IEC 60068-2-52:2017

(Main)Environmental testing - Part 2-52: Tests - Test Kb: Salt mist, cyclic (sodium chloride solution)

Environmental testing - Part 2-52: Tests - Test Kb: Salt mist, cyclic (sodium chloride solution)

IEC 60068-2-52:2017 specifies the application of the cyclic salt mist test to components or equipment designed to withstand a salt-laden atmosphere as salt can degrade the performance of parts manufactured using metallic and/or non-metallic materials. This third edition cancels and replaces the second edition published in 1996. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- the entire content has been harmonized with ISO 9227 as far as possible;

- an introduction has been added;

- the scope has been simplified;

- normative references have been updated;

- the general description of the test has been changed;

- a dry chamber has been added to the test apparatus;

- severities have been changed to test methods;

- test methods 7 and 8 have been added;

- information on the test report has been added;

- Figure 1 has been changed to Table 1;

- a typical test apparatus example has been added in a new Annex A;

- a description of each test method has been added in a new Annex B;

- bibliographical references have been added.

This bilingual version (2019-07) corresponds to the monolingual English version, published in 2017-11.

The French version of this standard has not been voted upon.

Essais d'environnement - Partie 2-52: Essais - Essai Kb: Brouillard salin, essai cyclique (solution de chlorure de sodium)

L'IEC 60068-2-52:2017 spécifie l'application de l'essai cyclique au brouillard salin aux composants ou équipements conçus pour résister à une atmosphère chargée en sel, car le sel peut détériorer le fonctionnement des parties fabriquées à partir de matériaux métalliques et/ou non métalliques.

Cette troisième édition annule et remplace la deuxième édition parue en 1996. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- le contenu a été harmonisé autant que possible avec l'ISO 9227;

- une introduction a été ajoutée;

- le domaine d'application a été simplifié;

- les références normatives ont été mises à jour;

- la description générale de l'essai a été modifiée;

- une chambre sèche a été ajoutée à l'appareillage d'essai;

- les sévérités ont été remplacées par les méthodes d'essai;

- les méthodes d'essai 7 et 8 ont été ajoutées;

- des informations sur le rapport d'essai ont été ajoutées;

- la Figure 1 a été remplacée par le Tableau 1;

- un exemple d'appareillage d'essai type a été ajouté à la nouvelle Annexe A;

- une description de chaque méthode d'essai a été ajoutée à la nouvelle Annexe B;

- des références bibliographiques ont été ajoutées.

La présente version bilingue (2019-07) correspond à la version anglaise monolingue publiée en 2017-11.

La version française de cette norme n'a pas été soumise au vote.

General Information

- Status

- Published

- Publication Date

- 06-Nov-2017

- Technical Committee

- TC 104 - Environmental conditions, classification and methods of test

- Drafting Committee

- MT 16 - TC 104/MT 16

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-Nov-2017

- Completion Date

- 08-Dec-2017

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60068-2-52:2017 - Environmental testing - Part 2-52: Tests - Test Kb: Salt mist, cyclic (sodium chloride solution) - is an international standard that specifies cyclic salt mist (salt spray) procedures to evaluate how components and equipment perform in salt-laden atmospheres. The third edition (2017) replaces the 1996 edition, has been harmonized with ISO 9227, and introduces significant updates such as a dry chamber, new test methods, and improved reporting requirements.

Key topics and technical requirements

This standard covers the full test program and apparatus requirements for cyclic corrosion testing with a sodium chloride solution. Major technical topics include:

- Test objectives: Assess corrosion and degradation on metallic and non‑metallic materials caused by salt-laden atmospheres.

- Cyclic test conditions: Defined sequences combining salt mist, humid, dry, and standard atmosphere phases to better simulate natural cyclic environments.

- Test apparatus: Requirements for salt mist chambers, humidity chambers, standard atmosphere chambers and the newly included dry chamber; Annex A provides a typical apparatus example.

- Salt solution preparation: Procedures for preparing, filtering and adjusting the pH of sodium chloride solutions (neutral or acidified).

- Test methods: Eight test methods are defined (test methods 1–8), reflecting different cyclic severities and exposure combinations; Annex B describes each method.

- Pre‑ and post‑test procedures: Initial measurements, preconditioning, removal, recovery and final measurements of test specimens.

- Documentation and reporting: Updated requirements for information to be included in the test report and in relevant product specifications.

- Harmonization and normative references: Content aligned with ISO 9227 and updated normative references.

Practical applications and users

IEC 60068-2-52 is used to evaluate durability and corrosion resistance in industries where salt exposure is a concern, including:

- Electronics and electrical equipment - connectors, enclosures, PCBs, and outdoor devices.

- Automotive and marine components - fasteners, coatings, sensors and structural parts.

- Telecommunications and infrastructure - base stations, cabinets and outdoor installations.

- Coating and materials manufacturers - verification of protective coatings, plating and material selection.

Typical users: test engineers, product designers, quality managers, materials scientists, and certification bodies who need standardized cyclic salt mist procedures for product validation, specification writing, and comparative testing.

Related standards

- ISO 9227 - Neutral salt spray (NSS) test (harmonized as far as possible with IEC 60068-2-52).

- Other parts of the IEC 60068 series on environmental testing (for broader environmental test planning and selection).

Keywords: IEC 60068-2-52, salt mist cyclic test, salt spray, cyclic corrosion testing, sodium chloride solution, environmental testing, corrosion testing, ISO 9227.

