IEC 62787:2021

(Main)Concentrator photovoltaic (CPV) solar cells and cell on carrier (CoC) assemblies - Qualification

Concentrator photovoltaic (CPV) solar cells and cell on carrier (CoC) assemblies - Qualification

IEC 62787:2021 specifies the minimum requirements for the qualification of concentrator photovoltaic (CPV) cells and Cell on Carrier (CoC) assemblies for incorporation into CPV receivers, modules and systems. The object of this qualification standard is to determine the optoelectronic, mechanical, thermal, and processing characteristics of CPV cells and CoCs to show that they are capable of withstanding assembly processes and CPV application environments. The qualification tests of this document are designed to demonstrate that cells or CoCs are suitable for typical assembly processes, and when properly assembled, are capable of passing IEC 62108.

This document defines qualification testing for two levels of concentrator photovoltaic device assembly:

a) cell, or bare cell; and

b) cell on carrier (CoC).

Cellules solaires photovoltaïques à concentration (PVC) et ensembles de cellules sur support (CoC) - Qualification

IEC 62787:2021 spécifie les exigences minimales relatives à la qualification des cellules photovoltaïques à concentration (CPV) et des assemblages de cellules sur support (CoC) pour intégration dans les récepteurs, modules et systèmes CPV.

La présente norme de qualification a pour objet de déterminer les caractéristiques optoélectroniques, mécaniques, thermiques et de traitement des cellules CPV et des CoC afin de montrer qu’elles sont capables de résister aux processus de l’assemblage et aux environnements d’application des CPV. Les essais de qualification du présent document visent à démontrer que les cellules ou les CoC sont adaptées à des processus d’assemblage classiques, et qu’elles sont capables de satisfaire à l’IEC 62108 si elles sont correctement assemblées.

Le présent document définit les essais de qualification pour deux niveaux d’un ensemble de dispositifs photovoltaïques à concentration:

a) cellule (ou cellule nue), et

b) cellule sur support (CoC).

General Information

- Status

- Published

- Publication Date

- 02-Feb-2021

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 7 - TC 82/WG 7

- Current Stage

- PPUB - Publication issued

- Start Date

- 03-Feb-2021

- Completion Date

- 26-Oct-2025

Overview

IEC 62787:2021 is an international standard published by the International Electrotechnical Commission (IEC) that specifies the minimum requirements for the qualification of concentrator photovoltaic (CPV) solar cells and Cell on Carrier (CoC) assemblies. This standard is essential for manufacturers, researchers, and engineers involved in the development and deployment of CPV technologies. Its primary purpose is to ensure that CPV cells and CoC assemblies meet stringent optoelectronic, mechanical, thermal, and processing criteria to withstand assembly processes and operational environments in CPV systems. Compliance with IEC 62787:2021 supports conformity with IEC 62108, which governs CPV modules and systems.

Key Topics

- Qualification Scope: Defines two levels of device assembly qualification-bare cells and cells mounted on carriers (CoC).

- Performance Characterization: Includes methods such as light and dark current-voltage (I-V) measurements, electroluminescence (EL) mapping, X-ray and scanning acoustic microscope (SAM) inspection, and thermal resistance assessment.

- Environmental Stress Tests: Covers evaluations including electrostatic discharge (ESD) damage threshold, metal adhesion, thermal cycling, high-temperature storage, damp heat exposure with light bias, and more to simulate real-world CPV conditions.

- Mechanical Reliability: Tests for wire/ribbon bond strength, die adhesion, connector shear strength, and bypass diode shear strength ensure robust mechanical integration.

- Documentation and Reporting: Specifies detailed reporting requirements to certify CPV cells and assemblies for qualification, enabling traceability and quality control.

Applications

IEC 62787:2021 is fundamental in the certification and quality assurance of CPV solar cells and assemblies integrated into CPV receivers, modules, and photovoltaic systems. Its practical applications include:

- Manufacturing Quality Control: Assists manufacturers in qualifying solar cells and assemblies for durability and operational reliability prior to mass production.

- Product Development: Guides R&D teams to validate new CPV cell designs and carrier assemblies against standardized environmental and stress conditions.

- System Integration: Ensures that cells and CoC assemblies are compatible with assembly lines and can withstand mechanical and thermal stresses during installation and operation.

