IEC 61730-1:2004

(Main)Photovoltaic (PV) module safety qualification - Part 1: Requirements for construction

Photovoltaic (PV) module safety qualification - Part 1: Requirements for construction

Describes the fundamental construction requirements for photovoltaic modules in order to provide safe electrical and mechanical operation during their expected lifetime. Addresses the prevention of electrical shock, fire hazards, and personal injury due to mechanical and environmental stresses. Pertains to the particular requirements of construction and is to be used in conjunction with IEC 61215 or IEC 61646.

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) - Partie 1: Exigences pour la construction

Décrit les exigences fondamentales de construction pour les modules photovoltaïques afin de fournir un fonctionnement électrique et mécanique sûr au cours de leur durée de vie. Couvre la prévention contre les chocs électriques, les risques de feu et les accidents corporels dus à des contraintes mécaniques et environnementales. Se rapporte aux exigences particulières de construction et sera utilisée conjointement avec la CEI 61215 ou la CEI 61646.

General Information

- Status

- Published

- Publication Date

- 13-Oct-2004

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 2 - TC 82/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 17-Aug-2016

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61730-1:2004, titled Photovoltaic (PV) Module Safety Qualification – Part 1: Requirements for Construction, published by the International Electrotechnical Commission (IEC), sets the fundamental safety construction requirements for photovoltaic (PV) modules. This international standard focuses on ensuring safe electrical and mechanical operation of PV modules throughout their expected lifetime by addressing risks of electrical shock, fire hazards, and personal injury arising from mechanical stress and environmental factors.

As a cornerstone document in PV module safety qualification, IEC 61730-1 complements related standards such as IEC 61215 and IEC 61646 by providing essential construction guidelines that work in tandem with performance and testing requirements outlined in those documents. This standard is crucial for manufacturers, safety certifiers, and designers aiming to ensure photovoltaic modules meet internationally recognized safety and durability criteria.

Key Topics

- Safety Focus: The standard emphasizes prevention of electrical shock, fire, and injury through strict construction requirements.

- Application Classes: Defines different use categories (Class A, B, C), accommodating various risk levels based on access and voltage/power parameters.

- Materials Requirements: Provides detailed guidelines on the use of metals, polymers, and other components to ensure integrity under electrical and mechanical stresses.

- Internal Wiring and Connections: Specifies secure wiring practices, splices, connectors, lead cables, and strain relief to maintain electrical safety.

- Bonding and Grounding: Addresses grounding techniques to reduce hazards associated with electrical faults.

- Creepage and Clearance: Sets minimum distances for electrical insulation to prevent unintended current flow that could be hazardous.

- Field Wiring Compartments: Outlines construction and protection for accessible wiring compartments, including seals, gaskets, and safety against sharp edges.

- Marking and Documentation: Requires clear labeling and provision of documents to support proper use, maintenance, and safety compliance.

- Coordinated Testing: Designed to align with IEC 61730-2 (testing requirements) and performance standards IEC 61215 or IEC 61646, enabling comprehensive safety and reliability assessments.

Applications

IEC 61730-1 applies primarily to the construction of crystalline silicon and thin-film photovoltaic modules destined for various installations, including residential, commercial, and utility-scale solar power systems. Its guidelines ensure that modules are fabricated to minimize risks across diverse environments where PV systems operate. This includes precautions against harsh weather conditions, UV exposure, mechanical impact, and electrical hazards.

The standard supports:

- Manufacturers in designing PV modules that comply with international safety standards.

- Certification Bodies working to evaluate the safety of PV products for market approval.

- Installers and System Designers ensuring selection and use of modules that meet regulatory safety norms.

- Regulatory Authorities referencing consistent safety criteria for photovoltaic installations.

By securing the fundamental construction elements, IEC 61730-1 plays a critical role in advancing the reliability and public trust in solar photovoltaic technologies worldwide.

Related Standards

IEC 61730-1 should be used in conjunction with the following key standards for a holistic evaluation of photovoltaic modules:

IEC 61730-2: Photovoltaic (PV) Module Safety Qualification – Part 2: Requirements for Testing

Focuses on test methods to verify the safety features established by IEC 61730-1 construction requirements.IEC 61215: Crystalline Silicon Terrestrial Photovoltaic (PV) Modules – Design Qualification and Type Approval

Addresses design and performance testing ensuring module durability and efficiency.IEC 61646: Thin-Film Terrestrial Photovoltaic (PV) Modules – Design Qualification and Type Approval

Similar to IEC 61215 but specific to thin-film PV modules.IEC 60529: Degrees of Protection Provided by Enclosures (IP Code)

Details the environmental sealing standards to protect modules and wiring from dust and water ingress.IEC 60364-5-51: Electrical Installations of Buildings – Selection and Erection of Electrical Equipment

Provides guidelines applicable to the safe installation of PV modules and associated wiring.

These related standards collectively ensure that photovoltaic modules not only conform to durable construction and safety requirements but also meet rigorous testing and operational performance standards relevant in global markets.

By adhering to IEC 61730-1:2004, stakeholders in the solar industry can assure safer photovoltaic module construction, reducing hazards and enhancing long-term reliability, while fostering compliance with international electrical safety norms. This reinforces the sustainable deployment of solar energy solutions worldwide.

IEC 61730-1:2004 - Photovoltaic (PV) module safety qualification - Part 1: Requirements for construction Released:10/14/2004 Isbn:2831876788

IEC 61730-1:2004+AMD1:2011+AMD2:2013 CSV - Photovoltaic (PV) module safety qualification - Part 1: Requirements for construction Released:3/14/2013 Isbn:9782889128815

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 61730-1:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Photovoltaic (PV) module safety qualification - Part 1: Requirements for construction". This standard covers: Describes the fundamental construction requirements for photovoltaic modules in order to provide safe electrical and mechanical operation during their expected lifetime. Addresses the prevention of electrical shock, fire hazards, and personal injury due to mechanical and environmental stresses. Pertains to the particular requirements of construction and is to be used in conjunction with IEC 61215 or IEC 61646.

Describes the fundamental construction requirements for photovoltaic modules in order to provide safe electrical and mechanical operation during their expected lifetime. Addresses the prevention of electrical shock, fire hazards, and personal injury due to mechanical and environmental stresses. Pertains to the particular requirements of construction and is to be used in conjunction with IEC 61215 or IEC 61646.

