IEC 62788-1-4:2016

(Main)Measurement procedures for materials used in photovoltaic modules - Part 1-4: Encapsulants - Measurement of optical transmittance and calculation of the solar-weighted photon transmittance, yellowness index, and UV cut-off wavelength

Measurement procedures for materials used in photovoltaic modules - Part 1-4: Encapsulants - Measurement of optical transmittance and calculation of the solar-weighted photon transmittance, yellowness index, and UV cut-off wavelength

IEC 62788-1-4:2016 provides a method for measurement of the optical transmittance of encapsulation materials used in photovoltaic (PV) modules. The standardized measurements in this procedure quantify the expected transmittance of the encapsulation to the PV cell. Subsequent calculation of solar-weighted transmittance allows for comparison between different materials. The results for unweathered material may be used in an encapsulation manufacturer's datasheets, in manufacturer's material or process development, in manufacturing quality control (material acceptance), or applied in the analysis of module performance. This measurement method can also be used to monitor the performance of encapsulation materials after weathering, to help assess their durability.

Procédures de mesure des matériaux utilisés dans les modules photovoltaïques - Partie 1-4: Encapsulants - Mesurage du facteur de transmission optique et calcul du facteur de transmission photonique à pondération solaire, de l'indice de jaunissement et de la fréquence de coupure des UV

L'IEC 62788-1-4:2016 fournit une méthode de mesure du facteur de transmission optique des matériaux d'encapsulation utilisés dans les modules photovoltaïques (PV). Les mesurages normalisés de cette procédure permettent de quantifier le facteur de transmission prévu de l'encapsulation vers la cellule PV. Le calcul ultérieur du facteur de transmission à pondération solaire permet de comparer les différents matériaux. Les résultats concernant les matériaux non exposés aux intempéries peuvent être utilisés dans les fiches techniques d'un fabricant d'encapsulation, dans le développement des matériaux ou du procédé du fabricant, dans le contrôle de la qualité de fabrication (acceptation du matériau) ou être appliqués dans l'analyse des performances du module. Cette méthode de mesure peut également être utilisée pour contrôler les performances des matériaux d'encapsulation après exposition aux intempéries, afin d'évaluer leur durabilité.

General Information

- Status

- Published

- Publication Date

- 26-Sep-2016

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 2 - TC 82/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Sep-2016

- Completion Date

- 15-Nov-2016

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62788-1-4:2016 is an international standard published by the International Electrotechnical Commission (IEC) that provides a detailed method for measuring the optical transmittance of encapsulant materials used in photovoltaic (PV) modules. This standard is essential for quantifying the amount of light that passes through encapsulants-the protective materials enveloping PV cells-and calculating key performance indicators such as the solar-weighted photon transmittance, yellowness index, and ultraviolet (UV) cut-off wavelength. These parameters help in comparing different encapsulation materials, assessing their durability, and improving PV module performance.

Key Topics

- Optical Transmittance Measurement: Standardized procedures to accurately measure how much solar radiation passes through PV module encapsulants, ensuring consistent and repeatable results.

- Solar-weighted Photon Transmittance: Calculation method to weight transmittance values according to the solar spectrum, allowing fair comparison of materials based on actual solar energy penetration.

- Yellowness Index (YI): Quantification of color changes in encapsulants post-weathering-important for assessing aesthetic and functional durability.

- UV Cut-off Wavelength: Measurement of the threshold wavelength below which UV radiation is blocked by the encapsulant, vital for understanding UV protection capabilities.

- Test Specimen Preparation and Conditioning: Guidelines covering unweathered and weathered sample handling for relevant and consistent testing.

- Measurement Apparatus and Calibration: Equipment specifications and calibration methods to ensure precision in optical measurements.

- Data Processing and Reporting: Procedures for analyzing measurement data and standardized reporting formats to aid manufacturers and researchers.

Applications

The procedures and metrics outlined in IEC 62788-1-4 are crucial for multiple stakeholders across the solar energy industry:

- Encapsulation Manufacturers: Use unweathered material data for product datasheets, materials development, and process optimization.

- PV Module Producers: Incorporate transmittance and durability metrics to enhance manufacturing quality control and material acceptance criteria.

- Research and Development: Evaluate new encapsulant formulations and their resistance to environmental degradation through tested yellowness index and UV blocking capabilities.

- Durability Monitoring: Track performance changes in encapsulants after accelerated or natural weathering to predict lifespan and long-term reliability of PV modules.

- Performance Analysis: Provide insights into how encapsulant properties influence overall module efficiency by analyzing solar-weighted photon transmittance in specific PV cell technologies.

Related Standards

IEC 62788-1-4 references and complements several essential international standards to ensure comprehensive evaluation of PV encapsulants:

- IEC 60904-3: Measurement principles for terrestrial photovoltaic solar devices with reference spectral irradiance data.

- ISO 291:2008: Standard atmospheres for conditioning and testing plastics.

- ISO 11664-1 and ISO 11664-2: Standards for colorimetry defining observers and standard illuminants.

- ISO 13468-2:1999: Determination of total luminous transmittance of transparent materials.

- ISO 17223:2014: Determination of yellowness index and its changes.

- ASTM E424-71:2007: Test methods for solar energy transmittance and reflectance of sheet materials.

These standards together provide a robust framework for consistent, repeatable, and internationally recognized measurement and assessment of PV encapsulant materials.

By adhering to IEC 62788-1-4:2016, manufacturers and researchers can ensure that photovoltaic encapsulants meet stringent performance criteria, optimize module efficiency, and maintain long-term reliability under solar exposure. This standard supports the development of more durable, transparent, and UV-protective encapsulant materials, thereby advancing solar photovoltaic technology worldwide.