- Market Compliance: Supports adherence to international norms, boosting confidence among stakeholders and end-users regarding the long-term performance of CPV products.

Related Standards

- IEC 62108 – Concentrator photovoltaic (CPV) modules and assemblies: Provides requirements for CPV module testing and performance, complementing IEC 62787 by focusing on modules and systems rather than individual cells.

- IEC 60749-22 – Semiconductor devices mechanical and environmental testing: Offers testing methods cited within IEC 62787 for bond strength and mechanical reliability.

- IEC 62137 – Mechanical tests for electronic components: Contains shear strength test setups referenced in qualification procedures.

- MIL-STD-883 – Military standard for microelectronic device testing: Provides criteria for die shear strength tests involved in CPV assembly qualification.

By adhering to IEC 62787:2021, industry professionals ensure that CPV cells and CoC assemblies meet comprehensive evaluation criteria critical for the advancement and reliability of high-efficiency concentrator photovoltaic technology. This promotes innovation, quality, and confidence in CPV solar energy solutions worldwide.

Frequently Asked Questions

IEC 62787:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Concentrator photovoltaic (CPV) solar cells and cell on carrier (CoC) assemblies - Qualification". This standard covers: IEC 62787:2021 specifies the minimum requirements for the qualification of concentrator photovoltaic (CPV) cells and Cell on Carrier (CoC) assemblies for incorporation into CPV receivers, modules and systems. The object of this qualification standard is to determine the optoelectronic, mechanical, thermal, and processing characteristics of CPV cells and CoCs to show that they are capable of withstanding assembly processes and CPV application environments. The qualification tests of this document are designed to demonstrate that cells or CoCs are suitable for typical assembly processes, and when properly assembled, are capable of passing IEC 62108. This document defines qualification testing for two levels of concentrator photovoltaic device assembly: a) cell, or bare cell; and b) cell on carrier (CoC).

IEC 62787:2021 specifies the minimum requirements for the qualification of concentrator photovoltaic (CPV) cells and Cell on Carrier (CoC) assemblies for incorporation into CPV receivers, modules and systems. The object of this qualification standard is to determine the optoelectronic, mechanical, thermal, and processing characteristics of CPV cells and CoCs to show that they are capable of withstanding assembly processes and CPV application environments. The qualification tests of this document are designed to demonstrate that cells or CoCs are suitable for typical assembly processes, and when properly assembled, are capable of passing IEC 62108. This document defines qualification testing for two levels of concentrator photovoltaic device assembly: a) cell, or bare cell; and b) cell on carrier (CoC).

IEC 62787:2021 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62787:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62787 ®

Edition 1.0 2021-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Concentrator photovoltaic (CPV) solar cells and cell on carrier (CoC) assemblies –

qualification

Cellules solaires photovoltaïques à concentration (PVC) et ensembles de

cellules sur support (CoC) – Qualification

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC online collection - oc.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur adapté à vos besoins.

les projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au

Restez informé sur les nouvelles publications IEC. Just

monde, avec plus de 22 000 articles terminologiques en

Published détaille les nouvelles publications parues.

anglais et en français, ainsi que les termes équivalents dans

Disponible en ligne et une fois par mois par email.

16 langues additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62787 ®

Edition 1.0 2021-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Concentrator photovoltaic (CPV) solar cells and cell on carrier (CoC) assemblies –

