IEC 61131-2:2017

(Main)Industrial-process measurement and control - Programmable controllers - Part 2: Equipment requirements and tests

Industrial-process measurement and control - Programmable controllers - Part 2: Equipment requirements and tests

IEC 61131-2:2017 specifies functional and electromagnetic compatibility requirements and related verification tests for any product where the primary purpose is performing the function of industrial control equipment, including PLC and/or PAC, and/or their associated peripherals which have as their intended use the control and command of machines, automated manufacturing and industrial processes, e.g. discrete, batch and continuous control.

This fourth edition cancels and replaces the third edition published in 2007. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) removal of safety requirements and instead pointing to IEC 61010-2-201;

b) addition of negative logic digital inputs and outputs;

c) addition of Type 3-d digital input;

d) addition of 2,7 GHz to 6 GHz requirement for Radio-frequency electro-magnetic amplitude modulated immunity;

e) clarification of temperature testing;

f) clarification of type testing;

g) deprecation of certain technologies;

h) general update of multiple aspects of functionality and EMC;

i) reorganization of clauses to associate requirements and verifications more closely.

Mesurage et contrôle des processus industriels - Automates programmables - Partie 2: Exigences et essais des équipements

Ll'IEC 61131-2:2017 spécifie les exigences de fonctionnement et de compatibilité électromagnétique, ainsi que les essais de vérification associés pour tout produit dont l'objectif principal est de remplir la fonction d'équipement de commande industriel, y compris les AP et/ou les PAC, et/ou ses périphériques associés qui sont prévus pour être utilisés comme dispositifs de contrôle et de commande de machines et de procédés de fabrication et autres processus industriels automatisés, par exemple, la commande pas à pas, le contrôle par lots et la régulation continue.

Cette quatrième édition annule et remplace la troisième édition parue en 2007. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) retrait des exigences de sécurité remplacées par des références à l'IEC 61010-2-201;

b) ajout d'entrées et de sorties numériques logiques négatives;

c) ajout d'une entrée numérique de type 3-d;

d) ajout d'une exigence de 2,7 GHz à 6 GHz pour l'immunité modulée en amplitude électromagnétique à fréquence radioélectrique;

e) clarification des essais de température;

f) clarification des essais de type;

g) abandon de certaines technologies;

h) actualisation générale de plusieurs aspects de la fonctionnalité et de la CEM;

i) réorganisation des articles pour une association plus étroite entre les exigences et les vérifications.

General Information

- Status

- Published

- Publication Date

- 22-Aug-2017

- Technical Committee

- SC 65B - Measurement and control devices

- Drafting Committee

- WG 7 - TC 65/SC 65B/WG 7

- Current Stage

- PPUB - Publication issued

- Start Date

- 23-Aug-2017

- Completion Date

- 11-Aug-2017

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61131-2:2017 is an international standard published by the International Electrotechnical Commission (IEC) that defines equipment requirements and testing procedures for programmable controllers used in industrial-process measurement and control. This fourth edition, a technical revision of the 2007 third edition, focuses on ensuring the functional performance and electromagnetic compatibility (EMC) of industrial control equipment such as Programmable Logic Controllers (PLCs), Programmable Automation Controllers (PACs), and their associated peripherals.

The standard addresses devices primarily intended for controlling and commanding machines and automated manufacturing processes, including discrete, batch, and continuous control systems. IEC 61131-2:2017 establishes requirements for environmental conditions, functional inputs/outputs, communication capabilities, and EMC performance, ensuring interoperability and reliability in industrial automation environments.

Key Topics

Scope and Compliance

The standard applies to industrial control products focused on controlling manufacturing processes. Compliance involves passing detailed type tests and meeting specified operational criteria across a range of environments.Functional Equipment Requirements

- Power input and memory backup requirements

- Digital I/O specifications, including positive and negative logic inputs and outputs

- Analog I/O compatibility, including support for HART® communication

- Communication interfaces and remote input/output station (RIOS) integration

- Self-test and diagnostic capabilities

Environmental and Mechanical Conditions

- Operating temperature ranges and relative humidity tolerance

- Altitude derating considerations for temperature

- Resistance to vibrations, mechanical shock, and free falls

- Transport and storage conditions ensuring device integrity

Electromagnetic Compatibility (EMC)

- Emission limits and immunity levels, including radio-frequency immunity from 2.7 GHz to 6 GHz

- Voltage dips and interruption resilience at power ports

- EMC installation guidelines to minimize interference and ensure operational stability

Marking and Documentation

Requirements for clear manufacturer markings and detailed information to support installation, operation, compliance verification, and maintenance.

