IEC 62192:2009

(Main)Live working - Insulating ropes

Live working - Insulating ropes

IEC 62192:2009 covers insulating ropes that are utilized during live working procedures in contact with parts of installations operating at voltages up to and including 800 kV r.m.s. Insulating ropes for live working procedure under rain and/or d.c. conditions are not covered by this standard.

Travaux sous tension - Cordes isolantes

La CEI 62192:2009 est applicable aux cordes isolantes utilisées lors de travaux sous tension et faisant contact avec des parties des installations exploitées à des tensions jusques et y compris 800 kV efficace. La présente norme ne s'applique pas aux cordes isolantes utilisées lors de travaux sous tension réalisés sous pluie et/ou sur des installations à courant continu.

General Information

- Status

- Published

- Publication Date

- 19-Feb-2009

- Technical Committee

- TC 78 - Live working

- Drafting Committee

- WG 12 - TC 78/WG 12

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Feb-2009

- Completion Date

- 15-Mar-2009

IEC 62192:2009 Overview

IEC 62192:2009 is the international standard that specifies requirements for insulating ropes used during live working on electrical installations operating at voltages up to and including 800 kV r.m.s. This standard ensures the electrical, mechanical, and physical properties of insulating ropes to enhance safety for skilled workers performing live work on high-voltage lines and equipment. Notably, it excludes ropes used under rain or direct current (d.c.) conditions.

Key Topics Covered

- Scope and Application

Defines insulating ropes designed for live working contact with energized parts at voltages up to 800 kV. It excludes ropes for use in rain or d.c. environments. - Physical and Dimensional Requirements

Ropes must be free of manufacturing defects such as poor impregnation or faulty twisting. Dimensions must meet manufacturer specifications within ±10%. Low water absorption and minimal capillary action are mandatory to maintain insulation properties. - Electrical Properties

Insulating ropes must exhibit firm dielectric characteristics under dry and humid conditions, ensuring safety during live operations. The standard also permits splicing, provided dielectric qualities are not compromised and manufacturer guidelines are followed. - Mechanical Requirements

The ropes must demonstrate appropriate mechanical strength, elongation limits, and durability, ensuring they withstand the stresses encountered during live working procedures. - Marking and Instructions

Clear markings and comprehensive usage and care instructions are required to guarantee proper handling and maintenance, extending rope life and maintaining safety. - Testing and Conformity Assessment

Outlines tests for leakage current, water absorption, elongation, marking durability, and periodic verification. These assessments are crucial to verify compliance and maintain operational safety. - Exclusions and Environmental Considerations

The standard explicitly excludes insulating ropes used under rain or direct current conditions. While environmental impacts across the rope’s lifecycle are acknowledged, the standard places responsibility for environmental consideration on all parties involved without codified mandates.

Practical Applications

IEC 62192:2009 compliant insulating ropes are essential tools for live working in electrical power systems, enabling safe handling and control of energized conductors and components:

- Utilities performing maintenance or emergency repairs on high-voltage overhead lines (up to 800 kV).

- Operators bridging live phase conductors or connecting phase conductors to earth during live-line procedures.

- Electrical contractors implementing safe work practices on energized installations.

- Manufacturers producing insulating ropes that meet international safety benchmarks.

By following IEC 62192, organizations can help reduce electrical hazards and improve worker protection, reinforcing conformity to globally recognized standards for live working equipment.

Related Standards

- IEC 61477: Live Working – Minimum requirements for utilization of live working tools and equipment, providing foundational guidance referenced within IEC 62192.

- IEC 60060-1: High-voltage test techniques – Part 1: General definitions and test requirements, essential for standardized electrical testing procedures.

- IEC 61318: Live working – Conformity assessment applicable to tools, devices, and equipment, detailing conformity verification processes.

- IEC 60212: Standard conditions for use prior to and during testing of solid electrical insulating materials, ensuring consistency in testing environments.

