IEC 60068-2-31:2008

(Main)Environmental testing - Part 2-31: Tests - Test Ec: Rough handling shocks, primarily for equipment-type specimens

Environmental testing - Part 2-31: Tests - Test Ec: Rough handling shocks, primarily for equipment-type specimens

IEC 60068-2-31:2008 deals with a test procedure for simulating the effects of rough handling shocks, primarily in equipment-type specimens, the effects of knocks, jolts and falls which may be received during repair work or rough handling in operational use. This procedure does not simulate the effects of impacts received during transportation as loosely constrained cargo. Where the effects of loose cargo transportation are to be assessed, test Ee: Bounce should be used. Also this procedure does not simulate the effects of shock applied to installed equipments. Where this effect is to be assessed refer to test Ea: Shock. Testing should only be specified for equipment likely to receive such rough handling, for example those of small to medium size and mass, and should only be applied to those faces and corners where there is a risk of such treatment being encountered. In general, equipment which is frequently handled and serviced (for example field equipment and unit spares) can be considered at risk, whereas equipment forming an integral part of a permanent installation would not normally be considered at risk and need not be tested. Testing may not be applicable to fragile unprotected equipment of irregular shape (for example aircraft nose radar) which, when removed from the installation would be contained in a handling frame or jig. It may however be applicable to these items of equipment when they are in their transit case or in their handling frame or jig. For equipment which stands only on one face (for example the normal base) the test is generally only applied to that face. Shock tests are performed on the specimen when fixed to the test machine. Drop and topple, free fall, repeated free fall and bounce tests are performed with the specimen free. This second edition cancels and replaces the first edition, published in 1969 and constitutes a technical revision. The major changes with regard to the previous edition concern the introduction of soft packaging tests, where appropriate. This new edition of IEC 60068-2-31 now incorporates the second edition of IEC 60068-2-32 (1975).

Essais d'environnement - Partie 2-31: Essais - Essai Ec: Choc lié à des manutentions brutales, essai destiné en premier lieu aux matériels

La CEI 60068-2-31:2008 consiste en une procédure d'essai pour la simulation des effets de chocs lié à des manutentions brutales, principalement pour les spécimens tels que des matériels, les effets des coups, des heurts et des chutes qui peuvent être reçus au cours de réparations ou de manutentions brutales durant leur fonctionnement. Cette méthode ne simule pas les effets d'impacts reçus pendant le transport sans arrimage. Lorsqu'il est prévu d'évaluer les effets du transport sans arrimage il convient d'utiliser l'essai Ee: de rebondissement. Cette méthode ne simule donc pas les effets de chocs appliqués aux équipements installés. Lorsque il est prevu d'évaluer cet effet, se référer à l'essai Ea de chocs. Il convient que cet essai ne soit normalement spécifié que pour les matériels susceptibles d'être ainsi manipulés, par exemple ceux dont la taille et la masse sont moyennes ou petites, et n'être appliqué qu'aux faces ou coins qui risquent de subir un tel traitement. En général, on peut considérer qu'un matériel qui est fréquemment manipulé et entretenu (par exemple, les matériels de servitude et les unités de rechange) court un tel risque, alors que l'on considérera qu'un matériel qui fait partie intégrante d'une installation fixe ne court normalement pas ce risque et n'a pas besoin d'être soumis à cet essai. Cet essai peut ne pas être applicable aux matériels fragiles et non protégés dont la forme est irrégulière (par exemple un radar frontal d'avion) qui, lorsqu'ils sont retirés de l'installation fixe, sont généralement placés dans un berceau ou un cadre de manutention. Il peut toutefois être applicable à ces matériels lorsqu'ils sont dans leur emballage de transport, ou dans leur berceau ou cadre de manutention. Pour les matériels qui ne tiennent dressés que sur une face (par exemple la base normale), on n'exécute généralement l'essai que sur cette seule face. On exécute les essais de chocs en fixant le spécimen à la machine d'essai. Les essais de chute et culbute, de chute libre, de chutes libres répétées et de rebondissement sont exécutés sur des spécimens non fixés. Cette deuxième édition annule et remplace la première édition, publiée en 1969, et constitue une révision technique. Les modifications principales par rapport à l'édition précédente concernent l'introduction, aux endroits appropriés, des essais sur les emballages. Par ailleurs, la deuxième édition de la CEI 60068-2-32 (1975) a été incorporée dans cette nouvelle édition de la CEI 60068-2-31.

