IEC TR 62131-5:2015

(Main)Environmental conditions - Vibration and shock of electotechnical equipment - Part 5: Equipment during storage and handling

Environmental conditions - Vibration and shock of electotechnical equipment - Part 5: Equipment during storage and handling

IEC TR 62131-5:2015(E) reviews the available dynamic data relating to the handling of electrotechnical equipment. The intention is that from all the available data an environmental description will be generated and compared to that set out in the IEC 60721 series.

General Information

- Status

- Published

- Publication Date

- 04-Aug-2015

- Technical Committee

- TC 104 - Environmental conditions, classification and methods of test

- Drafting Committee

- WG 15 - TC 104/WG 15

- Current Stage

- PPUB - Publication issued

- Start Date

- 05-Aug-2015

- Completion Date

- 30-Jun-2015

Overview

IEC TR 62131-5:2015 is a Technical Report from the International Electrotechnical Commission (IEC) that reviews measured dynamic data for the vibration and shock environment experienced by electrotechnical equipment during storage and handling. The report compiles field measurements (container handling, intermodal movements, air cargo pallets, forklifts, unsuspended trolleys, etc.), derives an environmental description from that data, and compares it to the environmental classifications set out in the IEC 60721 series.

Key topics and technical scope

- Data sources and quality assessment - evaluation of measurement campaigns and datasets used to characterize handling environments.

- Measured environments - container terminal operations, intermodal rail/road transfer, port crane and straddle-carrier handling, air cargo pallet handling at airports, forklift operations, and unsuspended trolley movement.

- Intra- and inter-source comparisons - analysis of variability within a dataset and between different handling scenarios and measurement studies.

- Environmental description - synthesis of vibration and shock levels (spectra, amplitudes, probability densities) representative of storage and handling.

- Comparison with IEC 60721 - mapping measured severity to the IEC 60721 environmental classification framework.

- Recommendations - guidance for applying measured data to testing, classification and specification of equipment handling conditions.

- Supporting material includes numerous figures and tables (vibration spectra, shock response spectra, amplitude distributions, and tabulated peak/severity summaries).

Practical applications and users

IEC TR 62131-5 is a practical resource for professionals who need realistic, field-derived environmental descriptions for storage and handling conditions:

- Product designers and reliability engineers - use measured vibration and shock profiles to design mechanical mounts, enclosures, and shock mitigation for electronic equipment.

- Test engineers and conformity assessors - define or validate shock and vibration test conditions and test procedures (including references to IEC 60068 series test methods).

- Packaging and logistics engineers - quantify handling risks and specify protective packaging or handling procedures for electrotechnical equipment.

- Manufacturers and suppliers - write transport/storage specifications and procurement requirements aligned to measured environmental severities.

- Standards developers and researchers - use the collated data to refine environmental classifications and test standards.

Related standards

- IEC 60721 series - environmental classification for storage, transport and use (the TR compares its derived descriptions to these classifications).

- IEC 60068 family (e.g., IEC 60068-2-29) - common test methods for shock and vibration referenced in the report.

IEC TR 62131-5:2015 is best used as a data-driven reference to bridge real-world handling measurements and formal environmental classifications for robust design, testing and logistics decisions.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC TR 62131-5:2015 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Environmental conditions - Vibration and shock of electotechnical equipment - Part 5: Equipment during storage and handling". This standard covers: IEC TR 62131-5:2015(E) reviews the available dynamic data relating to the handling of electrotechnical equipment. The intention is that from all the available data an environmental description will be generated and compared to that set out in the IEC 60721 series.

IEC TR 62131-5:2015(E) reviews the available dynamic data relating to the handling of electrotechnical equipment. The intention is that from all the available data an environmental description will be generated and compared to that set out in the IEC 60721 series.

