IEC 60825-2:2000

(Main)Safety of laser products - Part 2: Safety of optical fibre communication systems

Safety of laser products - Part 2: Safety of optical fibre communication systems

Provides requirements and specific guidance for the safe use of optical fibre and/or control communication systems where optical power may be accessible at great distance from the optical source. The objective of this part 2 of IEC 60825 is to: - protect people from optical radiation resulting from optical fibre communication systems. This requires the introduction of engineering requirements and work practices according to the degree of hazard; - lay down requirements for manufacturers and operating organizations in order to establish procedures and supply information so that proper precautions can be adopted; - ensure adequate warning to individuals of the hazards associated with optical fibre communication systems through signs, labels and instructions; - reduce the possibility of injury by minimizing unnecessary accessible radiation, give improved control of the optical radiation through protective features and provide safe usage of products by specifying user control measures. The contents of the interpretation sheet of August 2001 have been included in this copy.

General Information

- Status

- Published

- Publication Date

- 26-Aug-2001

- Technical Committee

- TC 76 - Optical radiation safety and laser equipment

- Drafting Committee

- WG 5 - TC 76/WG 5

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 28-Jun-2004

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60825-2:2000 - Safety of laser products, Part 2: Safety of optical fibre communication systems provides requirements and specific guidance for the safe use of optical fibre and control communication systems where optical radiation (including lasers and LEDs) can be accessible far from the optical source. The standard’s objective is to protect people from hazardous optical radiation by specifying engineering controls, work practices, labelling and information that manufacturers, installers and operators must provide. This edition also incorporates the August 2001 interpretation sheet updates.

Key topics and requirements

- Hazard classification and assessment

- Defines accessible locations and assigns hazard levels (1, 1M, 2, 2M, 3R, 3B, 4) according to potential accessible emissions and IEC 60825-1 classification principles.

- Engineering requirements

- Design measures to minimize accessible radiation (enclosures, protected cables, connector design).

- Use of automatic power reduction (APR) features to reduce accessible power within specified times after events (e.g., fibre break).

- Manufacturing and installation

- Requirements for product design, connector mechanics, and installation practices to control exposure risk at distance from source.

- Labelling and information

- Obligations for signs, labels and user instructions to ensure adequate warning and safe operation.

- Operating and maintenance guidance

- Service/test procedures, safety precautions and responsibilities for operating organizations and end-users.

- Annexes and guidance material

- Includes rationale, hazard analysis methods, application notes (examples: PON systems), and clarification of “laser hazard level.”

Practical applications and users

IEC 60825-2:2000 is directly applicable to:

- Telecommunications and broadband network designers (PONs, long-haul fibre links)

- Optical equipment manufacturers (transmitters, connectors, enclosures)

- System integrators and installers implementing safe cable routing and connector designs

- Data centre and network operators establishing safe access zones and maintenance procedures

- Health & safety officers and regulatory bodies assessing compliance and labelling requirements Practical uses include specifying connector safety features, APR implementation, determining where warning signs are needed, and informing maintenance/test protocols.

Related standards

- IEC 60825-1 - Equipment classification, requirements and user’s guide (used for hazard evaluation)

- IEC 60794-2 - Optical fibre cables - product specifications

By following IEC 60825-2:2000, organizations manage optical radiation risks in fibre communication systems through design controls, operational procedures and clear safety information - improving protection for technicians, installers and the public.

Buy Documents

IEC 60825-2:2000/ISH1:2001 - Interpretation Sheet 1 - Safety of laser products - Part 2: Safety of optical fibre communication systems Released:8/27/2001

IEC 60825-2:2000 - Safety of laser products - Part 2: Safety of optical fibre communication systems Released:5/30/2000 Isbn:2831851246

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 60825-2:2000 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety of laser products - Part 2: Safety of optical fibre communication systems". This standard covers: Provides requirements and specific guidance for the safe use of optical fibre and/or control communication systems where optical power may be accessible at great distance from the optical source. The objective of this part 2 of IEC 60825 is to: - protect people from optical radiation resulting from optical fibre communication systems. This requires the introduction of engineering requirements and work practices according to the degree of hazard; - lay down requirements for manufacturers and operating organizations in order to establish procedures and supply information so that proper precautions can be adopted; - ensure adequate warning to individuals of the hazards associated with optical fibre communication systems through signs, labels and instructions; - reduce the possibility of injury by minimizing unnecessary accessible radiation, give improved control of the optical radiation through protective features and provide safe usage of products by specifying user control measures. The contents of the interpretation sheet of August 2001 have been included in this copy.

Provides requirements and specific guidance for the safe use of optical fibre and/or control communication systems where optical power may be accessible at great distance from the optical source. The objective of this part 2 of IEC 60825 is to: - protect people from optical radiation resulting from optical fibre communication systems. This requires the introduction of engineering requirements and work practices according to the degree of hazard; - lay down requirements for manufacturers and operating organizations in order to establish procedures and supply information so that proper precautions can be adopted; - ensure adequate warning to individuals of the hazards associated with optical fibre communication systems through signs, labels and instructions; - reduce the possibility of injury by minimizing unnecessary accessible radiation, give improved control of the optical radiation through protective features and provide safe usage of products by specifying user control measures. The contents of the interpretation sheet of August 2001 have been included in this copy.

