IEC 61850-4:2011

(Main)Communication networks and systems for power utility automation - Part 4: System and project management

Communication networks and systems for power utility automation - Part 4: System and project management

IEC 61850-4:2011 applies to projects associated with process near automation systems of power utilities (UAS, utility automation system), like e.g. substation automation systems (SAS). It defines the system and project management for UAS systems with communication between intelligent electronic devices (IEDs) in the substation respective plant and the related system requirements. This second edition constitutes a technical revision to align the document more closely with the other parts of the IEC 61850 series, in addition to enlarging the scope from substation automation systems to all utility automation systems.

This publication is of core relevance for Smart Grid.

Réseaux et systèmes de communication pour l'automatisation des systèmes électriques - Partie 4: Gestion du système et gestion de projet

La CEI 61850-4:2011 s'applique à des projets associés aux procédés proches des systèmes d'automatisation des compagnies d'électricité (UAS), par exemple les systèmes d'automatisation de poste (SAS). Elle définit la gestion du système et la gestion de projet pour les systèmes UAS avec communication entre des dispositifs électroniques intelligents (IED) dans le poste ou le site ainsi que les exigences concernant les systèmes associés. La présente seconde édition constitue une révision technique avec des détails plus proches des autres parties de la série de Normes CEI 61850. Le domaine d'application porte non seulement sur les systèmes d'automatisation de poste, mais aussi sur tous les systèmes d'automatisation pour les compagnies d'électricité.

This publication is of core relevance for Smart Grid.

General Information

- Status

- Published

- Publication Date

- 10-Apr-2011

- Technical Committee

- TC 57 - Power systems management and associated information exchange

- Drafting Committee

- WG 10 - TC 57/WG 10

- Current Stage

- PPUB - Publication issued

- Start Date

- 11-Apr-2011

- Completion Date

- 30-Apr-2011

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61850-4:2011 (Edition 2.1, consolidated 2020) defines system and project management requirements for utility automation systems (UAS), including substation automation systems (SAS). Part 4 of the IEC 61850 series focuses on how projects with communication between Intelligent Electronic Devices (IEDs) should be engineered, documented, tested, commissioned and maintained through the system life cycle. This standard is of core relevance for Smart Grid projects and aligns Part 4 with other IEC 61850 parts.

Key topics and technical requirements

- Engineering requirements and workflows

- Engineering process definition, parameter classification (categories/types), and tool roles (system specification, system configuration, IED configuration, documentation).

- Requirements for flexibility, expandability and scalability of engineering tools and projects.

- Project documentation

- Automatic and standard documentation outputs: hardware lists, parameter sets and project artifacts to support commissioning and maintenance.

- System life cycle management

- Product/version management, announcement and handling of product discontinuation, long‑term support and backward compatibility considerations.

- Quality assurance and testing

- Division of responsibilities among manufacturers, system integrators and customers.

- Test classifications and stages: type tests, conformance tests, factory acceptance test (FAT), site acceptance test (SAT), routine and maintenance tests.

- Support and change management

- Procedures for tool changes, project interactions, and the impact assessment of product updates on existing systems.

Practical applications and who uses it

IEC 61850-4 is intended for professionals involved in the design, delivery and operation of utility automation and Smart Grid systems:

- Utility engineers and asset owners - to define lifecycle, procurement and acceptance criteria for UAS/SAS projects.

- System integrators and project managers - to manage engineering workflows, toolchains and project documentation.

- IED and software vendors - to align product versioning, backward compatibility and discontinuation notices with customer needs.

- Test engineers and acceptance teams - to implement FAT, SAT and conformance testing plans that meet industry expectations.

Practical uses include creating standardized engineering tool chains, ensuring consistent parameter management across IEDs, documenting projects for regulatory compliance, and reducing integration risk during commissioning and expansions.

Related standards

- Part of the IEC 61850 series (communication networks and systems for power utility automation). Users should consult other IEC 61850 parts for protocol, modeling, and communication specifics when implementing system and project management practices.

IEC 61850-4:2011+AMD1:2020 CSV - Communication networks and systems for power utility automation - Part 4: System and project management Released:11/3/2020

IEC 61850-4:2011 - Communication networks and systems for power utility automation - Part 4: System and project management

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 61850-4:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Communication networks and systems for power utility automation - Part 4: System and project management". This standard covers: IEC 61850-4:2011 applies to projects associated with process near automation systems of power utilities (UAS, utility automation system), like e.g. substation automation systems (SAS). It defines the system and project management for UAS systems with communication between intelligent electronic devices (IEDs) in the substation respective plant and the related system requirements. This second edition constitutes a technical revision to align the document more closely with the other parts of the IEC 61850 series, in addition to enlarging the scope from substation automation systems to all utility automation systems. This publication is of core relevance for Smart Grid.

IEC 61850-4:2011 applies to projects associated with process near automation systems of power utilities (UAS, utility automation system), like e.g. substation automation systems (SAS). It defines the system and project management for UAS systems with communication between intelligent electronic devices (IEDs) in the substation respective plant and the related system requirements. This second edition constitutes a technical revision to align the document more closely with the other parts of the IEC 61850 series, in addition to enlarging the scope from substation automation systems to all utility automation systems. This publication is of core relevance for Smart Grid.

IEC 61850-4:2011 is classified under the following ICS (International Classification for Standards) categories: 33.200 - Telecontrol. Telemetering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61850-4:2011 has the following relationships with other standards: It is inter standard links to IEC 61850-4:2011/AMD1:2020, IEC 61850-4:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61850-4:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61850-4 ®

Edition 2.1 2020-11

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

colour

inside

Communication networks and systems for power utility automation –

Part 4: System and project management

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and definitions clause of

IEC publications issued between 2002 and 2015. Some

IEC Customer Service Centre - webstore.iec.ch/csc entries have been collected from earlier publications of IEC

If you wish to give us your feedback on this publication or TC 37, 77, 86 and CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61850-4 ®

Edition 2.1 2020-11

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

colour

inside

Communication networks and systems for power utility automation –

Part 4: System and project management

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 33.200 ISBN 978-2-8322-9038-5

