IEC 60068-2-27:2008

(Main)Environmental testing - Part 2-27: Tests - Test Ea and guidance: Shock

Environmental testing - Part 2-27: Tests - Test Ea and guidance: Shock

IEC 60068-2-27:2008 provides a standard procedure for determining the ability of a specimen to withstand specified severities of non-repetitive or repetitive shocks. The purpose of this test is to reveal mechanical weakness and/or degradation in specified performances, or accumulated damage or degradation caused by shocks. In conjunction with the relevant specification, this may be used in some cases to determine the structural integrity of specimens or as a means of quality control. This test is primarily intended for unpackaged specimens and for items in their transport case when the latter may be considered to be part of the specimen. If an item is to be tested unpackaged, it is referred to as a test specimen. However, if the item is packaged, then the item itself is referred to as a product and the item and its packaging together are referred to as a test specimen. When used in conjunction with IEC 60068-2-47, this standard may be used for testing packaged products. This possibility was included in the 2005 version of IEC 60068-2-47 for the first time. This standard is written in terms of prescribed pulse shapes. Guidance for the selection and application of these pulses is given in Annex A and the characteristics of the different pulse shapes are discussed in Annex B. Wherever possible, the test severity and the shape of the shock pulse applied to the specimen should be such as to reproduce the effects of the actual transport or operational environment to which the specimen will be subjected, or to satisfy the design requirements if the object of the test is to assess structural integrity (see Clauses A.2 and A.4). For the purposes of this test, the specimen is always mounted to the fixture or the table of the shock testing machine during testing. The major changes with regard to the previous edition concern:

- the merging of IEC 60068-2-29 into this edition of IEC 60068-2-27; Part 2-29 will be withdrawn as soon as this edition is published;

- the introduction of soft packaged specimens as defined in the IEC ad hoc working group document agreed in Stockholm:2000.

Essais d'environnement - Partie 2: Essais - Essai Ea et guide: Chocs

IEC 60068-2-27:2008 fournit un mode opératoire normalisé pour déterminer l'aptitude d'un spécimen à supporter des chocs répétitifs ou non répétitifs de sévérités spécifiées. Le but de cet essai est de mettre en évidence une défaillance mécanique et/ou une dégradation des performances spécifiées, ou les dommages ou dégradations cumulés dus aux chocs. Il peut aussi être utilisé dans certains cas, conjointement à la spécification particulière, pour déterminer la robustesse de structure des spécimens ou comme essai d'assurance de la qualité. Cet essai est en premier lieu destiné aux spécimens non emballés et aux éléments placés dans leur coffret de transport lorsque ce dernier peut être considéré comme faisant partie du spécimen. Si un élément est à soumettre aux essais en étant non emballé, il est désigné comme un spécimen d'essai. Cependant, si l'élément est emballé, alors il est lui-même désigné comme produit et l'élément et son emballage sont désignés comme spécimen d'essai. Lorsque cette norme est utilisée conjointement avec la CEI 60068-2-47, elle peut être utilisée pour l'essai des produits emballés. Cette possibilité a été incluse dans la version de 2005 pour la première fois. La rédaction de cette norme s'appuie sur des formes d'impulsions prescrites. Un guide pour la sélection et l'application de ces impulsions est donné à l'Annexe A et les caractéristiques des différentes formes d'impulsion sont exposées à l'Annexe B. Chaque fois que possible, il convient que la sévérité d'essai et la forme de l'impulsion de choc appliquée au spécimen soient telles qu'elles reproduisent les effets du transport ou des conditions d'environnement réels auxquels le spécimen sera soumis ou qu'elles correspondent aux exigences de la conception si l'objet de l'essai est d'estimer la robustesse de structure (voir Articles A.2 et A.4). Pour les besoins de cet essai, le spécimen est toujours monté sur le bâti de fixation ou sur la table de la machine d'essai au choc pendant l'épreuve. Les modifications principales par rapport à l'édition précédente sont les suivantes:

- la fusion de la CEI 60068-2-29 dans la présente édition de la CEI 60068-2-27; la Partie 2-29 sera supprimée dès que cette édition sera publiée;

- l'introduction de spécimens dans emballages mous comme définis dans le document du groupe de travail ad hoc de la CEI conclu à Stockholm en 2000.

General Information

- Status

- Published

- Publication Date

- 26-Feb-2008

- Technical Committee

- TC 104 - Environmental conditions, classification and methods of test

- Drafting Committee

- MT 17 - TC 104/MT 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Feb-2008

- Completion Date

- 15-Mar-2008

Overview

IEC 60068-2-27:2008 is a globally recognized standard published by the International Electrotechnical Commission (IEC) that specifies test procedures for environmental shock testing. This part of IEC 60068 focuses on Test Ea and provides guidance on evaluating the ability of electrical and electronic components-referred to as specimens-to withstand shocks that occur during handling, transportation, and operation. The aim is to identify mechanical weaknesses, potential damage, or performance degradation caused by non-repetitive or repetitive shock events.

This standard applies particularly to unpackaged specimens and products including their transport packaging when considered part of the test specimen. It complements related standards such as IEC 60068-2-47, which addresses mounting for vibration and impact testing, and offers a framework for selecting standardized shock pulses designed to simulate real-world conditions. The standard includes detailed pulse shape definitions and guidance for proper selection and implementation.