Buy Documents

IEC 60068-2-52:2017 - Environmental testing - Part 2-52: Tests - Test Kb: Salt mist, cyclic (sodium chloride solution) Released:11/7/2017 Isbn:9782832250044

IEC 60068-2-52:2017 RLV - Environmental testing - Part 2-52: Tests - Test Kb: Salt mist, cyclic (sodium chloride solution) Released:11/7/2017 Isbn:9782832250273

IEC 60068-2-52:2017 - Environmental testing - Part 2-52: Tests - Test Kb: Salt mist, cyclic (sodium chloride solution) Released:11/7/2017 Isbn:9782832272312

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 60068-2-52:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 2-52: Tests - Test Kb: Salt mist, cyclic (sodium chloride solution)". This standard covers: IEC 60068-2-52:2017 specifies the application of the cyclic salt mist test to components or equipment designed to withstand a salt-laden atmosphere as salt can degrade the performance of parts manufactured using metallic and/or non-metallic materials. This third edition cancels and replaces the second edition published in 1996. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - the entire content has been harmonized with ISO 9227 as far as possible; - an introduction has been added; - the scope has been simplified; - normative references have been updated; - the general description of the test has been changed; - a dry chamber has been added to the test apparatus; - severities have been changed to test methods; - test methods 7 and 8 have been added; - information on the test report has been added; - Figure 1 has been changed to Table 1; - a typical test apparatus example has been added in a new Annex A; - a description of each test method has been added in a new Annex B; - bibliographical references have been added. This bilingual version (2019-07) corresponds to the monolingual English version, published in 2017-11. The French version of this standard has not been voted upon.

IEC 60068-2-52:2017 specifies the application of the cyclic salt mist test to components or equipment designed to withstand a salt-laden atmosphere as salt can degrade the performance of parts manufactured using metallic and/or non-metallic materials. This third edition cancels and replaces the second edition published in 1996. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - the entire content has been harmonized with ISO 9227 as far as possible; - an introduction has been added; - the scope has been simplified; - normative references have been updated; - the general description of the test has been changed; - a dry chamber has been added to the test apparatus; - severities have been changed to test methods; - test methods 7 and 8 have been added; - information on the test report has been added; - Figure 1 has been changed to Table 1; - a typical test apparatus example has been added in a new Annex A; - a description of each test method has been added in a new Annex B; - bibliographical references have been added. This bilingual version (2019-07) corresponds to the monolingual English version, published in 2017-11. The French version of this standard has not been voted upon.

IEC 60068-2-52:2017 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60068-2-52:2017 has the following relationships with other standards: It is inter standard links to IEC 60068-2-52:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60068-2-52:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60068-2-52 ®

Edition 3.0 2017-11

INTERNATIONAL

STANDARD

Environmental testing –

Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium chloride solution)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 60068-2-52 ®

Edition 3.0 2017-11

INTERNATIONAL

STANDARD

Environmental testing –

Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium chloride solution)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.040 ISBN 978-2-8322-5004-4

– 2 – IEC 60068-2-52:2017 © IEC 2017

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 General description of the test . 7

4.1 Description of each test condition . 7

4.1.1 General . 7

4.1.2 Salt mist . 8

4.1.3 Dry condition . 8

4.1.4 Humid condition . 8

4.1.5 Standard atmosphere . 8

5 Test apparatus . 8

5.1 General . 8

5.2 Salt mist chamber . 8

5.3 Humidity chamber . 8

5.4 Standard atmosphere chamber . 9

5.5 Dry chamber . 9

6 Salt solution . 9

6.1 Preparation of the sodium chloride solution . 9

6.2 pH adjustment . 9

6.2.1 Neutral salt solution . 9

6.2.2 Acidified salt solution . 9

6.3 Filtration . 9

7 Initial measurements . 9

8 Preconditioning . 9

9 Testing . 9

9.1 Test chamber . 9

9.2 Arrangement of the test specimen(s) . 10

9.3 Conditions during salt mist . 10

9.4 Test methods . 10

9.4.1 General . 10

9.4.2 Test method 1 . 10

9.4.3 Test method 2 . 10

9.4.4 Test method 3 . 10

9.4.5 Test method 4 . 11

9.4.6 Test method 5 . 11

9.4.7 Test method 6 . 11

9.4.8 Test method 7 . 11

9.4.9 Test method 8 . 11

9.5 Test cycles for test methods 1 to 8 . 11

9.6 Removal of the test specimen(s) . 12

10 Recovery (at the end of testing) . 12

11 Final measurements . 13

12 Information to be given in the relevant specification . 13

13 Information to be given in the test report. 13

Annex A (informative) Typical apparatus for cyclic salt mist, humid condition, dry

condition and standard atmosphere corrosion tests . 14

Annex B (informative) Description of each test method . 15

B.1 Test methods 1 and 2 . 15

B.2 Test methods 3 to 6 . 15

B.3 Test methods 7 and 8 . 15

Bibliography . 16

Figure A.1 – Example of test apparatus . 14

Table 1 – Test cycles for test methods 1 to 8 . 12

– 4 – IEC 60068-2-52:2017 © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-52 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test.

This third edition cancels and replaces the second edition published in 1996. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) the entire content has been harmonized with ISO 9227 as far as possible;

b) an introduction has been added;

c) the scope has been simplified;

d) normative references have been updated;

e) the general description of the test has been changed;

f) a dry chamber has been added to the test apparatus;

g) severities have been changed to test methods;

h) test methods 7 and 8 have been added;

i) information on the test report has been added;

j) Figure 1 has been changed to Table 1;

k) a typical test apparatus example has been added in a new Annex A;

l) a description of each test method has been added in a new Annex B;

m) bibliographical references have been added.

The text of this International Standard is based on the following documents:

FDIS Report on voting

104/751/FDIS 104/761/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60068 series, published under the general title Environmental

testing, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC 60068-2-52:2017 © IEC 2017

INTRODUCTION

The mechanism of corrosion on metallic materials in a chloride-containing atmosphere is

electrochemical, whereas the degradation effects experienced on non-metallic materials are

caused by complex chemical reactions of the salts with the materials involved. The rate at

which corrosive action takes place is dependent, to a large extent, on the supply of

oxygenated salt solution to the surface of the test specimen(s), the temperature of the test

specimen(s) and the temperature and humidity of the environment.

