IEC TR 61643-03:2024

(Main)Low-voltage surge protective devices - Part 03: SPD Testing Guide

Low-voltage surge protective devices - Part 03: SPD Testing Guide

IEC TR 61643-03:2024 applies to SPD testing in accordance with the IEC 61643-x1 series and for SPD coordination and system level immunity purposes.

It aims to provide guidance and helpful information for correct test execution and accurate interpretation of measurement results. It is also intended to further enhance repeatability and comparability throughout different test laboratories and to establish an acceptable accuracy level for the test results obtained.

The main subjects are: Test application, Test arrangement/setup, Probe application, SPD coordination testing, and System level immunity testing

General Information

- Status

- Published

- Publication Date

- 04-Jul-2024

- Technical Committee

- SC 37A - Low-voltage surge protective devices

- Current Stage

- PPUB - Publication issued

- Start Date

- 05-Jul-2024

- Completion Date

- 05-Jan-2024

Overview

IEC TR 61643-03:2024 - "Low‑voltage surge protective devices - Part 03: SPD testing guide" is a technical report from the IEC that provides practical guidance for testing surge protective devices (SPDs) used on low‑voltage power systems. It supplements the IEC 61643‑x1 series by describing correct test application, test arrangement, probe use, coordination testing and system‑level immunity testing. The report aims to improve repeatability and comparability across test laboratories and define acceptable accuracy levels for measurement results.

Key topics

- Test application & arrangement: recommended laboratory set‑ups, wiring and measurement loop practices to reduce measurement error and variability (including diagrams for common arrangements).

- Probe application - residual voltage measurements: guidance on where and how to place voltage probes to measure residual let‑through voltage accurately (covers methods for pigtail connections and loop minimization).

- Insulation resistance & dielectric withstand: test considerations for touchable surfaces and surfaces in contact with metal after installation; sample set‑ups for IR and dielectric tests.

- TOV (temporary overvoltage) testing: procedures for TOV tests on AC and DC SPDs, including setups for TT/IT systems and vector considerations.

- SPDs with multiple components: how to apply tests to complex SPDs (e.g., series spark gaps, gas discharge tubes with MOV bypass, trigger transformer arrangements).

- SPD coordination testing: methods for energy coordination including the Let‑Through Energy (LTE) method and energy/voltage protection coordination - test criteria and coordination techniques.

- System level immunity testing: discharge current tests under normal service conditions and induction tests due to lightning currents; classification guidance referencing IEC 61000‑4‑5.

- Interlaboratory comparisons & accuracy: Annex A documents investigation results (e.g., MET tests on MOVs) and recommendations to enhance comparability.

Practical applications

Who uses IEC TR 61643‑03:2024:

- Test laboratories - to standardize test execution and reporting for SPD verification and certification.

- SPD manufacturers & design engineers - to validate product performance, optimize probe routing, and demonstrate coordination in installations.

- Certification bodies & compliance engineers - for evaluating test accuracy, setting lab acceptance criteria and comparing results across labs.

- System integrators & electrical specifiers - to select and coordinate SPDs for system‑level immunity and fault scenarios (TOV conditions).

Typical use cases:

- Conducting residual voltage (let‑through) measurements with minimized measurement loop error.

- Performing SPD coordination tests (LTE and energy/voltage coordination) to protect downstream equipment.

- Running system‑level immunity tests (lightning induction/discharge current) in line with IEC 61000‑4‑5 guidance.

Related standards

- IEC 61643‑x1 series (SPD product standards)

- IEC 61000‑4‑5 (surge immunity testing)

- IEC 61643‑01 referenced within the TR for specific insulation/dielectric tests

Keywords: IEC TR 61643-03:2024, SPD testing, low-voltage surge protective devices, residual voltage, probe application, SPD coordination, system level immunity, TOV testing, LTE method.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC TR 61643-03:2024 is a technical report published by the International Electrotechnical Commission (IEC). Its full title is "Low-voltage surge protective devices - Part 03: SPD Testing Guide". This standard covers: IEC TR 61643-03:2024 applies to SPD testing in accordance with the IEC 61643-x1 series and for SPD coordination and system level immunity purposes. It aims to provide guidance and helpful information for correct test execution and accurate interpretation of measurement results. It is also intended to further enhance repeatability and comparability throughout different test laboratories and to establish an acceptable accuracy level for the test results obtained. The main subjects are: Test application, Test arrangement/setup, Probe application, SPD coordination testing, and System level immunity testing

