IEC 61196-1-212:2021

(Main)Coaxial communication cables - Part 1-212: Environmental test methods - UV stability

Coaxial communication cables - Part 1-212: Environmental test methods - UV stability

IEC 61196-1-212:2021 describes three methods to determine the UV resistance of sheath materials for electric and optical fibre cables. These tests apply for outdoor and indoor cable applications according to the product standard. The samples of sheath are taken from the finished cables. Although this test method is written principally for communication cables, it can be used for energy cables if called up by the relevant product standard.

General Information

- Status

- Published

- Publication Date

- 07-Jul-2021

- Technical Committee

- SC 46A - Coaxial cables

- Drafting Committee

- WG 3 - TC 46/SC 46A/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 08-Jul-2021

- Completion Date

- 09-Aug-2021

Overview

IEC 61196-1-212:2021 specifies accelerated test methods to assess UV stability of sheath materials used in coaxial communication cables. It defines three alternative laboratory exposure methods (xenon arc, fluorescent UV, mercury vapour) to determine how sheath materials from finished cables resist outdoor and indoor ultraviolet (UV) radiation. Although written for communication cables, the standard can be applied to energy cables when referenced by the relevant product standard.

Key topics and technical requirements

- Scope and samples

- Tests apply to sheath samples taken from the finished cable (minimum sample length given in the standard).

- Methods are intended for both outdoor and indoor cable applications as called up by product standards.

- Not intended for products protected by ≥ 2.0 % carbon black per IEC 60708 (excessive time to failure).

- Three UV exposure methods

- Method A - Xenon arc source: simulates natural daylight/UV; apparatus typically uses a rotating specimen holder or fixed holder with adequate air circulation. Example parameter: irradiance control targeting ~43 W/m² at 340 nm (see ISO 4892-2).

- Method B - Fluorescent UV lamps: uses UV-A and UV-B lamp types to simulate different UV bands.

- Method C - Mercury vapour lamp: historically used for telecommunication cables; Annex shows example mercury vapour apparatus and a water-immersion cycle option has been added.

- Outdoor vs indoor testing

- For outdoor application, Methods A and B include periodic water exposure (spray/immersion). Method C can be adapted with water cycles; round-robin results suggest applicability to outdoor conditions.

- Measurements and evaluation

- Assess loss in mechanical properties, change in appearance, and change in colour after exposure.

- Test duration, defined loss thresholds, measurement methods and test-reporting requirements are specified to support repeatable evaluation.

Practical applications and users

- Cable manufacturers use the standard for product development, material selection, and quality control to ensure sheath durability in UV-exposed environments.

- Independent test laboratories implement the prescribed apparatus and measurement protocols for compliance testing and comparative assessments.

- Specifiers and procurement teams reference IEC 61196-1-212 in product standards, tenders and acceptance criteria for outdoor/indoor cable installations.

- Standards writers and R&D groups apply the methods to support new formulations, aging studies, and lifetime assessments.

Related standards (select)

- ISO 4892-1 / ISO 4892-2 (laboratory light sources and xenon-arc guidance)

- IEC 60708 (carbon black requirements)

- IEC 60811 series (test methods for non-metallic cable materials)

- EN 16472 (mercury vapour lamp photoageing)

Keywords: IEC 61196-1-212, UV stability, coaxial communication cables, sheath materials, UV resistance, xenon arc, fluorescent UV lamp, mercury vapour, accelerated aging, outdoor cable testing.

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 61196-1-212:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Coaxial communication cables - Part 1-212: Environmental test methods - UV stability". This standard covers: IEC 61196-1-212:2021 describes three methods to determine the UV resistance of sheath materials for electric and optical fibre cables. These tests apply for outdoor and indoor cable applications according to the product standard. The samples of sheath are taken from the finished cables. Although this test method is written principally for communication cables, it can be used for energy cables if called up by the relevant product standard.

IEC 61196-1-212:2021 describes three methods to determine the UV resistance of sheath materials for electric and optical fibre cables. These tests apply for outdoor and indoor cable applications according to the product standard. The samples of sheath are taken from the finished cables. Although this test method is written principally for communication cables, it can be used for energy cables if called up by the relevant product standard.

