IEC 61215-2:2021

(Main)Terrestrial photovoltaic (PV) modules - Design qualification and type approval - Part 2: Test procedures

Terrestrial photovoltaic (PV) modules - Design qualification and type approval - Part 2: Test procedures

IEC 61215-2:2021 lays down requirements for the design qualification of terrestrial photovoltaic modules suitable for long-term operation in open-air climates. This document is intended to apply to all terrestrial flat plate module materials such as crystalline silicon module types as well as thin-film modules. The objective of this test sequence is to determine the electrical characteristics of the module and to show, as far as possible within reasonable constraints of cost and time, that the module is capable of withstanding prolonged exposure outdoors. This second edition of IEC 61215-2 cancels and replaces the first edition of IEC 61215-2 issued in 2016. This edition includes the following significant technical changes with respect to the previous edition:

a. Addition of cyclic (dynamic) mechanical load testing (MQT 20).

b. Addition of a test for detection of potential-induced degradation (MQT 21).

c. Addition of test methods required for bifacial PV modules.

d. Addition of test methods required for flexible modules. This includes the addition of the bending test (MQT 22).

e. Revision of simulator requirements to ensure uncertainty is both well-defined and minimized.

f. Correction to the hot spot endurance test, where the procedure for monolithically integrated (MLI) thin film technologies (MQT 09.2) previously included two sections describing a procedure only appropriate for silicon modules.

g. Selection of three diodes, rather than all, for testing in the bypass diode thermal test (MQT 18).

h. Removal of the nominal module operating test (NMOT), and associated test of performance at NMOT, from the IEC 61215 series.

Modules photovoltaïques (PV) pour applications terrestres - Qualification de la conception et homologation - Partie 2: Procédures d'essai

L'IEC 61215-2:2021 établit les exigences concernant la qualification de conception des modules photovoltaïques terrestres appropriés à un fonctionnement de longue durée dans des climats à l’air libre. Le présent document est destiné à s'appliquer à tous les matériaux de modules à plaque plane pour applications terrestres, tels que les types de modules au silicium cristallin et les modules à couches minces. L'objet de cette séquence d'essais est de déterminer les caractéristiques électriques du module et d’indiquer, dans la mesure du possible avec des contraintes de coût et de temps raisonnables, que le module est capable de supporter une exposition prolongée en site naturel. Cette deuxième édition de l’IEC 61215-2 annule et remplace la première édition de l’IEC 61215‑2 parue en 2016. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente.

a. Ajout de l’essai de charge mécanique cyclique (dynamique) (MQT 20 - Module Quality Test, essai de qualité du module).

b. Ajout d’un essai de détection de la dégradation induite par le potentiel (MQT 21).

c. Ajout de méthodes d’essai exigées pour les modules PV bifaces.

d. Ajout de méthodes d’essai exigées pour les modules flexibles. Cette disposition inclut l’ajout de l’essai de flexion (MQT 22).

e. Révision des exigences du simulateur pour assurer à la fois la définition appropriée et la réduction le plus possible de l’incertitude.

f. Correction de l’essai de tenue à l’échauffement localisé, dont la procédure pour les technologies à couches minces à intégration monolithique (MLI - monolithic integration) (MQT 09.2) comprenait précédemment deux sections décrivant une méthode uniquement adaptée aux modules en silicium.

g. Choix de trois diodes, plutôt que de toutes les diodes d’essai, pour l’essai thermique de la diode de dérivation (MQT 18).

h. Suppression de l’essai nominal de fonctionnement du module (NMOT - nominal module operating test), et de l’essai associé de performances à la température nominale de fonctionnement du module (NMOT - nominal module operating temperature), issus de la série IEC 61215.

General Information

- Status

- Published

- Publication Date

- 23-Feb-2021

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 2 - TC 82/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 24-Feb-2021

- Completion Date

- 05-Mar-2021

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61215-2:2021 - "Terrestrial photovoltaic (PV) modules - Design qualification and type approval - Part 2: Test procedures" defines the standardized test procedures used to qualify flat‑plate terrestrial PV modules (crystalline silicon and thin‑film) for long‑term outdoor operation. The standard’s objective is to determine electrical characteristics and, within reasonable cost/time constraints, demonstrate that modules can withstand prolonged outdoor exposure. Edition 2.0 (2021) replaces the 2016 edition and adds several new tests and updates to address bifacial, flexible and modern module technologies.

Key topics and technical requirements

- Scope and applicability: Applies to all terrestrial flat‑plate PV module materials (crystalline and thin‑film).

- Comprehensive test sequence: Visual inspection, maximum power determination, insulation, temperature coefficients, performance at STC and low irradiance, outdoor exposure, UV preconditioning, thermal cycling, damp heat, humidity‑freeze, hail, wet leakage, stabilization and final electrical measurements (MQT 01–MQT 19+).

- New and revised tests (notable changes in 2021 edition):

- Cyclic (dynamic) mechanical load test (MQT 20) for real‑world mechanical fatigue.

- Potential‑induced degradation (PID) test (MQT 21) to detect voltage‑induced performance loss.

- Bifacial module test methods and flexible module methods, including the bending test (MQT 22).

- Revised simulator requirements to better define and minimize measurement uncertainty.

- Corrections and clarifications such as hot‑spot endurance adjustments for monolithic thin‑film modules and selecting three diodes (instead of all) for bypass diode thermal testing (MQT 18).

- Removal of NMOT (nominal module operating temperature) test from the series.

- Pass/fail criteria and final measurements: Each MQT includes specific measurement procedures and acceptance criteria to demonstrate design robustness and electrical stability.

Applications and users

IEC 61215-2:2021 is intended for:

- PV module manufacturers - to design, test and document product qualification for market approval.

- Independent test laboratories - to perform standardized type‑approval and reliability testing.

- Certification bodies and product certifiers - to assess compliance for labels and warranties.

- Project developers, EPCs and procurement teams - to specify module qualification requirements in tenders and technical specifications.

- R&D and QA teams - to validate new module technologies (bifacial, flexible, MLI thin‑film) and production changes.

Using these test procedures supports reliable performance claims, reduces field failures, and helps ensure long‑term return on investment for PV installations.

