IEC 62382:2012

(Main)Control systems in the process industry - Electrical and instrumentation loop check

Control systems in the process industry - Electrical and instrumentation loop check

IEC 62382:2012 describes the steps recommended to complete a loop check, which comprises the activities between the completion of the loop construction (including installation and point-to-point checks) and the start-up of cold commissioning. This standard is applicable for the construction of new plants and for expansion/retrofits (i.e. revamping) of E&I installations in existing plants (including PLC, BAS, DCS, panel-mounted and field instrumentation). This second edition cancels and replaces the first edition published in 2006 and constitutes a technical revision. The main changes with respect to the previous edition are: The definition of the documents mentioned in the standards is in accordance with IEC 62708: Documents for Electrical and Instrumentation Projects in the Process Industry. Subclause 6.3 has been revised.

Systèmes de commande pour les procédés industriels - Contrôle de boucle des circuits électriques et des appareillages

La CEI 62382:2012 décrit la marche à suivre recommandée pour réaliser un contrôle de boucle, qui se compose des activités comprises entre l'achèvement de la construction de la boucle (installation et contrôles de point à point) et le début de la mise en service à froid. La présente norme s'applique à la construction de nouvelles usines, ainsi qu'à l'extension ou à la modernisation des installations de systèmes électriques, d'appareillage et de commande (Electrical and Instrumentation and control systems, E&I) dans les usines existantes (automates programmables, systèmes d'automatisation de bâtiment [Building Automation Systems, BAS], systèmes à commande distribuée, appareils montés sur panneau et appareils de terrain compris). Cette deuxième édition annule et remplace la première édition parue en 2006 et constitue une révision technique. Les principales modifications par rapport à l'édition précédente sont: La définition des documents mentionnés dans les normes est conforme à la CEI 62708: Documents for Electrical and Instrumentation Projects in the Process Industry. Le paragraphe 6.3 a été révisé.

General Information

- Status

- Published

- Publication Date

- 07-Nov-2012

- Technical Committee

- SC 65E - Devices and integration in enterprise systems

- Drafting Committee

- WG 3 - TC 65/SC 65E/WG 3

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 14-Aug-2024

- Completion Date

- 18-Jun-2021

Relations

- Revised

IEC 62382:2024 - Control systems in the process industry - Electrical and instrumentation loop check - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

IEC 62382:2012 Overview

IEC 62382:2012 is an international standard published by the International Electrotechnical Commission (IEC) focusing on control systems in the process industry. Specifically, it provides recommended steps to perform electrical and instrumentation loop checks. These checks are crucial activities conducted after loop construction-covering installation and point-to-point verification-but before cold commissioning start-up.

This standard applies broadly to the construction of new plants as well as expansions and retrofits of electrical and instrumentation (E&I) installations. It covers systems such as Programmable Logic Controllers (PLC), Building Automation Systems (BAS), Distributed Control Systems (DCS), panel-mounted devices, and field instrumentation. The second edition (2012) replaces the original 2006 publication with technical revisions, including updates aligned with IEC 62708 and revisions to key procedural subclauses.

Key Topics in IEC 62382:2012

Loop Check Definition & Scope

The process spans from loop construction completion to cold commissioning start-up. It ensures the integrity and functionality of instrumentation and control loops within process plants.Applicable Systems

Covers instrumentation and electrical loops related to control systems such as PLC, BAS, DCS, and field instrumentation in process industries.Procedural Steps

- Documentation verification according to IEC 62708 standards

- Visual inspection of equipment and connections

- Functional testing of sensors, actuators, motor loops, interlocks, and safety loops

- Additional quality and safety tests based on loop criticality

Project Phasing and Milestones

Highlights the place of loop checks in the wider project timeline with reference to mechanical completion, cold commissioning, and start-up phases.Quality Assurance and Safety

Provides guidelines for maintaining high-quality standards and ensuring personnel and equipment safety during loop checks.Documentation and Records

Specifies required input documents and test sheets, and outlines generation of loop check reports and records essential for project tracking and compliance.

Practical Applications

IEC 62382:2012 serves as a comprehensive guide for engineers, technicians, quality managers, and project supervisors involved in E&I installations within the process industry. Practical uses include:

- New Plant Construction: Ensuring proper installation and function of control loops prior to commissioning.

- Expansion and Retrofit Projects: Evaluating and verifying updated or added instrumentation loops in existing facilities.