– 2 – IEC 61850-4:2017+AMD1:2020 CSV

© IEC 2020

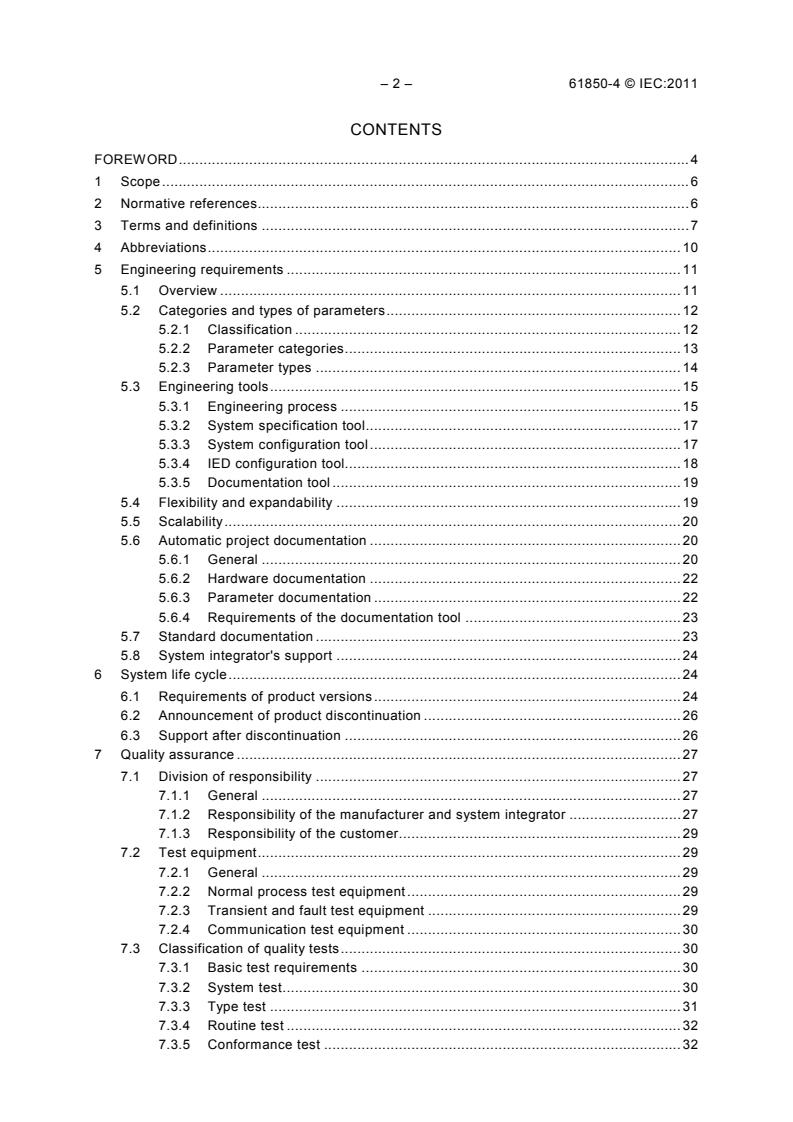

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Abbreviations . 10

5 Engineering requirements . 10

5.1 Overview . 10

5.2 Categories and types of parameters . 12

5.2.1 Classification . 12

5.2.2 Parameter categories . 13

5.2.3 Parameter types . 14

5.3 Engineering tools . 15

5.3.1 Engineering process . 15

5.3.2 System specification tool . 17

5.3.3 System configuration tool . 17

5.3.4 IED configuration tool . 17

5.3.5 Documentation tool . 19

5.3.6 Engineering tool workflow . 19

5.4 Flexibility and expandability . 23

5.5 Scalability . 23

5.6 Automatic project documentation . 24

5.6.1 General . 24

5.6.2 Hardware documentation . 25

5.6.3 Parameter documentation . 25

5.6.4 Requirements of the documentation tool . 26

5.7 Standard documentation . 26

5.8 System integrator's support . 27

5.9 System testing and engineering . 27

6 System life cycle . 27

6.1 Requirements of product versions . 27

6.2 Announcement of product discontinuation . 29

6.3 Support after discontinuation . 29

6.4 Backward compatibility . 29

6.4.1 General . 29

6.4.2 Components . 30

6.4.1 Use cases . 30

6.4.2 Impacts . 30

7 Quality assurance . 37

7.1 Division of responsibility . 37

7.1.1 General . 37

7.1.2 Responsibility of the manufacturer and system integrator . 37

7.1.3 Responsibility of the customer . 39

7.2 Test equipment . 40

7.2.1 General . 40

7.2.2 Normal process test equipment. 40

7.2.3 Transient and fault test equipment . 40

IEC 61850-4:2017+AMD1:2020 CSV – 3 –

© IEC 2020

7.2.4 Communication test equipment . 40

7.3 Classification of tests . 40

7.3.1 Basic test requirements . 40

7.3.2 System test . 41

7.3.3 Type test . 41

7.3.4 Routine test . 42

7.3.5 Conformance test . 42

7.3.6 Factory Acceptance Test (FAT) . 42

7.3.7 Site Acceptance Test (SAT) . 43

7.3.8 Maintenance tests (after commissioning) . 43

Annex A (informative) Announcement of discontinuation (example) . 45

Annex B (informative) Delivery obligations after discontinuation (example) . 46

Bibliography . 47

Figure 1 - Structure of the UAS and its environment . 11

Figure 2 - Structure of UAS and IED parameters . 13

Figure 3 – Engineering tasks and their relationship . 16

Figure 4 – IED configuration process . 18

Figure 5 - Engineering workflow steps from system to project . 19

Figure 6 - Change of system tool first stage . 20

Figure 7 - Change of system tool second stage . 21

Figure 8 – interaction between projects, first stage . 22

Figure 9 - interaction between projects, second stage . 22

Figure 10 - Project related documentation of UAS . 24

Figure 11 - Two meanings of the system life cycle . 28

Figure 12 - Template table of acceptable impacts . 31

Figure 13 : Backward compatibility first use case . 32

Figure 14 : Backward compatibility second use case . 33

Figure 15 : Backward compatibility third use case . 35

Figure 16 : Backward compatibility fourth use case . 36

Figure 17 - Stages of quality assurance – Responsibility of manufacturer and system

integrator . 38

Figure 18 - Contents of system test . 41

Figure 19 - Contents of type test . 42

Figure 20 - Contents of routine test . 42

Figure 21 - Testing stages for site acceptance test . 43

Figure A.1 – Announcement conditions . 45

Figure B.1 – Periods for delivery obligations . 46

– 4 – IEC 61850-4:2017+AMD1:2020 CSV

© IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

COMMUNICATION NETWORKS AND SYSTEMS

FOR POWER UTILITY AUTOMATION –

Part 4: System and project management

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their prepa-

ration is entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising with

the IEC also participate in this preparation. IEC collaborates closely with the International Organization for Stand-

ardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all inter-

ested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any misinter-

pretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications trans-

parently to the maximum extent possible in their national and regional publications. Any divergence between any

IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and ex-

penses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been pre-

pared for user convenience.

