IEC 61969-3:2023

(Main)Mechanical structures for electrical and electronic equipment - Outdoor enclosures - Part 3: Environmental requirements, tests and safety aspects

Mechanical structures for electrical and electronic equipment - Outdoor enclosures - Part 3: Environmental requirements, tests and safety aspects

IEC 61969-3:2023 specifies a set of basic environmental requirements and tests, as well as safety aspects for outdoor enclosures for electrical and electronic equipment, under conditions of non-weatherprotected locations above ground. The purpose of this document is to define a minimum level of environmental performance in order to meet requirements of storage, transport and final installation. The intention is to establish basic environmental performance criteria for outdoor enclosure compliance.

Structures mécaniques pour équipement électrique et électronique - Enveloppes de plein air - Partie 3: Exigences et essais d'environnement, et aspects liés à la sécurité

L’IEC 61969:2023 spécifie un ensemble d’exigences et d’essais d’environnement de base, ainsi que les aspects liés à la sécurité relatifs aux enveloppes de plein air pour équipement électrique et électronique, placées dans les conditions d’emplacement non protégé contre les intempéries, au-dessus du sol. L’objet du présent document est de définir un niveau minimal de performances environnementales, afin de répondre aux exigences de stockage, de transport et d’installation finale. Il s’agit d’établir des critères de performances environnementales de base en vue de la conformité des enveloppes de plein air.

General Information

- Status

- Published

- Publication Date

- 19-Nov-2023

- Technical Committee

- SC 48D - Mechanical structures for electrical and electronic equipment

- Drafting Committee

- MT 1 - TC 48/SC 48D/MT 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Nov-2023

- Completion Date

- 01-Dec-2023

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61969-3:2023 - Mechanical structures for electrical and electronic equipment - Outdoor enclosures - Part 3: Environmental requirements, tests and safety aspects - defines minimum environmental performance, test methods and safety aspects for empty outdoor enclosures intended for non-weatherprotected locations above ground. Edition 4.0 (2023-11) provides a structured set of requirements to ensure enclosures survive storage, transport and final installation while protecting housed electrical and electronic equipment.

Key topics and technical requirements

- Scope and objective: Establishes basic environmental performance criteria and pass/fail criteria for outdoor enclosures to meet storage, transport and installation requirements.

- Classification of environmental conditions: Aligns with IEC 60721-3-4 and ETSI EN 300 019 to define climatic and severity classes for stationary outdoor use.

- Environmental tests:

- Climatic tests (cold, dry heat, damp heat, temperature change cycles)

- Biological tests (mould growth and related assessments)

- Corrosion and chemically active substances (salt mist, mixed gas corrosion)

- Resistance to mechanically active substances (dust, sand)

- Mechanical tests:

- Operational mechanical tests (doors, hinges, seals under load)

- Transport tests (vibration and shock, rough handling)

- Lifting and stiffness tests

- Safety aspects:

- Locking devices, vandalism resistance, optional firearms resistance for metal enclosures

- Seismic requirements for mounting stability

- Performance aspects:

- Electromagnetic shielding performance

- Thermal management guidance (heat dissipation solutions and relation to acoustic noise)

- Acoustic noise emission considerations

- Normative references: Integrates established test standards such as IEC 60068 series, IEC 60529 (IP Code), IEC 61587 and others.

Practical applications - who uses this standard

- Outdoor enclosure manufacturers - design and validate enclosures for telecommunications cabinets, power distribution cabinets, street cabinets and outdoor network nodes.

- System integrators and specifiers - select enclosures that meet environmental and safety requirements for specific deployment sites.

- Test labs and certification bodies - use specified tests and pass/fail criteria for compliance assessment.

- Utilities, telecom operators and infrastructure owners - ensure deployed enclosures meet minimum durability, corrosion resistance, thermal and electromagnetic performance.

- Consultants and standards writers - reference the standard when creating procurement specs or local regulatory documents.

Related standards

- IEC 61969-1:2023 (design guidelines) and IEC 61969-2 (coordination dimensions)

- IEC 60068 series (environmental testing)

- IEC 60529 (IP Code - degrees of protection)

- IEC 60721 series (classification of environmental conditions)

- IEC 61587 (mechanical tests for cabinets/racks)

- ETSI EN 300 019 (alignment for transport/use conditions)

IEC 61969-3:2023 is the technical baseline to define consistent environmental and safety testing for outdoor enclosures, helping manufacturers and users ensure reliable field performance and regulatory alignment.

REDLINE IEC 61969-3:2023 - Mechanical structures for electrical and electronic equipment - Outdoor enclosures - Part 3: Environmental requirements, tests and safety aspects Released:11/20/2023 Isbn:9782832279281

IEC 61969-3:2023 - Mechanical structures for electrical and electronic equipment - Outdoor enclosures - Part 3: Environmental requirements, tests and safety aspects Released:20. 11. 2023

Frequently Asked Questions

IEC 61969-3:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Mechanical structures for electrical and electronic equipment - Outdoor enclosures - Part 3: Environmental requirements, tests and safety aspects". This standard covers: IEC 61969-3:2023 specifies a set of basic environmental requirements and tests, as well as safety aspects for outdoor enclosures for electrical and electronic equipment, under conditions of non-weatherprotected locations above ground. The purpose of this document is to define a minimum level of environmental performance in order to meet requirements of storage, transport and final installation. The intention is to establish basic environmental performance criteria for outdoor enclosure compliance.

IEC 61969-3:2023 specifies a set of basic environmental requirements and tests, as well as safety aspects for outdoor enclosures for electrical and electronic equipment, under conditions of non-weatherprotected locations above ground. The purpose of this document is to define a minimum level of environmental performance in order to meet requirements of storage, transport and final installation. The intention is to establish basic environmental performance criteria for outdoor enclosure compliance.