IEC 61730-1:2004 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61730-1:2004 has the following relationships with other standards: It is inter standard links to IEC 61730-1:2004/AMD2:2013, IEC 61730-1:2004/AMD1:2011, IEC 61730-1:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61730-1:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61730-1

Edition 1.0 2004-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Photovoltaic (PV) module safety qualification –

Part 1: Requirements for construction

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) –

Partie 1: Exigences pour la construction

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61730-1

Edition 1.0 2004-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Photovoltaic (PV) module safety qualification –

Part 1: Requirements for construction

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) –

Partie 1: Exigences pour la construction

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

R

CODE PRIX

ICS 27.160 ISBN 2-8318-7678-8

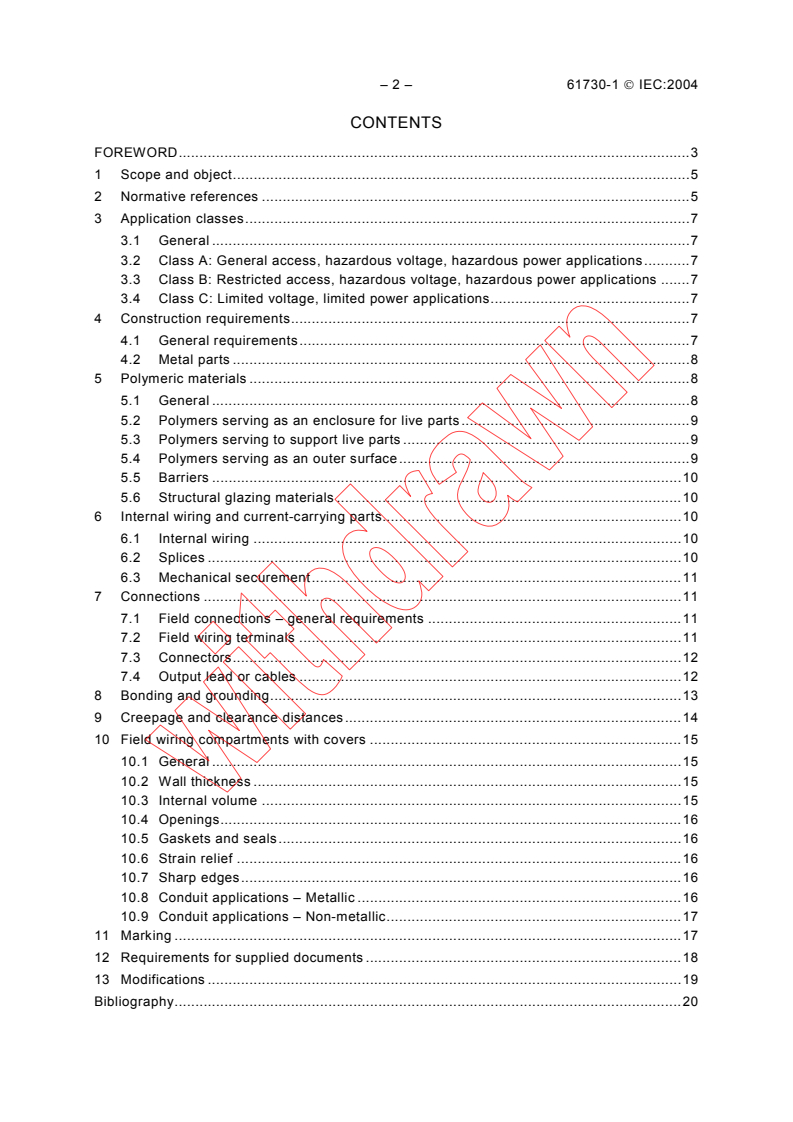

– 2 – 61730-1 © IEC:2004

CONTENTS

FOREWORD.3

1 Scope and object.5

2 Normative references .5

3 Application classes.7

3.1 General .7

3.2 Class A: General access, hazardous voltage, hazardous power applications.7

3.3 Class B: Restricted access, hazardous voltage, hazardous power applications .7

3.4 Class C: Limited voltage, limited power applications.7

4 Construction requirements.7

4.1 General requirements.7

4.2 Metal parts .8

5 Polymeric materials .8

5.1 General .8

5.2 Polymers serving as an enclosure for live parts.9

5.3 Polymers serving to support live parts .9

5.4 Polymers serving as an outer surface.9

5.5 Barriers .10

5.6 Structural glazing materials .10

6 Internal wiring and current-carrying parts.10

6.1 Internal wiring .10

6.2 Splices .10

6.3 Mechanical securement.11

7 Connections .11

7.1 Field connections – general requirements .11

7.2 Field wiring terminals .11

7.3 Connectors.12

7.4 Output lead or cables .12

8 Bonding and grounding.13

9 Creepage and clearance distances.14

10 Field wiring compartments with covers .15

10.1 General .15

10.2 Wall thickness .15

10.3 Internal volume .15

10.4 Openings.16

10.5 Gaskets and seals.16

10.6 Strain relief .16

10.7 Sharp edges.16

10.8 Conduit applications – Metallic .16

10.9 Conduit applications – Non-metallic.17

11 Marking .17

12 Requirements for supplied documents .18

13 Modifications .19

Bibliography.20

61730-1 © IEC:2004 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 1: Requirements for construction

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61730-1 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

The text of this standard is based on the following documents:

FDIS Report on voting

82/356/FDIS 82/365/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – 61730-1 © IEC:2004

IEC 61730 consists of the following parts, under the general title Photovoltaic (PV) module

safety qualification:

Part 1: Requirements for construction

Part 2: Requirements for testing

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

61730-1 © IEC:2004 – 5 –

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 1: Requirements for construction

1 Scope and object

This part of IEC 61730 describes the fundamental construction requirements for photovoltaic

(PV) modules in order to provide safe electrical and mechanical operation during their

expected lifetime. Specific topics are provided to assess the prevention of electrical shock,

fire hazards, and personal injury due to mechanical and environmental stresses. This part of

IEC 61730 pertains to the particular requirements of construction. IEC 61730-2 outlines the

requirements of testing.

This standard attempts to define the basic requirements for various application classes of PV

modules, but it cannot be considered to encompass all national or regional building codes.

The specific requirements for marine and vehicle applications are not covered. This standard

is not applicable to modules with integrated AC inverters (AC modules).

This standard is designed so that its test sequence can coordinate with those of IEC 61215 or

IEC 61646, so that a single set of samples may be used to perform both the safety and

performance evaluation of a photovoltaic module design.

The object of this document is to provide basic guidance in certifying the fundamental

construction of photovoltaic modules presented for safety approval by testing under

IEC 61730-2. These requirements are intended to minimise the misapplication and misuse of

modules or the breakdown of internal components which would result in fire, electric shock

and personal injury. The standard defines the basic safety construction requirements and

additional tests that are a function of the module end-use applications.

Component requirements are intended to provide evidence of performance of that component

appropriate to its application in the module construction and environment.

