IEC TS 63209-2:2022

(Main)Photovoltaic modules - Extended-stress testing - Part 2: Polymeric component materials

Photovoltaic modules - Extended-stress testing - Part 2: Polymeric component materials

IEC TS 63209-2:2022 includes a menu of tests to use for evaluation of the long-term reliability of materials used as backsheets and encapsulants in PV modules. It is intended to provide information to supplement the baseline testing defined in IEC 61215 and IEC 61730, which are qualification tests with pass-fail criteria. used for reliability analysis and is not intended to be used as a pass-fail test procedure. This document addresses polymeric materials in the crystalline silicon module laminates, specifically backsheets and encapsulants in Glass/Glass or Glass/Backsheet modules. The included environmental stress tests are intended to cause degradation that is most relevant to field experience, but these may not capture all failure modes which may be observed in various locations.

General Information

- Status

- Published

- Publication Date

- 16-Aug-2022

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 2 - TC 82/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 17-Aug-2022

- Completion Date

- 14-Sep-2022

IEC TS 63209-2:2022 - Photovoltaic modules - Extended-stress testing - Part 2: Polymeric component materials

Overview

IEC TS 63209-2:2022 provides a menu of extended-stress tests for evaluating the long-term reliability of polymeric materials used in photovoltaic (PV) modules - specifically backsheets and encapsulants in Glass/Glass and Glass/Backsheet crystalline-silicon modules. This Technical Specification is intended to supplement baseline qualification tests (IEC 61215, IEC 61730) by focusing on component-level degradation mechanisms, especially those driven by UV exposure and polymer interactions. The tests are intended for reliability analysis and trend evaluation, not for pass/fail certification.

Key Topics

- Component-level extended testing: Single-component procedures that build on IEC 62788 measurement methods to probe long-term degradation modes of encapsulants and backsheets.

- BOM-specific testing: Test coupons and mini-module assemblies that reflect real bill-of-materials (BOM) interactions to reveal interface and multi-component failure modes.

- Environmental stress exposures: A suite of stress sequences (UV, humidity, thermal cycling and combinations) intended to reproduce field-relevant polymer degradation, with emphasis on stresses that act slowly at module scale.

- Reporting & characterization: Use of Uniform Characterization Forms (UCF) to standardize product identification and reliability data reporting for materials and BOM tests.

- Scope limitations: Designed for reliability evaluation and trend analysis; not intended to produce service-life estimates or be a universal surrogate for all field environments.

Applications & Who Uses It

IEC TS 63209-2 is practical for:

- Component suppliers validating encapsulant and backsheet formulations for long-term UV and environmental durability.

- Module manufacturers screening material combinations (BOM) and optimizing laminate stacks before full module qualification.

- Test laboratories and reliability engineers conducting extended exposures, collecting standardized characterization data, and performing durability analyses.

- R&D teams investigating polymer degradation mechanisms and interface interactions.

- Procurement and quality managers using extended-stress data to support material selection and supplier qualification.

Practical uses include material screening, comparative durability studies, root-cause analysis of polymeric failures observed in the field, and supplementing module-level qualification for a more comprehensive reliability assessment.

Related standards

- IEC 61215 (PV module design qualification)

- IEC 61730 (PV module safety)

- IEC TS 63209-1 (Module-level extended-stress testing)

- IEC 62788 series (material measurement procedures; encapsulants, backsheets)

- IEC TS 62788-7-2 (accelerated weathering of polymeric materials)

- IEC TS 62804-1 (PID test methods for crystalline silicon)

Keywords: photovoltaic modules, extended-stress testing, polymeric materials, backsheets, encapsulants, IEC TS 63209-2, PV module reliability, BOM-specific testing, UV degradation.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC TS 63209-2:2022 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Photovoltaic modules - Extended-stress testing - Part 2: Polymeric component materials". This standard covers: IEC TS 63209-2:2022 includes a menu of tests to use for evaluation of the long-term reliability of materials used as backsheets and encapsulants in PV modules. It is intended to provide information to supplement the baseline testing defined in IEC 61215 and IEC 61730, which are qualification tests with pass-fail criteria. used for reliability analysis and is not intended to be used as a pass-fail test procedure. This document addresses polymeric materials in the crystalline silicon module laminates, specifically backsheets and encapsulants in Glass/Glass or Glass/Backsheet modules. The included environmental stress tests are intended to cause degradation that is most relevant to field experience, but these may not capture all failure modes which may be observed in various locations.