qualification

Cellules solaires photovoltaïques à concentration (PVC) et ensembles de

cellules sur support (CoC) – Qualification

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.160 ISBN 978-2-8322-9326-3

– 2 – IEC 62787:2021 © IEC 2021

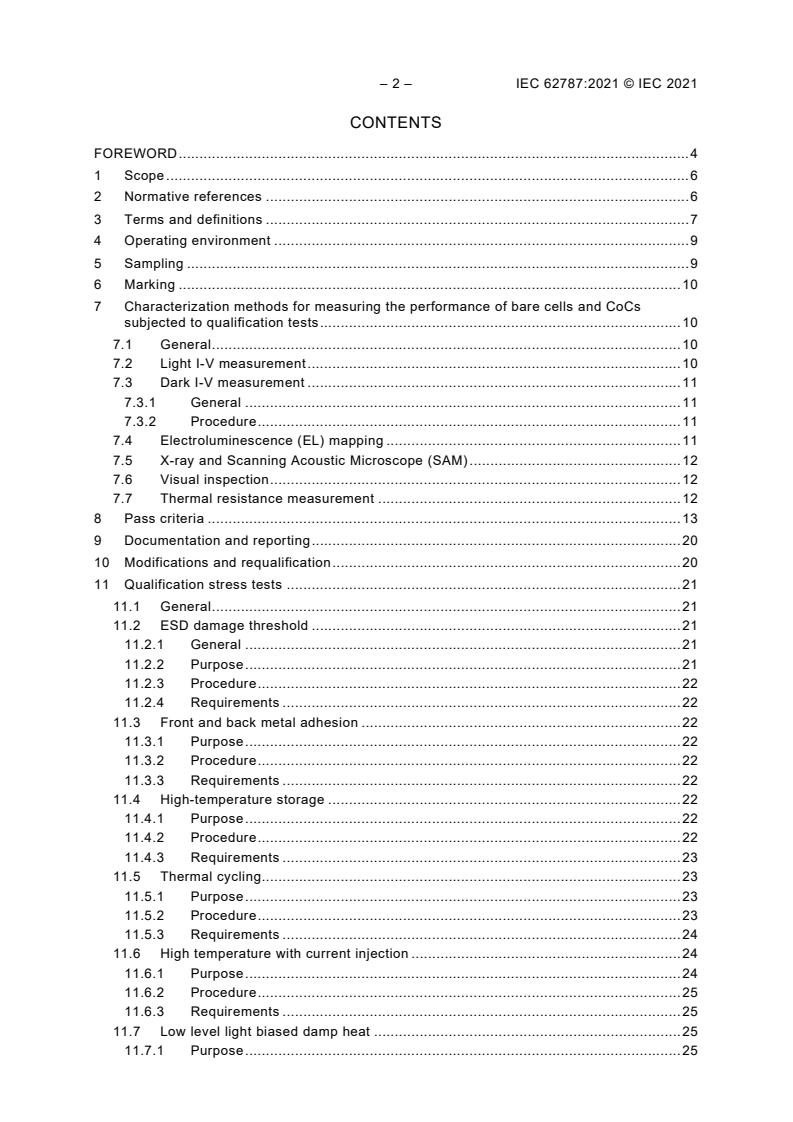

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Operating environment . 9

5 Sampling . 9

6 Marking . 10

7 Characterization methods for measuring the performance of bare cells and CoCs

subjected to qualification tests . 10

7.1 General . 10

7.2 Light I-V measurement . 10

7.3 Dark I-V measurement . 11

7.3.1 General . 11

7.3.2 Procedure . 11

7.4 Electroluminescence (EL) mapping . 11

7.5 X-ray and Scanning Acoustic Microscope (SAM) . 12

7.6 Visual inspection . 12

7.7 Thermal resistance measurement . 12

8 Pass criteria . 13

9 Documentation and reporting . 20

10 Modifications and requalification . 20

11 Qualification stress tests . 21

11.1 General . 21

11.2 ESD damage threshold . 21

11.2.1 General . 21

11.2.2 Purpose . 21

11.2.3 Procedure . 22

11.2.4 Requirements . 22

11.3 Front and back metal adhesion . 22

11.3.1 Purpose . 22

11.3.2 Procedure . 22

11.3.3 Requirements . 22

11.4 High-temperature storage . 22

11.4.1 Purpose . 22

11.4.2 Procedure . 22

11.4.3 Requirements . 23

11.5 Thermal cycling. 23

11.5.1 Purpose . 23

11.5.2 Procedure . 23

11.5.3 Requirements . 24

11.6 High temperature with current injection . 24

11.6.1 Purpose . 24

11.6.2 Procedure . 25

11.6.3 Requirements . 25

11.7 Low level light biased damp heat . 25

11.7.1 Purpose . 25

11.7.2 Procedure . 25

11.7.3 Requirements . 25

11.8 Solderability . 26

11.8.1 Purpose . 26

11.8.2 Procedure . 26

11.8.3 Requirements . 27

11.9 Illumination . 27

11.9.1 Purpose . 27

11.9.2 Procedure . 27

11.9.3 Requirements . 28

11.10 Wire/Ribbon bond strength . 28

11.10.1 Purpose . 28

11.10.2 Procedure . 28

11.10.3 Requirements . 30

11.11 Die adhesion . 31

11.11.1 Purpose . 31

11.11.2 Procedure . 31

11.11.3 Requirements . 31

11.12 Connector shear strength . 32

11.12.1 Purpose . 32

11.12.2 Procedure . 32

11.12.3 Pass/fail criteria . 33

11.13 Bypass diode shear strength . 33

11.13.1 Purpose . 33

11.13.2 Procedure . 33

11.13.3 Requirements . 33

Figure 1 – Schematics and photos of Cells on Carrier and bare cell test assembly . 8