IEC 61969-3:2023 is classified under the following ICS (International Classification for Standards) categories: 31.240 - Mechanical structures for electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61969-3:2023 has the following relationships with other standards: It is inter standard links to IEC 61969-3:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61969-3:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61969-3 ®

Edition 4.0 2023-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Mechanical structures for electrical and electronic equipment – Outdoor

enclosures –

Part 3: Environmental requirements, tests and safety aspects

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61969-3 ®

Edition 4.0 2023-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Mechanical structures for electrical and electronic equipment – Outdoor

enclosures –

Part 3: Environmental requirements, tests and safety aspects

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.240 ISBN 978-2-8322-7928-1

– 2 – IEC 61969-3:2023 RLV © IEC 2023

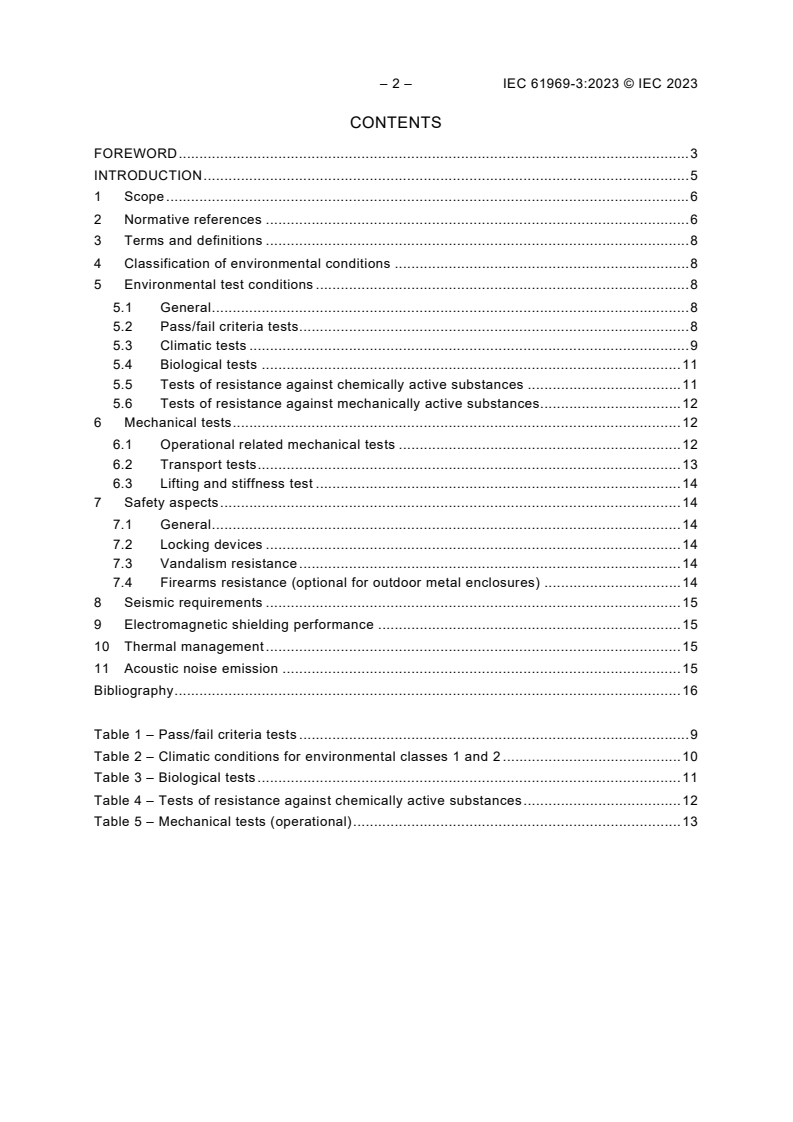

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 Coordination dimensions .

4 Environmental requirements, tests and safety aspects – Classification of

environmental conditions . 8

5 Environmental test conditions . 8

5.1 General . 8

5.2 Pass/fail criteria tests . 9

5.3 Climatic tests . 11

5.4 Biological tests . 13

5.5 Tests of resistance against chemically active substances . 13

5.6 Tests of resistance against mechanically active substances . 15

6 Mechanical tests . 15

6.1 General Operational related mechanical tests . 15

6.2 Transport tests . 16

6.3 Lifting and stiffness test . 17

7 Safety aspects . 18

7.1 General . 18

7.2 Locking devices . 18

7.3 Vandalism resistance . 18

7.4 Firearms resistance (optional for outdoor metal enclosures) . 18

8 Seismic requirements . 19

9 Electromagnetic shielding performance . 19

10 Thermal management . 19

11 Acoustic noise emission . 19

Bibliography . 20

Table 1 – Pass/fail criteria tests . 10

Table 2 – Climatic conditions for environmental classes 1 and 2 . 11

Table 3 – Biological tests . 13

Table 4 – Tests of resistance against mechanically active substances .

Table 4 – Tests of resistance against chemically active substances . 14

Table 5 – Mechanical tests (operational) . 16

Table 5 – Vibration and shock test .

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MECHANICAL STRUCTURES FOR ELECTRICAL AND

ELECTRONIC EQUIPMENT – OUTDOOR ENCLOSURES –

Part 3: Environmental requirements, tests and safety aspects

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition IEC 61969-3:2020. A vertical bar appears in the margin

wherever a change has been made. Additions are in green text, deletions are in

strikethrough red text.

– 4 – IEC 61969-3:2023 RLV © IEC 2023

IEC 61969-3 has been prepared by subcommittee 48D: Mechanical structures for electrical and

electronic equipment, of IEC technical committee 48: Electrical connectors and mechanical

structures for electrical and electronic equipment. It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2020. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) alignment with the content of ETSI EN 300 019 and IEC 60721 series latest editions,

particularly with the actualization of climate conditions;

b) rationale for the selected operating conditions from IEC 60721-3-4 are added;

c) tests are grouped according to the classification of conditions in IEC 60721-3-4;

d) test severities for vibration and shock tests are aligned with ETSI EN 300 019-2-4;

e) addition of pass/fail criteria for each test.

The text of this International Standard is based on the following documents:

Draft Report on voting

48D/765/FDIS 48D/766/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

This International Standard is to be used in conjunction with IEC 61969-1:2023.

A list of all parts in the IEC 61969 series, published under the general title Mechanical structures

for electrical and electronic equipment – Outdoor enclosures, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

INTRODUCTION

The products covered by IEC 61969 series are empty enclosures for outdoor locations, to be

equipped with application-specific combinations of electrical and electronic equipment, and to

be used at non-weatherprotected locations above ground.

IEC 61969 series consists of:

– a design guidelines general part: IEC 61969-1;

– a coordination dimensions standard: IEC 61969-2;

– an environmental requirements and tests, safety aspects standard: IEC 61969-3.

This document provides basic environmental requirements and tests, as well as safety aspects,

to be used for outdoor enclosures in absence of local regulatory documents, or of application-

specific environmental test requirements.

This document provides manufacturers and users of generic outdoor enclosures with minimum

performance compliance criteria. The thermal management solution depends on the specific

environment of the outdoor enclosure.

Since forced air heat dissipation and acoustic noise are closely related, noise limitations are

typically defined by local regulatory documents.

It is responsibility of the outdoor enclosure vendor to provide a solution for thermal management

within the local regulatory noise limitations.