Related standards

- Other parts of the IEC 61215 series (design qualification and type approval)

- PV module safety and conformity standards (for example, IEC 61730 - check current IEC catalogue for the latest cross‑references)

Buy Documents

IEC 61215-2:2021 RLV - Terrestrial photovoltaic (PV) modules - Design qualification and type approval - Part 2: Test procedures Released:2/24/2021 Isbn:9782832295007

IEC 61215-2:2021 - Terrestrial photovoltaic (PV) modules - Design qualification and type approval - Part 2: Test procedures Released:2/24/2021 Isbn:9782832293942

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 61215-2:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Terrestrial photovoltaic (PV) modules - Design qualification and type approval - Part 2: Test procedures". This standard covers: IEC 61215-2:2021 lays down requirements for the design qualification of terrestrial photovoltaic modules suitable for long-term operation in open-air climates. This document is intended to apply to all terrestrial flat plate module materials such as crystalline silicon module types as well as thin-film modules. The objective of this test sequence is to determine the electrical characteristics of the module and to show, as far as possible within reasonable constraints of cost and time, that the module is capable of withstanding prolonged exposure outdoors. This second edition of IEC 61215-2 cancels and replaces the first edition of IEC 61215-2 issued in 2016. This edition includes the following significant technical changes with respect to the previous edition: a. Addition of cyclic (dynamic) mechanical load testing (MQT 20). b. Addition of a test for detection of potential-induced degradation (MQT 21). c. Addition of test methods required for bifacial PV modules. d. Addition of test methods required for flexible modules. This includes the addition of the bending test (MQT 22). e. Revision of simulator requirements to ensure uncertainty is both well-defined and minimized. f. Correction to the hot spot endurance test, where the procedure for monolithically integrated (MLI) thin film technologies (MQT 09.2) previously included two sections describing a procedure only appropriate for silicon modules. g. Selection of three diodes, rather than all, for testing in the bypass diode thermal test (MQT 18). h. Removal of the nominal module operating test (NMOT), and associated test of performance at NMOT, from the IEC 61215 series.

IEC 61215-2:2021 lays down requirements for the design qualification of terrestrial photovoltaic modules suitable for long-term operation in open-air climates. This document is intended to apply to all terrestrial flat plate module materials such as crystalline silicon module types as well as thin-film modules. The objective of this test sequence is to determine the electrical characteristics of the module and to show, as far as possible within reasonable constraints of cost and time, that the module is capable of withstanding prolonged exposure outdoors. This second edition of IEC 61215-2 cancels and replaces the first edition of IEC 61215-2 issued in 2016. This edition includes the following significant technical changes with respect to the previous edition: a. Addition of cyclic (dynamic) mechanical load testing (MQT 20). b. Addition of a test for detection of potential-induced degradation (MQT 21). c. Addition of test methods required for bifacial PV modules. d. Addition of test methods required for flexible modules. This includes the addition of the bending test (MQT 22). e. Revision of simulator requirements to ensure uncertainty is both well-defined and minimized. f. Correction to the hot spot endurance test, where the procedure for monolithically integrated (MLI) thin film technologies (MQT 09.2) previously included two sections describing a procedure only appropriate for silicon modules. g. Selection of three diodes, rather than all, for testing in the bypass diode thermal test (MQT 18). h. Removal of the nominal module operating test (NMOT), and associated test of performance at NMOT, from the IEC 61215 series.

IEC 61215-2:2021 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61215-2:2021 has the following relationships with other standards: It is inter standard links to CEN ISO/TS 19392-1:2022, IEC 61215-2:2016/COR1:2018, IEC 61215-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61215-2:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61215-2 ®

Edition 2.0 2021-02

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Terrestrial photovoltaic (PV) modules – Design qualification and type approval –

Part 2: Test procedures

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61215-2 ®

Edition 2.0 2021-02

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Terrestrial photovoltaic (PV) modules – Design qualification and type approval –