General Information

- Status

- Published

- Publication Date

- 20-May-2008

- Technical Committee

- TC 104 - Environmental conditions, classification and methods of test

- Drafting Committee

- MT 17 - TC 104/MT 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 21-May-2008

- Completion Date

- 15-Jun-2008

Relations

- Effective Date

- 10-Feb-2026

Overview

IEC 60068-2-31:2008 is an international standard published by the International Electrotechnical Commission (IEC) that outlines environmental testing procedures specifically designed for simulating rough handling shocks. This standard is primarily intended for equipment-type specimens such as small to medium-sized field equipment and unit spares which may be subjected to knocks, jolts, or falls during operational use or repair work.

The key aim of IEC 60068-2-31 is to evaluate the mechanical robustness of equipment under conditions of rough handling-not transportation shocks as loose cargo, nor shocks applied to installed equipment. For transportation-related shock testing, IEC recommends using IEC 60068-2-55 (Bounce test), and for installed equipment shock, IEC 60068-2-27 (Shock test).

Key Topics

Scope and Applicability

- Applicable to equipment likely to receive rough handling shocks in service.

- Focus on small to medium size and mass specimens.

- Testing is restricted to faces and corners likely to be impacted during handling.

- Not suitable for fragile or irregularly shaped equipment unless tested in their transit cases or handling frames.

Test Procedures

The standard defines multiple test methods to simulate rough handling shocks:

Drop and Topple Test

Designed to simulate knocks or jolts during handling or repair work. It covers three types of impacts:- Dropping onto a face

- Dropping onto an edge or corner

- Toppling or push-over action

Free Fall – Procedure 1

A simple free-fall drop test assessing the potential damage caused by falls experienced during rough handling. The specimen is free during the fall.Free Fall – Procedure 2

This test simulates repeated free-fall shocks, suitable for components exposed to multiple impacts, such as connectors in service.Test Parameters

Tests allow for ±10% tolerance on height and angle measurements. Test severity correlates with specimen mass and geometry, focusing on realistic handling scenarios.

Test Equipment and Setup

- Shock tests are executed with specimens fixed to the test machine.

- Drop, topple, free-fall, and bounce tests involve specimens released freely.

- Tests consider mass, center of gravity, and dimensions to determine applicability and test parameters.

Applications

IEC 60068-2-31 is valuable for industries requiring assurance of equipment mechanical durability under rough handling conditions. Typical application areas include:

- Field Equipment: Portable instruments and devices frequently handled and serviced in operational environments.

- Unit Spares: Equipment parts and spares removed and replaced during maintenance.

- Transit Cases and Handling Frames: Testing items in protective containers or jigs to simulate handling during transportation within operational contexts.

- Manufacturing and Quality Assurance: Validation of equipment design against handling shock requirements to ensure longevity and reliability.

- Military and Aerospace: Evaluating ruggedized equipment that may encounter rough handling shocks during field deployment or logistics handling (excluding fragile radar components unless protected by handling frames).

By simulating practical real-life rough handling scenarios, this standard helps manufacturers reduce failure risks, increase product reliability, and ensure compliance with international durability norms.

Related Standards

IEC 60068-2-31 works alongside several other IEC and ISO standards to provide comprehensive environmental and mechanical testing guidelines:

IEC 60068-2-27 – Environmental Testing – Test Ea: Shock

For evaluating shock effects on installed or fixed equipment.IEC 60068-2-55 – Environmental Testing – Test Ee: Bounce

Designed to assess impacts during transportation as loosely constrained cargo.IEC Guide 104 – Preparation of Safety Publications

Framework for composing basic safety and group safety publications, providing guidance on environmental testing standards.ISO 48 – Determination of Rubber Hardness

Used for material characterization within packaging and cushioning relevant to handling tests.ISO 4180-2 – Transport Package Performance Test Schedules

Rules for compiling performance test data pertinent to packages and packaging systems.