IEC 62788-1-4:2016 - Measurement procedures for materials used in photovoltaic modules - Part 1-4: Encapsulants - Measurement of optical transmittance and calculation of the solar-weighted photon transmittance, yellowness index, and UV cut-off wavelength

IEC 62788-1-4:2016+AMD1:2020 CSV - Measurement procedures for materials used in photovoltaic modules - Part 1-4: Encapsulants - Measurement of optical transmittance and calculation of the solar-weighted photon transmittance, yellowness index, and UV cut-off wavelength Released:10/15/2020

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 62788-1-4:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Measurement procedures for materials used in photovoltaic modules - Part 1-4: Encapsulants - Measurement of optical transmittance and calculation of the solar-weighted photon transmittance, yellowness index, and UV cut-off wavelength". This standard covers: IEC 62788-1-4:2016 provides a method for measurement of the optical transmittance of encapsulation materials used in photovoltaic (PV) modules. The standardized measurements in this procedure quantify the expected transmittance of the encapsulation to the PV cell. Subsequent calculation of solar-weighted transmittance allows for comparison between different materials. The results for unweathered material may be used in an encapsulation manufacturer's datasheets, in manufacturer's material or process development, in manufacturing quality control (material acceptance), or applied in the analysis of module performance. This measurement method can also be used to monitor the performance of encapsulation materials after weathering, to help assess their durability.

IEC 62788-1-4:2016 provides a method for measurement of the optical transmittance of encapsulation materials used in photovoltaic (PV) modules. The standardized measurements in this procedure quantify the expected transmittance of the encapsulation to the PV cell. Subsequent calculation of solar-weighted transmittance allows for comparison between different materials. The results for unweathered material may be used in an encapsulation manufacturer's datasheets, in manufacturer's material or process development, in manufacturing quality control (material acceptance), or applied in the analysis of module performance. This measurement method can also be used to monitor the performance of encapsulation materials after weathering, to help assess their durability.

IEC 62788-1-4:2016 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62788-1-4:2016 has the following relationships with other standards: It is inter standard links to IEC 62788-1-4:2016/AMD1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62788-1-4:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62788-1-4 ®

Edition 1.0 2016-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Measurement procedures for materials used in photovoltaic modules –

Part 1-4: Encapsulants – Measurement of optical transmittance and calculation

of the solar-weighted photon transmittance, yellowness index, and UV cut-off

wavelength

Procédures de mesure des matériaux utilisés dans les modules

photovoltaïques –

Partie 1-4: Encapsulants – Mesurage du facteur de transmission optique

et calcul du facteur de transmission photonique à pondération solaire,

de l'indice de jaunissement et de la fréquence de coupure des UV

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC 65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62788-1-4 ®

Edition 1.0 2016-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Measurement procedures for materials used in photovoltaic modules –

Part 1-4: Encapsulants – Measurement of optical transmittance and calculation

of the solar-weighted photon transmittance, yellowness index, and UV cut-off

wavelength

Procédures de mesure des matériaux utilisés dans les modules

photovoltaïques –

Partie 1-4: Encapsulants – Mesurage du facteur de transmission optique

et calcul du facteur de transmission photonique à pondération solaire,

de l'indice de jaunissement et de la fréquence de coupure des UV

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.160 ISBN 978-2-8322-3634-5

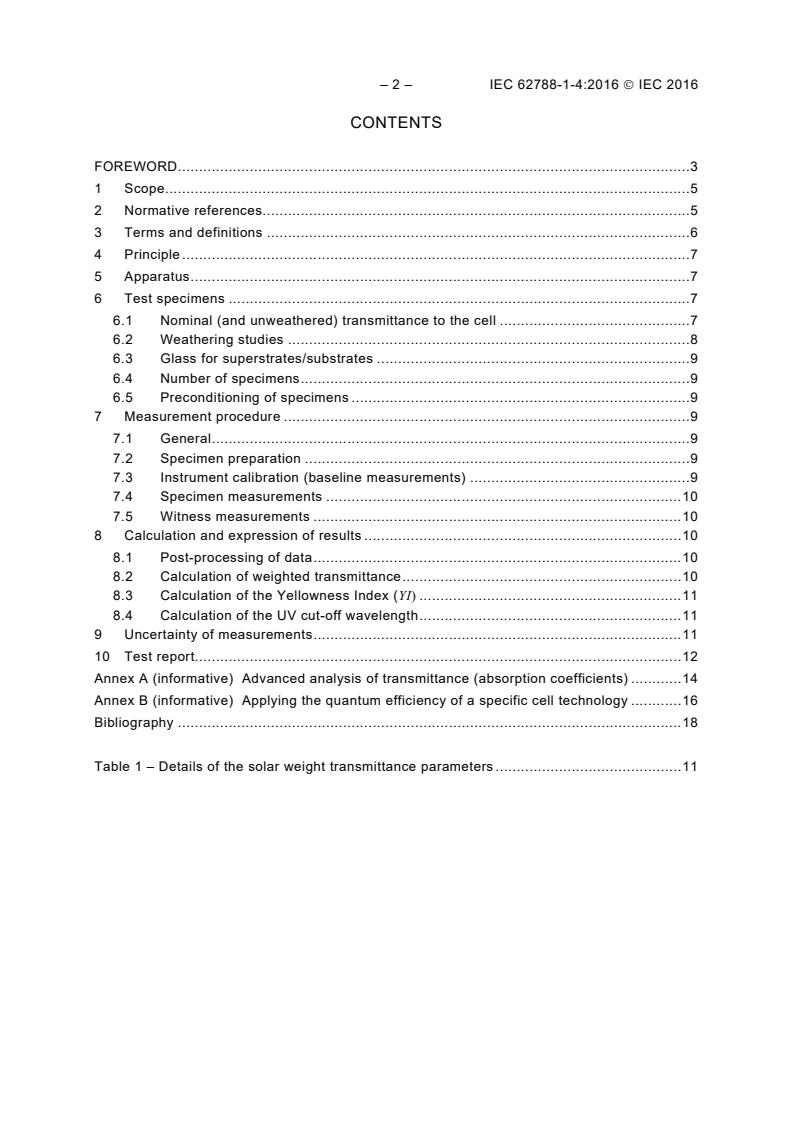

– 2 – IEC 62788-1-4:2016 IEC 2016

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references. 5

3 Terms and definitions . 6

4 Principle . 7

5 Apparatus . 7

6 Test specimens . 7

6.1 Nominal (and unweathered) transmittance to the cell . 7

6.2 Weathering studies . 8

6.3 Glass for superstrates/substrates . 9

6.4 Number of specimens . 9

6.5 Preconditioning of specimens . 9

7 Measurement procedure . 9

7.1 General . 9

7.2 Specimen preparation . 9

7.3 Instrument calibration (baseline measurements) . 9

7.4 Specimen measurements . 10

7.5 Witness measurements . 10

8 Calculation and expression of results . 10

8.1 Post-processing of data . 10

8.2 Calculation of weighted transmittance . 10

8.3 Calculation of the Yellowness Index (YI) . 11

8.4 Calculation of the UV cut-off wavelength . 11

9 Uncertainty of measurements . 11

10 Test report. 12

Annex A (informative) Advanced analysis of transmittance (absorption coefficients) . 14