IEC 60825-2:2000 is classified under the following ICS (International Classification for Standards) categories: 31.260 - Optoelectronics. Laser equipment; 33.180.01 - Fibre optic systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60825-2:2000 has the following relationships with other standards: It is inter standard links to EN ISO 15367-1:2003, IEC 60825-2:1993/AMD1:1997, IEC 60825-2:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60825-2:2000 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

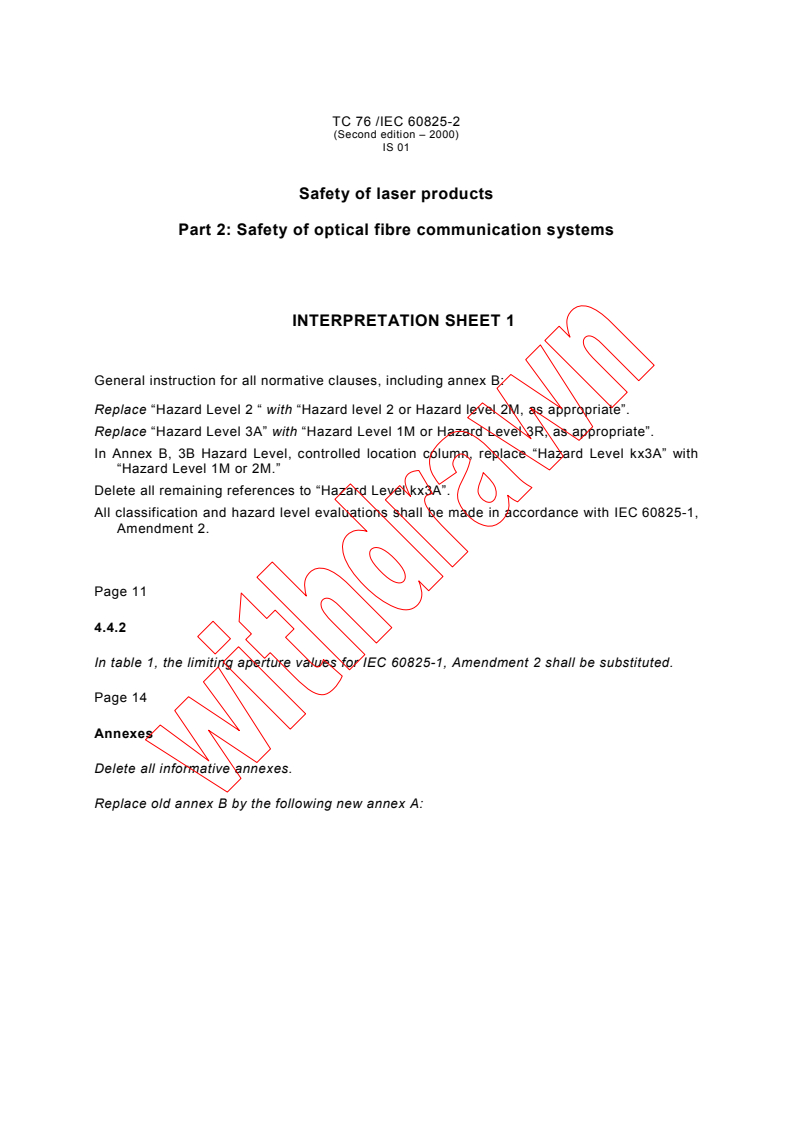

TC 76 /IEC 60825-2

(Second edition – 2000)

IS 01

Safety of laser products

Part 2: Safety of optical fibre communication systems

INTERPRETATION SHEET 1

General instruction for all normative clauses, including annex B:

Replace “Hazard Level 2 “ with “Hazard level 2 or Hazard level 2M, as appropriate”.

Replace “Hazard Level 3A” with “Hazard Level 1M or Hazard Level 3R, as appropriate”.

In Annex B, 3B Hazard Level, controlled location column, replace “Hazard Level kx3A” with

“Hazard Level 1M or 2M.”

Delete all remaining references to “Hazard Level kx3A”.

All classification and hazard level evaluations shall be made in accordance with IEC 60825-1,

Amendment 2.

Page 11

4.4.2

In table 1, the limiting aperture values for IEC 60825-1, Amendment 2 shall be substituted.

Page 14

Annexes

Delete all informative annexes.

Replace old annex B by the following new annex A:

Annex A

(normative)

Summary of engineering requirements at locations in

optical fibre communicati

...

INTERNATIONAL IEC

STANDARD

60825-2

Second edition

2000-05

Safety of laser products –

Part 2:

Safety of optical fibre communication systems

Sécurité des appareils à laser –

Partie 2:

Sécurité des systèmes de télécommunication

par fibres optiques

Reference number

Numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series.

Consolidated publications

Consolidated versions of some IEC publications including amendments are

available. For example, edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the

base publication, the base publication incorporating amendment 1 and the base

publication incorporating amendments 1 and 2.

Validity of this publication

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology.