IEC TR 61643-03:2024 applies to SPD testing in accordance with the IEC 61643-x1 series and for SPD coordination and system level immunity purposes. It aims to provide guidance and helpful information for correct test execution and accurate interpretation of measurement results. It is also intended to further enhance repeatability and comparability throughout different test laboratories and to establish an acceptable accuracy level for the test results obtained. The main subjects are: Test application, Test arrangement/setup, Probe application, SPD coordination testing, and System level immunity testing

IEC TR 61643-03:2024 is classified under the following ICS (International Classification for Standards) categories: 29.240.01 - Power transmission and distribution networks in general; 29.240.10 - Substations. Surge arresters. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TR 61643-03:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TR 61643-03 ®

Edition 1.0 2024-07

TECHNICAL

REPORT

Low-voltage surge protective devices –

Part 03: SPD testing guide

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TR 61643-03 ®

Edition 1.0 2024-07

TECHNICAL

REPORT

Low-voltage surge protective devices –

Part 03: SPD testing guide

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.240.01; 29.240.10 ISBN 978-2-8322-7999-1

– 2 – IEC TR 61643-03:2024 © IEC 2024

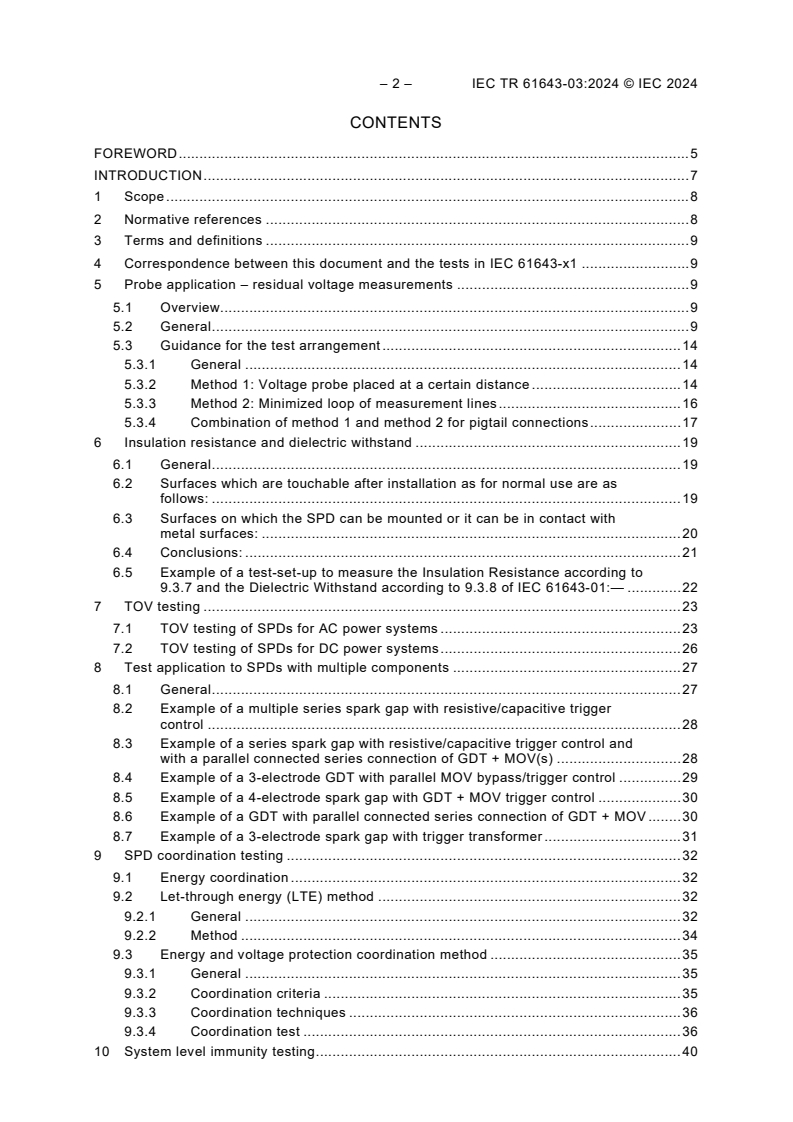

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Correspondence between this document and the tests in IEC 61643-x1 . 9

