IEC 62841-2-16:2024

(Main)Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-16: Particular requirements for hand-held fastener driving tools

Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-16: Particular requirements for hand-held fastener driving tools

IEC 62841-2-16:2024 is to be used in conjunction with IEC 62841-1:2014. This document supplements or modifies the corresponding clauses in IEC 62841-1, so as to convert it into the IEC Standard: Particular requirements for hand-held fastener driving tools. Where a particular subclause of IEC 62841-1 is not mentioned in this document, that subclause applies as far as reasonable. Where this document states "addition", "modification" or "replacement", the relevant text in IEC 62841-1 is to be adapted accordingly.

IEC 62841-1:2014, Clause 1 is applicable, except as follows:

Addition: This document applies to hand-held fastener driving tools

- intended for driving fasteners into or through concrete, fabric, fiberboard, metal, plastic, wood, wood products, cartons, and other materials; and

- whose energy to drive the fastener is derived directly or indirectly from an electric motor or magnetic drive.

This document does not apply to pneumatically driven tools where the compressed gas comes from an external source, such as a compressor or a tank.

This document does not apply to tools powered by combustible gases, even if electrically ignited.

NOTE 101 Tools powered by compressed air or combustible gases are covered by ISO 11148-13:2017.

Outils électroportatifs à moteur, outils portables et machines pour jardins et pelouses - Sécurité - Partie 2-16: Exigences particulières pour les machines à enfoncer les fixations portatives

L'IEC 62841-2-16:2024 doit être utilisé conjointement avec l'IEC 62841-1:2014. Le présent document complète ou modifie les articles correspondants de l'IEC 62841-1 de façon à la transformer en norme IEC: Exigences particulières pour les machines à enfoncer les fixations portatives. Lorsqu'un paragraphe particulier de l'IEC 62841-1 n'est pas mentionné dans le présent document, ce paragraphe s'applique pour autant que cela soit raisonnable. Lorsque le présent document mentionne "addition", "modification" ou "remplacement", le texte correspondant de l'IEC 62841-1 doit être adapté en conséquence.

L'Article 1 de l'IEC 62841-1:2014 s'applique, avec l'exception suivante:

Addition:

Le présent document s'applique aux machines à enfoncer les fixations portatives:

conçues pour enfoncer des fixations dans du béton, du tissu, des panneaux de fibres, du métal, du plastique, du bois, des produits en bois, du carton et d'autres matériaux; et

dont l'énergie utilisée pour enfoncer la fixation est produite directement ou indirectement par un moteur électrique ou un système d'entraînement magnétique.

Le présent document ne s'applique pas aux outils à entraînement pneumatique pour lesquels le gaz comprimé provient d'une source externe telle qu'un compresseur ou un réservoir.

Le présent document ne s'applique pas non plus aux outils qui fonctionnent aux gaz combustibles, même à allumage électrique.

General Information

- Status

- Published

- Publication Date

- 16-Feb-2026

- Technical Committee

- TC 116 - Safety of motor-operated electric tools

- Drafting Committee

- WG 8 - TC 116/WG 8

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Jun-2024

- Completion Date

- 19-Jul-2024

Relations

- Effective Date

- 26-Oct-2025

Overview - IEC 62841-2-16:2024 (Hand-held fastener driving tools)

IEC 62841-2-16:2024 is an IEC safety standard that supplements IEC 62841-1:2014 and provides the particular requirements for hand-held fastener driving tools whose driving energy is derived directly or indirectly from an electric motor or magnetic drive. It covers tools intended to drive fasteners into or through concrete, fabric, metal, wood, plastics and other materials. The document explicitly excludes pneumatically driven tools with external compressed-gas sources and tools powered by combustible gases (see ISO 11148-13:2017 for those).

Key topics and technical requirements

This part of the IEC 62841 series focuses on safety, construction and verification for electric fastener drivers. Major technical topics include:

- Scope & classification - definition of hand-held fastener driving tools and permitted operating modes.

- Marking and instructions - required labels, warnings and user documentation.

- Electrical safety - protection against access to live parts, starting controls, input/current limits, grounding/earthing provisions, internal wiring and terminals.

- Thermal & fire resistance - heating limits, resistance to heat and fire, and temperature-rise requirements.

- Environmental resistance - moisture resistance and resistance to rusting.

- Mechanical safety - mechanical hazards, mechanical strength, switch and trigger force, test torques and impact energy requirements.

- Endurance and abnormal operation tests - durability, overload, leakage current and electric strength tests.

- Creepage, clearances & insulation - minimum distances, measurement methods and annex guidance.

- Battery tool requirements - normative annexes cover battery tools, battery packs, and tools with non-isolated sources or mains connections.

- Measurement guidance - noise and vibration measurement procedures are provided in informative annexes.

Annexes include normative procedures (leakage current, electric strength, battery tool tests) and informative guidance (applying ISO 13849-1 for safety-related controls, noise and vibration testing).

Practical applications - who uses IEC 62841-2-16:2024

This standard is used by:

- Manufacturers and designers of electric hand-held fastener driving tools to design compliant, safe products.

- Test laboratories and certification bodies conducting conformity assessment and type testing.

- Safety engineers and compliance officers preparing risk assessments, user manuals and labeling.

- Procurement and OEMs specifying product safety requirements for purchase and integration.

Practical benefits include safer product design, consistent test methods for endurance, electrical and mechanical hazards, and clear requirements for battery-powered tools.

Related standards

- IEC 62841-1:2014 - General requirements (to be used in conjunction).

- ISO 11148-13:2017 - Fastener tools powered by compressed air/combustible gases.

- ISO 13849-1 - Referenced for safety-related control systems (see Annex E).

Keywords: IEC 62841-2-16:2024, hand-held fastener driving tools, electric motor-operated tools, safety standard, battery tools, creepage distances, leakage current, mechanical hazards.

Buy Documents

IEC 62841-2-16:2024 EXV - Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-16: Particular requirements for hand-held fastener driving tools Released:6/27/2024

IEC 62841-2-16:2024+AMD1:2026 CSV - Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-16: Particular requirements for hand-held fastener driving tools

IEC 62841-2-16:2024 - Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-16: Particular requirements for hand-held fastener driving tools Released:6/27/2024

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

IEC 62841-2-16:2024 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric motor-operated hand-held tools, transportable tools and lawn and garden machinery - Safety - Part 2-16: Particular requirements for hand-held fastener driving tools". This standard covers: IEC 62841-2-16:2024 is to be used in conjunction with IEC 62841-1:2014. This document supplements or modifies the corresponding clauses in IEC 62841-1, so as to convert it into the IEC Standard: Particular requirements for hand-held fastener driving tools. Where a particular subclause of IEC 62841-1 is not mentioned in this document, that subclause applies as far as reasonable. Where this document states "addition", "modification" or "replacement", the relevant text in IEC 62841-1 is to be adapted accordingly. IEC 62841-1:2014, Clause 1 is applicable, except as follows: Addition: This document applies to hand-held fastener driving tools - intended for driving fasteners into or through concrete, fabric, fiberboard, metal, plastic, wood, wood products, cartons, and other materials; and - whose energy to drive the fastener is derived directly or indirectly from an electric motor or magnetic drive. This document does not apply to pneumatically driven tools where the compressed gas comes from an external source, such as a compressor or a tank. This document does not apply to tools powered by combustible gases, even if electrically ignited. NOTE 101 Tools powered by compressed air or combustible gases are covered by ISO 11148-13:2017.