By implementing IEC 60068-2-31 compliant testing procedures, manufacturers and engineers ensure that their equipment withstands rough handling environments, improving product durability, customer satisfaction, and international market acceptance.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 60068-2-31:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Environmental testing - Part 2-31: Tests - Test Ec: Rough handling shocks, primarily for equipment-type specimens". This standard covers: IEC 60068-2-31:2008 deals with a test procedure for simulating the effects of rough handling shocks, primarily in equipment-type specimens, the effects of knocks, jolts and falls which may be received during repair work or rough handling in operational use. This procedure does not simulate the effects of impacts received during transportation as loosely constrained cargo. Where the effects of loose cargo transportation are to be assessed, test Ee: Bounce should be used. Also this procedure does not simulate the effects of shock applied to installed equipments. Where this effect is to be assessed refer to test Ea: Shock. Testing should only be specified for equipment likely to receive such rough handling, for example those of small to medium size and mass, and should only be applied to those faces and corners where there is a risk of such treatment being encountered. In general, equipment which is frequently handled and serviced (for example field equipment and unit spares) can be considered at risk, whereas equipment forming an integral part of a permanent installation would not normally be considered at risk and need not be tested. Testing may not be applicable to fragile unprotected equipment of irregular shape (for example aircraft nose radar) which, when removed from the installation would be contained in a handling frame or jig. It may however be applicable to these items of equipment when they are in their transit case or in their handling frame or jig. For equipment which stands only on one face (for example the normal base) the test is generally only applied to that face. Shock tests are performed on the specimen when fixed to the test machine. Drop and topple, free fall, repeated free fall and bounce tests are performed with the specimen free. This second edition cancels and replaces the first edition, published in 1969 and constitutes a technical revision. The major changes with regard to the previous edition concern the introduction of soft packaging tests, where appropriate. This new edition of IEC 60068-2-31 now incorporates the second edition of IEC 60068-2-32 (1975).

IEC 60068-2-31:2008 deals with a test procedure for simulating the effects of rough handling shocks, primarily in equipment-type specimens, the effects of knocks, jolts and falls which may be received during repair work or rough handling in operational use. This procedure does not simulate the effects of impacts received during transportation as loosely constrained cargo. Where the effects of loose cargo transportation are to be assessed, test Ee: Bounce should be used. Also this procedure does not simulate the effects of shock applied to installed equipments. Where this effect is to be assessed refer to test Ea: Shock. Testing should only be specified for equipment likely to receive such rough handling, for example those of small to medium size and mass, and should only be applied to those faces and corners where there is a risk of such treatment being encountered. In general, equipment which is frequently handled and serviced (for example field equipment and unit spares) can be considered at risk, whereas equipment forming an integral part of a permanent installation would not normally be considered at risk and need not be tested. Testing may not be applicable to fragile unprotected equipment of irregular shape (for example aircraft nose radar) which, when removed from the installation would be contained in a handling frame or jig. It may however be applicable to these items of equipment when they are in their transit case or in their handling frame or jig. For equipment which stands only on one face (for example the normal base) the test is generally only applied to that face. Shock tests are performed on the specimen when fixed to the test machine. Drop and topple, free fall, repeated free fall and bounce tests are performed with the specimen free. This second edition cancels and replaces the first edition, published in 1969 and constitutes a technical revision. The major changes with regard to the previous edition concern the introduction of soft packaging tests, where appropriate. This new edition of IEC 60068-2-31 now incorporates the second edition of IEC 60068-2-32 (1975).

IEC 60068-2-31:2008 is classified under the following ICS (International Classification for Standards) categories: 19.040 - Environmental testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60068-2-31:2008 has the following relationships with other standards: It is inter standard links to EN 60601-2-52:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60068-2-31:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60068-2-31

Edition 2.0 2008-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Environmental testing –

Part 2-31: Tests – Test Ec: Rough handling shocks, primarily for equipment-type

specimens

Essais d'environnement –

Partie 2-31: Essais – Essai Ec: Choc lié à des manutentions brutales, essai

destiné en premier lieu aux matériels

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60068-2-31

Edition 2.0 2008-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Environmental testing –