Information relating to the date of the reconfirmation of the publication is available

in the IEC catalogue.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is to be found at the following IEC sources:

• IEC web site*

•

Catalogue of IEC publications

Published yearly with regular updates

(On-line catalogue)*

• IEC Bulletin

Available both at the IEC web site* and as a printed periodical

Terminology, graphical and letter symbols

For general terminology, readers are referred to IEC 60050: International

Electrotechnical Vocabulary (IEV).

For graphical symbols, and letter symbols and signs approved by the IEC for

general use, readers are referred to publications IEC 60027: Letter symbols to be

used in electrical technology, IEC 60417: Graphical symbols for use on equipment.

Index, survey and compilation of the single sheets and IEC 60617: Graphical symbols

for diagrams.

* See web site address on title page.

INTERNATIONAL IEC

STANDARD

60825-2

Second edition

2000-05

Safety of laser products –

Part 2:

Safety of optical fibre communication systems

Sécurité des appareils à laser –

Partie 2:

Sécurité des systèmes de télécommunication

par fibres optiques

IEC 2000 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

W

International Electrotechnical Commission

For price, see current catalogue

TC 76 /IEC 60825-2

(Second edition – 2000)

IS 01

Safety of laser products

Part 2: Safety of optical fibre communication systems

INTERPRETATION SHEET 1

General instruction for all normative clauses, including annex B:

Replace “Hazard Level 2 “ with “Hazard level 2 or Hazard level 2M, as appropriate”.

Replace “Hazard Level 3A” with “Hazard Level 1M or Hazard Level 3R, as appropriate”.

In Annex B, 3B Hazard Level, controlled location column, replace “Hazard Level kx3A” with

“Hazard Level 1M or 2M.”

Delete all remaining references to “Hazard Level kx3A”.

All classification and hazard level evaluations shall be made in accordance with IEC 60825-1,

Amendment 2.

Page 11

4.4.2

In table 1, the limiting aperture values for IEC 60825-1, Amendment 2 shall be substituted.

Page 14

Annexes

Delete all informative annexes.

Replace old annex B by the following new annex A:

Annex A

(normative)

Summary of engineering requirements at locations in

optical fibre communication system

Hazard level Location type

Unrestricted Restricted Controlled

1 No requirements No requirements No requirements

1M 1) Labelling, and Labelling Labelling

2) Class 1* from

connector or connector

requires tool

2 and 2M 1) Labelling, and Labelling Labelling

2) Class 1* from

connector, or connector

requires tool

3R Not permitted ** 1) Labelling, and 1) Labelling, and

2) Class 1M* from 2) class 1M or 2M* from

connector, or connector or connector

connector requires requires tool

tool

3B Not permitted ** Not permitted** 1) Labelling,

and

2) Protected cables,

and

3) class 1M or 2M* from

connector or connector

requires tool

4 Not permitted ** Not permitted ** Not permitted**

* To be achieved by mechanical design of connector, automatic power reduction or other suitable

means.

** See 4.4.3. Where systems employ power levels of class 3R or more, protection systems such as

APR may be used to obtain the acceptable hazard level for the particular location type.

August 2001

– 2 – 60825-2 IEC:2000(E)

CONTENTS

Page

FOREWORD . 3

Clause

1 Scope . 5

2 Normative references. 5

3 Definitions. 6

4 Manufacturing requirements. 8

4.1 Engineering specifications . 8

4.2 Labelling. 9

4.3 Provision of information . 10

4.4 Assessment of hazard level . 10

4.5 Requirements for installation . 11

4.6 Requirements for restart pulses . 12

5 Guidance for service and maintenance . 12

5.1 Tests and measurements. 12

5.2 Safety precautions . 12

Annex A (informative) Rationale . 14

Annex B (normative) Summary of engineering requirements at locations in optical fibre

communication system . 15

Annex C (informative) Methods of hazard/safety analysis. 16

Annex D (informative) Application notes for the safe use

of optical fibre communication systems . 17

Annex E (informative) Clarification of the meaning of “laser hazard level”. 35

Bibliography . 37

Figure D.1 – PON (passive optical network)-based system. 34

Table 1 – Assessment of hazard level during shutdown time for systems employing

automatic power reduction (see 4.4.2). 11

Table D.1 – Optical fibre system power limits for 11 microns singlemode

and 0,18 numerical aperture multimode fibres . 30

Table D.2 – Automatic power reduction – Immediately accessible situations . 31

Table D.3 – Controlled access example scenarios. 32

Table D.4 – Restricted access example scenarios . 32

Table D.5 – Unrestricted access example scenarios. 33

Table D.6 – Examples of power limits for optical fibre communication systems

having automatic power reduction to reduce emissions to a lower hazard level . 34

©

60825-2 IEC:2000(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

SAFETY OF LASER PRODUCTS –

Part 2: Safety of optical fibre communication systems

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60825-2 has been prepared by IEC technical committee 76:

Optical radiation safety and laser equipment.

This second edition cancels and replaces the first edition published in 1993 and amendment 1

(1997). This second edition constitutes a technical revision.

The text of this standard is based on the first edition, amendment 1 and the following

documents:

FDIS Report on voting

76/208/FDIS 76/211/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

IEC 60825-2 constitutes part 2 of a series of publications under the general title: Safety of

laser products.