Apart from the corrosive effects, this cyclic salt mist test may be used to indicate deterioration

of some non-metallic materials by assimilation of salts. In the various test methods described

in this document, the period of spraying with the relevant salt solution is sufficient to wet the

test specimen(s) thoroughly. Because this wetting is repeated after intervals of storage under

humid conditions supplemented by storage under a standard atmosphere, it goes some way

to reproducing the effects of natural environments.

Furthermore, considering natural environments for corrosion on metallic materials, neutral or

acidified salt solution spray, humid, and dry conditions are also important factors as a cyclic

corrosion test. Each condition is repeated after intervals of other conditions in different

combinations to achieve corrosion on metallic materials and to get acceleration of corrosion.

The tests described in this document are accelerated compared with most expected

conditions of use. As a result, it may be difficult to establish an overall acceleration factor for

all kinds of test specimens. This also means that it is often not possible to use results gained

from these tests as a comparative guide to the long-term behaviour of different coating

systems since the corrosion stress during these tests differs significantly from the corrosion

stresses encountered during use. Nevertheless, the method described gives a means of

checking that the comparative quality of a metallic material is maintained.

This document may involve hazardous materials, operations and equipment. This document

does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this document to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior to use.

ENVIRONMENTAL TESTING –

Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

1 Scope

This part of IEC 60068-2 specifies the application of the cyclic salt mist test to components or

equipment designed to withstand a salt-laden atmosphere as salt can degrade the

performance of parts manufactured using metallic and/or non-metallic materials.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

ISO 9227, Corrosion tests in artificial atmospheres – Salt spray tests

3 Terms and definit

...

IEC 60068-2-52 ®

Edition 3.0 2017-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Environmental testing –

Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium chloride solution)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60068-2-52 ®

Edition 3.0 2017-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Environmental testing –

Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium chloride solution)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.040 ISBN 978-2-8322-5027-3

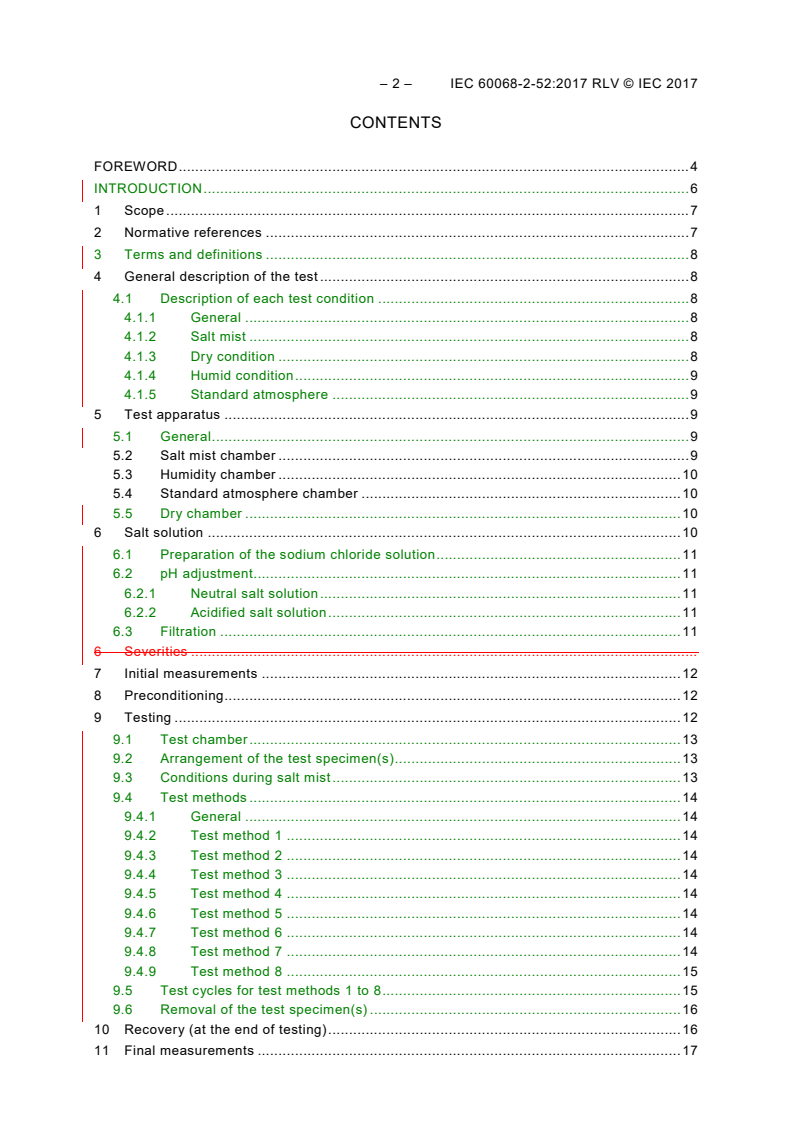

– 2 – IEC 60068-2-52:2017 RLV © IEC 2017

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 General description of the test . 8

