IEC TR 60825-10:2002

(Main)Safety of laser products - Part 10: Application guidelines and explanatory notes to IEC 60825-1

Safety of laser products - Part 10: Application guidelines and explanatory notes to IEC 60825-1

This technical report gives information on the physics relating to the dangers posed by laser products. It complements, but does not replace, the information in IEC 60825-1 by explaining the underlying principles, so that the user may correctly interpret its requirements. The application of this technical report is limited to laser products with finite accessible emissions of laser radiation.

General Information

- Status

- Withdrawn

- Publication Date

- 21-Feb-2002

- Withdrawal Date

- 05-Oct-2010

- Technical Committee

- TC 76 - Optical radiation safety and laser equipment

- Drafting Committee

- WG 8 - TC 76/WG 8

- Current Stage

- WPUB - Publication withdrawn

- Start Date

- 03-Sep-2010

- Completion Date

- 13-Feb-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

IEC TR 60825-10:2002 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Safety of laser products - Part 10: Application guidelines and explanatory notes to IEC 60825-1". This standard covers: This technical report gives information on the physics relating to the dangers posed by laser products. It complements, but does not replace, the information in IEC 60825-1 by explaining the underlying principles, so that the user may correctly interpret its requirements. The application of this technical report is limited to laser products with finite accessible emissions of laser radiation.

This technical report gives information on the physics relating to the dangers posed by laser products. It complements, but does not replace, the information in IEC 60825-1 by explaining the underlying principles, so that the user may correctly interpret its requirements. The application of this technical report is limited to laser products with finite accessible emissions of laser radiation.

IEC TR 60825-10:2002 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 31.260 - Optoelectronics. Laser equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 60825-10:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL IEC

REPORT

TR 60825-10

First edition

2002-02

Safety of laser products –

Part 10:

Application guidelines and

explanatory notes to IEC 60825-1

Sécurité des appareils à laser –

Partie 10:

Guide d'application et notes explicatives

concernant la CEI 60825-1

Reference number

IEC/TR 60825-10:2002(E)

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/catlg-e.htm) enables

you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/JP.htm) is also

available by email. Please contact the Customer Service Centre (see below) for

further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

TECHNICAL IEC

REPORT

TR 60825-10

First edition

2002-02

Safety of laser products –

Part 10:

Application guidelines and

explanatory notes to IEC 60825-1

Sécurité des appareils à laser –

Partie 10:

Guide d'application et notes explicatives

concernant la CEI 60825-1

IEC 2002 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

W

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

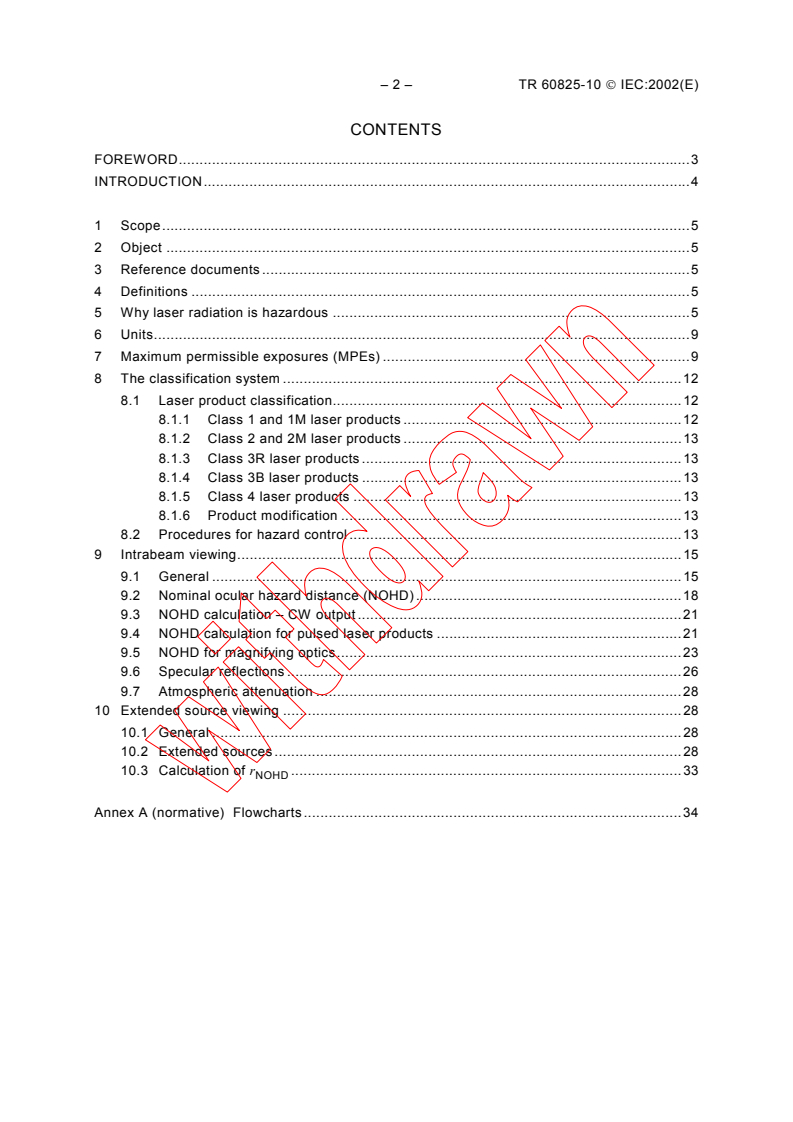

– 2 – TR 60825-10 IEC:2002(E)

CONTENTS

FOREWORD.3

INTRODUCTION.4

1 Scope.5

2 Object .5

3 Reference documents .5

4 Definitions .5

5 Why laser radiation is hazardous .5

6 Units.9

7 Maximum permissible exposures (MPEs) .9

8 The classification system .12

8.1 Laser product classification.12

8.1.1 Class 1 and 1M laser products .12

8.1.2 Class 2 and 2M laser products .13

8.1.3 Class 3R laser products .13

8.1.4 Class 3B laser products .13

8.1.5 Class 4 laser products .13

8.1.6 Product modification .13

8.2 Procedures for hazard control .13

9 Intrabeam viewing.15

9.1 General .15

9.2 Nominal ocular hazard distance (NOHD) .18

9.3 NOHD calculation – CW output .21

9.4 NOHD calculation for pulsed laser products .21

9.5 NOHD for magnifying optics.23

9.6 Specular reflections .26

9.7 Atmospheric attenuation .28

10 Extended source viewing .28

10.1 General .28

10.2 Extended sources .28

10.3 Calculation of r .33

NOHD

Annex A (normative) Flowcharts .34

TR 60825-10 IEC:2002(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY OF LASER PRODUCTS –

Part 10: Application guidelines and explanatory notes

to IEC 60825-1

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this technical report may be the subject of

patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. However, a

technical committee may propose the publication of a technical report when it has collected

data of a different kind from that which is normally published as an International Standard, for

example "state of the art".

Technical reports do not necessarily have to be reviewed until the data they provide are

considered to be no longer valid or useful by the maintenance team.

IEC 60825-10, which is a technical report, has been prepared by subcommittee 76: Optical

radiation safety and laser equipment.

The text of this technical report is based on the following documents:

Enquiry draft Report on voting

76/217/CDV 76/229/RVC

Full information on the voting for the approval of this technical report can be found in the report

on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives.

This document, which is purely informative, is not to be regarded as an International Standard.

– 4 – TR 60825-10 IEC:2002(E)

INTRODUCTION

This technical report is an informative document providing a simplified introduction to laser

hazard concepts, classification, intrabeam viewing and extended source viewing used in

IEC 60825-1, Safety of laser products – Part 1: Equipment classification, requirements and

user’s guide.

This technical report does not replace IEC 60825-1; however, if there is any real or apparent

conflict between this technical report and the standard, the standard must prevail.

TR 60825-10 IEC:2002(E) – 5 –

SAFETY OF LASER PRODUCTS –

Part 10: Application guidelines and explanatory notes

to IEC 60825-1

1 Scope

This technical report gives information on the physics relating to the dangers posed by laser

products. It complements, but does not replace, the information in IEC 60825-1 by explaining

the underlying principles. The application of this technical report is limited to laser products

with finite accessible emissions of laser radiation.

2 Object

This technical report provides a user of IEC 60825-1 with background information for that

standard (specifically the laser hazard, classification system, intrabeam viewing and extended

source viewing), giving the user an insight into the physics behind that standard, so that the

user may correctly interpret its requirements.

3 Reference documents

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60825-1:1993, Safety of laser products – Equipment classification, requirements and

user’s guide

Amendment 1 (1997)

Amendment 2 (2001)

4 Definitions

For the purpose of this technical report, the definitions in IEC 60825-1 apply.

5 Why laser radiation is hazardous

Electromagnetic radiation is not normally considered dangerous. However, the simple analysis

below shows that a 1 W laser can introduce more than five orders of magnitude greater light

into the eye (at 1 m distance) than an incandescent bulb of equal power placed at the same

distance, and more than one order of magnitude greater than that of the sun.

Laser radiation in the optical hazard region from 400 nm to 1 400 nm is focused to a small spot

on the retina. This increases the hazard in that region. The current example illustrates the

effect in the optical hazard region.

___________

There exists a consolidated edition (2001) that includes IEC 60825-1 (1993) and its Amendment 1 (1997) and

Amendment 2 (2001).