Annex B forms an integral part of this standard.

Annexes A, C, D and E are for information only.

– 4 – 60825-2 IEC:2000(E)

The committee has decided that the contents of this publication will remain unchanged until

2003. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this standard may be issued at a later date.

©

60825-2 IEC:2000(E) – 5 –

SAFETY OF LASER PRODUCTS –

Part 2: Safety of optical fibre communication systems

1 Scope

This part 2 of IEC 60825 provides requirements and specific guidance for the safe use of

optical fibre and/or control communication systems where optical power may be accessible at

great distance from the optical source. It does not apply to optical fibre systems primarily

designed to transmit optical power for applications such as material processing or medical

treatment.

Throughout this part of IEC 60825, light emitting diodes (LEDs) are included whenever the

word "laser" is used.

The objective of this part 2 of IEC 60825 is to:

– protect people from optical radiation resulting from optical fibre communication systems.

This requires the introduction of engineering requirements and work practices according to

the degree of hazard;

– lay down requirements for manufacturers and operating organizations in order to establish

procedures and supply information so that proper precautions can be adopted;

– ensure adequate warning to individuals of the hazards associated with optical fibre

communication systems through signs, labels and instructions;

– reduce the possibility of injury by minimizing unnecessary accessible radiation, give

improved control of the optical radiation through protective features and provide safe

usage of products by specifying user control measures.

Annex A gives a more detailed rationale for this part of IEC 60825.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 60825. For dated references, subsequent amend-

ments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this part of IEC 60825 are encouraged to investigate the possibility of

applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60794-2:1989, Optical fibre cables – Part 2: Product specifications

IEC 60825-1:1993, Safety of laser products – Part 1: Equipment classification, requirements

and user's guide

– 6 – 60825-2 IEC:2000(E)

3 Definitions

For the purpose of this part of IEC 60825, the following definitions apply. They are in addition

to those given in IEC 60825-1.

3.1

accessible location

any part within an optical fibre communication system at which, under reasonably foreseeable

circumstances, human access to laser radiation is possible

3.2

automatic power reduction

feature of an optical fibre communication system by which the accessible power is reduced to

a specified level within a specified time, whenever there is an event which could result in

human exposure to radiation, e.g. a fibre cable break

3.3

enclosed system

system in which, during normal operation, the optical radiation is totally enclosed, e.g. by

light-proof cabinets, components, total internal reflection or optical fibre cables and

connectors

3.4

end-user

person/organization using the optical fibre communication system in the manner the system

was designed to be used. The user cannot necessarily control the power generated and

transmitted within the system

3.5

hazard level

potential hazard at any accessible location within an optical fibre communication system. It is

based on the level of optical radiation which could become accessible in reasonably

foreseeable circumstances, e.g. a fibre cable break. It is closely related to the laser

classification procedure in IEC 60825-1

3.6

hazard level 1

hazard level 1 is allocated to any accessible location within an optical fibre communication

system at which, under reasonably foreseeable circumstances, human access to laser

radiation in excess of the accessible emission limits (AEL) of class 1 for the applicable

wavelengths and emission duration will not occur

3.7

hazard level 2

hazard level 2 is allocated to any accessible location within an optical fibre communication

system at which, under reasonably foreseeable circumstances, human access to laser

radiation in excess of the accessible emission limits of class 2 for the applicable wavelengths

and emission duration will not occur

3.8

hazard level 3A

hazard level 3A is allocated to any accessible location within an optical fibre communication

system at which, under reasonably foreseeable circumstances, human access to laser

radiation in excess of the accessible emission limits of class 3A for the applicable

wavelengths and emission duration will not occur

©

60825-2 IEC:2000(E) – 7 –

3.9

hazard level k × 3A

in the wavelength range 400 nm to 4 000 nm, a hazard level k × 3A is allocated to any

accessible location within an optical fibre communication system at which, under reasonably

foreseeable circumstances, human access to laser radiation in excess of the accessible

emission limits of hazard level k × 3A for the applicable wavelengths and emission duration

will not occur. For purposes of the k × 3A hazard level evaluation, class 3A AEL table is used;

the minimum measurement distance shall be increased to 250 mm from the apparent source

and the time base used shall be 10 s, provided longer viewing durations are not reasonably

foreseeable. For wavelengths greater than 1 400 mm, the radiant power limit shall be a factor

of 10 greater than for class 1

NOTE The value of k is not a constant and need not be calculated (see annex A for rationale).

3.10

hazard level 3B

hazard level 3B is allocated to any accessible location within an optical fibre communication

system at which, under reasonably foreseeable circumstances, human access to laser

radiation in excess of the accessible emission limits of class 3B for the applicable

wavelengths and emission duration will not occur

3.11

hazard level 4

hazard level 4 is allocated to any accessible location within an optical fibre communication

system at which, under reasonably foreseeable circumstances, human access to laser

radiation in excess of the accessible emission limits of class 3B for the applicable

wavelengths and emission duration may occur

3.12

light emitting diode (LED)

any semiconductor p-n junction device which can be made to produce electromagnetic

radiation by radiative recombination in the semiconductor, in the wavelength range from

180 nm to 1 mm. (The optical radiation is produced primarily by the process of spontaneous

emission, although some stimulated emission may be present.)