NOTE The additional construction requirements outlined in relevant ISO standards, or the national or local codes

which govern the installation and use of these modules in their intended locations, should be considered in addition

to the requirements contained within this document.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60112, Method for the determination of the proof and the comparative tracking indices of

solid insulating materials

IEC 60130 (all parts), Connectors for frequencies below 3 MHz

IEC 60189-2, Low-frequency cables and wires with PVC insulation and PVC sheath – Part 2:

Cables in pairs, triples, quads and quintuples for inside installations

– 6 – 61730-1 © IEC:2004

IEC 60216-1, Electrical insulating materials − Thermal endurance properties − Part 1: Ageing

procedures and evaluation of test results

IEC 60216-5, Electrical insulating materials − Thermal endurance properties − Part 5:

Determination of relative thermal endurance index (RTE) of an insulating material

IEC 60364-5-51, Electrical installations of buildings – Part 5-51: Selection and erection of

electrical equipment – Common rules

IEC 60417-DB:2002 , Graphical symbols for use on equipment

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60695-1-1, Fire hazard testing − Part 1-1: Guidance for assessing the fire hazard of

electrotechnical products − General guidelines

IEC 60947-1, Low-voltage switchgear and controlgear – Part 1: General rules

IEC 61140:2001, Protection against electric shock – Common aspects for installation and

equipment

IEC 61215, Crystalline silicon terrestrial photovoltaic (PV) modules – Design qualification and

type approval

IEC 61646, Thin-film terrestrial photovoltaic (PV) modules – Design qualification and type

approval

IEC 61721, Susceptibility of a photovaltaic (PV) module to accidental impact damage

(resistance to impact test)

IEC 61730-2:2004, Photovaltaic (PV) module safety qualification – Part 2: Requirements for

testing

ISO 261, ISO general purpose metric screw threads – General plan

ISO 262, ISO general purpose metric screw threads – Selected sizes for screws, bolts, and

nuts

ANSI/UL 746C, Standard for Polymeric Materials – Use in Electrical Equipment Evaluation

ANSI Z97.1, American National Standard for Safety Glazing Materials Used in Buildings –

Safety Performance Specifications and Methods of Test

ASTM D2303-97, Standard Test Methods for Liquid-Contaminant, Inclined-Plane Tracking and

Erosion of Insulating Materials

ASTM E162-02a, Standard Test Method for Surface Flammability of Materials Using a Radiant

Heat Energy Source

___________

“DB” refers to the IEC on-line database.

61730-1 © IEC:2004 – 7 –

3 Application classes

3.1 General

Photovoltaic modules may be installed in many different applications. Therefore, it is

important to evaluate the potential hazards associated with those applications and to evaluate

the construction of the module accordingly.

Relevant safety requirements and necessary tests shall be performed to verify the

conformance to the requirements of that application class. This clause defines those

application classes and construction qualities required for each class.

Application classes for PV-modules are defined as follows:

3.2 Class A: General access, hazardous voltage, hazardous power applications

Modules rated for use in this application class may be used in systems operating at greater

than 50 V DC or 240 W, where general contact access is anticipated. Modules qualified for

safety through this part of IEC 61730 and IEC 61730-2 and within this application class are

considered to meet the requirements for safety class II.

3.3 Class B: Restricted access, hazardous voltage, hazardous power applications

Modules rated for use in this application class are restricted to systems protected from public

access by fences, location, etc. Modules evaluated within this application class provide

protection by basic insulation, are considered to meet the requirements for safety class 0.

3.4 Class C: Limited voltage, limited power applications

Modules rated for use in this application class are restricted to systems operating at less than

50 V DC and 240 W, where general contact access is anticipated. Modules qualified for safety

through this part of IEC 61730 and IEC 61730-2 within this application class are considered to

meet the requirements for safety class III.

NOTE Safety classes are defined within IEC 61140.

4 Construction requirements

4.1 General requirements

4.1.1 All modules shall be able to operate under environmental condition type AB8 according

to IEC 60364-5-51.

4.1.2 A module shall be completely assembled when shipped from the factory, or shall be

provided in subassemblies, provided assembly of the product does not involve any action that

is likely to affect compliance with the requirements of the IEC 61730 series.

4.1.3 An assembly part, such as a terminal compartment cover, need not be affixed to the

module at the factory. Incorporation of a module into the final assembly shall not require any

alteration of the module from its originally evaluated form, unless specific details describing

necessary modification(s) are provided in the installation instructions.

– 8 – 61730-1 © IEC:2004

4.1.4 If a module must bear a definite relationship to another module for the intended

installation and operation (for example, to allow connectors to mate), it shall be constructed to

permit incorporation into the final assembly without the need for alteration.

4.1.5 The construction of a module shall be such that ground continuity is not interrupted by

installation.

4.1.6 Parts shall be prevented from loosening or turning if such loosening or turning may

result in a risk of fire, electric shock, or injury to persons.

4.1.7 Friction between surfaces, such as simple spring pressure, is not acceptable as the

sole means to inhibit the turning or loosening of a part.

4.1.8 Any adjustable or movable structural part shall be provided with a locking device to

reduce the likelihood of unintentional movement, if any such movement may result in a risk of

fire, electric shock, or injury to persons.

4.2 Metal parts

4.2.1 Metals used in locations that are exposed to moisture shall not be employed alone or

in combinations that could result in deterioration, such that the product would not comply with

the requirements in this standard.

4.2.2 Iron or mild steel serving as a necessary part of the product but not exposed to the

weather shall be plated, painted, or enamelled for protection against corrosion.

4.2.3 Simple sheared or cut edges and punched holes are not required to be additionally

protected.

5 Polymeric materials

5.1 General

Polymers are classified into four operational categories:

– polymers serving as an enclosure for live metal parts (such as a junction box);

– polymers serving as a support of live metal parts (such as integrated terminals);

– polymers serving as the outer surface for the module (such as the superstrate or

substrate);

– barriers.

Exception: Encapsulation materials are not required to meet these requirements.

All polymeric materials shall have a minimum relative thermal index (electrical and mechanical

as defined by IEC 60216-5) of 20 °C above the maximum measured operating temperature of

said material in application, as measured during the temperature test (IEC 61730-2,

MST 21).

NOTE Polymers serving as a superstrate or substrate have additional requirements, as specified in 5.3. and 5.4.

61730-1 © IEC:2004 – 9 –

5.2 Polymers serving as an enclosure for live parts

A polymeric material serving as the enclosure of a part involving a risk of fire or electric shock

shall comply with the following requirements:

a) 5-V flammability rating, either by material test or testing in the end-product design

(IEC 60695-1-1);

b) 5-V flammability rating, after water immersion and exposure of the end-product

(IEC 60695-1-1);

c) ultraviolet radiation resistance (if exposed to direct sunlight in the application), as

determined in accordance with ANSI/UL 746C, and

d) a minimum resistance to hot wire ignition rating of 30 (IEC 60695-1-1).