Figure 2 – Representative samples of CPV systems, where cells and CoCs are

deployed . 9

Figure 3 – Flow chart of qualification tests for bare solar cells . 18

Figure 4 – Flow chart of qualification tests for CoCs . 19

Figure 5 – Thermal Cycle Diagram for the CoC test and TCO-1 . 24

Figure 6 – Force diagram in the bond strength test (taken from IEC 60749-22:2002,

Annex A, Method B) . 29

Figure 7 – Minimum bond pull limits (normal to die) (taken from IEC 60749-22:2002,

Annex A, Method B) . 30

Figure 8 – Schematic of the test set up for the die adhesion test. 31

Figure 9 – Die shear strength criteria (minimum force versus die attach area) (taken

from MIL.ST-883-K) . 32

Figure 10 – Schematics of the position of the pushing tool (taken from

IEC 62137-1-2:2007) . 33

Table 1 – Qualification tests description for bare solar cells . 14

Table 2 – Qualification tests description for CoCs . 16

Table 3 – Thermal Cycle Options (TCO) of test 11.5 for CoCs . 23

Table 4 – Minimum pulling forces, PW (taken from IEC60749-22:2002, Method B) . 29

– 4 – IEC 62787:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CONCENTRATOR PHOTOVOLTAIC (CPV) SOLAR CELLS

AND CELL ON CARRIER (CoC) ASSEMBLIES –

QUALIFICATION

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62787 has been prepared by subcommittee 82: Solar photovoltaic

energy systems.

The text of this International Standard is based on the following documents:

FDIS Report on voting

82/1818/FDIS 82/1834/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC 62787:2021 © IEC 2021

CONCENTRATOR PHOTOVOLTAIC (CPV) SOLAR CELLS

AND CELL ON CARRIER (CoC) ASSEMBLIES –

QUALIFICATION

1 Scope

This document specifies the minimum requirements for the qualification of concentrator

photovoltaic (CPV) cells and Cell on Carrier (CoC) assemblies for incorporation into CPV

receivers, modules and systems.

The object of this qualification standard is to determine the optoelectronic, mechanical, thermal,

and processing characteristics of CPV cells and CoCs to show that they are capable of

withstanding assembly processes and CPV application environments. The qualification tests of

this document are designed to demonstrate that cells or CoCs are suitable for typical assembly

processes, and when properly assembled, are capable of passing IEC 62108.

This document defines qualification testing for two levels of concentrator photovoltaic device

assembly:

a) cell, or bare cell; and

b) cell on carrier (CoC).

NOTE Note that a variety of alternate names are used within the industry, such as solar cell assembly, receiver,

etc.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60721-2-1:2013, Classification of environmental conditions – Part 2-1: Environmental

conditions appearing in nature – Temperature and humidity

IEC 60749-3:2017, Semiconductor devices – Mechanical and climatic test methods – Part 3:

External visual examination

IEC 60749-6:2017, Semiconductor devices – Mechanical and climatic test methods – Part 6:

Storage at high temperature

IEC 60749-14:2003, Semiconductor devices – Mechanical and climatic test methods – Part 14:

Robustness of terminations (lead integrity)

IEC 60749-21:2011, Semiconductor devices – Mechanical and climatic test methods – Part 21:

Solderability

IEC 60749-22:2002, Semiconductor devices – Mechanical and climatic test methods – Part 22:

Bond strength

IEC 60904-1-1:2017, Photovoltaic devices – Part 1-1: Measurement of current-voltage

characteristics of multi-junction photovoltaic (PV) devices

IEC 61000-4-2:2008, Electromagnetic compatibility (EMC) – Part 4-2: Testing and

measurement techniques – Electrostatic discharge immunity test

IEC 61193-2:2007, Quality assessment systems – Part 2 selection and use of sampling plans

for inspection of electronic components and packages

IEC TS 61836:2016, Solar photovoltaic energy systems – Terms, definitions and symbols