3.13

local operator control

an optical communication system is under local operator control if the operating controls and

the optical output may be directly monitored simultaneously by a single operator who has

control over the potential human access to optical radiation

3.14

location with controlled access

location where access to the protective housing (enclosure) is controlled and is accessible

only to authorized persons who have received adequate training in laser safety and the

servicing of the system involved. Examples include optical cable ducts and switching centres

3.15

location with restricted access

location where access to the protective housing (enclosure) is restricted and not open to the

public. Examples include industrial and commercial premises

3.16

location with unrestricted access

location where access to the protective housing (enclosure) is unrestricted. Examples include

domestic premises and premises open to the public

– 8 – 60825-2 IEC:2000(E)

3.17

manufacturer

organization/individual who assembles optical devices and other components in order to

construct or modify an optical fibre communication system

3.18

operating organization

organization/individual who is responsible for the installation and/or operation of an optical

fibre communication system

3.19

optical fibre communication system

engineered assembly for the generation, transference and reception of optical radiation

arising from lasers, in which the transference is by means of optical fibre for communication

and/or control purposes

3.20

reasonably foreseeable event

event the occurrence of which under given circumstances can be predicted fairly accurately,

and the occurrence probability or frequency of which is not low or very low.

Examples of reasonably foreseeable events might include the following: component failure,

fibre cable break, optical connector disconnection, operator error or inattention to safe

working practices.

Reckless use or use for completely inappropriate purposes is not to be considered as a

reasonably foreseeable event

3.21

protected cable

a cable in which the fibre or fibres are contained within a robust sheath which permits normal

handling without breakage and/or exposure of the fibre ends. See also 4.1.2.2 and annex B

3.22

subassembly

any discrete unit of an optical fibre communication system which contains an optical emitter or

optical amplifier

4 Manufacturing requirements

4.1 Engineering specifications

4.1.1 General remarks

Optical fibre communication systems require certain built-in safety features, depending on

their hazard level. The manufacturer of the optical fibre communication system is responsible

for the allocation of the hazard level and for compliance with the manufacturing requirements.

These requirements are summarized in annex B.

Whenever alterations which may affect hazard levels are made to the optical fibre

communication system, the person or organization performing such a modification shall

reassess the hazard levels by carrying out tests and measurements, wherever appropriate, for

ensuring compliance and, where the hazard level has changed, relabelling.

Manufacturers of ready-for-use optical fibre communication systems which are to be supplied

to end-users are responsible for assessing the hazard levels of the optical system under all

reasonably foreseeable circumstances and for compliance with the appropriate manufacturing

and safety requirements.

©

60825-2 IEC:2000(E) – 9 –

Manufacturers of ready-for-use optical transmission subassemblies which are intended to be

used only as part of an OFCS need not classify such equipment but are responsible for

assessing the hazard levels of the optical system under all reasonably foreseeable

circumstances and for the compliance with the appropriate manufacturing and safety

requirements.

For other optical communication systems, the operating organization has the ultimate

responsibility for the safety of the system. This includes especially:

– the identification of the location type at all subdivisions of the entire transmission path;

– the assessment of hazard level at any accessible location in the case of reasonably fore-

seeable events;

– assuring compliance with the manufacturing and safety requirements.

Optical fibre communication systems that also transmit electrical power shall meet the

requirements of this standard in addition to any applicable electrical standard.

4.1.2 Cable design

The mechanical design of optical fibre cables shall be specified according to the hazard level

and location (see clause D.3 for examples).

If such cables are not at a controlled location:

4.1.2.1 In all systems, the mechanical characteristics of the individual single or multiple fibre

cable shall be not less than those required by IEC 60794-2.

4.1.2.2 Locations with hazard levels in excess of 3A shall have the above cable

requirements with further and adequate mechanical protection.

4.1.3 Cable connectors

4.1.3.1 All systems operating in unrestricted locations in which cable connectors are

accessible require the use of a tool for disconnection if hazard level 1 can be exceeded.

4.1.3.2 All systems operating in restricted locations in which cable connectors are

accessible require the use of a tool for disconnection if hazard level 3A can be exceeded.

4.1.3.3 All systems operating in controlled locations in which cable connectors are

accessible require the use of a tool for disconnection if hazard level k × 3A can be exceeded.

4.1.3.4 The positioning of the connector in a way that prevents human access to a higher

hazard level is an acceptable feature to ensure that these requirements are met.

4.1.4 Automatic power reduction

Automatic power reduction may be used to control the hazard levels defined in 3.6 to 3.11.

4.2 Labelling

4.2.1 Optical fibre cables should carry appropriate markings to distinguish them from cables

containing other services, e.g. electricity.

4.2.2 Sleeving, a tag or a tape shall be associated with each optical connector if the hazard

level at the location is in excess of hazard level 1. The sleeving, tag or tape shall be coloured

yellow, with the warning label according to figure 14 of IEC 60825-1 and the hazard level

number incorporated in the explanatory label according to figure 15 of IEC 60825-1, both

labels appropriately reduced in size.