IEC 61850-4 edition 2.1 contains the second edition (2011-04) [documents 57/1103/FDIS

and 57/1122/RVD] and its amendment 1 (2020-11) [documents 57/2256/FDIS and

57/2271/RVD].

IEC 61850-4:2017+AMD1:2020 CSV – 5 –

© IEC 2020

International Standard IEC 61850-4 has been prepared by IEC technical committee 57: Power

systems management and associated information exchange.

This edition aligns the document more closely with the other parts of the IEC 61850 series, in

addition to enlarging the scope from substation automation systems to all utility automation

systems.

A list of all parts of the IEC 61850 series, under the general title: Communication networks and

systems for power utility automation, can be found on the IEC website.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under "http://web-

store.iec.ch" in the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC 61850-4:2017+AMD1:2020 CSV

© IEC 2020

COMMUNICATION NETWORKS AND SYSTEMS

FOR POWER UTILITY AUTOMATION –

Part 4: System and project management

1 Scope

This part of IEC 61850 applies to projects associated with processes near automation systems

of power utilities (UAS, utility automation system), such as substation automation systems

(SAS). It defines the system and project management for UAS with communication between

intelligent electronic devices (IEDs) in the substation respective plant and the related system

requirements.

The specifications of this part pertain to the system and project management with respect to:

– the engineering process and its supporting tools;

– the life cycle of the overall system and its IEDs;

– the quality assurance beginning with the development stage and ending with discontinuation

and decommissioning of the UAS and its IEDs.

The requirements of the system and project management process and of special supporting

tools for engineering and testing are described.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60848, GRAFCET specification language for sequential function charts

IEC 61082 (all parts), Preparation of documents used in electrotechnology

IEC 61175, Industrial systems, installations and equipment and industrial products – Designa-

tion of signals

IEC 61850-6, Communication networks and systems for power utility automation – Part 6:

Configuration description language for communication in power utility automation systems

related to IEDs

IEC 61850-7 (all parts), Communication networks and systems for power utility automation –

Part 7: Basic communication structure

IEC 81346 (all parts), Industrial systems, installations and equipment and industrial products –

Structuring principles and reference designations

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

supporting tools

those tools that support the user in the engineering, the operation and the management of the

UAS and its IEDs

NOTE These tools are usually a part of the UAS.

IEC 61850-4:2017+AMD1:2020 CSV – 7 –

© IEC 2020

3.2

engineering tools

tools that support the creation and documentation of the conditions for adapting an automation

system to the specific plant (substation) and customer requirements

NOTE Engineering tools are divided into project management, configuration and documentation tools.

3.3

system specification tools

tools used to create a system requirement specification including the relation of system func-

tions to the plant/substation to be managed; especially a tool creating a specification in a for-

mally defined, standardized format for evaluation by other tools

3.4

system configuration tools

tools handling the communication between the IEDs in the system, configuration of issues com-

mon for several IEDs, and the logical association of the IED’s functions to the process to be

controlled and supervised

NOTE See also “system parameters”.

3.5

IED configuration tools

tools handling the specific configuration and download of configuration data to a specific IED

of a specific type

3.6

expandability

criteria for the efficient extension of an automation system (hardware and functional) by use of

the engineering tools

3.7

flexibility

criteria for the fast and efficient implementation of functional changes including hardware

3.8

scalability

criteria for a cost effective system while recognizing various functionalities, various IEDs,

substation sizes and substation voltage ranges

3.9

parameters

variables which define the behaviour of functions of the automation system and its IEDs within

a given range of values

3.10

system parameters

data which define the interaction of IEDs in the system

NOTE System parameters are especially important in the:

– configuration of the system;

– communication between IEDs;

– marshalling of data between IEDs;

– processing and visualization of data from other IEDs (for example, at the station level).

3.11

IED parameters

parameters defining the behaviour of an IED and its relation to the process

3.12

IED-parameter set

all parameter values and configuration data needed for the definition of the behaviour of the

IED and its adaptation to the substation conditions

– 8 – IEC 61850-4:2017+AMD1:2020 CSV

© IEC 2020

NOTE Where the IED has to operate autonomously, the parameter-set can be generated without system parameters

using an IED-specific parameterization tool. Where the IED is a part of the system, the parameter set may include

the IED related or complete set of system parameters, which should be coordinated by a general parameterization

tool at the system level.

3.13

UAS-parameter set

all parameter values and configuration data needed for the definition of the behaviour of the

overall UAS and its adaptation to the substation conditions

NOTE The parameter set includes the IED-parameter sets of all participating IEDs.

3.14

remote terminal unit (RTU)

used as an outstation in a supervisory control and data acquisition (SCADA) system

NOTE An RTU may act as an interface between the communication network to the SCADA system and the substa-

tion equipment. The function of an RTU may reside in one IED or may be distributed.

3.15

UAS product family

different IEDs of one manufacturer with various functionalities and with the ability to perform

within utility automation systems

NOTE The IEDs of a product family are unified in relation to the design, the operational handling, the mounting and

wiring conditions, and they use common or coordinated supporting tools.

3.16

UAS installation

the concrete instance of a substation automation system consisting of multiple interoperable

and connected IEDs of one or more manufacturers

3.17

configuration list

overview of all instances of IEDs and other installed products of a system, their hardware and

software versions including the software versions of relevant supporting tools

NOTE The configuration list also contains the configured communication connections and addresses.