Applications

IEC 61131-2:2017 is critical for manufacturers and users of industrial automation equipment such as PLCs and PACs used in:

Automated Manufacturing Plants

Ensuring reliable control of machinery and process automation lines across diverse manufacturing sectors.Process Industry Automation

Controlling batch, continuous, or discrete processes in industries like chemical, pharmaceutical, and food processing.Machine Control Systems

Integration with automated machines requiring precise digital and analog input/output controls, diagnostics, and communication.Safety-Critical Environments

Though safety requirements are referenced to IEC 61010-2-201, IEC 61131-2 ensures correct functional behavior and EMC performance critical to secure process operations.

Adhering to this standard helps optimize device reliability, interoperability, and regulatory compliance-keys to efficient and safe industrial control systems.

Related Standards

- IEC 61131-1 – General information and programming languages for programmable controllers

- IEC 61010-2-201 – Safety requirements specific to control equipment

- IEC 61131-9 – Distributed Clocks and Synchronization Interface (supporting discrete channel compatibility)

- HART® Communication Protocol – Ensured compatibility with analog inputs/outputs in IEC 61131-2 for remote device management

- EMC Standards such as CISPR and IEC 61000 series – Providing broader guidelines on electromagnetic emission and immunity testing

Keywords: IEC 61131-2:2017, programmable controllers standard, industrial process control, PLC requirements, PAC testing, EMC compliance, digital and analog I/O, industrial automation standards, IEC programmable controller equipment, industrial control system reliability, automated manufacturing process control

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

IEC 61131-2:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Industrial-process measurement and control - Programmable controllers - Part 2: Equipment requirements and tests". This standard covers: IEC 61131-2:2017 specifies functional and electromagnetic compatibility requirements and related verification tests for any product where the primary purpose is performing the function of industrial control equipment, including PLC and/or PAC, and/or their associated peripherals which have as their intended use the control and command of machines, automated manufacturing and industrial processes, e.g. discrete, batch and continuous control. This fourth edition cancels and replaces the third edition published in 2007. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) removal of safety requirements and instead pointing to IEC 61010-2-201; b) addition of negative logic digital inputs and outputs; c) addition of Type 3-d digital input; d) addition of 2,7 GHz to 6 GHz requirement for Radio-frequency electro-magnetic amplitude modulated immunity; e) clarification of temperature testing; f) clarification of type testing; g) deprecation of certain technologies; h) general update of multiple aspects of functionality and EMC; i) reorganization of clauses to associate requirements and verifications more closely.

IEC 61131-2:2017 specifies functional and electromagnetic compatibility requirements and related verification tests for any product where the primary purpose is performing the function of industrial control equipment, including PLC and/or PAC, and/or their associated peripherals which have as their intended use the control and command of machines, automated manufacturing and industrial processes, e.g. discrete, batch and continuous control. This fourth edition cancels and replaces the third edition published in 2007. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) removal of safety requirements and instead pointing to IEC 61010-2-201; b) addition of negative logic digital inputs and outputs; c) addition of Type 3-d digital input; d) addition of 2,7 GHz to 6 GHz requirement for Radio-frequency electro-magnetic amplitude modulated immunity; e) clarification of temperature testing; f) clarification of type testing; g) deprecation of certain technologies; h) general update of multiple aspects of functionality and EMC; i) reorganization of clauses to associate requirements and verifications more closely.