Part 2-31: Tests – Test Ec: Rough handling shocks, primarily for equipment-type

specimens

Essais d'environnement –

Partie 2-31: Essais – Essai Ec: Choc lié à des manutentions brutales, essai

destiné en premier lieu aux matériels

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

P

CODE PRIX

ICS 19.040 ISBN 2-8318-9794-7

– 2 – 60068-2-31 © IEC:2008

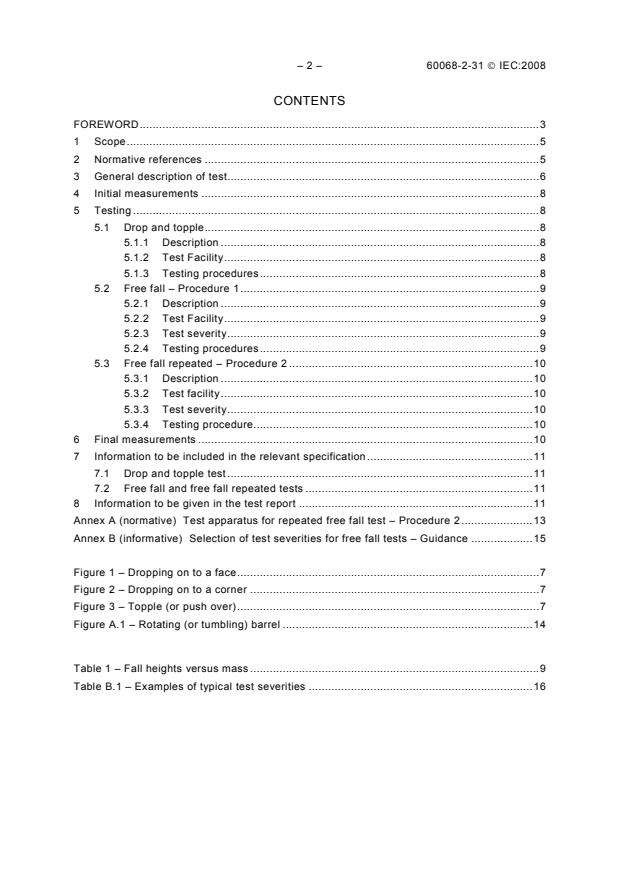

CONTENTS

FOREWORD.3

1 Scope.5

2 Normative references .5

3 General description of test.6

4 Initial measurements .8

5 Testing .8

5.1 Drop and topple.8

5.1.1 Description .8

5.1.2 Test Facility.8

5.1.3 Testing procedures.8

5.2 Free fall – Procedure 1.9

5.2.1 Description .9

5.2.2 Test Facility.9

5.2.3 Test severity.9

5.2.4 Testing procedures.9

5.3 Free fall repeated – Procedure 2 .10

5.3.1 Description .10

5.3.2 Test facility.10

5.3.3 Test severity.10

5.3.4 Testing procedure.10

6 Final measurements .10

7 Information to be included in the relevant specification.11

7.1 Drop and topple test .11

7.2 Free fall and free fall repeated tests .11

8 Information to be given in the test report .11

Annex A (normative) Test apparatus for repeated free fall test – Procedure 2.13

Annex B (informative) Selection of test severities for free fall tests – Guidance .15

Figure 1 – Dropping on to a face.7

Figure 2 – Dropping on to a corner .7

Figure 3 – Topple (or push over).7

Figure A.1 – Rotating (or tumbling) barrel .14

Table 1 – Fall heights versus mass .9

Table B.1 – Examples of typical test severities .16

60068-2-31 © IEC:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ENVIRONMENTAL TESTING –

Part 2-31: Tests –

Test Ec: Rough handling shocks,

primarily for equipment-type specimens

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60068-2-31 has been prepared by IEC technical committee 104:

Environmental conditions, classification and methods of test.

This second edition cancels and replaces the first edition, published in 1969 and constitutes a

technical revision.

The major changes with regard to the previous edition concern the introduction of soft

packaging tests, where appropriate. This new edition of IEC 60068-2-31 now incorporates the

second edition of IEC 60068-2-32 (1975).

IEC 60068-2-32 will be withdrawn once this standard has been issued.

– 4 – 60068-2-31 © IEC:2008

The text of this standard is based on the following documents:

FDIS Report on voting

104/458/FDIS 104/462/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

It has the status of a basic safety publication in accordance with IEC Guide 104.

A list of all the parts in the IEC 60068 series, under the general title Environmental testing,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60068-2-31 © IEC:2008 – 5 –

ENVIRONMENTAL TESTING –

Part 2-31: Tests –

Test Ec: Rough handling shocks,

primarily for equipment-type specimens

1 Scope

This part of IEC 60068 deals with a test procedure for simulating the effects of rough handling

shocks, primarily in equipment-type specimens, the effects of knocks, jolts and falls which

may be received during repair work or rough handling in operational use.

This procedure does not simulate the effects of impacts received during transportation as

loosely constrained cargo. Where the effects of loose cargo transportation are to be

assessed, test Ee: Bounce should be used. Also this procedure does not simulate the effects

of shock applied to installed equipments. Where this effect is to be assessed refer to test Ea:

Shock.

Testing should only be specified for equipment likely to receive such rough handling, for

example those of small to medium size and mass, and should only be applied to those faces

and corners where there is a risk of such treatment being encountered.

In general, equipment which is frequently handled and serviced (for example field equipment

and unit spares) can be considered at risk, whereas equipment forming an integral part of a

permanent installation would not normally be considered at risk and need not be tested.

Testing may not be applicable to fragile unprotected equipment of irregular shape (for

example aircraft nose radar) which, when removed from the installation would be contained in

a handling frame or jig. It may however be applicable to these items of equipment when they

are in their transit case or in their handling frame or jig.

For equipment which stands only on one face (for example the normal base) the test is

generally only applied to that face.

