IEC 61386-25:2011

(Main)Conduit systems for cable management - Part 25: Particular requirements - Conduit fixing devices

Conduit systems for cable management - Part 25: Particular requirements - Conduit fixing devices

IEC 61386-25:2011 specifies requirements and tests for conduit fixing devices used for support and/or retention of conduit for cable management.

This publication is to be read in conjunction with IEC 61386-1:2008.

Systèmes de conduits pour la gestion du câblage - Partie 25: Exigences particulières - Dispositifs de fixation de conduit

La CEI 61386-25:2011 spécifie les exigences et les essais applicables aux dispositifs de fixation de conduit utilisés pour supporter et/ou maintenir les conduits pour la gestion du câblage.

Cette publication doit être lue conjointement avec la CEI 61386-1:2008.

General Information

- Status

- Published

- Publication Date

- 21-Sep-2011

- Technical Committee

- SC 23A - Cable management systems

- Drafting Committee

- MT 13 - TC 23/SC 23A/MT 13

- Current Stage

- PPUB - Publication issued

- Start Date

- 22-Sep-2011

- Completion Date

- 15-Oct-2011

Overview

IEC 61386-25:2011 is an international standard published by the International Electrotechnical Commission (IEC) that defines the particular requirements for conduit fixing devices used in conduit systems for cable management. It specifies the performance criteria, testing methods, construction, and marking requirements for components that support and retain conduits, ensuring secure and safe cable installations.

This standard is part of the IEC 61386 series, which addresses conduit systems for cable management, and it supplements the general requirements established in IEC 61386-1:2008. IEC 61386-25 focuses exclusively on conduit fixing devices, critical for maintaining conduit positioning and stability throughout transport, installation, and operation.

Key Topics

Scope and Definitions

- Conduit fixing devices are defined as devices designed to provide retention of conduits at intervals along their length.

- The standard covers metallic, non-metallic, and composite conduit fixing devices.

- It addresses performance to withstand mechanical stresses and environmental factors.

General Requirements

- Devices must be designed for reliable performance under normal use.

- They shall endure stresses from transport, storage, installation, and actual application.

- Testing includes mechanical stress, temperature resistance, and environmental factors.

Classification

- Devices are classified based on their resistance to lateral load (light, medium, heavy) and axial load (none declared or as declared).

- The standard defines an upper temperature range from 40°C up to 400°C depending on the device application.

Marking and Documentation

- Each device must be marked with the manufacturer’s identification and product identification.

- Documentation should specify compatibility within conduit systems and include classification information for safe use.

- Marking can be directly on the product or its packaging if impractical on the product itself.

Construction and Dimensions

- The design should prevent sharp edges, burrs, or projections to avoid damage or injury.

- Fixings must withstand installation and operational stresses without harming the conduit.

- Devices must accommodate the range of conduit diameters declared by the manufacturer.

Testing Procedures

- Devices are subject to type tests covering mechanical strength, thermal properties, fire hazards, and electromagnetic compatibility.

- Conduit fixing devices that vary only by color are treated as the same product type for testing efficiency.

- Testing includes lateral and axial load resistance using standardized test setups.

- Non-metallic and composite devices undergo conditioning before testing to simulate real-world conditions.

Applications

IEC 61386-25:2011 is essential for manufacturers, installers, and engineers involved in the design, production, and use of conduit fixing devices for cable management systems across various industries. Applications include:

- Electrical installations in residential, commercial, and industrial buildings.

- Telecommunication infrastructure, where reliable conduit retention ensures cable integrity.

- Data centers and IT facilities, supporting intricate cabling networks.

- Manufacturing plants requiring robust conduit solutions under harsh conditions.

- Transportation sectors such as railways and automotive, where conduit stability is critical.

Implementing this standard ensures safety, durability, and compliance with international norms, facilitating global interoperability and quality assurance.

Related Standards

- IEC 61386-1:2008 – General requirements for conduit systems for cable management, providing foundational rules applicable across parts of IEC 61386.

- ISO 4287 – Specifies surface texture parameters, relevant for understanding surface conditions impacting conduit fixing devices.