- ISO 2307: Ropes – Determination of certain physical and mechanical properties, supporting comprehensive rope assessment beyond electrical performance.

Conclusion

IEC 62192:2009 is a critical international standard that defines the specifications for insulating ropes used in live working on high-voltage electrical installations. It ensures these ropes have reliable insulating, physical, and mechanical properties to improve worker safety under specific voltage conditions. Organizations involved in live-line maintenance, manufacturing, and safety compliance should align with IEC 62192 to meet rigorous international requirements, optimize safety, and support consistent operational quality.

Keywords: IEC 62192, insulating ropes, live working, high-voltage safety, electrical installations, live-line maintenance, dielectric properties, mechanical strength, electrical standards, insulating rope testing.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 62192:2009 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Live working - Insulating ropes". This standard covers: IEC 62192:2009 covers insulating ropes that are utilized during live working procedures in contact with parts of installations operating at voltages up to and including 800 kV r.m.s. Insulating ropes for live working procedure under rain and/or d.c. conditions are not covered by this standard.

IEC 62192:2009 covers insulating ropes that are utilized during live working procedures in contact with parts of installations operating at voltages up to and including 800 kV r.m.s. Insulating ropes for live working procedure under rain and/or d.c. conditions are not covered by this standard.

IEC 62192:2009 is classified under the following ICS (International Classification for Standards) categories: 13.260 - Protection against electric shock. Live working; 29.240.20 - Power transmission and distribution lines; 29.260.99 - Other electrical equipment for working in special conditions. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62192:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62192 ®

Edition 1.0 2009-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Insulating ropes

Travaux sous tension – Cordes isolantes

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62192 ®

Edition 1.0 2009-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Insulating ropes

