IEC 62402:2007

(Main)Obsolescence management - Application guide

Obsolescence management - Application guide

This International Standard gives guidance for establishing a framework for obsolescence management and for planning a cost-effective obsolescence management process that is applicable through all phases of the product life cycle.

Gestion de l'obsolescence - Guide d'application

La présente Norme internationale donne des indications pour établir un cadre pour la gestion de l'obsolescence et pour planifier un processus de gestion de l'obsolescence efficace applicable à toutes les phases du cycle de vie du produit.

General Information

- Status

- Published

- Publication Date

- 13-Jun-2007

- Technical Committee

- TC 56 - Dependability

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 29-May-2019

- Completion Date

- 30-Dec-2016

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62402:2007, titled Obsolescence Management – Application Guide, is an international standard published by the International Electrotechnical Commission (IEC). It provides comprehensive guidance on establishing a systematic framework for obsolescence management relevant to all phases of the product lifecycle. The standard focuses on planning and implementing cost-effective strategies to manage obsolescence, helping organizations minimize risks, reduce costs, and maintain product functionality over time.

Obsolescence, the process where products or components become outdated or discontinued, is a common challenge across industries involving electrical, electronic, and related technologies. IEC 62402 addresses this inevitable issue by recommending proactive and reactive approaches to obsolescence management, applicable to hardware and software products.

Key Topics

Obsolescence Phase Identification

Understanding the lifecycle stages of a product's availability and predicting when obsolescence will occur.Obsolescence Management Process

Steps including planning, assessment, strategy selection, implementation, and review to systematically handle obsolescence risks.Management Responsibility

Clarifies roles and responsibilities within organizations to ensure sustained commitment and integration of obsolescence management into business functions.Planning Strategies

Distinguishes between proactive strategies (such as lifetime buys, design for obsolescence, monitoring technologies) and reactive strategies (such as repair, redesign, or sourcing alternatives).Customer and Supplier Relations

Addresses contractual and regulatory considerations impacting obsolescence management and emphasizes collaborative approaches between suppliers, manufacturers, and customers.Software Obsolescence

Highlights specific challenges and strategies related to software products, including version control, compatibility, and planned upgrades.Risk and Impact Assessment

Tools and methods to evaluate the probability, cost, and impact of obsolescence events on operational continuity and product support.Supply Chain Management

Focus on coordination with suppliers to monitor component lifecycle status and availability, ensuring timely interventions.Documentation and Continuous Improvement

Emphasizes comprehensive record-keeping, management reviews, measurements, and adjustments to improve obsolescence processes over time.

Applications

IEC 62402 applies across a broad range of industries and product types, including:

Capital Equipment Management

Ensures sustainability and maintainability of expensive machinery over long operational periods.Infrastructure Systems

Helps manage obsolescence in critical public utilities, transportation systems, and communication networks.Consumer Durables and Consumables

Supports companies in extending product lifecycles and maintaining supply chain continuity.Software Lifecycle Management

Provides frameworks for dealing with software product updates, patches, and evolving dependencies.

Organizations adopting IEC 62402 benefit from reduced lifecycle costs, enhanced customer satisfaction, minimized downtime, and improved regulatory compliance. The standard guides companies in integrating obsolescence management into risk management, procurement, design, and maintenance processes.

Related Standards

IEC 60300 (Dependability Management)

Provides principles and implementation guidance related to dependability including reliability and maintainability, complementing obsolescence management efforts.ISO 31000 (Risk Management)

Offers a framework for managing risks which aligns with IEC 62402’s focus on assessing obsolescence risk impact.IEC 61508 (Functional Safety of Electrical/Electronic Systems)

Addresses safety lifecycle which may be impacted by obsolescence in safety-critical systems.IEC 61511 (Safety Instrumented Systems)

Covers application of functional safety and indirectly supports managing obsolescence of safety-related components.Industry-Specific Lifecycle and Quality Standards

Such as MIL-STD-975 (Military Standards) and ISO 9001 (Quality Management), which include provisions that intersect with obsolescence challenges.