– 6 – TR 60825-10 IEC:2002(E)

Moreover, unlike the incandescent light bulb, laser light in the ocular hazard region may be

focused to a small point on the retina measuring a few microns across. By comparison, the

image of the sun on the retina would be of the order of 0,15 mm on the retina. The effect of an

exposure to laser radiation could therefore be considerably worse than indicated by the

analysis below.

Consider a light bulb producing 1 W of optical radiation (see Figure 1) typical of the interior

light of a car. Light from the globe at 1 m has irradiance (power density) given by the power of

the light globe divided by the surface area of a sphere whose radius is 1 m, as shown by the

following equation:

1,0 W

– 2 −2

= 8,0 ×10 (1)

W ⋅ m

4π(1,0 m

)

NOTE The surface area of a sphere of radius r is given by 4πr .

Compare this with radiation from a 1,0 W laser in the ocular hazard region with a 1 mm beam

diameter at 1 m from the laser, with an approximate irradiance of:

1,0 W

6 –2

= 1,3 × 10 W ⋅ m (2)

π 2

–3

()1,0 × 10 m

NOTE The area of a circle of diameter d is given by πd /4.

Throughout IEC 60825-1 it is assumed that the diameter of the pupil of the eye is 7 mm. This is

a worst case occurring when the ambient light level is low. Under these circumstances the light

from the globe entering a pupil having an area of:

π 2

–5

–3 2

= 3,8×10 (3)

m

(7× 10 )

would be

–2 –2 –5 2 –6

(8,0 × 10 W ⋅ m ) × (3,8 × 10 m ) = 3,0 × 10 W (4)

TR 60825-10 IEC:2002(E) – 7 –

1,0 m

Irradiance =

-2 -2

8,0 × 10 W·m

-6

W

3,0 × 10

enters eye

1 watt light globe

Irradiance =

Sun

3 -2

1,0 × 10 W·m

-2

3,8 × 10 W

enters eye

1 mm

Irradiance =

1 W laser

6 -2

1,3 × 10 W·m

1,0 W

Pupil diameter is

enters eye

assumed to be 7 mm

IEC 571/02

Figure 1 – Comparison of the hazards of various light sources

Compare this with light entering the eye from a laser at 1 m. In the case of the laser with a

beam diameter of 1 mm and small divergence, all of the light will enter an eye with a pupil

diameter of 7 mm. This is 3,3 × 10 times as much light as would have entered the eye from a

bulb producing the same amount of visible radiation.

The reason for this difference is shown diagrammatically in Figure 1.

The radiation from any source (including laser radiation with a wavelength between 400 nm and

1 400 nm) is generally focused on the retina, the light sensitive area at the back of the eye (see

Figure 2). In the case of lasers, this may increase the irradiance (watts per square metre) of

the light by approximately five orders of magnitude.

NOTE The anatomy of the human eye is shown in Figure B.1 of IEC 60825-1.

– 8 – TR 60825-10 IEC:2002(E)

When a person 'looks at' an object, their eye is actually focusing that object on the fovea,

where there is the highest density of cone receptor cells (see Figure 2). The fovea is only

1,5 mm or so in diameter and is the area on the retina generating our most acute vision.

Images which need to be viewed in detail, such as the words on this page, are focused on the

foveola which is only 350 microns in diameter. It is this section of the retina which is most at

risk because of a natural tendency to `look at' objects which attract our interest.

The highest risk is normally seen at the fovea because this is the location of gaze produced by

the eye. It is also the section of the retina which has the most impact on visual function if

damaged. Depending on the area of the foveola and the fovea damaged, reading may be

precluded but individuals may still retain a measure of central and peripheral vision. Damage to

the area surrounding the retina can occur with little loss of effective sight other than some

reduction in peripheral vision which can occur without the affected person being aware of it.

The eye is remarkable in that it can detect light intensities varying over eight or nine orders of

magnitude. Part of this accommodation is effected by changing the size of the pupil, but this

only accounts for one order of magnitude. The change in pupil size occurs over a matter of

seconds. When viewing in bright light, the fovea is active in discriminating small detail and

colour, while the remainder of the retina provides peripheral vision, which primarily detects

movement. As the light level reduces, the fovea becomes less important to vision and the

remainder of the retina provides 'night vision'.

Retina

5 m

Fovea

0,1 m

340 μm

Cornea -2

E = 134 W·m

Lens

100 W lamp

Optic disk (where optic

with frosted glass

nerve and blood supply

5 m

17 mm

leaves eye)

Spot size = 25 μm

Laser

-2

1 mW HeNe laser E = 2,0 MW·m

IEC 572/02

Figure 2 – Cross-section of eye showing comparison of the irradiance at the retina

for an image of a lamp with an output of 100 W and an ideal diffraction limited spot

from a 1 mW HeNe laser

Damage to tissues can be caused by heat effects, thermo-acoustic transients, or photo-

chemical processes. The degree to which these effects are responsible for damage depends

on the physical parameters relating to the exposure.

