IEC 62381:2024

(Main)Automation systems in the process industry - Factory acceptance test (FAT), site acceptance test (SAT), and site integration test (SIT)

Automation systems in the process industry - Factory acceptance test (FAT), site acceptance test (SAT), and site integration test (SIT)

IEC 62381:2024 defines requirements and checklists for the factory acceptance test (FAT), the factory integration test (FIT), the site acceptance test (SAT), and the site integration test (SIT). These tests are carried out to demonstrate that the automation system meets the requirements of the applicable specification. This document provides a means for all parties, including the owner, the buyer, and the vendor, to clearly establish and agree on the scope of activities and responsibilities involved in performing these tests in order to achieve a timely delivery and acceptance of the automation system. The activities specified in this document can be used to develop test plans adapted to the specific requirements of the process/plant/equipment. The annexes of this document contain checklists which are available for consideration when preparing specific test procedures and documentation for a specific automation system.

This edition includes the following significant technical changes with respect to the previous edition:

a) General re-organization of the standard;

b) Current technology incorporated;

c) Optional factory integration test (FIT) added;

d) Replaced the forms in the annexes with detailed checklists of activities which can be used to develop project-specific test plans; and

e) Provided additional references to other applicable standards.

Systèmes d'automatisation dans l’industrie de transformation - Essais d'acceptation en usine (FAT), essais d'acceptation sur site (SAT) et essais d'intégration sur site (SIT)

L'IEC 62381:2024 définit les exigences et les listes de contrôle pour les essais d'acceptation en usine (FAT – factory acceptance test), les essais d’intégration en usine (FIT – factory integration test), les essais d'acceptation sur site (SAT – site acceptance test) et les essais d'intégration sur site (SIT – site integration test). Ces essais sont réalisés pour démontrer que le système d'automatisation satisfait aux exigences de la spécification applicable. Le présent document a pour objet de permettre à toutes les parties, y compris le maître d’ouvrage, l’acheteur et le fournisseur, de définir clairement et de convenir de l’étendue des activités et des responsabilités liées à l'exécution de ces essais, afin de finaliser la livraison et l'acceptation des systèmes d’automatisation dans les délais prévus. Les activités décrites dans le présent document peuvent être utilisées pour élaborer des plans d’essai adaptés aux exigences spécifiques du processus, de l'usine ou de l'équipement. Les annexes du présent document contiennent des listes de contrôle qui peuvent être prises en considération lors de l’élaboration des procédures et documents d’essai spécifiques pour un système d’automatisation particulier.

Les principales modifications par rapport à l'édition précédente sont les suivantes:

a) réorganisation générale de la norme;

b) intégration de la technologie actuelle;

c) ajout d’un essai d’intégration en usine (FIT) facultatif;

d) remplacement des formulaires dans les annexes par des listes de contrôle détaillées d’activités qui peuvent être utilisées pour élaborer des plans d’essai spécifiques à un projet; et

e) ajout de références supplémentaires à d’autres normes applicables.

General Information

- Status

- Published

- Publication Date

- 29-Jul-2024

- Technical Committee

- SC 65E - Devices and integration in enterprise systems

- Drafting Committee

- WG 3 - TC 65/SC 65E/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-Jul-2024

- Completion Date

- 16-Aug-2024

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62381:2024 is an international standard established by the International Electrotechnical Commission (IEC) that sets forth comprehensive requirements and checklists for accepting automation systems in the process industry. This latest edition focuses on the systematic execution of key tests including Factory Acceptance Test (FAT), Factory Integration Test (FIT), Site Acceptance Test (SAT), and Site Integration Test (SIT). By defining clear roles, responsibilities, and procedures, IEC 62381:2024 aims to ensure automation systems meet specified performance criteria, enabling timely delivery and acceptance.

The document serves as a practical guide for owners, buyers, vendors, and other stakeholders involved in automation projects. It provides adaptable methodologies to develop project-specific test plans tailored to process, plant, or equipment requirements. Significant updates in this edition include reorganization for clarity, incorporation of current technologies, introduction of the optional FIT, enhanced detailed checklists replacing former forms, and references to additional relevant standards.