3.18

configuration compatibility list

overview of all compatible hardware and software versions of components and IEDs, including

the software versions of relevant supporting tools operating together in an UAS-product family

NOTE The configuration compatibility list also contains the supported transmission protocols and protocol versions

for communication with other IEDs.

3.19

manufacturer

the producer of IEDs and/or supporting tools

NOTE A manufacturer may be able to deliver an UAS solely by use of his own IEDs and supporting tools (UAS

product family).

3.20

system integrator

a turnkey deliverer of UAS installations

NOTE The responsibility of system integration includes the engineering, the delivery and mounting of all participat-

ing IEDs, the factory and site acceptance tests and the trial operation. The quality assurance, the maintenance and

spare delivery obligations and the warranty are agreed in the contract between the system integrator and the cus-

tomer. A system integrator may use IEDs from several different manufacturers.

3.21

system life cycle

the term has two specific meanings:

a) for the manufacturer, the time period between the start of the production of a newly

developed UAS product family and the discontinuation of support for the relevant IEDs;

IEC 61850-4:2017+AMD1:2020 CSV – 9 –

© IEC 2020

b) for the customer, the time period between the commissioning of the system installation and

the decommissioning of the last IED of the system installation

3.22

test equipment

all tools and instruments which simulate and verify the input/outputs of the operating environ-

ment of the automation system such as switchgear, transformers, network control centres or

connected telecommunication units on one side, and the communication channels between the

IEDs of the UAS on the other side

3.23

conformance test

verification of data flow on communication channels in accordance with the standard conditions

concerning access organization, formats and bit sequences, time synchronization, timing, sig-

nal form and level, reaction to errors

NOTE The conformance test can be carried out and certified for the standard or specially described parts

of the standard. The conformance test should be carried out by an ISO 9001 certified and by the UCA

International User Group Subgroup testing qualified organization.

3.24

system test

validation of correct behaviour of the IEDs and of the overall automation system under various

application conditions

NOTE The system test marks the final stage of the development of IEDs as part of a UAS product family.

3.25

type test

verification of correct behaviour of the IEDs of the automation system by use of the system

tested software under the environmental test conditions corresponding with the technical data

NOTE This test marks the final stage of the hardware development and is the precondition for the start of the

production. This test is carried out with IEDs that have been manufactured through the normal production cycle, and

not with prototype HW.

3.26

factory acceptance test

FAT

customer agreed functional tests of the specifically manufactured system or its parts, using the

parameter set for the planned application

NOTE This test is typically performed in the factory of the system integrator by the use of process simulating test

equipment.

3.27

site acceptance test

SAT

verification of each data and control point and the correct functionality inside the automation

system and between the automation system and its operating environment at the whole installed

plant by use of the final parameter set

NOTE The SAT is a precondition for the automation system being put into operation.

3.28

system requirements specification

the specification of all requirements including functions, technical quality, and interfaces to the

surrounding world

NOTE The requirement specification is typically supplied by the customer.

3.29

system design specification

a description of a system design showing how a system requirement specification is fulfilled

with selected products, and how the required functions are implemented on them

NOTE The system design specification is typically provided by the system integrator.

– 10 – IEC 61850-4:2017+AMD1:2020 CSV

© IEC 2020

4 Abbreviations

ASDU application service data unit

CD ROM compact disc read only memory

CAD computer aided design

CT current transformer

FAT factory acceptance test

HMI human machine Interface

.icd IED capability description file

ICT IED configuration tool

.iid instantiated IED description file

IED intelligent electronic device

PE process environment

RTU remote terminal unit

SAS substation automation system

SAT site acceptance test

SCADA supervisory control and data acquisition

.scd substation configuration description file

SCT system configuration tool

.sed system exchange description file

.ssd system specification description file

TE telecommunication environment

UAS utility automation system

VT voltage transformer

5 Engineering requirements

5.1 Overview

The engineering of a utility automation system is based on a system requirement specification,

which defines the scope, functions, boundaries and additional restrictions and requirements for

the system, and includes:

– the definition of the necessary hardware configuration of the UAS: i.e. the definition of the

IEDs and their interfaces with one another and to the environment as shown in Figure 1;

– the adaptation of functionality and signal quantities to the specific operational requirements

by use of parameters;

– the documentation of all specific definitions (i.e. parameter set, terminal connections, etc.).

IEC 61850-4:2017+AMD1:2020 CSV – 11 –

© IEC 2020

Network control centre(s)

Human

telecommunication

IED

i

IED

2 IED

j

IED IED

1 Communi- k

cation

IED IED

y m

Sublevel

IED IED

x n

telecommunication

Primary equipment

and auxiliaries

Teleprotection

UAS

UAS-environment

IEC 104/02

Figure 1 - Structure of the UAS and its environment

As shown in Figure 1, the UAS consists of different IEDs which communicate with each other

via communication channels and which execute tasks concerning interactions with the environ-

ment of the automation system, such as:

– telecommunication environment (TE);

• network control centre(s);

• subordinate systems;

• teleprotection;

– the human as a local operator;

– process environment (PE) like switchgear, transformer, auxiliaries.

Typical IEDs may be:

– for the telecommunication environment:

• gateways;

• converters;

• RTUs (telecommunication side);

• protection relays (teleprotection side);

– for the human machine interface (HMI):

• gateways;

• personal computers;

• workstations;

• other IEDs with integrated HMIs;

– for the process environment (PE):

• bay control units;

• protection relays;

• RTUs (process side);

• meters;

– 12 – IEC 61850-4:2017+AMD1:2020 CSV

© IEC 2020

• autonomous controllers (i.e. voltage controllers);

• transducers;

• digital switchgear interface;

• digital power transformer interface;

• digital VTs and CTs.

5.2 Categories and types of parameters

5.2.1 Classification

Parameters are data, which control and support the operation of:

– hardware configuration (composition of IEDs);

– software of IEDs;

– process environment (primary equipment and auxiliaries);

– HMI with different supporting tools; and

– telecommunication environment

in an automation system and its IEDs in such a way that the operations of the plant and cus-

tomer specific requirements are fulfilled.

The total set of parameters and configuration data of an UAS is termed the UAS-parameter set.

It consists of the used parts of the parameter sets of all participating IEDs.