By integrating IEC 62402 with these standards, organizations can develop robust, multidisciplinary management systems that address the lifecycle challenges posed by obsolescence effectively.

Keywords: IEC 62402, obsolescence management, product lifecycle, obsolescence strategy, proactive obsolescence, reactive obsolescence, software obsolescence, supply chain management, risk assessment, cost-effective lifecycle management, electrical standards, international standard, product support.

Frequently Asked Questions

IEC 62402:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Obsolescence management - Application guide". This standard covers: This International Standard gives guidance for establishing a framework for obsolescence management and for planning a cost-effective obsolescence management process that is applicable through all phases of the product life cycle.

This International Standard gives guidance for establishing a framework for obsolescence management and for planning a cost-effective obsolescence management process that is applicable through all phases of the product life cycle.

IEC 62402:2007 is classified under the following ICS (International Classification for Standards) categories: 21.020 - Characteristics and design of machines, apparatus, equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62402:2007 has the following relationships with other standards: It is inter standard links to IEC 62402:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62402:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

CEI

NORME

First edition

INTERNATIONALE

Première édition

2007-06

Obsolescence management –

Application guide

Gestion de l’obsolescence –

Guide d’application

Reference number

Numéro de référence

IEC/CEI 62402:2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de

référence, texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou

remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

CEI

NORME

First edition

INTERNATIONALE

Première édition

2007-06

Obsolescence management –

Application guide

Gestion de l’obsolescence –

Guide d’application

PRICE CODE

W

CODE PRIX

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

Pour prix, voir catalogue en vigueur

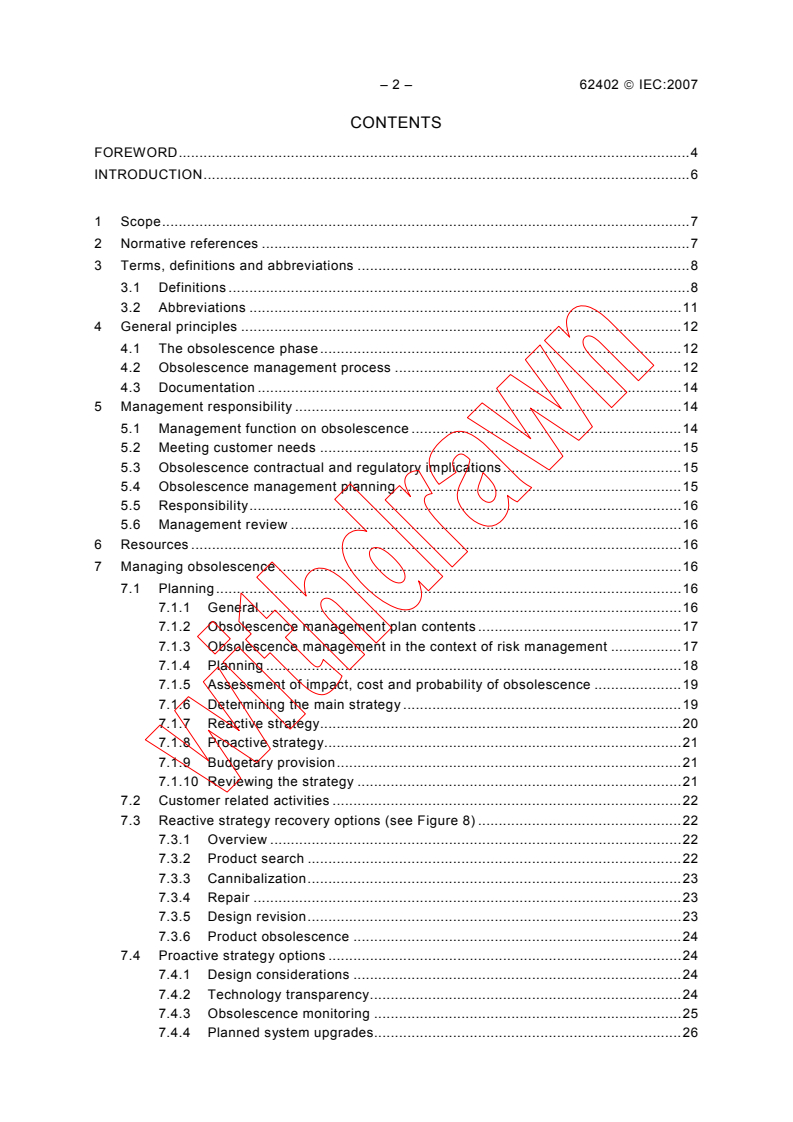

– 2 – 62402 © IEC:2007

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references .7

3 Terms, definitions and abbreviations .8

3.1 Definitions .8

3.2 Abbreviations .11

4 General principles .12

4.1 The obsolescence phase.12

4.2 Obsolescence management process .12

4.3 Documentation .14

5 Management responsibility .14

5.1 Management function on obsolescence .14

5.2 Meeting customer needs .15

5.3 Obsolescence contractual and regulatory implications.15

5.4 Obsolescence management planning .15

5.5 Responsibility.16

5.6 Management review .16

6 Resources .16

7 Managing obsolescence .16

7.1 Planning.16

7.1.1 General .16

7.1.2 Obsolescence management plan contents .17