Key Topics

Purpose and Scope

IEC 60068-2-27 defines procedures for shock testing designed to reveal structural integrity issues and degradation in electrical/electronic specimens subjected to mechanical shocks. Tests assess the specimen’s resistance to sudden acceleration forces, mimicking transport or operational shock events.Test Specimen Definition

The standard distinguishes between unpackaged test specimens and packaged products with their transport packs, allowing testing either way based on the practical scenario.Shock Pulse Shapes and Severities

Prescribed shock pulse shapes, such as half-sine, trapezoidal, and saw-tooth pulses, are standardized within the document. Annexes provide in-depth guidance on pulse selection to replicate actual environmental or operational conditions and illustrate typical severities used across industries.Test Setup and Mounting

Specimens are mounted on shock test machines or fixtures during testing to ensure reproducibility and accurate simulation of shock effects. The standard references IEC 60068-2-47 for mounting methods to ensure consistency and reliability.Integration with Other Standards

It merges the earlier IEC 60068-2-29 shock test protocols and introduces provisions for soft-packaged specimens following international working group recommendations.

Applications

IEC 60068-2-27:2008 shock testing is widely applied in industries dealing with electrotechnical products, where mechanical shock resistance is critical for:

Transportation Testing

Ensuring products maintain structural integrity and functionality despite shocks encountered during shipping, handling, and unloading processes.Quality Control

Verifying that design specifications and manufacturing quality standards are met for shock resistance, reducing failure rates in the field.Design Validation

Testing prototypes and final products to assess robustness under expected operational shock conditions, helping engineers refine design durability.Packaging Evaluation

When used alongside IEC 60068-2-47, it helps verify the effectiveness of packaging in protecting products from shock during transit.Safety and Compliance

Supporting compliance with international regulatory frameworks by providing a benchmark shock resistance standard, which enhances product reliability and consumer safety.

Related Standards

IEC 60068-1: Environmental Testing – General and Guidance

Provides foundational principles applicable to all test procedures in the IEC 60068 series, including shock tests.IEC 60068-2-47: Tests – Mounting of Specimens

Specifies mounting methods for specimens during dynamic tests such as shock and vibration to ensure reproducibility and valid results.IEC 60068-2-55: Tests – Test Ee and Guidance: Bounce

Addresses bounce tests which are complementary to shock tests in simulating mechanical stress.IEC 60721 Series: Classification of Environmental Conditions

Provides classifications for different environmental parameters and severities relevant to storage, transportation, and ground vehicle installations, thus informing the test severities in IEC 60068-2-27.

Conclusion

IEC 60068-2-27:2008 is a fundamental standard for environmental shock testing of electrotechnical products. Its rigorous test methods, detailed guidance on pulse selection, and integration with related standards make it essential for manufacturers, quality engineers, and design teams aiming to ensure product durability against mechanical shocks. Adhering to this standard helps enhance product reliability, optimize packaging, and meet international quality and safety expectations.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 60068-2-27:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 2-27: Tests - Test Ea and guidance: Shock". This standard covers: IEC 60068-2-27:2008 provides a standard procedure for determining the ability of a specimen to withstand specified severities of non-repetitive or repetitive shocks. The purpose of this test is to reveal mechanical weakness and/or degradation in specified performances, or accumulated damage or degradation caused by shocks. In conjunction with the relevant specification, this may be used in some cases to determine the structural integrity of specimens or as a means of quality control. This test is primarily intended for unpackaged specimens and for items in their transport case when the latter may be considered to be part of the specimen. If an item is to be tested unpackaged, it is referred to as a test specimen. However, if the item is packaged, then the item itself is referred to as a product and the item and its packaging together are referred to as a test specimen. When used in conjunction with IEC 60068-2-47, this standard may be used for testing packaged products. This possibility was included in the 2005 version of IEC 60068-2-47 for the first time. This standard is written in terms of prescribed pulse shapes. Guidance for the selection and application of these pulses is given in Annex A and the characteristics of the different pulse shapes are discussed in Annex B. Wherever possible, the test severity and the shape of the shock pulse applied to the specimen should be such as to reproduce the effects of the actual transport or operational environment to which the specimen will be subjected, or to satisfy the design requirements if the object of the test is to assess structural integrity (see Clauses A.2 and A.4). For the purposes of this test, the specimen is always mounted to the fixture or the table of the shock testing machine during testing. The major changes with regard to the previous edition concern: - the merging of IEC 60068-2-29 into this edition of IEC 60068-2-27; Part 2-29 will be withdrawn as soon as this edition is published; - the introduction of soft packaged specimens as defined in the IEC ad hoc working group document agreed in Stockholm:2000.

IEC 60068-2-27:2008 provides a standard procedure for determining the ability of a specimen to withstand specified severities of non-repetitive or repetitive shocks. The purpose of this test is to reveal mechanical weakness and/or degradation in specified performances, or accumulated damage or degradation caused by shocks. In conjunction with the relevant specification, this may be used in some cases to determine the structural integrity of specimens or as a means of quality control. This test is primarily intended for unpackaged specimens and for items in their transport case when the latter may be considered to be part of the specimen. If an item is to be tested unpackaged, it is referred to as a test specimen. However, if the item is packaged, then the item itself is referred to as a product and the item and its packaging together are referred to as a test specimen. When used in conjunction with IEC 60068-2-47, this standard may be used for testing packaged products. This possibility was included in the 2005 version of IEC 60068-2-47 for the first time. This standard is written in terms of prescribed pulse shapes. Guidance for the selection and application of these pulses is given in Annex A and the characteristics of the different pulse shapes are discussed in Annex B. Wherever possible, the test severity and the shape of the shock pulse applied to the specimen should be such as to reproduce the effects of the actual transport or operational environment to which the specimen will be subjected, or to satisfy the design requirements if the object of the test is to assess structural integrity (see Clauses A.2 and A.4). For the purposes of this test, the specimen is always mounted to the fixture or the table of the shock testing machine during testing. The major changes with regard to the previous edition concern: - the merging of IEC 60068-2-29 into this edition of IEC 60068-2-27; Part 2-29 will be withdrawn as soon as this edition is published; - the introduction of soft packaged specimens as defined in the IEC ad hoc working group document agreed in Stockholm:2000.