NOTE The various mechanisms for damage are shown in Figure B.2 of IEC 60825-1.

TR 60825-10 IEC:2002(E) – 9 –

Radiation from laser products can cause different effects depending on the wavelengths and

energy density of the radiation, and the part of the body exposed to the radiation.

NOTE See Figure B.3 of IEC 60825-1.

Hazards include absorption by and damage to the skin and the eye, setting fire to clothes and

other materials. The full range of hazards needs to be considered.

In assessing the hazard, a number of laser parameters are of importance. These include:

a) exposure duration;

b) pulse width;

c) wavelength;

d) CW or pulsed operation;

e) repetition rate, if applicable;

f) beam diameter;

g) beam divergence; and

h) viewing distance.

The hazard is often increased by telescopes or binoculars because they can gather additional

radiation and concentrate it in the eye. These parameters are discussed in detail in later

sections.

6 Units

Table 1 lists the common units and their symbols used in IEC 60825-1. Examples of these

quantities are given diagrammatically in Figure 3.

7 Maximum permissible exposures (MPEs)

IEC 60825-1 relies on the concept of maximum permissible exposures (MPEs). The MPEs are

derived primarily from animal and human data, but take account of human variability and laser

parameters. MPE levels are set by ICNIRP (International Commission on Non-Ionising

Radiation Protection). They are reevaluated from time to time in the light of available evidence.

Clause 3.51 of IEC 60825-1 defines the maximum permissible exposure as “That level of laser

radiation to which, under normal circumstances, persons may be exposed without suffering

adverse effects. The MPE levels represent the maximum level to which the eye or skin can be

exposed without consequential injury immediately after, or after a long time, and are related to

the wavelength of the radiation, the pulse duration or exposure time, the tissue at risk and, for

visible and near infra-red radiation in the range of 400 nm to 1 400 nm, the size of the retinal

image. Maximum permissible exposure levels are (in the existing state of knowledge) specified

in clause 13 (of IEC 60825-1).”

MPEs are expressed as irradiance or radiant exposure at the cornea, and are given as tables

in IEC 60825-1. MPEs for ocular exposure at the cornea are tabulated in Table 6 of IEC 60825-1

as a function of wavelength and exposure time. Table 8 of IEC 60825-1 tabulates the MPE of

skin to laser radiation.

The MPE values should be used as guides in the control of exposures and should not be

regarded as precisely defining the dividing lines between safe and dangerous levels. In any

case, exposure to laser radiation shall be a low as possible.

– 10 – TR 60825-10 IEC:2002(E)

Note that while the probability of an exposure at the level of the MPE causing eye damage is

very low, it may not be zero. Because of this, and the uncertainty in the derivation of MPEs, it is

good practice to avoid all unnecessary exposure to laser radiation at levels that approach the

MPE.

The biophysical effects of laser radiation are described in detail in Annex B of IEC 60825-1.

Thermal effects are those which occur when sufficient radiation energy has been absorbed by

a biological system to cause heating in the system. Most laser damage is due to the heating of

the absorbing tissue or tissues.

On the other hand, at certain wavelengths, photochemical effects or those caused by the

specific molecular absorption of a given radiation can lead to tissue damage. Following

the absorption, the molecule may undergo a chemical reaction unique to its excited state. This

photochemical reaction is believed to be responsible for damage at low levels of exposure.

By this mechanism, some biological tissues such as the skin, and the lens of the eye, may

show irreversible changes induced by prolonged exposure to moderate levels of UV radiation

and short wavelength radiation. For this reason the MPEs are correspondingly lower than for

wavelengths where the mechanism is thermal.

In Table 6 of IEC 60825-1 a calculation of both the retinal photochemical hazard levels and the

retinal thermal hazard levels is required for exposures greater than 10 s of radiation with a

wavelength between 400 nm and 600 nm and for exposures greater than 1,0 s of radiation with

a wavelength between 400 nm and 484 nm. In these cases the most restrictive hazard level

becomes the MPE.

In some cases, laser products produce radiation comprising multiple wavelengths. The multiple

wavelengths may affect similar tissue. For example there may be more than one wavelength

contributing to heat generation in the retina. Alternatively each wavelength may operate

independently. Table 5 of IEC 60825-1 provides a guide to determine whether the hazardous

effects of one or more wavelengths are additive or whether each should be treated separately.