Travaux sous tension – Cordes isolantes

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

S

CODE PRIX

ICS 13.260; 29.240.20; 29.260.99 ISBN 978-2-88910-641-7

– 2 – 62192 © IEC:2009

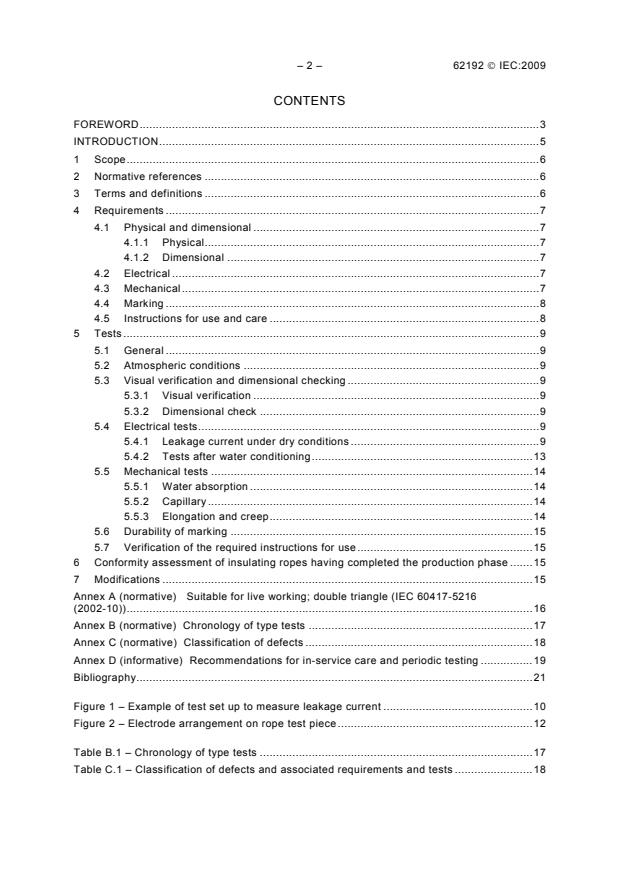

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .6

4 Requirements .7

4.1 Physical and dimensional .7

4.1.1 Physical.7

4.1.2 Dimensional .7

4.2 Electrical .7

4.3 Mechanical.7

4.4 Marking .8

4.5 Instructions for use and care .8

5 Tests .9

5.1 General .9

5.2 Atmospheric conditions .9

5.3 Visual verification and dimensional checking .9

5.3.1 Visual verification .9

5.3.2 Dimensional check .9

5.4 Electrical tests.9

5.4.1 Leakage current under dry conditions .9

5.4.2 Tests after water conditioning.13

5.5 Mechanical tests .14

5.5.1 Water absorption .14

5.5.2 Capillary.14

5.5.3 Elongation and creep.14

5.6 Durability of marking .15

5.7 Verification of the required instructions for use.15

6 Conformity assessment of insulating ropes having completed the production phase .15

7 Modifications .15

Annex A (normative) Suitable for live working; double triangle (IEC 60417-5216

(2002-10)).16

Annex B (normative) Chronology of type tests .17

Annex C (normative) Classification of defects .18

Annex D (informative) Recommendations for in-service care and periodic testing .19

Bibliography.21

Figure 1 – Example of test set up to measure leakage current .10

Figure 2 – Electrode arrangement on rope test piece .12

Table B.1 – Chronology of type tests .

Table C.1 – Classification of defects and associated requirements and tests .18

62192 © IEC:2009 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIVE WORKING –

INSULATING ROPES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62192 has been prepared by technical committee 78: Live

working.

The text of this standard is based on the following documents:

FDIS Report on voting

78/773/FDIS 78/787/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – 62192 © IEC:2009

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

62192 © IEC:2009 – 5 –

INTRODUCTION

Insulating ropes designed and manufactured according to this standard contribute to the

safety of the users, provided they are used by skilled persons, in accordance with safe

methods of work and the instructions for use.

This International Standard defines the required electrical properties of insulating ropes which

already meet other specifications relating to mechanical strength, physical and construction

properties, for use in live working at the power frequency system voltages up to and including

800 kV r.m.s.

This standard does not propose to address all the safety factors associated with the use of

the insulating rope. It is the responsibility of the user to establish appropriate safety practices.

Ropes which meet this standard can bridge two or more live phase conductors, or one phase

conductor and earth as required during live working. Effects of the use of insulating ropes on

the dielectric strength of the installation have to be evaluated. Depending on the configuration

of an installation, the use of insulating ropes will have different effects on its dielectric

strength.

Cotton, sisal and hemp ropes are unsuitable for this application, as are any other ropes that

exhibit electrical conductivity. Examples of ropes which are able to meet the requirements of

this standard are formed from fibres that have been treated with a wax or other chemical

which causes the surface of the rope to become hydrophobic.

This document has been prepared according to the requirements of IEC 61477 where

applicable.

The product covered by this standard may have an impact on the environment during some or

all stages of its life cycle. These impacts can range from slight to significant, be of short-term

or long-term, and occur at the global, regional or local level.

Except for a requirement for the selection of a testing dye and the disposal statement in the

instructions for use, this standard does not include requirements and test provisions for the

manufacturers of the product, or recommendations to the users of the product for

environmental improvement. However, all parties intervening in its design, manufacture,

packaging, distribution, use, maintenance, repair, reuse, recovery and disposal are invited to

take account of environmental considerations.

– 6 – 62192 © IEC:2009

LIVE WORKING –

INSULATING ROPES

1 Scope

This International Standard covers insulating ropes that are utilized during live working

procedures in contact with parts of installations operating at voltages up to and including

800 kV r.m.s.

Insulating ropes for live working procedure under rain and/or d.c. conditions are not covered

by this standard.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60212:1971, Standard conditions for use prior to and during the testing of solid electrical

insulating materials

IEC 60417, Graphical symbols for use on equipment

IEC 61318:2007, Live working – Conformity assessment applicable to tools, devices and

equipment

IEC 61477, Live working – Minimum requirements for the utilization of tools, devices and

equipment

ISO 2307, Ropes – Determination of certain physical and mechanical properties

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61318 and the

following apply.