– 6 – IEC 61969-3:2023 RLV © IEC 2023

MECHANICAL STRUCTURES FOR ELECTRICAL AND

ELECTRONIC EQUIPMENT – OUTDOOR ENCLOSURES –

Part 3: Environmental requirements, tests and safety aspects

1 Scope

This part of IEC 61969 specifies a set of basic environmental requirements and tests, as well

as safety aspects for outdoor enclosures for electrical and electronic equipment, under

conditions of non-weatherprotected locations above ground.

The purpose of this document is to define a minimum level of environmental performance in

order to meet requirements of storage, transport and final installation. The intention is to

establish basic environmental performance criteria for outdoor enclosure compliance.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-2-6, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-10, Environmental testing – Part 2-10: Tests – Test J and guidance: Mould growth

IEC 60068-2-11, Basic Environmental testing procedures – Part 2-11: Tests – Test Ka: Salt mist

IEC 60068-2-14, Environmental testing – Part 2-14: Tests – Test N: Change of temperature

IEC 60068-2-27, Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock

IEC 60068-2-30, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12 h + 12 h cycle)

IEC 60068-2-31, Environmental testing – Part 2-31: Tests – Test Ec: Rough handling shocks,

primarily for equipment-type specimens

IEC 60068-2-60, Environmental testing – Part 2-60: Tests – Test Ke: Flowing mixed gas

corrosion test

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady state

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60950-1, Information technology equipment – Safety – Part 1: General requirements

IEC 60721-3-2, Classification of environmental conditions – Part 3-2: Classification of groups

of environmental parameters and their severities –Transportation and handling

IEC 60721-3-4, Classification of environmental conditions – Part 3-4: Classification of groups

of environmental parameters and their severities – Stationary use at non-weatherprotected

locations

IEC 60794-1-21, Optical fibre cables – Part 1-21: Generic specification – Basic optical cable

test procedures – Mechanical tests methods

IEC 61300-2-10, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 2-10: Tests – Crush and load resistance

IEC 61300-2-56:2020, Fibre optic interconnecting devices and passive components – Basic test

and measurement procedures – Part 2-56: Tests – Wind resistance of mounted housing

IEC 61439-5, Low-voltage switchgear and controlgear assemblies – Part 5: Assemblies for

power distribution in public networks

IEC 61587-1, Mechanical structures for electrical and electronic equipment – Tests for

IEC 60917 and IEC 60297 series – Part 1: Environmental requirements, test setups and safety

aspects for cabinets, racks, subracks and chassis under indoor condition use and transportation

IEC 61587-2, Mechanical structures for electronic equipment – Tests for IEC 60917 and

IEC 60297 – Part 2: Seismic tests for cabinets and racks

IEC 61587-3, Mechanical structures for electronic equipment – Tests for IEC 60917 and

IEC 60297 – Part 3: Electromagnetic shielding performance tests for cabinets and subracks

IEC 61969-1:20202023, Mechanical structures for electrical and electronic equipment –

Outdoor enclosures – Part 1: Design guidelines

IEC 62194, Methods of evaluating the thermal performance of enclosures

IEC 62262, Degrees of protection provided by enclosures for electrical equipment against

external mechanical impacts (IK code)

IEC 62368-1, Audio/video, information and communication technology equipment – Part 1:

Safety requirements

ISO 2533, Standard atmosphere

ISO 3744, Acoustics – Determination of sound power levels and sound energy levels of noise

sources using sound pressure – Engineering methods for an essentially free field over a

reflecting plane

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 4892-3, Plastics – Methods of exposure to laboratory light sources – Part 3: Fluorescent

UV lamps

ETSI EN 300 019-2-2, Environmental Engineering (EE) – Environmental conditions and

environmental tests for telecommunications equipment – Part 2-2: Specification of

environmental tests – Transportation

– 8 – IEC 61969-3:2023 RLV © IEC 2023

ETSI EN 300 019-2-4, Environmental Engineering (EE) – Environmental conditions and

environmental tests for telecommunications equipment – Part 2-4: Specification of

environmental tests – Stationary use at non-weatherprotected locations

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61969-1 apply.

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

4 Coordination dimensions

This clause of IEC 61969-1:2020 applies.

4 Environmental requirements, tests and safety aspects – Classification of

environmental conditions

The environmental operating conditions are derived from IEC 60721-3-4, with the focus on

empty outdoor enclosures relevant requirements. Two classes of environmental performance

are described:

– class 1: Non-weatherprotected locations, standard performance: Covers all regions with a

moderate climate;

– class 2: Non-weatherprotected locations, extended performance: Covers all regions with

severe an extremely cold or extremely warm climate.

The individual outdoor enclosure tested to these basic environmental test requirements may

claim compliance to either class 1 or class 2 or a combination of class 1/class 2.

5 Environmental test conditions

5.1 General

The basic test conditions shown in Table 1, Table 2, Table 3 and Table 4 reflect typical outdoor

enclosure environments to be endured.

The minimum tests and test severities for the non-weatherprotected conditions as defined in

IEC 60721-3-4 can be found as:

– climatic conditions (K) given in Table 2;

– biological conditions (B) given in Table 3;

– chemical active substance (C) given in Table 4;

– mechanical active substance (S) given as pass/fail criterion PF2 in Table 1;

– mechanical conditions during operation (M) given in Table 5;

Two classes of test severities for the operating conditions are defined, each corresponding to

the relevant class of environmental performance defined in Clause 4:

– class 1 for operating conditions in temperate climatic environments. The refence for this

environment in IEC 60721-3-4 is 4K26/4Z4/4B2/4C2/4S12/4M11;

– class 2 for operating conditions with more extreme tropical and polar conditions

4K25/4Z5/4B2/4C2/4S12/4M11 and 4K27/4Z5/4B2/4C2/4S12/4M11 from IEC 60721-3-4.

5.2 Pass/fail criteria tests

Table 1 contains the pass/fail criteria tests that shall be performed after the climatic tests

(Table 2), the biological tests (Table 3), the resistance against chemically active substances

tests (Table 4) and the mechanical tests (Table 5). When the same test sample is used for

several tests, it is allowed to perform the relevant pass/fail tests at the end of the test sequence.

– 10 – IEC 61969-3:2023 RLV © IEC 2023

Table 1 – Pass/fail criteria tests

Test Environmental Test severity Acceptance conditions

parameters and test

Class 1 Class 2

methods

Examination of the internal and external

parts.

No defects which would

Inspection with the naked eye for flaws,

PF1 Visual examination adversely affect product

deformation, surface changes, rust, cracks

performance.

or other deteriorations that could impair

functionality.

The protection is satisfactory

if talcum powder has not

accumulated in a quantity or

location such that, as with

Protection against

any other kind of dust, it

a ingress of dust

PF2 IP5X could interfere with the

correct operation of the

IEC 60529

equipment or impair safety.