IEC 61131-2:2017 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control; 35.240.50 - IT applications in industry. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61131-2:2017 has the following relationships with other standards: It is inter standard links to IEC 61131-2:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61131-2:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61131-2 ®

Edition 4.0 2017-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Industrial-process measurement and control – Programmable controllers –

Part 2: Equipment requirements and tests

Mesurage et contrôle des processus industriels – Automates programmables –

Partie 2: Exigences et essais des équipements

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61131-2 ®

Edition 4.0 2017-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Industrial-process measurement and control – Programmable controllers –

Part 2: Equipment requirements and tests

Mesurage et contrôle des processus industriels – Automates programmables –

Partie 2: Exigences et essais des équipements

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 25.040.40; 35.240.50 ISBN 978-2-8322-4580-4

– 2 – IEC 61131-2:2017 © IEC 2017

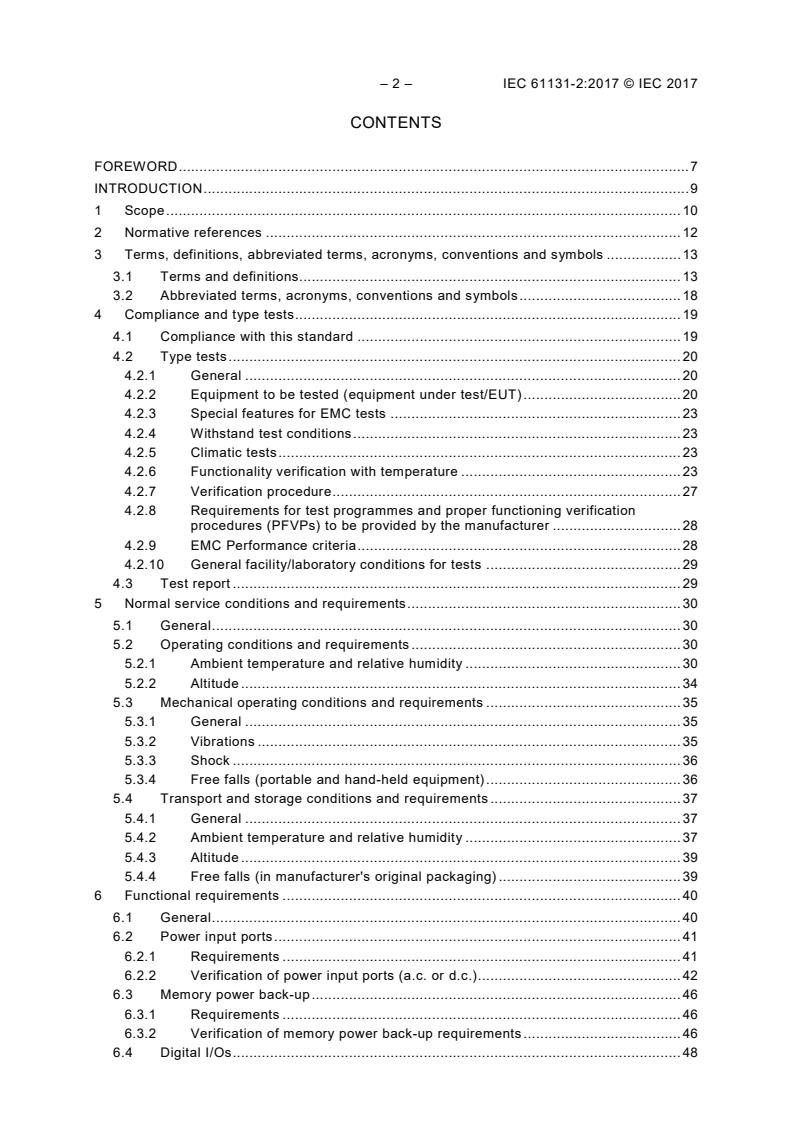

CONTENTS

FOREWORD . 7

INTRODUCTION . 9

1 Scope . 10

2 Normative references . 12

3 Terms, definitions, abbreviated terms, acronyms, conventions and symbols . 13

3.1 Terms and definitions. 13

3.2 Abbreviated terms, acronyms, conventions and symbols . 18

4 Compliance and type tests . 19

4.1 Compliance with this standard . 19

4.2 Type tests . 20

4.2.1 General . 20

4.2.2 Equipment to be tested (equipment under test/EUT) . 20

4.2.3 Special features for EMC tests . 23

4.2.4 Withstand test conditions . 23

4.2.5 Climatic tests . 23

4.2.6 Functionality verification with temperature . 23

4.2.7 Verification procedure . 27

4.2.8 Requirements for test programmes and proper functioning verification

procedures (PFVPs) to be provided by the manufacturer . 28

4.2.9 EMC Performance criteria . 28

4.2.10 General facility/laboratory conditions for tests . 29

4.3 Test report . 29

5 Normal service conditions and requirements . 30

5.1 General . 30

5.2 Operating conditions and requirements . 30

5.2.1 Ambient temperature and relative humidity . 30

5.2.2 Altitude . 34

5.3 Mechanical operating conditions and requirements . 35

5.3.1 General . 35

5.3.2 Vibrations . 35

5.3.3 Shock . 36

5.3.4 Free falls (portable and hand-held equipment) . 36

5.4 Transport and storage conditions and requirements . 37

5.4.1 General . 37

5.4.2 Ambient temperature and relative humidity . 37

5.4.3 Altitude . 39

5.4.4 Free falls (in manufacturer's original packaging) . 39

6 Functional requirements . 40

6.1 General . 40

6.2 Power input ports . 41

6.2.1 Requirements . 41

6.2.2 Verification of power input ports (a.c. or d.c.) . 42

6.3 Memory power back-up . 46

6.3.1 Requirements . 46

6.3.2 Verification of memory power back-up requirements . 46

6.4 Digital I/Os . 48

6.4.1 General . 48

6.4.2 Positive logic digital I/Os (sinking inputs / sourcing outputs) . 48

6.4.3 Negative logic digital I/Os (sourcing inputs / sinking outputs) . 48

6.4.4 Digital inputs (positive logic, current sinking) . 49

6.4.5 Digital outputs for alternating currents (positive logic, current sourcing) . 52