IEC TR 62131-5:2015 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 62131-5:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 62131-5 ®

Edition 1.0 2015-08

TECHNICAL

REPORT

colour

inside

Environmental conditions – Vibration and shock of electrotechnical equipment –

Part 5: Equipment during storage and handling

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC TR 62131-5 ®

Edition 1.0 2015-08

TECHNICAL

REPORT

colour

inside

Environmental conditions – Vibration and shock of electrotechnical equipment –

Part 5: Equipment during storage and handling

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.040 ISBN 978-2-8322-2815-9

– 2 – IEC TR 62131-5:2015 © IEC 2015

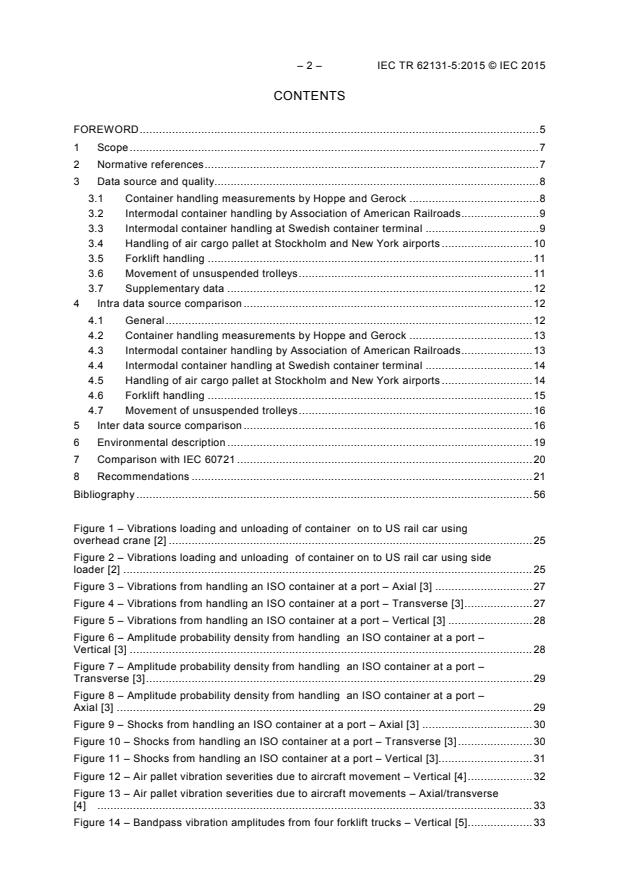

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Data source and quality. 8

3.1 Container handling measurements by Hoppe and Gerock . 8

3.2 Intermodal container handling by Association of American Railroads . 9

3.3 Intermodal container handling at Swedish container terminal . 9

3.4 Handling of air cargo pallet at Stockholm and New York airports . 10

3.5 Forklift handling . 11

3.6 Movement of unsuspended trolleys . 11

3.7 Supplementary data . 12

4 Intra data source comparison . 12

4.1 General . 12

4.2 Container handling measurements by Hoppe and Gerock . 13

4.3 Intermodal container handling by Association of American Railroads . 13

4.4 Intermodal container handling at Swedish container terminal . 14

4.5 Handling of air cargo pallet at Stockholm and New York airports . 14

4.6 Forklift handling . 15

4.7 Movement of unsuspended trolleys . 16

5 Inter data source comparison . 16

6 Environmental description . 19

7 Comparison with IEC 60721 . 20

8 Recommendations . 21

Bibliography . 56

Figure 1 – Vibrations loading and unloading of container on to US rail car using

overhead crane [2] . 25

Figure 2 – Vibrations loading and unloading of container on to US rail car using side

loader [2] . 25

Figure 3 – Vibrations from handling an ISO container at a port – Axial [3] . 27

Figure 4 – Vibrations from handling an ISO container at a port – Transverse [3] . 27

Figure 5 – Vibrations from handling an ISO container at a port – Vertical [3] . 28

Figure 6 – Amplitude probability density from handling an ISO container at a port –

Vertical [3] . 28

Figure 7 – Amplitude probability density from handling an ISO container at a port –

Transverse [3] . 29

Figure 8 – Amplitude probability density from handling an ISO container at a port –

Axial [3] . 29

Figure 9 – Shocks from handling an ISO container at a port – Axial [3] . 30

Figure 10 – Shocks from handling an ISO container at a port – Transverse [3] . 30

Figure 11 – Shocks from handling an ISO container at a port – Vertical [3]. 31

Figure 12 – Air pallet vibration severities due to aircraft movement – Vertical [4] . 32