Key Topics

Factory Acceptance Test (FAT)

FAT verifies that the automation system meets design and functional requirements prior to shipment. It involves vendor tests, thorough documentation review, test plan preparation, and execution of defined tests. Key outcomes include punch lists and corrective actions ensuring system readiness.Factory Integration Test (FIT)

FIT, newly introduced in this edition, assesses the integration of system components in a factory environment. This optional test verifies interoperability and functional integrity before delivery to the site.Site Acceptance Test (SAT)

SAT confirms the system's operational performance after installation at the customer site. It incorporates pre-SAT preparations such as scheduling, test plan finalization, and validating system functionality in the operational context.Site Integration Test (SIT)

SIT evaluates the system's integration with other site automation or control systems. This test ensures communication, coordination, and overall process automation functionality are optimized once installed.Test Documentation and Reporting

Each testing phase requires precise documentation including test plans, schedules, punch lists, reports, and final acceptance documents. These facilitate transparency, traceability, and agreement among all parties.Adaptable Test Planning

The standard emphasizes flexibility, allowing modification of test plans in response to project-specific changes, system upgrades, and integration complexities.

Applications

IEC 62381:2024 is essential for all stakeholders in the process industry involved in automation system procurement, installation, commissioning, and validation. Its application extends to:

- Chemical, petrochemical, and refining plants ensuring automated system compliance and quality.

- Automation vendors establishing contractually agreed test scopes and procedures.

- Plant owners and operators validating system readiness and operational reliability.

- Engineering companies developing test methodologies consistent with industry best practices.

- Quality assurance teams aiming for systematic acceptance criteria and mitigation of defects.

The standard supports optimized delivery schedules and risk mitigation by defining clear acceptance criteria and testing protocols, which directly contribute to minimizing operational downtime and costly post-installation failures.

Related Standards

IEC 62381:2024 should be used in conjunction with other relevant international standards to ensure comprehensive automation system compliance, including but not limited to:

- IEC 61508 series – Functional safety of electrical/electronic/programmable electronic safety-related systems.

- IEC 61131 series – Programmable controllers for industrial control systems.

- IEC 62443 series – Security for industrial automation and control systems.

- ISO 9001 – Quality management systems, applicable to process management.

- ISA-95 – Enterprise-control system integration for manufacturing operations.

By integrating IEC 62381:2024 with these and other standards, organizations can achieve holistic project governance encompassing safety, quality, security, and functional reliability.

Keywords: IEC 62381, Factory Acceptance Test, FAT, Factory Integration Test, FIT, Site Acceptance Test, SAT, Site Integration Test, SIT, process industry automation, automation system testing, acceptance criteria, automation standards, system validation, industrial automation.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

IEC 62381:2024 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Automation systems in the process industry - Factory acceptance test (FAT), site acceptance test (SAT), and site integration test (SIT)". This standard covers: IEC 62381:2024 defines requirements and checklists for the factory acceptance test (FAT), the factory integration test (FIT), the site acceptance test (SAT), and the site integration test (SIT). These tests are carried out to demonstrate that the automation system meets the requirements of the applicable specification. This document provides a means for all parties, including the owner, the buyer, and the vendor, to clearly establish and agree on the scope of activities and responsibilities involved in performing these tests in order to achieve a timely delivery and acceptance of the automation system. The activities specified in this document can be used to develop test plans adapted to the specific requirements of the process/plant/equipment. The annexes of this document contain checklists which are available for consideration when preparing specific test procedures and documentation for a specific automation system. This edition includes the following significant technical changes with respect to the previous edition: a) General re-organization of the standard; b) Current technology incorporated; c) Optional factory integration test (FIT) added; d) Replaced the forms in the annexes with detailed checklists of activities which can be used to develop project-specific test plans; and e) Provided additional references to other applicable standards.

IEC 62381:2024 defines requirements and checklists for the factory acceptance test (FAT), the factory integration test (FIT), the site acceptance test (SAT), and the site integration test (SIT). These tests are carried out to demonstrate that the automation system meets the requirements of the applicable specification. This document provides a means for all parties, including the owner, the buyer, and the vendor, to clearly establish and agree on the scope of activities and responsibilities involved in performing these tests in order to achieve a timely delivery and acceptance of the automation system. The activities specified in this document can be used to develop test plans adapted to the specific requirements of the process/plant/equipment. The annexes of this document contain checklists which are available for consideration when preparing specific test procedures and documentation for a specific automation system. This edition includes the following significant technical changes with respect to the previous edition: a) General re-organization of the standard; b) Current technology incorporated; c) Optional factory integration test (FIT) added; d) Replaced the forms in the annexes with detailed checklists of activities which can be used to develop project-specific test plans; and e) Provided additional references to other applicable standards.