– 10 – 60825-2 IEC:2000(E)

4.2.3 Groups of connectors such as patch panels may be labelled as a group, with just a

single clearly visible location hazard label rather than having each connector individually

labelled. If a group of connectors is enclosed within a box, a label shall be clearly visible both

before and after the access panel is opened, which may require the use of more than one label.

4.3 Provision of information

Manufacturers of ready-for-use optical fibre communication systems and manufacturers of

ready-for-use subassemblies shall provide the operating organization with the following

information, where applicable:

a) an adequate description of the engineering design features incorporated into the product

to prevent access to hazardous levels of optical radiation;

b) adequate instructions for proper assembly, maintenance and safe use, including clear

warnings concerning the precautions to be taken in order to avoid possible exposure to

hazardous radiation;

c) a statement, in SI units, of the power propagating in the fibre at all locations in the system,

together with the pulse duration and pulse repetition frequency, or the maximum

modulation frequency. The cumulative measurement uncertainty and any expected

variation in the measured quantities at any time after manufacture shall also be provided;

d) a statement of the range of operating wavelength(s) within the optical fibre communication

system at the time of manufacture and under specified conditions as well as the range of

emission wavelengths expected during normal operation at any time after manufacture;

e) the reaction time of any automatic power reduction system;

f) legible reproductions (in appropriate colours or in black and white) of all the labels and

hazard warnings to be displayed at locations within an optical fibre communication system

or subassembly, as appropriate;

g) a clear indication of all locations of apertures and fibre connectors;

h) a listing of controls, adjustments and procedures for operation and maintenance, including

a warning, where appropriate;

i) advice on safe operating procedures, and warnings concerning known malpractices,

malfunctions and hazardous failure modes. Where maintenance procedures are detailed,

they shall, wherever possible, include explicit instructions on the safe procedures to be

followed;

j) where installation or servicing requires that an automatic power reduction system is

overridden, information to enable the operating organization to specify a safe system of

work at such times, and a safe procedure for the reinstating and safe testing of the auto-

matic power reduction system;

k) any other information relevant to the safe use of the optical fibre communication system or

subassembly, as appropriate.

4.4 Assessment of hazard level

4.4.1 The hazard level is determined by the measurement of optical radiation accessible in

any reasonably foreseeable event. The methods for the determination of compliance with the

specified radiation limit values are the same as those described for classification in

IEC 60825-1. Measurements need to be taken under the appropriate conditions, e.g.

simulated fibre cable break, and shall be based on the relevant clauses in IEC 60825-1. The

assessment of the hazard level shall take place:

– 1 s after the reasonably foreseeable event for unrestricted locations, unless measurement

at a later time would result in a larger exposure;

– 3 s after the reasonably foreseeable event for restricted and controlled locations, unless

measurement at a later time would result in a larger exposure.

©

60825-2 IEC:2000(E) – 11 –

In circumstances where it is difficult to carry out direct measurements, an assessment of

hazard level based on calculations may be acceptable. For example, the knowledge of the

laser power and fibre attenuation may allow an assessment of the hazard at any particular

location.

4.4.2 Additionally, for locations with a hazard level lower than that which would be assigned

if no automatic power reduction were employed, the irradiance or radiant exposure during the

maximum time to reach the lower hazard level specified in 4.4.1 (1 s for unrestricted, 3 s for

restricted or controlled locations) shall not exceed the irradiance or radiant exposure limits

(MPE) for the corresponding conditions listed in table 1. The measurement aperture for the

MPE at 3 s, for wavelengths greater than or equal to 1 400 nm, shall be 3,5 mm for this

subclause only.

The restart of such systems shall not take place for another 100 s minus the reduction time in

seconds, unless the continuity of the link can be assured.

NOTE The 100 s interval is the time base for classification of invisible infra-red radiation for unintentional viewing.

Table 1 – Assessment of hazard level during shutdown time

for systems employing automatic power reduction (see 4.4.2)

Location type Maximum time to reach Limiting aperture Distance

lower hazard level from aperture

400 nm to Other

to fibre

(Exposure time basis

1 400 nm wavelengths

for 4.4.2) wavelengths

Unrestricted 1 s 7 mm 1 mm 100 mm

Restricted 3 s 7 mm 3,5 mm 100 mm

Controlled 3 s 7 mm 3,5 mm 250 mm

4.4.3 Tests shall be carried out under reasonably foreseeable fault conditions.

In some complex systems (e.g. where the optical output is dependent on the integrity of other

components and the performance of circuit design and software), it may be necessary to use

other recognized methods for hazard/safety assessment (see annex C).

4.4.4 For optical fibre communication systems with automatic power reduction, the hazard

level will be determined by the normal level of power in the fibre and the speed of the

automatic power reduction. The speed of power reduction required to obtain a specific hazard

level can be determined from the AEL tables in IEC 60825-1. For example, a relatively high

optical power level on a fibre together with a high speed automatic power reduction could

have the same hazard level as a relatively low optical power on the fibre together with a

slower automatic power reduction.