Figure 13 – Air pallet vibration severities due to aircraft movements – Axial/transverse

[4] . 33

Figure 14 – Bandpass vibration amplitudes from four forklift trucks – Vertical [5] . 33

Figure 15 – Bandpass vibration amplitudes from four forklift trucks – Lateral [5] . 34

Figure 16 – Bandpass vibration amplitudes from four forklift trucks – Axial [5] . 34

Figure 17 – Shock response spectra from 1 000 Kg forklift truck [5] . 35

Figure 18 – Shock response spectra from 1 500 Kg forklift truck [5] . 35

Figure 19 – Shock Response Spectra from 2 000 Kg Forklift Truck [5] . 36

Figure 20 – Shock response spectra from 3 500 Kg forklift truck [5] . 36

Figure 21 – Vibration at wheels of small trolley – Vertical [6] . 37

Figure 22 – Vibration at wheels of small trolley – Lateral [6] . 37

Figure 23 – Vibration at wheels of small trolley – Axial [6] . 38

Figure 24 – Vibration at wheels of medium trolley – Vertical [6] . 38

Figure 25 – Vibration at wheels of medium trolley – Lateral [6] . 39

Figure 26 – Vibration at wheels of medium trolley – Axial [6] . 39

Figure 27 – Vibration at wheels of large trolley – Vertical [6] . 40

Figure 28 – Vibration at wheels of large trolley – Lateral [6] . 40

Figure 29 – Vibration at wheels of large trolley – Axial [6] . 41

Figure 30 – Amplitude distribution at wheels of small trolley – Vertical [6] . 43

Figure 31 – Amplitude distribution at wheels of small trolley – Lateral [6] . 43

Figure 32 – Amplitude distribution at wheels of small trolley – Axial [6] . 44

Figure 33 – Shock response spectra at wheels of small trolley – Vertical [6] . 44

Figure 34 – Shock response spectra at wheels of small trolley – Lateral [6] . 45

Figure 35 – Shock response spectra at wheels of small trolley – Axial [6] . 45

Figure 36 – Comparison of acceleration and derived velocity for largest impacts [1] . 46

Figure 37 – Comparison of acceleration and derived drop height for largest impacts [1] . 46

Figure 38 – IEC 60721-3-2– Stationary vibration random severities . 47

Figure 39 – IEC 60721-4-2– Stationary vibration random severities . 47

Figure 40 – IEC 60721-3-2– Shock severities . 48

Figure 41 – IEC 60721-4-2– Shock severities for IEC 60068-2-29 test procedure . 48

Figure 42 – IEC 60721-4-2 – Shock severities for IEC 60068-2-29 test procedure . 49

Figure 43 – Comparison of Hoppe & Gerock [1] derived shocks with IEC 60721-3-2 . 49

Figure 44 – Comparison of unsuspended trolley [6] shocks with IEC 60721-3-2 . 50

Figure 45 – Comparison of US forklift [5] shocks with IEC 60721-3-2 . 50

Figure 46 – Comparison of Swedish port [3] shocks (dockside crane) with

IEC 60721-3-2 . 51

Figure 47 – Comparison of Swedish port [3] shocks (mobile crane) with IEC 60721-3-2 . 51

Figure 48 – Comparison of Swedish port [3] shocks (straddle carrier) with

IEC 60721-3-2 . 52

Figure 49 – Comparison of Swedish port [3] shocks (transport tug) with IEC 60721-3-2 . 52

Figure 50 – Comparison of Swedish air transport [4] vibrations with IEC 60721-3-2 . 53

Figure 51 – Comparison of unsuspended trolley [6] vibrations with IEC 60721-3-2. 53

Figure 52 – Comparison of Swedish port [3] vibrations (transport tug) with

IEC 60721-3-2 . 54

Figure 53 – Comparison of Swedish port [3] vibrations (dockside crane) with

IEC 60721-3-2 . 54

Figure 54 – Comparison of Swedish PORT [3] vibrations (mobile crane) with

IEC 60721-3-2 . 55

– 4 – IEC TR 62131-5:2015 © IEC 2015

Figure 55 – Comparison of Swedish port [3] Vibrations (straddle carrier) with

IEC 60721-3-2 . 55

Table 1 – Maximum vibration accelerations and displacements occurring during

handling of ISO containers at container terminal [1] . 22

Table 2 – Largest shocks occurring during handling of ISO containers by straddle

carrier [1] . 23

Table 3 – Largest shocks occurring during transfer of ISO containers on to rail cars [1] . 23