IEC 62841-2-16:2024 is to be used in conjunction with IEC 62841-1:2014. This document supplements or modifies the corresponding clauses in IEC 62841-1, so as to convert it into the IEC Standard: Particular requirements for hand-held fastener driving tools. Where a particular subclause of IEC 62841-1 is not mentioned in this document, that subclause applies as far as reasonable. Where this document states "addition", "modification" or "replacement", the relevant text in IEC 62841-1 is to be adapted accordingly. IEC 62841-1:2014, Clause 1 is applicable, except as follows: Addition: This document applies to hand-held fastener driving tools - intended for driving fasteners into or through concrete, fabric, fiberboard, metal, plastic, wood, wood products, cartons, and other materials; and - whose energy to drive the fastener is derived directly or indirectly from an electric motor or magnetic drive. This document does not apply to pneumatically driven tools where the compressed gas comes from an external source, such as a compressor or a tank. This document does not apply to tools powered by combustible gases, even if electrically ignited. NOTE 101 Tools powered by compressed air or combustible gases are covered by ISO 11148-13:2017.

IEC 62841-2-16:2024 is classified under the following ICS (International Classification for Standards) categories: 25.140.20 - Electric tools. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62841-2-16:2024 has the following relationships with other standards: It is inter standard links to IEC 62841-2-16:2024/AMD1:2026. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62841-2-16:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62841-2-16 ®

Edition 1.0 2024-06

EXTENDED VERSION

INTERNATIONAL

STANDARD

colour

inside

This extended version of IEC 62841-2-16:2024 includes the content of the references made to

IEC 62841-1:2014

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 2-16: Particular requirements for hand-held fastener driving tools

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62841-2-16 ®

Edition 1.0 2024-06

EXTENDED VERSION

INTERNATIONAL

STANDARD

colour

inside

This extended version of IEC 62841-2-16:2024 includes the content of the references made to

IEC 62841-1:2014

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety –

Part 2-16: Particular requirements for hand-held fastener driving tools

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 25.140.20 ISBN 978-2-8322-9350-8

– 2 – IEC 62841-2-16:2024 EXV © IEC 2024

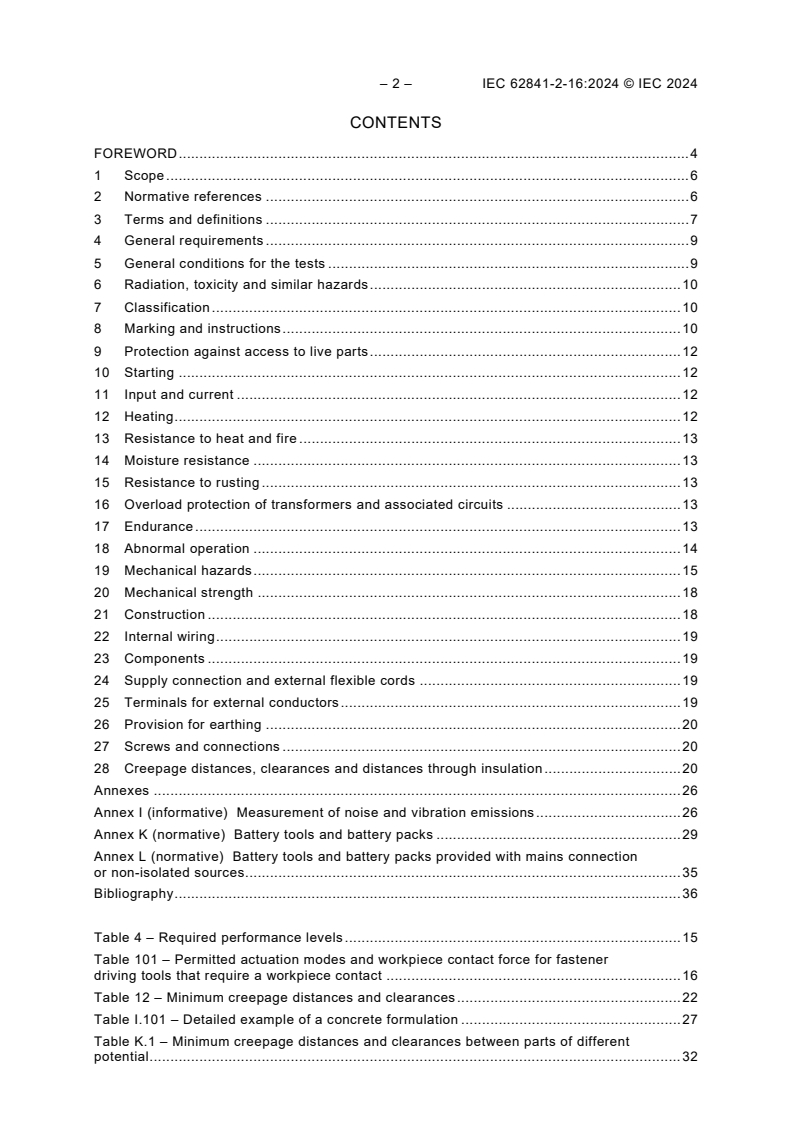

CONTENTS

FOREWORD . 5

INTRODUCTION . 8

1 Scope . 9

2 Normative references . 10

3 Terms and definitions . 15

4 General requirements . 24

5 General conditions for the tests . 24

6 Radiation, toxicity and similar hazards . 27

7 Classification . 28

8 Marking and instructions . 28

9 Protection against access to live parts . 41

10 Starting . 42

11 Input and current . 43

12 Heating . 43

13 Resistance to heat and fire . 48

14 Moisture resistance . 49

15 Resistance to rusting . 52

16 Overload protection of transformers and associated circuits . 53

17 Endurance . 53

18 Abnormal operation . 54

19 Mechanical hazards . 61

20 Mechanical strength . 65

21 Construction . 68

22 Internal wiring . 76

23 Components . 78

24 Supply connection and external flexible cords . 83

25 Terminals for external conductors . 88

26 Provision for earthing . 90

27 Screws and connections . 93

28 Creepage distances, clearances and distances through insulation . 95

Annex A (normative) Measurement of creepage distances and clearances. 104

Annex B (normative) Motors not isolated from the supply mains and having basic

insulation not designed for the rated voltage of the tool . 109

Annex C (normative) Leakage current . 111

Annex D (normative) Electric strength . 115

Annex E (informative) Methods of applying ISO 13849-1 to power tools . 117

Annex F (informative) Rules for routine tests . 119

Annex G Void. 121

Annex H (normative) Determination of a low-power circuit . 122

Annex I (informative) Measurement of noise and vibration emissions . 123

Annex J Void . 134

Annex K (normative) Battery tools and battery packs . 135

Annex L (normative) Battery tools and battery packs provided with mains connection