Annex B (informative) Applying the quantum efficiency of a specific cell technology . 16

Bibliography . 18

Table 1 – Details of the solar weight transmittance parameters . 11

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MEASUREMENT PROCEDURES FOR MATERIALS

USED IN PHOTOVOLTAIC MODULES –

Part 1-4: Encapsulants – Measurement of optical transmittance and

calculation of the solar-weighted photon transmittance,

yellowness index, and UV cut-off wavelength

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62788-1-4 has been prepared by IEC technical committee 82:

Solar photovoltaic energy systems.

The text of this standard is based on the following documents:

FDIS Report on voting

82/1148/FDIS 82/1165/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

– 4 – IEC 62788-1-4:2016 IEC 2016

A list of all parts in the IEC 62788 series, published under the general title Measurement

procedures for materials used in photovoltaic modules, can be found on the IEC website.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

MEASUREMENT PROCEDURES FOR MATERIALS

USED IN PHOTOVOLTAIC MODULES –

Part 1-4: Encapsulants – Measurement of optical transmittance and

calculation of the solar-weighted photon transmittance,

yellowness index, and UV cut-off wavelength

1 Scope

This part of IEC 62788 provides a method for measurement of the optical transmittance of

encapsulation materials used in photovoltaic (PV) modules. The standardized measurements

in this procedure quantify the expected transmittance of the encapsulation to the PV cell.

Subsequent calculation of solar-weighted transmittance allows for comparison between

different materials. The results for unweathered material may be used in an encapsulation

manufacturer’s datasheets, in manufacturer’s material or process development, in

manufacturing quality control (material acceptance), or applied in the analysis of module

performance.

This measurement method can also be used to monitor the performance of encapsulation

materials after weathering, to help assess their durability. The standardized measurements

are intended to examine an interior region within a PV module, e.g., without the effects of

oxygen diffusion around the edges of the cells. Subsequent calculation of yellowness index

allows for quantification of durability and consideration of appearance. The change in

transmittance, yellowness index, and ultraviolet (UV) cut-off wavelength may be used by

encapsulation or module manufacturers to compare the durability of different materials.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60904-3, Photovoltaic devices – Part 3: Measurement principles for terrestrial

photovoltaic (PV) solar devices with reference spectral irradiance data

ISO 291:2008, Plastics – Standard atmospheres for conditioning and testing

ISO 11664-1:2007, Colorimetry – Part 1: CIE standard colorimetric observers

ISO 11664-2:2007, Colorimetry – Part 2: CIE standard illuminants

ISO 13468-2:1999, Plastics – Determination of the total luminous transmittance of transparent

materials – Part 2: Double-beam instrument

ISO 17223:2014, Plastics – Determination of yellowness index and change in yellowness

index

ASTM E424-71:2007, Standard test methods for solar energy transmittance and reflectance

(Terrestrial) of sheet material

– 6 – IEC 62788-1-4:2016 IEC 2016

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

NOTE In cases where definitions already exist, refer to IEC TS 61836. Calculations related to these definitions

are given in Clause 8.

3.1

solar-weighted transmittance of photon irradiance

–2 –1 –1

proportion of the solar spectral photon irradiance (E , m ·s ·nm ) optically transmitted

pλ

through the specimen, throughout the range of the terrestrial solar spectrum (280 nm to

2 500 nm) (see Table 1)

–2 –1 –1

Note 1 to entry: The photon irradiance (E , m ·s ·nm ) accounts for the wavelength-specific energy of the

pλ

–2 –1

optical flux and should not be confused with spectral irradiance (E , W·m ·nm ).

λ

3.2

representative solar-weighted transmittance of photon irradiance

–2 –1 –1

proportion of the solar spectral photon irradiance (E , m ·s ·nm ) optically transmitted

pλ

through the specimen, throughout the range of the terrestrial solar spectrum (300 nm to

1 250 nm) (see Table 1)

Note 1 to entry: In the case of a PV device, the representative solar-weighted transmittance of photon irradiance

is defined throughout the range of the spectrum utilized by a representative PV device (which may not include

wavelengths as low as 280 nm or as great as 2 500 nm).

3.3

UV cut-off wavelength

λ

cUV

wavelength of light below which the encapsulation is considered optically absorbing and

above which the encapsulation is considered transmitting

Note 1 to entry: In this procedure, the absolute transmittance of 10 % (corresponding to the optical absorbance of

1) is considered as the threshold of the UV cut-off wavelength. As described further in [9] , the UV cut-off

wavelength may also be used to quantify the effects of weathering.

3.4

weathering

process of subjecting specimens to environmental conditions that could include ultra-violet

radiation, temperature, humidity, and ozone

Note 1 to entry: Weathering may occur in artificial or natural environments. Weathering could occur at the nominal

(field) or an accelerated rate.

3.5

yellowness index

YI

calculated value identifying the yellowness of the test specimen perceived by a human

observer (see ASTM E313-10)

Note 1 to entry: YI may be used to quantify the effects of weathering.

_____________

Numbers in square brackets refer to the Bibliography.

4 Principle

The total spectral transmittance of laminated specimens, containing encapsulation material,

shall be measured using a spectrophotometer equipped with an integrating sphere. Solar-

weighted transmittance, yellowness index, and UV cut-off wavelength will be subsequently

calculated from the transmittance measurements.

The transmittance measured using this procedure may be used in a more advanced optical

analysis to improve the accuracy of PV performance analysis or distinguish between different

encapsulation materials, as described in Annex A. The transmittance measured using this

procedure may be used to estimate module performance (current yield) if the quantum

efficiency of the PV cell is known, as described in Annex B. The method does not attempt to

account for variations in transmittance with the angle of incidence, which may vary with time

of day, sky conditions, and geometry of the module, especially if concentration is used.