Table 4 – Largest shocks occurring during transfer of ISO containers on to ships [1]. 24

Table 5 – Largest shocks occurring during transfer of ISO containers on to US rail cars

[2] . 24

Table 6 – Summary of vibration r.m.s. during port movements of ISO containers [3] . 26

Table 7 – Summary of peak shock severities during port movements of ISO containers

[3] . 26

Table 8 – Summary of shock levels from air cargo pallet ground operations [4] . 31

Table 9 – Summary of peak vibration levels from air cargo pallet ground operations [4] . 32

Table 10 – Summary of overall vibration severities [6] . 42

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL CONDITIONS – VIBRATION

AND SHOCK OF ELECTROTECHNICAL EQUIPMENT –

Part 5: Equipment during storage and handling

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

IEC TR 62131-5, which is a technical report, has been prepared by IEC technical committee

104: Environmental conditions, classification and methods of test.

– 6 – IEC TR 62131-5:2015 © IEC 2015

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

104/620A/DTR 104/639/RVC

Full information on the voting for the approval of this technical report can be found in the report

on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 62131 series, under the general title Environmental conditions –

Vibration and shock of electrotechnical equipment, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this standard may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

ENVIRONMENTAL CONDITIONS – VIBRATION

AND SHOCK OF ELECTROTECHNICAL EQUIPMENT –

Part 5: Equipment during storage and handling

1 Scope

IEC TR 62131-5, which is a technical report, reviews the available dynamic data relating to the

handling of electrotechnical equipment. The intention is that from all the available data an

environmental description will be generated and compared to that set out in the IEC 60721

series.

For each of the sources identified, the quality of the data is reviewed and checked for self

consistency. The process used to undertake this check of data quality and that used to

intrinsically categorize the various data sources is set out in IEC TR 62131-1.

This technical report primarily addresses data extracted from a number of different sources for

which reasonable confidence exist in its quality and validity. The report also reviews some data

for which the quality and validity cannot realistically be verified. These data are included to

facilitate validation of information from other sources. The report clearly indicates when utilising

information in this latter category.

This technical report addresses data from a number of data gathering exercises. The quantity

and quality of data in these exercises varies considerably as does the range of conditions

encompassed.

Not all of the data reviewed were made available in electronic form. To permit comparison to

be made, in this assessment, a quantity of the original (non-electronic) data has been manually

digitized.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies.

IEC 60068 (all parts), Environmental testing

IEC 60068-2-27, Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock

IEC 60068-2-29 , Environmental testing – Part 2-29: Tests –Test Eb Bump

IEC 60068-2-64, Environmental testing – Part 2-64: Tests – Test Fh: Vibration, broadband

random and guidance

IEC 60721 (all parts), Classification of environmental conditions

IEC 60721-3-2:1997, Classification of environmental conditions – Part 3: Classification of

groups of environmental parameters and their severities – Section 2: Transportation

___________

Withdrawn and now incorporated into IEC 60068-2-27.

– 8 – IEC TR 62131-5:2015 © IEC 2015

IEC TR 60721-4-2, Classification of environmental conditions – Part 4-2: Guidance for the

correlation and transformation of environmental condition classes of IEC 60721-3 to the

environmental tests of IEC 60068 – Transportation

IEC TR 62131-1, Environmental conditions – Vibration and shock of electrotechnical equipment

– Part 1: Process for validation of dynamic data

IEC TR 62131-2, Environmental conditions – Vibration and shock of electrotechnical equipment

– Part 2: Equipment transported in fixed wing jet aircraft

IEC TR 62131-3, Environmental conditions – Vibration and shock of electrotechnical equipment

– Part 3: Equipment transported in rail vehicles

IEC TR 62131-4, Environmental conditions – Vibration and shock of electrotechnical equipment

– Part 4: Equipment transported in road vehicles

3 Data source and quality

3.1 Container handling measurements by Hoppe and Gerock

Work by Hoppe and Gerock was under taken in the early 1970s and the resultant data are

reproduced in a number of publications (see [1]) .

