into subrack guidance height.

Width

HP: The subrack aperture is theoretically divided into n × horizontal pitches (HP) of

5,08 mm.

The plug-in unit front panel width is divided into n × 5,08 mm horizontal pitches.

Depth

D1: Subrack dimension between front attachment plane and backplane attachment plane.

Annex A

(normative)

Mounting support

A.1 Chassis/subrack mounting support in cabinets

Figure A.1 illustrates the mounting of a chassis with integrated subrack into a cabinet using

mounting supports for heavy load and/or in case of dynamic stress.

Example of a chassis with

integrated subrack

(see Figures 8 and 9).

max 2,0

Chassis mounting support

fixed to the cabinet uprights

(see IEC 60297-3-100)

IEC

Figure A.1 – Subrack/chassis mounting support

U–3,0+0,5/-0

– 24 – IEC 60297-3-108:2014 © IEC 2014

Annex B

(normative)

Environmental tests

B.1 Static and dynamic load test

For the proof of mechanical integrity the chassis/subrack loaded with plug-in units should be

tested in accordance with IEC 61587-1 (static load, vibration and shock).

B.2 Seismic test

In case of seismic requirements the chassis/subrack loaded with plug-in units should be

tested in accordance with IEC 61587-5 (resistance of the mechanical structure against

seismic impact).

B.3 Electromagnetic shielding performance test

In case of EMC requirements (electromagnetic compatibility) the chassis/subrack and plug-in

units should be tested in accordance with IEC 61587-3 (shielding performance level of the

mechanical design).

Annex C

(normative)

Thermal management

C.1 Air ducting

Figure C.1 illustrates a chassis with integrated subrack. The air ducting shall be from the front

inlet 2), distributed across the depth, vertical up through the subrack 1) and out at the rear 3).

The lower and upper compartments are adding to the height dimension of the subrack n × U,

dependent on the air volume or for the accommodation of fans. The air ducting from front to

rear is the preferred solution in accordance with IEC TS 62610-2.

3)

Air out

1)

2)

Air in

IEC

Key

1) Subrack with plug-in units

2) Compartment with louvered front for air inlet

3) Compartment with louvered rear for air outlet

Figure C.1 – Thermal management example

– 26 – IEC 60297-3-108:2014 © IEC 2014

Annex D

(informative)

Comparison of IEC 60297-3-101 with IEC 60297-3-108

Table D.1 – Comparison of dimensions and features

Comparative points IEC 60297-3-101 IEC 60297-3-108

Subrack Subrack R-type

Compatible with Incompatible with

Subrack dimensions (mm)

IEC 60297-3-101 IEC 60297-3-101

H1: Subrack heights n × 44,45 – 0,80 Yes –

H5: Subrack vertical aperture opening for –

n × 44,45 – 21,35 n × 44,45 – 33,00

plug-in units.

H6: Mounting centre distance for plug-in n × 44,45 – 10,85 – n × 44,45 -19,80

units, front panels, backplanes and

connector supports.

H8: Plug-in unit front panel height. –

n × 44,45 – 4,80 n × 44,45 – 13,80

H10: Printed board height or plug-in unit Yes –

n × 44,45 – 33,35

into subrack guidance height.

Subrack aperture definitions (HP) Yes –

n × 5,08

Subrack depth (D1 – D4, RD1, RD3 and ------ Yes –

RD4)

Other subrack features

Fixing screws for plug-in units, front M 2,5 – M 3

panels, backplanes and connector

supports.

Alignment pins for plug-in units Auxiliaries – Yes

according to

IEC 60297-3-103

Front panels for plug-in units ------ – Yes

Positions of fixing holes for front panel ------ – Yes

Printed board mounting to front panel, 88,90 + n × 44,45 - H 10 – 8,0

vertical

Printed board mounting to front panel, 2,54 + 3,57 = 6,11 - 4,0

horizontal

EMC provisions ------ – Yes

Injector/extractor handle for plug-in units Auxiliaries – Yes

according to

IEC 60297-3-102

Subrack mounting flanges ------ May be recessed by –

n × 25 mm

(Rear mount

supports can be

arranged)

_____________

– 28 – IEC 60297-3-108:2014 © IEC 2014

SOMMAIRE

AVANT-PROPOS . 30

INTRODUCTION . 32

1 Domaine d'application . 33

2 Références normatives . 33

3 Termes et définitions . 34

4 Vue d'ensemble de la disposition . 34

5 Bac de type RA . 35

5.1 Généralités . 35

5.2 Dimensions de montage arrière d'un bac de type RA . 37

6 Bac de type RB . 38

6.1 Généralités . 38

6.2 Dimensions de montage arrière d'un bac de type RB . 39

7 Rails de guidage d'un bac de type R . 39

8 Dispositions pour blindage électromagnétique et brides de montage . 40

9 Bac intégré au châssis . 41

9.1 Généralités . 41

9.2 Châssis/bac de type RA-C . 42

9.3 Châssis/bac de type RB-C . 42

10 Panneau avant/bloc enfichable compatibles avec un bac de type RA . 43

11 Panneau avant/bloc enfichable compatibles avec un bac de type RB . 45

12 Poignée d'insertion/extraction . 46

13 Dimensions de la carte imprimée . 46

14 Dimensions. 47

15 Nomenclature . 48

15.1 Plan de référence (donné dans les cases carrées des figures) .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...