7.1.3 Obsolescence management in the context of risk management .17

7.1.4 Planning .18

7.1.5 Assessment of impact, cost and probability of obsolescence .19

7.1.6 Determining the main strategy .19

7.1.7 Reactive strategy.20

7.1.8 Proactive strategy.21

7.1.9 Budgetary provision.21

7.1.10 Reviewing the strategy .21

7.2 Customer related activities .22

7.3 Reactive strategy recovery options (see Figure 8) .22

7.3.1 Overview .22

7.3.2 Product search .22

7.3.3 Cannibalization.23

7.3.4 Repair .23

7.3.5 Design revision.23

7.3.6 Product obsolescence .24

7.4 Proactive strategy options .24

7.4.1 Design considerations .24

7.4.2 Technology transparency.24

7.4.3 Obsolescence monitoring .25

7.4.4 Planned system upgrades.26

62402 © IEC:2007 – 3 –

7.4.5 Lifetime buy.26

7.4.6 Additional factors affecting the choice of obsolescence management

programme options.27

7.4.7 Skills training.27

7.5 Supply chain management .27

8 Measurement, analysis and improvement .27

9 Software obsolescence issues and strategies.28

9.1 Additional planning aspects for software.28

9.1.1 Software and hardware similarities and differences .28

9.1.2 Causes of software obsolescence.29

9.1.3 Determining the main strategy to combat software obsolescence .30

9.1.4 Reactive strategy – Do nothing until the need arises .31

9.1.5 Proactive strategy.31

9.2 Relationship between the customer and the supplier .32

9.3 Reactive strategy recovery options (see Figure 10) .32

9.3.1 Overview .32

9.3.2 Software search .32

9.3.3 Revision .32

9.3.4 Software obsolescence.33

9.4 Proactive strategy as applied to software separable from hardware (see

Figure 11) .33

9.4.1 Overview .33

9.4.2 Design considerations .33

9.4.3 Technology transparency/open systems .33

9.4.4 Contract support.34

9.4.5 Planned upgrades .34

9.4.6 Additional factors affecting choice of obsolescence management

programme options.34

Annex A (informative) Check list .36

Annex B (informative) Monitoring products.37

Bibliography.39

Figure 1 – Availability phases .12

Figure 2 – Process steps for managing obsolescence.13

Figure 3 – Obsolescence management versus product life cycle.13

Figure 4 – Relationship between OCM, OEM and the customer .14

Figure 5 – Process steps in project risk management versus obsolescence

management.18

Figure 6 – Reactive versus proactive strategy.20

Figure 7 – Proactive strategy .21

Figure 8 – Overview of reactive strategy recovery options .22

Figure 9 – Reactive versus proactive strategy in relation to software obsolescence .31

Figure 10 – Overview of recovery options .32

Figure 11 – Proactive options overview (software) .33

Figure B.1 – Simplified outline of monitoring of active electronic parts with suggested

solutions (see 7.4.3) .38

– 4 – 62402 © IEC:2007

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

OBSOLESCENCE MANAGEMENT –

APPLICATION GUIDE

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62402 has been prepared by IEC technical committee 56:

Dependability.