or non-isolated sources . 157

Bibliography . 176

Figure 1 – Test fingernail . 101

Figure 2 – Flexing test apparatus . 102

Figure 3 – Overload test of a class II armature . 103

Figure A.1 – Clearance gap for parallel sided and V-shaped groove . 105

Figure A.2 – Clearance gap for rib and uncemented joint with groove . 106

Figure A.3 – Clearance gap for uncemented joint and diverging-sided groove . 107

Figure A.4 – Clearance gap between wall and screw . 108

Figure B.1 – Simulation of fault conditions . 110

Figure C.1 – Diagram for leakage current measurement for single-phase connection

and three-phase tools suitable for single-phase supply . 113

Figure C.2 – Diagram for leakage current measurement for three-phase connection . 114

Figure C.3 – Circuit of the leakage current meter . 114

Figure H.1 – Example of an electronic circuit with low-power points . 122

Figure I.1 – Test bench . 132

Figure I.2 – Positions of a hand-held power tool and microphones for the

hemispherical / cylindrical measurement surface . 132

Figure I.3 – Microphone positions on a cubic measurement surface . 133

Figure I.4 – Directions of vibration measurement . 133

Figure K.1 – Measurement of clearances . 156

Figure L.1 – Measurement of clearances . 175

Table 1 – Maximum normal temperature rises (1 of 2) . 46

Table 2 – Maximum outside surface temperature rises . 48

Table 4 – Required performance levels . 60

Table 101 – Permitted actuation modes and workpiece contact force for fastener

driving tools that require a workpiece contact. 64

Table 5 – Impact energies . 66

Table 6 – Test torques . 67

Table 7 – Switch trigger force . 72

Table 8 – Minimum cross-sectional area and AWG sizes of supply cords . 84

Table 9 – Pull and torque value . 86

Table 10 – Quick-connect terminals for earthing conductors . 91

Table 11 – Torque for testing screws and nuts . 94

Table 12 – Minimum creepage distances and clearances . 97

Table D.1 – Test voltages . 115

Table F.1 – Test voltages for the electric strength test . 120

Table I.101 – Detailed example of a concrete formulation . 125

Table K.1 – Minimum creepage distances and clearances between parts of different

potential . 154

Table K.2 – Minimum total sum of creepage distances and clearances to accessible

surfaces . 155

– 4 – IEC 62841-2-16:2024 EXV © IEC 2024

Table L.1 – Minimum creepage distances and clearances between parts of opposite

polarity . 174

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY –

SAFETY –

Part 2-16: Particular requirements for hand-held fastener driving tools

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s),

which may be required to implement this document. However, implementers are cautioned that this may not

represent the latest information, which may be obtained from the patent database available at

https://patents.iec.ch. IEC shall not be held responsible for identifying any or all such patent rights.

This extended version (EXV) of the official IEC Standard provides the user with the

comprehensive content of the Standard.

made to IEC 62841-1:2014.

The specific content of IEC 62841-2-16:2024 is displayed on a blue background.

– 6 – IEC 62841-2-16:2024 EXV © IEC 2024

IEC 62841-2-16 has been prepared by IEC technical committee 116: Safety of motor-operated

electric tools. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

116/757/FDIS 116/800/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement,

available at www.iec.ch/members_experts/refdocs. The main document types developed by

IEC are described in greater detail at www.iec.ch/publications.

This document is to be used in conjunction with IEC 62841-1:2014.

This document supplements or modifies the corresponding clauses in IEC 62841-1, so as to

convert it into the IEC Standard: Particular requirements for hand-held fastener driving tools.

Where a particular subclause of IEC 62841-1 is not mentioned in this document, that

subclause applies as far as reasonable. Where this document states "addition", "modification"

or "replacement", the relevant text in IEC 62841-1 is to be adapted accordingly.

The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– terms defined in Clause 3: in bold type;

– notes: in small roman type.

Subclauses, notes, tables and figures which are additional to those in IEC 62841-1 are

numbered starting from 101.

Subclauses, notes, tables and figures in Annex K and Annex L which are additional to those in

the main body of this document are numbered starting from 301.

A list of all parts in the IEC 62841 series, published under the general title Electric motor-

operated hand-held tools, transportable tools and lawn and garden machinery – Safety, can

be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 8 – IEC 62841-2-16:2024 EXV © IEC 2024

INTRODUCTION

Individual countries may wish to consider the application of this Part 1 of IEC 62841, so far as

is reasonable, to tools not mentioned in an individual part of IEC 62841-2, IEC 62841-3 or

IEC 62841-4 and to tools designed on new principles.

Examples of standards dealing with non-safety aspects of hand-held tools, transportable

tools and lawn and garden machinery are

– standards dealing with EMC aspects;

– standards dealing with environmental aspects.

ELECTRIC MOTOR-OPERATED HAND-HELD TOOLS, TRANSPORTABLE

TOOLS AND LAWN AND GARDEN MACHINERY –

SAFETY –

Part 2-16: Particular requirements for hand-held fastener driving tools

1 Scope

This International Standard deals with the safety of electric motor-operated or magnetically

driven:

– hand-held tools (IEC 62841-2);

– transportable tools (IEC 62841-3);

– lawn and garden machinery (IEC 62841-4).

The above listed categories are hereinafter referred to as “tools” or “machines”.

The rated voltage is not more than 250 V for single-phase a.c. or d.c. tools, and 480 V for

three-phase a.c. tools. The rated input is not more than 3 700 W.

The limits for the applicability of this standard for battery tools are given in K.1 and L.1.

This standard deals with the hazards presented by tools which are encountered by all persons

in the normal use and reasonably foreseeable misuse of the tools.

Tools with electric heating elements are within the scope of this standard.

Requirements for motors not isolated from the supply, and having basic insulation not

designed for the rated voltage of the tools, are given in Annex B. Requirements for

rechargeable battery-powered motor-operated or magnetically driven tools and the battery

packs for such tools are given in Annex K. Requirements for such tools that are also operated

and/or charged directly from the mains or a non-isolated source are given in Annex L.