- Additional parts of the IEC 61386 series, each focusing on different components or aspects of conduit systems, complement IEC 61386-25 for comprehensive conduit management solutions.

By adhering to IEC 61386-25:2011, stakeholders ensure the mechanical reliability and safety of conduit fixing devices critical to effective cable management, enhancing the longevity and performance of electrical infrastructure worldwide.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61386-25:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Conduit systems for cable management - Part 25: Particular requirements - Conduit fixing devices". This standard covers: IEC 61386-25:2011 specifies requirements and tests for conduit fixing devices used for support and/or retention of conduit for cable management. This publication is to be read in conjunction with IEC 61386-1:2008.

IEC 61386-25:2011 specifies requirements and tests for conduit fixing devices used for support and/or retention of conduit for cable management. This publication is to be read in conjunction with IEC 61386-1:2008.

IEC 61386-25:2011 is classified under the following ICS (International Classification for Standards) categories: 29.120.10 - Conduits for electrical purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61386-25:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61386-25 ®

Edition 1.0 2011-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Conduit systems for cable management –

Part 25: Particular requirements – Conduit fixing devices

Systèmes de conduits pour la gestion du câblage –

Partie 25: Exigences particulières – Dispositifs de fixation de conduit

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61386-25 ®

Edition 1.0 2011-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Conduit systems for cable management –