4.1 Description of each test condition . 8

4.1.1 General . 8

4.1.2 Salt mist . 8

4.1.3 Dry condition . 8

4.1.4 Humid condition . 9

4.1.5 Standard atmosphere . 9

5 Test apparatus . 9

5.1 General . 9

5.2 Salt mist chamber . 9

5.3 Humidity chamber . 10

5.4 Standard atmosphere chamber . 10

5.5 Dry chamber . 10

6 Salt solution . 10

6.1 Preparation of the sodium chloride solution . 11

6.2 pH adjustment . 11

6.2.1 Neutral salt solution . 11

6.2.2 Acidified salt solution . 11

6.3 Filtration . 11

6 Severities .

7 Initial measurements . 12

8 Preconditioning . 12

9 Testing . 12

9.1 Test chamber . 13

9.2 Arrangement of the test specimen(s) . 13

9.3 Conditions during salt mist . 13

9.4 Test methods . 14

9.4.1 General . 14

9.4.2 Test method 1 . 14

9.4.3 Test method 2 . 14

9.4.4 Test method 3 . 14

9.4.5 Test method 4 . 14

9.4.6 Test method 5 . 14

9.4.7 Test method 6 . 14

9.4.8 Test method 7 . 14

9.4.9 Test method 8 . 15

9.5 Test cycles for test methods 1 to 8 . 15

9.6 Removal of the test specimen(s) . 16

10 Recovery (at the end of testing) . 16

11 Final measurements . 17

12 Information to be given in the relevant specification . 17

13 Information to be given in the test report. 17

Annex A (informative) Typical apparatus for cyclic salt mist, humid condition, dry

condition and standard atmosphere corrosion tests . 19

Annex B (informative) Description of each test method . 20

B.1 Test methods 1 and 2 . 20

B.2 Test methods 3 to 6 . 20

B.3 Test methods 7 and 8 . 20

Bibliography . 21

Figure 1 – Schematic time-scale of the different test severities (1) to (6) .

Figure A.1 – Example of test apparatus . 19

Table 1 – Test cycles for test methods 1 to 8 . 16

– 4 – IEC 60068-2-52:2017 RLV © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60068-2-52 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test.

This third edition cancels and replaces the second edition published in 1996. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) the entire content has been harmonized with ISO 9227 as far as possible;

b) an introduction has been added;

c) the scope has been simplified;

d) normative references have been updated;

e) the general description of the test has been changed;

f) a dry chamber has been added to the test apparatus;

g) severities have been changed to test methods;

h) test methods 7 and 8 have been added;

i) information on the test report has been added;

j) Figure 1 has been changed to Table 1;

k) a typical test apparatus example has been added in a new Annex A;

l) a description of each test method has been added in a new Annex B;

m) bibliographical references have been added.

The text of this International Standard is based on the following documents:

FDIS Report on voting

104/751/FDIS 104/761/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60068 series, published under the general title Environmental

testing, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 60068-2-52:2017 RLV © IEC 2017

INTRODUCTION

The mechanism of salt corrosion on metallic materials in a chloride-containing atmosphere is

electrochemical, whereas the degradation effects experienced on non-metallic materials are

caused by complex chemical reactions of the salts with the materials involved. The rate at

which corrosive action takes place is dependent, to a large extent, on the supply of

oxygenated salt solution to the surface of the test specimen(s), the temperature of the test

specimen(s) and the temperature and humidity of the environment.

Apart from the corrosive effects, this cyclic salt mist test may be used to indicate deterioration

of some non-metallic materials by assimilation of salts. In the various test methods described

in this document, the period of spraying with the relevant salt solution is sufficient to wet the

test specimen(s) thoroughly. Because this wetting is repeated after intervals of storage under

humid conditions (severities (1) and (2)) and in some cases severities ((3) to (6)) –

supplemented by storage under a standard atmosphere for testing, it goes some way to

reproducing the effects of natural environments.

Furthermore, considering natural environments for corrosion on metallic materials, neutral or

acidified salt solution spray, humid, and dry conditions are also important factors as a cyclic

corrosion test. Each condition is repeated after intervals of other conditions in different

combinations to achieve corrosion on metallic materials and to get acceleration of corrosion.

The tests described in this document are accelerated compared with most expected

conditions of use. As a result, it may be difficult to establish an overall acceleration factor for

all kinds of test specimens. This also means that it is often not possible to use results gained

from these tests as a comparative guide to the long-term behaviour of different coating

systems since the corrosion stress during these tests differs significantly from the corrosion

stresses encountered during use. Nevertheless, the method described gives a means of

checking that the comparative quality of a metallic material is maintained.

This document may involve hazardous materials, operations and equipment. This document

does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this document to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior to use.

ENVIRONMENTAL TESTING –

Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

1 Scope

This test is intended for application to components or equipment designed to withstand a salt-

laden atmosphere, depending on the chosen severity. Salt can degrade the performance of

parts manufactured using metallic and/or non-metallic materials.

Severities (1) and (2) are intended to be used for testing products which are used in a marine

environment, or in close proximity to the sea. Severity (1) should be used to test products

which are exposed to the environment for much of their operational life (e.g. ship radar, deck

equipment). Severity (2) should be used to test products which may be exposed to the marine

environment from time to time but will normally be protected by an enclosure (e.g.

navigational equipment which will normally be used on the bridge or in a control room).

Additionally, severities (1) and (2) are commonly used as a general corrosion test in

component quality assurance procedures.

Severities (3) to (6) are intended for products where, under normal use, there is a frequent

change between salt-laden and dry atmosphere, e.g. automobiles and their parts.

Severities (3) to (6), compared to severities (1) and (2), therefore include an additional

storage under a standard atmosphere for testing.

The period of dry atmosphere may happen, in practice, during breaks of operation, e.g. during

the weekend. This inclusion of such a dry period in severities (3) to (6) leads to corrosion

mechanism which can be quite different from those under constant humid conditions.

The test is accelerated compared with most service conditions. However, it is not possible to

establish an overall acceleration factor for all kinds of specimens (see IEC 60355).