5.3 Polymers serving to support live parts

A polymeric material serving as the support or insulation of a part involving a risk of fire or

electric shock shall:

a) have a flammability classification of HB, V-2, V-1, or V-0 and have a minimum high-current

arc ignition rating determined in accordance with IEC 60695-1-1, as shown in Table 1,

Table 1 − High arc ignition rating for given flammability classification

Flammability classification High-current arc ignition rating

HB 60

V-2 30

V-1 30

V-0 15

b) have a Comparative Tracking Index (CTI) of 250 V or more, if the system voltage rating is

600 V or less, as determined in accordance with IEC 60112,

c) have an inclined plane tracking rating of 1 h using the time to track method at

2,5 kV according to ASTM D2303, if the maximum system operating voltage rating is in the

601 V – 1 500 V range, and

d) comply with the requirements for exposure to ultraviolet light as determined in accordance

with the ANSI/UL 746C if exposed to direct sunlight during normal operation of the

product.

NOTE Polymeric materials that are exposed to direct sunlight but are protected by glass, or other transparent

medium, may be tested with an equivalent layer of that medium attenuating the ultraviolet light exposure during the

test.

5.4 Polymers serving as an outer surface

5.4.1 A polymeric substrate or superstrate shall have a thermal index, both electrical and

mechanical, as determined in accordance with IEC 60216-5 of at least 90°C. In addition, the

thermal index shall be at least 20 °C above the maximum measured operating temperature of

the material as measured during the temperature test given in IEC 61730-2, MST 21.

– 10 – 61730-1 © IEC:2004

5.4.2 Polymeric materials that serve as the outer enclosure for a module that (1) is intended

to be installed in a multi-module or -panel system or (2) has an exposed surface area greater

than 1 m or a single dimension larger than 2 m, shall have a maximum flame spread index of

100 as determined under ASTM E162-02a.

NOTE Materials that serve as the wiring enclosure for a module, in accordance with 6.1.1, need not comply.

5.4.3 If exposed to direct sunlight in the application, the polymeric material shall have been

evaluated for ultraviolet (UV) radiation resistance as determined in accordance with

ANSI/UL 746C.

5.4.4 Polymeric materials intended for use as a superstrate or substrate, without appropriate

IEC insulation pre-qualification, shall comply with the requirements of the partial discharge

test, IEC 61730-2, MST 15.

5.5 Barriers

A barrier of polymeric insulating material providing the sole insulation between a live part and

an accessible metal part or between uninsulated live parts not of the same potential shall be

of adequate thickness and of a material appropriate for the application, as defined by

IEC 61140. The barrier or liner shall be held in place and shall not be adversely affected to

the extent that its necessary properties fall below the minimum acceptable values for the

application.

5.6 Structural glazing materials

All structural glazing materials used as superstrates or substrates in the construction of

modules shall comply with the requirements for safety glazing as described in ANSI Z97.1-93

by material certification or by testing in accordance with MST 32.

6 Internal wiring and current-carrying parts

A current-carrying part and wiring shall have the mechanical strength and current-carrying

capacity necessary for its application.

6.1 Internal wiring

6.1.1 Wiring used within a module shall have an insulation rated for a minimum of 90°C, with

a gauge and voltage rating acceptable for the application as defined by the requirements of

IEC 60189-2, as applicable.

6.1.2 The wiring of a module shall be located so that after installation of the product in the

intended manner, the insulation will not be exposed to the degrading effects of direct sunlight.

Exception: The requirement does not apply to wiring with insulation rated “sunlight resistant”.

6.2 Splices

A splice shall be considered acceptable with insulation equivalent to that required for the

wiring involved.

61730-1 © IEC:2004 – 11 –

6.3 Mechanical securement

6.3.1 A joint or connection shall be mechanically secure and shall provide electrical contact

without strain on connections and terminals. Soldered connections between module

interconnections and cell metallizations are considered mechanically secure when held by

encapsulation systems.

6.3.2 An uninsulated live part, including a terminal, shall be secured to its supporting surface

so that it will be prevented from turning or shifting in position, if such motion may result in

reduction of spacings to less than required in Tables 3 and 4.

7 Connections

7.1 Field connections – general requirements

7.1.1 A module shall be provided with wiring terminals, connectors, or leads to

accommodate current-carrying conductors of the load circuit.

7.1.2 Field connections shall either be rated for exposure to direct sunlight as defined in

Clause 5 or so located that after installation they will not be exposed to the degrading effects

of direct sunlight.

7.2 Field wiring terminals

7.2.1 If the module contains a field wiring terminal block, it shall be rated for the appropriate

voltage and current for the application and constructed in compliance with the requirements of

IEC 60947-1.

7.2.2 If the module alternately contains wiring terminals integral to the construction of the

terminal enclosure, they shall comply with the following requirements:

7.2.2.1 Screws and nuts which clamp external conductors shall have a thread conforming

with ISO 261 or ISO 262, or a thread comparable in pitch and mechanical strength (e.g.

standard threads). The screws and nuts used for field wiring shall not serve to fix any other

component. These connections are also permitted to clamp internal conductors provided that

the internal conductors are so arranged that they will not be displaced when fitting the

external conductors.

7.2.2.2 Terminal screws shall have minimum sizes as shown in Table 2. Stud terminals shall

be provided with nuts and washers.

7.2.2.3 Terminals shall be so designed that they clamp the conductor between metal

surfaces with sufficient contact pressure and without damage to the conductor. Terminals

shall be so designed or located that the conductor cannot slip out when the clamping screws

or nuts are tightened. Terminals shall be so fixed that, when the means of clamping the

conductor is tightened or loosened:

a) the terminal itself does not work loose,

b) internal wiring is not subjected to stress,

c) creepage distances and clearances are not reduced below the values specified in

Clause 9.

– 12 – 61730-1 © IEC:2004

Table 2 – Sizes of terminals for supply conductors

Minimum nominal thread diameter

Rated current of equipment

mm

A

Pillar type or stud type Screw type

Up to and including 10 3,0 3,5

Over 10 up to and including 16 3,5 4,0

Over 16 up to and including 25 4,0 5,0

Over 25 up to and including 32 4,0 5,0

Over 32 up to and including 40 5,0 5,0

7.3 Connectors

7.3.1 A connector intended for use in the output circuit of a module shall be rated for the

appropriate voltage and current, as per the requirements of the IEC 60130 series. In addition,

the connector shall comply with the requirements of Clause 5, with respect to flammability,

comparative tracking index and relative thermal index for the support of live parts.

7.3.2 Unless a connector is appropriately evaluated for disconnect overload performance,

the connector shall be assumed to be suitable for assembly only and not reliable as a

disconnect means. See Clause 11.