IEC 60068-2-27:2008 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60068-2-27:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60068-2-27

Edition 4.0 2008-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Environmental testing –

Part 2-27: Tests – Test Ea and guidance: Shock

Essais d'environnement –

Partie 2-27: Essais – Essai Ea et guide: Chocs

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60068-2-27

Edition 4.0 2008-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Environmental testing –

Part 2-27: Tests – Test Ea and guidance: Shock

Essais d'environnement –

Partie 2-27: Essais – Essai Ea et guide: Chocs

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

W

CODE PRIX

ICS 19.040 ISBN 2-8318-9628-2

– 2 – 60068-2-27 © IEC:2008

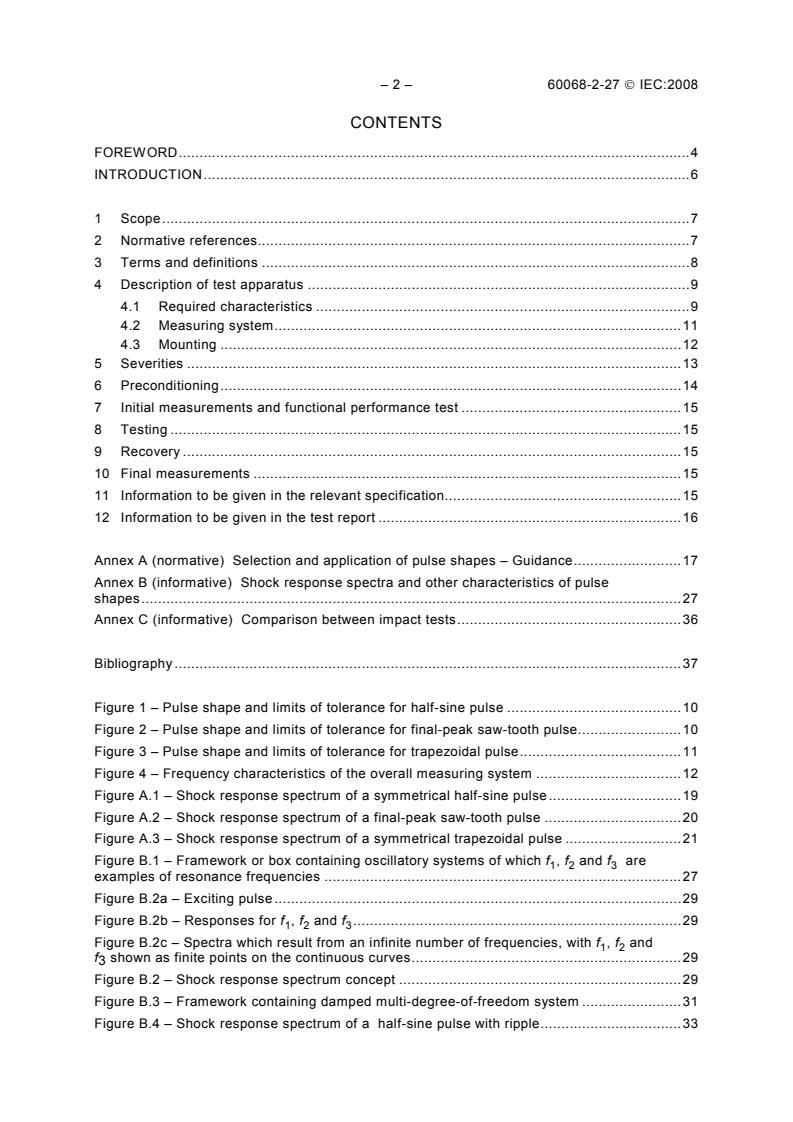

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references.7

3 Terms and definitions .8

4 Description of test apparatus .9

4.1 Required characteristics .9

4.2 Measuring system.11

4.3 Mounting .12

5 Severities .13

6 Preconditioning.14

7 Initial measurements and functional performance test .15

8 Testing .15

9 Recovery .15

10 Final measurements .15

11 Information to be given in the relevant specification.15

12 Information to be given in the test report .16

Annex A (normative) Selection and application of pulse shapes – Guidance.17

Annex B (informative) Shock response spectra and other characteristics of pulse

shapes.27

Annex C (informative) Comparison between impact tests.36

Bibliography .37

Figure 1 – Pulse shape and limits of tolerance for half-sine pulse .10

Figure 2 – Pulse shape and limits of tolerance for final-peak saw-tooth pulse.10

Figure 3 – Pulse shape and limits of tolerance for trapezoidal pulse.11

Figure 4 – Frequency characteristics of the overall measuring system .12

Figure A.1 – Shock response spectrum of a symmetrical half-sine pulse.19

Figure A.2 – Shock response spectrum of a final-peak saw-tooth pulse .20

Figure A.3 – Shock response spectrum of a symmetrical trapezoidal pulse .21

Figure B.1 – Framework or box containing oscillatory systems of which f , f and f are