IEC 62108:2016, Concentrator photovoltaic (CPV) modules and assemblies – Design

qualification and type approval

IEC 62137-1-2:2007, Surface mounting technology – Environmental and endurance test

methods for surface mount solder joint – Part 1-2: Shear strength test

IEC 62670-1:2013, Photovoltaic concentrators (CPV) – Performance testing – Part 1: Standard

conditions

IEC TS 62789:2014, Photovoltaic concentrator cell documentation

IEC 63202-2, Photovoltaic cells – Part 2: Electroluminescence image for crystalline silicon

solar cells

ECSS-E-ST-20-08C Rev 1, 18 July 2012, Space engineering – Photovoltaic assemblies and

components – Part 7.5.8: Coating adherence (CA)

MIL.ST-883-K, Test Method Standard – Microcircuits Method 2019.9 Die shear strength

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC TS 61836 and

IEC 62108 apply, as well as the following.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

bare cell

refers to a semiconductor die level. The physical form during a commercial transaction may be

a separated solar cell, a diced wafer on tape, or even a processed wafer. The one common

denominator is that the qualified configuration is completely unprotected and not ready for

interconnection with the rest of a CPV module

Note 1 to entry: For this qualified configuration, the customer is responsible for all integration and assembly.

Note 2 to entry: For some qualification tests, bare cells are mounted on a substrate, heatsink, or other type of

carrier (see Figure 1c). This provides mechanical stability, robust electrical contacts, and appropriate thermal

management, but it is not considered in the bare solar cell qualification.

3.2

Cell on Carrier

CoC

cell bonded and interconnected with a cell carrier, at a minimum (see Figure 1b). This is a

relatively small, assembled unit in a relatively complete and rugged package

– 8 – IEC 62787:2021 © IEC 2021

Note 1 to entry: A cell on carrier can optionally include a bypass diode, encapsulation of the cell and/or

interconnects and a connector to simplify series or parallel connection. Alternatively, a CoC can also include multiple

cells. A CoC does not include any optical element.

Note 2 to entry: Figure 1 shows an expanded schematic of common components in a CoC, along with two photos.

Note that these photos illustrate relatively simple packages containing one primary photovoltaic device.

a) CoC exploded schematic

b) Cell on Carrier (CoC) with connectors and 2x c) Bare cell test assembly is intended to provide a

packaged diodes. Intended for sale in this test vehicle for bare cell qualification. Bypass diodes

configuration. can be included or not. Not a CoC offered for sale.

Figure 1 – Schematics and photos of Cells on Carrier and bare cell test assembly

3.3

supplier

any entity that supplies CPV wafers (diced or undiced), CPV solar cells (separated on foils in

sawing frames, single cells in trays or in reel) or CoCs to a customer

3.4

customer

any entity that buys some of these products from the supplier

4 Operating environment

CPV systems are typically designed to be operated in the “open-air climates" defined in

IEC 60721-2-1 except the Polar one. Depending on the details of the system design, the bare

solar cells and CoCs may or may not be protected from exposure to damp heat, freezing,

condensation, and other elements of the CPV application environment. Figure 2 shows

schematics of two CPV system designs.

Figure 2 – Representative samples of CPV systems, where cells and CoCs are deployed

Regardless of the specific design approach taken, the high incident irradiance impinging on the

solar cells in CPV systems will cause them to operate at (local) temperatures that can be

significantly higher than the maximum ambient temperature specified for the system as a whole.

5 Sampling

Device samples used in qualification testing shall be selected randomly in accordance with

IEC 61193-2 from a minimum of two manufacturing batches and subjected to the defined

Process Identification Document (PID) manufacturing and screening steps.

– 10 – IEC 62787:2021 © IEC 2021

The number of devices to be tested in each qualification test shall not be less than the sample

sizes specified in Clause 8. In order to provide statistical meaning to the number of devices,

IEC 61193-2 has been used since it assigns a defect probability as a function of number of

samples.

The samples for each test of Table 1 and Table 2 shall be chosen randomly from the

000 bare cells/CoCs.

qualification lot. The qualification lot shall be a production lot of at least 1

The production lot shall be formed from at least two epitaxial runs and three metal/ARC

depositions carried out in different weeks.