3.1

creep

dimensional change with time in a test section of the rope when subjected to continued

working load

3.2

elongation

initial dimensional change in a test section of the rope subjected to rated working load for a

short period of time

62192 © IEC:2009 – 7 –

3.3

insulating rope

rope with electrical insulating properties suitable for use in contact with live parts

[IEV 651-09-01, modified]

3.4

rope

stout cord made from woven or twisted insulating or non-insulating material used for various

handling operations

NOTE Ropes, which may come into contact with live conductors, should be insulating. Ropes used to move tools

and other equipment into place, which are clear of live parts, may be non-insulating.

[IEC 60743, definition 10.1.1, modified]

4 Requirements

4.1 Physical and dimensional

4.1.1 Physical

Ropes shall be free of visual manufacturing defects such as incorrect impregnation or faulty

stranding or cabling.

Ropes covered by this standard shall demonstrate low water absorption and capillary action.

4.1.2 Dimensional

Diameter and circumference of ropes shall comply with the manufacturer specifications with a

tolerance of ± 10 %.

NOTE National or regional standards could specify dimensioning where needed.

4.2 Electrical

Ropes covered by this standard shall have appropriate dielectric properties under dry

conditions and when exposed to humid conditions.

Splicing of insulating ropes shall be possible, whilst keeping the ropes appropriate dielectric

properties and in accordance with the manufacturer’s instructions.

Insulating ropes to be used under rain condition, or d.c. stress are not covered by this

standard.

4.3 Mechanical

In addition to other specifications related to mechanical strength and construction properties,

ropes covered by this standard shall demonstrate limit elongation under normal loading

conditions.

– 8 – 62192 © IEC:2009

4.4 Marking

The insulating ropes shall be properly identified.

Ropes covered by this standard shall be marked with the following permanent items of

marking:

– name of the manufacturer, or trade mark,

– year of manufacture, coded with a colour tracer or other means.

The following information shall also be supplied, either by a marking or other means on the

rope or on each reel of rope or each smallest shipping container:

– symbol IEC 60417-5216 (2002-10) – Suitable for live working; double triangle (see

Annex A),

NOTE The exact ratio of the height of the figure to the base of the triangle is 1,43. For the purpose of

convenience, this ratio can be between the values of 1,4 and 1,5.

– number of the relevant IEC standard immediately adjacent to the symbol with year of

publication (four digits) (IEC 62192:2009),

– batch number,

– details of diameter,

– type of lay,

– fibre material,

– minimum breaking force,

– creep,

– recommended working load.

The marking shall be durable, clearly visible and legible to a person with normal or corrected

vision without additional magnification.

4.5 Instructions for use and care

Each reel of rope or each smallest shipping length shall be supplied with the manufacturer’s

written information and instructions for use and care. These instructions shall be prepared in

accordance with the general provisions given in IEC 61477.

The information and instructions shall include as a minimum:

– any special treatment of the fibres which makes them specially suitable for this

application,

– instructions for splicing,

– instructions for handling, cleaning, storage and transportation,

– instructions for periodic testing, repair, and disposal of the rope,

– period of years from the moment of production in which the mechanical characteristics

can be guaranteed (storage life).

62192 © IEC:2009 – 9 –

5 Tests

5.1 General

The present standard provides testing provisions to demonstrate compliance of the product to

the requirements of Clause 4. These testing provisions are primarily intended to be used as

type tests for validation of the design input. Where relevant, alternative means (calculation,

examination, tests, etc.) are specified within the test subclauses, for the purpose of insulating

ropes having completed the production phase.

Each type test shall be carried out on test pieces as specified below. If one or more test

pieces fail during the type test, the product has not met the requirements of this standard.