The text of this standard is based on the following documents:

FDIS Report on voting

56/1189/FDIS 56/1205/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

62402 © IEC:2007 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 62402 © IEC:2007

INTRODUCTION

Obsolescence affects all products and it impacts upon all stages of their life. The term

product includes

• capital equipment;

• infrastructure;

• consumer durables;

• consumables;

• software products.

Obsolescence is inevitable and it cannot be avoided, but forethought and careful planning can

minimize its impact and its potential high costs. The objective of obsolescence management

is to ensure that obsolescence is managed as an integral part of design, development,

production and in-service support in order to minimize cost and detrimental impact throughout

the product life cycle.

Obsolescence presents itself in two ways:

• the item is no longer suitable for current demands, or

• the item is no longer available from the original manufacturer, e.g. due to economic

constraints.

From the user's point of view, obsolescence then manifests itself as difficulty in obtaining

supplies. If the end-user is the general public, it will be in the interest of the supplier to protect

his brand image by having a defined obsolescence policy.

Commercial-off-the-shelf (COTS) products and custom designed items, e.g. new design tools

and new production processes, tend to have a much shorter life in terms of availability and

supportability than in the past. With the increased use of commercial items in complex

products expecting to have a long life cycle, it has become essential to include obsolescence

management within programme plans from the earliest stages. Furthermore environmental

considerations have the potential to affect the use of some materials during the life of the

product and should be considered from the outset.

Obsolescence management is essential to achieve optimum cost-effectiveness throughout the

life cycle of a product. The purpose of this standard is to provide guidance on planning a cost

effective obsolescence management process that takes into account essential factors to

ensure product life cycle costs are considered and applied. Obsolescence management

should also include the maintenance of the relevant knowledge and skill base sets.

Clause 4 provides overview of the process and its relation to others.

Clauses 5, 6 and 8 give guidance on management responsibility, resources, measurement

and improvement with regard to obsolescence management.

Clause 7 gives guidance on planning, strategies and options described for hardware

(including integral software).

Clause 9 gives guidance on planning, strategies and options for software that is separable

from its hardware.

62402 © IEC:2007 – 7 –

OBSOLESCENCE MANAGEMENT –

APPLICATION GUIDE

1 Scope

This International Standard gives guidance for establishing a framework for obsolescence

management and for planning a cost-effective obsolescence management process that is

applicable through all phases of the product life cycle, the term ‘product’ includes:

• capital equipment;

• infrastructure;

• consumer durables;

• consumables;

• software products.

Obsolescence management covers the following areas:

a) design of new products;

b) new technology insertion into existing products;

c) support and maintenance of legacy products.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-191, International Electrotechnical Vocabulary (IEV) – Part 191: Dependability and

quality of service

IEC 60300-1, Dependability management – Part 1: Dependability management systems

IEC 60300-2:2004, Dependability management – Part 2: Guidelines for dependability

management

IEC 62198, Project risk management – Application guidelines

IEC/TS 62239, Process management for avionics – Preparation of an electronic components

management plan

IEC 62258 (all parts), Semiconductor die products

IEC 62309, Dependability of products containing reused parts – Requirements for functionality

and tests

– 8 – 62402 © IEC:2007

3 Terms, definitions and abbreviations

For the purposes of this document, the terms and definitions given in IEC 60050-191 and the

following apply.