- Regulatory Compliance: Providing a standardized methodology that aligns with regulatory expectations such as Good Automated Manufacturing Practice (GAMP) and pharmaceutical standards including FDA 21 CFR and European Medicines Agency guidelines.

- Risk Mitigation: Reducing downtime, errors, and safety hazards by verifying correct instrumentation and control system operation through systematic loop checks.

- Documentation Management: Facilitating project management and audits with standardized loop check reports that support traceability and continuous improvement.

Related Standards

For cohesive implementation, IEC 62382:2012 references and complements several related IEC standards:

- IEC 61131 (All Parts): Programmable controllers used within control systems.

- IEC 62337: Guidelines on commissioning of electrical, instrumentation, and control systems in process industries focusing on phases and milestones.

- IEC 62424: Pertains to representation and data exchange between process control engineering diagrams (P&ID) and engineering tools.

- IEC 62708: Defines documentation for electrical and instrumentation projects relevant to standardizing documentation check processes in IEC 62382.

Keywords

Control systems, process industry, electrical loop check, instrumentation loop check, IEC 62382, loop verification, precommissioning, cold commissioning, PLC, DCS, BAS, electrical and instrumentation (E&I), quality assurance, safety loops, process control, commissioning standards, IEC standards.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

IEC 62382:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Control systems in the process industry - Electrical and instrumentation loop check". This standard covers: IEC 62382:2012 describes the steps recommended to complete a loop check, which comprises the activities between the completion of the loop construction (including installation and point-to-point checks) and the start-up of cold commissioning. This standard is applicable for the construction of new plants and for expansion/retrofits (i.e. revamping) of E&I installations in existing plants (including PLC, BAS, DCS, panel-mounted and field instrumentation). This second edition cancels and replaces the first edition published in 2006 and constitutes a technical revision. The main changes with respect to the previous edition are: The definition of the documents mentioned in the standards is in accordance with IEC 62708: Documents for Electrical and Instrumentation Projects in the Process Industry. Subclause 6.3 has been revised.

IEC 62382:2012 describes the steps recommended to complete a loop check, which comprises the activities between the completion of the loop construction (including installation and point-to-point checks) and the start-up of cold commissioning. This standard is applicable for the construction of new plants and for expansion/retrofits (i.e. revamping) of E&I installations in existing plants (including PLC, BAS, DCS, panel-mounted and field instrumentation). This second edition cancels and replaces the first edition published in 2006 and constitutes a technical revision. The main changes with respect to the previous edition are: The definition of the documents mentioned in the standards is in accordance with IEC 62708: Documents for Electrical and Instrumentation Projects in the Process Industry. Subclause 6.3 has been revised.

IEC 62382:2012 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62382:2012 has the following relationships with other standards: It is inter standard links to IEC 62382:2024, IEC 62382:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62382:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62382 ®

Edition 2.0 2012-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Control systems in the process industry – Electrical and instrumentation loop

check

Systèmes de commande pour les procédés industriels – Contrôle de boucle des

circuits électriques et des appareillages

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62382 ®

Edition 2.0 2012-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Control systems in the process industry – Electrical and instrumentation loop