IEC 62381:2024 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62381:2024 has the following relationships with other standards: It is inter standard links to IEC 62381:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62381:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62381 ®

Edition 3.0 2024-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Automation systems in the process industry –

Factory acceptance test (FAT), site acceptance test (SAT), and site integration

test (SIT)

Systèmes d'automatisation dans l’industrie de transformation –

Essais d'acceptation en usine (FAT), essais d'acceptation sur site (SAT) et

essais d'intégration sur site (SIT)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications, symboles

La recherche avancée permet de trouver des publications IEC graphiques et le glossaire. Avec un abonnement, vous aurez

en utilisant différents critères (numéro de référence, texte, toujours accès à un contenu à jour adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 500 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 25 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

IEC 62381 ®

Edition 3.0 2024-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Automation systems in the process industry –

Factory acceptance test (FAT), site acceptance test (SAT), and site integration

test (SIT)

Systèmes d'automatisation dans l’industrie de transformation –

Essais d'acceptation en usine (FAT), essais d'acceptation sur site (SAT) et

essais d'intégration sur site (SIT)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 25.040.40 ISBN 978-2-8322-9418-5

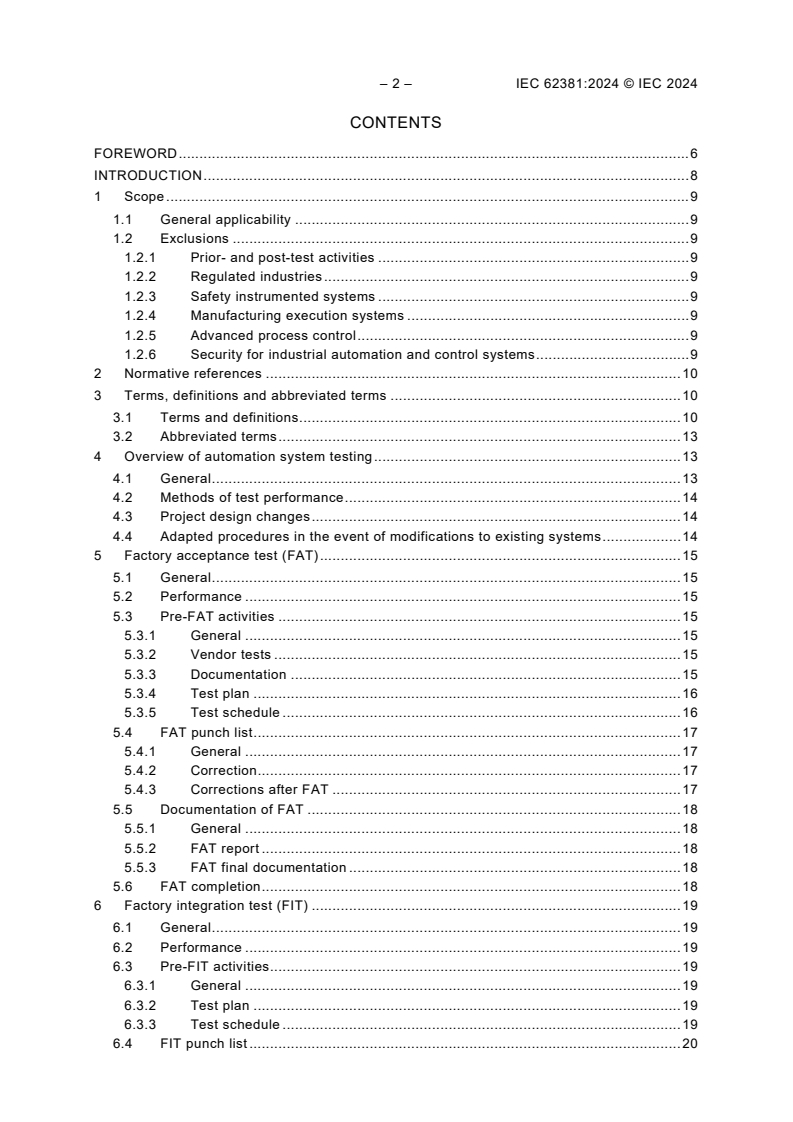

– 2 – IEC 62381:2024 © IEC 2024

CONTENTS

FOREWORD . 6

INTRODUCTION . 8

1 Scope . 9

1.1 General applicability . 9

1.2 Exclusions . 9

1.2.1 Prior- and post-test activities . 9

1.2.2 Regulated industries . 9

1.2.3 Safety instrumented systems . 9

1.2.4 Manufacturing execution systems . 9

1.2.5 Advanced process control . 9

1.2.6 Security for industrial automation and control systems . 9

2 Normative references . 10

3 Terms, definitions and abbreviated terms . 10

3.1 Terms and definitions . 10

3.2 Abbreviated terms . 13

4 Overview of automation system testing . 13

4.1 General . 13

4.2 Methods of test performance . 14

4.3 Project design changes . 14

4.4 Adapted procedures in the event of modifications to existing systems . 14

5 Factory acceptance test (FAT) . 15

5.1 General . 15

5.2 Performance . 15

5.3 Pre-FAT activities . 15

5.3.1 General . 15

5.3.2 Vendor tests . 15

5.3.3 Documentation . 15

5.3.4 Test plan . 16

5.3.5 Test schedule . 16

5.4 FAT punch list . 17

5.4.1 General . 17

5.4.2 Correction . 17

5.4.3 Corrections after FAT . 17

5.5 Documentation of FAT . 18

5.5.1 General . 18

5.5.2 FAT report . 18

5.5.3 FAT final documentation . 18

5.6 FAT completion . 18

6 Factory integration test (FIT) . 19

6.1 General . 19

6.2 Performance . 19

6.3 Pre-FIT activities . 19

6.3.1 General . 19

6.3.2 Test plan . 19

6.3.3 Test schedule . 19

6.4 FIT punch list . 20

6.4.1 General . 20

6.4.2 Correction . 20

6.4.3 Correction after FIT . 20

6.5 Documentation of FIT. 21

6.5.1 General . 21

6.5.2 FIT report . 21

6.5.3 FIT final documentation . 21