7.3.3 A connector intended for exposure to the outdoor environment shall be enclosed by

material which complies with the following:

a) the requirements of Clause 5, with respect to UV resistance,

b) resistance to inclusion of water, as per IEC 60529, equivalent to IP55,

c) the steel ball impact test, per IEC 61721,

d) the requirements of the accessibility test, IEC 61730-2, MST 11.

7.3.4 Separable multi-pole connectors shall be polarised. If two or more separable

connectors are provided, they shall be configured or arranged so that the other and vice-versa

will not accept the mating connector for one, if it will result in an improper connection.

7.3.5 For a connector incorporating a grounding member, the grounding member shall be the

first to make and the last to break contact with the mating connector.

7.3.6 Connectors that can be separated without the use of a tool shall not have accessible

conductive parts, as determined by 10.2 of IEC 61730-2.

7.4 Output lead or cables

Leads extending from the module shall be rated for the appropriate system voltage, ampacity,

wet locations, temperature and sunlight resistance.

61730-1 © IEC:2004 – 13 –

8 Bonding and grounding

8.1 A module with accessible conductive parts which form a perimeter framing or mounting

system, or have a conductive surface area of greater that 10 cm accessible after installation

shall have provision for grounding.

8.2 Modules rated as safety class II may be provided with provisions for functional

grounding. Such grounding means shall be isolated from live parts by reinforced insulation

(7.3.2.2 of IEC 61140).

8.3 Each exposed conductive part of the module that is accessible during normal use shall

be bonded together, as verified by 10.4 of IEC 61730-2.

Exception: If conductive materials are used only as fasteners for installation and separated

from the conductive components of the module by both appropriate insulation and spacings,

they are not required to be bonded.

8.4 Routine maintenance of a module shall not involve breaking or disturbing the bonding

path. A bolt, screw, or other part used for bonding purposes within a module or panel shall not

be intended for securing the complete device to the supporting surface or frame.

8.5 Bonding shall be by a positive means, such as clamping, riveting, bolted or screwed

connections, or welding, soldering or brazing. The bonding connection shall penetrate all non-

conductive coatings, such as paint, anodised coatings or vitreous enamel.

8.6 All joints in the bonding path shall be mechanically secure, independently of any

soldering.

8.7 If the bonding connection depends upon screw threads, two or more screws or two full

threads of a single screw shall engage the metal.

8.8 The diameter of the grounding screw or bolt shall be sized appropriately to the gauge of

the bonding conductor, as per Table 2.

8.9 A ferrous metal part in the grounding path shall be protected against corrosion by

metallic or non-metallic coatings, such as painting, galvanising, or plating. Stainless steel is

acceptable without additional coating.

8.10 A metal-to-metal multiple-bearing pin-type hinge is considered to be an acceptable

means for bonding.

8.11 A wiring terminal or bonding location of a module intended to accommodate a field

installed equipment-grounding conductor shall be identified with the appropriate symbol

(IEC 60417-5019(DB:2002-10)) or shall have a green-coloured part. No other terminal or

location shall be identified in this manner.

8.12 If a marking is used to identify an equipment grounding terminal, it shall be located on

or adjacent to the terminal, or on a wiring diagram affixed to the module or panel near the

terminal.

– 14 – 61730-1 © IEC:2004

9 Creepage and clearance distances

9.1 The creepage and clearance distances between uninsulated live parts not of the same

potential and between a live part and an accessible metal part, shall not be less than the

values specified in Tables 3 and 4.

These spacing requirements do not apply to the inherent spacings of a component. Such

spacings shall comply with the requirements for the component in question. These distances

also do not apply to solid insulation materials. Those insulation properties can be assessed

through the tests outlined in IEC 61730-2.

9.2 Creepage and clearance distances at field wiring terminals are to be judged on module

open-circuit voltage (V ). If additional unmarked terminals exist in the terminal block, or if

oc

wiring terminals are marked specifically for grounding, the creepage and clearance distances

will be judged on the basis of the maximum system operating voltage.

Table 3 – Minimum acceptable creepage and clearance distances

between field wiring terminals

Voltage

mm

V

0 – 50 6,5

51 – 300 9,5

301 – 600 12,5

601 – 1 000 16

1 001 – 1 500 25

Table 4 – Minimum acceptable clearance distances between

internal current-carrying parts and accessible points

Maximum system Clearance

voltage mm

V Class C Class B Class A

0 – 50 2 2 2

51 – 300 3,2 6,4

301 – 600 3,2 6,4

601 – 1 000 4,2 8,4

1 001 – 1 500 8 11

NOTE The encapsulant materials used in PV construction cannot be considered totally non-hygroscopic and the

lamination process does not provide a truly sealed system. Therefore, creepage and clearance distances specified

are based on pollution degree 2, material grade IIIa & IIIb, also case A, impulse voltage 8 kV. Rounding was done

upward to promote conservative margins.

9.3 The spacings at a field-wiring terminal are to be measured with and without wire

connected to the terminal. The wire shall be connected as it would be in actual use. If the

terminal will properly accommodate it, and if the product is not marked to restrict its use, the

wire is to be one size larger than that required, otherwise, the wire is to be the size required.

9.4 Surfaces separated by a gap of 0,4 mm or less are considered to be in contact with each

other for the purpose of judging creepage distances.

61730-1 © IEC:2004 – 15 –

10 Field wiring compartments with covers

10.1 General

Modules designed for the application of a permanently attached wiring system by an installer

in the field shall be provided with an enclosed wiring compartment, which provides protection

of the conductors and connections from environmental stress, protection from accessibility to

live uninsulated parts and strain relief for the attached wiring system.

NOTE The considerations mentioned in Clause 5 apply to non-metallic wiring compartments.

10.2 Wall thickness

A wiring compartment intended for the attachment of a field-applied permanent wiring system

shall provide the minimum wall thickness, based on the material used, as specified in Table 5.

Table 5 − Minimum wall thickness for given material

a)

Material Minimum thickness

mm

Sheet steel, uncoated 1,35

Sheet steel, zinc coated 1,42

Sheet aluminium 1,59

Cast iron, aluminium, brass, or bronze 2,4

Polymeric materials 3

a)

If the wall thickness is less than the specified values, acceptability is to be determined from the results of the

impact test, the crushing resistance test, the conduit bending tests, and the end-product 5 V flammability tests. For

enclosure with conduit, see Table 6.

10.3 Internal volume

A minimum internal volume for each intended conductor, including integral conductors of the

module, shall be provided in a wiring compartment, within ±5 % as given in Table 6.

Table 6 − Minimum internal volume/conductor for given conductor size

Conductor size Minimum internal volume, each conductor

cm

1,5 mm 25

No. 14 AWG 33

2,5 mm 40

No. 12 AWG 36,9

4 mm 60

In the space comprising the minimum required volume, no enclosure dimension shall be less

than 20 mm.