Part 2: Test procedures

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.160 ISBN 978-2-8322-9500-7

– 2 – IEC 61215-2:2021 RLV © IEC 2021

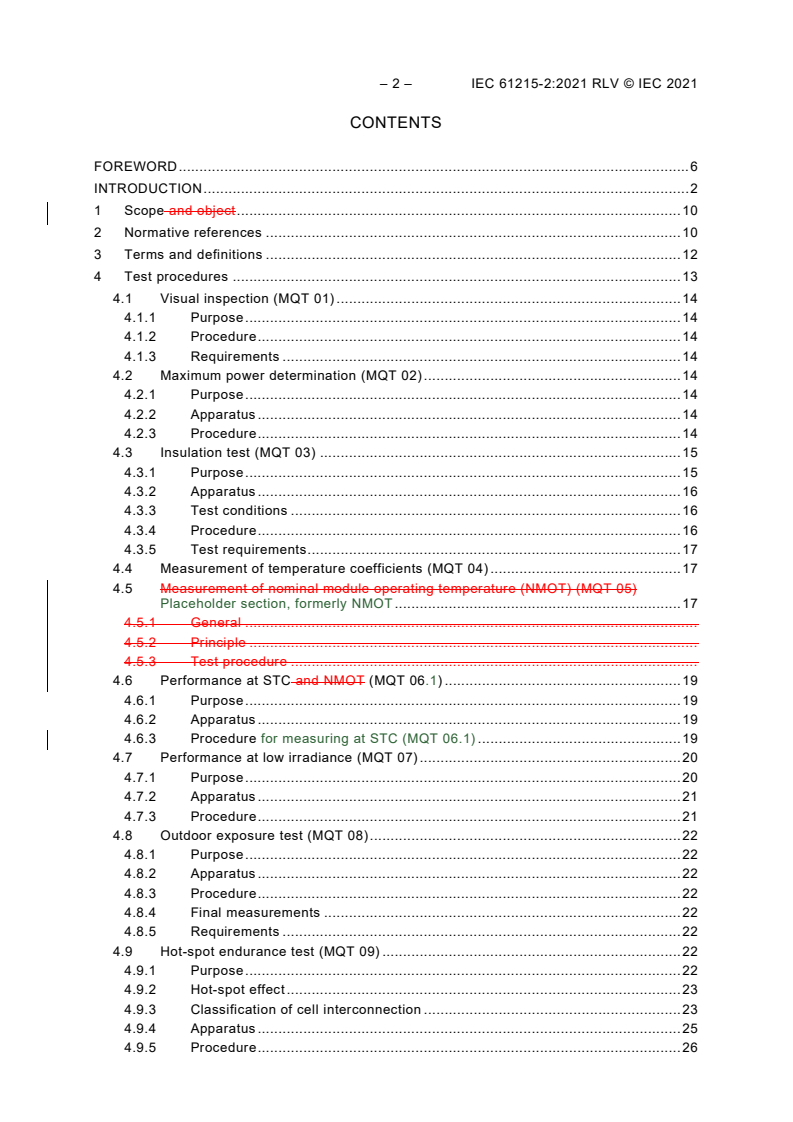

CONTENTS

FOREWORD . 6

INTRODUCTION . 2

1 Scope and object . 10

2 Normative references . 10

3 Terms and definitions . 12

4 Test procedures . 13

4.1 Visual inspection (MQT 01) . 14

4.1.1 Purpose . 14

4.1.2 Procedure . 14

4.1.3 Requirements . 14

4.2 Maximum power determination (MQT 02) . 14

4.2.1 Purpose . 14

4.2.2 Apparatus . 14

4.2.3 Procedure . 14

4.3 Insulation test (MQT 03) . 15

4.3.1 Purpose . 15

4.3.2 Apparatus . 16

4.3.3 Test conditions . 16

4.3.4 Procedure . 16

4.3.5 Test requirements . 17

4.4 Measurement of temperature coefficients (MQT 04) . 17

4.5 Measurement of nominal module operating temperature (NMOT) (MQT 05)

Placeholder section, formerly NMOT . 17

4.5.1 General .

4.5.2 Principle .

4.5.3 Test procedure .

4.6 Performance at STC and NMOT (MQT 06.1) . 19

4.6.1 Purpose . 19

4.6.2 Apparatus . 19

4.6.3 Procedure for measuring at STC (MQT 06.1) . 19

4.7 Performance at low irradiance (MQT 07) . 20

4.7.1 Purpose . 20

4.7.2 Apparatus . 21

4.7.3 Procedure . 21

4.8 Outdoor exposure test (MQT 08) . 22

4.8.1 Purpose . 22

4.8.2 Apparatus . 22

4.8.3 Procedure . 22

4.8.4 Final measurements . 22

4.8.5 Requirements . 22

4.9 Hot-spot endurance test (MQT 09) . 22

4.9.1 Purpose . 22

4.9.2 Hot-spot effect . 23

4.9.3 Classification of cell interconnection . 23

4.9.4 Apparatus . 25

4.9.5 Procedure . 26

4.9.6 Final measurements . 39

4.9.7 Requirements . 39

4.10 UV preconditioning test (MQT 10) . 39

4.10.1 Purpose . 39

4.10.2 Apparatus . 39

4.10.3 Procedure . 40

4.10.4 Final measurements . 40

4.10.5 Requirements . 40

4.11 Thermal cycling test (MQT 11) . 41

4.11.1 Purpose . 41

4.11.2 Apparatus . 41

4.11.3 Procedure . 42

4.11.4 Final measurements . 43

4.11.5 Requirements . 43

4.12 Humidity-freeze test (MQT 12) . 44

4.12.1 Purpose . 44

4.12.2 Apparatus . 44

4.12.3 Procedure . 44

4.12.4 Final measurements . 44

4.12.5 Requirements . 44

4.13 Damp heat test (MQT 13) . 45

4.13.1 Purpose . 45

4.13.2 Apparatus . 45

4.13.3 Procedure . 45

4.13.4 Final measurements . 46

4.13.5 Requirements . 46

4.14 Robustness of terminations (MQT 14) . 46

4.14.1 Purpose . 46

4.14.2 Retention of junction box on mounting surface (MQT 14.1) . 46

4.14.3 Test of cord anchorage (MQT 14.2) . 47

4.15 Wet leakage current test (MQT 15) . 47

4.15.1 Purpose . 51

4.15.2 Apparatus . 51

4.15.3 Procedure . 51

4.15.4 Requirements . 52

4.16 Static mechanical load test (MQT 16) . 52

4.16.1 Purpose . 52

4.16.2 Apparatus . 53

4.16.3 Procedure . 53

4.16.4 Final measurements . 52

4.16.5 Requirements . 54

4.17 Hail test (MQT 17) . 54

4.17.1 Purpose . 54

4.17.2 Apparatus . 54

4.17.3 Procedure . 55

4.17.4 Final measurements . 56

4.17.5 Requirements . 56

4.18 Bypass diode testing (MQT 18) . 57

4.18.1 Bypass diode thermal test (MQT 18.1) . 57

– 4 – IEC 61215-2:2021 RLV © IEC 2021

4.18.2 Bypass diode functionality test (MQT 18.2) . 60

4.19 Stabilization (MQT 19) . 61

4.19.1 General . 61

4.19.2 Criterion definition for stabilization . 61

4.19.3 Light induced stabilization procedures . 62

4.19.4 Other stabilization procedures . 63

4.19.5 Initial stabilization (MQT 19.1) . 63

4.19.6 Final stabilization (MQT 19.2) . 63

4.19.7 Stress-specific stabilization – BO LID (MQT 19.3). 64

4.20 Cyclic (dynamic) mechanical load test (MQT 20) . 64

4.20.1 Purpose . 64

4.20.2 Procedure . 64

4.20.3 Final measurements . 64

4.20.4 Requirements . 65

4.21 Potential induced degradation test (MQT 21) . 65

4.21.1 Purpose . 65

4.21.2 Samples . 65

4.21.3 Apparatus . 65

4.21.4 Procedure . 65

4.21.5 Final measurements . 65

4.21.6 Requirements . 66

4.22 Bending test (MQT 22) . 66

4.22.1 Purpose . 66

4.22.2 Apparatus . 66

4.22.3 Procedure . 66

4.22.4 Final measurements . 66

4.22.5 Requirements . 66

Annex A (informative) Recommended setup for managing weights during mechanical

loading (MQT 16) . 67

Bibliography . 71

Figure 1 – Case S, series connection with optional bypass diode . 24

Figure 2 – Case PS, parallel-series connection with optional bypass diode . 24

Figure 3 – Case SP, series-parallel connection with optional bypass diode . 25

Figure 4 – Module I-V characteristics with different cells totally shadowed . 27

Figure 5 – Module I-V characteristics with the test cell shadowed at different levels . 30

Figure 6 – Hot-spot effect in a MLI thin-film module with serially connected cells . 31

Figure 7 – Module I-V characteristics with different cells totally shadowed where the

module design includes bypass diodes .

Figure 8 – Module I-V characteristics with the test cell shadowed at different levels

where the module design includes bypass diodes .

Figure 7 – Thermal cycling test – Temperature and applied current profile . 42

Figure 8 – Proper attachment of 5 N weight to junction box for module utilizing a)

electrical termination leads, b) or wire for attachment, and c) only one junction box . 43

Figure 9 – Humidity-freeze cycle – Temperature and humidity profile . 45

Figure 10 – Hail-test equipment . 55

Figure 11 – a) Typical arrangement for the cord anchorage pull test for component

testing from IEC 62790. b) Typical schematic arrangement for cord anchorage pull test

on PV module mounted junction box .

Figure 12 – Typical arrangement for torsion test .

Figure 11 – Hail test impact locations: top for wafer/cell based technologies, bottom for

monolithic processed thin film technologies . 57

Figure 12 – Bypass diode thermal test . 59

Figure A.1 – 3D view (at left of figure), end view (at top right), and side view (at bottom

right) of gantry crane over mounting jig and loading jig . 67

Figure A.2 – 3D close up views of mounting jig (right) and loading jig (left) . 68

Figure A.3 – 2D view of mounting jig and loading jig . 69

Figure A.4 – 3D view of loading jig . 69

Figure A.5 – Close-up view of loading jig . 70

Table 1 – Pull forces for cord anchorage test .

Table 2 – Values for torsion test .