No dust shall deposit where

it could lead to tracking

along the creepage distance.

If any water has entered, it

shall not:

– be sufficient to interfere

with the correct operation

of the equipment or

impair safety;

– deposit on insulation

parts where it could lead

to tracking along the

creepage distance;

– reach live parts or

windings not designed to

operate when wet;

– accumulate near the

Protection against

IPX4

cable end or enter the

ingress of water

PF3

cable if any.

IEC 60529

If the enclosure is provided

with drain-holes, it should be

proved by inspection that

any water which enters does

not accumulate and that it

drains away without doing

any harm to the equipment.

For enclosures without

drain-holes, the relevant

product standard shall

specify the acceptance

conditions if water can

accumulate to reach live

parts.

IPX5 No ingress of water

a

The IP5X pass/fail criterion for protection against ingress of dust is used to cover the mechanical active

substance condition 4S12 of IEC 60721-3-4.

5.3 Climatic tests

The climatic tests from Table 2 shall be performed on test samples with hinges, locks and

handles in operating condition.

Table 2 – Climatic conditions for environmental classes 1 and 2

Test severity

Environmental

Duration Method

parameters

Class 1 Class 2

IEC 60068-2-1:

a Low air temperature −40 °C −50 °C 16 h

A

IEC 60068-2-2:

b High air temperature +85 °C +85 °C 16 h

B

IEC 60068-2-78:

c Damp heat +30 °C, 93 % +30 °C, 93 % 96 h

Cb

−40 °C to +23 °C −40 °C to + 85 °C

IEC 60068-2-14:

d Change of temperature 2 cycles

Nb

1 °C/min 1 °C/min

144 h

IEC 60068-2-30:

e Condensation 90 % to 100 % RH 90 % to 100 % RH

Db

(6 cycles)

Precipitation (rain, snow,

f IPX4 IPX5 - IEC 60529

hail, etc.)

Movement of the

g 50 m/s 60 m/s - -

surrounding air

h Formation of ice and frost Minimum requirement: No mechanical deformation -

Minimum requirement: No reduction in mechanical

i Ultraviolet degradation properties (tensile strength and elongation at yield) by ISO 4892-2

more than 20 %.

For comparable conditions, the International Standard Air, in accordance to ISO 2533 (15 °C at 1 013, 25 hPa)

shall be used.

This maximum temperature includes the effects of heat dissipation caused by active electronics and includes

solar load.

– 12 – IEC 61969-3:2023 RLV © IEC 2023

Test Environmental Test severity

Pass/fail criteria to be

parameters and test

checked

Class 1 Class 2

methods

a

Visual examination (PF1)

Cold

Protection against ingress of

IEC 60068-2-1: Test A

K1 −40 °C for 16 h −50 °C for 16 h

dust (PF2) and water (PF3)

after test.

b

Visual examination (PF1)

Dry heat

Protection against ingress of

IEC 60068-2-2: Test B

K2 +85 °C for 16 h

dust (PF2) and water (PF3)

after test.

Change of temperature Temperature range: −40 °C to + 85 °C Visual examination (PF1)

IEC 60068-2-14: Test Nb Dwell time at extreme temperatures: 4 h Protection against ingress of

K3

dust (PF2) and water (PF3)

Rate of change of temperature:1 °C/min

after test.

Number of cycles: 2 (12 h/cycle)

c

K4 Temperature range: +25 °C to +55 °C Visual examination (PF1)

Damp heat, cyclic

Humidity: >90 % RH Protection against ingress of

IEC 60068-2-30: Test Db

dust (PF2) and water (PF3)

Number of cycles: 6 (24 h/cycle)

after test.

K5 Ultraviolet light resistance Xenon lamp (340 nm) Visual examination (PF1)

ISO 4892-2 (for painted or Exposure cycle: Cycle 1 No reduction in mechanical

polymer coated metal) properties after test (for

Exposure time: 1 000 h

example: average tensile

strength and elongation at

Ultraviolet light resistance Fluorescent lamp type 1A (340 nm)

yield) by more than 20 %.

ISO 4892-3 (for full Exposure cycle: Cycle 1 with alternating

polymer outer enclosures) UV and condensation cycles:

– UV cycle: 8 h at (+60 ± 3) °C

– Condensation cycle: 4 h at (+50 ±

3) °C

Exposure time: 2 160 h

Test are performed on moulded dumbbells

For comparable conditions, the International Standard Air, in accordance with ISO 2533 (15 °C at 1 013, 25 hPa)

shall be used.

a

This minimum temperature includes the effects of heat radiation during the night with open sky.

b

This maximum temperature includes the effects of heat dissipation caused by active electronics and includes

solar load.

c

The damp heat, cyclic test replaces the less severe IEC 60068-2-78 damp heat, steady state test.

Following the test, compliance is checked by visual inspection of the internal and external parts;

no rust, cracking or other deterioration shall be detected with impact to the required function;

no ingress of water.

Hinges, locks and handles for example shall be in operating condition.

The test in accordance with Table 1, item h, shall prove that access to the internal equipment

is possible without causing permanent degradation of protection levels.

5.4 Biological tests

Table 3 – Biological tests

Test severity

Environmental

Purpose Method

parameters

Class 1 Class 2

Flora: Presence of mould, IEC 60068-2-10:

a

Minimum requirement: No reduction

fungus, etc. J

To check the

in mechanical properties (tensile

material for

Fauna: Presence of rodents

strength and elongation at yield) by

resistance

b and others harmful to the

more than 20 %.

equipment

Environmental

Pass/fail criteria to be

Test parameters and test Test severities for class 1 and 2

checked

method

Flora: Presence of mould, Test samples: moulded dumbbells Visual grading ≤2

fungus, etc.

Test variant 1 In case visual rating is 0, no

IEC 60068-2-10: Test J further tests are required.

Inoculation conditions:

In case of visual grading 1 or

– Temperature: (29 ± 1) °C

2 the degradation of material

B1

properties will be checked.

– Relative humidity: ≥ 90 % RH

No reduction in mechanical

Duration: 28 days properties (for example

average tensile strength and

elongation at yield) by more

than 20 %.

Fauna: Presence of rodents

B2 and others harmful to the None None

equipment

Following the test, compliance is checked by visual inspection.

5.5 Tests of resistance against chemically active substances

The resistance tests to corrosion by chemically active substances are listed in Table 4. The test

severities were taken from ETSI EN 300 019-2-2 and ETSI EN 300 019-2-4.

Large housings (like street cabinets) can be tested by using representative samples of used

materials.