check

Systèmes de commande pour les procédés industriels – Contrôle de boucle des

circuits électriques et des appareillages

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX S

ICS 25.040.40 ISBN 978-2-83220-480-1

– 2 – 62382 © IEC:2012

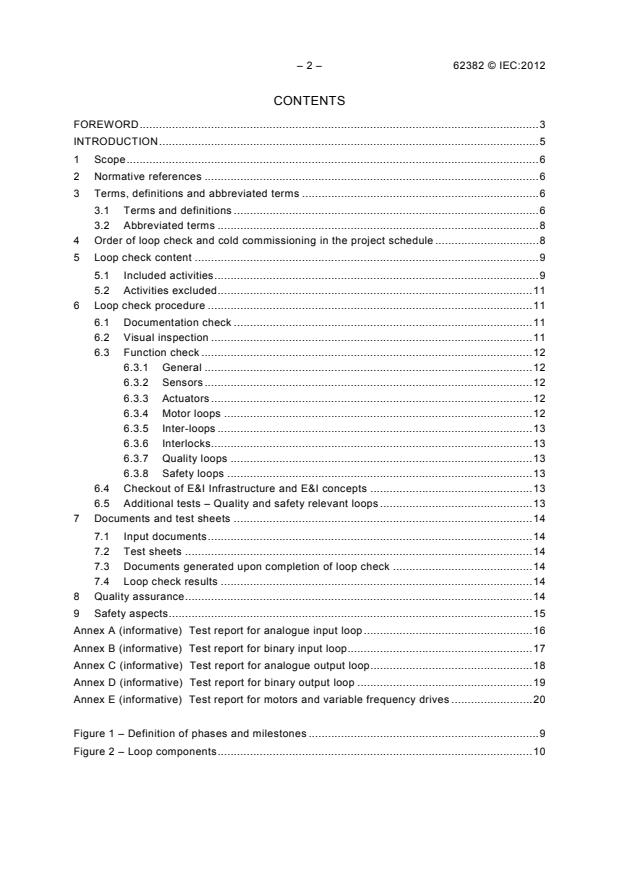

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and abbreviated terms . 6

3.1 Terms and definitions . 6

3.2 Abbreviated terms . 8

4 Order of loop check and cold commissioning in the project schedule . 8

5 Loop check content . 9

5.1 Included activities . 9

5.2 Activities excluded . 11

6 Loop check procedure . 11

6.1 Documentation check . 11

6.2 Visual inspection . 11

6.3 Function check . 12

6.3.1 General . 12

6.3.2 Sensors . 12

6.3.3 Actuators . 12

6.3.4 Motor loops . 12

6.3.5 Inter-loops . 13

6.3.6 Interlocks . 13

6.3.7 Quality loops . 13

6.3.8 Safety loops . 13

6.4 Checkout of E&I Infrastructure and E&I concepts . 13

6.5 Additional tests – Quality and safety relevant loops . 13

7 Documents and test sheets . 14

7.1 Input documents . 14

7.2 Test sheets . 14

7.3 Documents generated upon completion of loop check . 14

7.4 Loop check results . 14

8 Quality assurance . 14

9 Safety aspects . 15

Annex A (informative) Test report for analogue input loop . 16

Annex B (informative) Test report for binary input loop . 17

Annex C (informative) Test report for analogue output loop . 18

Annex D (informative) Test report for binary output loop . 19

Annex E (informative) Test report for motors and variable frequency drives . 20

Figure 1 – Definition of phases and milestones . 9

Figure 2 – Loop components . 10

62382 © IEC:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CONTROL SYSTEMS IN THE PROCESS INDUSTRY –

ELECTRICAL AND INSTRUMENTATION LOOP CHECK

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62382 has been prepared by subcommittee 65E: Devices and

integration in enterprise systems, of IEC technical committee 65: Industrial-process

measurement, control and automation.

This second edition cancels and replaces the first edition published in 2006. This edition

constitutes a technical revision.

The main changes with respect to the previous edition are listed below:

– The definition of the documents mentioned in the standards is in accordance with

IEC 62708: Documents for Electrical and Instrumentation Projects in the Process Industry.

– Subclause 6.3 has been revised.

The text of this standard is based on the following documents:

FDIS Report on voting

65E/271/FDIS 65E/282/RVD

– 4 – 62382 © IEC:2012

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

62382 © IEC:2012 – 5 –

INTRODUCTION

The inspection and verification of the individual measurements and controls in conjunction

with the control systems used to monitor these devices (DCS, PLC, etc.) is referred to as loop

check. In industry, numerous methods and philosophies are used to check the instrumentation

and controls after mechanical installation within projects for modified or new facilities.

This standard was created to provide a better understanding of what loop check consists of

and also to provide a standard methodology for executing a loop check.

The annexes of this standard contain forms which may be used in the check procedures.

Buyers of this standard may copy these forms for their own purposes only in the required

amount.

– 6 – 62382 © IEC:2012

CONTROL SYSTEMS IN THE PROCESS INDUSTRY –

ELECTRICAL AND INSTRUMENTATION LOOP CHECK

1 Scope

This International Standard describes the steps recommended to complete a loop check,

which comprises the activities between the completion of the loop construction (including

installation and point-to-point checks) and the start-up of cold commissioning. This standard is

applicable for the construction of new plants and for expansion/retrofits (i.e. revamping) of

E&I installations in existing plants (including PLC, BAS, DCS, panel-mounted and field

instrumentation). It does not include a detailed checkout of power distribution systems, except

as they relate to the loops being checked (i.e. a motor starter or a power supply to a four-wire

transmitter).