Table 1 – Voltage stress levels . 17

Table 2 – Ice-ball masses and test velocities . 55

Table 3 – Impact locations . 56

– 6 – IEC 61215-2:2021 RLV © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TERRESTRIAL PHOTOVOLTAIC (PV) MODULES –

DESIGN QUALIFICATION AND TYPE APPROVAL –

Part 2: Test procedures

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made to

the previous edition IEC 61215-2:2016. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 61215-2 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

This second edition of IEC 61215-2 cancels and replaces the first edition of IEC 61215-2 issued

in 2016; it constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Addition of cyclic (dynamic) mechanical load testing (MQT 20).

b) Addition of a test for detection of potential-induced degradation (MQT 21).

c) Addition of test methods required for bifacial PV modules.

d) Addition of test methods required for flexible modules. This includes the addition of the

bending test (MQT 22).

e) Revision of simulator requirements to ensure uncertainty is both well-defined and minimized.

f) Correction to the hot spot endurance test, where the procedure for monolithically integrated

(MLI) thin film technologies (MQT 09.2) previously included two sections describing a

procedure only appropriate for silicon modules.

g) Selection of three diodes, rather than all, for testing in the bypass diode thermal test

(MQT 18).

h) Removal of the nominal module operating test (NMOT), and associated test of performance

at NMOT, from the IEC 61215 series.

Informative Annex A of IEC 61215-1:2021 explains the background and reasoning behind some

of the more substantial changes that were made in the IEC 61215 series in progressing from

edition 1 to edition 2.

The text of this standard is based on the following documents:

FDIS Report on voting

82/1829/FDIS 82/1853/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61215 series, published under the general title Terrestrial

photovoltaic (PV) modules – Design qualification and type approval, can be found on the IEC

website.

– 8 – IEC 61215-2:2021 RLV © IEC 2021

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

INTRODUCTION

Whereas Part 1 of this standards series describes requirements (both in general and specific

with respect to device technology), the sub-parts of Part 1 define technology variations and

Part 2 defines a set of test procedures necessary for design qualification and type approval.

The test procedures described in Part 2 are valid for all device technologies.

– 10 – IEC 61215-2:2021 RLV © IEC 2021

TERRESTRIAL PHOTOVOLTAIC (PV) MODULES –

DESIGN QUALIFICATION AND TYPE APPROVAL –

Part 2: Test procedures

1 Scope and object

This International Standard series lays down IEC requirements for the design qualification and

type approval of terrestrial photovoltaic modules suitable for long-term operation in general

open-air climates, as defined in IEC 60721-2-1. This part of IEC 61215 is intended to apply to

all terrestrial flat plate module materials such as crystalline silicon module types as well as thin-

film modules.

This document lays down requirements for the design qualification of terrestrial photovoltaic

modules suitable for long-term operation in open-air climates. The useful service life of modules

so qualified will depend on their design, their environment and the conditions under which they

are operated. Test results are not construed as a quantitative prediction of module lifetime.

th

In climates where 98 percentile operating temperatures exceed 70 °C, users are

recommended to consider testing to higher temperature test conditions as described in

IEC TS 63126 . Users desiring qualification of PV products with lesser lifetime expectations are

recommended to consider testing designed for PV in consumer electronics, as described in

IEC TS 63163 (under development). Users wishing to gain confidence that the characteristics

tested in IEC 61215 appear consistently in a manufactured product may wish to utilize

IEC 62941 regarding quality systems in PV manufacturing.

This document is intended to apply to all terrestrial flat plate module materials such as

crystalline silicon module types as well as thin-film modules.

This document does not apply to modules used with concentrated sunlight although it may be

utilized for low concentrator modules (1 to 3 suns). For low concentration modules, all tests are

performed using the irradiance, current, voltage and power levels expected at the design

concentration.

The objective of this test sequence is to determine the electrical and thermal characteristics of

the module and to show, as far as possible within reasonable constraints of cost and time, that

the module is capable of withstanding prolonged exposure in general open-air climates. The

actual lifetime expectancy of modules so qualified will depend on their design, their environment

and the conditions under which they are operated.

The objective of this test sequence is to determine the electrical characteristics of the module

and to show, as far as possible within reasonable constraints of cost and time, that the module

is capable of withstanding prolonged exposure outdoors. Accelerated test conditions are

empirically based on those necessary to reproduce selected observed field failures and are

applied equally across module types. Acceleration factors may vary with product design and

thus not all degradation mechanisms may manifest. Further general information on accelerated

test methods including definitions of terms may be found in IEC 62506.

Some long-term degradation mechanisms can only reasonably be detected via component

testing, due to long times required to produce the failure and necessity of stress conditions that

are expensive to produce over large areas. Component tests that have reached a sufficient

_________________

1 th

Information on 98 percentile operating temperature as a function of system location and mounting configuration

is included in IEC TS 63126.

level of maturity to set pass/fail criteria with high confidence are incorporated into the IEC 61215

series via addition to Table 1 in IEC 61215-1:2021. In contrast, the tests procedures described

in this series, in IEC 61215-2, are performed on modules.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050, International Electrotechnical Vocabulary (available at http://www.electropedia.org)

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60068-2-21, Environmental testing – Part 2-21: Tests – Test U: Robustness of terminations

and integral mounting devices

IEC 60068-2-78:2012, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60721-2-1, Classification of environmental conditions – Part 2-1: Environmental conditions

appearing in nature – Temperature and humidity

IEC 60891, Photovoltaic devices – Procedures for temperature and irradiance corrections to

measured I-V characteristics

IEC 60904-1, Photovoltaic devices – Part 1: Measurements of photovoltaic current-voltage

characteristics

IEC 60904-1-1, Photovoltaic devices – Part 1-1: Measurement of current-voltage characteristics

of multi-junction photovoltaic (PV) devices

IEC TS 60904-1-2, Photovoltaic devices – Part 1-2: Measurement of current-voltage

characteristics of bifacial photovoltaic (PV) devices

IEC 60904-2, Photovoltaic devices – Part 2: Requirements for photovoltaic reference devices

IEC 60904-3, Photovoltaic devices – Part 3: Measurement principles for terrestrial photovoltaic

(PV) solar devices with reference spectral irradiance data

IEC 60904-7, Photovoltaic devices – Part 7: Computation of the spectral mismatch correction

for measurements of photovoltaic devices

IEC 60904-8, Photovoltaic devices – Part 8: Measurement of spectral responsivity of a

photovoltaic (PV) device

IEC 60904-9:2020, Photovoltaic devices – Part 9: Classification of solar simulator performance

requirements characteristics

IEC 60904-10, Photovoltaic devices – Part 10: Methods of linearity measurement

IEC TR 60904-14: Photovoltaic devices – Part 14: Guidelines for production line measurements

of single-junction PV module maximum power output and reporting at standard test conditions

– 12 – IEC 61215-2:2021 RLV © IEC 2021

IEC 61140, Protection against electric shock – Common aspects for installation and equipment

IEC 61215-1:2021, Terrestrial photovoltaic (PV) modules – Design qualification and type

approval – Part 1: Test requirements

IEC 61215-1-1, Terrestrial photovoltaic (PV) modules – Design qualification and type approval

– Part 1-1: Special requirements for testing of crystalline silicon photovoltaic (PV) modules