6 Marking

Due to the very small bare solar cell dimensions any marking on cell is usually not possible.

Therefore, an ID mapping needs to be applied. Regarding CoC under test, they shall be clearly

marked or identified for later tracking of data records. The required information for both bare

cells and CoCs are:

– name, monogram, or symbol of manufacturer;

– type or model number;

– serial number;

– polarity of terminals or leads;

– the date, place of manufacture, and cell materials should be marked, or be traceable from

the serial number.

7 Characterization methods for measuring the performance of bare cells and

CoCs subjected to qualification tests

7.1 General

The optoelectronic performance characterization based on illumination I-V curves tries to

identify optoelectronic performance degradation of test samples caused by the required

qualification tests. Therefore, illumination I-V curve has to be performed before and after

qualification tests. The goal of the illumination I-V curve is on the relative power degradation,

not on the absolute power output. Scanning Acoustic Microscopy (SAM) is also required but

only for CoCs.

In addition, electroluminescence mapping and dark I-V curve can provide diagnostic information

about defects and changes within the device. Before and after qualification testing, dark I-V

curve can be carried out for the voltage and current ranges of interest. Electroluminescence

images are not explicitly suggested through this document, but they could be of great help when

captured for each device at different current injection levels before and after some qualification

tests.

7.2 Light I-V measurement

This is a compulsory characterization method. All test samples shall be measured at 25 °C,

under AM1.5D spectrum as specified in IEC 62670-1, and at an overall light intensity

representative of the intended application. For the purposes of this characterization method, 1

,

sun equivalent of the AM1.5D spectrum will have a total power density (irradiance) of 0,1 W/cm

so that a light intensity of 100 W/cm = 1 000 suns. The parameters and measurement methods

for the light I-V measurement are defined in IEC 60904-1-1:2017.

Illumination I-V curve has to be performed before and after qualification tests. The focus of the

illumination I-V curve is on the relative power degradation, not on the absolute power output.

The relative power degradation, P , is defined as follows:

d

𝑃𝑃−𝑃𝑃

i f

𝑃𝑃 (%) = 100 (1)

d

𝑃𝑃

i

where

P is the maximum power measured after the given test, and

f

P is the maximum power measured before the given test.

i

At a minimum, J (short circuit current density), V (open circuit voltage), FF (fill factor), P

sc oc max

(maximum power) and efficiency should be used in this document and have to be included in

the qualification report for pre/post stress test evaluation.

7.3 Dark I-V measurement

7.3.1 General

This is a compulsory characterization method for the Electrostatic Discharge (ESD) Damage

Threshold test while is optional for the rest. The high operating current density of CPV devices,

can sometimes mask detection of low level defects or the onset of degradation. Dark I-V

measurements performed before and after a qualification test can provide a more sensitive

measure of damage or degradation.

The dark I-V measurement is a cost-effective method to monitor and diagnose power

degradation of bare solar cells and CoCs following intermediate stress tests, or to monitor the

electric performance stability of the control samples.

7.3.2 Procedure

If the dark I-V is used for diagnostic purpose, it should be measured during initial measurements

to establish a reference for later dark I-Vs.

a) Choose a suitable power source, which could be a conventional DC power supply, as long

as it will generate current up to 1,5 times the rated current point corresponding to the

photocurrent at the specified maximum concentration. The current should be adjustable so

-4

that there are at least 30 separate points in the range of 10 to 1,5 times rated I at the

sc

specified maximum concentration. The interval of the points should be nearly equal-spaced

with a lower pitch around I ;

sc

b) For CoCs, short the blocking diode by placing a jumper lead across the leads of the blocking

diode, if there is one installed;

c) Connect the power source’s positive lead to sample’s positive lead, and the power source’s

negative lead to sample’s negative lead;

d) Block completely the light impinging the cells;

e) Temperature shall be controlled and repetitive in order to comparing measured I-V results;

f) Apply current to the device and record current, voltage and temperature. Complete this

procedure as quickly as possible to avoid significant heating of the devices during the test.

7.4 Electroluminescence (EL) mapping

This is an optional characterization method. Forward bias current injected into the cells can

recombine at defects, or recombine radiatively. To capture the full range of information, EL

images are recommended to be taken with current injection within the range from 1 % to 10 %

of I at maximum concentration in order to prevent false failures. No matter this

sc

recommendation, other current injection levels are allowed as well as to capture EL maps at

different injected current levels. When characterizing bare solar cells they have to be properly

heat sunk in order to avoid thermal runaway. Any spiking due to power source or circuit

connection/disconnection has to be avoided. See IEC 63202-2 for guidance.