Table 1 – Commonly used units and symbols

Quantity Unit Abbreviation Symbol Formulae

Area Square metre m A See Figure 3

Exposure time Second s T —

–2 –1

b

a

Integrated radiance Joule per square J m sr L

L = H/Ω

metre per steradian

–2

Irradiance Watt per square W m EE = P/A

metre

Linear angle Radian rad See Figure 3

φ

-2 –1

b a

Radiance Watt per square W m sr L L = E/Ω

metre per steradian

Radiant energy Joule J QQ = PT

–2

Radiant exposure Joule per square J m HH = Q/A

metre

Radiant power Watt W P = Q/T

P, Φ

Solid angle Steradian sr See Figure 3

Ω

a

In this case H (or E) is the radiant exposure (or irradiance) measured at the diffuse reflector or divergent

source.

Ω is the solid angle into which the radiation is directed.

b

L is used for both integrated radiance and radiance in different parts of IEC 60825-1

TR 60825-10 IEC:2002(E) – 11 –

Intrabeam

viewing

πd

A

=

Area A

Q

Radiant exposure H =

A

P

Irradiance E

=

A

Linear angle

Linear angle =

d

d

φ

φ ≅

radians

r

for small φ

r

Solid angle

Area A

Solid angle

πφ

A πd

steradians

≅ = =

Ω Ω

r 4r

r

Diffuse reflections

Radiance

E

-2 -1

L =

W⋅m ⋅ sr

π

-2 -1

Radiance W⋅m ⋅ sr

IEC 573/02

Figure 3 – Commonly used units

– 12 – TR 60825-10 IEC:2002(E)

8 The classification system

8.1 Laser product classification

The product classification is the primary indication of whether the laser product is capable of

causing injury. It is the responsibility of the manufacturer to label and provide information about

its laser product in accordance with Section 2 of IEC 60825-1. A guide for the implementation

of safe practice for the user is set out in Section 3 of IEC 60825-1. It is therefore necessary

that both the manufacturer and, where a hazard exists, the user, understand the system of

classification. The details of the classification system are set out in Section 2 of IEC 60825-1,

and the philosophy behind it is described below.

The classification of a laser product is based on the radiation emitted during the normal

operation and any reasonably foreseeable fault condition for that product. In some cases the

removal of protective shielding or access panels may lead to the possibility of an exposure in

excess of that allowable for that class of laser. Such panels should be clearly marked by the

manufacturer, and should only be removed by persons with the appropriate level of knowledge

and training in laser safety.

In the process of taking the measurements required for classification, the concept of

measurement aperture is used. The size of the spot on the retina will depend on a number of

factors including the diameter of the beam, and whether the beam is focused on the retina. The

worst case (that is the smallest retinal spot) is one for which the beam just fills the pupil

(assumed to be of 7 mm diameter) and the beam is accurately focused. For this reason, when

–2

the MPE is specified as an irradiance (W⋅m ) it is assumed that, if the beam is less than 7 mm

its power should be averaged over 7 mm. That is, it should be assumed that the beam is

expanded to 7mm diameter. If the beam diameter is greater than 7 mm, only that power

entering a 7 mm aperture should be considered. The same principle applies if the MPE is

–2

expressed as a radiant exposure (J⋅m ).

The measurement procedures for classification are specified in IEC 60825-1. The procedures

specify a range of measurement apertures which vary with wavelength and the class of laser

and which relate to the diameter of the pupil and the assumed diameter of viewing optics, or in

some cases a limiting aperture is specified for measurement convenience and standardization.

The limits used for classification are called accessible emission limits (AELs). They are derived

from the MPEs using limiting apertures and are expressed either as a power limit, an energy

limit, an irradiance limit, a radiant exposure limit, or an combination of these.

A laser is correctly classified if its parameters exceed those of the next lower class, and are

less than or equal to the limits of its class.

NOTE Because the AELs are based on MPEs, the classification system is an indication of whether the laser

product is likely to cause injury. An exposure to visible laser radiation less than that required to cause injury may

still be uncomfortable and cause temporary blindness or distraction. For this reason all exposure to laser radiation

should be as low as possible.

8.1.1 Class 1 and 1M laser products

Class 1 laser products are safe under reasonably foreseeable conditions of operation. In

general they would not allow exposure to sufficient radiant energy to damage the eye or skin.

The AELs for Class 1 laser products are set out in Table 1 of IEC 60825-1.

Class 1M laser products are safe under reasonably foreseeable conditions of operation

provided that they are not viewed with magnifying optics of any kind. Class 1M usually relates

to laser products with high divergence or large beam diameters compared to the limiting

aperture.

Magnifying optical instruments are designed to magnify the image on the retina. See 9.5 for

more details.

TR 60825-10 IEC:2002(E) – 13 –

8.1.2 Class 2 and 2M laser products

Class 2 laser products would not cause permanent damage to the eye under reasonably

foreseeable conditions of operation, provided that any exposure can be terminated by the blink

reflex (assumed to take 0,25 s). Because classification assumes the blink reflex, only laser

products with a visible output (400 nm to 700 nm wavelengths) can be classified as Class 2.