This part of IEC 60068-2 specifies the application of the cyclic salt mist test to components or

equipment designed to withstand a salt-laden atmosphere as salt can degrade the

performance of parts manufactured using metallic and/or non-metallic materials.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-1: 1988, Environmental testing – Part 1: General and guidance

IEC 60068-2-3: 1969, Environmental testing – Part 2: Tests – Test Ca: Damp heat, steady

state

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

– 8 – IEC 60068-2-52:2017 RLV © IEC 2017

IEC 60355: 1971, An appraisal of the problems of accelerated testing for atmospheric

corrosion

ISO 9227, Corrosion tests in artificial atmospheres – Salt spray tests

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 General description of the test

For severities (1) and (2), the test procedure is separated into a specified number of periods

of spraying by a salt mist at a temperature between 15 °C and 35 °C, each followed by a

+2

storage period under humid conditions at 40 °C ± 2 °C, (93 ) % relative humidity.

−3

For severities (3), (4), (5) and (6) the test procedure is separated into a specified number of

test cycles. Each test cycle consists of four periods of spraying by a salt mist at a temperature

between 15 °C and 35 °C, each followed by a storage period under humid conditions at

+2

40 °C ± 2 °C, (93 ) % relative humidity, and of one storage period under a standard

−3

atmosphere for testing at 23 °C ± 2 °C and 45 % to 55 % relative humidity after these four

periods of spraying and storage under humid conditions.

If the spray period and storage period are carried out in different chambers, care should be

taken to avoid loss of salt solution deposits on the specimen and to avoid any damage to the

specimen due to handling.

The specimen is never energized during the spray period, and not normally during the storage

period.

4.1 Description of each test condition

4.1.1 General

This document consists of the cyclic test conditions of salt mist, dry condition, humid condition

and standard atmosphere. The effect of each test condition is as follows.

NOTE Salt mist is also called salt spray.

The test specimen(s) is typically not energized during the test.

4.1.2 Salt mist

The test specimen is corroded by an electrochemical or complex chemical reaction with

neutral or acidified salt solution. Salt solution forms a thin electrolytic film on the test

specimen surface. This can initiate corrosion and can allow it to proceed.

4.1.3 Dry condition

Heated air in the chamber may cause evaporation of water from the test specimen surface

from decreasing relative humidity and increased specimen temperature. This causes the

concentration of the solution to increase and speeds up chemical reactions, accelerating the

corrosion process. Salt precipitates out of the solution onto the test specimen surface during

this condition. Evaporation and heating rates may vary based on the test chamber and test

specimen.

4.1.4 Humid condition

4.1.4.1 Dry condition to humid condition

As the relative humidity increases, precipitated salt crystals on the specimen surface absorb

water vapour until a liquid electrolytic solution forms, reinitializing the corrosion process.

4.1.4.2 Salt mist to humid condition

The humid condition maintains the existing wetness on the test specimen surface at the end

of the salt mist period, without excessive dilution of the solution that may result from

condensing humidity.

4.1.5 Standard atmosphere

The test specimen is allowed to equilibrate with standard laboratory conditions, which results

in gradual drying and relaxation from most corrosion reactions. The period of dry atmosphere

may occur, in practice, during breaks of operation, for example during the weekend. The

inclusion of such a dry period may lead to corrosion mechanisms which can be quite different

from those under constant wet conditions. The test schedule shall be chosen in order to

respect the timelines given in 9.4. Additional dry periods (e.g. during a weekend) shall be

avoided.

5 Test apparatus

5.1 General

Each test method includes two or more environmental conditions, which may be achieved by

the use of multiple chambers or a single chamber that automatically transitions from one

condition to the next. In either case, transitions are not assumed to be instantaneous. Care

shall be taken to minimize any adverse effects associated with handling of specimens during

transfer between chambers.

5.2 Salt mist chamber

The chamber for this test shall be constructed of such materials that will not influence the

corrosive effects of the salt mist shall conform to the requirements of ISO 9227. It shall

maintain a temperature of 35 °C ± 2 K.

NOTE A schematic diagram of one possible design of spray cabinet is shown in Annex A.

The detailed construction of the chamber, including the method of producing the salt mist is

optional, provided that:

a) the conditions in the chamber are within the limits specified;

b) a sufficiently large volume with constant, homogeneous conditions (not affected by

turbulence) is available; these conditions should not be influenced by the specimen under

test;

c) no direct spray impinges upon the specimen under test;

d) drops of liquid accumulating on the ceiling, the walls, or other parts cannot drip on the

specimen;

– 10 – IEC 60068-2-52:2017 RLV © IEC 2017

e) the chamber shall be properly vented to prevent pressure build-up and allow uniform

distribution of the salt mist. The discharge end of the vent shall be protected from strong

draughts which can cause strong air currents in the chamber.

4.1.1 Atomizer(s)

The atomizer(s) shall be of such a design and construction as to produce a finely divided, wet,

dense mist. The atomizer(s) shall be made of material that is non-reactive to the salt solution.

4.1.2 The sprayed solution shall not be re-used.

4.1.3 Air supply

If use is made of compressed air, that air shall, when entering the atomizer(s), be essentially

free from all impurities, such as oil and dust.

Means shall be provided to humidify the compressed air as required to meet the operating

conditions. The air pressure shall be suitable to produce a finely divided dense mist with the

atomizer(s) used.

To ensure against clogging of the atomizer(s) by salt deposition, the air is recommended to

have a relative humidity of at least 85 % at the point of release from the nozzle. A satisfactory

method is to pass the air in very fine bubbles through a tower containing water, which should

be automatically maintained at a constant level. The temperature of this water shall be not

less than that of the chamber.

The air pressure shall be capable of adjustment so that the collection rate as specified in 9.2

can be maintained.

5.3 Humidity chamber

The chamber shall conform to the requirements of IEC 60068-2-3, i.e. IEC 60068-2-78. It shall

+2

maintain a relative humidity of (93 ) % at a temperature of 40 °C ± 2 °C 93 % ± 3 % at a

−3

temperature of 40 °C ± 2 K or a relative humidity of over 95 % at a temperature of 50 °C ± 2

K.