5 Probe application – residual voltage measurements . 9

5.1 Overview. 9

5.2 General . 9

5.3 Guidance for the test arrangement . 14

5.3.1 General . 14

5.3.2 Method 1: Voltage probe placed at a certain distance . 14

5.3.3 Method 2: Minimized loop of measurement lines . 16

5.3.4 Combination of method 1 and method 2 for pigtail connections . 17

6 Insulation resistance and dielectric withstand . 19

6.1 General . 19

6.2 Surfaces which are touchable after installation as for normal use are as

follows: . 19

6.3 Surfaces on which the SPD can be mounted or it can be in contact with

metal surfaces: . 20

6.4 Conclusions: . 21

6.5 Example of a test-set-up to measure the Insulation Resistance according to

9.3.7 and the Dielectric Withstand according to 9.3.8 of IEC 61643-01:— . 22

7 TOV testing . 23

7.1 TOV testing of SPDs for AC power systems . 23

7.2 TOV testing of SPDs for DC power systems . 26

8 Test application to SPDs with multiple components . 27

8.1 General . 27

8.2 Example of a multiple series spark gap with resistive/capacitive trigger

control . 28

8.3 Example of a series spark gap with resistive/capacitive trigger control and

with a parallel connected series connection of GDT + MOV(s) . 28

8.4 Example of a 3-electrode GDT with parallel MOV bypass/trigger control . 29

8.5 Example of a 4-electrode spark gap with GDT + MOV trigger control . 30

8.6 Example of a GDT with parallel connected series connection of GDT + MOV . 30

8.7 Example of a 3-electrode spark gap with trigger transformer . 31

9 SPD coordination testing . 32

9.1 Energy coordination . 32

9.2 Let-through energy (LTE) method . 32

9.2.1 General . 32

9.2.2 Method . 34

9.3 Energy and voltage protection coordination method . 35

9.3.1 General . 35

9.3.2 Coordination criteria . 35

9.3.3 Coordination techniques . 36

9.3.4 Coordination test . 36

10 System level immunity testing . 40

10.1 General . 40

10.2 SPD discharge current test under normal service conditions: . 40

10.3 Induction test due to lightning currents: . 40

10.4 Recommended test classification of system level immunity (following

IEC 61000-4-5): . 40

Annex A (informative) Critical investigation on the impulse current specification for T1

SPDs when testing Metal Oxide Varistors . 42

A.1 History and background . 42

A.2 General information . 42

A.3 Test program and instructions . 43

A.3.1 Detailed instructions . 43

A.4 Details and results of interlaboratory comparison tests . 44

A.4.1 Single disc results . 45

A.4.2 Double block results . 46

A.5 Conclusions from interlaboratory test results . 47

A.6 Further investigations and comparison tests in CTI . 47

A.6.1 Examples. 48

A.6.2 Overview single disc results. 49

A.6.3 Overview double block results . 49

A.7 Final conclusions . 49

Annex B (informative) Illustration of the terms mode of protection, current path and

current branch . 51

B.1 Examples of SPDs with one single mode of protection . 51

B.2 Examples of multimode SPDs . 52

Bibliography . 55

Figure 1 – 8/20 current impulse and induced voltage . 10

Figure 2 – Test arrangement A . 11

Figure 3 – Test arrangement B . 12

Figure 4 – Test arrangement C . 13

Figure 5 – Measured voltages of test arrangements A, B and C during 8/20 current

application . 13

Figure 6 – Routing of the measurement lines of an SPD having a single mode of

protection . 15

Figure 7 – Wrong routings of the measurement lines . 15

Figure 8 – Routing of the measurement lines of a multimode SPD, example 1 . 16

Figure 9 – Routing of the measurement lines of a multimode SPD, example 2 . 16

Figure 10 – Example for the application of method 2 at an SPD having a single mode

of protection. 17

Figure 11 – Example for the application of method 1 and method 2 where the SPD is

provided with pigtail connections . 18

Figure 12 – Wrong routings of the pigtails together with the measurement lines where

the SPD is provided with pigtail connections . 18

Figure 13 – Examples of a three-phase and single-phase test setup for use in testing