4.5 Requirements for installation

4.5.1 Optical fibre communication systems operating in unrestricted locations shall have a

hazard level of 1, 2 or 3A.

4.5.2 Optical fibre communication systems operating in restricted locations shall have

a hazard level of 1, 2, 3A or k × 3A.

4.5.3 Optical fibre communication systems operating in controlled locations shall have a

hazard level of 1, 2, 3A, k × 3A or 3B.

4.5.4 No optical fibre communication system shall have locations with a hazard level of 4.

– 12 – 60825-2 IEC:2000(E)

4.6 Requirements for restart pulses

Restart pulses used after automatic power shutdown shall be limited to hazard level 1 in

unrestricted locations, hazard level 3A in restricted locations and hazard level k × 3A in

controlled locations.

5 Guidance for service and maintenance

5.1 Tests and measurements

5.1.1 Tests, measurements and operations in cable ducts and switching centres should be

considered as service or maintenance operations. Wherever possible, diagnostic tests should

be carried out in such a way as not to increase the hazard level at any location. It may be

necessary to have administrative controls which, in some cases, may involve a permit to work

system. When connecting test equipment, due regard should be given to establishing the

actual power levels introduced into the system in assessing the hazard.

5.1.2 There shall be clearly defined conditions under which automatic power reduction

facilities may be overridden.

When overridden, the hazard level shall be reassessed by the operating organization and the

appropriate safety precautions described in 5.2 and its associated subclauses shall be taken

as appropriate to the reassessed hazard level.

5.1.3 Any viewing optics for fibre examination and splicing should reduce exposure to below

the relevant maximum permissible exposure (MPE) and should be approved for use by the

operating organization.

5.1.4 Wherever reasonably practical, servicing, maintenance and repair should be carried

out with no power propagating in the fibre, otherwise the system should be operated at the

lowest power consistent with the need.

5.1.5 The system operating organization shall establish that work practices prevent human

exposure to radiation in excess of the relevant MPE.

5.2 Safety precautions

5.2.1 General remarks

5.2.1.1 In locations where, during service or maintenance, radiation levels in excess of

class 3A may be encountered (e.g. during switching, in controlled locations), appropriate eye

protection should be provided.

5.2.1.2 Before working on any optical fibre cable or system, the staff should check the

operating status and hazard level. In the case of systems that are installed and activated,

this will be indicated by the appropriate hazard level warning labels. During installation, these

labels may not have been provided yet and, in their absence, precautions appropriate to the

classification of any test equipment containing optical sources connected to the fibre should

be used.

5.2.1.3 During the installation or testing of an optical fibre cable or network, only test

equipment of laser class 1, 2 or 3A should be used.

If, in a particular instance, it is essential to use test equipment of a higher class, the

accessible fibre ends and connectors at all locations should be secured and labelled with

the appropriate hazard level before testing proceeds.

©

60825-2 IEC:2000(E) – 13 –

5.2.1.4 Entry points to controlled areas with a hazard level of k × 3A and above shall have:

– a sign bearing the warning label according to figure 14 in IEC 60825-1 and indicating the

hazard level number incorporated in the explanatory label according to figure 15 of

IEC 60825-1;

– a sign limiting access to authorized persons only and explaining the existence of a

potential hazard.

5.2.1.5 Each person engaged in the installation or service of an optical fibre cable or system

should:

– observe all rules, procedures and practices established for the safe operation of optical

fibre communication systems;

– immediately notify the supervisor of conditions or practices that have the potential to

cause personnel injury or property damage;

– immediately report to the supervisor any known or suspected abnormal exposure to optical

radiation.

5.2.2 Precautions in locations with hazard levels greater than hazard level 2

5.2.2.1 Only the staff who have attended an optical fibre safety training course should be

permitted to work on optical fibre systems in a location with hazard levels k × 3A and 3B.

5.2.2.2 The staff should not view directly any energized fibre end or connector end at a

location with a hazard level 3A, k × 3A or 3B. Only viewing aids with appropriate attenuation

should be used at a location with a hazard level 3A, k × 3A or 3B, under all circumstances.

5.2.2.3 Where possible, optical transmission or test equipment should be shut down, put into

a low-power state or disconnected before any work is done on exposed fibres, connectors etc.

In that case, unintentional switching on should be prevented by a remote control switch or

another suitable method. The status of the line (power on or off) should be clearly indicated.

5.2.2.4 The staff should ensure that optical fibre communication systems and test equipment

in locations with a hazard level k × 3A or 3B are properly operated and controlled so as to

protect unauthorized personnel.

5.2.3 Training programme

The employer of staff installing or maintaining optical fibre communication systems should

establish and maintain an adequate programme for the control of hazards. Safety and training

programmes should be instituted for staff working on fibres or communication systems with a

hazard level of k × 3A or 3B. Such programmes should be directed by individuals competent

in the field of laser and optical fibre communication system safety. The programmes should

provide, as a minimum:

– background information on optical fibre communication systems;

– safety information concerning the laser classification system and hazard levels;

– guidance on the safe use of laser optical fibre communication systems, and adequacy of

safety practices.