5.4 Standard atmosphere chamber

The chamber shall conform to the requirements of 5.2 of IEC 60068-1, (table second line,

wide range), i.e. It shall maintain a relative humidity of 45 % to 55 % at a temperature of

23 °C ± 2 °C 50 % ± 5 % at a temperature of 23 °C ± 2 K.

5.5 Dry chamber

The chamber shall maintain a relative humidity of less than 30 % at a temperature of

60 °C ± 2 K.

6 Salt solution

5.1 5 % sodium chloride (NaCl) solution

5.1.1 The salt used for the test shall be high-quality sodium chloride (NaCl) containing, when

dry, not more than 0,1 % sodium iodide and not more than 0,3 % of total impurities.

The salt solution concentration shall be 5 % ± 1 % by weight.

The solution shall be prepared by dissolving 5 ± 1 parts by weight of salt in 95 parts by weight

of distilled or demineralized water.

NOTE – The relevant specification may call for other salt solutions, the composition and characteristics (density,

pH value, etc.) of which should be stated clearly in the specification, e.g. to simulate the special effects of a marine

environment.

5.1.2 The pH value of the solution shall be between 6,5 and 7,2 at a temperature of 20 °C ± 2 °C.

The pH value shall be maintained within this range during conditioning; for this purpose,

diluted hydrochloric acid or sodium hydroxide may be used to adjust the pH value, provided

that the concentration of NaCl remains within the prescribed limits. The pH value shall be

measured when preparing each new batch of solution.

6.1 Preparation of the sodium chloride solution

The solution shall conform to the requirements of ISO 9227.

NOTE The sodium chloride concentration of the sprayed solution collected is 50 g/l ± 5 g/l.

6.2 pH adjustment

6.2.1 Neutral salt solution

The pH adjustment shall conform to the requirements of ISO 9227 for the neutral salt solution

test.

6.2.2 Acidified salt solution

Add the following reagents to 10 litres of the prepared neutral 5 % sodium chloride solution as

follows: 12 ml of nitric acid (HNO , ρ = 1,42 g/ml), 17,3 ml of sulfuric acid (H SO , ρ = 1,84

3 2 4

g/ml) and sufficient quantity of 10 % mass fraction of sodium hydroxide (NaOH) solution to

adjust the pH of the solution to 3,5 ± 0,1 (about 300 ml will be required). The pH of the

sprayed solution collected within the chamber is 3,4 to 3,6 at 25 °C ± 2 K.

6.3 Filtration

If necessary, filter the solution before placing it in the reservoir of the apparatus to remove

any solid matter which might block the apertures of the spraying device.

6 Severities

6.1 The severity of the test is defined as follows.

For severities (1) and (2):

by the combination of the number of spray periods and the duration of the storage under

humid conditions following each spray period.

For severities (3) to (6):

by the number of test cycles consisting of four spraying periods with storage under humid

conditions after each one, and one additional storage period under a standard atmosphere for

testing after these four periods of spraying and storage under humid conditions.

6.2 The relevant specification shall indicate which of the six following severities shall be

used.

Severity (1): four spray periods, each of 2 h, with a humidity storage period of seven days

after each.

– 12 – IEC 60068-2-52:2017 RLV © IEC 2017

NOTE – The humidity storage period should be suitably reduced so that the spray period plus storage period is

seven days.

Severity (2): three spray periods, each of 2 h, with a humidity storage period between 20 h

and 22 h after each.

Severity (3): one test cycle consisting of:

four spray periods, each of 2 h, with a humidity storage period between 20 h and 22 h after

each; afterwards one storage period of three days under a standard atmosphere for testing

at 23 °C ± 2 °C and 45 % to 55 % humidity.

Severity (4): two test cycles as specified in severity (3).

Severity (5): four test cycles as specified in severity (3).

Severity (6): eight test cycles as specified in severity (3).

6.3 A schematic survey of time-scale of all the test severities is given in figure 1.

7 Initial measurements

The test specimen(s) shall be visually inspected and, if necessary, electrically and

mechanically checked as required by the relevant specification.

8 Preconditioning

The relevant specification shall prescribe specify the cleaning procedure to be applied

immediately before the test; it shall also state whether temporary protective coatings shall be

removed.

NOTE – The cleaning method used should not interfere with the effect of the salt mist on the

test specimen(s), nor introduce any secondary corrosion. Touching of the test surfaces by

hand should be avoided as far as possible before the test.

9 Testing

9.1 The specimen shall be placed in the salt mist chamber, and sprayed with the salt

solution, for a period of 2 h at a temperature between 15 °C and 35 °C.

9.2 The salt mist conditions shall be maintained in all parts of the exposure zone, that a

clean collecting receptacle with a horizontal collecting area of 80 cm , placed at any point in

the exposure zone, shall collect between 1,0 ml and 2,0 ml of solution per hour, averaged

over the collecting period. A minimum of two receptacles shall be used. The receptacles shall

be placed such that they are not shielded by the specimen and so that no condensate from

any source shall be collected.

NOTE – When calibrating the spray rate of the chamber, a minimum spray period of 8 h should be used, for

accurate measurement purposes.

9.3 Severities (1) and (2)

At the end of the spray period, the specimen shall be transferred to the humidity chamber and

+2

stored at a temperature of 40 °C ± 2 °C and a relative humidity of (93 ) % in accordance

−3

with IEC 60068-2-3.

The spraying with salt solution as in 9.1 and the storage as in this subclause constitutes one

cycle.

The required severity for the number of cycles and the duration of storage shall be in

accordance with 6.2.