Hand-held electric tools, which can be mounted on a support or working stand for use as fixed

tools without any alteration of the tool itself, are within the scope of this standard and such

combination of a hand-held tool and a support is considered to be a transportable tool and

thus covered by the relevant Part 3.

This document applies to hand-held fastener driving tools

– intended for driving fasteners into or through concrete, fabric, fiberboard, metal, plastic,

wood, wood products, cartons, and other materials; and

– whose energy to drive the fastener is derived directly or indirectly from an electric motor

or magnetic drive.

This document does not apply to pneumatically driven tools where the compressed gas comes

from an external source, such as a compressor or a tank.

This document does not apply to tools powered by combustible gases, even if electrically

ignited.

NOTE 101 Tools powered by compressed air or combustible gases are covered by ISO 11148-13:2017.

This standard does not apply to:

– 10 – IEC 62841-2-16:2024 EXV © IEC 2024

– tools intended to be used in the presence of explosive atmosphere (dust, vapour or gas);

– tools used for preparing and processing food;

– tools for medical purposes;

NOTE 1 IEC 60601 series covers a variety of tools for medical purposes.

– tools intended to be used with cosmetics or pharmaceutical products;

– heating tools;

NOTE 2 IEC 60335-2-45 covers a variety of heating tools.

– electric motor-operated household and similar electrical appliances;

NOTE 3 IEC 60335 series covers a variety of electric motor-operated household and similar electrical appliances.

– electrical equipment for industrial machine-tools;

NOTE 4 IEC 60204 series deals with electrical safety of machinery.

– small low voltage transformer operated bench tools intended for model making, e.g. the

making of radio controlled model aircraft or cars, etc.

NOTE 5 In the United States of America, the following conditions apply:

This standard deals with tools used in non-hazardous locations in accordance with the National Electrical Code,

NFPA 70.

NOTE 6 In Canada, the following conditions apply:

This standard deals with tools used in non-hazardous locations in accordance with the Canadian Electric Code,

Part 1, CSA C22.1, and General Requirements – Canadian Electrical Code, Part II, CAN/CSA-C22.2 No. 0.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60061, Lamp caps and holders together with gauges for the control of interchangeability

and safety, available at http://std.iec.ch/iec60061

IEC 60065:2001, Audio, video and similar electronic apparatus – Safety requirements

Amendment 2:2010

Amendment 1:2005

IEC 60068-2-75:1997, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

IEC/TR 60083, Plugs and socket-outlets for domestic and similar general use standardized in

member countries of IEC

IEC 60085:2007, Electrical insulation – Thermal evaluation and designation

IEC 60127 (all parts), Miniature fuses

IEC 60227 (all parts), Polyvinyl chloride insulated cables of rated voltages up to and including

450/750 V

IEC 60238, Edison screw lampholders

_________

There exists a consolidated version (Edition 7.2:2011) which includes IEC 60065:2001 and its Amendment 1

(2005) and Amendment 2 (2010).

IEC 60245 (all parts), Rubber insulated cables – Rated voltages up to and including

450/750 V

IEC 60252-1, AC motor capacitors – Part 1: General – Performance, testing and rating –

Safety requirements – Guidance for installation and operation

IEC 60320 (all parts), Appliance couplers for household and similar general purposes

IEC 60320-1, Appliance couplers for household and similar general purposes – Part 1:

General requirements

IEC 60335-1:2010, Household and similar electrical appliances – Safety – Part 1: General

requirements

IEC 60384-14, Fixed capacitors for use in electronic equipment – Part 14: Sectional

specification – Fixed capacitors for electromagnetic interference suppression and connection

to the supply mains

IEC 60417, Graphical symbols for use on equipment, available at http://www.graphical-

symbols.info/graphical-symbols/equipment/db1.nsf/$enHome?OpenForm

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

Amendment 1:1999

Amendment 2:2013

IEC 60664-1, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

IEC 60664-3, Insulation coordination for equipment within low-voltage systems – Part 3: Use

of coating, potting or moulding for protection against pollution

IEC 60664-4:2005, Insulation coordination for equipment within low-voltage systems – Part 4:

Consideration of high-frequency voltage stress

IEC 60695-2-11:2000, Fire hazard testing – Part 2-11: Glowing/hot-wire based test methods –

Glow-wire flammability test method for end-products

IEC 60695-2-13:2010, Fire hazard testing – Part 2-13: Glowing/hot-wire based test methods –

Glow-wire ignition temperature (GWIT) test method for materials

IEC 60695-10-2:2003, Fire hazard testing – Part 10-2: Abnormal heat – Ball pressure test

IEC 60695-11-10:2013, Fire hazard testing – Part 11-10: Test flames – 50 W horizontal and

vertical flame test methods

IEC 60730-1:2010, Automatic electrical controls for household and similar use – Part 1:

General requirements

IEC 60825-1:2007, Safety of laser products – Part 1: Equipment classification and

requirements

IEC 60884 (all parts), Plugs and socket-outlets for household and similar purposes

_________

There exists a consolidated version (Edition 2.2:2013) which includes IEC 60529:1989 and its Amendment 1

(1999) and Amendment 2 (2013).

– 12 – IEC 62841-2-16:2024 EXV © IEC 2024

IEC 60906-1, IEC system of plugs and socket-outlets for household and similar purposes –

Part 1: Plugs and socket-outlets 16 A 250 V a.c.

IEC 60990:1999, Methods of measurement of touch current and protective conductor current

IEC 60998-2-1, Connecting devices for low-voltage circuits for household and similar

purposes – Part 2-1: Particular requirements for connecting devices as separate entities with

screw-type clamping units

IEC 60998-2-2, Connecting devices for low-voltage circuits for household and similar

purposes – Part 2-2: Particular requirements for connecting devices as separate entities with

screwless-type clamping units

IEC 60999-1:1999, Connecting devices – Electrical copper conductors – Safety requirements

for screw-type and screwless-type clamping units – Part 1: General requirements and

2 2

up to 35 mm

particular requirements for clamping units for conductors from 0,2 mm

(included)

IEC 61000-4-2:2008, Electromagnetic compatibility (EMC) – Part 4-2: Testing and

measurement techniques – Electrostatic discharge immunity test

IEC 61000-4-3:2006, Electromagnetic compatibility (EMC) – Part 4-3: Testing and

measurement techniques – Radiated, radio-frequency, electromagnetic field immunity test

Amendment 1:2007

Amendment 2:2010

IEC 61000-4-4:2012, Electromagnetic compatibility (EMC) – Part 4-4: Testing and

measurement techniques – Electrical fast transient/burst immunity test

IEC 61000-4-5:2005, Electromagnetic compatibility (EMC) – Part 4-5: Testing and

measurement techniques – Surge immunity test

IEC 61000-4-6:2008, Electromagnetic compatibility (EMC) – Part 4-6: Testing and

measurement techniques – Immunity to conducted disturbances, induced by radio-frequency

fields

IEC 61000-4-11:2004, Electromagnetic compatibility (EMC) – Part 4-11: Testing and

measurement techniques – Voltage dips, short interruptions and voltage variations immunity

tests

IEC 61032:1997, Protection of persons and equipment by enclosures – Probes for verification

IEC 61056-1, General purpose lead-acid batteries (valve-regulated types) – Part 1: General

requirements, functional characteristics – Methods of test

IEC 61058-1:2000, Switches for appliances – Part 1: General requirements

Amendment 1:2001

Amendment 2:2007

IEC 61210, Connecting devices – Flat quick-connect terminations for electrical copper

conductors – Safety requirements

_________

There exists a consolidated version (Edition 3.2:2010) which includes IEC 61000-4-3:2006 and its Amendment

1 (2007) and Amendment 2 (2010).