Shock tests are performed on the specimen when fixed to the test machine. Drop and topple,

free fall, repeated free fall and bounce tests are performed with the specimen free.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-2-27, Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock

IEC 60068-2-55:1987, Environmental testing – Part 2-55: Tests – Test Ee and guidance:

Bounce

IEC Guide 104,The preparation of safety publications and the use of basic safety publications

and group safety publications

ISO 48:2007, Rubber, vulcanized or thermoplastic – Determination of hardness (hardness

between 10 IRHD and 100 IRHD)

– 6 – 60068-2-31 © IEC:2008

ISO 4180-2:1980, Complete, filled transport packages – General rules for the compilation of

performance test schedules – Part 2: Quantitative data

3 General description of test

Rough handling shocks can be simulated by one or more of the following tests:

a) Drop and topple

A simple test intended to assess the effects of knocks or jolts likely to be received

primarily by equipment-type specimens during repair work or rough handling on a table or

bench.

b) Free fall – Procedure 1

A simple test to assess the effects of falls likely to be experienced due to rough handling.

It is also suitable to demonstrate a degree of robustness.

c) Free fall – Procedure 2

A test that additionally simulates repetitive shocks likely to be received by certain

component-type specimens, for example connectors in service.

The topple test need not be applied to specimens which have dimensions which make them

stable whilst being handled. Reference to points 1) and 2) below should be made for

information on the “c – g ratio” and “height ratio” to establish if the test is necessary.

The falling or topple actions produced by the test procedures given in 5.1.3.1, 5.1.3.2 and

5.1.3.3 are illustrated by Figures 1, 2 and 3.

The drop and topple test includes three distinct procedures:

i) dropping on to a face (5.1.3.1);

ii) dropping on to an edge or a corner (5.1.3.2);

iii) toppling (or pushover) (5.1.3.3).

The purpose of each of these procedures is basically the same, but they represent different

kinds of handling.

The test is not intended to be a precise test and a tolerance of ±10 % is allowed on the

heights and angles prescribed in 5.1.2.

NOTE For a more precise shock test, test Ea: Shock (IEC 60068-2-27) should be used.

The topple test need not be applied to specimens which have dimensions which make them

stable while being handled. When considering the applicability of the topple test, two

dimensional ratios are important:

1) the ratio of the height of the centre of gravity from the base, to the smaller dimension of

the base, hereinafter referred to as the c – g ratio;

2) the ratio of the height of the specimen to the smaller dimension of the base, hereinafter

referred to as the height ratio.

If the c – g ratio is small, for example less than 0,25, the specimen is unlikely to fall over due

to sudden sideways displacements. If the height ratio is small, for example less than 0,5, the

specimen is unlikely to topple over due to a sudden sideways force or blow at the top. In such

cases the writer of the relevant specification should consider whether the topple test is

applicable.

60068-2-31 © IEC:2008 – 7 –

a

h

IEC 782/08

h = distance between edge of specimen and test surface

a = angle between bottom face of specimen and test surface

Figure 1 – Dropping on to a face

Dimensions in millimetres

a

h

IEC 783/08

h = distance between edge of specimen and test surface

a = angle between bottom face of specimen and test surface

Figure 2 – Dropping on to a corner

IEC 784/08

Figure 3 – Topple (or push over)

– 8 – 60068-2-31 © IEC:2008

4 Initial measurements

Before commencement of the test, the specimen shall be visually examined and electrically

and mechanically checked as required by the relevant specification.

5 Testing

5.1 Drop and topple

5.1.1 Description

Having taken into account the manner in which the specimen will be handled in use and

during repair, the relevant specification shall state the test procedure to be used and whether

covers, cables, etc., are to be in position or not. The relevant specification shall also state

whether the specimen is, or is not, operational during the test.

In the test procedure where the specimen is dropped on to a face or corner, it is possible for

the specimen to topple onto a different face instead of falling back onto the test face as

intended. This shall be avoided by a suitable method.

In any of the test procedures, the specimen shall not be allowed to continue rolling about the

next edge.

Where the number of bottom edges exceeds four, the number of drops or topples shall be

limited to four and the relevant specification shall prescribe the edges to be used for the test.

5.1.2 Test facility

The test facility surface shall be smooth, hard, rigid, unyielding, horizontal and, for example,

made of concrete or steel. The steel plate shall be wet floated, that is, installed while the

concrete is still wet in order to remove voids, or bonded to the concrete. The seismic reaction

mass of the facility shall be at least 20 times the mass of the specimen under test. The

thickness of the steel plate shall be a minimum of 25 mm. With a specimen in excess of

500 kg, the steel plate shall be at least 40 mm thick, level within two degrees to the horizontal

and with a Brinell hardness of 90 – 300.