3.1 Definitions

3.1.1

bench marking

testing and comparing similar products or processes

3.1.2

bridge buy

lifetime buy for a given period, e.g. during replacement product development

3.1.3

cannibalization

re-use of components and assemblies taken from products within the inventory to support

other products

3.1.4

commercial-off-the-shelf

COTS

conforming to the manufacturer’s data sheet and available to any purchaser

NOTE A single user is not able to influence the specification.

3.1.5

end of life

EOL

discontinuance of production by the original manufacturer

NOTE EOL should not be confused with ‘time to wear out’ or ‘end of use’.

3.1.6

hardware

physical components of a system including its associated data and documentation

3.1.7

infrastructure

facilities, plant and people who design, manufacture, operate and support the product

3.1.8

integrated logistic support

ILS

management method by which all the logistic support services required by a customer can be

brought together in a structured way and in harmony with a product

[IEC 60300-3-12:2001, Subclause 3.2]

62402 © IEC:2007 – 9 –

3.1.9

intellectual property rights

IPR

patents, designs (whether registered or not), registered trade marks, and copyright

NOTE These are rights defined and regulated by international agreement. Confidential technical information

(usually in reports, drawings, specifications or data), and general “know-how” comprise other rights under

international law. Although to an extent intangible, they constitute a form of property, possess value and can be

bought, sold or licensed.

3.1.10

legacy product

product whose development is complete

3.1.11

legacy system

system whose development is complete

3.1.12

lifetime buy

LTB

purchase of a supply of components sufficient to support the product throughout its life cycle

or until the next planned technology change

3.1.13

materiel

systems, products, stores, supplies, spares and related documentation, manuals, computer

software and firmware

3.1.14

original component manufacturer

OCM

manufacturer of an item, material or component that is intended for embodiment into an

assembly or a product by an original equipment manufacturer (OEM)

3.1.15

original equipment manufacturer

OEM

manufacturer of an assembly or a product

NOTE 1 OEM is a common term used to identify a position in the supply chain.

NOTE 2 The assembly or product might be regarded as a component by a customer.

3.1.16

obsolescence

3.1.16.1 transition from availability from the original manufacturer to unavailability

3.1.16.2 permanent transition from operability to non-functionality due to external

reasons

3.1.17

obsolescence management

co-ordinated activities to direct and control an organization with regard to obsolescence

3.1.18

obsolescence management plan

description of the strategies for the identification and mitigation of the effects of obsolescence

through all stages of the life of a product

– 10 – 62402 © IEC:2007

3.1.19

obsolescent

subject to an announced future end of

• service provision;

• support of software;

• production by the OCM;

• processed material supply

3.1.20

obsolete

no longer available

NOTE This might be because of the lack of availability of

• service provision;

• support of software;

• production by the OCM and there is no replacement available;

• processed material supply.

3.1.21

proactive strategy

development and implementation of an obsolescence management plan in advance

3.1.22

product

result of a process

NOTE There are four generic product categories, as follows:

• service (e.g. transport, after sales support);

• software (e.g. computer program, dictionary);

• hardware (e.g. mechanical component, electrical component or assembly);

• process material (e.g. lubricant).

[ISO 9000:2005, definition 3.4.2 modified]

3.1.23

product change note/notice/notification

PCN

notice from a supplier announcing a change of process, an error on a data-sheet or the

obsolescence of a component

3.1.24

product discontinuance notice

PDN

notice of discontinuance of production by the original manufacturer

NOTE It is also often referred to as an EOL notice.

3.1.25

project manager

individual or body with authority and responsibility for managing a project to achieve specific

objectives

62402 © IEC:2007 – 11 –

3.1.26

reactive strategy

reaction to problems of obsolescence as and when they occur

3.1.27

software

programs, procedures, rules, data and documentation associated with programmable aspects

of systems hardware and infrastructure

3.1.28

support

total resources required to operate and maintain systems or products throughout their

operating phase, including all aspects of software, hardware and complete design knowledge

3.1.29

technology insertion

updates or upgrades to legacy products (utilizing developing technologies)

NOTE 1 Update: new version, same features.