For application in the pharmaceutical or other highly specialized industries, additional

guidelines (for example, Good Automated Manufacturing Practice (GAMP)), definitions and

stipulations should apply in accordance with existing standards, for example, for GMP

Compliance 21 CFR (FDA) and the Standard Operating Procedure of the European Medicines

Agency (SOP/INSP/2003).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61131 (all parts), Programmable controllers

IEC 62337, Commissioning of electrical, instrumentation and control systems in the process

industry – Specific phases and milestones

IEC 62424,Representation of process control engineering – Requests in P&I diagrams and

data exchange between P&ID tools and PCE-CAE tools

IEC 62708, Documents for Electrical and Instrumentation Projects in the Process Industry

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

precommissioning

phase, during which the activities of non-operating adjustments, cold alignment checks,

cleaning, and testing of machinery take place

EXAMPLE Please refer to the annexes.

___________

This standard is under consideration.

62382 © IEC:2012 – 7 –

3.1.2

mechanical completion

milestone, which is achieved when the plant, or any part thereof, has been erected and

tested in accordance with drawings, specifications, instructions, and applicable codes and

regulations to the extent necessary to permit cold commissioning

Note 1 to entry: This includes completion of all necessary electrical and instrumentation work. This is a milestone

marking the end of the precommissioning activities.

3.1.3

cold commissioning

phase, during which the activities associated with the testing and operation of equipment or

facilities using test media such as water or inert substances prior to introducing any chemical

in the system take place

3.1.4

start-up

milestone marking the end of cold commissioning

Note 1 to entry: At this stage, the operating range of every instrument loop is already adjusted to reflect the

actual working condition.

3.1.5

hot commissioning

phase, during which the activities associated with the testing and operation of equipment or

facilities using the actual chemical process prior to making an actual production run take

place

3.1.6

start of production

milestone marking the end of hot commissioning

Note 1 to entry: At this stage, the plant is ready for full and continuous operation.

3.1.7

performance test

milestone at which the production plant runs to its design capacity

Note 1 to entry: This test, carried out by the owner’s personnel with the help and supervision of the contractor,

should demonstrate the contractor’s process performance and consumption guarantees as specified in the

contract.

3.1.8

acceptance of plant

milestone at which the plant is formally turned over from the contractor to the owner

3.1.9

basic software

software which, at a minimum, contains the graphic faceplates, base-level alarms and switch

points, basic interlocking and analogue control. In the case of safety loops, any safety switch

point should be included if it is not in the basic database

3.1.10

loop list

tabulated list of all E&I tags with tagging, function and PID reference

3.1.11

loop diagram

representation of hardware and/or basic software functions of a control loop with graphical

symbols e.g. according to IEC 62424. It shows equipment in its topological order and wiring

including the terminals

– 8 – 62382 © IEC:2012

3.1.12

loop sheet

data sheet with all essential E&I data concerning tagging, function, description, measuring

range, location, process data, instrument data, etc

3.1.13

function diagram or logic diagram

description of the E&I functions according to IEC 61131. Use of this term/such a diagram is

limited to digital signal processing only.

3.1.14

cause and effect matrix

actuators and sensors assigned to coloums and rows according their function, including their

related switching and/or alarm function

3.1.15

user requirement specification

rough user specification in view of the customer to be detailed by the requirement

specification

3.1.16

requirement specification

complete description of all requirements for the realisation (e.g. of an automation system)

3.1.17

trip point list and configuration parameter list

tabulated list of all variable parameter for E&I equipment

3.2 Abbreviated terms

BAS Building automation systems

C&E Cause & effect matrix

DCS Distributed control system

E&I Electrical and instrumentation and control systems

ESD Emergency shut-down system

FAT Factory acceptance testing

FUP Functional or logic diagram

HMI Human machine interface

HW Hardware

MC Mechanical completion

MCC Motor control centre

PLC Programmable logic controller

SAT Site acceptance test

SIT Site integration test

SW Software

4 Order of loop check and cold commissioning in the project schedule

The loop checks will ideally occur in the precommissioning phase of the schedule shown in

Figure 1.

62382 © IEC:2012 – 9 –

However, normal occurrence is that the loop checks begin when any specific loop is

completed and turned over to the checkout crew even if it is during the "construction" phase.

The loop check could substantially overlap the "construction" phase.

Acceptance

of plant

Construction Precommissioning Commissioning Production

PHASES

Cold Hot

Completion of Mechanical St a rt- up Start of

MILESTONES

erection completion production Performance

test

IEC 2057/06

NOTE Construction and precommissioning activities could be overlapping.