6.4.6 Digital outputs for direct current (current sourcing) . 57

6.4.7 Requirements for discrete channel compatibility with IEC 61131-9 SDCI . 61

6.4.8 Special digital I/O interfaces . 61

6.5 Analog I/Os . 61

6.5.1 General . 61

6.5.2 Analog inputs. 61

6.5.3 Analog outputs . 61

6.5.4 Analog temperature inputs . 62

6.5.5 Requirements for analog channel compatibility with HART® (Highway

Addressable Remote Transducer) . 62

6.5.6 Verification of analog I/Os . 62

6.6 Communication interface requirements . 64

6.6.1 General . 64

6.6.2 Verification of communication interface requirements . 64

6.7 Main processing unit(s) and memory(ies) requirements. 64

6.7.1 General . 64

6.7.2 Verification of processing unit requirements . 64

6.8 Remote input/output station (RIOS) requirements . 65

6.8.1 General . 65

6.8.2 Verification of local and remote I/O stations . 65

6.9 Peripherals (PADTs, TEs, HMIs) requirements . 66

6.9.1 General . 66

6.9.2 Verification of peripheral (PADTs, TEs, HMIs) requirements . 67

6.10 Self-tests and diagnostics requirements . 67

6.10.1 General . 67

6.10.2 Verification of self-tests and diagnostics . 67

6.11 Functional earth . 68

6.12 Requirements for information on normal service and function . 68

7 Electromagnetic compatibility (EMC) requirements . 68

7.1 General . 68

7.2 Emission requirements . 70

7.3 EMC immunity requirements . 71

7.3.1 Immunity levels . 71

7.3.2 Voltage dips and interruptions power ports . 77

7.4 Requirements for information on EMC installation . 78

8 Marking requirements and information to be provided by the manufacturer . 78

8.1 Verification . 78

8.2 General marking requirements . 78

8.2.1 Minimum marking requirement . 78

8.2.2 Functional identifications . 79

8.2.3 Functional earth terminals markings . 79

8.2.4 Documentation markings . 79

8.3 Information format and content . 79

8.3.1 Information format . 79

– 4 – IEC 61131-2:2017 © IEC 2017

8.3.2 Information content . 80

8.3.3 Information on compliance with this standard. 80

8.3.4 Information on shipping and storage . 80

8.3.5 Information on a.c. and d.c. power supply . 80

8.3.6 Information on digital inputs (current sinking) . 81

8.3.7 Information on digital outputs for alternating currents (current sourcing) . 81

8.3.8 Information on digital outputs for direct current (current sourcing). 82

8.3.9 Information on analog inputs . 82

8.3.10 Information on analog outputs . 84

8.3.11 Information on communication interfaces . 86

8.3.12 Information on main processing unit(s) and memory(ies) . 86

8.3.13 Information on remote input/output station (RIOS) . 86

8.3.14 Information on peripherals (PADTs, TEs, HMIs) . 87

8.3.15 Information on self-tests and diagnostics . 87

8.4 Information on EMC installation . 88

8.5 Information on reliability . 88

Annex A (informative) Temperature derating for altitude . 89

A.1 Standard atmosphere modelling . 89

A.1.1 Ambient temperature . 89

A.1.2 Aerostatics equation . 89

A.1.3 Air density . 90

A.1.4 Radiation . 90

A.1.5 Derating ratio . 91

A.1.6 Comparison with IEEE1613 . 91

Annex B (informative) Digital input standard operating range equations . 93

Annex C (normative) Zone C – EMC immunity levels . 94

Annex D (normative) Legacy techniques that are out-dated and not recommended for