– 12 – IEC 62787:2021 © IEC 2021

7.5 X-ray and Scanning Acoustic Microscope (SAM)

SAM is the characterization method preferred to know the state of the joint between the back

of the solar cell and the carrier. So, its use is compulsory only for CoCs. Since the availability

of SAM is not as widespread as X-ray, the following protocol is recommended:

– To measure by x-ray before the qualification test in order to measure the voids area. Only

<5 % voids in total area and <1 % for the biggest void are allowed.

– After the qualification test, SAM is performed and no cracks are allowed.

In order to know the scientific background of SAM, some references can be followed.

7.6 Visual inspection

In several tests of Table 1 and Table 2 the pass criteria is the absence of Major Visual Defects

(MVD). Optical devices with magnification between 3x and 10x and large vision field shall be

used. For the purposes of design qualification and type approval, the following are considered

to be major visual defects:

• broken, cracked, bent, misaligned or torn external surfaces, terminals and contacts;

• broken or cracked solar cells;

• voids, pits, visible corrosion, contamination or delamination;

• loss of mechanical integrity;

• plate of CoC delaminated, peeling, dented or with detachments;

• hot spots and burnt parts;

• non-uniformity of the antireflection coating.

For additional details about visual defects consider IEC 60749-3:2017 and also check the

product specifications in the supplier brochure.

Furthermore, some CoC qualification tests require the visual confirmation of some defects such

as dice displacement, wire breakage, area of solder coverage, etc.

7.7 Thermal resistance measurement

This is a characterization method for CoC test at high temperature with current injection for

identifying thermal defects that shall be carried out before and after test. The procedure is:

• Place the CoC in good thermal contact onto a carrier with a programmable temperature

controller, under natural convection. Place a very thin thermocouple between the CoC and

the carrier just beneath the solar cell location. The programmable temperature can be

achieved by Peltier cooling module, liquid chiller, etc. Set the temperature at (40 ± 0,4) °C.

• Forward bias the CoC at 0,5 I (achieved at maximum concentration). After a transient

sc

period the steady state solar cell temperature is achieved where the voltage of the CoC is

measure so, the dissipated power of CoC (P ) can be determined.

CoC

• Measure the backplate CoC temperature (T ) by the thermocouple.

bp

• Take a picture of the solar cell with an Infrared Thermographic Camera (ITC), at the normal

direction to the CoC surface. This ITC shall have a pixel resolution well below the solar cell

size. Take the maximum solar cell temperature (T ) shown by infrared picture.

c

___________

, “An Overview of

M. Yazdan Mehr, A. Bahrami, H. Fischer, S. Gielen, R. Corbei, W.D. van Driel, G. Q. Zhang

Scanning Acoustic Microscope, a Reliable Method for Non-destructive Failure Analysis of Microelectronic

th

Components”, 2015 16 international Conference on Thermal, Mechanical and Multi-Physics Simulation and

Experiments in Microelectronics and Microsystems, DOI: 10.1109/EuroSimE.2015.7103077.

• Calculate the thermal resistance between the cell and the back plate of the CoC (R )

th,c−bp

with formula (2).

𝑇𝑇−𝑇𝑇

c bp

𝑅𝑅 = (2)

th,c−bp

𝑃𝑃

CoC

8 Pass criteria

A bare cell type should be judged to have passed the qualification tests and therefore to be

IEC 62787 type approved, if all test samples meet the requirements of all tests shown in Table 1.

Similarly, a CoC type should be judged to have passed the qualification tests and therefore to

be IEC 62787 type approved, if all test samples meet the requirements of all tests shown in

Table 2. Besides, bare solar cells used in manufacturing CoCs shall be previously qualified

following this document.

Unless otherwise specified in the applicable test procedure, all failures observed in stress tests

shall be documented regardless of the failure mode. Omission of any failures from the test

analysis and results shall be clearly justified and the information related to those failures shall

be available for review upon request (NCR – non-conformance report).