IEC 61730-1:2016, Photovoltaic (PV) module safety qualification – Part 1: Requirements for

construction

IEC 61730-2, Photovoltaic (PV) module safety qualification – Part 2: Requirements for testing

IEC TS 61836, Solar photovoltaic energy systems – Terms, definitions and symbols

IEC 61853-2, Photovoltaic (PV) module performance testing and energy rating – Part 2:

Spectral response, incidence angle, and module operating temperature measurements

IEC TS 62782, Photovoltaic (PV) modules – Cyclic (dynamic) mechanical load testing

IEC 62790, Junction boxes for photovoltaic modules – Safety requirements and tests

IEC TS 62804-1:2015, Photovoltaic (PV) modules – Test methods for the detection of potential-

induced degradation – Part 1: Crystalline silicon

IEC TS 63163: – Terrestrial photovoltaic (PV) modules for consumer products – Design

qualification and type approval

ISO 868, Plastics and ebonite – Determination of indentation hardness by means of a durometer

(Shore hardness)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050 and IEC TS

61836 and IEC 61215-1:2021 apply, as well as the following.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

accuracy

quality which characterizes the ability of a measuring instrument to provide an indicated value

close to a true value of the measurand [consistent with the International Vocabulary of

Metrology (VIM), 5.18]

Note 1 to entry: This term is used in the "true value" approach.

Note 2 to entry: Accuracy is all the better when the indicated value is closer to the corresponding true value.

_________________

To be published.

Under preparation. Stage at the time of publication: ADTS.

[SOURCE: IEC 60050-311:2001, 311-06-08]

3.2

control device

irradiance sensor (such as a reference cell or module) that is used to detect drifts and other

problems of the solar sun simulator

3.3

electrically stable power output level

state of the PV module where it will operate under long-term natural sunlight exposure in

general open-air climates, as defined in IEC 60721-2-1

3.4

repeatability

closeness of agreement between the results of successive measurements of the same

measurand, carried out under the same conditions of measurement, i.e.:

– by the same measurement procedure,

– by the same observer,

– with the same measuring instruments,

– used under the same conditions,

– in the same laboratory,

at relatively short intervals of time [≈ VIM, 3.6].

Note 1 to entry: The concept of "measurement procedure" is defined in VIM, 2.5.

[SOURCE: IEC 60050-311:2001, 311-06-06]

3.5

reproducibility

closeness of agreement between the results of measurements of the same value of a quantity,

when the individual measurements are made under different conditions of measurement:

– principle of measurement,

– method of measurement,

– observer,

– measuring instruments,

– reference standards,

– laboratory,

– under conditions of use of the instruments, different from those customarily used,

after intervals of time relatively long compared with the duration of a single measurement [≈

VIM 3.7].

Note 1 to entry: The concepts of "principle of measurement" and "method of measurement" are respectively defined

in VIM 2.3 and 2.4.

Note 2 to entry: The term "reproducibility" also applies to the instance where only certain of the above conditions

are taken into account, provided that these are stated.

[SOURCE: IEC 60050-311:2001, 311-06-07]

3.5

Gate No. 1

a pass / fail comparison between the performance of a module and its nameplate specifications,

as described in IEC 61215-1:2021

– 14 – IEC 61215-2:2021 RLV © IEC 2021

3.6

Gate No. 2

a pass / fail comparison between the performance of a module before versus after stress, as

described in IEC 61215-1:2021

4 Test procedures

The subclauses below provide detailed instructions for performing each module quality test

(MQT). Reporting and test sequence requirements for qualification are described in

IEC 61215-1.

4.1 Visual inspection (MQT 01)

4.1.1 Purpose

To detect any visual defects in the module.

4.1.2 Procedure

Carefully inspect each module under an illumination of not less than 1 000 lux for conditions

and observations as defined in IEC 61215-1:2021.

Make note of and/or photograph any defects that may be major visual defects as defined in

IEC 61215-1. Also make note of and/or photograph the nature and position of any cracks,

bubbles or delaminations, etc., which may worsen and adversely affect the module performance

in subsequent tests. Record any other relevant information regarding origin of failure and

associated test or lab conditions.

4.1.3 Requirements

No evidence of major visual defects permitted, as defined in IEC 61215-1:2021.

4.2 Maximum power determination (MQT 02)

4.2.1 Purpose

To determine the maximum power of the module after stabilization as well as before and after

the various environmental stress tests. For determining the power loss from the stress tests,

reproducibility of the test is a very important factor.

4.2.2 Apparatus

a) A radiant source (natural sunlight or a solar simulator class BBA or better in accordance

with IEC 60904-9).

b) A PV reference device in accordance with IEC 60904-2. If a class BBA simulator or better

is used, the reference device shall be a reference module of the same size with the same

cell technology to match spectral responsivity. If such a matched reference device is not

available one of the following two options need to be followed:

1) a Class AAA simulator shall be utilized, or

2) the spectral responsivity of the module according to IEC 60904-8 and the spectral

distribution of the solar simulator need to be measured and the module data corrected

according to IEC 60904-7.

c) A suitable mount for supporting the test specimen and the reference device in a plane

normal to the radiant beam.

d) Apparatus for measuring an I-V curve in accordance with IEC 60904-1.

a) Apparatus for measuring I-V characteristics in accordance with IEC 60904-1.

b) A PV reference device in accordance with IEC 60904-2.

c) At least one of the following two options to reduce the spectral mismatch component of

uncertainty shall be utilized:

• Perform a spectral mismatch correction. The spectral responsivity of the module shall

be measured according to IEC 60904-8. The spectral response data may originate from

the same lab that is performing IEC 61215-2:2021, or from a different lab. The sample

used to obtain the spectral response data may be the test module or may be a reference

cell made with the same bill of materials as the test module. The spectral distribution of

the solar simulator shall then be utilized to correct for spectral mismatch according to

IEC 60904-7.

• Use a matched reference cell or module. The reference device shall be of the same

cell technology as the test module, to match spectral responsivity. There is no

requirement on the cell or module size.

d) A radiant source: natural sunlight or a solar simulator of class CAA or better in accordance

with IEC 60904-9. For very large modules, as defined in IEC 61215-1:2021, a class CBA

simulator may be used.

NOTE 1 Class CBA is defined according to IEC 60904-9: The AM1.5 spectral match is categorized as C, non-

uniformity of irradiance for the module size categorized as B, and temporal stability of irradiance categorized

as A.

To achieve a high accuracy of power measurement, the spectral irradiance distribution of

the solar simulator should cover the whole wavelength range that is spanned by the spectral

responsivity of the PV device under test. See IEC TR 60904-14 and IEC 60904-9:2020.

e) A suitable mount for supporting the test specimen and the reference device in a plane

normal to the radiant beam.

NOTE 2 MQT 02 measurement procedures are intended for minimal uncertainty, for example as performed by an

accredited testing laboratory. Lesser requirements, such as use of CAB class simulators, may be appropriate for

other applications, such as quality control in the factory. Applications that only require repeatability, such as

comparing module performance before and after an extended stress, may wish to relax spectral mismatch correction

requirements.