– 16 – 61730-1 © IEC:2004

10.4 Openings

All openings shall be provided with appropriate coverings (such as knockouts, plugs, etc.),

whose functions comply with the requirements of 5.2.1, the wet leakage test of Subclause

10.20 of IEC 61646 and the accessibility test of Subclause 10.2 of IEC 61730-2, and should

only be able to be removed by the use of a tool.

10.5 Gaskets and seals

Gaskets and seals shall not deteriorate beyond limits during accelerated ageing, and shall not

be used where they may be subject to flexing during normal operation. See accelerated

ageing test, IEC 60216-1.

10.6 Strain relief

Strain relief shall be provided so that stress on a lead intended for field connection, or

otherwise likely to be handled in the field, including a flexible cord, is not transmitted to the

electrical connection inside the module. Mechanical securement means which comply with

10.14 of IEC 61215 meet this requirement.

10.7 Sharp edges

10.7.1 The enclosure shall be smooth and free from sharp edges, burrs, or the like that may

damage insulation or conductors.

Compliance shall be done by inspection.

10.7.2 This requirement also applies to the inner edges of conduit openings and knockouts.

10.8 Conduit applications – Metallic

10.8.1 A threaded hole in a metal wiring compartment intended for the connection of rigid

metal conduit shall be reinforced to provide metal not less than 6,4 mm (1/4 in.) thick, and

shall be tapered unless a conduit end stop is provided.

10.8.2 If threads for the connection of conduit are tapped all the way through a hole in a

compartment wall, or if an equivalent construction is employed, there shall not be less than

3,5 nor more than 5 threads in the metal and the construction shall be such that a conduit

bushing can be attached as intended.

10.8.3 If threads for the connection of conduit are not tapped all the way through a hole in a

compartment wall, there shall not be less than 5 full threads in the metal and there shall be a

smooth, rounded inlet hole for the conductors which shall afford protection to the conductors

equivalent to that provided by a standard conduit bushing.

10.8.4 For a non-threaded opening in a metal wiring compartment intended to accommodate

rigid metallic conduit, a flat surface of sufficient area shall be provided around the opening to

accept the bearing surfaces of the bushing and lock washer.

10.8.5 Conduit shall comply with the Conduit bending test described in Clause 11 of

IEC 61730-2, MST 33.

61730-1 © IEC:2004 – 17 –

10.9 Conduit applications – Non-metallic

10.9.1 The sides, end walls, and bottom of a non-metallic wiring enclosure specified for

conduit applications shall not have a thickness less than the values specified in Table 7.

Table 7 – Wall thickness of polymeric boxes intended for conduit

Trade size of conduit Minimum wall thickness

mm mm

13 to 25 3

26 to 50 4

51 to 100 5

10.9.2 A non-metallic wiring compartment intended to accommodate non-metallic conduit

shall have the following:

a) one or more unthreaded condui

...

IEC 61730-1 ®

Edition 1.2 2013-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic (PV) module safety qualification –

Part 1: Requirements for construction

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) –

Partie 1: Exigences pour la construction

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 61730-1 ®

Edition 1.2 2013-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic (PV) module safety qualification –

Part 1: Requirements for construction

Qualification pour la sûreté de fonctionnement des modules photovoltaïques (PV) –