Figure 1 – Definition of phases and milestones

The loop check has the following characteristics:

• it follows the E&I construction phase and FAT of the DCS in a project;

• it is the last systematic check before mechanical completion to ensure that:

• all E&I documents (loop sheets, etc.) are available and correspond to their latest revision;

• all instrumentation and equipment is delivered according to the design specifications if not

already verified during FAT or quality check during equipment receiving;

• installation has occurred in accordance to engineering documents, applicable codes and

local regulations;

• loop functionality is correct.

This provides that:

• in a project, the quality check for E&I engineering, and for the delivered instrumentation

and equipment and their installation;

• the base for the commissioning phase which consists of the following phases:

a) cold commissioning

phase during which functional testing of equipment and facilities, using test media

such as water or inert substances, takes place;

b) hot commissioning (chemical start-up)

phase during which activities associated with the testing and operation of equipment

using the actual process chemicals (initial start-up of process) are performed.

The main activities in the cold and hot commissioning phases are system verification

tuning of loops and instruments and control schemes.

5 Loop check content

5.1 Included activities

The loop check includes the following elements of a "single loop" (sensor and/or actuator).

• Hardware components:

– the installed instruments or components in the field or in their final destination;

– 10 – 62382 © IEC:2012

– the equipment in E&I rooms;

– hard wired functionality between sensor and actuator loops (if applicable);

– the input and output (if applicable) cards of process control systems.

• The basic software components (including the graphic faceplates, base level alarms and

switch points, basic interlocking and basic analogue control) to test the field devices. The

loop check uses the basic graphics/faceplates of the control system (see Figure 2). Note

that primary inputs and outputs may be connected not only to DCS but also to ESD, PLC,

unit controllers and other subsystems. They all are visualized on DCS.

The actual loop check involves the three following phases (see details in Clause 6):

a) Documentation checkout

Check for the completeness and consistency of loop documents, including any documents

from the installation or FAT.

b) Visual inspection of loop devices for correct installation and tagging.

c) Function check

A testing device is used to exercise all the components of the loop (including hardware,

wiring and software). It checks that all the components function correctly and that the DCS

or panel readouts are accurate.

IEC 2124/12

1)

Check of the operational configuration is completed during cold commissioning or hot commissioning.

Figure 2 – Loop components

During the loop check the following three types of deficiencies can be found:

d) Installation failures

Installation failures are discrepancies with the specified hardware or the method of

installation (wrong installation, wrong instruments, etc.). The construction contractor

should fix these problems.

e) Configuration failures

62382 © IEC:2012 – 11 –

Configuration failures are discrepancies with the original software specification. The

programming contractor or E&I engineering should fix these problems.

f) E&I engineering failures

Engineering failures are to be suspected when, despite good installation of the right

instruments, the desired functionality cannot be realized (for example, fault in wiring

diagram; etc.) These problems should be corrected by E&I engineering.

Additional deficiencies might be in the process design, but this can only be determined after

process start-up.

5.2 Activities excluded

The loop check does not consist of:

• test activities possible without construction being completed:

• software testing using simulation tools;

• other factory acceptance tests performed at the contractor or vendor’s factories;

• other software checkout activities (FAT,etc.);

• detailed construction and mechanical inspections performed during the construction

phase:

• cable testing during construction (Hipot, Meggering, etc.);

• point-to-point wiring checks;

• the testing of the internal workings of package units (i.e. process subunits, machinery,

complex analysers, etc.) is excluded; only the I/O testing of this equipment is included in

the loop check;

• activities belonging to the commissioning phase: tuning of loops, instruments and control

schemes (for example, calibrating of level transmitters by filling tanks; verification of

complex control schemes; tuning of continuous control schemes; etc.).

6 Loop check procedure

6.1 Documentation check

The documentation check consists of the following activities.

• The checkout of the loop should first establish that all documentation pertaining to that

loop is available, consistent and correctly labelled if the loop is a safety, quality or

environmental loop.

• The pertinent documentation shall, as a minimum, contain a loop diagram and a

specification containing all calibration and functional data necessary to verify the correct

operation of the loop (loop sheet).

6.2 Visual inspection

The visual inspection consists of the following activities.

• The installation should be visually checked against the documents to ensure that the

correct instruments were installed and that the installation is in accordance with the

hardware specifications and loop diagrams/circuit diagrams.