4.2.3 Procedure

Determ

...

IEC 61215-2 ®

Edition 2.0 2021-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Terrestrial photovoltaic (PV) modules – Design qualification and type approval –

Part 2: Test procedures

Modules photovoltaïques (PV) pour applications terrestres – Qualification de la

conception et homologation –

Partie 2: Procédures d'essai

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61215-2 ®

Edition 2.0 2021-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Terrestrial photovoltaic (PV) modules – Design qualification and type approval –

Part 2: Test procedures

Modules photovoltaïques (PV) pour applications terrestres – Qualification de la

conception et homologation –

Partie 2: Procédures d'essai

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.160 ISBN 978-2-8322-9394-2

– 2 – IEC 61215-2:2021 © IEC 2021

CONTENTS

FOREWORD . 6

INTRODUCTION . 8

1 Scope . 9

2 Normative references . 9

3 Terms and definitions . 11

4 Test procedures . 12

4.1 Visual inspection (MQT 01) . 12

4.1.1 Purpose . 12

4.1.2 Procedure . 12

4.1.3 Requirements . 12

4.2 Maximum power determination (MQT 02) . 12

4.2.1 Purpose . 12

4.2.2 Apparatus . 12

4.2.3 Procedure . 13

4.3 Insulation test (MQT 03) . 13

4.3.1 Purpose . 13

4.3.2 Apparatus . 14

4.3.3 Test conditions . 14

4.3.4 Procedure . 14

4.3.5 Test requirements . 15

4.4 Measurement of temperature coefficients (MQT 04) . 15

4.5 Placeholder section, formerly NMOT . 15

4.6 Performance at STC (MQT 06.1) . 15

4.6.1 Purpose . 15

4.6.2 Apparatus . 15

4.6.3 Procedure for measuring at STC (MQT 06.1) . 16

4.7 Performance at low irradiance (MQT 07) . 16

4.7.1 Purpose . 16

4.7.2 Apparatus . 16

4.7.3 Procedure . 17

4.8 Outdoor exposure test (MQT 08) . 17

4.8.1 Purpose . 17

4.8.2 Apparatus . 17

4.8.3 Procedure . 17

4.8.4 Final measurements . 18

4.8.5 Requirements . 18

4.9 Hot-spot endurance test (MQT 09) . 18

4.9.1 Purpose . 18

4.9.2 Hot-spot effect . 18

4.9.3 Classification of cell interconnection . 19

4.9.4 Apparatus . 20

4.9.5 Procedure . 21

4.9.6 Final measurements . 28

4.9.7 Requirements . 28

4.10 UV preconditioning test (MQT 10) . 28

4.10.1 Purpose . 28

4.10.2 Apparatus . 28

4.10.3 Procedure . 29

4.10.4 Final measurements . 29

4.10.5 Requirements . 29

4.11 Thermal cycling test (MQT 11) . 29

4.11.1 Purpose . 29

4.11.2 Apparatus . 29

4.11.3 Procedure . 30

4.11.4 Final measurements . 31

4.11.5 Requirements . 31

4.12 Humidity-freeze test (MQT 12) . 32

4.12.1 Purpose . 32

4.12.2 Apparatus . 32

4.12.3 Procedure . 32

4.12.4 Final measurements . 32

4.12.5 Requirements . 32

4.13 Damp heat test (MQT 13) . 33

4.13.1 Purpose . 33

4.13.2 Apparatus . 33

4.13.3 Procedure . 33

4.13.4 Final measurements . 34

4.13.5 Requirements . 34

4.14 Robustness of terminations (MQT 14) . 34

4.14.1 Purpose . 34

4.14.2 Retention of junction box on mounting surface (MQT 14.1) . 34

4.14.3 Test of cord anchorage (MQT 14.2) . 34

4.15 Wet leakage current test (MQT 15) . 35

4.15.1 Purpose . 35

4.15.2 Apparatus . 35

4.15.3 Procedure . 35

4.15.4 Requirements . 35

4.16 Static mechanical load test (MQT 16) . 36

4.16.1 Purpose . 36

4.16.2 Apparatus . 36

4.16.3 Procedure . 37

4.16.4 Final measurements . 37

4.16.5 Requirements . 37

4.17 Hail test (MQT 17) . 37

4.17.1 Purpose . 37

4.17.2 Apparatus . 37

4.17.3 Procedure . 38

4.17.4 Final measurements . 39

4.17.5 Requirements . 39

4.18 Bypass diode testing (MQT 18) . 40

4.18.1 Bypass diode thermal test (MQT 18.1) . 40

4.18.2 Bypass diode functionality test (MQT 18.2) . 43

4.19 Stabilization (MQT 19) . 44

4.19.1 General . 44

4.19.2 Criterion definition for stabilization . 44

– 4 – IEC 61215-2:2021 © IEC 2021

4.19.3 Light induced stabilization procedures . 45

4.19.4 Other stabilization procedures . 46

4.19.5 Initial stabilization (MQT 19.1) . 46

4.19.6 Final stabilization (MQT 19.2) . 46

4.19.7 Stress-specific stabilization – BO LID (MQT 19.3). 47

4.20 Cyclic (dynamic) mechanical load test (MQT 20) . 47

4.20.1 Purpose . 47

4.20.2 Procedure . 47

4.20.3 Final measurements . 47

4.20.4 Requirements . 48

4.21 Potential induced degradation test (MQT 21) . 48

4.21.1 Purpose . 48

4.21.2 Samples . 48

4.21.3 Apparatus . 48

4.21.4 Procedure . 48

4.21.5 Final measurements . 48

4.21.6 Requirements . 49

4.22 Bending test (MQT 22) . 49

4.22.1 Purpose . 49

4.22.2 Apparatus . 49

4.22.3 Procedure . 49

4.22.4 Final measurements . 49

4.22.5 Requirements . 49

Annex A (informative) Recommended setup for managing weights during mechanical

loading (MQT 16) . 50

Bibliography . 54

Figure 1 – Case S, series connection with optional bypass diode . 19

Figure 2 – Case PS, parallel-series connection with optional bypass diode . 19

Figure 3 – Case SP, series-parallel connection with optional bypass diode . 20

Figure 4 – Module I-V characteristics with different cells totally shadowed . 21

Figure 5 – Module I-V characteristics with the test cell shadowed at different levels . 23

Figure 6 – Hot-spot effect in a MLI thin-film module with serially connected cells . 24

Figure 7 – Thermal cycling test – Temperature and applied current profile . 30

Figure 8 – Proper attachment of 5 N weight to junction box for module utilizing a)

electrical termination leads, b) or wire for attachment, and c) only one junction box . 31