9.4 Severities (3) to (6)

At the end of the spray period, the specimen shall be transferred to the humidity chamber and

+2

stored at a temperature of 40 °C ± 2 °C and a relative humidity of (93 ) % in accordance

−3

with IEC 60068-2-3 for a period of 20 h to 22 h. This shall be repeated a further three times.

The specimen shall then be stored under a standard atmosphere for testing at 23 °C ± 2 °C

and 45 % to 55 % relative humidity for a period of three days.

The four spray periods (see 9.1) and storage periods of this subclause followed by three days

under a standard atmosphere for testing constitutes one test cycle.

The required severity for the number of test cycles shall be in accordance with 6.2.

9.5 The removal of the specimen from the salt mist chamber to the humidity chamber shall

be carried out so as to minimize the loss of salt solution from the specimen(s).

NOTE – If the salt mist chamber can maintain the humidity and temperature conditions of IEC 60068-2-3, the

specimen may remain in it for the humidity storage period.

9.6 If the specimen consists of more than one item they shall not be in contact with each

other or with other metal parts and shall be so arranged as to exclude any influence of one

part upon another.

9.1 Test chamber

For test methods 1 and 2, a salt mist chamber and humidity chamber are used.

For test methods 3 to 6, a salt mist chamber, humidity chamber and standard atmosphere

chamber are used.

For test methods 7 and 8, a salt mist chamber, dry chamber and humidity chamber are used.

All test methods may be performed in a single chamber provided it is capable of maintaining

the required conditions. If not, care should be taken to avoid loss of salt solution deposits on

the test specimen(s) and to avoid any damage to the test specimen(s) due to manual

handling. For test methods 7 and 8, each condition should be carried out in the same

chamber due to the difficulty in achieving the rapid drying and re-wetting intended if

specimens are manually moved from one chamber to another.

It is recommended to use a specific chamber for testing test method 8 exclusively. Cross

effects of remaining acidified salt solution when consequently using test method 1 to 7 cannot

be ignored.

9.2 Arrangement of the test specimen(s)

The arrangement shall conform to the requirements of ISO 9227.

9.3 Conditions during salt mist

The test conditions shall conform to the requirements of ISO 9227.

– 14 – IEC 60068-2-52:2017 RLV © IEC 2017

9.4 Test methods

9.4.1 General

The relevant specification shall indicate which of the eight following test methods shall be

used. A description of each test method is given in Annex B. When not specified, the test

method shall be agreed by the interested parties.

The user should be aware of mass loss for each test condition.

9.4.2 Test method 1

One cycle is seven days. One cycle shall consist of spraying the specimen with a salt solution

at 35 °C ± 2 K for 2 h, followed by the humid condition at 40 °C ± 2 K, 93 % ± 3 % RH for six

days and 22 h. The required number of cycles is four (28 days).

In the case of manual handling, the transition time (maximum 2 h) should be included in the

humid condition period of six days and 22 h.

9.4.3 Test method 2

One cycle is one day. One cycle shall consist of spraying the specimen with a salt solution at

35 °C ± 2 K for 2 h, followed by the humid condition at 40 °C ± 2 K, 93 % ± 3 % RH for 22 h.

The required number of cycles is three (three days).

In the case of manual handling, the transition time (maximum 2 h) should be included in the

humid condition period of 22 h.

9.4.4 Test method 3

One cycle is seven days. One cycle shall consist of spraying the specimen with a salt solution

at 35 °C ± 2 .K for 2 h, followed by the humid condition at 40 °C ± 2 K, 93 % ± 3 % RH for 22

h. This shall be repeated four times. The test specimens shall then be stored under standard

atmosphere at 23 °C ± 2 K and 50 % ± 5 % RH for three days. The required number of cycle

is one (seven days).

In the case of manual handling, the transition time (maximum 2 h) should be included in the

humid condition period of 22 h and standard atmosphere period of three days.

9.4.5 Test method 4

The required number of cycles as specified in test method 3 shall be two (14 days).

9.4.6 Test method 5

The required number of cycles as specified in test method 3 shall be four (28 days).

9.4.7 Test method 6

The required number of cycles as specified in test method 3 shall be eight (56 days).

9.4.8 Test method 7

One cycle is 8 h. One cycle shall consist of spraying the specimen with a salt solution at

35 °C ± 2 K for 2 h, followed by the dry condition at 60 °C ± 2 K, under 30 % RH for 4 h and

then the humid condition at 50 °C ± 2 K, over 95 % RH for 2 h.

The transition times (time allowed to reach the temperature and relative humidity specified for

a condition after changing to that condition) for temperature and humidity shall be specified

between the following choices and reported:

– salt mist to dry condition: within 30 min or between 30 min and 60 min;

– dry condition to humid condition: within 15 min or between 15 min and 30 min;

– humid condition to salt mist: within 30 min.

Those transition times shall be included in the next condition period of the pair, for example

the salt mist to dry condition transition time is included in the period of the dry condition.

Spraying the specimen with a salt solution begins instantaneously once the salt mist is

started.

The recommended number of cycles are 3 (1 day), 6 (2 days), 12 (4 days), 30 (10 days), 45

(15 days), 60 (20 days), 90 (30 days), 150 (50 days) and 180 (60 days).

9.4.9 Test method 8

One cycle is 8 h, as specified in test method 7 using acidified salt solution instead of neutral

salt solution.

The recommended number of cycles is the same as in test method 7.

9.5 Test cycles for test methods 1 to 8

The test cycles for test methods 1 to 8 shall be in accordance with Table 1.

– 16 – IEC 60068-2-52:2017 RLV © IEC 2017

Table 1 – Test cycles for test methods 1 to 8

Test Details of the cycle Recommended

methods number of cycles

Salt mist Humid condition

35 °C ± 2 K 40 °C ± 2 K

2 h 93 % ± 3 % RH

6 day and 22 h

Test method

4 cycles (28 days)

One cycle = 7 days

In the case of manual handling, the transition time (max. 2 h) should be

included in the humid condition period of 6 days and 22 h.