1 2 3

examples of resonance frequencies .27

Figure B.2a – Exciting pulse.29

Figure B.2b – Responses for f , f and f .29

1 2 3

Figure B.2c – Spectra which result from an infinite number of frequencies, with f , f and

1 2

f shown as finite points on the continuous curves.29

Figure B.2 – Shock response spectrum concept .29

Figure B.3 – Framework containing damped multi-degree-of-freedom system .31

Figure B.4 – Shock response spectrum of a half-sine pulse with ripple.33

60068-2-27 © IEC:2008 – 3 –

Figure B.5 – Spectrum of a final-peak saw-tooth 300 m/s , 18 ms pulse compared with

the spectra of 200 m/s half-sine pulses with durations between 3 ms and 20 ms .35

Table 1 – Severities for shock testing .14

Table A.1 – Examples of pulse shapes and test severities typically employed for various

applications.23

Table A.2 – Examples of severities typically employed for various applications .24

– 4 – 60068-2-27 © IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-27: Tests – Test Ea and guidance: Shock

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-27 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test

This fourth edition cancels and replaces the third edition, published in 1987, and includes the

merging of IEC 60068-2-29, second edition (1987). It constitutes a technical revision.

The major changes with regard to the previous edition concern:

− the merging of IEC 60068-2-29 into this edition of IEC 60068-2-27; Part 2-29 will be

withdrawn as soon as this edition is published;

− the introduction of soft packaged specimens as defined in the IEC ad hoc working group

document agreed in Stockholm:2000.

60068-2-27 © IEC:2008 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

104/448/FDIS 104/457/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

It has the status of a basic safety publication in accordance with IEC Guide 104.

This standard is to be used in conjunction with IEC 60068-1.

A list of all the parts in the IEC 60068 series, under the general title Environmental testing, can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60068-2-27 © IEC:2008

INTRODUCTION

This part of IEC 60068 deals with components, equipments and other electrotechnical

products, hereinafter referred to as “specimens”, which, during transportation, storage and

handling, or in use, may be subjected either to conditions involving relatively infrequent non-

repetitive or repetitive shocks. The shock test may also be used as a means of establishing the

satisfactory design of a specimen in so far as its structural integrity is concerned and as a

means of quality control. It consists of subjecting a specimen either to non-repetitive or

repetitive shocks of standard pulse shapes with specified peak acceleration and duration.

Specification writers will find a list of details to be considered for inclusion in specifications in

Clause 11. The necessary guidance is given in Annex A.

60068-2-27 © IEC:2008 – 7 –

ENVIRONMENTAL TESTING –

Part 2-27: Tests – Test Ea and guidance: Shock

1 Scope

This part of IEC 60068 provides a standard procedure for determining the ability of a specimen

to withstand specified severities of non-repetitive or repetitive shocks.

The purpose of this test is to reveal mechanical weakness and/or degradation in specified

performances, or accumulated damage or degradation caused by shocks. In conjunction with

the relevant specification, this may be used in some cases to determine the structural integrity

of specimens or as a means of quality control (see Clause A.2).

This test is primarily intended for unpackaged specimens and for items in their transport case

when the latter may be considered to be part of the specimen. If an item is to be tested

unpackaged, it is referred to as a test specimen. However, if the item is packaged, then the

item itself is referred to as a product and the item and its packaging together are referred to as

a test specimen. When used in conjunction with IEC 60068-2-47, this standard may be used for

testing packaged products. This possibility was included in the 2005 version of IEC 60068-2-47

for the first time.

This standard is written in terms of prescribed pulse shapes. Guidance for the selection and

application of these pulses is given in Annex A and the characteristics of the different pulse

shapes are discussed in Annex B.

Wherever possible, the test severity and the shape of the shock pulse applied to the specimen

should be such as to reproduce the effects of the actual transport or operational environment

to which the specimen will be subjected, or to satisfy the design requirements if the object of

the test is to assess structural integrity (see Clauses A.2 and A.4).

For the purposes of this test, the specimen is always mounted to the fixture or the table of the

shock testing machine during testing.

NOTE The term “shock testing machine” is used throughout this standard, but other means of applying pulse

shapes are not excluded.

One of the responsibilities of a technical committee is, wherever applicable, to make use of

basic safety publications in the preparation of its publications.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60068-1, Environmental testing – Part 1: General and guidance

IEC 60068-2-47:2005, Environmental testing – Part 2-47: Tests – Mounting of specimens for

vibration, impact and similar dynamic tests

IEC 60068-2-55, Environmental testing – Part 2-55: Tests – Test Ee and guidance: Bounce

– 8 – 60068-2-27 © IEC:2008

IEC 60721-3-1, Classification of environmental conditions – Part 3: Classification of groups of

environmental parameters and their severities – Section 1: Storage

IEC 60721-3-5, Classification of environmental conditions – Part 3: Classification of groups of

environmental parameters and their severities – Section 5: Ground vehicle installations

Guide 104, The preparation of safety publications and the use of basic safety publications and

group safety publications

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

[1]

NOTE The terms used are, for the most part, defined in ISO 2041 or IEC 60068-1. The following additional

terms and definitions are also applicable for the purposes of this standard.