There exists a consolidated version (Edition 3.2:2008) which includes IEC 61058-1:2000 and its Amendment 1

(2001) and Amendment 2 (2007).

IEC 61540:1997, Electrical accessories – Portable residual current devices without integral

overcurrent protection for household and similar use (PRCDs)

Amendment 1:1998

IEC 61558-1, Safety of power transformers, power supplies, reactors and similar products –

Part 1: General requirements and tests

IEC 61558-2-4, Safety of transformers, reactors, power supply units and similar products for

supply voltages up to 1 100 V – Part 2-4: Particular requirements and tests for isolating

transformers and power supply units incorporating isolating transformers

IEC 61558-2-6, Safety of transformers, reactors, power supply units and similar products for

supply voltages up to 1 100 V – Part 2-6: Particular requirements and tests for safety isolating

transformers and power supply units incorporating safety isolating transformers

IEC 61558-2-16, Safety of transformers, reactors, power supply units and similar products for

supply voltages up to 1 100 V – Part 2-16: Particular requirements and tests for switch mode

power supply units and transformers for switch mode power supply units

IEC 61951-1, Secondary cells and batteries containing alkaline or other non-acid electrolytes

– Portable sealed rechargeable single cells – Part 1: Nickel-cadmium

IEC 61951-2, Secondary cells and batteries containing alkaline or other non-acid electrolytes

– Portable sealed rechargeable single cells – Part 2: Nickel-metal hydride

IEC 61960, Secondary cells and batteries containing alkaline or other non-acid electrolytes –

Secondary lithium cells and batteries for portable applications

IEC 61984, Connectors – Safety requirements and tests

IEC 62133, Secondary cells and batteries containing alkaline or other non-acid electrolytes –

Safety requirements for portable sealed secondary cells, and for batteries made from them,

for use in portable applications

IEC 62233, Measurement methods for electromagnetic fields of household appliances and

similar apparatus with regard to human exposure

IEC 62471, Photobiological safety of lamps and lamp systems

IEC/TR 62471-2:2009, Photobiological safety of lamps and lamp systems – Part 2: Guidance

on manufacturing requirements relating to non-laser optical radiation safety

IEC 62841-1:2014, Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety – Part 1: General requirements

ISO 630-2:2021, Structural steels – Part 2: Technical delivery conditions for structural steels

for general purposes

ISO 1463, Metallic and oxide coatings – Measurement of coating thickness – Microscopical

method

ISO 2178, Non-magnetic coatings on magnetic substrates – Measurement of coating

thickness – Magnetic method

_________

There exists a consolidated version (Edition 1.1:1999) which includes IEC 61540:1997 and its Amendment 1

(2001).

– 14 – IEC 62841-2-16:2024 EXV © IEC 2024

ISO 2768-1, General tolerances – Part 1: Tolerances for linear and angular dimensions

without individual tolerance indications

ISO 3744, Acoustics – Determination of sound power levels and sound energy levels of noise

sources using sound pressure – Engineering methods for an essentially free field over a

reflecting plane

ISO 3864-2, Graphical symbols – Safety colours and safety signs – Part 2: Design principles

for product safety labels

ISO 3864-3, Graphical symbols – Safety colours and safety signs – Part 3: Design principles

for graphical symbols for use in safety signs

ISO 4871:1996, Acoustics – Declaration and verification of noise emission values of

machinery and equipment

ISO 5347 (all parts), Methods for the calibration of vibration and shock pick-ups

ISO 5349-1, Mechanical vibration – Measurement and evaluation of human exposure to hand-

transmitted vibration – Part 1: General requirements

ISO 5349-2, Mechanical vibration – Measurement and evaluation of human exposure to hand-

transmitted vibration – Part 2: Practical guidance for measurement in the workplace

ISO 7000:2012, Graphical symbols for use on equipment – Index and synopsis

ISO 7010, Graphical symbols – Safety colours and safety signs – Registered safety signs

ISO 7574-4, Acoustics – Statistical methods for determining and verifying stated noise

emission values of machinery and equipment – Part 4: Methods for stated values for batches

of machines

ISO 8041, Human response to vibration – Measuring instrumentation

ISO 9772:2012, Cellular plastics – Determination of horizontal burning characteristics of small

specimens subjected to a small flame

ISO 11201, Acoustics – Noise emitted by machinery and equipment – Determination of

emission sound pressure levels at a work station and at other specified positions in an

essentially free field over a reflecting plane with negligible environmental corrections

ISO 11203, Acoustics – Noise emitted by machinery and equipment – Determination of

emission sound pressure levels at a work station and at other specified positions from the

sound power level

ISO 12100, Safety of machinery – General principles for design – Risk assessment and risk

reduction

ISO 13849-1, Safety of machinery – Safety-related parts of control systems – Part 1: General

principles for design

ISO 13850, Safety of machinery – Emergency stop – Principles for design

ISO/TR 11690-3, Acoustics – Recommended practice for the design of low-noise workplaces

containing machinery – Part 3: Sound propagation and noise prediction in workrooms

ISO 16063-1, Methods for the calibration of vibration and shock transducers – Part 1: Basic

concepts

ISO 28927-13:2022, Hand-held portable power tools – Test methods for evaluation of

vibration emission – Part 13: Fastener driving tools

EN 12096, Mechanical vibration – Declaration and verification of vibration emission values

EN 12549:1999, Acoustics – Noise test code for fastener driving tools – Engineering method

EN 15895:2011, Cartridge operated hand-held tools – Safety requirements – Fixing and hard

marking tools

ASTM B 258, Standard specification for standard nominal diameters and cross-sectional

areas of AWG sizes of solid round wires used as electrical conductors

UL 969, Standard for marking and labeling systems

NOTE 1 In the United States of America, the following normative reference applies:

US, Code of Federal Regulations (CFR) Title 21, Food and Drugs.