6.6 FIT completion . 21

7 Site acceptance test (SAT) . 21

7.1 Performance . 21

7.2 Pre-SAT activities . 22

7.2.1 General . 22

7.2.2 Test plan . 22

7.2.3 Test schedule . 23

7.3 SAT punch list . 23

7.3.1 General . 23

7.3.2 Correction . 23

7.3.3 Correction after SAT . 23

7.4 Documentation of SAT . 24

7.4.1 General . 24

7.4.2 SAT report . 24

7.4.3 SAT final documentation . 24

7.5 SAT completion . 24

8 Site integration test (SIT) . 24

8.1 Performance . 24

8.2 Pre-SIT activities . 25

8.2.1 General . 25

8.2.2 Test plan . 25

8.2.3 Test schedule . 25

8.3 SIT punch list . 26

8.3.1 General . 26

8.3.2 Correction . 26

8.3.3 Correction after SIT . 26

8.4 Documentation of SIT . 27

8.4.1 General . 27

8.4.2 SIT report . 27

8.4.3 SIT final documentation . 27

8.5 SIT completion . 27

Annex A (informative) Factory acceptance testing checklist . 28

A.1 General . 28

A.2 Assemble documentation . 28

A.2.1 General . 28

A.2.2 User requirements specification . 28

A.2.3 Functional requirements specification . 28

A.2.4 Information to vendor . 29

A.2.5 Vendor documentation . 29

A.3 Develop a written test plan and specification . 29

A.3.1 General . 29

A.3.2 Documentation . 29

– 4 – IEC 62381:2024 © IEC 2024

A.3.3 Hardware/software inventory . 30

A.3.4 Mechanical inspection . 30

A.3.5 Wiring and termination inspection . 30

A.3.6 Start-up, shut-down and re-start test and general system functions . 30

A.3.7 System alarm test . 31

A.3.8 Hardware redundancy and diagnostics (including fail and changeover of

redundant units) . 31

A.3.9 Operator interface . 31

A.3.10 Engineering workstation functionality . 31

A.3.11 User management . 32

A.3.12 Network and system security . 32

A.3.13 Test I/O to the operator display. 32

A.3.14 Complete I/O tests . 33

A.3.15 Bus interfaces. 33

A.3.16 Intelligent field devices . 33

A.3.17 FAT open item . 33

A.3.18 Test of communication links to subsystems . 34

A.3.19 Application programming . 34

A.3.20 Check of other system functions . 34

A.4 Develop a test schedule . 35

A.5 FAT certificate . 35

Annex B (informative) Site acceptance testing checklist . 36

B.1 General . 36

B.2 Develop a written test plan and specification . 36

B.2.1 General . 36

B.2.2 Documentation . 36

B.2.3 Hardware/software inventory . 36

B.2.4 Mechanical inspection . 36

B.2.5 Wiring and terminal inspection . 37

B.2.6 System energization . 37

B.2.7 Hardware redundancy and diagnostics . 37

B.2.8 Operator interface . 37

B.2.9 Network and system security . 37

B.2.10 I/O test . 37

B.2.11 Bus interfaces. 37

B.2.12 Intelligent field devices . 37

B.2.13 Application programming . 38

B.3 Develop a test schedule . 38

B.4 SAT certificate . 38

Annex C (informative) Site integration testing checklist . 39

C.1 General . 39

C.2 Develop a written test plan and specification . 39

C.2.1 General . 39

C.2.2 Documentation . 39

C.2.3 Visual inspection . 39

C.2.4 Communications . 39

C.2.5 Operator interface . 39

C.2.6 Hardwired I/O . 40

C.2.7 Functionality . 40

C.3 Develop a test schedule . 40

C.4 SIT certificate . 40

Bibliography . 41

Figure 1 – Project phases and E&I testing . 14

Table A.1 – Test schedule . 35

Table B.1 – Test schedule . 38

Table C.1 – Test schedule . 40