The type tests shall be performed according to the chronological order specified in Annex B.

5.2 Atmospheric conditions

Unless otherwise stated, the lengths of insulating rope submitted to type tests shall be

preconditioned for 4 h ± 0,5 h and tested under the normal atmospheric conditions provided in

Table I of IEC 60212, at a temperature of between 15 °C and 35 °C, with a relative humidity

between 25 % and 75 % (taking into account Note 5 of Table I of IEC 60212).

5.3 Visual verification and dimensional checking

5.3.1 Visual verification

Ropes shall be visually verified to check if the requirements of 4.1.1 and 4.4 are fulfilled.

When visual verification is specified, it shall be understood to be visual verification by a

person with normal or corrected vision without additional magnification.

5.3.2 Dimensional check

Nominal diameter and nominal circumference of ropes shall be measured to check for

compliance with 4.1.2.

5.4 Electrical tests

Unless otherwise specified, the electrical tests shall be carried out in accordance with

IEC 60060-1.

A total of six test pieces are required for the electrical tests.

5.4.1 Leakage current under dry conditions

5.4.1.1 General

The test shall be performed on three test pieces with a length of 2 000 mm each. A voltage of

100 kV r.m.s. shall be applied, across a 300 mm length of rope for 1 min and the leakage

current during this period shall be measured (see Figure 1 for example of a test set-up).

– 10 – 62192 © IEC:2009

100 kV r.m.s.

R

M 2

IEC 267/09

Key

1 Test piece

2 Shielded wire

3 Faraday box. A shielded container enclosing and guarding the resistor R and the voltmeter M. Both

the screen and the shield of the measuring lead by-pass R and M, by providing a path for stray

capacitive currents to ground.

R A 100 Ω, 50 W wirewound non-inductive resistor is recommended. A 50 W resistor at a minimum is

recommended because a hazardous condition would exist if the resistor should fail and create an

open circuit.

M Battery operated, true RMS, solid state voltmeter

Figure 1 – Example of test set up to measure leakage current

5.4.1.2 Test procedure

The test piece shall be mounted in the vertical position with a distance of 1 500 mm between

the attachment points, and tensioned at the lower attachment point with a 4,5 kg mass.

Two electrodes shall be formed by wrapping tinned copper wire of a diameter between

0,5 mm and 1 mm tightly around the test piece. The electrodes shall be centred in the test

section with a clearance of 300 mm between the electrodes and mounted to provide a good

electrical contact. Figure 2 illustrates the connection.

62192 © IEC:2009 – 11 –

Dimensions in millimetres

A

B

C

D

K

IEC 268/09

Figure 2a – Electrode arrangement for test before water conditioning

1 500

600 T = 300 600

– 12 – 62192 © IEC:2009

Dimensions in millimetres

A

B

C

D

K

IEC 269/09

Figure 2b – Electrode arrangement for test after water conditioning

Key

A Rope attachment point (bracket parallel jaw or equivalent)

B High voltage electrode

C Low voltage electrode

D Weight attachment point

K

Mass 4,5 kg

T Test length

Figure 2 – Electrode arrangement on rope test piece

A power frequency voltage of 100 kV shall be applied to the upper electrode and the lower

electrode shall be connected to earth through a micro-ammeter. The voltage shall be raised to

100 kV in a 15 s to 30 s interval and maintained at 100 kV for a period of 1 min. After 1 min,

the voltage shall be decreased to zero in not more than 5 s.

The leakage current shall be measured during the 1 min exposure to the 100 kV voltage.

1 500

600 T = 600 300

62192 © IEC:2009 – 13 –

5.4.1.3 Test criteria

The leakage current test under dry conditions shall be considered as passed if

– the maximum leakage current is stable and does not exceed 100 μA (0,1 mA) at the

end of the 1 min,

– during the test, the rope does not initiate a flashover, and

– at the end of test, the rope does not show burn marks or other signs of damage after a

visual verification.