IEC 61196-1-212:2021 is classified under the following ICS (International Classification for Standards) categories: 33.120.10 - Coaxial cables. Waveguides. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61196-1-212:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61196-1-212 ®

Edition 1.0 2021-07

INTERNATIONAL

STANDARD

colour

inside

Coaxial communication cables –

Part 1-212: Environmental test methods – UV stability

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61196-1-212 ®

Edition 1.0 2021-07

INTERNATIONAL

STANDARD

colour

inside

Coaxial communication cables –

Part 1-212: Environmental test methods – UV stability

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 33.120.10 ISBN 978-2-8322-9984-5

– 2 – IEC 61196-1-212:2021 © IEC 2021

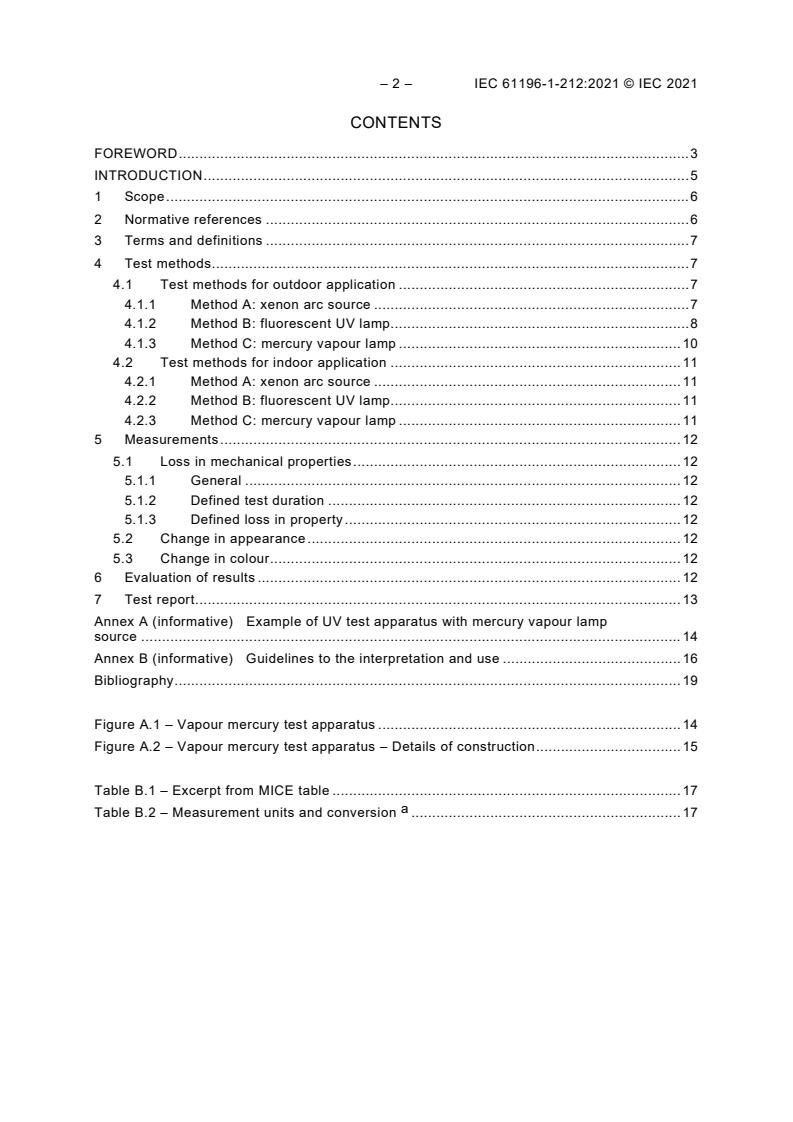

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Test methods . 7

4.1 Test methods for outdoor application . 7

4.1.1 Method A: xenon arc source . 7

4.1.2 Method B: fluorescent UV lamp. 8

4.1.3 Method C: mercury vapour lamp . 10

4.2 Test methods for indoor application . 11

4.2.1 Method A: xenon arc source . 11

4.2.2 Method B: fluorescent UV lamp. 11

4.2.3 Method C: mercury vapour lamp . 11

5 Measurements . 12

5.1 Loss in mechanical properties . 12

5.1.1 General . 12

5.1.2 Defined test duration . 12

5.1.3 Defined loss in property . 12

5.2 Change in appearance . 12

5.3 Change in colour . 12

6 Evaluation of results . 12

7 Test report . 13

Annex A (informative) Example of UV test apparatus with mercury vapour lamp

source . 14

Annex B (informative) Guidelines to the interpretation and use . 16

Bibliography . 19

Figure A.1 – Vapour mercury test apparatus . 14

Figure A.2 – Vapour mercury test apparatus – Details of construction . 15

Table B.1 – Excerpt from MICE table . 17

a

Table B.2 – Measurement units and conversion . 17

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

COAXIAL COMMUNICATION CABLES –

Part 1-212: Environmental test methods – UV stability

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61196-1-212 has been prepared by subcommittee 46A: Coaxial cables, of IEC technical

committee 46: Cables, wires, waveguides, RF connectors, RF and microwave passive

components and accessories. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

46A/1452/CDV 46A/1487/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

– 4 – IEC 61196-1-212:2021 © IEC 2021

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement,

available at www.iec.ch/members_experts/refdocs. The main document types developed by

IEC are described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 61196 series, published under the general title Coaxial

communication cables, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

UV hazard assessment for synthetic compounds is possible using a number of UV sources.