With respect to handling methods and input procedure, parameter set contents is divided into

two categories:

– configuration parameters;

– operating parameters.

With respect to origin and function, the parameters are divided into types:

– system parameters;

– process parameters;

– functional parameters.

In Figure 2, the overview of the parameter structure is given.

IEC 61850-4:2017+AMD1:2020 CSV – 13 –

© IEC 2020

UAS - parameter set

…

IED - parameter set

n

IED - parameter set

Configuration parameters Operating parameters

Functional parameters

System parameters Process parameters

Switchable parameters

Non-switchable parameters

IEC 105/02

Figure 2 - Structure of UAS and IED parameters

The categories and types of parameters in Figure 2 are described below.

5.2.2 Parameter categories

5.2.2.1 Configuration parameters

The configuration parameters define the global behaviour of the whole UAS and its IEDs. As a

rule, they are only assigned a value during the initial parameterization, but they should be up-

dated when extending or functionally changing the UAS.

The generation and modification of the configuration parameters should be carried out off-line,

i.e. separately from the operation of the automation system. During the input of configuration

parameters, a temporary restriction of the system operation is allowed.

Observe that the term parameter in a more narrow sense means some variables, whose setting

defines the wanted behaviour. System and IED configuration needs however often more than

just setting of values. If we want to differentiate these different kinds of configuration, we talk

about “configuration data” meaning more complex parameterizations, while “configuration pa-

rameters” means an adjustment by value setting alone.

The configuration parameters of an IED usually include system and process parameters. Ob-

serve that UAS configuration parameters are typically defined at system level. They contain or

specify IED related system parameters.

5.2.2.2 Operating parameters

The operating parameters define the behaviour of partial functions of the system. They shall be

changeable on-line during the normal operation of the system. The modification is allowed with-

out restricting the system operation and within a framework of ranges of parameter values.

Protection functions, as far as combined in IEDs with other functions, shall not be influenced

during the parameterization of these functions.

The range and the basic settings of these parameters are determined at the initial parameteri-

zation or at a modification stage, separate from the operation of the system. The operating

parameters can be put on-line into the system via:

– telecommunication interface;

– HMI;

– integrated service interface of the IEDs.

– 14 – IEC 61850-4:2017+AMD1:2020 CSV

© IEC 2020

The operating parameters usually include process and functional parameters, for example limit

values, target values, command output times, delay times in switching sequences, etc.

5.2.3 Parameter types

5.2.3.1 System parameters

System parameters consist of configuration data which determines the co-operation of IEDs

including the internal structures and procedures of the system in relation to its technological

limits and available components.

For example, the system configuration data determines the configuration of hardware compo-

nents in the system (IEDs and their physical connections), the communication procedure be-

tween the IEDs (protocol, baud rate) and the scope of required and available functions in the

software of IEDs at the station level.

Additionally, the system configuration data describes data flow relations between functions on

different IEDs, for example interlocking, visualization of information in the substation single line

diagram and others.

Furthermore, the system configuration data includes the assignment of texts to events at the

station level and the determination of data flows in the system, for example to

– HMI (display, event report);

– printer;

– archive;

– telecommunication with network control centre or further substations.

System parameter values should be consistent in all parts of the system and its IEDs. The

consistency of the system parameter values should be maintained and validated by a general

system configuration and parameterisation tool at the system level.

5.2.3.2 Process parameters

Process parameters describe all types of information that is exchanged between the PE and

the UAS.

The process parameters are responsible for qualitative features at the process interface such

as command output times, suppression of transient events (filter time), measured value damp-

ing (threshold value), and of the process itself, e.g. switch run times.

Furthermore, the process parameters include the assignment of texts to events for visualization

at the IED-level.

5.2.3.3 Functional parameters

Functional parameters describe the qualitative and quantitative features of functionality used

by the customer. Normally, the functional parameters are changeable on-line.

For example, the functional parameters determine the target values (set points) of controllers,

the starting and tripping conditions of protection relays, automatic sequences such as opera-

tions after measurement overflow or commands in relation to specific events. The functional

parameters are responsible for algorithms of automatic control, protection, blocking and adjust-

ment.

The functional parameters are divided into switchable and non-switchable parameter value

groups.

A set of functional parameter values for a group of functional parameters can be resident in an

IED in parallel with other sets of functional parameter values. In this case, only one set of these

functional parameter values is active at a time. It shall be possible to switch between the sets

on-line.

IEC 61850-4:2017+AMD1:2020 CSV – 15 –

© IEC 2020

5.3 Engineering tools

5.3.1 Engineering process

The system engineering process creates the conditions for designing and configuring an auto-

mation system to the specific plant (e.g. substation) and to the operating philosophy of the

customer based on the system requirements specification from the customer.

Within the engineering process, we can distinguish different actor roles:

– The project requirement engineer sets up the scope of the project, its boundaries, interfaces,

functions and special requirements ranging from needed environmental conditions, reliabil-

ity and availability requirements up to process related naming and eventual specific address

range restrictions or product usage. He defines what he wants to have application wise and

how he wants to operate the system (project requirement specification). He finally accepts

the delivered system.

– The project design engineer defines, based on the requirements specification, how the sys-

tem shall look like; its architecture, requirements on the products needed to fulfil the re-

quired functions, how the products should work together. He thus defines the system design

specification.

– The manufacturer supplies the products from which the system is built. If necessary, he

supplies a project specific IED configuration.

– The system integrator builds the system, engineers the interoperation between its compo-

nents based on the system design specification and the concretely available products from

the manufacturers, and integrates the products into a running system. This results in a sys-

tem configuration description.

– The IED parameterizing engineer uses the set-up possibilities of the system and device

configuration to adjust the process, functional and system parameters of an IED to the pro-

ject-specific characteristics.

– The testing and commissioning engineer tests the system on the basis of the system con-

figuration description, system design and requirements specification and additional docu-

mentation, and puts the system into operation.

It can be that the same person or organisation has more than one role, e.g. a manufacturer is

also system integrator, or a customer does system integration by himself. This influences the

packaging and formal organisation, however not the tasks which have principally to be per-

formed.

The concrete engineering process is dependent also on responsibilities for parts of the system,

and how they relate together. Even if a system integrator is also manufacturer, he might have

to integrate products from other manufacturers. A customer might want to have a system with

interfaces to a system of another customer. Across these organisational interfaces a data ex-

change in a standardized form should be possible.