If the current is fluctuating more than 10 μA at the end of 1 min, and the leakage current has

not exceeded 100 μA and there has been no flashover, the test shall be continued for an

additional 5 min. If at the end of that time the rope has not flashed over and the current has

stabilized at less than 100 μA the test shall be considered as passed.

5.4.2 Tests after water conditioning

The tests shall be performed on three other test pieces with a length of 2 000 mm each.

5.4.2.1 Conditioning

Before the tests, the test pieces shall be kept submerged for a period of 15 min in water

having a resistivity of (100 ± 15) Ω·m.

5.4.2.2 Leakage current after water conditioning

5.4.2.2.1 Test set-up

Within 1 min after removal from the wetting tank, a mass of 4,5 kg shall be attached to the

test piece below the lower electrode to facilitate the parting of any fibres that become

weakened by electrical activity. The test piece shall be allowed to dry for 15 min in

atmospheric conditions as specified in 5.2. Two electrodes shall be formed 600 mm apart by

wrapping tinned copper wire of a diameter between 0,5 mm and 1 mm tightly around rope.

A power frequency voltage of 100 kV r.m.s. shall be applied to the upper electrode, and the

lower electrode shall be connected to earth through a micro-ammeter. See Figures 1 and 2.

5.4.2.2.2 Electrical test procedure and criteria

The voltage shall be raised from 0 kV to 100 kV in not less than 15 s nor more than 30 s.

When reached, the voltage of 100 kV r.m.s. shall be maintained for 5 min. After 5 min, the

voltage shall be decreased to zero in not more than 5 s.

The test shall be considered as passed if

– the measured leakage current does not exceed 500 μA r.m.s. after 1 min and by the end

of the test is below 250 μA r.m.s., and

– at the end of the test the insulating rope shows no burn marks or other signs of damage

after a visual verification.

5.4.2.3 Mechanical test after water conditioning

Following the electrical test, the mechanical strength of the same test pieces shall be

determined by measuring the breaking strength according to ISO 2307.

The test shall be considered as passed if the mechanical strength meets manufacturer

specification for the particular type of construction.

– 14 – 62192 © IEC:2009

5.5 Mechanical tests

A minimum of three test pieces are required for the mechanical tests.

5.5.1 Water absorption

A rope test piece of a minimum length of 1,5 m shall be conditioned by immersing it for 24 h ±

1 h in water at 23 °C ± 2 °C.

The test shall be considered as passed if after 7 h ± 0,5 h of drying in a place with relative

humidity less than 80 %, the water content is less than 2 % by weight.

5.5.2 Capillary

A dye shall be selected in accordance with occupational health and environmental

requirements.

A rope test piece of a minimum length of 125 mm shall be used for the test. One end of the

test piece shall be cut and 10 mm of the rope dipped in the acceptable aqueous dye solution

for 10 s.

The test shall be considered as passed if there is no dye penetration exceeding 3 mm in the

rope.

5.5.3 Elongation and creep

5.5.3.1 Elongation

Under 1 % working load condition, a rope test piece of a minimum length of 900 mm shall be

measured. The length of the test piece shall be noted. This will be designated as initial length

l .

ei

The load shall then be increased within 1 min to 16,7 % of the working load, and held at that

value for 10 min. The load shall then be decreased within 1 min to 1 % of the working load

and held at that value for a period of 1 min. The length of the test piece shall then be

.

measured again within 1 min. This will be designated as final length l

ef

The elongation shall be expressed as a percentage and given by:

(l – l ) × 100/ l

ef ei ei

where

l is the initial length, expressed in mm, under the initial 1 % working load condition;

ei

l is the length, expressed in mm, under the final 1 % working load condition at the end of the

ef

elongation test.

The test shall be considered as passed if the measured elongation is less than 11 %.