NOTE 2 In Canada, the following normative reference applies:

C.R.C., c. 1370, Radiation Emitting Devices Regulations

NOTE 3 In Europe (EN 62841-1), the following normative references apply:

CR 1030-1, Hand-arm vibration – Guidelines for vibration hazards reduction – Part 1: Engineering methods by

design of machinery

EN ISO 11688-1, Acoustics – Recommended practice for the design of low-noise machinery and equipment –

Part 1: Planning (ISO/TR 11688-1)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

Where the terms voltage and current are used, they imply the r.m.s. values, unless otherwise

specified.

Where in this standard the expressions “with the aid of a tool”, “without the aid of a tool”, and

“requires the use of a tool”, are used, the word “tool” means a hand tool, for example a

screwdriver, which may be used to operate a screw or other fixing means.

3.1

accessible part

conductive part or surface of insulating materials that can be touched by means of the test

probe B of IEC 61032:1997

3.2

accessory

device that is attached only to the output mechanism of the tool

3.3

adjustable guard

guard which is adjustable as a whole or which incorporates adjustable part(s). For manually

adjustable guards, the adjustment remains fixed during a particular operation

– 16 – IEC 62841-2-16:2024 EXV © IEC 2024

3.4

all-pole disconnection

disconnection of all supply conductors except the protective earthing (grounding) conductor

by a single initiating action

3.5

attachment

device attached to the housing or other component of the tool and which may or may not be

attached to the output mechanism and does not modify the normal use of the tool within the

scope of this standard

3.6

basic insulation

insulation applied to live parts to provide protection against electric shock. Insulation applied

to live parts not intended to provide electric shock protection is considered to be insulation

for functional purposes, such as magnet wire insulation

3.7

battery

assembly of one or more cells intended to provide electrical current to the tool

3.8

class I tool

tool in which protection against electric shock does not rely on basic, double or reinforced

insulation only, but which includes an additional safety precaution in that conductive

accessible parts are connected to the protective earthing conductor in the fixed wiring of the

installation in such a way that conductive accessible parts cannot become live in the event of

a failure of the basic insulation

Note 1 to entry: Also considered as class I tools are tools with double insulation and/or reinforced insulation

throughout, but also having an earthing terminal or earthing contact.

3.9

class II tool

tool in which protection against electric shock does not rely on basic insulation only, but in

which additional safety precautions, such as double insulation or reinforced insulation, are

provided, there being no provision for protective earthing or reliance upon installation

conditions

3.10

class III tool

tool in which protection against electric shock relies on supply at safety extra-low voltage,

and in which voltages higher than those of safety extra-low voltages are not generated

3.11

class II construction

part of a tool for which protection against electric shock relies upon double insulation or

reinforced insulation

3.12

class III construction

part of a tool for which protection against electric shock relies upon safety extra-low voltage,

and in which voltages higher than those of safety extra-low voltages are not generated

3.13

clearance

shortest distance between two conductive parts, or between a conductive part and the outer

surface of the enclosure, considered as though metal foil were pressed into contact with

accessible surfaces of insulating material, measured through air

Note 102 to entry: Examples of clearances are given in Annex A.

3.14

control device

device used by the user to adjust and/or regulate an electrical or mechanical function of the

tool

3.15

creepage distance

shortest path between two conductive parts, or between a conductive part and the outer

surface of the enclosure, considered as though metal foil were pressed into contact with

accessible surfaces of insulating material, measured along the surface of the insulating

material

Note 1 to entry: Examples of creepage distances are given in Annex A.

3.16

detachable part

part which can be removed or opened without the aid of a tool, or a part which is removed in

accordance with the instruction for use, except externally accessible brush caps, even if

removal requires the use of a tool

Note 1 to entry: A non-detachable part is covered by the requirements of 21.22.

3.17

double insulation

insulation system comprising both basic insulation and supplementary insulation

3.18

electronic circuit

circuit incorporating at least one electronic component

3.19

electronic component

part in which conduction is achieved principally by electrons moving through a vacuum, gas or

semiconductor, with the exclusion of neon indicators

Note 1 to entry: Examples of electronic components are diodes, transistors, triacs and monolithic integrated

circuits. Resistors, capacitors and inductors are not considered electronic components.

3.20

explosion

failure that occurs, when an enclosure opens violently and major components are forcibly

expelled in a manner that could result in injury

3.21

extra-low voltage

voltage supplied from a source within the tool and, which, when the tool is supplied at rated

voltage, does not exceed 50 V between conductors and between conductors and earth

3.22

fixed guard

guard af

...

IEC 62841-2-16 ®

Edition 1.1 2026-02

INTERNATIONAL

STANDARD

CONSOLIDATED VERSION

Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery - Safety -

Part 2-16: Particular requirements for hand-held fastener driving tools

ICS 25.140.20 ISBN 978-2-8327-1086-9

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or

by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either

IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC copyright

or have an enquiry about obtaining additional rights to this publication, please contact the address below or your local

IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by a publications previews, graphical symbols and the glossary.

variety of criteria (reference number, text, technical With a subscription you will always have access to up to date

committee, …). It also gives information on projects, content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published containing more than 22 500 terminological entries in English

details all new publications released. Available online and and French, with equivalent terms in 25 additional languages.

once a month by email. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 General requirements . 9

5 General conditions for the tests . 9

6 Radiation, toxicity and similar hazards . 9

7 Classification . 9

8 Marking and instructions . 9

9 Protection against access to live parts . 12

10 Starting . 12

11 Input and current . 12

12 Heating . 12

13 Resistance to heat and fire . 13

14 Moisture resistance . 13

15 Resistance to rusting . 13

16 Overload protection of transformers and associated circuits . 13

17 Endurance . 13

18 Abnormal operation . 14

19 Mechanical hazards . 15

20 Mechanical strength . 18

21 Construction . 18

22 Internal wiring . 19

23 Components . 19

24 Supply connection and external flexible cords . 19

25 Terminals for external conductors . 19

26 Provision for earthing . 20

27 Screws and connections . 20

28 Creepage distances, clearances and distances through insulation . 20

Annexes . 26

Annex I (informative) Measurement of noise and vibration emissions . 26

Annex K (normative) Battery tools and battery packs . 29

Annex L (normative) Battery tools and battery packs provided with mains connection