– 14 – IEC 61969-3:2023 RLV © IEC 2023

Table 4 – Tests of resistance against chemically active substances

Test severity

Environmental

Duration Method

Class 1 Class 2

parameters

Mean value Maximum value

Salts: Sea and road salt 4 weeks IEC 60068-2-11:

a +35 °C,5 % NaCl

mist (672 h) Ka

3 3

0,3 mg/m 1,0 mg/m

b Sulphur dioxide

3 3 3 3

0,11 cm /m 0,37 cm /m

3 3

0,1 mg/m 0,5 mg/m

c

Hydrogen sulphide

3 3 3 3

0,071 cm /m 0,36 cm /m

IEC 60068-2-60:

10 days

Ke

3 3

0,1 mg/m 0,3 mg/m

d Chlorine

3 3 3

0,034 cm /m 0,1 cm /m

3 3

0,5 mg/m 1,0 mg/m

e Nitrogen oxides

3 3 3 3

0,26 cm /m 0,52 cm /m

Tests of Table 3 may be combined with tests of Table 1.

Environmental Test severity

Pass/fail criteria to be

Test parameters and test

checked

Class 1 Class 2

method

Salt mist Temperature: Temperature: Visual examination (PF1)

+35 °C +35 °C

IEC 60068-2-11: Test Ka Contact materials for the

Solution: 5 % NaCl Solution: 5 % NaCl electromagnetic shielding

and grounding shall remain

Duration: 5 days Duration: 28 days

free of corrosion.

Class 1: No signs of surface

corrosion of protective

C1

enclosure. A colour change

due to passivation is

allowed.

Class 2: Surface corrosion of

the protective enclosure is

allowed. It shall remain

possible to open and close

the door(s).

Flowing mixed gas Temperature: (25 ± 1) °C Visual examination (PF1)

corrosion test

Relative humidity: (75 ± 3) % RH Surface corrosion of the

IEC 60068-2-60: Test Ke protective enclosure is

Duration: 10 days

method 4 with severities allowed. It shall remain

from ETSI EN 300 019-2-4 possible to open and close

the door(s).

1,0 mg/m

Sulphur dioxide SO

Contact materials for the

3 3

0,37 cm /m electromagnetic shielding

and grounding shall remain

C2

0,5 mg/m

free of corrosion.

Hydrogen sulphide H S

3 3

0,36 cm /m

0,3 mg/m

Chlorine Cl

3 3

0,1 cm /m

1,0 mg/m

Nitrogen oxides NO

3 3

0,52 cm /m

Following each of the tests of Table 3, compliance is checked by visual inspection of the outside

of the used materials or coatings.

Surface corrosion of the protective enclosure is allowed.

The enclosure design shall provide protection for electromagnetic interference gaskets and for

protective earthing contacts, where no corrosion is permitted.

5.6 Tests of resistance against mechanically active substances

Table 4 – Tests of resistance against mechanically active substances

Test severity

Environmental

Method

parameters

Classes 1 and 2

a Sand

b Dust (suspension) IP5X IEC 60529

c Dust (sedimentation)

Following the test, shall be executed according to the next assessment: no measurable dust

shall have entered the enclosure (this is more severe than in IEC 60529 for IP5X, and IP6X

may be applied for an intended requirement).

The resistance against mechanical active substances like sand and dust is covered by the

test PF2 in Table 1.

6 Mechanical tests

6.1 General Operational related mechanical tests

The purpose of these mechanical tests is to ensure that the outdoor enclosure will withstand

handling, storage, transport and protect installed equipment from exposure to mechanical stress.

For seismic compliance, see Clause 9. Installations in public areas typically require compliance

to more severe local regulatory laws. These and any additional application specific

requirements need to be observed. Should the outdoor enclosure be installed in a public place,

the power input requirements may have to be in compliance with IEC 61439-5.

The purpose of the mechanical tests in Table 5 is to ensure that the outdoor enclosure will

withstand handling and give protection of installed equipment from exposure to mechanical

stress during operation. The test severities of tests M1, M2 and M3 were taken from

ETSI EN 300 019-2-4, T 4.1E. For seismic compliance, see Clause 8.

– 16 – IEC 61969-3:2023 RLV © IEC 2023

Table 5 – Mechanical tests (operational)

Environmental Test severities

Pass/fail criteria to be

Test parameters and test

checked

Class 1 Class 2

methods

M1 Wind resistance 30 m/s (110 km/h) 50 m/s (180 km/h) Visual inspection (PF1). No

deformation or damage of

The applied force

IEC 61300-2-56:2020 The applied force

parts that affect form, fit and

shall be calculated shall be calculated

function shall be observed.

according to the according to the

method described method described

in Annex B of in Annex B of

IEC 61300-2-56: IEC 61300-2-56:

2020 2020

a

M2 5 Hz to 9 Hz: 1,2 mm displacement Visual inspection (PF1). No

Vibration, sinusoidal

deformation or damage of

IEC 60068-2-6: Test Fc 9 Hz to 500 Hz: 4 m/s acceleration

parts that affect form, fit and

function shall be observed.

Axes: 3 mutually perpendicular

Protection against ingress of

10 sweeps per axis

dust (PF2) and water (PF3)

after test.

a

M3 Half sine pulse Visual inspection (PF1). No

Shock (operational)

deformation or damage of

Duration: 11 ms

IEC 60068-2-27: Test Ea

parts that affect form, fit and

function shall be found.

Acceleration: 50 m/s

Protection against ingress of

Axes 3

dust (PF2) and water (PF3)

after test.

Number of shocks: 3 shocks in each

direction per axis (= 18 shocks in total)

M4 Crush Load (N): 1 750 (Pa) × Width (m) Visual inspection (PF1). No

× Depth (m) deformation or damage of

IEC 61300-2-10

parts that affect form, fit and

Load evenly distributed on top surface of

function shall be found.

the housing.

Protection against ingress of

Duration: 10 min

dust (PF2) and water (PF3)

after test.

M5 Impact IK09 (10 J) IK10 (20 J) Visual inspection (PF1). No

deformation or damage of

IEC 62262

parts that affect form, fit and

function shall be found.

Protection against ingress of

dust (PF2) and water (PF3)

after test.

a

The outdoor enclosure shall be mounted to the shock/vibration table by using the intended ground/floor

mounting features.

6.2 Transport tests

The dynamic tests of an outdoor enclosure shall be conducted under the intended transport

conditions. Since outdoor enclosure dynamic transport stress is considerably more severe than

typical handling and storage stress, no further dynamic tests are required. For the purpose of

this test, no transport packing material is used. The outdoor enclosure shall be mounted to the

shock/vibration table by using the intended ground/floor mounting features.