NOTE 2 Upgrade: new version, additional features.

3.1.30

life cycle costs

LCC

cumulative cost of a product over its life cycle

[IEC 60300-3-3:2005, Subclause 3.3]

3.2 Abbreviations

COTS commercial-off-the-shelf

EOL end of life

ILS integrated logistics support

IPR intellectual property rights

LCC life cycle costs

LTB life time buy

OCM original component manufacturer

OEM original equipment manufacturer

PCN product change note/notice/notification

PDN product discontinuance notice

– 12 – 62402 © IEC:2007

4 General principles

4.1 The obsolescence phase

Production

Obsolescent

volume

Qualification Obsolete

Production

Samples

Time

Availability phase Obsolescence phase

Figure 1 – Availability phases

As a general principle, the obsolescence phase of a product begins immediately after the

information about discontinuance is issued and the product is considered as obsolescent, as

shown in Figure 1. The information at the obsolescent phase change is often in the form of a

product discontinuance notice (PDN), end-of-life (EOL) notification or lifetime buy (LTB)

notification. A product change notice (PCN) may also cause a product to enter the

obsolescence phase for certain manufacturers (OCM or OEM). For a software product, the

obsolescence phase commences once the original software manufacturer indicates that the

software is no longer supported.

A product may be considered obsolete once it is no longer available from the original

manufacturer, even thought some product is still in the supply chain.

4.2 Obsolescence management process

Dependability management encompasses obsolescence management, which is the process of

assuring that the product is manufacturable and supportable for the intended life, see

Figure 2. The process consists of planned and co-ordinated activities for providing availability

of a product during its intended life, by the economic and practicable provision of replacement

components and support activities. Figure 3 shows the relationship between obsolescence

management and product life cycle.

62402 © IEC:2007 – 13 –

Obsolescence management

Plan for Design for Check for Act as

obsolescence obsolescence obsolescence planned

Develop Implement pro- Check for Consult the plan

obsolescence active measures obsolescence to and apply an

management as early as ensure early appropriate

plan in the possible, reaction reactive option

framework of preferably in the to handle

product life design phase occurred

cycle obsolescence

management

Figure 2 – Process steps for managing obsolescence

Information about future obsolescence of parts

or equipment from OCM/OEM

Product life cycle phases

Concept and Design and Operation and

Installation Disposal

Manufacturing

definition development maintenance

Plan for Design for Check for Act as

and

obsolescence obsolescence obsolescence planned

Obsolescence management process

Figure 3 – Obsolescence management versus product life cycle

Obsolescence management can be viewed from two organizations within the supply chain, the

user and the supplier. All members of the supply chain are responsible to their customers or

users in assisting them in pro-actively managing obsolescence issues. Figure 4 shows the

typical relationship between these organizations.

– 14 – 62402 © IEC:2007

Start of selling Decision to make obsolescent Lifetime buy option

OCM Item, material or

Product life cycle of supplied material or item

component

obsolete

Information to OEM, e.g. PDN

Obsolescence

Obsolescence management

solution

implemented

OEM of

the product,

Act to handle obsolescence

system or

program

Extended

Product life cycle (system or program) product

life

Customer information

Customer Product life cycle of customers equipment

NOTE For clarity, only the case of obsolescence information originating with the OCM is shown. To obtain mutual

benefit, obsolescence originating with the OEM should lead to communication with the OCM.

Figure 4 – Relationship between OCM, OEM and the customer

4.3 Documentation

The documentation for obsolescence management should include but not be limited to

a) a general statement of obsolescence policy and objectives;

b) documented procedures, describing the obsolescence management process, related

activities and responsibilities;

c) documents needed by the organization to ensure the effective planning, operation and

control of obsolescence management, e.g. an obsolescence management plan.

Also see IEC/TS 62239 for component records.

5 Management responsibility

5.1 Management function on obsolescence

The management function on dependability should be identified with specific roles and

objectives in relation to quality and other technical disciplines as needed by the organization

or project. This should include its function in regard to obsolescence.