new design . 97

D.1 Background . 97

D.2 Ambient temperature . 97

D.3 Type 2 digital input . 97

D.3.1 Definition . 97

D.3.2 Background . 97

D.4 Analog inputs . 98

D.5 Analog outputs . 99

D.6 CRT displays . 99

Annex E (informative) Application reasoning for a.c. and d.c. interruptions . 101

Annex F (normative) Digital I/O: Current-sourcing input and current-sinking output . 102

F.1 Digital I/O (negative logic) . 102

F.2 Function and verification . 104

Bibliography . 105

Figure 1 – Equipment in the scope and not in the scope . 11

Figure 2 – Example EUT configurations . 21

Figure 3 – General temperature test environment . 24

Figure 4 – Vented equipment . 25

Figure 5 – Non-vented equipment . 26

Figure 6 – Panel mounted equipment extending through the wall of a cabinet . 27

Figure 7 – Typical interface/port diagram of a modular control equipment . 41

Figure 8 – Gradual shut-down/start-up test . 44

Figure 9 – Fast supply voltage variation test . 45

Figure 10 – Slow supply voltage variation test . 45

Figure 11 – Positive logic (sinking inputs / sourcing outputs) . 48

Figure 12 – U-I operation regions of current-sinking inputs . 49

Figure 13 – Input Type 3 Diagnostic. 51

Figure 14 – Temporary overload waveform for digital a.c. outputs . 53

Figure 15 – Temporary overload waveform for digital d.c. outputs . 58

Figure 16 – EMC zones . 69

Figure A.1 – A small atmosphere element . 89

Figure E.1 – d.c. distribution to control equipment and faults . 101

Figure F.1 – Negative logic (sourcing inputs / sinking outputs) . 102

Figure F.2 – Positive logic with faults . 103

Figure F.3 – Negative logic with faults . 104

Table 1 – Criteria to prove the performance of an EUT against EMC disturbances . 29

Table 2 – General facility/laboratory conditions for tests . 29

Table 3 – Operating environments, ambient temperature and relative humidity . 30

Table 4 – Dry-heat withstand and immunity tests . 31

Table 5 – Cold withstand and immunity tests . 32

Table 6 – Change of temperature, withstand and immunity tests . 33

Table 7 – Cyclic (12 + 12) damp-heat withstand test . 34

Table 8 – Multiplication factors for equipment ambient temperature of operation at

altitudes up to 5 000 m . 35

Table 9 – Sinusoidal vibration conditions . 35

Table 10 – Immunity vibration test . 36

Table 11 – Immunity shock test . 36

Table 12 – Free fall on concrete floor for portable and hand-held equipment . 37

Table 13 – Storage environments, ambient temperature and relative humidity . 38

Table 14 – Transportation environments, ambient temperature and humidity . 38

Table 15 – Free fall on concrete floor in manufacturer’s original packaging . 39

Table 16 – Rated values and operating ranges of incoming power supply . 41

Table 17 – Voltage interruptions (functional requirements) . 42

Table 18 – Voltage ripple and frequency range immunity test. 43

Table 19 – Gradual shut-down/start-up test . 44

Table 20 – Supply voltage variation tests . 44

Table 21 – Voltage interruptions immunity test (Functional tests) . 46

Table 22 – Back-up duration withstand test . 47

Table 23 – Change of energy source test . 47

Table 24 – Operating ranges for digital inputs (current sinking) . 50

Table 25 – Rated values and operating ranges for current sourcing digital a.c. outputs . 52