For the purposes of this document, three alternative methods are given.

1) Method A uses a xenon arc source to simulate the UV effect on cable sheath. The effect is

measured by the variation of mechanical characteristics and/or change in colour after

exposure.

2) Method B uses a fluorescent lamp to simulate the UV effect on cable sheath. Two different

lamps may be used: type I (called UV-A lamps) and type II (called UV-B lamps). The effect

is measured, as for method A, by the variation of mechanical characteristics and/or

change in colour after exposure.

3) Method C uses a mercury vapour lamp to simulate the UV effect on cable sheath. As for

methods A and B, the effect is determined by the variation of mechanical characteristics

and/or change in colour after exposure. This test has been typically used for

telecommunication cables.

For outdoor cable application only, the test specimens are periodically subjected to water

attack, for methods A and B. A recent modification of method C now allows for a water

immersion cycle.

For method C, the round robin tests made without water (see Annex B) indicate the method

may be applicable to outdoor environments.

Other sources and determination methods are capable of detecting and analysing the UV

hazard for a cable sheath. Examples of such methods are metal halide lamps or sunshine

carbon arc lamps, in combination with proper filters in order to cut off most radiation having

wavelengths lower than 290 nm. Contracting parties may agree to use such other methods,

but such methods cannot claim conformity to this document. If used, it is recommended that

such methods have at least equivalent sensitivity and detection levels as those in this

document.

Informative Annex B gives guidelines for the use and interpretation of results.

NOTE It is useful to recall the introduction to ISO 4892-1:2016, which says, "The relative durability of materials in

actual-use exposures can be very different depending on the location of the exposure because of differences in UV

radiation, time of wetness, temperature, pollutants and other factors. Therefore, even if results from a specific

accelerated laboratory test are found to be useful for comparing the relative durability of materials exposed in a

particular outdoor location or in particular actual-use conditions, it cannot be assumed that they will be useful for

determining the relative durability of materials exposed in a different outdoor location or in different actual-use

conditions."

– 6 – IEC 61196-1-212:2021 © IEC 2021

COAXIAL COMMUNICATION CABLES –

Part 1-212: Environmental test methods – UV stability

1 Scope

This part of IEC 61196 describes three methods to determine the UV resistance of sheath

materials for electric and optical fibre cables. These tests apply for outdoor and indoor cable

applications according to the product standard. The samples of sheath are taken from the

finished cables.

Although this test method is written principally for communication cables, it can be used for

energy cables if called up by the relevant product standard.

Where a sheath is of cross-linked (thermosetting) material, it is recalled that the preparation

of moulded plaques is made before crosslinking.

Methods differ by the nature of the UV source.

Due to the excessive time to failure, the methods described are inappropriate to products

where UV resistance is conferred by ≥2,0 % carbon black content meeting the requirements

defined in IEC 60708.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60708, Low-frequency cables with polyolefin insulation and moisture barrier polyolefin

sheath

IEC 60811-202, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 202: General tests – Measurement of thickness of non-metallic sheath

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

ISO 4892-1:2016, Plastics – Methods of exposure to laboratory light sources – Part 1:

General guidance

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 9370, Plastics – Instrumental determination of radiant exposure in weathering tests –

General guidance and basic test method

EN 16472, Plastics – Method for artificial accelerated photoageing using medium pressure

mercury vapour lamps

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

median value

when several test results have been obtained and ordered in an increasing (or decreasing)

succession, middle value if the number of available values is odd, and mean of the two middle

values if the number is even

[SOURCE: IEC 60811-100:2012, 3.1]

4 Test methods

4.1 Test methods for outdoor application

4.1.1 Method A: xenon arc source

4.1.1.1 General

According to ISO 4892-1:2016, Clause C.2, the xenon arc lamp, when appropriately filtered,

produces radiations with a spectral power distribution that is a good simulation of average

daylight throughout the UV and visible region.