5 Apparatus

The test instrument shall consist of a double beam spectrophotometer equipped with an

integrating sphere. A single beam spectrophotometer may be used if the port reflectance can

be properly accounted for, as in Annex A and [2]. Details regarding the construction and

configurations of the test instrument may be found in ISO 13468-2 or ASTM E424-71. A

measurement range of at least 280 nm to 2 500 nm is required for calculation of the solar-

weighted transmittance using the AM1.5 global spectrum as in IEC 60904-3. A wavelength

increment no larger than 1 nm is preferred for the measurement, however increments up to

5 nm are permitted with linear interpolation to 1 nm.

An integrating sphere of at least 100 mm in diameter with a port area of < 5 %, as in [11], is

recommended to reduce the error in the measurement. The port area as in [9] should not

exceed 13 %.

6 Test specimens

6.1 Nominal (and unweathered) transmittance to the cell

Specimens shall be constructed using a laminate structure of glass/encapsulation, as

described in Annex A and [12].

The solar-weighted transmittance and representative solar-weighted transmittance, as

calculated in Clause 8, may be used for the purpose of reporting on an encapsulation

manufacturer’s datasheet.

The specimens shall contain an examination region free from visible flaws including:

scratches, pits, sink marks, bubbles, or other imperfections. The examination region shall be

at least 50 % larger in diameter than the measurement area of the test instrument.

NOTE 1 A spot size of 1 cm × 1 cm is common in many commercial spectrophotometer instruments. Use of

specimens at least 2 to 3 times this size will improve uniformity (resulting from fabrication) and handling (during

measurement).

The size (length and width) should be adequate to allow the specimen to fit inside the test

instrument.

The nominal thickness of the encapsulation specimens shall be equal to the thickness

intended for use in PV modules.

Specimens should be cured (if applicable) according to the manufacturer’s specification and

using a process as similar as possible to the method used in the intended manufacturing

process.

– 8 – IEC 62788-1-4:2016 IEC 2016

The thickness of the encapsulation portion of the test specimen shall be measured after its

preparation. The thickness shall be taken as the average of three measurements obtained at

different locations on the test region of the specimen.

Glass plates shall be parallel with minimal edge pinch or edge flare. I.e. the encapsulation

thickness at any of the corners shall not be more than 10 % different than that in the centre of

the sample. In a typical bag laminator this will require the use of a frame around the samples

during lamination, but any other means of accomplishing this specification is acceptable.

The back surface of the specimens (the exposed encapsulation intended to face to the

integrating sphere) shall not be intentionally textured.

For additional resolution to more accurately distinguish between materials, subsequent

studies may utilize a thicker encapsulation layer that may be analysed to determine the

optical attenuation coefficient as described in Annex A.

If the encapsulation material is intended to be used with superstrates other than glass, the

same procedure may be used in a subsequent study. Specimens using polymeric superstrates

may be prone to optical polarization occurring within the instrument. As in [9] and [12], a

depolarizer should be used with the instrument to minimize the effects of polarization.

NOTE 2 The effect of haze in specimens prone to optical haze can be mitigated through the use of a diffusing

film, as described in [13].

6.2 Weathering studies

A glass/encapsulation/glass laminate specimen geometry is recommended.

The size (length and width) should be adequate to allow the specimen to fit inside the test

instrument.

As described in [14], the minimum size of 5 cm × 5 cm is recommended for weathering

specimens based on previous examinations of poly (ethylene-co-vinyl acetate).

Large specimens are preferred in weathering studies, because a test region may be

distinguished, where the diffusion of oxygen or moisture is limited.

Other geometries may be used with this procedure to evaluate the effects of weathering. For

example, a permeable polymeric backsheet facilitates the examination of moisture ingress.

Some PV modules make use of an edge seal to reduce moisture permeation.

Separate “blank” pieces of superstrate or substrate may be weathered with the test

specimens to quantify the degradation of those components.

The specimens shall contain an examination region free from visible flaws including:

scratches, pits, sink marks, bubbles or other imperfections. The examination region shall be

at least 50 % larger in diameter than the measurement area of the test instrument.

The nominal thickness of the encapsulation specimens shall be as intended for use in the PV

module. Specimens should be cured (if applicable) according to the manufacturer’s

specification and as similar as possible to the method used in the intended manufacturing

procedure.

The thickness of the encapsulation in the laminate may be controlled by inserting a removable

material around the specimen perimeter.

6.3 Glass for superstrates/substrates

Measurements of the nominal (unweathered) transmittance to the cell for the purpose of

encapsulation manufacturer’s datasheets shall be performed using (3 ± 0,2) mm thick silica

glass. The glass shall have smooth, defect-free surfaces that are sufficiently flat and parallel

such that the diffuse component of transmitted light is less than 1 % between 280 nm and

2 500 nm.

The solar-weighted transmittance of photon irradiance of silica glass, which may be used to

verify that the composition of the glass is appropriate, is approximately 93 %, because the

reduction in transmittance comes from reflections at the surfaces. As in [1] and [12], the

transmittance of the glass should be greater than 90 % at 280 nm.

The glass shall not be coated or contain antireflective layers. The glass shall not be

intentionally textured.

Subsequent examination beyond that intended for the encapsulation material datasheet,

including weathering, may be performed according to this procedure using other superstrate

and/or substrate materials that can incorporate other optical features, e.g., antireflective

coatings, surface texture, and untempered PV glass.

6.4 Number of specimens

A minimum of 3 replicates shall be used for the determination of the transmittance to the cell

or in weathering studies. Optical characteristics, including transmittance, YI, and the UV cut-

off wavelength shall be subsequently calculated using the average of the three separate

specimens, with the range of the measurements indicated to identify their variability.

6.5 Preconditioning of specimens

Specimens used for the purpose of datasheet reporting shall be maintained at (23 ± 2) °C,

(50 ± 5) % RH for at least 24 h, as recommended in ISO 291, prior to optical measurement.

The use of elevated temperature and humidity conditions in a weathering study may result in

a supersaturated moisture condition within specimens, affecting their optical transmittance

when they are returned to the laboratory ambient condition. In such cases, specimen

conditioning, including a controlled environmental chamber, may be applied to prevent

spurious effects, e.g., optical haze or moisture related absorptance. Specimen-condition

effects may be verified using periodic measurements. Refer to the weathering test procedure

for any specific details related to specimen conditioning and storage intermittent to

weathering.