– 6 – IEC 61131-2:2017 © IEC 2017

Table 26 – Overload test circuit values . 55

Table 27 – Endurance test circuit values . 55

Table 28 – Overload and short-circuit tests for digital outputs . 56

Table 29 – Rated values and operating ranges (d.c.) for current-sourcing digital d.c.

outputs . 57

Table 30 – Overload and short-circuit tests for digital outputs . 60

Table 31 – Rated values and impedance limits for analog inputs . 61

Table 32 – Rated values and impedance limits for analog outputs . 61

Table 33 – Analog output overload immunity test . 63

Table 34 – Insertion/withdrawal of removable units . 66

Table 35 – EMC zones & ptotection considerations . 70

Table 36 – Enclosure port tests, Zones A and B . 71

Table 37 – Conducted immunity tests, Zone B . 72

Table 38 – Conducted immunity tests, zone A . 73

Table 39 – Electrostatic discharge immunity test . 74

Table 40 – Radiated electromagnetic field immunity test . 75

Table 41 – Power-frequency magnetic field immunity test . 75

Table 42 – Fast transient burst immunity test . 76

Table 43 – High-energy surge immunity test . 76

Table 44 – Conducted r.f. immunity test . 77

Table 45 – Voltage dips and interruptions (EMC requirements) . 77

f

Table 46 – Voltage dips and interruptions immunity test (EMC tests) . 78

Table 47 – Analog input static characteristics . 83

Table 48 – Analog input dynamic characteristics . 83

Table 49 – Analog input general characteristics . 84

Table 50 – Analog input miscellaneous characteristics . 84

Table 51 – Analog output static characteristics . 84

Table 52 – Analog output dynamic characteristics . 85

Table 53 – Analog output general characteristics . 85

Table 54 – Analog output miscellaneous characteristics . 85

Table A.1 – Component temperature derating with altitude, 2 000 m as reference . 91

Table A.2 – Component temperature derating with altitude, 1 500 m as reference, and

20 °C at the sea level standard temperature . 91

Table C.1 – Enclosure port tests, Zone C . 94

Table C.2 – Conducted immunity tests, Zone C. 95

Table C.3 – Damped oscillatory wave immunity test . 96

Table D.1 – Standard operating ranges for Type 2 digital inputs (current sinking) . 98

Table D.2 – Rated values and impedance limits for analog inputs . 99

Table D.3 – Rated values and impedance limits for analog outputs . 99

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INDUSTRIAL-PROCESS MEASUREMENT AND CONTROL –

PROGRAMMABLE CONTROLLERS –

Part 2: Equipment requirements and tests

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61131-2 has been prepared by subcommittee 65B: Measurement

and control devices, of IEC technical committee 65: Industrial-process measurement, control

and automation.

This fourth edition cancels and replaces the third edition published in 2007. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) removal of safety requirements and instead pointing to IEC 61010-2-201;

b) addition of negative logic digital inputs and outputs;

c) addition of Type 3-d digital input;

d) addition of 2,7 GHz to 6 GHz requirement for Radio-frequency electro-magnetic amplitude

modulated immunity;

– 8 – IEC 61131-2:2017 © IEC 2017

e) clarification of temperature testing;

f) clarification of type testing;

g) deprecation of certain technologies;

h) general update of multiple aspects of functionality and EMC;

i) reorganization of clauses to associate requirements and verifications more closely.

The text of this standard is based on the following documents:

FDIS Report on voting

65B/1083/FDIS 65B/1091/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 61131 series, published under the general title Industrial-process

measurement and control – Programmable controllers, can be found on the IEC website.

Future standards in this series will carry the new general title as cited above. Titles of existing

standards in this series will be updated at the time of the next edition.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

IEC 61131-2 is part of a series of standards on industrial control equipment, including

programmable controllers, and their associated peripherals and should be read in conjunction

with the other parts of the series. However, it can be read and applied alone.

Where a conflict exists between this and other IEC standards, the provisions of this standard

should be considered to govern in the area of industrial control equipment, including

programmable controllers, and their associated peripherals.