3.1

check point

point located on the fixture, on the table surface of the shock-testing machine or on the

specimen as close as possible to the fixing point, and in any case rigidly connected to it

NOTE 1 A number of check points are used as a means of ensuring that the test requirements are satisfied.

NOTE 2 If more than four fixing points exist, the relevant specification should state the number of fixing points to

be used as check points.

NOTE 3 In special cases, for example, for large or complex specimens, the check points will be prescribed by the

relevant specification if not close to the fixing points.

NOTE 4 Where a large number of small specimens are mounted on one fixture, or in the case of a small specimen

where there are a number of fixing points, a single check point (that is the reference point) may be selected for the

derivation of the control signal. This signal is then related to the fixture rather than to the fixing points of the

specimen(s). This procedure is only valid when the lowest resonance frequency of the loaded fixture is well above

the upper frequency of the test.

3.2

fixing point

part of the specimen in contact with the fixture or the table of the shock-testing machine at a

point where the specimen is normally fastened in service

NOTE If a part of the real mounting structure is used as the fixture, the fixing points are taken as those of the

mounting structure and not of the specimen.

3.3

g

n

standard acceleration due to the earth's gravity, which itself varies with altitude and

geographical latitude

NOTE For the purposes of this standard, the value of g is rounded up to the nearest unity, that is 10 m/s .

n

3.4

repetition rate

number of shocks per second

3.5

shock severity

combination of the peak acceleration, the duration of the nominal pulse and the number of

shocks

___________

Figures in square brackets refer to the bibliography.

60068-2-27 © IEC:2008 – 9 –

3.6

velocity change

absolute value of the sudden change of velocity resulting from the application of the specified

acceleration

NOTE The change of velocity is normally considered sudden if it takes place in a time that is short compared with

the fundamental period of the test specimen.

4 Description of test apparatus

4.1 Required characteristics

When the shock-testing machine with or without fixture is loaded with the specimen, the

waveform measured at the check point(s) shall consist of a pulse approximating to one of the

nominal acceleration against time curves given by the broken lines in Figures 1, 2 and 3.

4.1.1 Basic pulse shapes

Three types of pulse, namely the half-sine pulse, the final-peak saw-tooth pulse and the

trapezoidal pulse, are included in this standard. The choice of pulse shape depends on a

number of factors, and the difficulties inherent in making such a choice preclude a preferred

order being given in this standard (see Clause A.3).

The specified basic pulse shapes are given below (see Clause A.3):

− half-sine: one half-cycle of a sine wave, as shown in Figure 1;

− final-peak saw-tooth: asymmetrical triangle with short fall time, as shown in Figure 2;

− trapezoidal: symmetrical trapezoid with short rise and fall times, as shown in Figure 3.

The true value of the actual pulse shall be within the limits of tolerance shown by the solid lines

in the relevant figure.

NOTE Where it is not practicable to achieve a pulse shape falling within the specified tolerance, the relevant

specification should state the alternative procedure to be applied (see Clause A.5).

– 10 – 60068-2-27 © IEC:2008

Integration time

1,5 D

1,2 A

A

0,8 A

+0,2 A

0,2 A 0,2 A

0 0

–0,2 A –0,2 A

0,4 D 0,1 D

D D

2,5 D 2,5 D

2,4 D = T

6 D = T

IEC 303/08

Key (applicable for all three Figures 1 to 3)

– – – nominal pulse A = peak acceleration of nominal pulse

limits of tolerance T = minimum time during which the pulse shall be monitored for

shocks produced using a conventional shock-testing machine

D = duration of nominal pulse T = minimum time during which the pulse shall be monitored for

shocks produced using a vibration generator

Figure 1 – Pulse shape and limits of tolerance for half-sine pulse

Integration time

1,5 D

1,2 A

A

0,8 A

0,2 A 0,2 A

0 0

–0,2 A –0,2 A

0,4 D 0,1 D

0,1 D

D D

2,5 D 2,5 D

2,4 D = T

6 D = T

IEC 304/08

Figure 2 – Pulse shape and limits of tolerance for final-peak saw-tooth pulse

60068-2-27 © IEC:2008 – 11 –

Integration time

1,5 D

0,1 D 0,1 D

1,2 A

A

0,8 A

0,4 A

0,4 A

0,2 A 0,2 A

0 0

–0,2 A –0,2 A

0,4 D D D

2,5 D 2,5 D

2,4 D = T

6 D = T

IEC 305/08

Figure 3 – Pulse shape and limits of tolerance for trapezoidal pulse

4.1.2 Repetition rate

The repetition rate shall be such that the relative motion within the specimen between shocks

shall be substantially zero and the value of acceleration at the check point shall be within the

limits shown in Figure 1 (see Clause A.7).

NOTE A formula for evaluation of repetition rate is shown in Clause A.7.

4.1.3 Velocity change tolerances

For all pulse shapes, the actual velocity change shall be within ±15 % of the value

corresponding to the nominal pulse.

Where the velocity change is determined by integration of the actual acceleration pulse, this

shall be effected from 0,4 D before the pulse to 0,1 D beyond the pulse, where D is the

duration of the nominal pulse.

NOTE If the velocity change tolerance cannot be achieved without the use of elaborate facilities, the relevant

specification should state the alternative procedure to be adopted (see Clauses A.5 and A.6).

4.1.4 Cross axis motion

The positive or negative peak acceleration at the check point(s), perpendicular to the intended

shock direction, shall not exceed 30 % of the value of the peak acceleration of the nominal

pulse in the intended direction, when determined by 4.2.