SPDs for application in TT systems under TOVs caused by faults in the high (medium)

voltage system . 24

Figure 14 – Example of a three-phase test setup for use in testing SPDs for use in IT

systems under TOVs caused by faults in the high (medium) voltage system . 25

Figure 15 – Vector diagram for the voltages in the test setup in Figure 14 . 26

– 4 – IEC TR 61643-03:2024 © IEC 2024

Figure 16 – Example of a test setup for use in testing SPDs intended to be connected

to a DC system, which is derived from an AC TT system without separation, under

TOVs caused by faults in the high (medium) voltage system . 27

Figure 17 – Example of a test setup for use in testing SPDs intended to be connected

to a DC TT system, which is derived from another earthed DC system, under TOVs

caused by faults in the high (medium) voltage system . 27

Figure 18 – multiple series spark gap with resistive /capacitive trigger control . 28

Figure 19 – series spark gap with capacitive trigger control . 29

Figure 20 – 3-electrode GDT with parallel MOV bypass/trigger control . 29

Figure 21 – 4-electrode spark gap with GDT + MOV trigger control . 30

Figure 22 – GDT with parallel connected series connection of GDT + MOV . 31

Figure 23 – 3-electrode spark gap with trigger transformer . 31

Figure 24 – LTE – Coordination method with standard pulse parameters . 33

Figure 25 – SPDs arrangement for the coordination test . 38

Figure 26 – Example of a circuit used to perform discharge current tests under normal

service conditions . 41

Figure 27 – Example circuit of an induction test due to lightning currents . 41

Figure B.1 – SPD with one mode of protection comprising one current path and

consisting of one current branch . 51

Figure B.2 – SPD with one mode of protection comprising three current paths (blue,

green, yellow arrows), but consisting of only one current branch . 52

Figure B.3 – SPD with three modes of protection (L-N, N-PE and L-PE) whereby the

mode L-PE is composed of a series connection of the modes L-N and N-PE, the modes

of protection L-N and N-PE comprise one current path and consist of one current

branch each, the mode of protection L-PE comprises one current path but consists of

two current branches (L-N and N-PE) . 52

Figure B.4 – SPD with two modes of protection (L-N, N-PE) or three modes of

protection (L-N, N-PE, L-PE) as declared by the manufacturer, each mode of

protection comprises one current path (blue, green, yellow arrows), but each mode of

protection or current path consists of two current branches (e.g. L to common

connection point and N to common connection point) . 53

Figure B.5 – SPD with two modes of protection (L-N, N-PE) or three modes of

protection (L-N, N-PE, L-PE) as declared by the manufacturer, each mode of

protection comprises two current paths (blue, green, orange arrows) . 54

Figure B.6 – SPD with two modes of protection (L-N, N-PE) or three modes of

protection (L-N, N-PE, L-PE) as declared by the manufacturer and containing three

current branches (blue, green, yellow arrows) in total, each mode of protection

containing two current branches . 54

Table 1 – Correspondence between this document and the IEC 61643-x1 series . 9

Table 2 – Values to be calculated . 34

Table 3 – Normalised division factors for a CWG . 34

Table 4 – Resulting calculation from Table 2 and Table 3 . 35

Table 5 – Test procedure for coordination . 39

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LOW-VOLTAGE SURGE PROTECTIVE DEVICES –

Part 03: SPD Testing Guide

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch or

www.iso.org/patents. IEC shall not be held responsible for identifying any or all such patent rights.

IEC TR 61643-03 has been prepared by subcommittee 37A: Low-voltage Surge Protective

Devices, of IEC technical committee 37: Surge Arrestors. It is a Technical Report.

The text of this Technical Report is based on the following documents:

Draft Report on voting

37A/XX/DTR 37A/XX/RVDTR

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Report is English.