7 Measurement procedure

7.1 General

Transmittance measurements shall be performed in accordance with the procedure in

ISO 13468-2.

7.2 Specimen preparation

Prior to measurement, specimens should be free of dust, grease or other contaminants. The

specimens and instrument should be in thermal equilibrium prior to measurement.

7.3 Instrument calibration (baseline measurements)

Allow the instrument lamp to adequately equilibrate after it has been lighted, observing the

typical warm-up period, e.g., 15 min or as recommended by the instrument manufacturer.

Perform the correction scan(s) to compensate for the instrument baseline signal.

– 10 – IEC 62788-1-4:2016 IEC 2016

The 100 % transmittance baseline measurement should be performed in air, with no

superstrate, specimen, or substrate material present. The 0 % transmittance baseline

measurement should also be performed, if possible.

Periodic measurement of the baseline is recommended to minimize instrument drift and

ensure the measured values are accurate. The instrument drift occurring over an extended

measurement session may be instrument specific.

It is recommended to maintain the instrument drift below 0,05 % to minimize the uncertainty of

measurement (Clause 9). The instrument drift should be considered in the instrument bias

when the uncertainty of measurements is determined.

7.4 Specimen measurements

Perform the transmittance measurements for the test specimens over the wavelength range of

at least 280 nm to 2 500 nm using a 1 nm increment.

Linear interpolation to a 1 nm increment may be used when only a coarser measurement

increment (maximum of 5 nm) is available. The error associated with a coarser increment may

be more influential at shorter wavelengths (where YI and the UV cut-off wavelength are

determined) than at longer wavelengths (where only the solar-weighted transmittance is

affected). When applied, the use of linear interpolation should be noted in the test report.

Discontinuities associated with changes in the optical components (including detector, light

source, and/or monochromator) may occur during the measurement. Such discontinuities can

be minimized via the instrument settings.

It may be useful to extend the range of measurement in durability studies to provide insight

into the results. For example, by measuring UV wavelengths as low as 200 nm, the integrity of

UV absorbers and stabilizers can be confirmed from the UV cut-off wavelength.

The spectral bandwidth of the measurement should be less than or equal to the increment of

the measurement, i.e., 1 nm or 5 nm.

7.5 Witness measurements

Perform the transmittance measurements on a witness specimen at the beginning of each

measurement session to ensure proper operation of the instrument and minimize the

measurement error. Perform the transmittance measurements of any witness specimens using

the same procedure applied to the test specimen(s). The witness specimens may include a

traceable standard specimen, laboratory working witness specimen, or the silica

superstrate/substrate material.

8 Calculation and expression of results

8.1 Post-processing of data

The measurements obtained from three separate specimens shall be averaged at each

wavelength increment. The range (difference of the maximum and minimum) shall also be

determined at each wavelength increment.

8.2 Calculation of weighted transmittance

The solar-weighted transmittance may be calculated from formula (1):

[ ] [ ]

τλ E λ dλ

pλ

∫

τ =

sw

(1)

[ ]

E λ dλ

pλ

∫

Where

τ refers to the solar-weighted transmittance (%);

sw

τ is the measured transmittance of the specimen (%);

λ is the wavelength of light (nm); and

E is the reference global spectral photon irradiance (as given in IEC 60904-3).

pλ

The details for the calculation of the various solar-weighted transmittance parameters are

identified in Table 1. The parameters include: the “solar-weighted” transmittance, which may

be applied generally, based on a broad solar spectrum; and the “representative solar-

weighted” transmittance, which may be applied for most commercially available single junction

terrestrial PV cells (including silicon, cadmium telluride, copper indium gallium selenide, and

gallium arsenide) based on their useable wavelength range. The solar-weighted transmittance

(as well as YI) obtained from the spectrophotometer measurements (1 nm interval) shall be

calculated using a discretized sum, by means of the modified trapezoidal integration

technique, as in IEC 60904-3. The denominator for formula (1) is specified in Table 1 for the

purpose of verification, based on IEC 60904-3.

Table 1 – Details of the solar weight transmittance parameters

Parameter Symbol Lower bound Upper bound

[ ]

E λ dλ

pλ

wavelength wavelength

∫

nm nm –2 –1

m ·s

“solar-weighted” transmittance τ 280 2 500

4,15502132187479 × 10

sw

“representative solar-weighted” τ 300 1 250

3,03000915425 × 10

rsw

transmittance

NOTE The solar-weighted spectral transmittance may be more specifically applied to estimate module

performance, i.e., current yield, if the quantum efficiency of the PV cell is known, as described in Annex B.

8.3 Calculation of the Yellowness Index (YI)

YI shall be calculated according to the procedure in ISO 17223. The three tristimulus

coefficients shall be determined using the CIE Standard D65 Illuminant spectrum (as in

ISO 11664-2), and the CIE 1964 XYZ colour space (for a human observer with a 10° field of

view, as in ISO 11664-1). YI shall be calculated for a wavelength increment, e.g., 1 nm,

consistent with the measured transmittance data.

NOTE Additional details related to the YI may be found in ASTM E313-10 and ASTM E308-08.

8.4 Calculation of the UV cut-off wavelength

The UV cut-off wavelength, λ , shall be determined as the longest wavelength (to the

cUV

nearest nm) in the UV range (where λ≤400 nm) where the transmittance equals 10 % or less.

In cases where the UV cut-off wavelength is known to be less than 280 nm, the range of

measurement should be extended below 280 nm to quantify its specific value.

9 Uncertainty of measurements

The uncertainty associated with the randomness of measurement may be estimated from:

– 12 – IEC 62788-1-4:2016 IEC 2016

n

∆τ[λ]E [λ]dλ

pλ

∫

σ = = S (σ [λ]) (2)

ran n τ

∑

E [λ]dλ

pλ i=1

∫

where

σ represents the random variation of measurement;

ran

∆τ is the uncertainty of the transmittance measurement;

λ is the wavelength of light;

E is the reference spectral photon irradiance;

pλ

S is the coefficient for Student’s t-distribution (3,18245 for 3 specimens at the 95 %

n

confidence interval), and

σ is the standard deviation of the transmittance measurements (at each wavelength

τ

increment).