NOTE If the cross axis motion tolerance cannot be achieved, the relevant specification should state the alternative

procedure to be adopted (see Clause A.5).

4.2 Measuring system

The characteristics of the measuring system shall be such that it can be determined that the

true value of the actual pulse, as measured above, in the intended direction at the

checkpoint(s) is within the tolerances required by the Figures 1, 2 and 3.

The requirements of Figure 4 apply to the frequency response of the measuring system without

the use of a low-pass filter on the control signal. When a low-pass filter is used, the

characteristics of the filter should be such that its cut-off frequency f (–3 dB point) is not lower

g

than:

– 12 – 60068-2-27 © IEC:2008

15,

f =

g

D

where

f is the cut-off frequency of a low-pass filter in kHz;

g

D is the pulse duration in ms.

The frequency response of the overall measuring system, which includes the accelerometer,

can have a significant effect on the accuracy and shall be within the limits shown in Figure 4

(see also Clause A.5).

+1 dB

0 dB

–1 dB

24 dB octave

–10 dB

Frequency Hz

f f f f

1 2 3 4

IEC 306/08

Duration of Low-frequency High-frequency Frequency beyond which the response

pulse cut-off cut-off may rise above +1 dB

ms Hz kHz kHz

f f f f

1 2 3 4

0,2 and 0,3 20 120 20 40

0,5 10 50 15 30

1 4 20 10 20

2and 3 2 10 5 10

6 1 4 2 4

11 0,5 2 1 2

16, 18 and 30 0,2 1 1 2

NOTE For shocks of duration equal to or less than 0,5 ms, the value of f and f indicated in Figure 4 may be

3 4

unnecessarily high. In such instances, the relevant specification should state which alternative values are to be

adopted.

Figure 4 – Frequency characteristics of the overall measuring system

4.3 Mounting

The specimen shall be mounted on the table of the shock-testing machine or fixture in

accordance with IEC 60068-2-47.

60068-2-27 © IEC:2008 – 13 –

5 Severities

The relevant specification shall prescribe the pulse shape and the shock severity. Shocks shall

be applied in all three axes and in both a positive and negative direction, as required by the

relevant specification. The effects of gravity shall be considered when considering the attitude

of the test. Unless real usage conditions are known or otherwise specified, one of the pulse

shapes given in 4.1.1 and a severity shown on the same line in Table 1 shall be used. The

preferred combinations are in bold. The corresponding velocity changes are also given in

Table 1.

The number of shocks in each direction may be chosen from the following values:

3 ± 0

100 ± 5

500 ± 5

1 000 ± 10

5 000 ± 10

NOTE If the effects of the known environment on the specimen cannot be reproduced by severities given here, the

relevant specification may prescribe an appropriate severity using one of the standard pulse shapes, shown in

Figures 1, 2 and 3 (see also Clause A.4).

– 14 – 60068-2-27 © IEC:2008

Table 1 – Severities for shock testing

Final-peak

Corresponding

Half-sine

saw-tooth Trapezoidal

duration of the

Peak Foot-

nominal pulse –3 –3 –3

notes

acceleration ΔV = 2 /π AD × 10 ΔV = 0,5 AD × 10 ΔV = 0,9 AD × 10

(A) (D)

m/s g ms m/s m/s m/s

n

a

50 5 6 0,2 0,2 0,3

50 5 30 1 0,8 1,4

60 6 11 0,4 0,3 0,6

b

100 10 16 1 0,8 1,4

100 10 11 0,7 0,6 1

c

100 10 6 0,4 0,3 0,5

150 15 6 0,6 0,5 0,8

c

150 15 11 1,1 0,8 1,5

1,1

200 20 11 1,4 2 b

250 25 6 1 0,8 1,4

c

300 30 6 1,1 0,9 1,6

300 30 18 3,4 2,7 4,9

400 40 6 1,5 1,2 2,2

c

400 40 11 2,8 2,2 4

500 50 3 1 0,8 1,4

500 50 11 3,5 2,8 5

800 80 6 3,1 2,4 4,3

c

1 000 100 2 1,3 1 1,8 c

1 000 100 6 3,8 3 5,4

1 000 100 11 7 5,5 9,9

2 000 200 3 3,8 3 5,4

2 000 200 6 7,6 6 10,8

3,2

5 000 500 1 2,5 4,5

10 000 1 000 1 6,4 5 9

15 000 1 500 0,5 4,8 3,8 6,8

30 000 3 000 0,2 3,8 3 5,4

30 000 3 000 0,3 5,7 4,5 8,1

50 000 5 000 0,3 9,5 7,5 13,5 d

100 000 10 000 0,2 12,7 10 18

d

a

Preferred pulse shapes are printed in bold letters.

b

Recommendations given in RTCA DO 160E/F: 6 g “functional shock”, 3 per direction; 20 g “crash shock”, 1 per

direction.

c

Preferred severities for repetitive shocks.

d

These shocks may not be achievable within the stringent requirements of this standard.

6 Preconditioning

The relevant specification may call for preconditioning.

60068-2-27 © IEC:2008 – 15 –

7 Initial measurements and functional performance test

The specimen shall be submitted to visual, dimensional, functional and any other checks as

prescribed by the relevant specification.

8 Testing

The number of shocks prescribed by the relevant specification shall be applied successively in

each direction of three mutually perpendicular axes of the specimen. When testing a number of

identical specimens, they may be oriented so that the shocks are applied simultaneously along

these three axes (see Clause A.7).