• Valves and flowmeters are checked for correct installation with the direction of flow.

• Can local instrumentation be easily read?

• Are all the elements of the loop available, accessible, labelled and installed in a clean and

neat manner (including junction boxes, panels, cabinets, racks)?

• Is the tagging clear and unambiguous (no danger of false interpretation)?

– 12 – 62382 © IEC:2012

• Are the field elements adequately protected from mechanical or environmental damage?

6.3 Function check

6.3.1 General

The function checks concerning field devices are ideally performed in well defined blocks

(related technical blocks like process units or related racks in E&I rooms). The actual method

and order of checkout should be defined by the project team prior to starting the loop check.

The purpose of the function check is to exercise all components of a loop during one test and

measure their accuracy. Checking out a loop in pieces does not qualify as a function check

and shall not substitute for the function check.

Detailed checks have to be done according following list. Simulations could be done in

different ways depending on the type of device (4 – 20 mA, HART or fieldbus).

6.3.2 Sensors

Functional checking of sensors is as follows.

• Checking of tag number and parameters.

• Simulation of transmitter signal in increments to full span to ensure that the DCS or panel

readout follows the input.

• Simulation of transmitter signal out of DCS range (high and low), checking of substitute

value and failure reaction in DCS.

• Simulation of a sensor failure to verify the correct failure reaction.

• Disconnection of the sensor, checking of the failure reaction in DCS.

• Reconnection of the sensor, checking if device is correctly and automatically initiated

(fieldbus); checking of behaviour of the live list (fieldbus).

6.3.3 Actuators

Functional checking of actuators is as follows.

• Checking of tag number and parameters.

• If the loop has an analogue output, the actuator should be observed to verify that it follows

the incremental output changes within a specified tolerance.

• Simulation of an actuator failure to verify the correct failure reaction.

• Simulation of a limit switch failure, checking of failure reaction in DCS.

• Disconnection of actuator, checking of the failsafe position and the failure reaction in DCS.

• Reconnection of actuator, checking if device is correctly and automatically initiated;

checking of behaviour of the live list (fieldbus).

• Disconnection of air supply and checking of failsafe behaviour.

6.3.4 Motor loops

Functional checking of motor loops is as follows.

• Checking of parameters in motor protection device, compare with motor data

• Simulation of motor protection device signals to verify correct readout in DCS.

• Simulation of motor protection device failure and checking of correct reaction in DCS.

• Checking of correct operation with motor protection device in test mode and removed

motor fuses

• Checking of correct function of local ON/OFF switches

62382 © IEC:2012 – 13 –

6.3.5 Inter-loops

The check of inter-loop functionality (like analogue control loops or interlock functions) is

preferably done for integrated units after a successful checkout of the separate sensor and

actuator loop. This is most effectively completed during cold commissioning.

IMPORTANT A recheck is required for E&I loops that have been modified or disconnected

after successful checkout has been completed.

6.3.6 Interlocks

Verification of interlocks according to logic diagrams is only based on static signals and not

on dynamic process information.

6.3.7 Quality loops

These loops should be checked similar to standard loops. However the accuracy of the field

device should be verified. This could be done by testing the device by the manufacturer, and

should be documented with a test certificate. The procedure of the initial and the periodical

checks has to be defined and documented.

6.3.8 Safety loops

In a first step these loops should be checked similar to standard loops. The additional

validation of safety loops is following a dedicated procedure, which is not described here.

6.4 Checkout of E&I Infrastructure and E&I concepts

Prior to, or during, loop checkout, E&I infrastructure should be checked for mechanical

completion and full functionality. This covers a checklist on the overall condition of E&I rooms,

field installations, energy supplies, grounding systems and cabinet equipment.

During the function check of loops, it is good practice to checkout E&I fundamentals and

concepts.

• Check of loop reaction during a failure or malfunction

• Check of the "fail-safe" action – does the loop go to a safe state when a component

malfunctions?

• What happens when the span limits are exceeded – do the readings and alarms conform

to manufacturers specifications or desired actions?

• If the DCS malfunctions, do the final element’s actions conform to the specifications?

• Check of the function of redundant controls or power supplies:

• Does the redundancy function works as specified during the failure of the primary

element? Does it switch back correctly?

The loop-related concept checkout results are to be recorded on the loop test report. Loop-

related concept checkout is performed for each loop typical and for all safety and quality

loops. For non-safety loops, these tests are performed only frequently enough so that each

concept is checked.