5.5.3.2 Creep

The rope test piece used for the elongation test shall also be used for this test. The load shall

then be increased within 1 min to 16,7 % of the working load, and the rope length shall be

measured. This length will be designated as initial creep length l . The test load shall be held

ci

at 16,7 % of the working load for 60 min.

The length of the test piece shall be measured at the end of the test without reducing the

load. This will be designated as creep length l .

cf

62192 © IEC:2009 – 15 –

The creep shall be expressed as a percentage and given by:

(l – l ) × 100/ l

cf ci ci

where

l is the initial length, expressed in mm, at the start of the test at 16,7 % of the working load;

ci

l is the length, expressed in mm, at the end of the test at 16,7 % of the working load.

cf

The test shall be considered as passed if the creep is less than 5 % additional.

5.6 Durability of marking

The markings shall be rubbed vigorously for 1 min with a clean cloth soaked in water, then

with a clean cloth soaked in isopropanol (CH -CH(OH)-CH ).

3 3

NOTE It is the employer’s duty to ensure that any relevant legislation and any specific safety instructions

regarding the use of isopropanol are fully observed.

The test shall be considered as passed if the markings are still legible and the characters do

not run or smear.

5.7 Verification of the required instructions for use

The requirement of 4.5 shall be verified by examination of the information and instructions for

use.

6 Conformity assessment of insulating ropes having completed the production

phase

For conducting the conformity assessment during the production phase, IEC 61318 shall be

used in conjunction with the present standard.

Annex C provides the classification of defects and identifies the associated tests applicable in

case of production follow-up.

7 Modifications

Any modification of the insulating rope shall require additional type tests or that the type tests

be repeated, in whole or in part, if it is determined that the modification so justifies and also

may require a change in rope reference literature.

– 16 – 62192 © IEC:2009

Annex A

(normative)

Suitable for live working; double triangle

(IEC 60417-5216 (2002-10))

62192 © IEC:2009 – 17 –

Annex B

(normative)

Chronology of type tests

The numbers given in the different test groups of Table B.1 indicate the chronological order in

which the tests within a group shall be made. Within a group, tests with the same sequential

number can be performed in the more convenient order.

Test groups do not have to be performed in the given order.

Table B.1 – Chronology of type tests

Test description Test Groups of test piece

subclause

Group 1 Group 2 Group 3 Group 4 Group 5

Visual verification 5.3.1 1 1 1

Dimensional check 5.3.2 1 1 1

Water absorption 5.5.1 2

Leakage current under dry 5.4.1 2

conditions

Leakage current after water 5.4.2.2 2

conditioning

Mechanical test after water 5.4.2.3 3

conditioning

Capillary 5.5.2 1

Elongation and creep 5.5.3 1

Durability of marking 5.6 1

Verification of the required 5.7 1

instructions for use

Number of test pieces 1 3 3 1 1

– 18 – 62192 © IEC:2009

Annex C

(normative)

Classification of defects

This annex was developed to address the level of defects of manufactured insulating ropes

(critical, major or minor) in a consistent manner (see IEC 61318). For each requirement

identified in Table C.1, both the type of defect and the associated test are specified.

Table C.1 – Classification of defects and associated requirements and tests

Requirements Type of defects Tests

Critical Major Minor

4.1 Physical X 5.3.1

Dimensional X 5.3.1

4.1.1 Water absorption X Alternative test or

alternative means is

under consideration

4.2 Electrical X Alternative test or

alternative means is

under consideration

4.3 Elongation and creep X Alternative test or

alternative means is

under consideration

4.4 Marking

- absence X 5.3.1

- durability X 5.6

4.5 Instructions for use X 5.7

(absence)

62192 © IEC:2009 – 19 –

Annex D

(informative)

Recommendations for in-service care and periodic testing

D.1 Identification

Insulating rope needs to be identified as such by the user for control of its use. It may be

specified with a special colour and with an identification tracer of a different colour to identify

year of manufacture.