A typical project will start with the project requirement engineer creating a project requirement

specification that defines the scope of the project, single line diagrams, device ratings and other

required data. The aim is to create a set of technical specifications that can be used for tender-

ing and engineering, irrespective of whether design and installation work will be done in-house

or by external parties. Beneath general interfacing requirements, this includes also the identifi-

cation or at least naming rules for primary and secondary equipment, and any communication

addresses or addressing schemes needed to interface with other systems of the customer.

Further needed redundancy requirements, response times, availability and safety measures

have to be stated beneath the environmental, physical and geographical restrictions for the

project.

IEC 61850-6 provides a formal means to define the single line diagram with customer’s func-

tional names and the intended automation system functionality at the primary equipment iden-

tified in the single line description (.ssd, system specification description). This formal descrip-

tion is based on the hierarchical structure of IEC 81346-1, allows however instead of identifica-

tions according to IEC 81346-2 also customer specific identifications, and additionally customer

specific descriptive text. It further defines a formal way to exchange function and communication

– 16 – IEC 61850-4:2017+AMD1:2020 CSV

© IEC 2020

related interface descriptions between systems respective between system projects (by means

of an .sed, system exchange description).

Based on this requirement specification and its knowledge about existing solutions and prod-

ucts, the project design engineer designs the functional and physical system architecture inclu-

sive communication system to reach the needed response times and reliability, and produces

the specifications for the products to be used. The details form a system design specification,

which is typically approved by the project requirement engineer, and is then used as a base for

the product manufacturer to deliver the needed products with the specified configuration. The

resulting system design specification can be supported by a formal description of IEDs, the

functions on them, and their relation to the process functionality as defined in IEC 61850-6

(.scd, system configuration description). The system integrator uses this specification to order

the fitting products and to build the system from the products. The manufacturer supplied IEDs,

before integration into the system, come with a formal description of their functional and com-

munication engineering capability (.icd, IED capabilit

...

IEC 61850-4 ®

Edition 2.0 2011-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Communication networks and systems for power utility automation –

Part 4: System and project management

Réseaux et systèmes de communication pour l'automatisation des systèmes

électriques –

Partie 4: Gestion du système et gestion de projet

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61850-4 ®

Edition 2.0 2011-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Communication networks and systems for power utility automation –

Part 4: System and project management

Réseaux et systèmes de communication pour l'automatisation des systèmes

électriques –

Partie 4: Gestion du système et gestion de projet

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX W

ICS 33.200 ISBN 978-2-88912-439-8

– 2 – 61850-4 © IEC:2011

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references. 6

3 Terms and definitions . 7

4 Abbreviations . 10

5 Engineering requirements . 11

5.1 Overview . 11

5.2 Categories and types of parameters . 12

5.2.1 Classification . 12

5.2.2 Parameter categories . 13

5.2.3 Parameter types . 14

5.3 Engineering tools . 15

5.3.1 Engineering process . 15

5.3.2 System specification tool . 17

5.3.3 System configuration tool . 17

5.3.4 IED configuration tool. 18

5.3.5 Documentation tool . 19

5.4 Flexibility and expandability . 19

5.5 Scalability . 20

5.6 Automatic project documentation . 20

5.6.1 General . 20

5.6.2 Hardware documentation . 22

5.6.3 Parameter documentation . 22

5.6.4 Requirements of the documentation tool . 23

5.7 Standard documentation . 23

5.8 System integrator's support . 24

6 System life cycle . 24

6.1 Requirements of product versions . 24

6.2 Announcement of product discontinuation . 26

6.3 Support after discontinuation . 26

7 Quality assurance . 27

7.1 Division of responsibility . 27

7.1.1 General . 27

7.1.2 Responsibility of the manufacturer and system integrator . 27

7.1.3 Responsibility of the customer. 29

7.2 Test equipment . 29

7.2.1 General . 29

7.2.2 Normal process test equipment . 29

7.2.3 Transient and fault test equipment . 29

7.2.4 Communication test equipment . 30

7.3 Classification of quality tests . 30

7.3.1 Basic test requirements . 30

7.3.2 System test . 30

7.3.3 Type test . 31

7.3.4 Routine test . 32

7.3.5 Conformance test . 32

61850-4 © IEC:2011 – 3 –

7.3.6 Factory Acceptance Test (FAT) . 32

7.3.7 Site Acceptance Test (SAT) . 32

Annex A (informative) Announcement of discontinuation (example) . 34

Annex B (informative) Delivery obligations after discontinuation (example) . 35

Bibliography . 36

Figure 1 – Structure of the UAS and its environment . 11

Figure 2 – Structure of UAS and IED parameters . 13

Figure 3 – Engineering tasks and their relationship . 16

Figure 4 – IED configuration process . 18

Figure 5 – Project related documentation of UAS . 21

Figure 6 – Two meanings of the system life cycle . 25

Figure 7 – Stages of quality assurance – Responsibility of manufacturer and system

integrator . 27

Figure 8 – Contents of system test . 30

Figure 9 – Contents of type test . 31

Figure 10 – Contents of routine test . 32

Figure 11 – Testing stages for site acceptance test . 33

Figure A.1 – Announcement conditions . 34

Figure B.1 – Periods for delivery obligations . 35

– 4 – 61850-4 © IEC:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

COMMUNICATION NETWORKS AND SYSTEMS

FOR POWER UTILITY AUTOMATION –

Part 4: System and project management

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote internation-

al co-operation on all questions concerning standardization in the electrical and electronic fields. To this end

and in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical

Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”).

Their preparation is entrusted to technical committees; any IEC National Committee interested in the subject

dealt with may participate in this preparatory work. International, governmental and non-governmental organiza-

tions liaising with the IEC also participate in this preparation. IEC collaborates closely with the International Or-

ganization for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all inter-

ested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any misinter-

pretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence be-

tween any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and ex-

penses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publica-

tions.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61850-4 has been prepared by IEC technical committee 57: Power

systems management and associated information exchange.

This second edition cancels and replaces the first edition published in 2002. It constitutes a

technical revision to align the document more closely with the other parts of the IEC 61850

series, in addition to enlarging the scope from substation automation systems to all utility au-

tomation systems.