– 6 – IEC 62381:2024 © IEC 2024

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

AUTOMATION SYSTEMS IN THE PROCESS INDUSTRY –

FACTORY ACCEPTANCE TEST (FAT), SITE ACCEPTANCE TEST (SAT),

AND SITE INTEGRATION TEST (SIT)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 62381 has been prepared by subcommittee 65E: Devices and integration in enterprise

systems, of IEC technical committee 65: Industrial-process measurement, control and

automation. It is an International Standard.

This third edition cancels and replaces the second edition published in 2012. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) General re-organization of the standard;

b) Current technology incorporated;

c) Optional factory integration test (FIT) added;

d) Replaced the forms in the annexes with detailed checklists of activities which can be used

to develop project-specific test plans; and

e) Provided additional references to other applicable standards.

The text of this International Standard is based on the following documents:

Draft Report on voting

65E/1080/FDIS 65E/1092/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

– 8 – IEC 62381:2024 © IEC 2024

INTRODUCTION

There is an increasing trend in the process industry to shorten the time period for project

execution. At the same time, the complexity of automation systems is being increased due to

the number of connected systems and the use of new technologies, for example, wired and

wireless field sensor networks.

Experience has shown that the owner, the buyer and the vendor have long and extensive

discussions to unambiguously establish the scope of activities and responsibilities in order to

achieve timely delivery and acceptance of automation systems.

This document provides requirements and guidance on acceptance testing of control system

installations, which can lead to a mutual understanding about the scope of activities of each

party.

AUTOMATION SYSTEMS IN THE PROCESS INDUSTRY –

FACTORY ACCEPTANCE TEST (FAT), SITE ACCEPTANCE TEST (SAT),

AND SITE INTEGRATION TEST (SIT)

1 Scope

1.1 General applicability

This International Standard defines requirements and checklists for the factory acceptance test

(FAT), the factory integration test (FIT), the site acceptance test (SAT), and the site integration

test (SIT). These tests are carried out to demonstrate that the automation system meets the

requirements of the applicable specification.

This document provides a means for all parties, including the owner, the buyer, and the vendor,

to clearly establish and agree on the scope of activities and responsibilities involved in

performing these tests in order to achieve a timely delivery and acceptance of the automation

system. The activities specified in this document can be used to develop test plans adapted to

the specific requirements of the process/plant/equipment.

The annexes of this document contain checklists which are available for consideration when

preparing specific test procedures and documentation for a specific automation system.

1.2 Exclusions

1.2.1 Prior- and post-test activities

Engineering and manufacturing activities prior to or after the FAT, FIT, SAT and SIT, such as

loop checks and commissioning, are not covered by this document.