– 6 – IEC TR 61643-03:2024 © IEC 2024

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 61643, published under the general title Low-voltage surge

protective devices, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

INTRODUCTION

It has been assumed in the preparation of this document that the execution of its provisions is

entrusted to appropriately qualified and experienced persons.

Throughout this document, when the “IEC 61643-x1 series” is mentioned, it refers to all parts

of the IEC 61643 series of standards that deal with testing of SPDs, e.g. IEC 61643-01,

IEC 61643-11.

This part of the IEC 61643 series addresses correct test execution and accurate interpretation

of measurement results and is also intended to further enhance repeatability and comparability

throughout different test laboratories and to establish an acceptable accuracy level for the test

results obtained.

The new SPD classification T1 SPD, T2 SPD and T3 SPD is relating to the former test class

oriented classification Class I tests, Class II tests and Class III tests.

– 8 – IEC TR 61643-03:2024 © IEC 2024

LOW-VOLTAGE SURGE PROTECTIVE DEVICES –

Part 03: SPD Testing Guide

1 Scope

This part of IEC 61643, which is a Technical Report, applies to SPD testing in accordance with

the IEC 61643-x1 series and for SPD coordination and system level immunity purposes.

It aims to provide guidance and helpful information for correct test execution and accurate

interpretation of measurement results. It is also intended to further enhance repeatability and

comparability throughout different test laboratories and to establish an acceptable accuracy

level for the test results obtained.

The main subjects are:

– Test application

– Test arrangement/setup

– Probe application

– SPD coordination testing

– System level immunity testing

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

For the purposes of this document the normative references given in IEC 61643-01:— and the

following apply.

IEC 61643-01:—, Low-voltage surge protective devices – Part 01: General requirements and

test methods

, Low-voltage surge protective devices – Part 11: Surge protective devices

IEC 61643-11:—

connected to low-voltage power systems – Requirements and test methods

IEC 61643-12:2020, Low-voltage surge protective devices – Part 12: Surge protective devices

connected to low-voltage power systems – Selection and application principles

IEC 61643-41:— , Low-voltage surge protective devices – Part 41: Surge protective devices

connected to DC low-voltage power systems – Requirements and test methods

___________

Under preparation. Stage at the time of publication: IEC/ACDV 61643-01:2023.

Under preparation. Stage at the time of publication: IEC/ACDV 61643-11:2023.

Under preparation. Stage at the time of publication: IEC/ACDV 61643-41:2023.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 61543-01:— apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Correspondence between this document and the tests in IEC 61643-x1

Table 1 provides information on which clauses of this document should apply to certain tests

from the IEC 61643-x1 series.

Table 1 – Correspondence between this document and the IEC 61643-x1 series

IEC 61643-03 clause reference Relevance for test clauses in the IEC 61643-x1

series

5 Probe application – residual voltage measurements 9.1.1, Table 3, pass criterion D

9.3.4 measured limiting voltage,

9.3.5 operating duty test,

9.6.5.3 Measurement of voltage rate of rise du/dt

6 Insulation resistance and dielectric withstand 9.3.7 Insulation resistance

9.3.8 Dielectric withstand

7 TOV testing 9.3.9 Behaviour under temporary overvoltages (TOVs)

7.1 TOV testing of SPDs for AC power systems IEC 61643-11:—, 9.3.9.101 TOVs caused by faults in

the high (medium) voltage system

7.2 TOV testing of SPDs for DC power systems IEC 61643-41:—, 9.3.9 Behaviour under temporary

overvoltages (TOVs)

8 Test application to SPDs with multiple components General

Annex A Critical investigation on the impulse current 9.1.2 Impulse discharge current

specification for T1 SPDs when testing

Metal Oxide Varistors

5 Probe application – residual voltage measurements

5.1 Overview

Residual voltages measurements are very sensitive measurements due to the fact that they are

carried out at high frequencies in presence of magnetic fields which may strongly interfere with

the results of these measurements to such an extent that different measurements from one

measurement to another one, or between different testing entities may not be comparable.

This clause intends to provide guidelines on testing techniques for making correct residual

voltages measurements to limit these deviations and discrepancies.