Results of infrastructure concept checkout are recorded on the E&I general infrastructure test

report.

6.5 Additional tests – Quality and safety relevant loops

All quality-relevant and safety-measure-relevant tags are to be rechecked after successful

completion of the loop check.

– 14 – 62382 © IEC:2012

For safety measures it is important that the functionality of the entire E&I measurement as a

whole is verified (sensor loop + binary control loop, or, interlock + actuator loop).

These specific additional checks are to be verified by a second E&I checkout crew or

specifically tested during cold commissioning.

7 Documents and test sheets

7.1 Input documents

The prepared documentation set according to the process unit contains the following:

a) loop list;

b) loop sheet;

c) loop diagram;

function or logic diagram

d) trip point list and configuration parameter list;

e) test reports;

f) calculation and documents (i.e., intrinsic safety);

g) certificates, if any (i.e., motor megger checks or point-to-point checks) from the

construction phase are available, should also be included as part of the documentation

package.

All project, safety, code, local regulations/law-related documents as required by the specific

project should be available.

7.2 Test sheets

The following annexes or PC tools (Excel files) contain examples of test reports per loop type.

• Test report for analogue input loop Annex A

• Test report for binary input loop Annex B

• Test report for analogue output loop (control valve) Annex C

• Test report for binary output loop (on/off valve) Annex D

• Test report for motors and variable frequency drives Annex E

7.3 Documents generated upon completion of loop check

The following documents shall be generated.

• Marked-up E&I documentation to reflect as-built condition.

• Loop test report: signed and completed with loop check results.

7.4 Loop check results

The results of the loop checks shall be indicated as follows:

P = Pass (correct when checked)

F = Fail (not passed when checked; shall include a clear problem description; may require

engineering involvement)

PR = Pass after repair (repair action by checkout/repair crew required)

8 Quality assurance

The test reports are drafted in such a way that all relevant items are covered at least once.

62382 © IEC:2012 – 15 –

Quality is guaranteed by the following measures:

• The loop check is always performed in the same manner (independent of the particular

tester).

• Test reports are updated with the latest information.

• The testers confirm with their signature that a complete loop check agrees with the test

procedures.

9 Safety aspects

For safety installations, extra checklists and working plans are set up in addition to the normal

loop-check procedure. These documents typically describe a very detailed check procedure

and are periodically repeated after production start-up.

– 16 – 62382 © IEC:2012

Annex A

(informative)

Test report for analogue input loop

Instrument type:

Results

1. Documentation check (Italics denote: normally not present)

Loop documentation complete? Cable test - point-to-point connection test complete

P PR F

Date

PCS specification HW present Wiring diagram present Name

Instrument certificates present Test sheet SW-FAT present

Signature

Release of construction present PCS Specification SW present

2. Visual inspection

Are the elements of the loop complete, coded, installed in a clean and neat manner? P PR F

Cable glands and connections tight? Construction/flow direction OK Date

All cards and nests installed and properly labeled?

Name

Do the instruments conform to the circuit diagrams (loop diagram) and specification sheets? Signature

Individual configuration of cards, transmitters, etc. complete (e.g. dip sw itches properly set)?

3. Function check

Function of PCS loop successful?

P PR F

Date

Fuses placed in system

Name

Cards, nests and instruments operational?

Signature

Accept. error of span %

Accept. error of meas. % 1.5 Span -30 200 °C

Calibration Value Accepted Indicator

device error Field /PU DCS Panel Rec./other Results

3,5 mA False measurement

4 mA -30 0.45

12 mA 85 1.5

20 mA 200 3

False measurement

22 mA

Open circuit

Span and units on read out OK?

SW/Spec: alarm and sw itch levels OK? No check due to operational reasons?

Loop brought back ready for commissioning?

Explanation:

Description of failure (use other side) P Pass

Remarks:

PR Pass after repair

F Fail

Status: Date

Issued to checkout crew

Issued to repair crew

Description of repair (use other side)

Issued to constr. for repair

Issued to progr. for repair

Issued to engineering

Loop filed and complete

Name Date Signature

62382 © IEC:2012 – 17 –

Annex B

(informative)

Test report for binary input loop

January 2002

Test report for binary input loop

Complex Process area Subprocess Techn. item Business unit Building xyz-coord

L0001

ANTPCS6 V401 TA10 KU 80 317 Tag-description

Function Purpose Phase Min. Level BA001

LSA Loop check after installation Precommissioning

Remark: This check is performed/documented after successful point-to-point wiring check and base software implementation.