Those data appear to have formed the basis for the road transportation severities in a number

of national standards. Moreover, as far as can be identified, they are probably the original basis

for the severities in IEC 600721-3-2. As the measured data also include a number of handling

conditions, it is likely they were also considered in setting such severities. Although the

measured data presented are limited, the scope of the measurements is sufficient to justify

their inclusion here.

The Hoppe and Gerock work relating to handling, involved vibration and shock measurements

on ISO containers at the container terminal, Hamburg/Burchardkai, during both in-yard

transport and handling. The measurements included both 6 m (20 foot) and 12 m (40 foot)

units when empty and loaded. Loaded 6 m and 12 m containers were also transferred onto a

container train by means of a gantry crane. Dock side to ship measurements were made on

loaded 6 m containers only.

Acceleration measurements were made at six locations within the containers; door end centre

(in three orthogonal axes), door end right hand side (vertical only), centre of container (vertical

only) and at the forward wall centre (vertical only). All six measurements were recorded

simultaneously and continuously on an analogue FM recorder. The frequency range covered

was 1 Hz to 1 250 Hz. All PSD analysis was undertaken using a 3 Hz frequency resolution and

a record duration of 32 s.

The ISO containers used comprised steel framed structures with plywood walls with roofs

reinforced with laminated fibreglass. The 6 m container was manufactured in 1969/70, it had an

empty mass of 1 950 Kg and a loaded mass of 20 320 Kg. The 12 m containers were

manufactured in 1970/71, had an empty mass of 3 490 Kg and a loaded mass of 30 480 Kg.

The container vibration measurements made during movement around the container terminal

are summarised in Table 1. The measurements were found to contain predominant resonances

associated with the suspension of the straddle or van carrier used to undertake the movements

(typically at between 2 Hz to 3 Hz), the spreader used to support the container (6 Hz to 7 Hz)

___________

Numbers in square brackets refer to the Bibliography.

and of the containers themselves (at around 160 Hz, 240 Hz and 400 Hz). The largest

accelerations and displacements were consistently found to occur in the vertical direction and

at the centre of the container. The largest derived displacement arose from carriage of the

empty 6 m container at the maximum permissible speed. For the other container conditions the

maximum speed was 20 km/h to 25 km/h.

The corresponding shock measurements when the containers were handled by the straddle or

van carrier are summarized in Table 2. These include peak amplitudes occurring during pick

up, set down on to the ground as well as set down on to another container. Again the largest

accelerations were consistently found to occur in the vertical direction and at the centre of the

container. The largest shocks were noted to occur during engagement and disengagement of

the spreader.

The Hoppe and Gerock work also included measurements picking up and setting down

containers on to rail vehicles (summarized in Table 3) and during transfer on to ships

(summarized in Table 4).

The shock measurements are all presented in terms of peak acceleration amplitude and shock

duration. No time histories are presented so the method used for the derivation of shock

duration cannot be verified. Only one Shock Response Spectra (SRS) for handling is presented

and its origins are unclear.

Although the information in this report is limited the quality of the information is reasonable and

meets the required validation criteria for data quality (single data item).

3.2 Intermodal container handling by Association of American Railroads

This relatively recent (1991) work from the Association of American Railroads (see [2])

concerns the measurement and analysis of vibration and shock conditions experienced by

standard ISO containers when transported by both rail and road. The objective was primarily to

establish the relationship between the vibration and shock conditions experienced during rail

and road movements. However, the work also includes shock and vibration measurements that

occurred during handling. The data source relates almost entirely to ISO containers on the US

and Canadian rail system.

The report indicates that the handling measurements utilized a self contained recorder. The

recorder was programmed to record data in 7,7 sblocks of data when a threshold of 0,1 g was

exceeded for more than 3,9 ms. These recorder settings were selected in an attempt to collect

data virtuously continuously. The sample rate was 256 samples per second (sps) filtered at 30

Hz with a Butterworth low pass filter. The pre-programmable data recorders housed three

orthogonal accelerometers capable of DC measurement (using piezoresistive accelerometers)

in the vehicle fore/aft, lateral and vertical axes.