Part 25: Particular requirements – Conduit fixing devices

Systèmes de conduits pour la gestion du câblage –

Partie 25: Exigences particulières – Dispositifs de fixation de conduit

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX Q

ICS 29.120.10 ISBN 978-2-88912-696-5

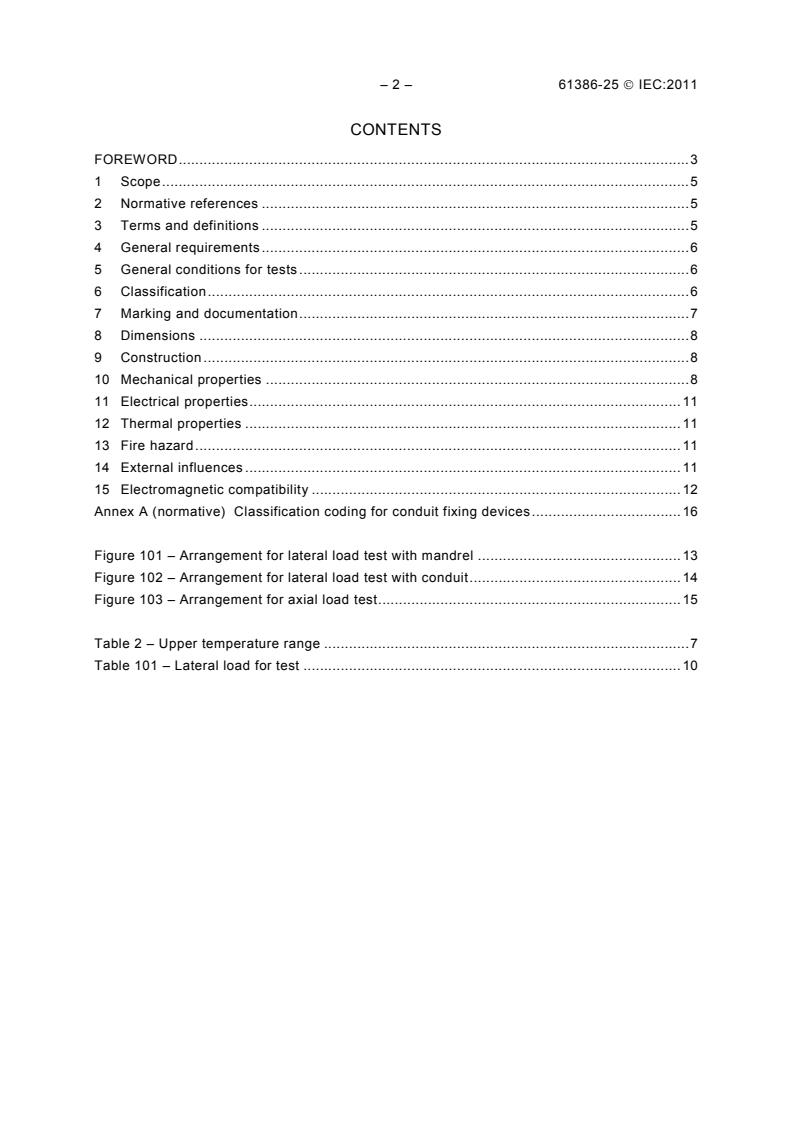

– 2 – 61386-25 IEC:2011

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 General requirements . 6

5 General conditions for tests . 6

6 Classification . 6

7 Marking and documentation . 7

8 Dimensions . 8

9 Construction . 8

10 Mechanical properties . 8

11 Electrical properties . 11

12 Thermal properties . 11

13 Fire hazard . 11

14 External influences . 11

15 Electromagnetic compatibility . 12

Annex A (normative) Classification coding for conduit fixing devices . 16

Figure 101 – Arrangement for lateral load test with mandrel . 13

Figure 102 – Arrangement for lateral load test with conduit . 14

Figure 103 – Arrangement for axial load test . 15

Table 2 – Upper temperature range . 7

Table 101 – Lateral load for test . 10

61386-25 IEC:2011 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CONDUIT SYSTEMS FOR CABLE MANAGEMENT –

Part 25: Particular requirements –

Conduit fixing devices

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61386-25 has been prepared by subcommittee 23A: Cable

management systems, of IEC technical committee 23: Electrical accessories.

The text of this standard is based on the following documents:

FDIS Report on voting

23A/635/FDIS 23A/637/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This standard is to be read in conjunction with IEC 61386-1:2008, Conduit systems for cable

management – Part 1: General requirements.

– 4 – 61386-25 IEC:2011

The clauses of the particular requirements of this Part 25 add to or modify the corresponding

clauses in Part 1. Where the text of Part 25 indicates an "addition" to or a "deletion” or a

“replacement" of the relevant requirement, test specification or explanation of Part 1, these

changes are made to the relevant text of Part 1, which then becomes part of the standard.

Where no change is necessary, the words "This clause of Part 1 is applicable" are used in

Part 25. Subclauses or figures that are additional to those in Part 1 are numbered starting

from 101.

NOTE The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– notes: in small roman type.

A list of all the parts in the IEC 61386 series, under the general title Conduit systems for cable

management, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

61386-25 IEC:2011 – 5 –

CONDUIT SYSTEMS FOR CABLE MANAGEMENT –

Part 25: Particular requirements –

Conduit fixing devices

1 Scope

This clause of Part 1 is applicable except as follows:

Replacement in the first paragraph of the words “conduit fittings” by “conduit fittings and

conduit fixing devices”.

Addition at the end of the clause:

This part of IEC 61386 specifies requirements and tests for conduit fixing devices used for

support and/or retention of conduit for cable management.

2 Normative references

This clause of Part 1 is applicable with the following exception:

Addition:

ISO 4287, Geometrical Product Specifications (GPS) – Surface texture: Profile method –

Terms, definitions and surface texture parameters

3 Terms and definitions

This clause of Part 1 is applicable, except as follows:

Addition:

3.101

conduit fixing device

device designed to provide retention of conduit(s) when installed at intervals along the length

of the conduit. A conduit fixing device is designed so that it can be securely fixed to a

mounting surface.

3.102

metallic conduit fixing device

fixing device consisting of metal only

3.103

non-metallic conduit fixing device

fixing device consisting of non-metallic material only

3.104

composite conduit fixing device

fixing device comprising both metal and non-metallic materials

– 6 – 61386-25 IEC:2011

3.105

retention

limitation of the lateral and/or axial movement of the conduit

4 General requirements

This clause of Part 1 is applicable except as follows:

Replacement:

4.1 Conduit fixing devices shall be so designed and constructed that in normal use their

performance is reliable.

4.2 Conduit fixing devices shall withstand the stresses likely to occur during transport,

storage, recommended installation practice and application.