The final (reported) uncertainty may be estimated from:

2 2

σ = (σ ) +(σ ) (3)

tot inst ran

where

σ represents the total uncertainty;

tot

σ is the instrument bias (accounting for the particular make of the instrument, the

inst

instrument settings (including integration time), as well as instrument drift); and

σ is the random variation of measurement (the accuracy of the instrument as well as the

ran

specimen variability).

σ may be evaluated for the test instrument from the average of 10 measurements

ran

(multiplied by the corresponding S value of 2,22814) with no specimen present (nominal

n

transmittance of 100 %). Similarly, σ may be evaluated for the test instrument from a series

inst

of successive periodic measurements with no specimen present, with the rate of drift being

determined from a trendline fit. While σ may vary with the lamp age, a single representative

tot

evaluation is expected to adequately represent the test instrument used within a particular

test laboratory.

Calculate the uncertainty for other test results (such as YI) using the same method as for

transmittance, i.e., the method of propagation of error. These estimates should also account

for the uncertainty associated with instrument bias in addition to random error.

The repeatability and reproducibility of the method, including solar-weighted transmittance,

yellowness index, and the UV cut-off wavelength, are described in Annex A and [12].

10 Test report

A report of the tests shall be prepared by the test agency. The report shall contain the detail

specification for the specimens. Each certificate or test report shall include at least the

following information:

a) a title;

b) name and address of the test laboratory and location where the tests were carried out;

c) unique identification of the certification or report and of each page;

d) name and address of client, where appropriate;

e) description and identification of the item tested, including specimen type, specimen

thickness (and its range of variation), the specimen size (length and width), the

superstrate/substrate material(s) and their characteristics;

f) characterization and condition of the test item, including the method and details of

specimen preparation (including curing, lamination, or similar processing if applicable) and

preconditioning;

g) date of receipt of test item and date(s) of test, where appropriate;

h) identification of test method used; including the make and model of the spectrophotometer

and the integrating sphere;

i) reference to sampling procedure, where relevant;

j) any deviations from, additions to, or exclusions from, the test method and any other

information relevant to a specific test, such as environmental conditions; and the

procedure(s) and condition(s) used for weathering and any preconditioning conducted

prior to measurements;

k) measurements, examinations and derived results supported by tables, graphs, sketches

and photographs as appropriate including the complete set of the tabulated average

transmittance values and the corresponding range of the averaged values; the estimated

uncertainty of the transmittance measurement (instrument); the averaged solar-weighted

transmittance of photon irradiance and the corresponding range of the averaged values;

the averaged representative solar-weighted transmittance of photon irradiance and the

corresponding range of the averaged values (as well as the wavelength range

considered); the UV cut-off wavelength and its uncertainty; and any failures observed;

l) the yellowness index and its uncertainty (which should be determined after each

weathering interval in addition to its original value in the case of weathering experiments);

m) a statement of the estimated uncertainty of the test results (where relevant); the

measurement of the witness specimen (if utilized) and its deviation from its witness

values. When applicable, the details of the witness specimen (such as its preparation,

composition, and thickness) shall be specified;

n) a signature and title, or equivalent identification of the person(s) accepting responsibility

for the content of the certificate or report, and the date of issue;

o) where relevant, a statement to the effect that the results relate only to the items tested;

p) a statement that the certificate or report shall not be reproduced except in full, without the

written approval of the laboratory.

– 14 – IEC 62788-1-4:2016 IEC 2016

Annex A

(informative)

Advanced analysis of transmittance (absorption coefficients)

The measurements described in this procedure may be supplemented to allow for a more

rigorous optical analysis. The determination of the optical attenuation coefficient allows the

optical transmittance to be generalized and extended to any possible configuration. Such

analysis may be used to improve the accuracy of PV performance analysis, account for

changes in the module design (such as the thickness of the encapsulation), or to distinguish

between different encapsulation materials. Characteristics including transmittance, YI, and the

UV cut-off wavelength strongly vary with the specimen thickness; the methods described in

this annex may therefore be used to standardize measurements to a representative thickness.

Optical transmittance also depends upon the material layers present within the specimen. A

more rigorous analysis, summarized in this annex, may be used to consider loss of

transmitted light, including the reflectance at material interfaces.

Hemispherical reflectance and transmittance data may be used to calculate the attenuation

coefficient for a minimally absorbing material. The terminology “low absorbing” implies that

light reflected from the rear interface is not fully absorbed prior to reaching the front interface.

For this method, the specimen is ideally flat, free standing, of uniform known thickness, and

minimally scattering, i.e., minimal optical haze. The method is based on work presented in [1].

As described in [2] and [3], the absorptance is first determined using the formula:

α [λ]= 1−τ [λ]−ρ [λ]

(A.1)

c m m

Nomenclature in the formula includes: α , the calculated optical absorptance (normalized

c

intensity); τ , the measured optical transmittance (normalized intensity); ρ , the measured

m m

optical reflectance (normalized intensity); and λ, the wavelength (m). The measured

reflectance should be corrected to an absolute scale (using a certified calibrated reflectance

specimen) for spectrophotometers that report relative reflectance measurements. The

absolute reflectance of the specimen may be determined if its measured relative reflectance is

multiplied by the reflectance of a calibrated specimen. The measured transmittance and

measured reflectance include the effects of multiple passes of light, occurring as the result of

internal reflections, as described in [4].

A subsequent analysis of the measured reflectance and transmittance data may be used to

account for the internal reflections, in order to represent a single optical pass through the

material. The reflections occurring at the air/sample interface as well as the absorptance for a

single pass (occurring normal to the specimen), can be determined from the measured values

using the formulas:

2 2

2 2

− 1+ τ λ + 2ρ λ − ρ λ + 1+(τ [λ]) + 2ρ [λ]−(ρ [λ]) + 4(ρ [λ]− 2)ρ [λ]

( []) [] ( [])

m m m m m

m m m

(A.2)

ρ[λ]

=

i

2(ρ [λ]− 2)

m

ρ[λ]α [λ]−α [λ]

i c c

α [λ]= (A.3)

sp

ρ[λ]α [λ]+ρ[λ]−1

i c i

(A.4)

ψ[λ]=− ln(1−α [λ])

sp

z

New nomenclature in the formulas includes: ρ , the reflectance at the

...