Figure 9 – Humidity-freeze cycle – Temperature and humidity profile . 33

Figure 10 – Hail-test equipment . 38

Figure 11 – Hail test impact locations: top for wafer/cell based technologies, bottom for

monolithic processed thin film technologies . 40

Figure 12 – Bypass diode thermal test . 42

Figure A.1 – 3D view (at left of figure), end view (at top right), and side view (at bottom

right) of gantry crane over mounting jig and loading jig . 50

Figure A.2 – 3D close up views of mounting jig (right) and loading jig (left) . 51

Figure A.3 – 2D view of mounting jig and loading jig . 52

Figure A.4 – 3D view of loading jig . 52

Figure A.5 – Close-up view of loading jig . 53

Table 1 – Voltage stress levels . 14

Table 2 – Ice-ball masses and test velocities . 38

Table 3 – Impact locations . 39

– 6 – IEC 61215-2:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TERRESTRIAL PHOTOVOLTAIC (PV) MODULES –

DESIGN QUALIFICATION AND TYPE APPROVAL –

Part 2: Test procedures

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61215-2 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

This second edition of IEC 61215-2 cancels and replaces the first edition of IEC 61215-2 issued

in 2016; it constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Addition of cyclic (dynamic) mechanical load testing (MQT 20).

b) Addition of a test for detection of potential-induced degradation (MQT 21).

c) Addition of test methods required for bifacial PV modules.

d) Addition of test methods required for flexible modules. This includes the addition of the

bending test (MQT 22).

e) Revision of simulator requirements to ensure uncertainty is both well-defined and minimized.

f) Correction to the hot spot endurance test, where the procedure for monolithically integrated

(MLI) thin film technologies (MQT 09.2) previously included two sections describing a

procedure only appropriate for silicon modules.

g) Selection of three diodes, rather than all, for testing in the bypass diode thermal test

(MQT 18).

h) Removal of the nominal module operating test (NMOT), and associated test of performance

at NMOT, from the IEC 61215 series.

Informative Annex A of IEC 61215-1:2021 explains the background and reasoning behind some

of the more substantial changes that were made in the IEC 61215 series in progressing from

edition 1 to edition 2.

The text of this standard is based on the following documents:

FDIS Report on voting

82/1829/FDIS 82/1853/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61215 series, published under the general title Terrestrial

photovoltaic (PV) modules – Design qualification and type approval, can be found on the IEC

website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates that it

ding of its

contains colours which are considered to be useful for the correct understan

contents. Users should therefore print this document using a colour printer.

– 8 – IEC 61215-2:2021 © IEC 2021

INTRODUCTION

Whereas Part 1 of this standards series describes requirements (both in general and specific

with respect to device technology), the sub-parts of Part 1 define technology variations and

Part 2 defines a set of test procedures necessary for design qualification and type approval.

The test procedures described in Part 2 are valid for all device technologies.

TERRESTRIAL PHOTOVOLTAIC (PV) MODULES –

DESIGN QUALIFICATION AND TYPE APPROVAL –

Part 2: Test procedures

1 Scope

This document lays down requirements for the design qualification of terrestrial photovoltaic

modules suitable for long-term operation in open-air climates. The useful service life of modules

so qualified will depend on their design, their environment and the conditions under which they

are operated. Test results are not construed as a quantitative prediction of module lifetime.

th

In climates where 98 percentile operating temperatures exceed 70 °C, users are

recommended to consider testing to higher temperature test conditions as described in

IEC TS 63126 . Users desiring qualification of PV products with lesser lifetime expectations are

recommended to consider testing designed for PV in consumer electronics, as described in

IEC TS 63163 (under development). Users wishing to gain confidence that the characteristics

tested in IEC 61215 appear consistently in a manufactured product may wish to utilize

IEC 62941 regarding quality systems in PV manufacturing.

This document is intended to apply to all terrestrial flat plate module materials such as

crystalline silicon module types as well as thin-film modules.

This document does not apply to modules used with concentrated sunlight although it may be

utilized for low concentrator modules (1 to 3 suns). For low concentration modules, all tests are

performed using the irradiance, current, voltage and power levels expected at the design

concentration.

The objective of this test sequence is to determine the electrical characteristics of the module

and to show, as far as possible within reasonable constraints of cost and time, that the module

is capable of withstanding prolonged exposure outdoors. Accelerated test conditions are

empirically based on those necessary to reproduce selected observed field failures and are

applied equally across module types. Acceleration factors may vary with product design and

thus not all degradation mechanisms may manifest. Further general information on accelerated

test methods including definitions of terms may be found in IEC 62506.

Some long-term degradation mechanisms can only reasonably be detected via component

testing, due to long times required to produce the failure and necessity of stress conditions that

are expensive to produce over large areas. Component tests that have reached a sufficient

level of maturity to set pass/fail criteria with high confidence are incorporated into the IEC 61215

series via addition to Table 1 in IEC 61215-1:2021. In contrast, the tests procedures described

in this series, in IEC 61215-2, are performed on modules.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

_________________

1 th

Information on 98 percentile operating temperature as a function of system location and mounting configuration

is included in IEC TS 63126.

– 10 – IEC 61215-2:2021 © IEC 2021

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60068-2-21, Environmental testing – Part 2-21: Tests – Test U: Robustness of terminations

and integral mounting devices

IEC 60068-2-78:2012, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60891, Photovoltaic devices – Procedures for temperature and irradiance corrections to

measured I-V characteristics

IEC 60904-1, Photovoltaic devices – Part 1: Measurements of photovoltaic current-voltage

characteristics

IEC 60904-1-1, Photovoltaic devices – Part 1-1: Measurement of current-voltage characteristics

of multi-junction photovoltaic (PV) devices

IEC TS 60904-1-2, Photovoltaic devices – Part 1-2: Measurement of current-voltage

characteristics of bifacial photovoltaic (PV) devices

IEC 60904-2, Photovoltaic devices – Part 2: Requirements for photovoltaic reference devices

IEC 60904-3, Photovoltaic devices – Part 3: Measurement principles for terrestrial photovoltaic

(PV) solar devices with reference spectral irradiance data

IEC 60904-7, Photovoltaic devices – Part 7: Computation of the spectral mismatch correction

for measurements of photovoltaic devices

IEC 60904-8, Photovoltaic devices – Part 8: Measurement of spectral responsivity of a

photovoltaic (PV) device

IEC 60904-9:2020, Photovoltaic devices – Part 9: Classification of solar simulator

characteristics

IEC 60904-10, Photovoltaic devices – Part 10: Methods of linearity measurement

IEC TR 60904-14: Photovoltaic devices – Part 14: Guidelines for production line measurements

of single-junction PV module maximum power output and reporting at standard test conditions

IEC 61140, Protection against electric shock – Common aspects for installation and equipment

IEC 61215-1:2021, Terrestrial photovoltaic (PV) modules – Design qualification and type

approval – Part 1: Test requirements

IEC 61215-1-1, Terrestrial photovoltaic (PV) modules – Design qualification and type approval

– Part 1-1: Special requirements for testing of crystalline silicon photovoltaic (PV) modules