5.1.3 Testing procedures

5.1.3.1 Dropping onto a face

The specimen, standing in its normal position of use, is tilted along one bottom edge so that

the distance between the opposite edge and the test surface is 25 mm, 50 mm or 100 mm, as

prescribed by the relevant specification, or so that the angle made by the bottom and the test

surface is 30°, whichever condition is less severe.

It is then allowed to fall freely onto the test surface.

The specimen shall be subjected to one drop along each of four bottom edges (see also

Figure 1).

5.1.3.2 Dropping onto an edge or a corner

The specimen, standing in its normal position of use, is raised above the test surface by

placing a wooden stud 10 mm high under one corner, and a 20 mm wooden stud under the

other adjacent corner of one of the bottom edges. The specimen is then lifted above the test

surface by rotating it about the edge on the two studs, until the other corner adjacent to the

10 mm stud is raised 25 mm, 50 mm or 100 mm, as prescribed in the relevant specification, or

60068-2-31 © IEC:2008 – 9 –

so that the angle made by the specimen and the test surface is 30°, whichever condition is

less severe.

It is then allowed to fall freely on the test surface.

The specimen shall be subjected to one drop on each of the four bottom corners by applying

the test along the four bottom edges in turn (see Figure 2).

5.1.3.3 Topple or push-over

The specimen, standing in its normal position of use, is tilted about one bottom edge until it

reaches a position of instability. It is then allowed to fall over freely from this position on to an

adjacent face.

The specimen shall be subjected to one topple about each of four bottom edges (see also

Figure 3).

5.2 Free fall – Procedure 1

5.2.1 Description

The specimen shall be allowed to fall freely in its normal attitudes of transport or use, as

prescribed in the relevant specification.

Unless otherwise prescribed in the relevant specification, the specimen shall be subjected to

two falls from each prescribed attitude.

5.2.2 Test facility

The test facility used for free fall, procedure 1, is identical to that described in 5.1.2.

5.2.3 Test severity

Test severity is defined by the height of fall which shall be taken from the following series,

taking into account the mass of the specimen, unless real usage conditions are known or as

otherwise specified:

Table 1 – Fall heights versus mass

25 mm Mass < 50 kg

50 mm, 100 mm, 250 mm, 500 mm Mass < 10 kg

750 mm, 1 000 mm 1500 mm Mass < 1 kg

a

The values in bold type are preferred values.

b

For specimens in their transit case or for packed specimens, use the fall heights given in

ISO 4180-2.

5.2.4 Testing procedures

The specimen shall be dropped onto the surface of the test facility, see 5.2.2, from a height

selected from values in 5.2.3 and as prescribed in the relevant specification.

The height shall be measured from the part of the specimen nearest to the test surface, when

the specimen is suspended prior to letting it fall.

– 10 – 60068-2-31 © IEC:2008

The method of releasing the specimen shall allow free fall from the position of suspension

with a minimum of disturbance at the moment of release.

Where justified, other impact surfaces and hitting angle of the specimen may be prescribed in

the relevant specification.

5.3 Free fall repeated – Procedure 2

5.3.1 Description

The specimen shall be placed in the test apparatus and subjected to the prescribed number of

falls. If the specimen is normally attached to a cable, the relevant specification shall state the

type of cable to be used. When the specimen is normally attached to a cable, a free length of

100 mm of cable shall remain connected to the specimen during the test, unless otherwise

prescribed in the relevant specification.

5.3.2 Test facility

A suitable apparatus for use as the test facility is described in Annex A.

The specimen shall fall onto a smooth, hard, rigid test surface which, unless otherwise

prescribed by the relevant specification, shall be of steel of 3 mm thickness, backed by

hardwood of between 10 mm and 19 mm thickness.

NOTE 1 The tumbling barrel may not be appropriate for heavy specimens or if the shape of specimen prevents

repeated free fall.

5.3.3 Test severity

The total number of falls shall be as prescribed in the relevant specification and shall be taken

from the following series:

50, 100, 200, 500, 1 000

The height of the fall shall be 500 mm or 1000 mm.

NOTE The height of the fall should be related to the intended usage of the specimen.

5.3.4 Testing procedure

Each specimen is tested individually, and to simulate practical conditions, a length of cable

(see 5.3.1) is normally attached to the specimen during the test, which consists of subjecting

the specimen to a prescribed number of falls from a specified height onto a hard surface. The

effect of the test is checked in relation to the changes, if any, in the mechanical and electrical

parameters of the specimen.