Partie 1: Exigences pour la construction

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.160 ISBN 978-2-8891-2881-5

– 2 – 61730-1 IEC:2004+A1:2011

+A2:2013

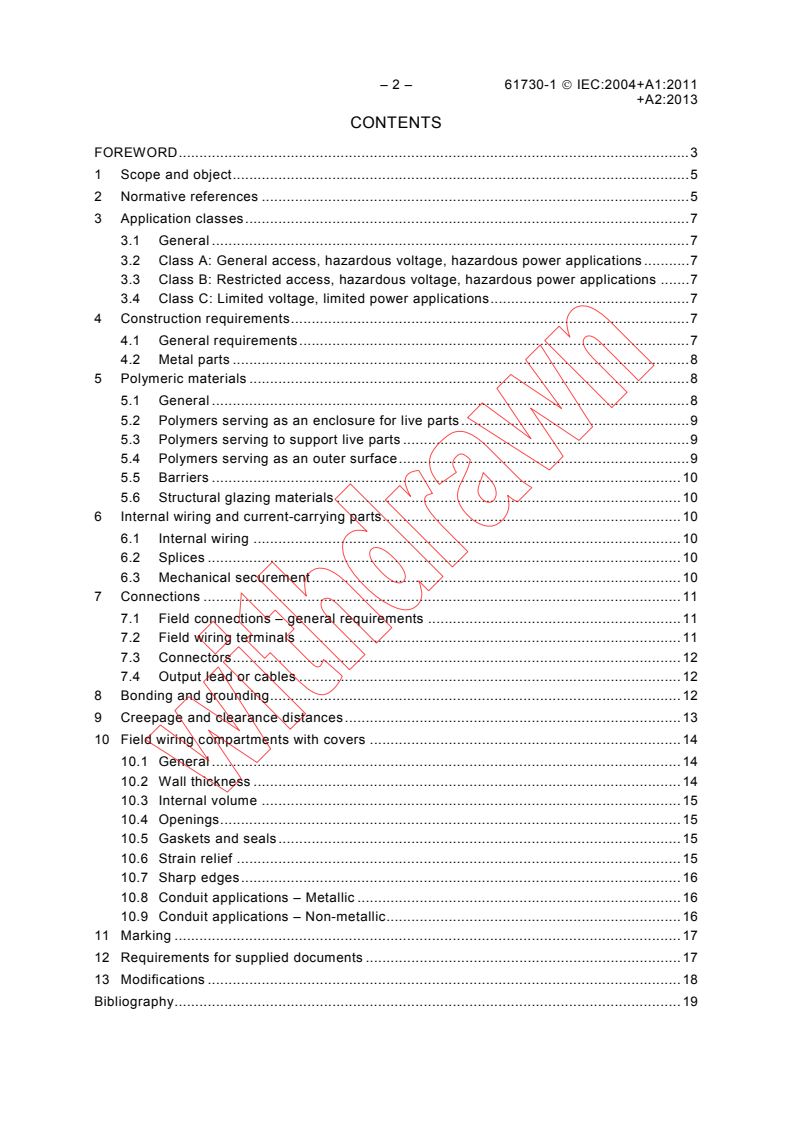

CONTENTS

FOREWORD . 3

1 Scope and object . 5

2 Normative references . 5

3 Application classes . 7

3.1 General . 7

3.2 Class A: General access, hazardous voltage, hazardous power applications . 7

3.3 Class B: Restricted access, hazardous voltage, hazardous power applications . 7

3.4 Class C: Limited voltage, limited power applications . 7

4 Construction requirements . 7

4.1 General requirements . 7

4.2 Metal parts . 8

5 Polymeric materials . 8

5.1 General . 8

5.2 Polymers serving as an enclosure for live parts . 9

5.3 Polymers serving to support live parts . 9

5.4 Polymers serving as an outer surface . 9

5.5 Barriers . 10

5.6 Structural glazing materials . 10

6 Internal wiring and current-carrying parts. 10

6.1 Internal wiring . 10

6.2 Splices . 10

6.3 Mechanical securement . 10

7 Connections . 11

7.1 Field connections – general requirements . 11

7.2 Field wiring terminals . 11

7.3 Connectors . 12

7.4 Output lead or cables . 12

8 Bonding and grounding . 12

9 Creepage and clearance distances . 13

10 Field wiring compartments with covers . 14

10.1 General . 14

10.2 Wall thickness . 14

10.3 Internal volume . 15

10.4 Openings . 15

10.5 Gaskets and seals . 15

10.6 Strain relief . 15

10.7 Sharp edges . 16

10.8 Conduit applications – Metallic . 16

10.9 Conduit applications – Non-metallic . 16

11 Marking . 17

12 Requirements for supplied documents . 17

13 Modifications . 18

Bibliography . 19

61730-1 IEC:2004+A1:2011 – 3 –

A2:2013

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 1: Requirements for construction

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 61730-1 consists of the first edition (2004) [documents

82/356/FDIS and 82/365/RVD], its amendment 1 (2011) [documents 82/659A/FDIS and

82/677/RVD] and its amendment 2 (2013) [documents 82/754/FDIS and 82/762/RVD]. It

bears the edition number 1.2.

The technical content is therefore identical to the base edition and its amendments and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendments 1 and 2. Additions and deletions

are displayed in red, with deletions being struck through.

– 4 – 61730-1 IEC:2004+A1:2011

+A2:2013

International Standard IEC 61730-1 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

IEC 61730 consists of the following parts, under the general title Photovoltaic (PV) module

safety qualification:

Part 1: Requirements for construction

Part 2: Requirements for testing

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

61730-1 IEC:2004+A1:2011 – 5 –

A2:2013

PHOTOVOLTAIC (PV) MODULE SAFETY QUALIFICATION –

Part 1: Requirements for construction

1 Scope and object

This part of IEC 61730 describes the fundamental construction requirements for photovoltaic

(PV) modules in order to provide safe electrical and mechanical operation during their

expected lifetime. Specific topics are provided to assess the prevention of electrical shock,

fire hazards, and personal injury due to mechanical and environmental stresses. This part of

IEC 61730 pertains to the particular requirements of construction. IEC 61730-2 outlines the

requirements of testing.

This standard attempts to define the basic requirements for various application classes of PV

modules, but it cannot be considered to encompass all national or regional building codes.

The specific requirements for marine and vehicle applications are not covered. This standard

is not applicable to modules with integrated AC inverters (AC modules).

This standard is designed so that its test sequence can coordinate with those of IEC 61215 or

IEC 61646, so that a single set of samples may be used to perform both the safety and

performance evaluation of a photovoltaic module design.

The object of this document is to provide basic guidance in certifying the fundamental

construction of photovoltaic modules presented for safety approval by testing under

IEC 61730-2. These requirements are intended to minimise the misapplication and misuse of

modules or the breakdown of internal components which would result in fire, electric shock

and personal injury. The standard defines the basic safety construction requirements and

additional tests that are a function of the module end-use applications.

Component requirements are intended to provide evidence of performance of that component

appropriate to its application in the module construction and environment.

NOTE The additional construction requirements outlined in relevant ISO standards, or the national or local codes

which govern the installation and use of these modules in their intended locations, should be considered in addition

to the requirements contained within this document.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60065, Audio, video and similar electronic apparatus – Safety requirements

IEC 60112, Method for the determination of the proof and the comparative tracking indices of

solid insulating materials

IEC 60130 (all parts), Connectors for frequencies below 3 MHz

IEC 60189-2, Low-frequency cables and wires with PVC insulation and PVC sheath – Part 2:

Cables in pairs, triples, quads and quintuples for inside installations

IEC 60216-1, Electrical insulating materials − Thermal endurance properties − Part 1: Ageing

procedures and evaluation of test results

IEC 60216-5, Electrical insulating materials − Thermal endurance properties − Part 5:

Determination of relative thermal endurance index (RTE) of an insulating material

– 6 – 61730-1 IEC:2004+A1:2011

+A2:2013

IEC 60364-5-51, Electrical installations of buildings – Part 5-51: Selection and erection of

electrical equipment – Common rules

IEC 60417-DB:2002 , Graphical symbols for use on equipment

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60587, Electrical insulating materials used under severe ambient conditions – Test

methods for evaluating resistance to tracking and erosion

IEC 60695-1-1, Fire hazard testing − Part 1-1: Guidance for assessing the fire hazard of

electrotechnical products − General guidelines

IEC 60695-2-10, Fire hazard testing – Part 2-10: Glowing/hot-wire based test methods –

Glow-wire apparatus and common test procedure

IEC 60695-2-20, Fire hazard testing – Part 2-20: Glowing/hot wire based test methods – Hot-

wire coil ignitability – Apparatus, test method and guidance

IEC 60695-11-10, Fire hazard testing – Part 11-10: Test flames 50 W horizontal and vertical

flame test methods

IEC 60695-11-20, Fire hazard testing – Part 11-20: Test flames – 500 W flame test methods

IEC 60947-1, Low-voltage switchgear and controlgear – Part 1: General rules

IEC 61140:2001, Protection against electric shock – Common aspects for installation and

equipment

IEC 61215, Crystalline silicon terrestrial photovoltaic (PV) modules – Design qualification and

type approval

IEC 61646, Thin-film terrestrial photovoltaic (PV) modules – Design qualification and type

approval

IEC 61721, Susceptibility of a photovaltaic (PV) module to accidental impact damage

(resistance to impact test)

IEC 61730-2:2004, Photovaltaic (PV) module safety qualification – Part 2: Requirements for

testing

IEC 61984, Connectors – Safety requirements and tests

ISO 261, ISO general purpose metric screw threads – General plan

ISO 262, ISO general purpose metric screw threads – Selected sizes for screws, bolts, and

nuts

ANSI/UL 746C, Standard for Polymeric Materials – Use in Electrical Equipment Evaluation

ANSI Z97.1, American National Standard for Safety Glazing Materials Used in Buildings –

Safety Performance Specifications and Methods of Test

ASTM D2303-97, Standard Test Methods for Liquid-Contaminant, Inclined-Plane Tracking and

Erosion of Insulating Materials

ASTM E162-02a, Standard Test Method for Surface Flammability of Materials Using a Radiant

Heat Energy Source

___________

“DB” refers to the IEC on-line database.

The 2004 edition of this publication was withdrawn in 2007. A new edition is currently under consideration.