–2

The MPE for visible radiation for 0,25 s is 25 W⋅m . This irradiance is equivalent to 1 mW

entering an aperture of 7 mm diameter (the assumed size of the pupil).

Thus the AEL for Class 2 laser products is 1,0 mW for collimated beams or beams from small

sources. This can be seen in Table 2 of IEC 60825-1. Note that the parameter C equals 1 for

well-collimated beams, as indicated in the notes to Tables 1 to 4 of IEC 60825-1. C takes on

another value for extended sources, and this is discussed in detail in Clause 10 of this

technical report.

Class 2 laser products are not hazardous as long as staring at them is not a requirement of

their design. However, they may cause flash blindness. The use of viewing optics such as

binoculars with Class 2 laser products does not usually create a hazard as long as the

objective lens diameter is not greater than 50 mm.

In the case of Class 2M laser products, a hazard may exist if they are viewed through

magnifying optics such as eye loupes, binoculars or telescopes.

8.1.3 Class 3R laser products

Class 3R laser products emit radiation in the wavelength range from 302,5 nm to 10 nm where

direct intrabeam viewing is potentially hazardous but the risk is lower than for Class 3B lasers,

and fewer manufacturing requirements and control measures for the user apply than for Class

3B lasers. The accessible emission limit is within five times the AEL of Class 2 in the

wavelength range from 400 nm to 700 nm and within five times the AEL of Class 1 for other

wavelengths.

8.1.4 Class 3B laser products

Class 3B laser products are unsafe for eye exposure at all wavelengths, but are generally not

so powerful that a short exposure would damage skin. Usually only ocular protection would be

required. Diffuse reflections are safe if viewed for less than 10 s. Table 4 in IEC 60825-1

shows the AELs for Class 3B laser products.

8.1.5 Class 4 laser products

Class 4 laser products are generally powerful enough to burn skin and cause fires and may

ionise the atmosphere when focused. As such, a range of additional safety measures are

required.

8.1.6 Product modification

If the user of a laser product makes changes to the product or does not use it in the manner

intended by the manufacturer, reclassification may be required. Under these circumstances the

person or organization that modifies the laser product takes on the responsibilities of a

manufacturer (see 4.1.1 of IEC 60825-1).

8.2 Procedures for hazard control

The procedures for hazard control are set out in Clause 12 of IEC 60825-1. The primary

considerations include the capacity of the laser product to cause injury (as indicated broadly by

its classification), the environment in which it is used and the level of knowledge of people who

might be exposed.

– 14 – TR 60825-10 IEC:2002(E)

Where a hazard is likely to exist, a laser safety officer (LSO) should be appointed. It is the

LSO's responsibility to evaluate the hazard and establish appropriate procedures.

Safe operation of Class 3B and Class 4 laser products outdoors relies on the concept of

nominal ocular hazard distance, which is discussed in Clause 9.

Class 3B laser products need to be operated in a controlled area, with appropriate beam stops

and with precautions taken to prevent unintended specular reflections. Eye protection is

required if there is any possibility of exposure. Diffuse reflections are safe, provided the

distance between the diffusely reflecting screen and the observer exceeds 130 mm and the

exposure does not exceed 10 s.

For Class 4 laser products additional precautions are required. Beams can cause fires and

injuries to the skin as well as eye injuries. Beam paths should be enclosed and the area should

be restricted to properly trained and protected personnel during operations. Remote control

should be used where practicable, there should be good room illumination and eye protection

should be worn. Fire resistant materials should be used as backstops. Special precautions

should be taken for lasers radiating at invisible wavelengths.

In choosing eye protection, the degree of protection should be considered. Laser eye

protectors are rated according to their “optical density” (D ) defined as:

λ

H

= log (5)

D

λ

MPE

where H is the expected radiant exposure at the unprotected eye.

–2 –2

This equation is used when the MPE is in units of J⋅m . In cases where the MPE is in W⋅m ,

the following form should be used:

E

= log (6)

D

λ

MPE

where E is the expected irradiance at the unprotected eye.

The units of MPE determine whether H or E should be used.

0 0

The major considerations include:

a) wavelengths of operation;

b) radiant exposure or irradiance;

c) MPE;

d) optical density;

e) visible radiation transmission requirements;

f) the exposure level at which damage to the eyewear occurs;

g) need for prescription glasses;

h) comfort and ventilation;

i) degradation;

j) strength;

k) peripheral vision requirements.

TR 60825-10 IEC:2002(E) – 15 –

In cases where eye protection would otherwise be required, operations should only be

undertaken with the approval of the laser safety officer. More detailed information on hazard

identification as well as guidance on the selection of appropriate laser eye protectors is given

in IEC 60825-1.