or non-isolated sources. 35

Annex AA (normative) Product safety labels . 36

Bibliography . 37

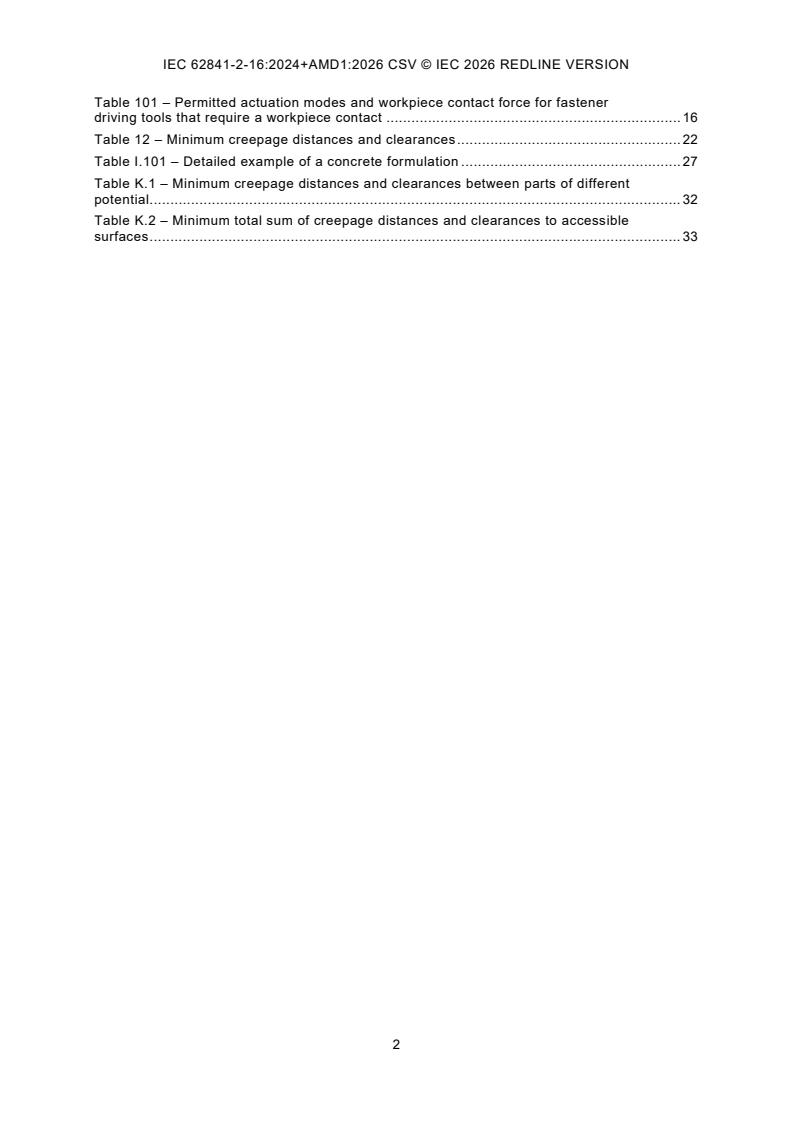

Figure AA.1 – Product safety label for tools capable of only contact actuation or

contact actuation with automatic reversion actuation modes . 36

Table 4 – Required performance levels . 15

Table 101 – Permitted actuation modes and workpiece contact force for fastener

driving tools that require a workpiece contact . 16

Table 12 – Minimum creepage distances and clearances . 22

Table I.101 – Detailed example of a concrete formulation . 27

Table K.1 – Minimum creepage distances and clearances between parts of different

potential. 32

Table K.2 – Minimum total sum of creepage distances and clearances to accessible

surfaces . 33

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Electric motor-operated hand-held tools, transportable tools

and lawn and garden machinery - Safety -

Part 2-16: Particular requirements for hand-held fastener driving tools

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 62841-2-16 edition 1.1 contains the first edition (2024-06) [documents 116/757/FDIS and

116/800/RVD] and its amendment 1 (2026-02) [documents 116/936/FDIS and 116/939/RVD].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions are in green text, deletions are in strikethrough red text.

A separate Final version with all changes accepted is available in this publication.

IEC 62841-2-16 has been prepared by IEC technical committee 116: Safety of motor-operated

electric tools. It is an International Standard.

The text of this International Standard is based on the following documents:

Draft Report on voting

116/757/FDIS 116/800/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

This document is to be used in conjunction with IEC 62841-1:2014.

This document supplements or modifies the corresponding clauses in IEC 62841-1, so as to

convert it into the IEC Standard: Particular requirements for hand-held fastener driving tools.

Where a particular subclause of IEC 62841-1 is not mentioned in this document, that subclause

applies as far as reasonable. Where this document states "addition", "modification" or

"replacement", the relevant text in IEC 62841-1 is to be adapted accordingly.

The following print types are used:

– requirements: in roman type;

– test specifications: in italic type;

– terms defined in Clause 3: in bold type;

– notes: in small roman type.

Subclauses, notes, tables and figures which are additional to those in IEC 62841-1 are

numbered starting from 101.

Subclauses, notes, tables and figures in Annex K and Annex L which are additional to those in

the main body of this document are numbered starting from 301.

A list of all parts in the IEC 62841 series, published under the general title Electric motor-

operated hand-held tools, transportable tools and lawn and garden machinery – Safety, can be

found on the IEC website.

The committee has decided that the contents of this document and its amendment will remain

unchanged until the stability date indicated on the IEC website under webstore.iec.ch in the

data related to the specific document. At this date, the document will be

– reconfirmed,

– withdrawn, or

– revised.

1 Scope

IEC 62841-1:2014, Clause 1 is applicable, except as follows:

Addition:

This document applies to hand-held fastener driving tools

– intended for driving fasteners into or through concrete, fabric, fiberboard, metal, plastic,

wood, wood products, cartons, and other materials; and

– whose energy to drive the fastener is derived directly or indirectly from an electric motor or

magnetic drive.

This document does not apply to pneumatically driven tools where the compressed gas comes

from an external source, such as a compressor or a tank.

This document does not apply to tools powered by combustible gases, even if electrically

ignited.

NOTE 101 Tools powered by compressed air or combustible gases are covered by ISO 11148-13:2017.

2 Normative references

IEC 62841-1:2014, Clause 2 is applicable, except as follows:

Addition:

IEC 60664-3, Insulation coordination for equipment within low-voltage systems – Part 3: Use of

coating, potting or moulding for protection against pollution

IEC 60664-4:2005, Insulation coordination for equipment within low-voltage systems – Part 4:

Consideration of high-frequency voltage stress

IEC 62841-1:2014, Electric motor-operated hand-held tools, transportable tools and lawn and

garden machinery – Safety – Part 1: General requirements

ISO 630-2:2021, Structural steels – Part 2: Technical delivery conditions for structural steels

for general purposes

ISO 28927-13:2022, Hand-held portable power tools – Test methods for evaluation of vibration

emission – Part 13: Fastener driving tools

EN 12549:1999, Acoustics – Noise test code for fastener driving tools – Engineering method

EN 15895:2011, Cartridge operated hand-held tools – Safety requirements – Fixing and hard

marking tools

EN 15895:2025, Powder actuated hand-held fixing and hard marking tools - Safety

requirements

3 Terms and definitions

IEC 62841-1:2014, Clause 3 is applicable, except as follows:

Addition:

3.101

activate

move or otherwise engage a trigger or workpiece contact so that it is in a state that allows

the fastener driving tool to be actuated or that satisfies one requirement for the fastener

driving tool to be actuated

3.102

actuate

cause movement of the tool component(s) intended to drive a fastener

3.103

actuation mode

sequence by which a fastening operation is performed

3.103.1

contact actuation

actuation mode which allows the tool to operate by activating the workpiece contact whilst

the trigger is continually depressed and held

Note 101 to entry: Contact actuation is also known as bump mode.