61730-1 IEC:2004+A1:2011 – 7 –

A2:2013

3 Application classes

3.1 General

Photovoltaic modules may be installed in many different applications. Therefore, it is

important to evaluate the potential hazards associated with those applications and to evaluate

the construction of the module accordingly.

Relevant safety requirements and necessary tests shall be performed to verify the

conformance to the requirements of that application class. This clause defines those

application classes and construction qualities required for each class.

Application classes for PV-modules are defined as follows:

3.2 Class A: General access, hazardous voltage, hazardous power applications

Modules rated for use in this application class may be used in systems operating at greater

than 50 V DC or 240 W, where general contact access is anticipated. Modules qualified for

safety through this part of IEC 61730 and IEC 61730-2 and within this application class are

considered to meet the requirements for safety class II.

3.3 Class B: Restricted access, hazardous voltage, hazardous power applications

Modules rated for use in this application class are restricted to systems protected from public

access by fences, location, etc. Modules evaluated within this application class provide

protection by basic insulation, are considered to meet the requirements for safety class 0.

3.4 Class C: Limited voltage, limited power applications

Modules rated for use in this application class are restricted to systems operating at less than

50 V DC and 240 W, where general contact access is anticipated. Modules qualified for safety

through this part of IEC 61730 and IEC 61730-2 within this application class are considered to

meet the requirements for safety class III.

NOTE Safety classes are defined within IEC 61140.

4 Construction requirements

4.1 General requirements

4.1.1 All modules shall be able to operate under environmental condition type AB8 according

to IEC 60364-5-51.

4.1.2 A module shall be completely assembled when shipped from the factory, or shall be

provided in subassemblies, provided assembly of the product does not involve any action that

is likely to affect compliance with the requirements of the IEC 61730 series.

4.1.3 An assembly part, such as a terminal compartment cover, need not be affixed to the

module at the factory. Incorporation of a module into the final assembly shall not require any

alteration of the module from its originally evaluated form, unless specific details describing

necessary modification(s) are provided in the installation instructions.

4.1.4 If a module must bear a definite relationship to another module for the intended

installation and operation (for example, to allow connectors to mate), it shall be constructed to

permit incorporation into the final assembly without the need for alteration.

4.1.5 The construction of a module shall be such that ground continuity is not interrupted by

installation.

– 8 – 61730-1 IEC:2004+A1:2011

+A2:2013

4.1.6 Parts shall be prevented from loosening or turning if such loosening or turning may

result in a risk of fire, electric shock, or injury to persons.

4.1.7 Friction between surfaces, such as simple spring pressure, is not acceptable as the

sole means to inhibit the turning or loosening of a part.

4.1.8 Any adjustable or movable structural part shall be provided with a locking device to

reduce the likelihood of unintentional movement, if any such movement may result in a risk of

fire, electric shock, or injury to persons.

4.2 Metal parts

4.2.1 Metals used in locations that are exposed to moisture shall not be employed alone or

in combinations that could result in deterioration, such that the product would not comply with

the requirements in this standard.

4.2.2 Iron or mild steel serving as a necessary part of the product but not exposed to the

weather shall be plated, painted, or enamelled for protection against corrosion.

4.2.3 Simple sheared or cut edges and punched holes are not required to be additionally

protected.

5 Polymeric materials

5.1 General

All polymeric materials shall have a minimum relative thermal endurance index (electrical and

mechanical as defined by IEC 60216-5) of 20 °C above the maximum measured operating

temperature of said material in application, as measured during the temperature test

(IEC 61730-2, MST 21).

NOTE Polymers serving as a superstrate or substrate have additional requirements, as specified in 5.3. and 5.4.

Polymers are classified into four five operational categories:

– polymers serving as an enclosure for live metal parts (such as a junction box) shall meet

requirements as specified in 5.2;

– polymers serving as a support of live metal parts (such as integrated terminals) shall meet

the requirements of 5.3;

polymers serving as the outer surface for the module (such as a frontsheet and

backsheet) which do not provide the major mechanical strength for the module shall meet

the requirements of 5.4;

polymers serving as the outer surface for the module (such as the a superstrate or a

substrate) which provide rigid reinforcement or serve as the carrier for the active cells;

• If the superstrate or substrate polymers are intended for contact with active cells they

shall meet requirements as specified in 5.3.

• If the superstrate or substrate polymers are intended for use as an outer surface they

shall meet requirements as specified in 5.4.

• If superstrate or substrate polymers are intended for both contact with active cells or

other circuit elements and for use as the outer surface they shall meet requirements

as specified in both 5.3 and 5.4.

– barriers shall meet the requirements of 5.5.

Exception: Encapsulation materials are not required to meet these requirements.

61730-1 IEC:2004+A1:2011 – 9 –

A2:2013

5.2 Polymers serving as an enclosure for live parts

A polymeric material serving as the enclosure of a part involving a risk of fire or electric shock

shall comply with the following requirements:

a) 5-V flammability rating (IEC 60695-11-20), either by material test or testing in the end-

product design component (IEC 60695-1-1);

b) 5-V flammability rating either by material test or testing the end-product design

(IEC 60695-11-20), after the water immersion and exposure testof the end-product

(IEC 60695-1-1);

c) ultraviolet radiation resistance (if exposed to direct sunlight in the application), as

determined in accordance with ANSI/UL 746C or ISO 4892-2. Test condition defined by

2 2

Xenon cycle 1 at 0,35 W/m /nm or 41 W/m (in the wavelength range from 300 nm to 400

nm), test duration 1 000 h; equivalent pass/fail-criteria as in UL 746C shall be applied, and

d) a minimum resistance to hot wire ignition rating of 30 (IEC 60695-1-1 60695-2-20).

5.3 Polymers serving to support live parts

A polymeric material serving as the support or insulation of a part involving a risk of fire or

electric shock shall:

a) have a flammability classification of HB, V-2, V-1, or V-0 in accordance with IEC 60695-11-10

and have a minimum high-current arc ignition rating determined in accordance with

IEC 60695-1-1 ANSI/UL 746C, as shown in Table 1,

Table 1 − High arc ignition rating for given flammability classification

Flammability classification High-current arc ignition rating

HB 60

V-2 30

V-1 30

V-0 15

b) have a Comparative Tracking Index (CTI) of 250 V or more, if the system voltage rating is

600 V or less, as determined in accordance with IEC 60112,

NOTE 1 Polymeric materials having a CTI of 250 or more are within material group IIIa of IEC 60664-1.

c) have an inclined plane tracking rating of 1 h using the time to track method at

2,5 kV according to ASTM D2303 IEC 60587, if the maximum system operating voltage

rating is in the 601 V – 1 500 V range, and

d) comply with the requirements for exposure to ultraviolet light as determined in accordance