Measurements were made on a trailer carrying a 12 m (40 foot) ISO container, whilst it was

loaded on and off rail cars. The loading and unloading adopted both overhead crane and a

sideloader. The peak acceleration levels from these operations are summarized in Table 5 and

the associated acceleration power spectral densities are shown in Figures 1 and 2.

The information in this report is limited to a trailer carrying 12 m (40 foot) ISO containers. It

may also be specific to the US and Canadian rail systems. However, the quality of the

information is good and meets the required validation criteria for data quality (single data item).

3.3 Intermodal container handling at Swedish container terminal

These very recent measurements (2007) were undertaken by Mariterm AB in conjunction with

Helsingborgs container port (see [3]). The measurements relate to the handling of a 12 m

(40 foot) empty container at the Helsingborgs container port.

– 10 – IEC TR 62131-5:2015 © IEC 2015

The measurements were acquired using a data acquisition DT9816 recorder; this allowed

measurement of 6 channels (2 × three orthogonal axes) of acceleration measurements. The

digital recorder comprised a 12 bit ADC sampling at 1 500 sps. Four channels of

measurements were low pass filtered at 370 Hz (one tri-axial and the fore/aft channel of the

other) and two channels at 500 Hz. The accelerometers were positioned along the centre line

of the container, on the floor and around 6 m apart. Although, the measurement axis of each

channel is known, the specific identification of the tri-axial accelerometer is unclear. For this

reason, the measurements are designated as from transducer groups 1 and 2.

The recorder measurement range was set to 10 g, which in comparison to other exercises, is

somewhat low. Moreover, a few of the shocks, specifically in the vertical axis, appear to

exceed this measurement range.

Measurements were made during handling of the container by a dockside container crane,

movement by a container tug, handling by a container crane and handling by a straddle carrier.

For each condition several separate measurement runs were made. Some attempt appears to

have been made at making the measurements during different severities of handling

conditions.

The report [3] supplies both sample time histories (albeit encompassing the entire record,

typically 10 min to 20 min) and summary peak acceleration data along with approximate

duration of the shock event. However, in addition to the report, the electronic measured data

were also made available.

From the electronic data, summary information on the vibration severities are assembled in

Table 6 and summary information of the highest shocks measured is presented in Table 7.

Envelopes of the vibration acceleration power spectral densities, from each of the four handling

conditions and for each axis, are presented in Figures 3 to 5. Amplitude probability densities,

again for each of the four handling conditions and for each axis, are presented in Figures 6

to 8. Shock response spectra are presented in Figures 9 to 11.

Although the information in the hardcopy report is limited, the quality of the electronic

information is good and meets the required validation criteria for data quality (single data item).

3.4 Handling of air cargo pallet at Stockholm and New York airports

The Swedish Packaging Research Institute reported a field study of loadings on an air cargo

pallet in 1988 (see [4]). The measurements were made both on board a Boeing 747 Combi

(freight and passenger) aircraft and also during cargo handling operations at both Stockholm

airport (Arlanda) and New York (John F. Kennedy Airport). Shock and vibration acting on the

cargo during handling were measured and analysed.

A tri-axial accelerometer was mounted on the pallet with double-sided tape and was placed

approximately midway along the length of the pallet, about 0,5 m from the pallet edge. A fourth,

separate, vertical accelerometer was mounted near the end of the pallet, approximately 0,5 m

from the corner. The transducers were not mounted on the cargo in an attempt to establish

acceleration measurements sensibly independent of cargo type. Nevertheless, the pallet loads

chosen were 'typical'. During the outward stages (stages 1 to 3) the weight of the test pallet

was 1 470 kg and during the return journey (stages 4 and 5) the weight was 2 550 kg. The

measurement encompassed five stages:

– Stage 1 Arlanda terminal to aircraft, pallet weight 1 470 kg;

– Stage 2 Arlanda movement at aircraft, pallet weight 1 470 kg;

– Stage 3 JFK aircraft to terminal, pallet weight 1 470 kg;

– Stage 4 JFK terminal to aircraft, pallet weight 2 550 kg;

– Stage 5 JFK loading on aircraft, pallet weight 2 550 kg.