1.2.2 Regulated industries

For applications in the pharmaceutical or other highly specialized industries, additional

guidelines (for example, good automated manufacturing practice (GAMP)), definitions and

stipulations apply in accordance with other applicable existing standards.

1.2.3 Safety instrumented systems

The user can utilize this document to develop necessary testing for basic checks of a safety

system, however, this document does not cover validation of a safety system. IEC 61511

provides requirements for checks and validation of safety instrumented systems.

1.2.4 Manufacturing execution systems

Testing and verification of manufacturing execution systems (MES) is not covered by this

document.

1.2.5 Advanced process control

Testing and verification of advanced process control (APC) is not covered by this document.

1.2.6 Security for industrial automation and control systems

Although this document includes a limited number of network checks, it does not cover complete

network and system security. IEC 62443 provides requirements for automation and control

systems cyber security.

– 10 – IEC 62381:2024 © IEC 2024

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62382, Control systems in the process industry – Electrical and instrumentation loop check

3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1.1

advanced process control

APC

several tools and techniques whose common characteristic is taking process automation

beyond the limits of single-loop control

Note 1 to entry: APC includes model-based software that is used to direct the process operation and is commonly

referred to as multivariable predictive control or model predictive control.

3.1.2

automation system

complete system for the monitoring and control of production facilities

Note 1 to entry: An automation system can include a BPCS and can also include a SIS and other subsystems.

3.1.3

basic process control system

BPCS

system which responds to input signals from the process, its associated equipment, other

programmable systems and/or operators and generates output signals causing the process and

its associated equipment to operate in the desired manner but which does not perform any SIF

Note 1 to entry: A BPCS includes all of the devices necessary to ensure that the process operates in the desired

manner.

Note 2 to entry: A BPCS typically can implement various functions such as process control functions, monitoring,

and alarms.

[SOURCE: IEC 61511-1:2016, 3.2.3]

3.1.4

buyer

company purchasing the equipment or control system from the vendor

Note 1 to entry: The buyer can be the owner of the equipment or control system, or the buyer can be another

company.

3.1.5

cold commissioning

phase, during which the activities associated with the testing and operation of equipment or

facilities using test media such as water or inert substances prior to introducing any chemical

in the system take place

3.1.6

control system

system which responds to input signals from the process and/or from an operator and generates

output signals causing the process to operate in the desired manner

Note 1 to entry: The control system includes sensors and final elements and can be either a BPCS or a SIS or a

combination of the two.

[SOURCE: IEC 61511-1:2016, 3.2.10]

3.1.7

detailed design specification

separate document that shows how the system functions and meets the requirements

established in the functional requirements specification

3.1.8

factory acceptance test

FAT

activity, including inspection and testing, to demonstrate that the automation system,

subsystem, or component is in accordance with the specification and is typically conducted at

the vendor's facility

3.1.9

factory integration test

FIT

activity, including inspection and testing, conducted at the vendor's facility to demonstrate that

the merging of some or all of the various subsystems and components into one overall

automation system functions in accordance with the specification

3.1.10

functional requirements specification

FRS

specification listing the detailed operational requirements for a control system (i.e., what the

system does, not how it does it)

3.1.11

hot commissioning

phase during which the activities associated with the testing and operation of equipment or

facilities using the actual chemical process prior to making an actual production run take place

3.1.12

manufacturing execution system

MES

computerized system used in manufacturing to track and document the transformation of raw

materials to finished goods

3.1.13

owner

company that operates the production facilities where the automation system is or will be

installed

– 12 – IEC 62381:2024 © IEC 2024

3.1.14

precommissioning

phase during which the activities of non-operating adjustments, cold alignment checks,

cleaning, and testing of machinery take place

3.1.15

process industry

industry that has a continuous or batch flow and uses chemical reactions, separations, or mixing

techniques in order to create new products, modify existing products or treat waste, and

includes the following types of industries: chemical, petrochemical, water and wastewater

treatment, paper, cement, etc.

Note 1 to entry: Process industry does not include such industries as equipment/machine manufacturing or other

similar industries. It does not include industries which are subject to regulations which have specialized validation

requirements.

3.1.16

punch list

list of all problems found, the corrective action to be taken, party responsible and date

completed

Note 1 to entry: Other information categories can be added as required.