5.2 General

According to the induction law, an alternating magnetic field induces a voltage into a conductor

loop. The induced voltage depends on the loop size and the frequency and the amount of

magnetic field. The intensity of a magnetic field decreases with increasing distance to its

source.

– 10 – IEC TR 61643-03:2024 © IEC 2024

The residual voltage is measured with 8/20 current impulses. The magnetic field generated by

this 8/20 current impulse induces a voltage into the loop build up by the voltage measurement

lines that are connected to the device under test. This voltage is added to the voltage drop

between the two points where the measurement lines are connected to. This induced voltage

depends on and is directly proportional to the size of the loop build by the voltage measurement

lines and to the peak value of the 8/20 current impulse and may have values of several 10 V up

to some kV. The wave shape of the induced voltage follows the derivative di/dt of the 8/20

current impulse and reaches its maximum at the beginning of the 8/20 current impulse. A zero

crossing and therefore 0 V occurs at the crest value of the 8/20 current impulse. A typical

waveshape of the induced voltage is shown in Figure 1.

Figure 1 – 8/20 current impulse and induced voltage

In general, the test procedure to measure the residual voltage with 8/20 current impulses

requires the connection of the voltage measuring system as close as possible to the SPD. This

is caused by the fact that a voltage drop occurs along the length of a conductor when a current

flows through. This voltage drop also influences the measured voltage between the two points

to which the measurement lines are connected.

To show the influence of the loop size of the voltage measurement lines and the voltage drop

of the conductors to the test sample when the 8/20 current impulse flows, three test

arrangements are assumed.

Test arrangement A is given in Figure 2 and shows a large loop size of the voltage measurement

lines that are connected far from the test sample.

Test arrangement B is given in Figure 3 and shows a smaller loop size of the voltage

measurement lines that are connected directly to the test sample.

Test arrangement C is given in Figure 4 and shows a loop size as small as possible of the

voltage measurement lines that are twisted and connected directly to the test sample.

Figure 5 shows the measured voltage time behaviour of the test arrangements A, B and C during

8/20 current application when the device under test is a voltage limiting SPD.

Key

1 HV output connection of impulse current generator

2 Ground connection of impulse current generator

3 Device under test (SPD)

4 Conductor to connect the SPD to the impulse current generator

5 Voltage probe

6 Loop area created by the voltage measurement lines (hash shaded area)

Figure 2 – Test arrangement A

– 12 – IEC TR 61643-03:2024 © IEC 2024

Key

1 HV output connection of impulse current generator

2 Ground connection of impulse current generator

3 Device under test (SPD)

4 Conductor to connect the SPD to the impulse current generator

5 Voltage probe

6 Loop area created by the voltage measurement lines (hash shaded area)

Figure 3 – Test arrangement B

Key

1 HV output connection of impulse current generator

2 Ground connection of impulse current generator

3 Device under test (SPD)

4 Conductor to connect the SPD to the impulse current generator

5 Voltage probe

6 Loop area created by the voltage measurement lines (hash shaded area)

Figure 4 – Test arrangement C

Figure 5 – Measured voltages of test arrangements A, B

and C during 8/20 current application

– 14 – IEC TR 61643-03:2024 © IEC 2024

5.3 Guidance for the test arrangement

5.3.1 General

The guidance for test arrangements to measure the residual voltage with 8/20 current impulses

given in 5.3.2 and 5.3.3 may be applied if:

• it is unknown or it is assumed, that the influence of the magnetic field of the 8/20 current

or the loop size of the measurement lines is too big, or

• the measured residual voltage exceeds the voltage protection level Up of an SPD

defined by the manufacturer, or

• agreed or required by the manufacturer of the SPD.

The following two alternate test arrangements are proposed. Depending on the equipment

available and as required by the manufacturer of the SPD one of these methods could be

chosen.

In addition, the use of differential probes and/or a scope with isolated inputs should be

considered.

5.3.2 Method 1: Voltage probe placed at a certain distance

If the design of the SPD and/or the size of the voltage probe does not allow to connect the

voltage probes very close to the device under test (DUT) without creating a large loop area, the

following test setup may be appropriate to minimize the loop build up by the measurement lines

and the SPD itself.