62402 © IEC:2007 – 15 –

Top management should

– establish an obsolescence management policy that is consistent with the overall business

strategy;

– establish obsolescence management in the framework of dependability management

system, see IEC 60300-1;

– provide adequate resources to support obsolescence management activities consistent

with the organization’s business. This may include the use of external component

monitoring services.

5.2 Meeting customer needs

The needs and expectations of customers regarding obsolescence should be translated into

objectives for formulating a specific obsolescence management plan.

As a minimum, early information about obsolescence issues should be provided. This can

range from information on the organization’s internet ‘home page’, to directly addressed

information to the customer.

Where applicable, early customer involvement in obsolescence management planning can be

essential to ensure achieving the best solution for the customer.

Meeting customer needs and expectations also demands proper deployment of resources and

assignment of dedicated technical responsibilities.

NOTE The customer referred to above can be an OEM or the OEM customer.

5.3 Obsolescence contractual and regulatory implications

Some obsolescence-related activities may be determined by contractual, regulatory and

statutory requirements. Personnel assigned to obsolescence tasks should be aware of such

situations and act accordingly. Typical contractual, regulatory and statutory issues involving

obsolescence are long-term delivery obligations and those given in IEC 60300-2 Subclause

5.3 and IEC/TS 62239 for electronic component management plans.

5.4 Obsolescence management planning

In the framework of the dependability management planning, an obsolescence management

plan should be used to ensure adequate selection and timely implementation of relevant

obsolescence activities.

The objective of the obsolescence management plan should be to describe strategies for

identification and mitigation of the effects of obsolescence through all stages of the product

life cycle. The plan can be part of another plan or a separate document.

The objectives include but are not limited to

i) achieving the optimum compromise between life cycle costs for the system, product

performance and product availability, maintainability and safety;

ii) including all materiel regardless of whether it has been developed specifically for a

customer.

The plan should consider the following:

a) all in-house processes, skills and infrastructure necessary for production and support of

the product and their maintenance;

– 16 – 62402 © IEC:2007

b) compatibility with the customer’s current support arrangements;

c) identifying the items that present the greatest risk from obsolescence;

d) provision of clear basis upon which obsolescence management objectives can be

negotiated with OEM and partners in collaborative projects;

e) robustness within an environment of change;

f) consideration of the need for component, material or product re-qualification following

item substitution (also see Subclause 7.3.5a) “Equivalent” or 7.3.5b) “Alternative”);

g) the processes for communication between the organization, customers and the suppliers;

h) maintenance of the plan.

5.5 Responsibility

A representative should be appointed and given authority by top management to manage,

monitor, evaluate and coordinate the obsolescence issues. This appointment is to promote

effective and efficient operation and improvement of obsolescence management. The

obsolescence management representative should report to top management and may

communicate with customers and OCMs on matters pertaining to obsolescence.

5.6 Management review

Top management should review obsolescence management performance on a regular basis

to determine the continuing suitability of the chosen strategy and policy.

Top management should also review obsolescence issues on a regular basis to determine the

continuing suitability of obsolescence management activities.

6 Resources

The organization should provide adequate resources to sustain effective obsolescence

management to meet business objectives.

These include human resources, such as personnel for obsolescence planning and

monitoring, financial resources, e.g. for covering activities to prevent or compensate for

obsolescence issues, as well as information resources, e.g. on time information about

obsolete material or components.

7 Managing obsolescence

7.1 Planning

7.1.1 General

An increased incidence of obsolescence is likely to be a significant factor in cost,

supportability, manufacturability and product life cycle. It is essential therefore that the

organization involves the customers and suppliers in pro-actively managing obsolescence

from the outset.

Obsolescence management planning can be performed either for the whole organization, thus

covering all items that might become obsolete or on a project level where each project

resolves its obsolescence independently.