IEC TS 63209-2:2022 includes a menu of tests to use for evaluation of the long-term reliability of materials used as backsheets and encapsulants in PV modules. It is intended to provide information to supplement the baseline testing defined in IEC 61215 and IEC 61730, which are qualification tests with pass-fail criteria. used for reliability analysis and is not intended to be used as a pass-fail test procedure. This document addresses polymeric materials in the crystalline silicon module laminates, specifically backsheets and encapsulants in Glass/Glass or Glass/Backsheet modules. The included environmental stress tests are intended to cause degradation that is most relevant to field experience, but these may not capture all failure modes which may be observed in various locations.

IEC TS 63209-2:2022 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 63209-2:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 63209-2 ®

Edition 1.0 2022-08

TECHNICAL

SPECIFICATION

colour

inside

Photovoltaic modules – Extended-stress testing –

Part 2: Polymeric component materials

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TS 63209-2 ®

Edition 1.0 2022-08

TECHNICAL

SPECIFICATION

colour

inside

Photovoltaic modules – Extended-stress testing –

Part 2: Polymeric component materials

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.160 ISBN 978-2-8322-5293-2

– 2 – IEC TS 63209-2:2022 © IEC 2022

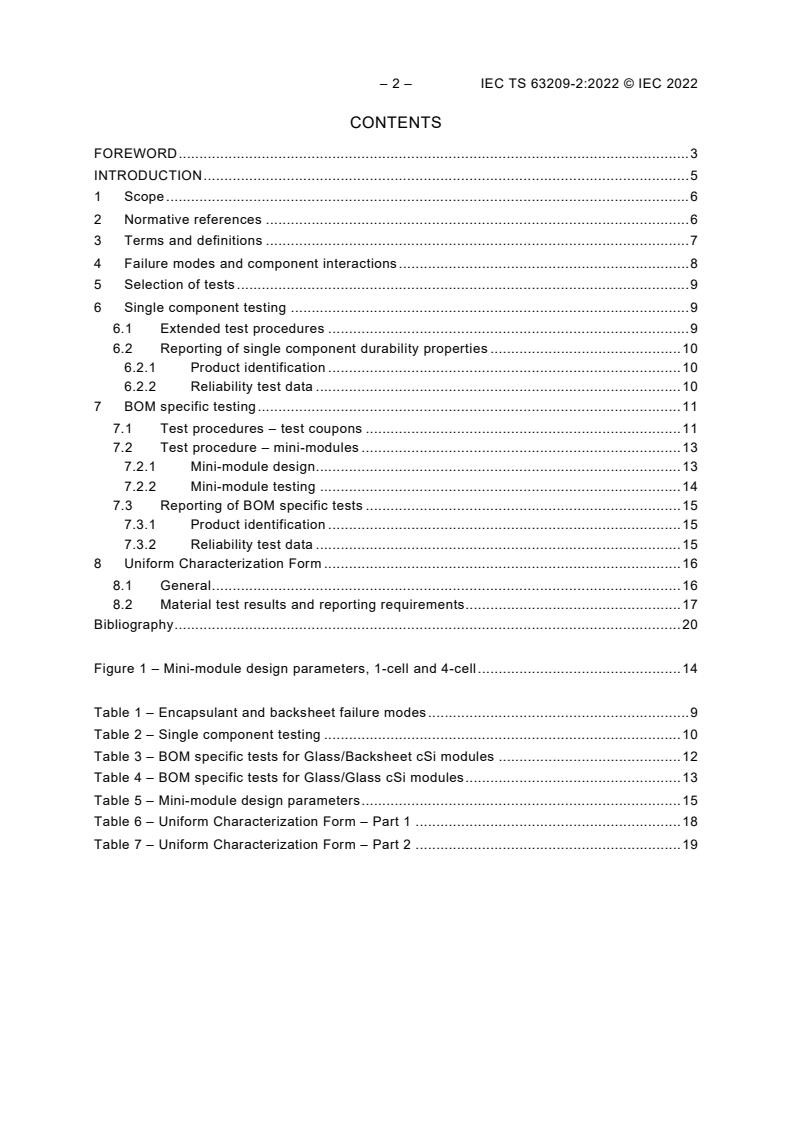

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Failure modes and component interactions . 8