– 14 – 60825-2 IEC:2000(E)

Annex A

(informative)

Rationale

The safety of laser products, equipment classification, requirements and user's guide are

covered by IEC 60825-1. This part is primarily aimed at self-contained products which are

under effective local control. An optical fibre communication system would be safe under

normal operating conditions because the optical radiation is totally enclosed under intended

operation. However, because of the extended nature of these systems (where optical power,

under certain conditions, may be accessible many kilometres from the optical source), the

precautions to minimize the hazard will be different from those concerning more conventional

laser sources which are normally under local operator control. (It should be noted that many

optical fibre communication systems contain LEDs, which are included in the scope of

IEC 60825-1.)

The potential hazard of an optical fibre communication system depends on the likelihood of

the protective housing being breached (e.g. a disconnected fibre connector or a broken cable)

and on the nature of the optical radiation that might subsequently become accessible. The

engineering requirements and user precautions that are required to minimize the hazard are

specified in this part of IEC 60825.

Each accessible location within an optical fibre communication system is allocated, by the

system operating organization or his delegate, a hazard level which gives a guide as to the

potential hazard if optical radiation becomes accessible. These hazard levels are described

as hazard levels 1 to 4, in a fashion similar to the classification procedure described in

IEC 60825-1. In addition, a distinction is made between the higher and lower power ranges

within the 3B class (see later in this annex for further explanation).

Where operating organizations subcontract parts of a system to installers or manufacturers of

subsystems, the duties of all parties concerned should be clearly regulated in an agreement.

In summary, the primary differences between IEC 60825-1 and this part 2 are as follows:

– a whole optical fibre communication system will not be classified in the same way as

required by IEC 60825-1. This is because, under intended operation, the optical radiation

is totally enclosed, and it can be argued that a rigorous interpretation of IEC 60825-1

would give a class 1 allocation to all systems, which may not reflect the potential hazard

accurately. However, if the emitter can be operated separately, it must be classified

according to IEC 60825-1;

– each accessible location in the extended enclosed optical transmission system will be

designated by a hazard level on similar procedures as those for classification in

IEC 60825-1, but this level will be based not on accessible radiation but on radiation that

could become accessible under reasonably foreseeable circumstances (e.g. a fibre cable

break, a disconnected fibre connector etc.);

– the nature of the safety precautions required for any particular hazard level will depend on

the type of location, i.e. domestic premises, industrial areas where there would be limited

access, and switching centres where there would be controlled access. For example, it is

specified that, in the home, a disconnected fibre connector should only be able to emit

radiation corresponding to class 1, whilst, in controlled areas, it could be higher;

–the k × 3A hazard level was introduced to reflect more realistically the true hazard

associated with viewing optical fibre components. The longer measurement distance

reflects more common behavioural practices. The shorter time base reflects the fact that it

is not normal human behaviour to fixate on a small spot for extended periods of time.

Hence, the k × 3A level allows for increased power levels in optical fibre systems without

increasing the risk of ocular damage under reasonably foreseeable circumstances. The

value of "k" should not be calculated. The designation k × 3A is only used to indicate that

hazard level k × 3A is higher than hazard level 3A.

©

60825-2 IEC:2000(E) – 15 –

Annex B

(normative)

Summary of engineering requirements at locations in

optical fibre communication system

Hazard level Location type

Unrestricted Restricted Controlled

1 No requirements No requirements No requirements

2 1) Labelling, and Labelling Labelling

2) Class 1* from

connector, or connector

requires tool

3A 1) Labelling, and Labelling Labelling

2) Class 1* from connector

or connector requires tool

Not permitted ** 1) Labelling, and Labelling

k × 3A

2) Protected cables,

and

3) Class 3A* from

connector, or connector

requires tool

3B Not permitted ** Not permitted** 1) Labelling,

and

2) Protected cables,

and

3) k × 3A* from connector

or connector requires tool

4 Not permitted ** Not permitted ** Not permitted**

* To be achieved by mechanical design of connector, automatic power reduction or other suitable means.

** See 4.4.3. Where systems employ power levels of class 3A or more, protection systems such as APR may be

used to obtain the acceptable hazard level for the particular location type.

– 16 – 60825-2 IEC:2000(E)

Annex C

(informative)

Methods of hazard/safety analysis

Some methods of hazard/safety analysis are as follows:

a) preliminary hazard analysis (PHA) including circuit analysis. This method may be used in

its own right, but is an essential first stage in the application of other methods of

hazard/safety assessment;

b) failure modes and effects analysis (FMEA);

*

c) failure modes, effects and criticality analysis (FMECA) (see IEC 60812 [1] );

d) fault tree analysis (FTA);

e) event tree analysis;

f) hazards and operability studies (HAZOPS);

g) cause-consequence analysis.

Appropriate testing should be implemented to supplement the analysis whenever necessary.

The method of analysis and any assumptions made in the performance of the analysis are to

be stated by the manufacturer.

___________

*

Figures in square brackets refer to the bibliography.

©

60825-2 IEC:2000(E) – 17 –

Annex D

(informative)

Application notes for the safe use

of optical fibre communication systems

D.1 Introduction

This annex provides guidance on the application of this standard to specific practical

situations. It applie

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...