If there are some failures observed during the tests, the following judgment and re-test

procedure shall apply:

a) Three or more tests failed of Table 1 or Table 2 are not allowed, the device shall be deemed

not to have met the qualification requirements.

b) When one or two test types fail because of two or more samples do not meet the pass

criteria of the same test of Table 1 (for bare cells) or Table 2 (for CoCs), the device shall be

deemed not to have met the qualification requirements.

c) When one or two test types fail because one sample fails the same test, another two

samples meeting the requirements could be subjected to test from the beginning.

d) In case c), if all samples pass the test, the device shall be judged to have met the

qualification requirements.

e) In case c), if one or more of these samples also fails, the device shall be deemed not to

have met the qualification requirements.

f) In case a), b) or e), all the tests described in Table 1 (for bare cells) or in Table 2 (for CoCs)

shall be re-performed, usually after some design or processing improvement. A non-

conformance report shall be required.

– 14 – IEC 62787:2021 © IEC 2021

Table 1 – Qualification tests description for bare solar cells

Test name Subclause Reference Test description Number of Pass criteria Remarks

standards samples

<10 % dark voltage

loss at the current

Incremental voltage 5 (on

ESD damage point corresponding to Dark I-V measurement before and after. Report passing and failing

tests to establish ESD representative

11.2 IEC 61000-4-2

threshold the photocurrent at the voltage levels.

damage threshold. carriers)

specified maximum

concentration.

To introduce solar

Front and cells 24 h in a climatic

ECSS-E-ST-20- No contact material on

back metal 11.3 chamber at 95 °C / 32

08C Rev 1 the adhesive tape

adhesion 90 %RH (pure water

and no condensation)

• No MVD

1 000 h at 80 °C

High IEC 60749-6

(climatic chamber The test shall be carried out on solar cells/wafer inside their

• <5 % illumination

temperature 11.4 customized to 32

packaging

temperature) and

power degradation

storage 80 °C

<40 % RH

for each individual

• No cell cracks.

300 cycles within a T

ranging from −40 °C • No MVD (with 10x

Thermal to 125 °C, dwell > magnification)

11.5 IEC 62108 32 Dark I-V (info only) and light I-V before and after test

cycling 5 min within ±3 °C of

• <5 % nominal

extremes. No current

power degradation

injection

for each individual.

1 000 h at 130 °C

(solar cell

temperature, i.e. pn

junction temperature)

• No MVD

High with a simultaneous

Dark I-V (info only) recommendable before and after test.

20 (on

temperature current injection of 0,5

• <5 % nominal

11.6 N/A representative

The way to know the pn junction temperature is by measuring

I . I is the achieved

with current

sc sc

power degradation

carriers)

voltage variations at a given current injection.

injection

at the maximum

for each individual

concentration

specified in the

manufacturer

brochure

• No MVD,

Low level Light biased to 150 5 (on

light biased 11.7 N/A suns, 65 °C /65 % RH representative Dark I-V (info only) and Light I-V before and after test

• <5 % power

damp heat for 500 h carriers)

degradation.

Test name Subclause Reference Test description Number of Pass criteria Remarks

standards samples

• Evidence of proper

solder wetting:

solder coverage:

Two alternative

The areas to be

methods:

inspected of shall

have a minimum of

• Reflow process at

95 % solder

a temperature of

coverage minimum.

240 °C for 10 s.

Pinholes, voids,

Alternatively,

porosity,

apply the time and

Solderability 11.8 IEC 60749-21 5 Dark I-V (info only) and Light I-V before and after test

nonwetting, or

temperature

dewetting shall not

suggested by the

exceed 5 % of the

supplier

total area to be

• Application of flux,

inspected.

solder dip in a

• No MVD

solder bath and

flux removal

• <3 % nominal

power degradation

for each individual

• N/A for

indoor test.

200 h continuous

• For outdoor

illumination (at

test: to

maximum specified

• No MVD

follow the

concentration ratio)

2 (on

specs of

and at open circuit Cell temperature determined from open circuit voltage

• <5 % nominal

Illumination 11.9 representative

IEC 62108

condition with a solar measurements. Cell temperature is externally controlled

power degradation

carriers).

(outdoor

cell temperature (i.e.

for each individual

exposure

pn junction

test) that do

temperature) of

not infringe

120 °C

the rest of

this test.

The conditions shown correspond to minimum acceptable levels of stress, and higher levels of stress may be used (with technical justification included in the fina

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...