Where the attitude of the specimen, when mounted or transported, is known, and since shocks

are generally of greatest significance in one direction of one axis, the relevant specification

shall state the specified number of shocks that shall be applied and in which axis, direction and

attitude. Otherwise, three axes and two directions shall be tested. For example, usually the

highest levels of shock acceleration are along the vertical axis. When the attitude during

transportation is known, the shocks should be applied in what will be the vertical axis in the

upward direction. Where the attitude is unknown, the specified number of shocks shall be

applied in each of the axes prescribed by the relevant specification (see Clause A.7).

The relevant specification shall state whether the specimen shall operate during testing and if

any functional monitoring is required.

9 Recovery

It is sometimes necessary to provide a period of time after testing and before final

measurements to allow the specimen to attain the same conditions, for example of

temperature, as existed for the initial measurements. The relevant specification shall then

prescribe the conditions for recovery.

10 Final measurements

The specimen shall be submitted to the visual, dimensional and functional checks and any

others as prescribed by the relevant specification.

The relevant specification shall provide the criteria upon which the acceptance or rejection of

the specimen shall be based.

11 Information to be given in the relevant specification

When this test is included in a relevant specification, the following details shall be given in so

far as they are applicable, paying particular attention to the items marked with an asterisk (*)

as this information is always required.

Clause

a) Pulse shape* 4.1.1 and A.3

b) Tolerances 4.1.1 and A.5

c) Velocity change 4.1.3 and A.6

d) Cross axis motion 4.1.4

e) Excitation axis, testing attitude and testing axes* 8

f) Method of mounting* 4.3

– 16 – 60068-2-27 © IEC:2008

g) Severity* 5 and A.4

h) Directions and number of shocks* 5 and 8

i) Preconditioning 6

j) Initial measurements 7

k) Functional performance test 7

l) Operating modes and functional monitoring 8

m) Recovery 9

n) Acceptance and rejection criteria* 10

o) Final measurements 10

12 Information to be given in the test report

As a minimum the test report shall show the following information:

1. Customer (name and address)

2. Test laboratory (name and address)

3. Test report identification (date of issue, unique number)

4. Test dates

5. Purpose of the test (development test, qualification)

6. Test standard, edition (relevant test procedure)

7. Test specimen description (unique identity, drawing, photo, quantity,

comments on initial status of test specimen, etc.)

8. Mounting of test specimen (fixture identity, drawing, photo excitation axis)

9. Excitation axis (testing attitude and testing axes)

10. Performance of test apparatus (cross motion, etc.)

11. Measuring system, sensor location (description, drawing, photo)

12. Uncertainties of measuring system (calibration data, last and next date)

13. Initial, intermediate or final measurements

14. Required severities (from test specification)

15. Test severities with documentation (measuring points)

16. Test results (comment on status of test specimen)

17. Observations during testing and actions taken

18. Summary of test

19. Test manager (name and signature)

20. Distribution (list of those receiving report)

NOTE A test log should be written, where the test is documented as, for example, a chronological list of test runs

with test parameters, observations during testing and actions taken, and data sheets on measurements made. The

test log can be attached to the test report.

60068-2-27 © IEC:2008 – 17 –

Annex A

(normative)

Selection and application of pulse shapes –

Guidance

A.1 Introduction

The test described in this standard provides a method to represent the effects on a specimen

when subjected to transportation or during operation. The test does not necessarily reproduce

the real environment.

The parameters given are standardized and suitable tolerances are chosen in order to obtain

similar results when a test is carried out at different locations by different people. The

standardization of values also enables components to be grouped into categories

corresponding to their ability to withstand certain severities given in this standard.

A.2 Applicability of test

Many specimens are liable to be subjected to shocks during use, storage and handling and

transportation. These shocks will be at widely varying levels and will also be of a complex

nature.

The shock test provides a convenient method for establishing the ability of a specimen to

withstand conditions of both non-repetitive and repetitive shocks. The test is performed on the

specimen when mounted to the fixture or table of the shock-testing machine. If the specimen is

installed or transported as loose cargo and subjected to repetitive shocks, then the test shall

be performed according to IEC 60068-2-55 (see Annex C).

The shock test is also suitable for structural integrity tests on component type specimens for

qualification and/or for quality control purposes. It is normal under these circumstances to

utilize high acceleration shocks with the main purpose of applying a known force to the internal

structure of a specimen, particularly those containing cavities, that is hollow spaces, (see

Clause 1).

To ensure that all test information is provided, the specification writer should refer to Clause 11

of this standard.

A.3 Pulse shapes (see Clause 1)

For test purposes, there are three ‘classical’ shock pulse shapes which are in general use and

any of these may be used (see also 4.1.1 and Table 1).

The half-sine pulse has application when reproducing the effects of a shock resulting from

impact with, or retardation by, a linear rate system, for example impact involving a resilient

structure.

The final-peak saw-tooth pulse has a more uniform response spectrum than the half-sine and

trapezoidal pulse shapes.

The trapezoidal pulse produces a higher response over a wider frequency spectrum than the

half-sine pulse. It should be applied when the purpose of the test is to reproduce the effects of

shock environments such as the “explosive bolt” phase of a space probe/satellite launch.

– 18 – 60068-2-27 © IEC:2008

NOTE The half-sine pulse shape is the most generally applicable. The trapezoidal pulse shape is not primarily

intended for component type specimens.