4.3 Compliance is checked by carrying out all specified tests.

5 General conditions for tests

This clause of Part 1 is applicable, except as follows:

5.1 Replacement:

Tests in accordance with this standard are type tests. Conduit fixing devices, having the same

classification, which vary in colour only, are considered to be the same product type and only

one colour needs to be tested.

Conduit fixing devices are tested as part of a conduit system.

Where a conduit fixing device accommodates a range of conduit sizes, the conduit fixing

device shall be tested using the smallest and the largest conduit size.

5.4 Replacement:

Samples of non-metallic and composite conduit fixing devices shall be conditioned for at least

240 h, at a temperature of (23 ± 2) °C and a relative humidity between 40 % and 60 %. All

tests shall be carried out immediately after general conditioning.

5.5 Replacement:

Unless otherwise specified, the samples for each test shall be in a clean and new condition.

Due regard shall be taken of the manufacturer's instructions, especially where force is

required in the assembly of the joint.

5.6 and 5.9 Not applicable.

6 Classification

This clause of Part 1 is applicable except as follows:

6.1.1, 6.1.3, 6.1.4 and 6.1.5 Not applicable.

Addition:

61386-25 IEC:2011 – 7 –

6.1.101 Resistance to lateral load

1 Light

2 Medium

3 Heavy

6.1.102 Resistance to axial load

1 None declared

2 As declared by the manufacturer

6.2.2 Upper temperature range

Replacement of Table 2:

Table 2 – Upper temperature range

Application and installation –

Classification

Temperature not more than: °C

0 40

1 60

2 90

3 105

4 120

5 150

6 250

7 400

6.3, 6.4.1 and 6.4.2 Not applicable.

7 Marking and documentation

This clause of Part 1 is applicable except as follows:

Replacement:

7.1 Each conduit fixing device shall be marked with

– the manufacturer's or responsible vendor's name or trade mark or identification mark,

– a product identification mark, which may be, for example, a catalogue number, a

symbol or the like, in such a way that it can be identified in the manufacturer’s or

responsible vendor’s literature.

7.1.1 The manufacturer shall be responsible for indicating the compatibility of conduit fixing

devices within conduit systems according to the IEC 61386 series.

7.1.2 The manufacturer shall provide in his literature its classification in accordance with

Clause 6 and all information necessary for the proper and safe transport, storage, installation

and use.

– 8 – 61386-25 IEC:2011

7.2 Replacement:

The conduit fixing device shall be marked in accordance with 7.1, on the product wherever

possible, but where this is impractical, then the mark may be on a label attached to the

product, or on the smallest supplied package.

7.3 and 7.4 Not applicable.

8 Dimensions

This clause of Part 1 is replaced by the following text:

Conduit fixing devices shall be capable of accommodating the size or range of conduit

diameters as declared by the manufacturer or responsible vendor.

9 Construction

This clause of Part 1 is applicable except as follows:

Replacement:

9.1 Within the conduit fixing device there shall be no sharp edges, burrs or surface

projections which are likely to damage the conduit system, or inflict injury on the installer or

user.

Compliance is checked by inspection, if necessary after cutting the samples apart.

9.2 Fixing means shall be designed to withstand the mechanical stresses occurring during

installation and normal use.

Screws, if any, used for assembly of the conduit fixing device, shall not cause damage to the

conduit system components when correctly assembled.

Compliance for screw fixing using preformed threads is checked by the test in 9.3, followed by

inspection.

Compliance for screw fixing using thread-forming screws is checked by the test in 9.4,

followed by inspection.

Compliance for reusable fixings other than screws is checked by assembly and removal ten

times according to the manufacturer’s instruction.

Compliance for non-reusable fixings is checked by assembly to the manufacturer’s instruction.

9.5 and 9.6 Not applicable.

10 Mechanical properties

This clause of Part 1 is applicable except as follows:

Replacement:

10.1.1 Conduit fixing devices shall have adequate mechanical strength.

61386-25 IEC:2011 – 9 –

10.1.2 Compliance is checked by the tests specified in 10.3, 10.101 and 10.102.

10.2 Compression test Not applicable.

10.3.1 Replacement:

Twelve assemblies of a conduit fixing device and a steel mandrel or conduit are subjected to

the impact test by means of the apparatus shown in Figure 2.