The measurement lines connecting the voltage probe to the DUT should be as small as possible.

Their insulation should be as small as possible but thick enough to withstand, when twisted

together, the expected residual voltage. The measuring lines should be routed along the

shortest distance between the connections of the DUT along the housing of the DUT. From the

midpoint of the shortest distance between the connections of DUT, the measurement lines

should be twisted with a twist rate of at least 30 twists per meter and routed at around 90° ±10°

away from the axis created by the DUT and its conductors to the impulse current generator.

The shortest distance between the connections of DUT onto its housing may vary depending

on the mode of protection under test. A typical example of an SPD having a single mode of

protection is given in Figure 6. Two typical examples of a multimode SPD are given in Figure 8

and Figure 9.

Figure 7 shows a wrong routing of the measurement lines, where the loop between the

measurement lines and the DUT is too large.

The voltage probe should be placed in a distance of 200 mm minimum up to 500 mm maximum

away from the DUT.

Figure 6 – Routing of the measurement lines of an SPD having

a single mode of protection

Loop area created by the pigtails together with the voltage measurement lines (hash shaded

area)

Figure 7 – Wrong routings of the measurement lines

– 16 – IEC TR 61643-03:2024 © IEC 2024

Figure 8 – Routing of the measurement lines of a multimode SPD, example 1

Figure 9 – Routing of the measurement lines of a multimode SPD, example 2

5.3.3 Method 2: Minimized loop of measurement lines

If the design of the SPD and the size of the voltage probe allows to connect the voltage probe

directly or via short measurement lines placed close to the DUT the following test setup may be

appropriate to minimize the loop build by the measurement lines and the SPD itself.

The voltage probe (with reduced dimensions) is placed as close as possible to the SPD. The

voltage probe is either connected directly to the DUT or via a separate connecting wire which

is as straight and as short as possible. It should be considered that the connecting wire itself is

not part of the test circuit for the impulse current and no impulse flows through it.

To minimize the loop size even further, the ground connection wire 5 (connected to 4 on the

ground side) should be twisted around the body of the voltage probe.

If possible, the voltage probe should be positioned in parallel to the impulse current flow through

the SPD. Therefore the design of the SPD (single mode/ multimode) and the corresponding flow

of surge current should to be considered.

Figure 10 shows an example for the application of method 2 to an SPD having a single mode

of protection.

Key

1 HV output connection of impulse current generator

2 Ground connection of impulse current generator

3 Device under test (SPD)

4 Conductor to connect the SPD to the impulse current generator

5 Conductor to connect the SPD to the voltage probe

6 Voltage probe

7 Loop area created by the voltage measurement lines (hash shaded area)

Figure 10 – Example for the application of method 2 at

an SPD having a single mode of protection

5.3.4 Combination of method 1 and method 2 for pigtail connections

Figure 11 describes the probe voltage connection for products with pigtail connections.

– 18 – IEC TR 61643-03:2024 © IEC 2024

Figure 12 shows a wrong routing of the SPD pigtails together with the measurement lines, where the

loop created by the SPD pigtails and the measurement lines is too large.

Figure 11 – Example for the application of method 1 and method 2

where the SPD is provided with pigtail connections

Loop area created by the pigtails together with the voltage measurement lines (hash shaded area)

Figure 12 – Wrong routings of the pigtails together with the measurement lines

where the SPD is provided with pigtail connections

6 Insulation resistance and dielectric withstand

6.1 General

In this clause guidance is given on how to correctly perform the testing of the insulation

resistance and the dielectric withstand of SPDs:

– between live parts and the SPD’s body,

– between electrically separated circuits,

– between live parts of the SPD´s main circuits and live parts of any electrically separated

circuit(s)

– between live parts of different electrically separated circuit(s)

6.2 Surfaces which are touchable after installation as for normal use are as follows:

Normal use means:

Built in an enclosure including a cover.