The field data recorded during the trip have been computer analysed in the time and frequency

domains. The frequency domain analysis was carried out using both conventional spectral

analysis and autoregressive modelling techniques. The sampling frequency chosen was 100 Hz

and the signal was low-pass filtered at 31,5 Hz. The number of records, each spanning

256 samples, depended on the conditions under investigation. However, this was limited to

350 records, i.e. a sampling time of no more than 15 min. The window mostly used for the

frequency analysis was the Blackman window. For the analysis using autoregressive modelling

for the spectral estimation, the Hamming window was used.

A summary of the recorded extreme handling shock values and r.m.s. values are given in

Table 8. A summary of the corresponding vibration data is shown in Table 9. The vibration data

comprise acceleration levels (g) exceeded for 1 % of the time of the trial. Vibration spectra for

each stage are shown in Figures 12 and 13 for the vertical and transverse axes respectively.

3.5 Forklift handling

This 1975 measurement exercise (see [5]) was undertaken by M.B. Gens at the Sandia

Laboratories in the US adopted a common payload and four different size forklift trucks.

Although a little old these measurements are the basis for conditions in several standards.

The measurement exercise addressed the transient conditions arising from traversing a test

track made up of paved and unpaved areas. The paved areas included asphalt streets with

manhole covers and metal utility covers as well as concrete aprons and driveways. The paved

surfaces included both new and smooth surfaces as well as old and deteriorated surfaces. The

unpaved areas were not intended as a driving surface and included steps of up to 25 mm.

Experienced drivers were used, each instructed to travel at highest speed possible consistent

with retaining the payload. In general, speeds were reported to be less than 10 mph (16 km/h)

and mostly below 5 mph (8 km/h).

The measurements were made both on a pallet carrying a payload and the payload itself. The

report indicates the payload as having a mass of 1 000 lb (500 Kg). The four forklift trucks were

characterized as

– 1 000 kg (2 000 lb) capacity, electric powered and solid tyres;

– 1 500 kg (3 000 lb) capacity, petrol powered and pneumatic tyres;

– 2 000 kg (4 000 lb) capacity, petrol powered and pneumatic tyres;

– 3 500 kg (7 000 lb) capacity, petrol powered and pneumatic tyres.

The measurements were made using two groups of orthogonally orientated transducers; one

group selected and set to measure accelerations up to 50 g peak-to-peak, the other to 10 g

peak-to-peak. Tri-axial measurements from both groups were made at two locations; one close

to the input from the forks and the other on the skin of the payload. All measurements were

recorded on an FM tape recorder.

The 5 Hz band pass analysis of the data elicited the conclusion that no steady state continuous

randomly distributed excitation was present in the forklift environment. Discrete excitations, on

the other hand were prevalent. A total of 49 vibration spectra (from all four forklift trucks) were

combined to allow plots of mean, mean plus three standard deviations as well an envelope of

maximum response. The responses for the pallet measurements (effectively the excitations

applied to the payload) are shown in Figures 14 to 16 for the vertical, lateral and axial axes

respectively. The envelopes of largest shock response spectra for each of the four forklift

trucks are shown in Figures 17 to 20.

3.6 Movement of unsuspended trolleys

This very recent (2009) measurement exercise (see [6]) was undertaken, by Drager Medical, to

determine the vibration and shock conditions arising from the movement of medical trolleys

over flooring typically occurring within modern building and outside in car park type surfaces.

The three trolleys have small, unsuspended castor type wheels which are common to many

– 12 – IEC TR 62131-5:2015 © IEC 2015

items of modern electro-technical equipment. They are also typical of handling trolleys

commonly used to move small packages on and off trucks and around warehouses. All the

movement occurred at walking speed.

The measurements were made on three different medical devices as set out below. In each

case the tri-axial acceleration vibration measurement were made on the support system, just

above the wheels:

– small trolley – A small medical ventilator, mass 22,5 kg, castors 100 mm diameter, castor

surface PA6 of hardness Shore A 80;

– medium trolley – Anaesthetic workstation, mass 147 kg, castors 125 mm diameter, castor

surface polyurethane of hardness Shore D 40;

– large trolley – Intensive care ventilator, mass 54 kg, castors 125 mm diameter, castor

surface polyurethane of hardness Shore D 40.