Information on the shock response spectra associated with these pulses is given in Annex B.

Where the shock response spectrum of the operational/transportation environment is known,

reference should be made to Figures A.1, A.2 and A.3 in order to select the shape of the pulse

most nearly conforming to it. Where the shock response spectrum of the

operational/transportation environment is not known, reference should be made to Tables A.1

and A.2 which list the test severities and pulse shapes applicable to specimens intended for

various classes of transportation and operational use.

For packaged items, the shocks encountered during handling and transportation are often of a

simple nature which makes it possible to use a half-sine pulse derived from the observed

velocity change.

60068-2-27 © IEC:2008 – 19 –

Figure A.1 – Shock response spectrum of a symmetrical half-sine pulse

Normalized

maximum response

Maximum response for A = 490 m/s

m/s

Acceleration

a

max

A

A

2,0 1 000

Exciting

pulse

1,8

1,6

1,4

0 D Time

1,2

1,0 500

0,8

0,6

0,4

0,2

1 10 100 1 000 Hz Frequency for D = 0,011s

Generalized frequency fD

0,02 0,05 0,1 0,2 0,5 1 2 5 10

I = initial

R = residual

IEC 308/08

– 20 – 60068-2-27 © IEC:2008

Figure A.2 – Shock response spectrum of a final-peak saw-tooth pulse

Normalized

maximum response

Maximum response for A = 490 m/s

a

m/s

max

Acceleration

A

2,0 1 000 A

Exciting

pulse

1,8

1,6

1,4 0

0 D Time

1,2

1,0

0,8

0,6

0,4

0,2

1 10 100 1 000 Hz Frequency for D = 0,011s

Generalized frequency fD

0,02 0,05 0,1 0,2 0,5 1 2 5 10

I = initial

R = residual

IEC 307/08

60068-2-27 © IEC:2008 – 21 –

Figure A.3 – Shock response spectrum of a symmetrical trapezoidal pulse

Normalized

maximum response

Maximum response for A = 490 m/s

Acceleration

m/s

a

max

A

A

Exciting

2,0 1 000

pulse

1,8

1,6

0 D Time

1,4

1,2

1,0

0,8

0,6

0,4

0,2

1 10 100 1 000 Hz Frequency for D = 0,011s

Generalized frequency fD

0,02 0,05 0,1 0,2 0,5 1 2 5 10

I = initial

R = residual

IEC 309/08

– 22 – 60068-2-27 © IEC:2008

A.4 Test severity

Whenever possible, the test severity and the shape of the shock pulse applied to the specimen

should be related to the environment to which the specimen will be subjected, during either

transportation, storage and handling, or operation, or to the design requirements if the object of

the test is to assess structural integrity.

It is often suitable to perform, on the same specimens, a test of non-repeated shocks (three

shocks in each axis and in each direction) using higher levels of stress to determine the ability

of the specimen to withstand the maximum stress that it may encounter during its normal life.

Also a test of repeated shocks at lower levels of stress may be conducted to determine the

ability of the specimen to withstand the repeatedly occurring shocks , maybe during operation,

during which the effect of material fatigue may be determined.

The transportation environment is frequently more severe than the operational environment

and in these circumstances the test severity chosen may need to be related to the former.

However, although the specimen may only need to survive the transportation environment, it

will normally be required to function during the operational environment, where appropriate.

Therefore, it may be necessary to carry out shock tests under both conditions, with

measurements of certain parameters after the “transportation environment” test and functional

checks during the “operational environment” test.

Consideration should be given to the possible need to allow an adequate safety margin

between the test severity and the conditions of the real environment.

When the real operational or transportation environment is unknown, the appropriate severity

should be selected from Table 1 which lists the test severities applicable for various classes of

transportation and operational use.

It is emphasized that the shock test is empirical and is basically a robustness test conducted in

order to give a measure of confidence. It is not intended to simulate precisely the real

environment.

In determining the test severity, the specification writer should take into account the

information given in relevant standards in the IEC 60721 series, namely IEC 60721-3-1 and

IEC 60721-3-5, remembering that these publications list values of shocks encountered in

practice whereas the intention of this standard is to standardize shock pulses for testing that

are likely to produce the same effects as real life shocks.

60068-2-27 © IEC:2008 – 23 –

Table A.1 – Examples of pulse shapes and test severities typically employed

for various applications

NOTE 1 This table lists severities which are not mandatory but are typical for the various applications. It should be

remembered that there will be instances where real severities differ from those shown in the table.

NOTE 2 Severities given in Table A.1 relate to test of non-repetitive shocks (three shocks in each axis and in each

direction). For test severities of repetitive shocks see Table A.2.

Severity

Peak Duration Pulse Component use Equipment use

acceleration shape

m/s g ms

n

150 15 11 Half-sine General test for robustness,

Final-peak handling and transport

saw-tooth

Land-based items permanently

Trapezoidal

installed or only transported by

road, rail or air in secured

shock-resistant packages

300 30 18 Half-sine Structural integrity of

Final-peak mountings

saw-tooth

Installed or transported in a

Trapezoidal

secured position on normal

road or rail vehicles or in

transport aircraft

500 50 11 Half-sine Items in secured packages Items installed or transported

Final-peak transported by wheeled in a secured position in full

saw-tooth vehicles (normal road and cross-country vehicles

a

Trapezoidal rail) subsonic or supersonic

Items carried loose in normal

transport aircraft, merchant

road or rai

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...