IEC 61730-1:2016, Photovoltaic (PV) module safety qualification – Part 1: Requirements for

construction

IEC 61730-2, Photovoltaic (PV) module safety qualification – Part 2: Requirements for testing

IEC TS 61836, Solar photovoltaic energy systems – Terms, definitions and symbols

IEC TS 62782, Photovoltaic (PV) modules – Cyclic (dynamic) mechanical load testing

IEC 62790, Junction boxes for photovoltaic modules – Safety requirements and tests

IEC TS 62804-1:2015, Photovoltaic (PV) modules – Test methods for the detection of potential-

induced degradation – Part 1: Crystalline silicon

IEC TS 63163: – Terrestrial photovoltaic (PV) modules for consumer products – Design

qualification and type approval

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC TS 61836 and

IEC 61215-1:2021 apply, as well as the following.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

accuracy

quality which characterizes the ability of a measuring instrument to provide an indicated value

close to a true value of the measurand [consistent with the International Vocabulary of

Metrology (VIM), 5.18]

Note 1 to entry: This term is used in the "true value" approach.

Note 2 to entry: Accuracy is all the better when the indicated value is closer to the corresponding true value.

[SOURCE: IEC 60050-311:2001, 311-06-08]

3.2

control device

irradiance sensor (such as a reference cell or module) that is used to detect drifts and other

problems of the solar simulator

3.3

electrically stable power output level

state of the PV module where it will operate under long-term natural sunlight

3.4

repeatability

closeness of agreement between the results of successive measurements of the same

measurand, carried out under the same conditions of measurement, i.e.:

– by the same measurement procedure,

– by the same observer,

– with the same measuring instruments,

– used under the same conditions,

– in the same laboratory,

at relatively short intervals of time [≈ VIM, 3.6].

_________________

Under preparation. Stage at the time of publication: ADTS.

– 12 – IEC 61215-2:2021 © IEC 2021

Note 1 to entry: The concept of "measurement procedure" is defined in VIM, 2.5.

[SOURCE: IEC 60050-311:2001, 311-06-06]

3.5

Gate No. 1

a pass / fail comparison between the performance of a module and its nameplate specifications,

as described in IEC 61215-1:2021

3.6

Gate No. 2

a pass / fail comparison between the performance of a module before versus after stress, as

described in IEC 61215-1:2021

4 Test procedures

The subclauses below provide detailed instructions for performing each module quality test

(MQT). Reporting and test sequence requirements for qualification are described in

IEC 61215-1.

4.1 Visual inspection (MQT 01)

4.1.1 Purpose

To detect any visual defects in the module.

4.1.2 Procedure

Carefully inspect each module under an illumination of not less than 1 000 lux for conditions

and observations as defined in IEC 61215-1:2021.

Make note of and/or photograph any defects that may be major visual defects as defined in

IEC 61215-1. Also make note of and/or photograph the nature and position of any cracks,

bubbles or delaminations, etc., which may worsen and adversely affect the module performance

in subsequent tests. Record any other relevant information regarding origin of failure and

associated test or lab conditions.

4.1.3 Requirements

No evidence of major visual defects permitted, as defined in IEC 61215-1:2021.

4.2 Maximum power determination (MQT 02)

4.2.1 Purpose

To determine the maximum power of the module after stabilization as well as before and after

the various environmental stress tests.

4.2.2 Apparatus

a) Apparatus for measuring I-V characteristics in accordance with IEC 60904-1.

b) A PV reference device in accordance with IEC 60904-2.

c) At least one of the following two options to reduce the spectral mismatch component of

uncertainty shall be utilized:

• Perform a spectral mismatch correction. The spectral responsivity of the module shall

be measured according to IEC 60904-8. The spectral response data may originate from

the same lab that is performing IEC 61215-2:2021, or from a different lab. The sample

used to obtain the spectral response data may be the test module or may be a reference

cell made with the same bill of materials as the test module. The spectral distribution of

the solar simulator shall then be utilized to correct for spectral mismatch according to

IEC 60904-7.

• Use a matched reference cell or module. The reference device shall be of the same

cell technology as the test module, to match spectral responsivity. There is no

requirement on the cell or module size.

d) A radiant source: natural sunlight or a solar simulator of class CAA or better in accordance

with IEC 60904-9. For very large modules, as defined in IEC 61215-1:2021, a class CBA

simulator may be used.

NOTE 1 Class CBA is defined according to IEC 60904-9: The AM1.5 spectral match is categorized as C, non-

uniformity of irradiance for the module size categorized as B, and temporal stability of irradiance categorized

as A.

To achieve a high accuracy of power measurement, the spectral irradiance distribution of

the solar simulator should cover the whole wavelength range that is spanned by the spectral

responsivity of the PV device under test. See IEC TR 60904-14 and IEC 60904-9:2020.

e) A suitable mount for supporting the test specimen and the reference device in a plane

normal to the radiant beam.

NOTE 2 MQT 02 measurement procedures are intended for minimal uncertainty, for example as performed by an

accredited testing laboratory. Lesser requirements, such as use of CAB class simulators, may be appropriate for

other applications, such as quality control in the factory. Applications that only require repeatability, such as

comparing module performance before and after an extended stress, may wish to relax spectral mismatch correction

requirements.

4.2.3 Procedure

Determine the current-voltage characteristic of the module in accordance with IEC 60904-1 at

a specific set of irradiance and temperature conditions (a recommended range is a cell

2 2

temperature between 20 °C and 50 °C and an irradiance between 700 W/m and 1 100 W/m )

using the apparatus described in 4.2.2. In special circumstances when modules are designed

for operation under a different range of conditions, the current-voltage characteristics can be

measured using temperature and irradiance levels similar to the expected operating conditions.

For linear modules (as defined in IEC 60904-10) temperature and irradiance corrections can be

made in accordance with IEC 60891 in order to compare sets of measurements made on the

same module before and after environmental tests. For nonlinear modules (as defined in

IEC 60904-10) the measurement shall be performed within ±5 % of the specified irradiance and

within ±2 °C of the specified temperature. However, every effort should be made to ensure that

peak power measurements are made under similar operating conditions, that is minimize the

magnitude of the correction by making all peak power measurements on a particular module at

approximately the same temperature and irradiance.

For flexible modules, the maximum power determination shall be measured with the flexible

module in the flat position.

4.3 Insulation test (MQT 03)

4.3.1 Purpose

To determine whether or not the module is sufficiently well insulated between live parts and

accessible parts.

– 14 – IEC 61215-2:2021 © IEC 2021

4.3.2 Apparatus

a) DC voltage source, with current limitation, capable of applying the voltage as specified in

the third column of Table 1 for the various module classes.

b) An instrument to measure the insulation resistance.

4.3.3 Test conditions

The test shall be made on modules at ambient temperature of the surrounding atmosphere (see

IEC 60068-1) and in a relative humidity not exceeding 75 %.

The voltage stress levels applied to the module are determined by the module’s maximum