The text of this standard is based on the following documents:

FDIS Report on voting

57/1103/FDIS 57/1122/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

61850-4 © IEC:2011 – 5 –

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61850 series, under the general title: Communication networks and

systems for power utility automation, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data related to

the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 61850-4 © IEC:2011

COMMUNICATION NETWORKS AND SYSTEMS

FOR POWER UTILITY AUTOMATION –

Part 4: System and project management

1 Scope

This part of IEC 61850 applies to projects associated with process near automation systems of

power utilities (UAS, utility automation system), like e.g. substation automation systems (SAS).

It defines the system and project management for UAS systems with communication between

intelligent electronic devices (IEDs) in the substation respective plant and the related system

requirements.

The specifications of this part pertain to the system and project management with respect to:

– the engineering process and its supporting tools;

– the life cycle of the overall system and its IEDs;

– the quality assurance beginning with the development stage and ending with discon-

tinuation and decommissioning of the UAS and its IEDs.

The requirements of the system and project management process and of special supporting

tools for engineering and testing are described.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60848, GRAFCET specification language for sequential function charts

IEC 61082 (all parts), Preparation of documents used in electrotechnology

IEC 61175, Industrial systems, installations and equipment and industrial products – Designa-

tion of signals

IEC 61850-6, Communication networks and systems for power utility automation – Part 6:

Configuration description language for communication in electrical substations related to IEDs

IEC 61850-7 (all parts), Communication networks and systems for power utility automation –

Part 7: Basic communication structure

IEC 81346 (all parts), Industrial systems, installations and equipment and industrial products –

Structuring principles and reference designations

IEC 81346-1, Industrial systems, installations and equipment and industrial products – Structur-

ing principles and reference designations – Part 1: Basic rules

IEC 81346-2, Industrial systems, installations and equipment and industrial products – Structur-

ing principles and reference designations – Part 2: Classification of objects and codes for clas-

ses

61850-4 © IEC:2011 – 7 –

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

supporting tools

those tools that support the user in the engineering, the operation and the management of the

UAS and its IEDs

NOTE These tools are usually a part of the UAS.

3.1.1

engineering tools

tools that support the creation and documentation of the conditions for adapting an automation

system to the specific plant (substation) and customer requirements

NOTE Engineering tools are divided into project management, configuration and documentation tools.

3.1.2

system specification tools

tools used to create a system requirement specification including the relation of system func-

tions to the plant/substation to be managed; especially a tool creating a specification in a for-

mally defined, standardized format for evaluation by other tools

3.1.3

system configuration tools

tools handling the communication between the IEDs in the system, configuration of issues

common for several IEDs, and the logical association of the IED’s functions to the process to

be controlled and supervised

NOTE See also “system parameters”.

3.1.4

IED configuration tools

tools handling the specific configuration and download of configuration data to a specific IED of

a specific type

3.2

expandability

criteria for the efficient extension of an automation system (hardware and functional) by use of

the engineering tools

3.3

flexibility

criteria for the fast and efficient implementation of functional changes including hardware

3.4

scalability

criteria for a cost effective system while recognizing various functionalities, various IEDs,

substation sizes and substation voltage ranges

3.5

parameters

variables which define the behaviour of functions of the automation system and its IEDs within

a given range of values

– 8 – 61850-4 © IEC:2011

3.5.1

system parameters

data which define the interaction of IEDs in the system

NOTE System parameters are especially important in the:

– configuration of the system;

– communication between IEDs;

– marshalling of data between IEDs;

– processing and visualization of data from other IEDs (for example, at the station level).

3.5.2

IED parameters

parameters defining the behaviour of an IED and its relation to the process

3.6

IED-parameter set

all parameter values and configuration data needed for the definition of the behaviour of the

IED and its adaptation to the substation conditions

NOTE Where the IED has to operate autonomously, the parameter-set can be generated without system parame-

ters using an IED-specific parameterization tool. Where the IED is a part of the system, the parameter set may

include the IED related or complete set of system parameters, which should be coordinated by a general parameter-

ization tool at the system level.

3.7

UAS-parameter set

all parameter values and configuration data needed for the definition of the behaviour of the

overall UAS and its adaptation to the substation conditions

NOTE The parameter set includes the IED-parameter sets of all participating IEDs.

3.8

remote terminal unit

RTU

used as an outstation in a supervisory control and data acquisition (SCADA) system

NOTE An RTU may act as an interface between the communication network to the SCADA system and the substa-

tion equipment. The function of an RTU may reside in one IED or may be distributed.

3.9

UAS product family

different IEDs of one manufacturer with various functionalities and with the ability to perform

within utility automation systems

NOTE The IEDs of a product family are unified in relation to the design, the operational handling, the mounting

and wiring conditions, and they use common or coordinated supporting tools.

3.10

UAS installation

the concrete instance of a substation automation system consisting of multiple interoperable

and connected IEDs of one or more manufacturers

3.11

configuration list

overview of all instances of IEDs and other installed products of a system, their hardware and

software versions including the software versions of relevant supporting tools

NOTE The configuration list also contains the configured communication connections and addresses.

61850-4 © IEC:2011 – 9 –

3.12

configuration compatibility list

overview of all compatible hardware and software versions of components and IEDs, including

the software versions of relevant supporting tools operating together in an UAS-product family

NOTE The configuration compatibility list also contains the supported transmission protocols and protocol ver-

sions for communication with other IEDs.

3.13

manufacturer

the producer of IEDs and/or supporting tools

NOTE A manufacturer may be able to deliver an UAS solely by use of his own IEDs and supporting tools (UAS

product family).

3.14

system integrator

a turnkey deliverer of UAS installations

NOTE The responsibility of system integration includes the engineering, the delivery and mounting of all participat-

ing IEDs, the factory and site acceptance tests and the trial operation. The quality assurance, the maintenance and

spare delivery obligations and the warranty are agreed in the contract between the system integrator and the cus-

tomer. A system integrator may use IEDs from several different manufacturers.