Changes in installation or software functionality require recheck.

Irrelevant boxes are crossed out or filled in with N/A (not applicable).

Liquiphant

Instrument type:

Results

1. Documentation check (Italics denote: normally not present)

Loop documentation complete? Cable test - point to point connection test complete

P PR F

Date

PCS specification HW present Wiring diagram present Name

Instrument certificates present Test sheet SW-FAT present

Signature

Release of construction present PCS specification SW present

2. Visual inspection

Are the elements of the loop complete, coded, installed in a clean and neat manner?

P PR F

Cable glands and connections tight? Construction/flow direction OK

Date

All cards & nests installed and properly labeled? Name

Do the instruments conform to the circuit diagrams (loop diagram) and specification sheets?

Signature

Individual configuration of cards, transmitters, etc. complete (e.g. dip switches properly set)?

3. Function check

Function of PCS loop successful?

P PR F

Date

Fuses placed in system

Name

Cards, nests and instruments operational?

Signature

Calibration Value Indicator

device Field /PU DCS Panel Rec./other Result

0/0 V

1/24 V

Device alarm No check due to operational reasons?

Open circuit

Explanation:

SW/Spec: alarm and switch levels OK?

P Pass

PR Pass after repair

Loop brought back ready for commissioning? F Fail

DResemcarriptksion : of failure (use other side)

Status:

Date

Issued to checkout crew

Issued to repair crew

Issued to constr. for repair

Issued to progr. for repair

Description of repair (use other side)

Issued to engineering

Loop filed and complete

Name Date Signature

– 18 – 62382 © IEC:2012

Annex C

(informative)

Test report for analogue output loop

Janaury 2002

Test report for analogue output loop (control valve)

Complex Process area Subprocess Techn. item Business unit Building xyz-coord

Y0001

ANTPCS6 V401 TA10 KU 80 115.2 Tag-description

Function Purpose Phase Product out BA001

YCOS Loop check after installation Precommissioning

Remark: This check is performed/documented after successful point-to-point wiring check and base software implementation.

Changes in installation or software functionality require recheck.

Irrelevant boxes are crossed out or filled in with N/A (not applicable).

Instrument type: Control membranevalve CT

Results

1. Documentation check (Italics denote: normally not present)

Loop documentation complete? Cable test - point-to-point connection test complete

P PR F

Date

PCS specification HW present Wiring diagram present Name

Instrument certificates present PCS specification SW present

Signature

Release of construction present Test sheet SW-FAT present

2. Visual inspection

Are the elements of the loop complete, coded, installed in a clean and neat manner?

P PR F

Construction/flow direction OK

Cable glands and connections tight? Date

All cards and nests installed and properly labelled?

Name

Do the instruments conform to the circuit diagrams (loop diagram) and specification sheets?

Signature

Individual configuration of cards, transmitters, etc. complete (e.g. dip switches properly set)?

3. Function check

Function of PCS loop successful?

P PR F

Fuses placed in system Date

Instrument air open

Name

Cards, nests and instruments operational?

Signature

Indication limit switches

Setpoint Field /PU DCS Panel Recorder/other Results

OPEN

CLOSE

Analog output Indication analog output

Setpoint

device Air to open Air to close Field /PU DCS Panel Recorder/other Results

False value

3,5 mA

0% 4,0 mA 20,0 mA

10% 5,6 mA 18,4 mA

50% 12,0 mA 12,0 mA

100% 20,0 mA 4,0 mA

False value

22 mA

SW/Spec: control functions OK? SW/Spec: interlock functions OK?

Solenoid forced?

Valve operation as specified?

Air fail position CLOSE of valve OK? No check due to operational reasons?

DCS malfunctioning: action final element (valve) conform to specification?

Loop brought back ready for commissioning?

Description of failure (use other side) Explanation:

Remarks:

P Pass

PR Pass after repair

F Fail

Status:

Date

Issued to checkout crew

Description of repair (use other side)

Issued to repair crew

Issued to constr. for repair

Issued to progr. for repair

Issued to engineering

Loop filed and complete

Name Date Signature

62382 © IEC:2012 – 19 –

Annex D

(informative)

Test report for binary output loop

January 2002

Test report for binary output loop (On/off valve, .)

Complex Process area Subprocess Techn. item Business unit Building xyz-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...