IEC 62788-1-4 ®

Edition 1.1 2020-10

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Measurement procedures for materials used in photovoltaic modules –

Part 1-4: Encapsulants – Measurement of optical transmittance and calculation

of the solar-weighted photon transmittance, yellowness index, and UV cut-off

wavelength

Procédures de mesure des matériaux utilisés dans les modules

photovoltaïques –

Partie 1-4: Encapsulants – Mesurage du facteur de transmission optique

et calcul du facteur de transmission photonique à pondération solaire,

de l'indice de jaunissement et de la fréquence de coupure des UV

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and definitions clause of

IEC publications issued between 2002 and 2015. Some

IEC Customer Service Centre - webstore.iec.ch/csc entries have been collected from earlier publications of IEC

If you wish to give us your feedback on this publication or TC 37, 77, 86 and CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues entre 2002 et 2015. Plus certaines

entrées antérieures extraites des publications des CE 37, 77,

Service Clients - webstore.iec.ch/csc 86 et CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62788-1-4 ®

Edition 1.1 2020-10

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Measurement procedures for materials used in photovoltaic modules –

Part 1-4: Encapsulants – Measurement of optical transmittance and calculation

of the solar-weighted photon transmittance, yellowness index, and UV cut-off

wavelength

Procédures de mesure des matériaux utilisés dans les modules

photovoltaïques –

Partie 1-4: Encapsulants – Mesurage du facteur de transmission optique

et calcul du facteur de transmission photonique à pondération solaire,

de l'indice de jaunissement et de la fréquence de coupure des UV

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.160 ISBN 978-2-8322-8968-6

IEC 62788-1-4 ®

Edition 1.1 2020-10

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Measurement procedures for materials used in photovoltaic modules –

Part 1-4: Encapsulants – Measurement of optical transmittance and calculation

of the solar-weighted photon transmittance, yellowness index, and UV cut-off

wavelength

Procédures de mesure des matériaux utilisés dans les modules

photovoltaïques –

Partie 1-4: Encapsulants – Mesurage du facteur de transmission optique

et calcul du facteur de transmission photonique à pondération solaire,

de l'indice de jaunissement et de la fréquence de coupure des UV

– 2 – IEC 62788-1-4:2016+AMD1:2020 CSV

IEC 2020

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Principle . 7

5 Apparatus . 7

6 Test specimens . 7

6.1 Nominal (and unweathered) transmittance to the cell . 7

6.2 Weathering studies . 8

6.3 Glass for superstrates/substrates . 9

6.4 Number of specimens . 9

6.5 Preconditioning Conditioning of specimens . 9

7 Measurement procedure . 9

7.1 General . 9

7.2 Specimen preparation . 10

7.3 Instrument calibration (baseline measurements) . 10

7.4 Specimen measurements . 10

7.5 Witness measurements . 10

7.5.1 Witness specimen(s) . 11

7.5.2 Procedure for the witness specimen prior to the test specimen(s) . 11

7.5.3 Measurement of the test specimen(s) . 11

7.5.4 Procedure for the witness specimen after the test specimen(s) . 11

8 Calculation and expression of results . 11

8.1 Post-processing of data . 11

8.2 Calculation of weighted transmittance . 12

8.3 Calculation of the Yellowness Index (YI) . 12

8.4 Calculation of the UV cut-off wavelength . 12

9 Uncertainty of measurements . 13

10 Test report . 13

Annex A (informative) Advanced analysis of transmittance (absorption coefficients) . 15

Annex B (informative) Applying the quantum efficiency of a specific cell technology . 17

Bibliography . 19

Table 1 – Details of the solar weight transmittance parameters . 12

IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MEASUREMENT PROCEDURES FOR MATERIALS

USED IN PHOTOVOLTAIC MODULES –

Part 1-4: Encapsulants – Measurement of optical transmittance and

calculation of the solar-weighted photon transmittance,

yellowness index, and UV cut-off wavelength

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been

prepared for user convenience.

IEC 62788-1-4 edition 1.1 contains the first edition (2016-09) [documents 82/1148/FDIS

and 82/1165/RVD] and its amendment 1 (2020-10) [documents 82/1767/FDIS and

82/1791/RVD].

In this Redline version, a vertical line in the margin shows where the technical content

is modified by amendment 1. Additions are in green text, deletions are in strikethrough

red text. A separate Final version with all changes accepted is available in this

publication.

– 4 – IEC 62788-1-4:2016+AMD1:2020 CSV

IEC 2020

International Standard IEC 62788-1-4 has been prepared by IEC technical committee 82:

Solar photovoltaic energy systems.

A list of all parts in the IEC 62788 series, published under the general title Measurement

procedures for materials used in photovoltaic modules, can be found on the IEC website.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

IEC 2020

MEASUREMENT PROCEDURES FOR MATERIALS

USED IN PHOTOVOLTAIC MODULES –

Part 1-4: Encapsulants – Measurement of optical transmittance and

calculation of the solar-weighted photon transmittance,

yellowness index, and UV cut-off wavelength

1 Scope

This part of IEC 62788 provides a method for measurement of the optical transmittance of

encapsulation materials used in photovoltaic (PV) modules. The standardized measurements

in this procedure quantify the expected transmittance of the encapsulation to the PV cell.

Subsequent calculation of solar-weighted transmittance allows for comparison between

different materials. The results for unweathered material may be used in an encapsulation

manufacturer’s datasheets, in manufacturer’s material or process development, in

manufacturing quality control (material acceptance), or applied in the analysis of module

performance.

This measurement method can also be used to monitor the performance of encapsulation

materials after weathering, to help assess their durability. The standardized measurements

are intended to examine an interior region within a PV module, e.g., without the effects of

oxygen diffusion around the edges at the periphery of the cells. Subsequent calculation of

yellowness index allows for quantification of durability and consideration of appearance. The

change in transmittance, yellowness index, and ultraviolet (UV) cut-off wavelength may be

used by encapsulation or module manufacturers to compare the durability of different

materials.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60904-3, Photovoltaic devices – Part 3: Measurement principles for terrestrial

photovoltaic (PV) solar devices with reference spectral irradiance data

ISO 291:2008, Plastics – Standard atmospheres for conditioning and testing

ISO 11664-1:2007, Colorimetry – Part 1: CIE standard colorimetric observers

ISO 11664-2:2007, Colorimetry – Part 2: CIE standard illuminants

ISO 13468-2:1999, Plastics – Determination of the total luminous transmittance of transparent

materials – Part 2: Double-beam instrument

ISO 17223:2014, Plastics – Determination of yellowness index and change in yellowness

index

ASTM E424-71:2007, Standard test methods for solar energy transmittance and reflectance

(Terrestrial) of sheet material

– 6 – IEC 62788-1-4:2016+AMD1:2020 CSV

IEC 2020

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

NOTE In cases where definitions already exist, refer to IEC TS 61836. Calculations related to these definitions

are given in Clause 8.