– only the yellow marked surfaces are

touchable

– 20 – IEC TR 61643-03:2024 © IEC 2024

6.3 Surfaces on which the SPD can be mounted or it can be in contact with metal

surfaces:

The SPD can be installed in a metallic

cabinet or casing

– red marked surfaces can be of

metal or conductive material

The cover could also be metallic or

conductive

– red marked surfaces of the SPD can

be in contact with metallic or

conductive parts

6.4 Conclusions:

“Body” includes the red + yellow marked

surfaces and the mounting surface.

The red + yellow marked surfaces are

covered with metal foil for testing.

The metal foil also covers screw holes,

but the foil is not pushed into the holes

during the application of the test finger

Sufficient distance is kept between the

metal foil and the live terminal

entrance(s) to ensure that no flashover

occurs during testing.

The mounting surface including any

recessed surface for mounting rails, or

similar, are also covered with foil.

The PE terminal is connected to the metal

foil.

– 22 – IEC TR 61643-03:2024 © IEC 2024

6.5 Example of a test-set-up to measure the Insulation Resistance according to 9.3.7

and the Dielectric Withstand according to 9.3.8 of IEC 61643-01:—

Test according to 9.3.7.2, item a) of

IEC 61643-01:—

Between all interconnected live parts of

the SPD’s main circuit(s) (all terminals

being connected together, but excluding

the PE, PEN or PEM

terminals/connections) and the SPD’s

body.

Test according to 9.3.7.2, item b) of

IEC 61643-01:—

Between all interconnected live parts

from each electrically separated circuit,

if there is any, and the SPDs body.

Test according to 9.3.7.2, item c) of

IEC 61643-01:—

between all interconnected live parts of

the SPD’s main circuit(s) (all terminals

being connected together, but excluding

the PE, PEN or PEM

terminals/connections) and all

interconnected live parts of each

electrically separated circuit, if there are

any.

Test according to 9.3.7.2, item d) of

IEC 61643-01:—

between all interconnected live parts of

any electrically separated circuit and all

interconnected live parts of all other

electrically separated circuits, if there is

more than one.

NOTE R /U insulation resistance test equipment

iso ac

7 TOV testing

7.1 TOV testing of SPDs for AC power systems

Figure 13 provides additional examples of test setups to IEC 61643-11 for use in testing SPDs

for application in TT systems and for testing TOVs caused by faults in the high (medium) voltage

system.

– 24 – IEC TR 61643-03:2024 © IEC 2024

Figure 13 – Examples of a three-phase and single-phase test setup for use in testing

SPDs for application in TT systems under TOVs caused by faults in the high (medium)

voltage system

Figure 14 provides an additional example of a test setup to IEC 61643-11 for use in testing

SPDs for application in IT systems and for testing TOVs caused by faults in the high (medium)

voltage system. Figure 15 provides the corresponding vector diagram for the voltages in this

test setup.

Figure 14 – Example of a three-phase test setup for use in testing SPDs for use in IT

systems under TOVs caused by faults in the high (medium) voltage system

The earthing point for the example test setup is choosen to be located in phase L2 for

measurement reference purposes and for protection considerations, to ensure that no point of

the test setup exceeds 1 200 V RMS to earth. This earthing point may in principle be choosen

anywhere depending on laboratory system configuration, but may have an influence on

measurement setup.

This earthing point for the test setup has no relation to the earth fault simulation provided by

the test setup.

– 26 – IEC TR 61643-03:2024 © IEC 2024

Figure 15 – Vector diagram for the voltages in the test setup in Figure 14

7.2 TOV testing of SPDs for DC power systems

Figure 16 provides an example of a test setup to IEC 61643-41:— for use in testing SPDs

intended to be connected to a DC system, which is derived from an AC TT system without

separation, under TOVs caused by faults in the high (medium) voltage system.

Figure 16 – Example of a test setup for use in testing SPDs intended to be connected to

a DC system, which is derived from an AC TT system without separation, under TOVs

caused by faults in the high (medium) voltage system

Figure 17 provides an example of a test setup to IEC 61643-41:— for use in testing SPDs

intended to be connected to a DC TT system, which is derived from another earthed DC system,

under TOVs caused by faults in the high (medium) voltage system.

Figure 17 – Example of a test setup for use in testing SPDs intended to be connected to

a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...