5 Selection of tests . 9

6 Single component testing . 9

6.1 Extended test procedures . 9

6.2 Reporting of single component durability properties . 10

6.2.1 Product identification . 10

6.2.2 Reliability test data . 10

7 BOM specific testing . 11

7.1 Test procedures – test coupons . 11

7.2 Test procedure – mini-modules . 13

7.2.1 Mini-module design. 13

7.2.2 Mini-module testing . 14

7.3 Reporting of BOM specific tests . 15

7.3.1 Product identification . 15

7.3.2 Reliability test data . 15

8 Uniform Characterization Form . 16

8.1 General . 16

8.2 Material test results and reporting requirements . 17

Bibliography . 20

Figure 1 – Mini-module design parameters, 1-cell and 4-cell . 14

Table 1 – Encapsulant and backsheet failure modes . 9

Table 2 – Single component testing . 10

Table 3 – BOM specific tests for Glass/Backsheet cSi modules . 12

Table 4 – BOM specific tests for Glass/Glass cSi modules . 13

Table 5 – Mini-module design parameters . 15

Table 6 – Uniform Characterization Form – Part 1 . 18

Table 7 – Uniform Characterization Form – Part 2 . 19

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PHOTOVOLTAIC MODULES – EXTENDED-STRESS TESTING –

Part 2: Polymeric component materials

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC TS 63209-2 been prepared by IEC technical committee 82: Solar photovoltaic energy

systems. It is a Technical Specification.

The text of this Technical Specification: is based on the following documents:

Draft Report on voting

82/2015/DTS 82/2058A/RVDTS

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Specification is English.

A list of all parts in the IEC 63209 series, published under the general title Photovoltaic modules

– Extended-stress testing, can be found on the IEC website.

– 4 – IEC TS 63209-2:2022 © IEC 2022

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at http://www.iec.ch/standardsdev/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

INTRODUCTION

This document is intended as a guide for component suppliers, module manufacturers and

downstream durability assessments, and focuses on polymeric materials in crystalline silicon

module laminates.

IEC TS 63209 series describes environmental stress tests which provide data for evaluation of

the long-term reliability of PV modules, probing areas not addressed in the IEC 61215 and

IEC 61730 series. IEC TS 63209-1 provides a menu of extended environmental stress tests for

PV modules, and this document, IEC TS 63209-2, describes complementary component level

testing which probes degradation modes which are not easily understood or addressed by

module level testing. This document additionally describes an overlapping suite of component

level tests useful for screening individual components and component combinations for a

specific bill of materials (BOM).

The testing in this document is intended for reliability evaluation only, with no pass/fail

requirements.

This document does not describe any new test or stress exposures, but takes the single

component testing described in the IEC 62788 series as a base line for stress exposures which

are then extended. As degradation of one component can be influenced by other components

(e.g. some backsheets tested with one encapsulant may perform differently than with another,

and vice versa), a slate of BOM-specific tests and related stress exposures are included which

are described in IEC 62788 component standards, but are not typically part of component data

sheets.

This document details component level stress sequences, sample construction and evaluation

test methods which can assist in a durability analysis. A particular focus is given to UV stress

alone and in combination with other stressors. UV exposures, in particular, are difficult to

perform accurately at the module level due to time and space constraints. Polymeric

components are known to have UV-induced degradation modes which progress relatively

slowly. Testing at a component level allows for smaller sample sizes, longer stress exposures,

and test coupons designed to target relevant properties after applied stress.

– 6 – IEC TS 63209-2:2022 © IEC 2022

PHOTOVOLTAIC MODULES – EXTENDED-STRESS TESTING –

Part 2: Polymeric component materials

1 Scope

This part of IEC TS 63209 includes a menu of tests to use for evaluation of the long-term

reliability of materials used as backsheets and encapsulants in PV modules. It is intended to

provide information to supplement the baseline testing defined in IEC 61215 and IEC 61730,

which are qualification tests with pass-fail criteria. It may be used by PV stakeholders in

conjunction with IEC TS 63209-1, to provide more extended stress testing of the component

materials than can practically be accomplished with PV modules. The data set resulting from

testing is used for reliability analysis and is not intended to be used as a pass-fail test

procedure. This document addresses polymeric materials in the crystalline silicon module

laminates, specifically backsheets and encapsulants in Glass/Glass or Glass/Backsheet

modules. Although not specifically addressed, it is expected to also have applicability to thin

film technologies.

The included environmental stress tests are intended to cause degradation that is most relevant

to field experience, but these may not capture all failure modes which may be observed in

various locations.

The individual component standards provide a starting point for testing, and baseline data for

reference in this document may be available from a characterization sheet developed in

accordance with the Uniform Characterization Forms (UCF) of IEC TS 62788-2 and

IEC 62788-1-1. Extended tests using the same methods allows for trend analysis.

Additional testing is included to address interactions with other polymeric packaging material,

as individual components can perform differently depending on adjacent materials. These tests

are designed with BOM-specific coupons and mini-modules, intended to complement the

specific module bill of materials used in the IEC TS 63209-1 module tests.

As both test specimen form factor and I-V characteristics can play a role in degradation, some

multicomponent tests are designed to use a polymeric stack, while others use mini-modules.

The included stress tests are not designed to test to failure, but to be representative of stress

levels of the long-term application.