The intended velocity of the movements was 0,5 m/s although the real velocity appears to have

varied between 0,5 m/s and 0,7 m/s. Movement was in the X (axial) axis with the Z axis

vertical. The typical 5 surface types traversed were

• composite stone,

• granite plates 70 cm × 70 cm,

• pvc floor 60 cm × 60 cm at 0,5 m/s and 0,7 m/s,

• asphalt light grey,

• asphalt rough.

The transducers and measurement system are indicated as within calibration. The digital

recorder sample rate was 8 192 sps and the remainder of the measurement chain was capable

of measurements of at least 3 kHz. The recorder utilized a 16 bit ADC, an anti-aliasing filter of

3,2 kHz. The measurement record lengths varied between 1 min and 3 min although 120 s was

commonly achieved. In this case the measured data and all the analysis are available digitally.

Shown in Figures 21 to 29 are the vibration severities for each of the three axes for each of the

three devices. A summary of the corresponding overall acceleration root mean square values

are presented in Table 10. Amplitude Probability Density (APD) values for the device which

experienced the most severe conditions (the small medical ventilator) are show in Figures 30 to

32. Corresponding Shock Response Spectra (SRS) for the same device are shown in Figures

33 to 35.

3.7 Supplementary data

The data collection exercises which preceded this particular assessment attempted to

supplement the data with any relevant sets of information, arising from reputable sources, but

for which the data quality could not be adequately verified. Although no additional sources were

identified, a SRETS study (see [7]) undertaken during 1998 reviewed the types and

occurrences of damage that occur as a result of transportation and particularly that identified

during handling related to transportation. Although that report (see [8]) contains no specific

information on the mechanical environments occurring during handling, it does give a good

review of the different types of damage a range of items may experience during handling.

4 Intra data source comparison

4.1 General

The purpose of the following subclauses is to review each data source for self consistency.

The process for evaluating the vibration data takes into account the variations arising from the

different methods of handling.

4.2 Container handling measurements by Hoppe and Gerock

Although the extent of the vibration information, tabulated in the Hoppe and Gerock report, is

relatively limited it does, with one exception, appear reasonably consistent. The acceleration

amplitudes are quite low, possibly giving rise to concerns over measurement accuracy. The

derived displacements are relatively high, for the low acceleration levels, suggesting low

frequency excitations (which are confirmed in the report). With that said, the report does not

make clear the method used for deriving displacements from the acceleration measurements.

The concern is that high displacements can arise if this is not undertaken appropriately. The

distribution of amplitudes between full and empty containers, as well as between axes, is

largely as would be expected. The one value that is out of line with the remainder is the vertical

measurement on empty containers. The acceleration amplitude indicated is more than double

any other tabulated value and the listed peak displacement is four times greater than any other.

The occurrence of this condition is explained in the report as due to high movement speeds.

The indicated peak displacement is essentially the same as the largest equivalent drop height

suggested from consideration of the shocks.

The tabulated handling impact acceleration amplitude values, presented in the Hoppe and

Gerock report, indicate an underlying trend. That is smaller empty container generally generate

the worst case conditions whilst the largest loaded containers generally result in lower impact

acceleration amplitudes. This is entirely as would be expected.

The shock data quotes acceleration amplitudes as well as durations. As a consequence of the

different approaches used, the validity of tabulated shock durations, without a description of

how they were derived, is always questionable. A verification exercise has been undertaken,

which assumes the shocks are a result of impacts between two elastic bodies. The exercise

indicates that the accelerations and the derived velocities follow a realistic and consistent

relationship, Figures 36 and 37 refer respectively. Only a few values fall outside the main trend

but even those are only to an extent expected from measured data. The largest indicated

velocity change is 0,6 m/s with the majority of impacts occurring below 0,4 m/s. The values

suggest that size of container or its loaded state makes no underlying difference to the velocity.

The largest equivalent drop height, derived from the velocities, is a little less than 19 mm.

The Hoppe and Gerock report supplies only a single shock response spect

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...