Conduit fixing devices which can be used with any type of conduit, with outside diameters

according IEC 60423, shall be tested using a steel mandrel with an outside diameter

according to the minimum diameter of the relevant size.

( )

The manufacturing tolerance of the mandrel shall be mm up to and including 20 mm and

−0,02

( )

mm above nominal size 20 mm.

−0,03

Conduit fixing devices which can only be used with a specific conduit shall be tested using

that conduit.

The test assembly is fixed on a vertical surface as shown in Figure 101 or Figure 102 but with

only one fixing device.

Conduit fixing devices, whose maximum dimension is less than 20 mm, are not subjected to

this test.

10.3.2 Replacement of the last paragraph:

The test shall be made on the weakest part of the conduit fixing device.

10.3.3 Replacement:

After the test, the mandrel or conduit shall remain inside the conduit fixing device and there

shall be no sign of disintegration nor shall there be any crack visible to normal or corrected

vision without magnification.

At least nine of the twelve samples shall pass the test.

10.4 Bending test Not applicable.

10.5 Flexing test Not applicable.

10.6 Collapse test Not applicable.

10.7 Tensile test Not applicable.

10.8 Suspended load test Not applicable.

Addition:

10.101 Lateral load test

10.101.1 Two conduit fixing devices are mounted with a mandrel as shown in Figure 101 or

with an appropriate length of conduit as shown in Figure 102.

Conduit fixing devices which can be used with any type of conduit, with outside diameters

according to IEC 60423, shall be tested using a steel mandrel with an outside diameter

– 10 – 61386-25 IEC:2011

according to the minimum diameter of the relevant size, applying a load, including the weight

of the steel mandrel, according to the classification in 6.1.101, and Table 101.

The steel mandrel shall have a surface roughness of 7 µm Ra in accordance with ISO 4287. The

( )

manufacturing tolerance of the mandrel shall be mm up to and including 20 mm and

−0,02

( )

mm above nominal size 20 mm.

−0,03

Conduit fixing devices which can only be used with a specific conduit shall be tested using

that conduit and the manufacturer shall declare the performance of the combination of conduit

and fixing device. For the purpose of applying the load, a steel rod with an outside diameter of

30 % to 50 % of the inside diameter of the conduit is inserted through the conduit and a load

including the weight of the steel rod, according to the classification in 6.1.101, and Table

101, is applied across the two ends of the steel rod.

The test is carried out on 3 pairs of conduit fixing devices wall mounted and another 3 pairs of

conduit fixing devices ceiling mounted.

10.101.2 For metallic fixing devices, the test load, as declared by the manufacturer or

+10

responsible vendor, is applied, without shock, for a period of (300 ) s at ambient

temperature.

10.101.3 For non-metallic and composite fixing devices, the sample assembly is then placed

in a full draft air circulating oven. The tests are carried out after the oven temperature has

reached and maintained the declared maximum temperature according to Table 2 with a

+2 +5

tolerance of ( ) °C. The load is applied, without shock, and held for a period of (60 ) min.

−2 0

Table 101 – Lateral load for test

Conduit Light lateral load Medium lateral load Heavy lateral load

size up to (classification code 2) (classification code 3) (classification code 4)

mm kg kg kg

6 0,1 0,2 0,4

8 0,2 0,4 0,8

10 0,3 0,6 1,2

12 0,5 1 2

16 0,8 1,6 3,2

20 1 2 4

25 2 4 8

32 3,3 6,6 13,2

40 5,1 10,2 20,4

50 8,0 16 32

63 12,7 25,4 50,8

75 18 36 72

90 25,9 51,8 103,6

110 38,7 77,4 154,8

NOTE 1 Load tolerance up to but not including 1 kg: + 5 %

NOTE 2 Load tolerance 1 kg to 10 kg: + 2 %

NOTE 3 Load tolerance above 10 kg: + 1 %

61386-25 IEC:2011 – 11 –

10.101.4 After the test, the conduit shall still be supported by the conduit fixing devices. This

test is not intended to check the fixing into the mounting surface.