3.1.17

safety instrumented function

SIF

safety function to be implemented by a safety instrumented system (SIS)

[SOURCE: IEC 61511-1:2016, 3.2.66]

3.1.18

safety instrumented system

SIS

instrumented system used to implement one or more SIFs

Note 1 to entry: A SIS is composed of any combination of sensor(s), logic solver(s), and final element(s) (e.g., see

Figure 6 of IEC 61511:2016). It also includes communication and ancillary equipment (e.g., cables, tubing, power

supply, impulse lines, heat tracing).

Note 2 to entry: A SIS can include software.

Note 3 to entry: A SIS can include human action as part of a SIF.

[SOURCE: IEC 61511-1:2016, 3.2.67, modified – Figure 6 and reference to ISA

TR84.00.04:2015 part 1 have been omitted.]

3.1.19

site acceptance test

SAT

activity, including inspection and testing, conducted at the site of the installation, to demonstrate

that the installation of the automation system, any subsystem, or any component is in

accordance with the applicable standards, codes, specifications, and installation instructions

3.1.20

site integration test

SIT

activity, including inspection and testing, conducted at the site of the installation, to demonstrate

that the merging of the various subsystems and components into one overall automation system

is completed and that all components work together in accordance with the specification

3.1.21

tag

unique identifier assigned to a process measurement, calculation, or device within the

automation system

3.1.22

user requirements specification

URS

document that defines the user's (owner's) requirements for the automation system

3.1.23

vendor

manufacturer, distributor, or systems integrator of the automation system, subsystem, or

component

3.2 Abbreviated terms

The following abbreviated terms are used (for terms not otherwise defined in this Clause 3):

DCS Distributed control system

E&I Electrical and instrumentation

ERP Enterprise resource planning

HMI Human machine interface

I/O Input and output

P&ID Piping (or process) and instrumentation diagram

PLC Programmable logic controller

UPS Uninterruptible power supply

4 Overview of automation system testing

4.1 General

An automation system is to be tested at various stages in its development and implementation.

Each new automation system shall be subjected to three tests to demonstrate proper operation

in accordance with project-specific requirements: factory acceptance test (FAT), site

acceptance test (SAT) and site integration test (SIT). Loop tests shall be performed in

accordance with IEC 62382, which typically occur after SIT. All these tests shall be completed,

with any open items documented and agreed upon by all parties involved in the tests, prior to

the system being placed in operation. An optional fourth test, factory integration test (FIT) can

also be performed on all or part of the system while at the vendor's factory.

The typical order of execution of these tests is:

• The factory acceptance test (FAT) is performed on the automation system, subsystem or

component before it leaves the vendor's factory to demonstrate that it functions in

accordance with the project-specific requirements.

• The factory integration test (FIT) is a fourth, optional testing point to demonstrate that the

merging of some or all the various subsystems and components function as specified. This

test is performed after or in conjunction with the FAT, before the automation system,

subsystem or component leaves the vendor's factory.

• The site acceptance test (SAT) is performed after installation on site to demonstrate the

automation system, subsystem, or component is in accordance with the applicable

standards, codes, specifications, and installation instructions. This test is performed after

each subsystem is installed.

– 14 – IEC 62381:2024 © IEC 2024

• The site integration test (SIT) is performed after the SAT to demonstrate that the merging

of the various subsystems and components into one overall automation system is complete

and that all subsystems and components work together as specified in the test plan. This

test can be performed on two or more subsystems or components after each has been

installed and successfully completed a SAT or after all subsystems and components have

been installed and successfully completed a SAT.

Figure 1 provides a general illustration of a portion of the timeline of a project from construction

to production and when the above tests occur. The industry and the specifics of a project can

vary the relative timing of each test.

Figure 1 – Project phases and E&I testing

4.2 Methods of test performance

This document provides checklists for developing test plans for the automation system.

Traditionally, these tests are performed using manual methods. With modern systems, these

tests can also be performed using automated methods, depending on the system's capability.

If automated methods are used, it is the vendor's responsibility to demonstrate that the

automated tests completely cover all aspects of the test plan and are validated.

4.3 Project design changes

Changes made to the project design during or at any time after FAT, whether to the detailed

design scope or as a correction/adjustment made during testing, s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...