3.1

solar-weighted transmittance of photon irradiance

–2 –1 –1

proportion of the solar spectral photon irradiance (E , m ·s ·nm ) optically transmitted

pλ

through the specimen, throughout the range of the terrestrial solar spectrum (280 nm to

2 500 nm) (see Table 1)

–2 –1 –1

Note 1 to entry: The photon irradiance (E , m ·s ·nm ) accounts for the wavelength-specific energy of the

pλ

–2 –1

optical flux and should not be confused with spectral irradiance (E , W·m ·nm ).

λ

3.2

representative solar-weighted transmittance of photon irradiance

–2 –1 –1

, m ·s ·nm ) optically transmitted

proportion of the solar spectral photon irradiance (E

pλ

through the specimen, throughout the range of the terrestrial solar spectrum (300 nm to

1 250 nm) (see Table 1)

Note 1 to entry: In the case of a PV device, the representative solar-weighted transmittance of photon irradiance

is defined throughout the range of the spectrum utilized by a representative PV device (which may not include

wavelengths as low as 280 nm or as great as 2 500 nm).

3.3

UV cut-off wavelength

λ

cUV

wavelength of light below which the encapsulation is considered optically absorbing and

above which the encapsulation is considered transmitting

Note 1 to entry: In this procedure, the absolute transmittance of 10 % (corresponding to the optical absorbance of

1) is considered as the threshold of the UV cut-off wavelength. As described further in [9] , the UV cut-off

wavelength may also be used to quantify the effects of weathering.

3.4

weathering

process of subjecting specimens to environmental conditions that could include ultra-violet

radiation, temperature, humidity, and ozone

Note 1 to entry: Weathering may occur in artificial or natural environments. Weathering could occur at the nominal

(field) or an accelerated rate.

3.5

yellowness index

YI

calculated value identifying the yellowness of the test specimen perceived by a human

observer (see ASTM E313-10)

Note 1 to entry: YI may be used to quantify the effects of weathering.

_____________

Numbers in square brackets refer to the Bibliography.

IEC 2020

4 Principle

The total spectral transmittance of laminated specimens, containing encapsulation material,

shall be measured using a spectrophotometer equipped with an integrating sphere. Solar-

weighted transmittance, yellowness index, and UV cut-off wavelength will be subsequently

calculated from the transmittance measurements.

The transmittance measured using this procedure may be used in a more advanced optical

analysis to improve the accuracy of PV performance analysis or distinguish between different

encapsulation materials, as described in Annex A. The transmittance measured using this

procedure may be used to estimate module performance (current yield) if the quantum

efficiency of the PV cell is known, as described in Annex B. The method does not attempt to

account for variations in transmittance with the angle of incidence, which may vary with time

of day, sky conditions, and geometry of the module, especially if optical concentration is used.

5 Apparatus

The test instrument shall consist of a double beam spectrophotometer equipped with an

integrating sphere. A single beam spectrophotometer may be used if the port reflectance can

be properly accounted for, as in Annex A and [2]. Details regarding the construction and

configurations of the test instrument may be found in ISO 13468-2 or ASTM E424-71. A

measurement range of at least 280 nm to 2 500 nm is required for calculation of the solar-

weighted transmittance using the AM1.5 global spectrum as in IEC 60904-3. A wavelength

increment no larger than 1 nm is preferred for the measurement, however increments up to

5 nm are permitted with linear interpolation to 1 nm.

An integrating sphere of at least 100 mm in diameter with a port area of < 5 %, as in [11], is

recommended to reduce the error in the measurement. The port area as in [9] should not

exceed 13 %.

6 Test specimens

6.1 Nominal (and unweathered) transmittance to the cell

Specimens shall be constructed using a laminate structure of glass/encapsulation, as

described in Annex A and [12].

The solar-weighted transmittance and representative solar-weighted transmittance, as

calculated in Clause 8, may be used for the purpose of reporting on an encapsulation

manufacturer’s datasheet.

The specimens shall contain an examination region free from visible flaws including:

scratches, pits, sink marks, bubbles, or other imperfections. The examination region shall be

at least 50 % larger in diameter than the measurement area of the test instrument.

NOTE 1 A spot size of 1 cm × 1 cm is common in many commercial spectrophotometer instruments. Use of

specimens at least 2 to 3 times this size will improve uniformity (resulting from fabrication) and handling (during

measurement).

The size (length and width) should be adequate to allow the specimen to fit inside the test

instrument.

The nominal thickness of the encapsulation encapsulant specimens shall be equal to the

thickness intended for use in PV modules.

Specimens should be cured (if applicable) according to the manufacturer’s specification and

using a process as similar as possible to the method used in the intended manufacturing

process.

– 8 – IEC 62788-1-4:2016+AMD1:2020 CSV

IEC 2020

The thickness of the encapsulation portion of the test specimen shall be measured after its

preparation. The thickness shall be taken as the average of three measurements obtained at

different locations on the test region of the specimen.

Glass plates shall be parallel with minimal edge pinch or edge flare. I.e. the encapsulation

thickness at any of the corners shall not be more than 10 % different than that in the centre of

the sample. In a typical bag laminator this will require the use of a frame around the samples

during lamination, but any other means of accomplishing this specification is acceptable.

The back surface of the specimens (the exposed encapsulation intended to face to the

integrating sphere) shall not be intentionally textured.

For additional resolution to more accurately distinguish between materials, subsequent

studies may utilize a thicker encapsulation layer that may be analysed to determine the

optical attenuation coefficient as described in Annex A.

If the encapsulation material is intended to be used with superstrates other than glass, the

same procedure may be used in a subsequent study. Specimens using polymeric superstrates

may be prone to optical polarization occurring within the instrument. As in [9] and [12], a