Table 5 shows the chosen severity classes.

Table 5 – Vibration and shock test

Test severity

Class 1 Class 2

Environmental parameters Method

(controlled transport (limited transport

condition) condition)

5 Hz to 9 Hz/3,5 mm 5 Hz to 9 Hz/3,5 mm

displacement displacement

9 Hz to

9 Hz-200 Hz/10 m/s

Vibration, sinusoidal 200 Hz/10 m/s

a acceleration IEC 60068-2-6: Fc

3 axes, 10 cycles acceleration

200 Hz to 200 Hz to

2 2

500 Hz/15 m/s 500 Hz/15 m/s

acceleration acceleration

5 Hz to 20 Hz:

2 3

11 m /s

ETSI EN 300 019-2-2

b Vibration, random -

Class 2.3

20 Hz to 200 Hz:

−3 dB/oct.

Peak acceleration Peak acceleration

Shock, 1/2 sine wave vertical IEC 60068-2-27: Ea

2 2

c axes only Shock response

100 m/s 100 m/s

No of shocks: 3 spectrum type I

Time: 11 ms Time: 11 ms

Free fall:

enclosure mass < 20 kg 0,25 m 1,25 m

IEC 60068-2-31: Ec

d

20 kg to 100 kg 0,25 m 1,00 m

> 100 kg 0,10 m 0,25 m

Alternative test.

2 The test is excited in the packaging condition.

Following the test, no deformation or damage of parts that affect form, fit and function shall be

found.

Two classes for the test severities for the transport tests are defined:

– class 1: Conditions according to classification 2K12/2B2/2C2/2S2/2M4 of IEC 60721-3-2.

This applies to handling, transport by rail, river, sea, air (jet aircraft only) and road transport

using good vehicles on good roads. This category includes transport of goods within

ISO containers;

– class 2: Conditions according to classification 2K12/2B2/2C2/2S2/2M5 of IEC 60721-3-2.

This includes the conditions of class 1 plus road transport using poor vehicles and/or on

poor roads as well as handling using trolleys with no suspension.

The requirements and relevant tests covering transport and handling of the packaged product

can be agreed between vendor and user.

6.3 Lifting and stiffness test

If lifting eyes are provided, the performance test as per IEC 61587-1 shall be applied.

Following the test, no deformation or damage of parts that affect form, fit and function shall be

found.

– 18 – IEC 61969-3:2023 RLV © IEC 2023

7 Safety aspects

7.1 General

General safety requirements: The outdoor enclosure, once fully equipped and installed, shall

not present a danger or hazard to people and shall prevent unauthorized access. To protect

authorized personnel (during assembly, installation, test and maintenance phases), the outdoor

enclosure shall be free of defects such as sharp edges, burrs, etc. Compliance to IEC 60950-1

and IEC 62368-1 is required, as applicable, for the electrical and electronic equipment that is

installed inside the outdoor enclosure.

NOTE The above safety standards do not directly apply to an empty outdoor enclosure.

Regulatory safety requirements: The outdoor enclosure shall also comply with the local

enforced regulatory safety requirements.

Provisions shall be made for providing electrical safety measures according to the relevant

requirements in IEC 62368-1, for the electrical and electronic equipment that can be installed

inside the outdoor enclosure.

Installations in public areas typically require compliance to more severe local regulatory laws.

These and any additional application specific requirements need to be observed. Should the

outdoor enclosure be installed in a public place, the power input requirements may have to be

in compliance with IEC 61439-5.

For requirements and relevant tests covering safety aspects, both general and of local

regulatory (to be agreed between vendor and user), Table 2 of IEC 61969-1:20202023 shall

apply.

7.2 Locking devices

Outdoor enclosure access locking functions such as used on doors, covers, roofs, etc., are

application and/or regulatory specific. The outdoor enclosure shall have the capability to be

locked and unlocked only by authorized crafts people.

7.3 Vandalism resistance

Outdoor enclosure vandalism resistance required on any locking functions such as used with

doors, covers, roofs, etc., are application and/or regulatory specific. The outdoor enclosure

shall provide for heavy duty key locking and hinges hardware.

Compliance check: The outdoor enclosure shall be resistant to provide resistance against

unauthorized access. Test method shall be agreed between vendor and user.

7.4 Firearms resistance (optional for outdoor metal enclosures)

Outdoor enclosure firearms resistance is application and/or regulatory specific.

The outdoor metal enclosure shall be designed for withstanding a 12-gauge shotgun blast of

no. 7 ½ shot at a distance of 15 m without penetration of the enclosure wall by any pellets.

Test procedure (IEC 60794-1-21 method E13A):

The enclosure shall be positioned as in a typical installation and all unique vertical surfaces

shall be subjected to a blast from a 12-gauge shotgun fired at a distance of 15 m. The load

used shall be a 70 mm shell loaded with 28 or 32 grams of no. 6 steel shot fired from a 28 inch

modified choke barrel.

Assessment following the test:

The outer skin shell of the enclosure may be deformed but still maintaining protection, and

without any penetration of the enclosure wall by any pellets.

8 Seismic requirements

Outdoor enclosure seismic compliance is application and/or regulatory specific. If seismic

compliance is requested, tests shall be conducted in accordance with IEC 61587-2.

9 Electromagnetic shielding performance

This requirement is optional, dependent on the area where needed.

If electromagnetic shielding compliance is required, test should be conducted in accordance

with IEC 61587-3 unless otherwise specified.

10 Thermal management

For the operation of electronic equipment housed in outdoor enclosures, passive and/or active

thermal management devices are used. Since the active heat management devices typically

include fans, noise emission may have to comply with local regulatory requirements. Preferably,

outdoor enclosure heat management should be based on convection air cooling (passive). If

environmental compliance testing is required, tests should be conducted in accordance with

IEC 62194 unless otherwise specified.

11 Acoustic noise emission

The final location of the installed outdoor enclosure will determine the acoustic noise limits

tolerated. Typically, regional and location specific regulatory requirements are in place. Sound

power noise tests shall be conducted in accordance with ISO 3

...