10.102 Axial load test

10.102.1 Conduit fixing devices declaring axial conduit retention according to 6.1.102 are

tested as follows:

Conduit fixing devices which can be used with any type of conduit, with outside diameters

according to IEC 60423, shall be tested using a steel mandrel of appropriate length with an

outside diameter according the minimum diameter of the relevant size.

The steel mandrel shall have a surface roughness of 7 µm Ra in accordance with ISO 4287. The

( )

manufacturing tolerance of the mandrel shall be mm up to and including 20 mm and

−0,02

( )

mm above nominal size 20 mm. The mandrel is assembled to a conduit fixing device,

−0,03

in accordance with the manufacturer’s instructions and Figure 103.

Conduit fixing devices which can only be used with a specific conduit shall be tested using

that conduit and the manufacturer shall declare the performance of the combination of conduit

and fixing device.

A sample of conduit with appropriate length is assembled to a conduit fixing device, in

accordance with the manufacturer’s instructions and Figure 103.

For metallic fixing devices, the test load, as declared by the manufacturer or responsible

vendor, is applied, without shock, for a period of (300 ± 10) s at ambient temperature.

For non-metallic and composite fixing devices, the sample assembly is then placed in a full

draft air circulating oven. The tests are carried out after the oven temperature has reached

and maintained the declared maximum temperature according to Table 2 with a tolerance of

+2

( ) °C. The load is applied, without shock. Then the axial load is maintained for (300 ± 10) s.

−2

10.102.2 After the test, the conduit shall remain properly assembled to the conduit fixing

device, the conduit shall not have displaced more than 2 mm through the conduit fixing device

and there shall be no damage visible to normal or corrected vision without magnification.

11 Electrical properties

This clause of Part 1 is not applicable.

12 Thermal properties

This clause of Part 1 is not applicable.

13 Fire hazard

This clause of Part 1 is applicable. If declared as non-flame propagating, conduit fixing

devices are tested as conduit fittings at a glow wire temperature of 650 °C.

14 External influences

This clause of Part 1 is applicable except as follows:

– 12 – 61386-25 IEC:2011

14.1.2 Degree of protection – Ingress of foreign solid objects

This subclause of Part 1 is not applicable.

14.1.3 Degree of protection – Ingress of water

This subclause of Part 1 is not applicable.

15 Electromagnetic compatibility

This clause of Part 1 is applicable.

Figures

Addition:

61386-25 IEC:2011 – 13 –

400 mm

300 mm

400 mm

300 mm 2

IEC 2084/11

Key

1 Vertical mounting surface

2 Conduit fixing device

3 Steel mandrel

4 Load (including weight of mandrel)

5 Horizontal mounting surface

Figure 101 – Arrangement for lateral load test with mandrel

– 14 – 61386-25 IEC:2011

450 mm

400 mm

300 mm

4 3

450 mm

400 mm

300 mm

IEC 2085/11

Key

1 Vertical mounting surface

2 Conduit fixing device

3 Conduit

4 Steel rod

5 Load (including weight of steel rod)

6 Horizontal mounting surface

Figure 102 – Arrangement for lateral load test with conduit

61386-25 IEC:2011 – 15 –

IEC 2086/11

Key

1 Vertical mounting surface

2 Conduit fixing device

3 Steel mandrel or conduit

4 Load (including weight of mandrel)

Figure 103 – Arrangement for axial load test

– 16 – 61386-25 IEC:2011

Annex A

(normative)

Classification coding for conduit fixing devices

Replacement:

NOTE Annex A shows the classification coding format for declared properties of the conduit fixing device, which

may be incorporated in the manufacturer's literature.

First digit – Resistance to lateral load

(see 6.1.101)

Light lateral load 2

Medium lateral load 3

Heavy lateral load 4

Second digit – Resistance to impact

(see 6.1.2)

Very light imp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...