9 Intrabeam viewing

9.1 General

For a given amount of radiant power or energy entering the eye, one might expect the damage

threshold to depend on the size of the image focused onto the retina in the case of thermal

hazards. Paradoxically, this only occurs when the angle subtended at the eye by the source, α

(see Figure 4) exceeds the coefficient called α (equal to 1,5 mrad) in IEC 60825-1. At

min

angular subtenses less than α damage thresholds are determined by the total energy or

min

power entering the eye and not by the irradiance or radiant exposure of the retinal image.

This effect results from the fact that, for small retinal image sizes, tissue cooling is dominated

by radial conduction from the centre of the image formed on the retina. Although the heating

rate of individual cells reduces with increasing image size, the lengthening of the radial cooling

path from the centre of the image means that the cells in the image centre sustain a

temperature rise for a given exposure time which is constant for a range of image sizes. This

exposure condition is referred to as ‘point source viewing’.

At angular subtenses above α , “extended source viewing” conditions apply. Cooling into the

min

vitreous humour gradually becomes the dominant cooling mechanism. Consequently, damage

processes become dependent on the image size and, therefore, on the value of angular

subtense. This is the basis for the coefficient C in IEC 60825-1.

At angular subtenses above α , damage thresholds depend upon the radiance or integrated

max

radiance of the image as described in 10.2.

As far as IEC 60825-1 is concerned, for all α > α extended source viewing conditions exist.

min

For all α < α point source or intrabeam viewing exists.

min

All laser beams diverge or converge to some extent. In the case of Class 3B and Class 4 laser

products, the MPE is exceeded at the output of the laser. For a laser beam the irradiance

–2 –2

(W⋅m ) and the radiant exposure (J⋅m ) generally decrease as the cross-sectional area of

the beam increases with increasing distance from the source. This is shown in Figure 5.

– 16 – TR 60825-10 IEC:2002(E)

Viewing a collimated beam (α < α )

min

Heat dissipation

Viewing a extended source (α > α )

max

Heat dissipation

Image size

F = 17 mm

r

α

α

d

i

D

I

D d

I i

α ≅

=

r F

D

I

≅

d F Fα

=

i

r IEC 574/02

Figure 4 – Angular subtense, retinal cooling and image size

for wavelengths in the retinal hazard region

TR 60825-10 IEC:2002(E) – 17 –

D

L

Laser

φ

a

r

Diameter, D = rφ + a

L

π

D

L

Area, A =

Power

Irradiance, E =

A

Energy

Radiant exposure,

H =

A

IEC 575/02

Figure 5 – Divergence of laser radiation without an external beam waist

It may be necessary to determine whether a potential exposure at some distance r from the

laser would be hazardous (see Figure 5). This can be done by comparing the actual exposure

with the relevant MPE. The first step is to determine the MPE for the wavelength and the likely

exposure time. Taking the simplest case of a visible CW laser, the MPE can be determined

from Table 6 of IEC 60825-1. The determination of MPEs for pulsed lasers is discussed in

detail in 9.4.

This derivation only applies to beams which diverge from the laser in the far field region of the

beam. For beams which converge to a waist external to the laser a more accurate analysis

beyond the scope of this document is required.

–2 –2 –2

The MPE will be in units of either W⋅m or J⋅m . If the MPE is in units of W⋅m the radiation

–2

output of the laser product in watts should be determined. If the MPE is in units of J⋅m the

radiation output of the laser in joules should be determined. This can be done with the following

equations:

Q

P = (7)

t

or Q = P × t (8)

where:

P is the power, in watts

Q is the energy, in joules, and

t is the time for Q to be delivered, in seconds.

– 18 – TR 60825-10 IEC:2002(E)

The output of the laser product in watts or joules, should be divided by the area of the beam at

–2 –2

the observer to obtain the irradiance (in W⋅m ) or the radiant exposure (in J⋅m ). If the

exposure exceeds the MPE then the exposure should be avoided. If the diameter of the beam

at the distance r is less than the limiting aperture (7 mm for a laser radiation between 400 nm

and 1 400 nm), the beam should be assumed to have a diameter equal to the limiting aperture

(see 8.1).

NOTE When comparing any exposure to a MPE, it is essential that the units in which the exposure is be identical to

those of the MPE.

On occasions it may be necessary to convert irradiance to radiant exposure and vice versa,

This can be achieved as follows:

H

E = (9)

t

or H = E × t (10)

where

E is the irradiance, in watts per square metre,

H is the radiant exposure, in joules per square metre, and

t is the time, in seconds.

An alternative approach is to determine the distance from the laser product at which an

exposure is just below the MPE. This is called he nominal ocular hazard distance (NOHD). At

smaller distances the exposure will exceed the MPE.