This standard defines for industrial control equipment the following:

• Testing and verifications methods (Clause 4);

• Operating conditions (5.2);

• Temperature and climatic tests (5.2.1);

• Mechanical requirements and tests (5.3);

• Functional requirements and tests for power supplies, I/Os and other components

(Clause 6);

• EMC requirements and tests (Clause 7);

• Marking and documentation requirements (Clause 8).

Product safety requirements for PLC and the other types of industrial control equipment now

in the scope of this standard are specified in IEC 61010-2-201, which replaces the

requirements of Clauses 11 to 14 of IEC 61131-2:2007.

The operating conditions and the temperature derating for altitudes are aligned with

IEC 61010-2-201:– .

___________

Under preparation. Stage at the time of publication: IEC /CDV 61010-2-201:2016.

– 10 – IEC 61131-2:2017 © IEC 2017

INDUSTRIAL-PROCESS MEASUREMENT AND CONTROL –

PROGRAMMABLE CONTROLLERS –

Part 2: Equipment requirements and tests

1 Scope

This part of IEC 61131 specifies functional and electromagnetic compatibility requirements

and related verification tests for industrial control equipment of the following types:

• programmable controllers (PLC);

• programmable automation controller (PAC);

• remote I/O;

• programming and debugging tools (PADTs);

• industrial PC (computers) and industrial panel PC;

• displays and human-machine Interfaces (HMI) for industrial use;

• distributed control system (DCS), and DCS components that are listed here in the scope;

• any product where the primary purpose is performing the function of industrial control

equipment, including PLC and/or PAC, and/or their associated peripherals which have as

their intended use the control and command of machines, automated manufacturing and

industrial processes, e.g. discrete, batch and continuous control.

In this document “control equipment” is equivalent to “industrial control equipment” as are

PLC and PAC.

Equipment in the scope

Control, HMI, etc

PADT

Multiple human-

machine interfaces, PC

PLC

DCS

I/O

Networks

Interfaces/Ports

Data, power, etc., interconnections

Interfaces/Ports

Equipment

Sensors

Actuators

power

Interfaced

devices and

signals

Equipment not in the scope

IEC

Figure 1 – Equipment in the scope and not in the scope

Components of the above named equipment (see Figure 1) included in the scope of this

standard are:

• (auxiliary) stand-alone power supplies;

• peripherals such as digital and analog I/O;

• industrial network equipment.

Control equipment and their associated peripherals are intended to be used in an industrial

environment and may be provided as open or enclosed equipment.

If control equipment or its associated peripherals are intended for use in other environments

(light industrial, commercial, residential), then the specific requirements, standards and

installation practices for those other environments shall be additionally applied to the control

equipment and its associated peripherals.

Equipment covered in this standard is intended for use in overvoltage category II

(IEC 60664-1) in low-voltage installations, where the rated equipment supply voltage does not

exceed AC 1 000 V r.m.s. (50/60 Hz), or DC 1 000 V. If control equipment or their associated

peripherals are applied in overvoltage category III installations, then additional analysis will

be required to determine the suitability of the equipment for those applications.

The object of this standard is to establish the definitions and identify the principal

characteristics relevant to the selection and application of control equipment and their

associated peripherals.

– 12 – IEC 61131-2:2017 © IEC 2017

This standard also specifies:

a) service (operating, storage and transportation) requirements for control equipment and

their associated peripherals (Clause 5);

b) functional requirements for control equipment and their associated peripherals (Clause 6);

c) EMC requirements for control equipment and their associated peripherals (Clause 7);

d) information that the manufacturer is required to supply (Clause 8).

Safety requirements for control equipment and their associated peripherals are specified in

IEC 61010-2-201.

The requirements of IEC Guide 106, “Guide for specifying environmental conditions for

equipment performance rating”, and IEC Guide 107 “Electromagnetic compatibility – Guide to

the drafting of electromagnetic compatibility publications,”are incorporated herein.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Test A: Cold

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Test B: Dry heat

IEC 60068-2-6, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-14, Environmental testing – Part 2-14: Tests – Test N: Change of temperature

IEC 60068-2-27, Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock

IEC 60068-2-30, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12 + 12 h cycle)

IEC 60068-2-31, Environmental testing –

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...