D.2 Storage

D.2.1 In the field

The insulating rope should be kept dry and clean in a sealed container to protect against

contamination. Insulating rope should never be placed directly on the ground.

D.2.2 In the storage room

Insulating ropes should be stored the same way as insulating sticks with a free flow of air to

avoid moisture build-up.

D.3 Handling

During handling, precautions should be taken to avoid rope contamination.

The rope should be kept in the sealed container until it is used, be taken directly from the

container and put back in the container immediately after use to avoid any build up of

moisture within the rope core.

D.4 Periodic testing

D.4.1 In the field before each use

The rope should be inspected visually to detect defects, signs of tracking and pollution.

D.4.2 In a test facility

Subject to use, the dry and wet electrical and breaking strength may be checked each year.

D.5 Application safety factor

The range of mechanical safety factor for material handling and for personnel depends upon

the regulations and utility practices. For example, a mechanical safety factor for material

handling of 3 to 1 to 5 to 1 and for personnel of 8 to 1 to 10 to 1 is used in North America.

– 20 – 62192 © IEC:2009

D.6 Use with capstan

The capstan should be sized for the rope being used.

The material of the capstan drum and its surface finish should be selected in the appropriate

way to avoid any contamination of the rope during friction (example: polished chromed

surface).

D.7 Cleaning, repair and recycling

The repair of ropes is not recommended, but cleaning is possible if undertaken in accordance

with the manufacturer’s instructions.

Recycling for uses not requiring insulation is acceptable.

62192 © IEC:2009 – 21 –

Bibliography

IEC 60050-651:1999, International Electrotechnical Vocabulary – Part 651: Live working

)

IEC 60743:2001, Live working – Terminology for tools, equipment and devices

Amendment 1 (2008)

___________

___________

)

There exists a consolidated edition 2.1 (2008) that comprises edition 2 and Amendment 1.

– 22 – 62192 © CEI:2009

SOMMAIRE

AVANT-PROPOS.23

INTRODUCTION.25

1 Domaine d’application .26

2 Références normatives.26

3 Termes et définitions .26

4 Exigences .27

4.1 Exigences physiques et dimensionnelles .27

4.1.1 Exigences physiques .27

4.1.2 Exigences dimensionnelles.27

4.2 Exigences électriques .27

4.3 Exigences mécaniques.27

4.4 Marquage.28

4.5 Instructions d’utilisation et précautions d’emploi .28

5 Essais .29

5.1 Généralités.29

5.2 Conditions atmosphériques .29

5.3 Vérification visuelle et contrôle dimensionnel .29

5.3.1 Vérification visuelle .29

5.3.2 Contrôle dimensionnel .29

5.4 Essais électriques .29

5.4.1 Courant de fuite sous conditions sèches.29

5.4.2 Essais après conditionnement dans l’eau .33

5.5 Essais mécaniques.34

5.5.1 Absorption d’eau .34

5.5.2 Capillarité.34

5.5.3 Allongement et fluage.34

5.6 Durabilité du marquage .35

5.7 Vérification des instructions d’emploi exigées.35

6 Evaluation de la conformité des cordes isolantes issues de la production.35

7 Modifications .35

Annexe A (normative) Approprié aux travaux sous tension; double triangle

(CEI 60417-5216 (2002-10)) .36

Annexe B (normative) Chronologie des essais de type.37

Annexe C (normative) Classification des défauts .38

Annexe D (informative) Recommandations pour les précautions d’emploi et les essais

périodiques.39

Bibliographie.41

Figure 1 – Exemple de montage d’essai pour la mesure du courant de fuite .

Figure 2 – Disposition des électrodes sur l’éprouvette d’essai de corde .32

Tableau B.1 – Chronologie des essais de type.37

Tableau C.1 – Classification des défauts et exigences et essais associés .38

62192 © CEI:2009 – 23 –

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

TRAVAUX SOUS TENSION –

CORDES ISOLANTES

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...