3.15

system life cycle

the term has two specific meanings:

a) for the manufacturer, the time period between the start of the production of a newly

developed UAS product family and the discontinuation of support for the relevant IEDs;

b) for the customer, the time period between the commissioning of the system installation and

the decommissioning of the last IED of the system installation

3.16

test equipment

all tools and instruments which simulate and verify the input/outputs of the operating environ-

ment of the automation system such as switchgear, transformers, network control centres or

connected telecommunication units on one side, and the communication channels between the

IEDs of the UAS on the other side

3.17

conformance test

verification of data flow on communication channels in accordance with the standard conditions

concerning access organization, formats and bit sequences, time synchronization, timing, sig-

nal form and level, reaction to errors

NOTE The conformance test can be carried out and certified for the standard or specially described parts of the

standard. The conformance test should be carried out by an ISO 9001 certified organization or system integrator.

3.18

system test

validation of correct behaviour of the IEDs and of the overall automation system under various

application conditions

NOTE The system test marks the final stage of the development of IEDs as part of a UAS product family.

3.19

type test

verification of correct behaviour of the IEDs of the automation system by use of the system

tested software under the environmental test conditions corresponding with the technical data

– 10 – 61850-4 © IEC:2011

NOTE This test marks the final stage of the hardware development and is the precondition for the start of the

production. This test is carried out with IEDs that have been manufactured through the normal production cycle, and

not with prototype HW.

3.20

factory acceptance test

FAT

customer agreed functional tests of the specifically manufactured system or its parts, using the

parameter set for the planned application

NOTE This test is typically performed in the factory of the system integrator by the use of process simulating test

equipment.

3.21

site acceptance test

SAT

verification of each data and control point and the correct functionality inside the automation

system and between the automation system and its operating environment at the whole

installed plant by use of the final parameter set

NOTE The SAT is a precondition for the automation system being put into operation.

3.22

system requirements specification

the specification of all requirements including functions, technical quality, and interfaces to the

surrounding world

NOTE The requirement specification is typically supplied by the customer.

3.23

system design specification

a description of a system design showing how a system requirement specification is fulfilled

with selected products, and how the required functions are implemented on them

NOTE The system design specification is typically provided by the system integrator.

4 Abbreviations

ASDU application service data unit

CD ROM compact disc read only memory

CAD computer aided design

CT current transformer

FAT factory acceptance test

HMI human machine Interface

IED intelligent electronic device

PE process environment

RTU remote terminal unit

SAS substation automation system

SAT site acceptance test

SCADA supervisory control and data acquisition

TE telecommunication environment

UAS utility automation system

VT voltage transformer

61850-4 © IEC:2011 – 11 –

5 Engineering requirements

5.1 Overview

The engineering of a utility automation system is based on a system requirement specification,

which defines the scope, functions, boundaries and additional restrictions and requirements for

the system, and includes:

– the definition of the necessary hardware configuration of the UAS: i.e. the definition of the

IEDs and their interfaces with one another and to the environment as shown in Figure 1;

– the adaptation of functionality and signal quantities to the specific operational requirements

by use of parameters;

– the documentation of all specific definitions (i.e. parameter set, terminal connections, etc.).

Network control centre(s)

Human

telecommunication

IEDi

IED

2 IED

j

IED IED

1 Communi- k

cation

IED IED

y m

Sublevel

IED IED

x n

telecommunication

Primary equipment

and auxiliaries

Teleprotection

UAS

UAS-environment

IEC 104/02

Figure 1 – Structure of the UAS and its environment

As shown in Figure 1, the UAS consists of different IEDs which communicate with each other

via communication channels and which execute tasks concerning interactions with the environ-

ment of the automation system, such as:

– telecommunication environment (TE);

• network control centre(s);

• subordinate systems;

• teleprotection;

– the human as a local operator;

– process environment (PE) like switchgear, transformer, auxiliaries.

Typical IEDs may be:

– for the telecommunication environment:

• gateways;

• converters;

• RTUs (telecommunication side);

– 12 – 61850-4 © IEC:2011

• protection relays (teleprotection side);

– for the human machine interface (HMI):

• gateways;

• personal computers;

• workstations;

• other IEDs with integrated HMIs;

– for the process environment (PE):

• bay control units;

• protection relays;

• RTUs (process side);

• meters;

• autonomous controllers (i.e. voltage controllers);

• transducers;

• digital switchgear interface;

• digital power transformer interface;

• digital VTs and CTs.

5.2 Categories and types of parameters

5.2.1 Classification

Parameters are data, which control and support the operation of:

– hardware configuration (composition of IEDs);

– software of IEDs;

– process environment (primary equipment and auxiliaries);

– HMI with different supporting tools; and

– telecommunication environment

in an automation system and its IEDs in such a way that the operations of the plant and cus-

tomer specific requirements are fulfilled.

The total set of parameters and configuration data of an UAS is termed the UAS-parameter set.

It consists of the used parts of the parameter sets of all participating IEDs.

With respect to handling methods and input procedure, parameter set contents is divided into

two categories:

– configuration parameters;

– operating parameters.

With respect to origin and function, the parameters are divided into types:

– system parameters;

– process parameters;

– functional parameters.

In Figure 2, the overview of the parameter structure is given.

61850-4 © IEC:2011 – 13 –

UAS - parameter set

…

IED - parameter set

n

IED - parameter set

Configuration parameters Operating parameters

System parameters Process parameters Functional parameters

Switchable parameters

Non-switchable parameters

IEC 105/02

Figure 2 – Structure of UAS and IED parameters

The categories and types of parameters in Figure 2 are described below.

5.2.2 Parameter categories

5.2.2.1 Configuration parameters

The configuration parameters define the global behaviour of the whole UAS and its IEDs. As a

rule, they are only assigned a value during the initial parameterization, but they should be up-

dated when extending or functionally changing the UAS.

The generation and modification of the configuration parameters should be carried out off-line,

i.e. separately from the operation of the automation system. During the input of configuration

parameters, a temporary restriction of the system operation is allowed.

Observe that the term parameter in a more narrow sense means some variables, whose setting

defines the wanted behaviour. System and IED configuration needs however often more than

just setting of values. If we want to differentiate these different kinds of configuration, we talk

about “configuration data” meaning more complex parameterizations, while “configuration pa-

rameters” means an adjustment by value setting alone.

The configuration parameters of an IED usually include system and process parameters. Ob-