Salt mist Humid condition

35 °C ± 2 K 40 °C ± 2 K

2 h 93 % ± 3 % RH

22 h

Test method

3 cycles (3 days)

One cycle = 1 day

In the case of manual handling, the transition time (max. 2 h) should be

included in the humid condition period of 22 h.

Salt mist Humid condition Standard

Test method

35 °C ± 2 K 40 °C ± 2 K atmosphere 1 cycle (7 days)

2 h 93 % ± 3 % RH 23 °C ± 2 K

22 h 50 % ± 5 % RH

Test method 3 days

2 cycles (14 days)

Repeat 4 times

Test method

4 cycles (28 days)

One cycle = 7 days

In the case of manual handling, the transition time (max. 2 h) should be

Test method

8 cycles (56 days)

included in the humid condition period of 22 h and standard atmosphere

period of 3 days.

Salt mist Dry condition Humid condition

35 °C ± 2 K 60 °C ± 2 K 50 °C ± 2 K

2 h ≤ 30 % RH ≥ 95 % RH

Test method

4 h 2 h

3, 6, 12, 30, 45,

60, 90, 150, 180

One cycle = 8 h

cycles

(1, 2, 4, 10, 15,

The transition times (time allowed to reach the temperature and relative

20, 30, 50, 60

humidity specified for a condition after changing to that condition) are

days)

within 30 min or between 30 min and 60 min from salt mist to dry condition,

Test method

within 15 min or between 15 min and 30 min from dry condition to humid

condition and within 30 min from humid condition to salt mist. Those

transition times shall be included in next condition period.

NOTE The ± tolerances given for temperature and relative humidity are the allowable fluctuations which are

defined as the positive and negative deviations from the setting of the sensor at the operational control set point

during equilibrium conditions. This does not mean that the set value can vary by plus/minus the amount

indicated from the given value.

9.6 Removal of the test specimen(s)

The test is recommended to be carried out in the same chamber (see Figure A.1). If not, care

should be taken to avoid loss of salt solution deposits on the test specimen(s) and to avoid

any damage to the test specimen(s) due to handling.

10 Recovery (at the end of testing)

The relevant specification shall state whether or not the test specimen(s) shall be washed. If

the test specimen(s) is to be washed, it shall be washed using running tap water for 5 min,

rinsed in distilled or demineralized deionized water, shaken by hand or subjected to air blast

to remove droplets of water, then dried for 1 h at 55 °C ± 2 K and allowed to cool under

controlled recovery conditions (IE

...

IEC 60068-2-52 ®

Edition 3.0 2017-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Environmental testing –

Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium chloride solution)

Essais d'environnement –

Partie 2-52: Essais – Essai Kb: Brouillard salin, essai cyclique (solution de

chlorure de sodium)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60068-2-52 ®

Edition 3.0 2017-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Environmental testing –

Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium chloride solution)

Essais d'environnement –

Partie 2-52: Essais – Essai Kb: Brouillard salin, essai cyclique (solution de

chlorure de sodium)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 19.040 ISBN 978-2-8322-7231-2

– 2 – IEC 60068-2-52:2017 © IEC 2017

CONTENTS

CONTENTS . 2

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 General description of the test . 7

4.1 Description of each test condition . 7

4.1.1 General . 7

4.1.2 Salt mist . 8

4.1.3 Dry condition . 8

4.1.4 Humid condition . 8

4.1.5 Standard atmosphere . 8

5 Test apparatus . 8

5.1 General . 8

5.2 Salt mist chamber . 8

5.3 Humidity chamber . 8

5.4 Standard atmosphere chamber . 9

5.5 Dry chamber . 9

6 Salt solution . 9

6.1 Preparation of the sodium chloride solution . 9

6.2 pH adjustment . 9

6.2.1 Neutral salt solution . 9

6.2.2 Acidified salt solution . 9

6.3 Filtration . 9

7 Initial measurements . 9

8 Preconditioning . 9

9 Testing . 9

9.1 Test chamber . 9

9.2 Arrangement of the test specimen(s) . 10

9.3 Conditions during salt mist . 10

9.4 Test methods . 10

9.4.1 General . 10

9.4.2 Test method 1 . 10

9.4.3 Test method 2 . 10

9.4.4 Test method 3 . 10

9.4.5 Test method 4 . 11

9.4.6 Test method 5 . 11

9.4.7 Test method 6 . 11

9.4.8 Test method 7 . 11

9.4.9 Test method 8 . 11

9.5 Test cycles for test methods 1 to 8 . 11

9.6 Removal of the test specimen(s) . 12

10 Recovery (at the end of testing) . 12

11 Final measurements . 13

12 Information to be given in the relevant specification . 13

13 Information to be given in the test report. 13

Annex A (informative) Typical apparatus for cyclic salt mist, humid condition, dry

condition and standard atmosphere corrosion tests . 14

Annex B (informative) Description of each test method . 15

B.1 Test methods 1 and 2 . 15

B.2 Test methods 3 to 6 . 15

B.3 Test methods 7 and 8 . 15

Bibliography . 16

Figure A.1 – Example of test apparatus . 14

Table 1 – Test cycles for test methods 1 to 8 . 12

– 4 – IEC 60068-2-52:2017 © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-52 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test.

This bilingual version (2019-07) corresponds to the monolingual English version, published in

2017-11.

This third edition cancels and replaces the second edition published in 1996. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) the entire content has been harmonized with ISO 9227 as far as possible;

b) an introduction has been added;

c) the scope has been simplified;

d) normative references have been updated;

e) the general description of the test has been changed;

f) a dry chamber has been added to the test apparatus;