The exposure apparatus is typically constituted by a rotating specimen holder drum, which

rotates around the light source, as per ISO 4892-1:2016, Figure A.1.

Apparatus having a fixed specimen holder is also permitted. In this case, it is important that

air can circulate around the sample to allow a homogeneous repartition of temperature.

4.1.1.2 Apparatus

The testing apparatus is equipped with the following lamps and filters and is set with the

parameters prescribed below:

– a ray source consisting of a xenon arc lamp ("long arc" type) equipped with borosilicate

filters so that the typical irradiance should be 43 W/m (1 ± 15 %) with a spectrum

between 300 nm and 400 nm;

– a means to provide automatic control of temperature, humidity and cycles;

– a generator of deionised water with a conductivity not greater than 5 µS/cm (the pH should

be recorded); the water shall leave no observable stains or deposits and should therefore

contain less than 1 ppm of solids; the rate of flow should be sufficient to guarantee that all

the test specimens can be washed;

– a means to control the irradiance to produce (43,0 ± 0,2) W/m at 340 nm (if the apparatus

is not equipped with irradiance control, follow the device manufacturer's recommendations

to produce this irradiance).

More details are given in ISO 4892-2.

– 8 – IEC 61196-1-212:2021 © IEC 2021

4.1.1.3 Sample and test specimen preparation

A sample, at least 600 mm long, shall be taken of the finished cable or of the outer sheath

removed from the finished cable. It shall be used to prepare 12 test specimens. Test

specimens shall be prepared according to IEC 60811-202.

In case, for geometrical reasons, it is not possible to use the above samples (finished cable or

outer sheath), test specimens shall be cut from a finished cable, a moulded plaque prepared

from pieces of the cable sheath or a moulded plaque produced from granules of the same

material and colour of the cable sheath. The thickness of the test pieces shall be

(1,0 ± 0,1) mm.

4.1.1.4 Procedure

Six test specimens shall be suspended vertically so that the external surface is uniformly

exposed to the action of the actinic rays. During the test, the temperature indicated by the

black-panel or the black-standard thermometer shall remain in the range (60 ± 3) °C and the

relative humidity shall remain in the range of (50 ± 5) % (only in the dry period in the case of a

test for outdoor application). The rotating drum carrying the test specimens shall turn at a

speed of (1 ± 0,1) r/min. If a flat specimen plane is used, the minimum irradiance in any point

of the specimen exposure area shall be at least 90 % of maximum irradiance.

Test specimens are cycled through periods of UV exposure, followed by periods of no

radiation during which temperature changes occur.

The periods of each cycle, total time of 120 min, are the following:

– 102 min of dry UV exposure at a temperature of (60 ± 3) °C , followed by

– 18 min of deionised water exposure, without radiation, at a temperature of (50 ± 5) °C.

The overall duration of the test shall be as defined in the relevant product standard. In the

absence of such a definition, guidance is given in Annex B.

After the exposure, the exposed test specimens shall be removed from the equipment and

conditioned at ambient temperature for at least 16 h.

The six other test specimens shall be kept at ambient temperature and protected from any

light source during the UV treatment; they shall be tested at the same time as the exposed

test specimens.

4.1.2 Method B: fluorescent UV lamp

4.1.2.1 General

According to ISO 4892-3:2016 [6] , 4.1.1, there are different types of fluorescent UV lamps

that may be used as laboratory light sources:

– type I lamps (commonly called UV-A lamps), with the preferred option of the UV-A 340

lamp, having a spectral radiation that peaks at 340 nm;

– type II lamps (commonly called UV-B lamps), having a spectral radiation that peaks near

the 313 nm mercury line; these type II fluorescent UV lamps emit significant amount of

radiation below 300 nm, the nominal cut off wavelength for solar radiation, which may

result in ageing processes not completely equal to those occurring outdoors. The

method using UV-B lamps is however frequently used by agreement between the parties.

___________

1 Temperature indicated by the black-panel or the black-standard thermometer.

Numbers in square brackets refer to the Bibliography.

The exposure apparatus is typically constituted by a device where specimens are positioned

in a flat plane in front of an array of light sources, as per ISO 4892-1:2016, Figure A.2.

4.1.2.2 Apparatus

The testing apparatus is equipped as follows:

– a ray source consisting of type I or type II fluorescent UV lamps, having a typical

irradiance peak of at least 0,68 W/m at 340 nm for the UV-A 340 lamp, and at 313 nm for

the UV-B 313 lamp;

– an exposure chamber constructed from inert materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...