IEC 61969-3 ®

Edition 4.0 2023-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Mechanical structures for electrical and electronic equipment – Outdoor

enclosures –

Part 3: Environmental requirements, tests and safety aspects

Structures mécaniques pour équipement électrique et électronique –

Enveloppes de plein air –

Partie 3: Exigences et essais d'environnement, et aspects liés à la sécurité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur les adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 300 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 19 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61969-3 ®

Edition 4.0 2023-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Mechanical structures for electrical and electronic equipment – Outdoor

enclosures –

Part 3: Environmental requirements, tests and safety aspects

Structures mécaniques pour équipement électrique et électronique –

Enveloppes de plein air –

Partie 3: Exigences et essais d'environnement, et aspects liés à la sécurité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.240 ISBN 978-2-8322-7748-5

– 2 – IEC 61969-3:2023 © IEC 2023

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 Classification of environmental conditions . 8

5 Environmental test conditions . 8

5.1 General . 8

5.2 Pass/fail criteria tests . 8

5.3 Climatic tests . 9

5.4 Biological tests . 11

5.5 Tests of resistance against chemically active substances . 11

5.6 Tests of resistance against mechanically active substances . 12

6 Mechanical tests . 12

6.1 Operational related mechanical tests . 12

6.2 Transport tests . 13

6.3 Lifting and stiffness test . 14

7 Safety aspects . 14

7.1 General . 14

7.2 Locking devices . 14

7.3 Vandalism resistance . 14

7.4 Firearms resistance (optional for outdoor metal enclosures) . 14

8 Seismic requirements . 15

9 Electromagnetic shielding performance . 15

10 Thermal management . 15

11 Acoustic noise emission . 15

Bibliography . 16

Table 1 – Pass/fail criteria tests . 9

Table 2 – Climatic conditions for environmental classes 1 and 2 . 10

Table 3 – Biological tests . 11

Table 4 – Tests of resistance against chemically active substances . 12

Table 5 – Mechanical tests (operational) . 13

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MECHANICAL STRUCTURES FOR ELECTRICAL AND

ELECTRONIC EQUIPMENT – OUTDOOR ENCLOSURES –

Part 3: Environmental requirements, tests and safety aspects

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 61969-3 has been prepared by subcommittee 48D: Mechanical structures for electrical and

electronic equipment, of IEC technical committee 48: Electrical connectors and mechanical

structures for electrical and electronic equipment. It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2020. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) alignment with the content of ETSI EN 300 019 and IEC 60721 series latest editions,

particularly with the actualization of climate conditions;

b) rationale for the selected operating conditions from IEC 60721-3-4 are added;

– 4 – IEC 61969-3:2023 © IEC 2023

c) tests are grouped according to the classification of conditions in IEC 60721-3-4;

d) test severities for vibration and shock tests are aligned with ETSI EN 300 019-2-4;

e) addition of pass/fail criteria for each test.

The text of this International Standard is based on the following documents:

Draft Report on voting

48D/765/FDIS 48D/766/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

This International Standard is to be used in conjunction with IEC 61969-1:2023.

A list of all parts in the IEC 61969 series, published under the general title Mechanical structures

for electrical and electronic equipment – Outdoor enclosures, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

INTRODUCTION

The products covered by IEC 61969 series are empty enclosures for outdoor locations, to be

equipped with application-specific combinations of electrical and electronic equipment, and to

be used at non-weatherprotected locations above ground.

IEC 61969 series consists of:

– a design guidelines general part: IEC 61969-1;

– a coordination dimensions standard: IEC 61969-2;

– an environmental requirements and tests, safety aspects standard: IEC 61969-3.

This document provides basic environmental requirements and tests, as well as safety aspects,

to be used for outdoor enclosures in absence of local regulatory documents, or of application-

specific environmental test requirements.

This document provides manufacturers and users of generic outdoor enclosures with minimum

performance compliance criteria. The thermal management solution depends on the specific

environment of the outdoor enclosure.

Since forced air heat dissipation and acoustic noise are closely related, noise limitations are

typically defined by local regulatory documents.

It is responsibility of the outdoor enclosure vendor to provide a solution for thermal management

within the local regulatory noise limitations.

– 6 – IEC 61969-3:2023 © IEC 2023

MECHANICAL STRUCTURES FOR ELECTRICAL AND

ELECTRONIC EQUIPMENT – OUTDOOR ENCLOSURES –

Part 3: Environmental requirements, tests and safety aspects

1 Scope

This part of IEC 61969 specifies a set of basic environmental requirements and tests, as well

as safety aspects for outdoor enclosures for electrical and electronic equipment, under

conditions of non-weatherprotected locations above ground.

The purpose of this document is to define a minimum level of environmental performance in

order to meet requirements of storage, transport and final installation. The intention is to

establish basic environmental performance criteria for outdoor enclosure compliance.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-2-6, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-10, Environmental testing – Part 2-10: Tests – Test J and guidance: Mould growth

IEC 60068-2-11, Environmental testing – Part 2-11: Tests – Test Ka: Salt mist

IEC 60068-2-14, Environmental testing – Part 2-14: Tests – Test N: Change of temperature

IEC 60068-2-27, Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock

IEC 60068-2-30, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12 h + 12 h cycle)

IEC 60068-2-60, Environmental testing – Part 2-60: Tests – Test Ke: Flowing mixed gas

corrosion test

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60721-3-2, Classification of environmental conditions – Part 3-2: Classification of groups

of environmental parameters and their severities –Transportation and handling

IEC 60721-3-4, Classification of environmental conditions – Part 3-4: Classification of groups

of environmental parameters and their severities – Stationary use at non-weatherprotected

locations

IEC 60794-1-21, Optical fibre cables – Part 1-21: Generic specification – Basic optical cable

test procedures – Mechanical tests methods

IEC 61300-2-10, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 2-10: Tests – Crush and load resistance

IEC 61300-2-56:2020, Fibre optic interconnecting devices and passive components – Basic test

and measurement procedures – Part 2-56: Tests – Wind resistance of mounted housing

IEC 61439-5, Low-voltage switchgear and controlgear assemblies – Part 5: Assemblies for

power distribution in public networks

IEC 61587-1, Mechanical structures for electrical and electronic equipment – Tests for

IEC 60917 and IEC 60297 series – Part 1: Environmental requirements, test setups and safety

aspects

IEC 61587-2, Mechanical structures for electronic equipment – Tests for IEC 60917 and

IEC 60297 – Part 2: Seismic tests for cabinets and racks

IEC 61587-3, Mechanical structures for electronic equipment – Tests for IEC 60917 and

IEC 60297 – Part 3: Electromagnetic shielding performance tests for cabinets and subracks

IEC 61969-1:2023, Mechanical structures for electrical and electronic equipment – Outdoor

enclosures – Part 1: Design guidelines

IEC 62194, Methods of evaluating the thermal performance of enclosures

IEC 62262, Degrees of protection provided by enclosures for electrical equipment against

external mechanical impacts (IK code)

IEC 62368-1, Audio/video, information and communication technology equipment – Part 1:

Safety requirements

ISO 2533, Standard atmosphere

ISO 3744, Acoustics – Determination of sound power levels and sound energy levels of noise

sources using sound pressure – Engineering methods for an essentially free field over a

reflecting plane

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 4892-3, Plastics – Methods of exposure to laboratory light sources – Part 3: Fluorescent

UV lamps

ETSI EN 300 019-2-2, Environmental Engineering (EE) – Environmental conditions and

environmental tests for telecommunications equipment – Part 2-2: Specification of

environmental tests – Transportation

ETSI EN 300 019-2-4, Environmental Engineering (EE) – Environmental conditions and

environmental tests for telecommunications equipment – Part 2-4: Specification of

environmental tests – Stationary use at non-weatherprotected locations

– 8 – IEC 61969-3:2023 © IEC 2023

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

4 Classification of environmental conditions

The environmental operating conditions are derived from IEC 60721-3-4, with the focus on

empty outdoor enclosures relevant requirements. Two classes of environmental performance

are described:

– class 1: Non-weatherprotected locations, standard performance: Covers all regions with a

moderate climate;

– class 2: Non-weatherprotected locations, extended performance: Covers regions with an

extremely cold or extremely warm climate.

The individual outdoor enclosure tested to these basic environmental test requirements may

claim compliance to either class 1 or class 2 or a combination of class 1/class 2.

5 Environmental test conditions

5.1 General

The minimum tests and test severities for the non-weatherprotected conditions as defined in

IEC 60721-3-4 can be found as:

– climatic conditions (K) given in Table 2;

– biological conditions (B) given in Table 3;

– chemical active substance (C) given in Table 4;

– mechanical active substance (S) given as pass/fail criterion PF2 in Table 1;

– mechanical conditions during operation (M) given in Table 5;

Two classes of test severities for the operating conditions are defined, each corresponding to

the relevant class of environmental performance defined in Clause 4:

– class 1 for operating conditions in temperate climatic environments. The refence for this

environment in IEC 60721-3-4 is 4K26/4Z4/4B2/4C2/4S12/4M11;

– class 2 for operating conditions with more extreme tropical and polar conditions

4K25/4Z5/4B2/4C2/4S12/4M11 and 4K27/4Z5/4B2/4C2/4S12/4M11 from IEC 60721-3-4.

5.2 Pass/fail criteria tests

Table 1 contains the pass/fail criteria tests that shall be performed after the climatic tests

(Table 2), the biological tests (Table 3), the resistance against chemically active substances

tests (Table 4) and the mechanical tests (Table 5). When the same test sample is used for

several tests, it is allowed to perform the relevant pass/fail tests at the end of the test sequence.

Table 1 – Pass/fail criteria tests

Test Environmental Test severity Acceptance conditions

parameters and test

Class 1 Class 2

methods

Examination of the internal and external

parts.

No defects which would

Inspection with the naked eye for flaws,

PF1 Visual examination adversely affect product

deformation, surface changes, rust, cracks

performance.

or other deteriorations that could impair

functionality.

The protection is satisfactory

if talcum powder has not

accumulated in a quantity or

location such that, as with

Protection against

any other kind of dust, it

a ingress of dust

PF2 IP5X could interfere with the

correct operation of the

IEC 60529

equipment or impair safety.

No dust shall deposit where

it could lead to tracking

along the creepage distance.

If any water has entered, it

shall not:

– be sufficient to interfere

with the correct operation

of the equipment or

impair safety;

– deposit on insulation

parts where it could lead

to tracking along the

creepage distance;

– reach live parts or

windings not designed to

operate when wet;

– accumulate near the

Protection against

IPX4

cable end or enter the

ingress of water

PF3

cable if any.

IEC 60529

If the enclosure is provided

with drain-holes, it should be

proved by inspection that

any water which enters does

not accumulate and that it

drains away without doing

any harm to the equipment.

For enclosures without

drain-holes, the relevant

product standard shall

specify the acceptance

conditions if water can

accumulate to reach live

parts.

IPX5 No ingress of water

a

The IP5X pass/fail criterion for protection against ingress of dust is used to cover the mechanical active

substance condition 4S12 of IEC 60721-3-4.

5.3 Climatic tests

The climatic tests from Table 2 shall be performed on test samples with hinges, locks and

handles in operating condition.

– 10 – IEC 61969-3:2023 © IEC 2023

Table 2 – Climatic conditions for environmental classes 1 and 2

Test Environmental Test severity

Pass/fail criteria to be

parameters and test

checked

Class 1 Class 2

methods

a

Visual examination (PF1)

Cold

Protection against ingress of

K1 IEC 60068-2-1: Test A −40 °C for 16 h −50 °C for 16 h

dust (PF2) and water (PF3)

after test.

b

Visual examination (PF1)

Dry heat

Protection against ingress of

K2 IEC 60068-2-2: Test B +85 °C for 16 h

dust (PF2) and water (PF3)

after test.

Change of temperature Temperature range: −40 °C to + 85 °C Visual examination (PF1)

IEC 60068-2-14: Test Nb Dwell time at extreme temperatures: 4 h Protection against ingress of

K3

dust (PF2) and water (PF3)

Rate of change of temperature:1 °C/min

after test.

Number of cycles: 2 (12 h/cycle)

c

K4 Temperature range: +25 °C to +55 °C Visual examination (PF1)

Damp heat, cyclic

Humidity: >90 % RH Protection against ingress of

IEC 60068-2-30: Test Db

dust (PF2) and water (PF3)

Number of cycles: 6 (24 h/cycle)

after test.

K5 Ultraviolet light resistance Xenon lamp (340 nm) Visual examination (PF1)

ISO 4892-2 (for painted or Exposure cycle: Cycle 1 No reduction in mechanical

polymer coated metal) properties after test (for

Exposure time: 1 000 h

example: average tensile

strength and elongation at

Ultraviolet light resistance Fluorescent lamp type 1A (340 nm)

yield) by more than 20 %.

ISO 4892-3 (for full Exposure cycle: Cycle 1 with alternating

polymer outer enclosures) UV and condensation cycles:

– UV cycle: 8 h at (+60 ± 3) °C

– Condensation cycle: 4 h at (+50 ±

3) °C

Exposure time: 2 160 h

Test are performed on moulded dumbbells

For comparable conditions, the International Standard Air, in accordance with ISO 2533 (15 °C at 1 013, 25 hPa)

shall be used.

a

This minimum temperature includes the effects of heat radiation during the night with open sky.

b

This maximum temperature includes the effects of heat dissipation caused by active electronics and includes

solar load.

c

The damp heat, cyclic test replaces the less severe IEC 60068-2-78 damp heat, steady state test.