These tests are not intended to provide service life estimates, or to be indicative of fitness for

use in specific climate/mounting configurations. For example, the same module deployed in two

different locations or with different mounting methods may degrade in different ways, so a single

test protocol cannot be expected to exactly match the performance in both environments;

correlation to field will depend upon where and how the product is deployed.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC TS 60904-13:2018, Photovoltaic devices – Part 13: Electroluminescence of photovoltaic

modules

IEC 61215-1-1:2021, Terrestrial photovoltaic (PV) modules – Design qualification and type

approval -Part 1-1: Special requirements for testing of crystalline silicon photovoltaic (PV)

modules

IEC 61215-2:2021, Terrestrial photovoltaic (PV) modules – Design qualification and type

approval – Part 2: Test procedures

IEC 61730-2, Photovoltaic (PV) module safety qualification – Part 2: Requirements for testing

IEC TS 61836, Solar photovoltaic energy systems – Terms, definitions and symbols

IEC 62788-1-1, Measurement procedures for materials used in photovoltaic modules – Part 1-1:

Encapsulants – Polymeric materials used for encapsulants

IEC 62788-1-6, Measurement procedures for materials used in photovoltaic modules – Part 1-6:

Encapsulants – Test methods for determining the degree of cure in ethylene-vinyl acetate

IEC 62788-1-7:2020, Measurement procedures for materials used in photovoltaic modules –

Part 1-7: Encapsulants – Test procedure of optical durability

IEC TS 62788-2, Measurement procedures for materials used in photovoltaic modules – Part 2:

Polymeric materials – Frontsheets and backsheets

IEC TS 62788-6-3, Measurement procedures for materials used in photovoltaic modules – Part

6-3: Adhesion testing of interfaces within PV modules

IEC TS 62788-7-2:2017, Measurement procedures for materials used in photovoltaic modules

– Part 7-2: Environmental exposures – Accelerated weathering tests of polymeric materials

IEC TS 62804-1, Photovoltaic (PV) modules – Test methods for the detection of potential-

induced degradation – Part 1: Crystalline silicon

IEC TS 63209-1:2021, Photovoltaic modules – Extended-stress testing – Part 1: Modules

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC TS 62788-2,

IEC 62788-1-1, IEC 62788-1-7, IEC TS 63209-1, IEC TS 61836 along with the following apply:

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

Bill of Materials

BOM

list of the specific materials used to build a specific PV module, excluding equal alternates

3.2

Uniform Characterization Form

UCF

list of properties to be evaluated according to the tests in this document

– 8 – IEC TS 63209-2:2022 © IEC 2022

3.3

Single Cantilever Beam

SCB

adhesion test using a single cantilever beam as described in IEC TS 62788-6-3

4 Failure modes and component interactions

Degradation of polymeric materials can occur both by chemical changes to a specific material,

such as thermo-oxidative degradation, hydrolysis, photolysis, and by morphological changes,

such as reordering of type or degree of crystallinity, which can significantly alter key properties.

Subsequent mechanical, thermo-mechanical, or hydromechanical stresses such as obtained

with thermal cycling, coefficient of thermal expansion (CTE) differentials, or from volume

changes associated with moisture ingress/egress, can then induce physical degradation, such

as delamination and cracking. Observed failure modes for backsheets and encapsulants are

shown in Table 1.

Degradation of single components is evaluated by monitoring changes to key characteristics

after single stresses (exposure to damp heat (DH), thermal, and ultraviolet (UV) as specified in

the IEC 62788 series, using the Xe exposures defined in IEC TS 62788-7-2. In this document,

the UV stress is extended and includes multiple data points to observe changes and allow for

extrapolation to longer UV exposures. Specifics are detailed in the individual single component

sections.

Observed failure modes of backsheets and encapsulants include: frontside (through glass)

cracking, backside cracking, interlayer delamination, and discoloration as well as delamination

and increased optical absorption of the encapsulant.

Failure modes can be influenced by other module components (see Bibliography for references

providing pictures and more details). These interactions can result in both positive and negative

effects as shown in Table 1. BOM specific testing is used to evaluate these effects, and

adhesion.

Table 1 – Encapsulant and backsheet failure modes

Component Degradation mode Interactions with other components

cell side yellowing

encapsulant

cell side cracking

plus: UV filter

minus: chemical interactions with base polymer,

backsheet / encapsulant delamination

additives or impurities

loss of transmission (clear)

interlayer delamination n/a

air side yellowing n/a

encapsulant, connectors, cells

Backsheet

• connectors provide localized stress points which

can induce cracks

• thickness and compliance of encapsulant can

mitigate the stress from cell edges/connectors

encapsulant, con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...