62402 © IEC:2007 – 17 –

If the planning is focused on a specific project, the project manager should produce an outline

obsolescence management plan at the earliest stages of a project. However, everyone

involved in the project should recognize that the finally agreed strategy will be influenced by

proposals offered by contractors during the bidding phase. A costed obsolescence

management plan for a specified project life should be a feature of an invitation to tender. The

plan should be subject to planned review and maintenance.

7.1.2 Obsolescence management plan contents

The obsolescence management plan should initially record the choice of strategy. The level of

detail in the plan should increase as the product proceeds through its life cycle. Subsidiary

documentation should contain a full record of the factors in the analysis and trade-off

arguments. Details of plans, decisions and analyses should be recorded for later reference.

As well as the record of decisions, the obsolescence management plan should also identify

the following aspects:

a) the scope (the items covered);

b) objectives of the obsolescence activities;

c) the obsolescence management roles and responsibilities of the customer and OCM;

d) the current authority responsible for review and maintenance of the plan and the

milestones for future transfer of ownership of the plan if applicable;

e) the interval between reviews (can be combined with other reviews);

f) for each item under consideration a checklist is given in Annex A.

Guidance on strategies and options described for hardware (including integral software) can

be found later on in this clause.

Guidance on strategies and options described for software that is separable from its hardware

can be found in Clause 9.

7.1.3 Obsolescence management in the context of risk management

Obsolescence issues should be considered as early as possible in the life cycle to reduce the

risks.

In the course of the planning activities, the steps of risk management as outlined in

IEC 62198 are as shown in Figure 5.

– 18 – 62402 © IEC:2007

The risk management process

Establishing Risk identification Risk assessment Risk treatment Risk review and

the context monitoring

For obsolescence management this means in particular:

Define general Determine Assess impact, Derive strategy Review and

plan aspects products and cost and monitor situation,

Reactive or

customers probability

pro-active

For each item: affected, of obsolescence Act accordingly

Define part, contractual and a

Prevention

material, regulatory

Budget

component data boundaries

b

recovery

a

General prevention measures are: avoidance (of obsolescence), probability reduction, consequence

limitation, risk sharing (e.g. by means of contractual arrangements). In particular for obsolescence technology

transparency, obsolescence monitoring, planned system upgrades, lifetime buy can be considered.

b

Recovery measures can be component search, cannibalization, design revision.

NOTE For plan contents, see 7.1.2, for planning, see 7.1.4.

Figure 5 – Process steps in project risk management versus obsolescence management

The risks associated with obsolescence should be reviewed when changes occur such as

obsolete components being replaced.

7.1.4 Planning

Only limited information can be available in the early stages of a project, so the plan should

be progressively developed and reviewed as the project matures; the plan should take into

account the technology, complexity, cost and operational considerations of the product. The

plan should be used throughout the life of the product to define obsolescence management

activities and responsibilities.

The plan should record the chosen options (see 7.1.6) for the project, with reasons for the

choice. It may be appropriate to apply different management options to different components

of the same project and the choices should be regularly reviewed to ensure that they are still

appropriate.

The plan should be based on the best understanding of the project and its implementation at

the time. If it is clear that early reconsideration is appropriate, this fact should be recorded

with a recommendation of the longest time that should be allowed to elapse before review.

The plan should never appear to be absolute or beyond question unless the product itself is

approaching the end of its life. The essential factor in choosing between options is optimum

value for money over the life of the project taking account of cash flow constraints.

Regardless of the option chosen, the associated costs should be included in the cost of

ownership and recorded in the life-cycle management plan.

62402 © IEC:2007 – 19 –

The main steps in constructing the plan are as follows:

a) define general plan aspects;

b) for every item identified:

1) define general aspects of the item;

2) define products, customers and obligations;

3) assess impact, cost and probability of obsolescence – what is the risk associated

with reactive strategy (see 7.1.7 for hardware and 9.1.4 for software);

4) derive main strategy; if a proactive strategy is chosen then

• define preventive measures;

• assess impact, cost and probability of obsolescence – what is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...