The test apparatus shall be such that the prescribed number of falls from the specified height

selected from values given in 5.3.3 and stated in the relevant specification may be applied to

individual specimens. The number of falls selected from the list given below should be related

to the intended usage of the item.

Annex A describes one suitable form of apparatus employing a rotating barrel.

6 Final measurements

The specimen shall be visually examined and electrically and mechanically checked, as

required by the criteria prescribed in the relevant specification.

60068-2-31 © IEC:2008 – 11 –

The rate of fall shall be approximately ten falls per minute.

7 Information to be included in the relevant specification

When the test is included in the relevant specification, the following details shall be given as

far as they are applicable.

7.1 Drop and topple test Clause

a) Initial measurements 4

b) Testing 5.1.1

c) Fitting of cables, covers, etc. 5.1.1

d) Whether the specimen is operational or not during the test 5.1.1

e) Edges to be used in the test, where there are more than 5.1.1

four bottom edges

f) Height of drop onto a face 5.1.3.1

g) Height of drop onto a corner 5.1.3.2

h) Final measurements 6

7.2 Free fall and free fall repeated tests

a) Initial measurements 4

b) Test surface if other than concrete or steel 5.1.2

c) Height of fall Table 1, 5.3.4

d) Attitude from which the specimen is dropped 5.2.1

e) Number of falls, if other than two 5.2.1

f) Final measurements 6

g) Type of cable to be attached 5.3.1

8 Information to be given in the test report

As a minimum, the test report shall show the following information:

1. Customer (name and address)

2. Test laboratory (name and address)

3. Test report identification (date of issue, unique number)

4. Test dates

5. Type of test (free fall or drop and topple)

6. Purpose of the test (development test, qualification, etc.)

7. Test standard, edition (relevant test procedure)

8. Test specimen description (unique identity, drawing, photo, quantity, etc.)

9. Mounting of test specimen (test apparatus used, if applicable)

10. Performance of test apparatus (description and mass of test surface)

11. Initial and final measurements

12. Required severities (from test specification)

13. Test severities with documentation

14. Test results (comment on status of test specimen)

15. Observations during testing and actions taken

16. Summary of test

– 12 – 60068-2-31 © IEC:2008

17. Test manager (name and signature)

18. Distribution (list of those receiving report)

NOTE A test log should be written in which the test is documented, e.g. with a chronological list of test runs that

includes test parameters, observations during testing and actions taken as well as data sheets on measurements

made. The test log can be attached to the test report.

60068-2-31 © IEC:2008 – 13 –

Annex A

(normative)

Test apparatus for repeated free fall test –

Procedure 2

One suitable form of apparatus for the repeated free fall test (see 5.3.4) is based on a barrel

which rotates and causes a free fall combined with a tumbling motion of the specimen. Where

a large number of specimens have to be tested, the barrel may contain a number of sections,

one specimen being placed in each section, so that simultaneous testing may be carried out.

The width of each section, W, is not specified but shall preferably be between 200 mm and

300 mm, depending on the size of the specimen.

The dimensions of the barrel, and/or its sections shall be as shown in Figure A.1. The smooth,

rigid, steel test surface at each end, 3 mm in thickness, is backed by wood of between 10 mm

and 19 mm thickness (see also 5.1.2).

Each compartment in which the specimen rests between falls is backed by a wedge-shaped

piece made of chip-resistant rubber with a hardness of 80 ± 20 IRHD , as defined in ISO 48,

and the sliding surfaces of that same compartment are made of smooth, hard plastics

laminated sheet.

The rotating barrel is designed so that the shaft does not protrude into the interior.

The rotating barrel is provided with an aperture with a lid which may be made of transparent

acrylic material.

—————————

International rubber hardness degrees.

– 14 – 60068-2-31 © IEC:2008

Dimensions in millimetres

Block of wood A

45°

Plastics

laminated sheet

Rubber For fastening

of ends

Steel

A

W

Section A-A

a) The body of the rotating barrek is of sheet of 1,5 mm thickness

IEC 785/08

Figure A.1 – Rotating (or tumbling) barrel

10-19

a)

500 100 75

W

60068-2-31 © IEC:2008 – 15 –

Annex B

(informative)

Selection of test severities for free fall tests –

Guidance

B.1 Object

The free fall test is applicable to specimens which during transportation, handling or repair

work are liable to be dropped from their means of transport or from a work surface. The test is

not applicable to very heavy specimens or to those with large dimensions, for example large

power transformers.

B.2 Selection of test severities

The specification writer intending to prescribe this test should refer to Clause 7 of this

standard to ensure that all such information is included in the relevant specification.