9.2 Nominal ocular hazard distance (NOHD)

In the analysis of point source viewing conditions, the concept of NOHD is used and is related

to that of MPE. The NOHD is the nominal distance at which the exposure equals the MPE.

The concept of NOHD is used when laser products such as range finders or display lasers are

to be used in the open air. It represents the distance within which exposure exceeds the MPE

and eye protection is required.

Assuming linear divergence, from Figure 6 and the definition of the angle φ it is evident that:

D = NOHD ×φ + a (11)

NOHD

where:

D is the diameter of the beam at the NOHD,

NOHD

a is the diameter of beam at the exit from the laser, and

φ is the divergence angle.

NOTE In 3.10 of IEC 60825-1 the beam diameter is defined as the diameter of the smallest circle which contains

63% of the total beam energy. In the case of a Gaussian beam the diameter is the distance between two opposite

points at which the irradiance or radiant exposure has fallen to 1/e of its peak value.

The area of the beam at the NOHD (A ) is given by the following equation:

NOHD

π ×

D

NOHD

= (12)

A

NOHD

TR 60825-10 IEC:2002(E) – 19 –

The irradiance at the NOHD (E ) is given by the following equation:

NOHD

P 4 × P

= = = MPE (13)

E

NOHD

A

π ×

NOHD

D

NOHD

where

P is the radiant power of the laser, and

D is the diameter of the beam at the NOHD.

NOHD

Irradiance or Radiant

Exposure equals MPE

Laser a

φ

D

NOHD

NOHD

Exposure does not

Exposure exceeds MPE

exceed MPE

IEC 576/02

Figure 6 – The concept of nominal ocular hazard distance

Replacing D with (NOHD × φ + a) from equation 11 gives:

NOHD

4 × P

MPE = (14)

π × ×φ

(NOHD + a)

where

a is the diameter of the beam at the exit from the laser, and

P is the radiant power of the laser.

Rearranging this equation to obtain NOHD explicitly gives:

0,5

1 4 × P a

NOHD = − (15)

φ π × MPE φ

– 20 – TR 60825-10 IEC:2002(E)

where

P is the radiant power of the laser,

a is the diameter of the beam at the exit from the laser, and

φ is the beam divergence angle.

The above equations are approximations applicable to a generalized situation.

If a is small compared to the term in square brackets in equation 15, it can conservatively be

neglected.

If a is not small and the calculated NOHD is negative, the result indicates that the laser is safe

for that exposure at all distances.

The above formula relates to laser products with Gaussian beams. For laser products of

unknown mode structure, a factor is introduced to account for possible `hot spots' in the beam.

This matter is referred to in Annex A5 of IEC 60825-1. In this technical report the factor is

given the symbol k. For beams of unknown mode structure it has the value of 2,5. If the mode

structure is known to be Gaussian, then k = 1.

If the mode structure is known and is non-Gaussian, the appropriate value for k should be

determined. The full equation then becomes:

0,5

1 4 × k × P a

NOHD ≈ − (16)

−2

φ φ

π × MPE( )

W⋅ m

where P is the radiant power produced by the laser.

This formula has been derived for the case where the MPE of the laser is given as an

–2

irradiance (W⋅m ). In cases where the MPE is given as a radiant exposure, the corresponding

NOHD equation is:

0,5

1 4 × k × Q a

NOHD ≈ − (17)

−2

φ φ

π × MPE( )

J ⋅ m

The preceding equations form the basis of the calculation of NOHD. In cases where the second

term can (conservatively) be ignored, a further approximation can be obtained as follows:

1,784 P

NOHD ≈ for k = 2,5; and (18)

φ MPE

1,128 P

NOHD ≈ k = 1 for Gaussian beams. (19)

φ MPE

–2 –2

The above two equations are true for MPEs in W⋅m . If the stated MPE is in J⋅m then the P

in watts should be replaced by Q in joules.

___________

For Gaussian beam propagation, more exact equations are given in KOLGENICK, H. and LI, T. Laser Beams

and Resonators. Appl. Opt., 1996, 5, p.1550–1567 and Proc IEEE, 1996, 54(10), p.1312–1329.

TR 60825-10 IEC:2002(E) – 21 –

9.3 NOHD calculation – CW output

For Class 3R, Class 3B and Class 4 laser products it may be necessary to calculate the NOHD.

Flowchart 1 of Annex A describes a technique for calculating the NOHD for a product with a

CW output. The first step is to tabulate the relevant parameters (box 2). Since the MPE

depends on the maximum likely exposure time it is necessary to determine an exposure time

consistent with the standard. The MPE should be determined for each wavelength, using the

appropriate exposure time in Table 6 of IEC 60825-1 (box 3). If only one wavelength is involved

(box 4A) the MPE can be determined from Tabl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...