Where possible, the test severity applied to the specimen should be related to the expected

handling and transport conditions to which the specimen will be subjected. However, it is

neither realistic nor economical to expect all specimens to survive the most severe mis-

handling which can be encountered in service, for example, dropping from an aircraft loading

platform or from a crane. For tests on specimens where it is required to demonstrate

serviceability, the height of the fall should be selected taking into account the risk of

occurrence, the tolerable level of damage and the conditions of operational use,

transportation and storage.

The appropriate severity, selected from 5.2.3, and 5.3.3 should be related to the mass of the

specimen, the type of handling and transport, and whether the test is to be applied to

unpacked specimens such as sub-assemblies, components, non-portable equipment, or

transportable items which are housed in integral transport cases.

In the absence of precise information on these aspects, a suitable severity should be selected

by the specification writer from Table B.1 which lists examples of severities appropriate to

various transport or handling conditions.

This table is not mandatory, but lists severities which are typical. It should be borne in mind

that there will be instances where the actual severities experienced in handling differ from

those shown in the table.

– 16 – 60068-2-31 © IEC:2008

Table B.1 – Examples of typical test severities

Specimen mass

Height

Example of

of

Type of

In integral unpacked

fall

handling

Unpacked

specimen

transport

mm

cases

kg

kg

a

25 ≥ 50 >500 Cubicles

Fork lift trucks

a

50 >10 < 50 ≤200 Cabinets

Fork lift trucks

a

100 >10 < 50 ≤100 Switchboards

Cranes

Storage,

250 >10 < 50 ≤75 Portable cases

Stacking

Fall from conveyor

500 <10 ≤40 Small items

belts

Fall from work

Components,

1 000 ≤1 ≤15 benches or

small assemblies

tailboard of truck

a

This is limited to simulate the impact when lowered to the loading level by a fork

lift truck or crane, not dropping from the platform of the truck or sling of the crane.

____________

– 18 – 60068-2-31 © CEI:2008

SOMMAIRE

AVANT-PROPOS.19

1 Domaine d'application .21

2 Références normatives.21

3 Description général de l’essai.22

4 Mesures initiales .24

5 Epreuve.24

5.1 Chute et culbute .24

5.1.1 Description .24

5.1.2 Installation d’essai.24

5.1.3 Méthodes d'essai.24

5.2 Chutes libres – Méthode 1.25

5.2.1 Description .25

5.2.2 Installation d’essai.25

5.2.3 Sévérité de l'essai .25

5.2.4 Méthodes d'essai.26

5.3 Chutes libres répétées – Méthode 2 .26

5.3.1 Description .26

5.3.2 Installation d’essai.26

5.3.3 Sévérité de l'essai .26

5.3.4 Méthode d’essais.26

6 Mesures finales .27

7 Renseignements à inclure dans la spécification particulière .27

7.1 Essais de chute et culbute.27

7.2 Essais de chute libre et de chutes libres répétées .27

8 Renseignements à fournir dans le rapport d’essai .27

Annexe A (normative) Appareillage d’essais pour les essais de chutes libres répétées

– Méthode 2.29

Annexe B (informative) Sélection des sévérités d’essai pour les essais de chutes

libres – Guide .31

Figure 1 – Chute sur une face.

Figure 2 – Chute sur un coin.23

Figure 3 – Culbute .23

Figure A.1 – Tonneau rotatif .30

Tableau 1 – Hauteurs de chute par rapport à la masse .25

Tableau B.1 – Exemples de sévérités d’essais types .32

60068-2-31 © CEI:2008 – 19 –

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

ESSAIS D'ENVIRONNEMENT –

Partie 2-31: Essais –

Essai Ec: Choc lié à des manutentions brutales,

essai destiné en premier lieu aux matériels

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60068-2-31 a été établie par le comité d'études 104 de la

CEI: Conditions, classification et essais d'environnement.

Cette deuxième édition annule et remplace la première édition, publiée en 1969, et constitue

une révision technique.

Les modifications principales par rapport à l’édition précédente concernent l’introduction, aux

endroits appropriés, des essais sur les emballages. Par ailleurs, la deuxième édition de la

CEI 60068-2-32 (1975) a été incorporée dans cette nouvelle édition de la CEI 60068-2-31:

La CEI 60068-2-32 sera supprimée une fois que la présente norme aura été publiée.

– 20 – 60068-2-31 © CEI:2008

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

104/458/FDIS 104/462/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

Elle a le statut de publication fondamentale de sécurité, conformément au Guide CEI 104.

Une liste de toutes les parties de la série CEI 60068, présentées sous le titre général Essais

d’environnement, peut être consultée sur le site web de la CEI.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant la date de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...