3.103.2

contact actuation with automatic reversion

actuation mode that is capable of contact actuation and where the tool cannot actuate if the

trigger is depressed without operation of the workpiece contact within the trigger time-out

period

Note 101 to entry: Additional actuation is possible only after the trigger is released and re-activated.

3.103.3

dual activation

actuation mode where two devices, such as triggers, levers, or switches, work in conjunction

with each other such that two sequential dissimilar actions are required to actuate the tool

3.103.4

full sequential actuation

actuation mode which allows single driving operations via the trigger after the workpiece

contact has been activated and during which additional actuation can occur only when all

operating controls are released and re-activated in the same sequence

3.103.5

single sequential actuation

actuation mode which allows single driving operations via the trigger, after the workpiece

contact has been activated, and during which additional actuation can occur only when the

trigger has been returned to the non-driving position whilst the workpiece contact remains in

the activated position

3.104

actuation system

trigger or workpiece contact activated separately or in some combination or sequence to

actuate the tool

3.105

coil nailer

fastener driving tool that drives fasteners from a collated coil of nails for production

applications

Note 101 to entry: Roofing nailers are an example of a coil nailer.

Note 102 to entry: The primary purpose of this tool is production applications.

3.106

fastener

mechanical device used for securing fixings to surfaces or joining materials together, such as

nails, staples and pins, for use in fastener driving tools

3.107

fastener driving tool

hand-held tool in which energy is transmitted in a linear motion to a fastener for the purpose

of driving the fastener into defined materials

Note 101 to entry: Fasteners are typically driven by mechanical or pneumatic means.

3.108

heavy duty brad finish nailer

fastener driving tool capable of driving nails of 1,2 mm (18 gauge) or larger nominal diameter

wire

Note 101 to entry: The fasteners described here are consistent, except for description, with those described for

heavy duty bradders in ISO 11148-13:2017.

Note 102 to entry: These tools are primarily for production applications.

3.109

heavy duty stapler

fastener driving tool capable of driving staples with a staple leg width of 1,6 mm or larger

and a nominal staple leg thickness of 1,4 mm or larger

Note 101 to entry: The fasteners described here are consistent, except for description, with those described for

heavy duty staplers in ISO 11148-13:2017.

Note 102 to entry: These tools are primarily for production applications.

3.110

horizontal-down

tool orientation where the tool nose is normal to a horizontal work surface and pointed

downwards

3.111

horizontal-up

tool orientation where the tool nose is normal to a horizontal work surface and pointed upwards

3.112

light duty tool

fastener driving tool that is only capable of driving fasteners with a diameter of 1,2 mm

(18 gauge) or less and where

– the mass of the fastener is less than 0,5 g and the length of the fastener does not exceed

26 mm; or

– the mass of the fastener is less than 0,4 g and the length of the fastener does not exceed

36 mm

Note 101 to entry: Heavy duty brad finish nailers, heavy duty staplers and pinners are considered not to be

light duty tools.

3.113

multi-blow tool

fastener driving tool that drives fasteners through multiple impacts on the head of the

fastener and not through the forcible ejection of the fastener

Note 101 to entry: An example of a multi-blow tool, also known as a percussion nailer, is a palm nailer.

3.114

pinner

fastener driving tool capable of driving headless fasteners up to 51 mm in length and a

maximum diameter of 0,64 mm (23 gauge)

3.115

staple leg thickness

maximum dimension of staple leg cross-section measured parallel to the staple crown axis

3.116

staple leg width

maximum dimension of staple leg cross-section measured perpendicular to the staple crown

axis

3.117

trigger

control element activated manually by a tool operator

3.118

trigger time-out period

for tools with contact actuation with automatic reversion actuation mode, the duration of

time a trigger can be depressed without operation of the workpiece contact before the tool

becomes inoperable

3.119

workpiece contact

control element or assembly on the fastener driving tool intended to be activated by the

workpiece

Note 101 to entry: This includes retractable workpiece contacts that are normally retracted and extend when the

trigger is activated.

3.119.1

protected workpiece contact

workpiece contact that is recessed such that it cannot be activated by pressing against a flat

surface

Note 101 to entry: Protected workpiece contacts are found on tools that are designed to affix cable, tubing and

the like with staples where the workpiece contact presses against the material being affixed.

3.120

production application

high-volume professional application such as pallets, furniture, manufactured housing,

upholstery, sheathing and roofing

Note 101 to entry: Tools that are designed for production applications include heavy duty staplers, heavy duty

finish nailers and coil nailers

3.121

selective actuation

actuation system that allows discrete selection of two or more of the following actuation

modes: single sequential actuation, full sequential actuation, contact actuation or contact

actuation with automatic reversion

4 General requirements

IEC 62841-1:2014, Clause 4 is applicable.

5 General conditions for the tests

IEC 62841-1:2014, Clause 5 is applicable, except as follows:

5.17 Addition:

The mass of the tool includes the heaviest fastener magazine in accordance with

8.14.2 b) 102), but excludes any fasteners.

5.101 For tests that are conducted without fasteners, the test may be conducted using a test

fixture that simulates a fastener in order to avoid abnormal stresses that may occur in the tool.

5.102 For tools that employ a function that does not permit the tool to actuate without

fasteners, tests that require the tool to actuate shall be conducted with fasteners or the

function shall be disabled. If required, special hardware or software (or both) may be used in

order to disable the function.

6 Radiation, toxicity and similar hazards

IEC 62841-1:2014, Clause 6 is applicable.

7 Classification

IEC 62841-1:2014, Clause 7 is applicable.

8 Marking and instructions

IEC 62841-1:2014, Clause 8 is applicable, except as follows:

8.1 Replacement of the third dash:

– rated input, in watts or rated current, in amperes;

8.2 Addition:

Fastener driving tools shall be marked with safety information which shall be written in one of

the official languages of the country in which the machine is to be sold or marked with the

appropriate symbol:

– "Wear eye protection" or symbol M004 of ISO 7010;

– "Wear ear protection", or symbol M003 of ISO 7010. This marking may be omitted if the

measured sound pressure level at the operator's ear in accordance with Annex I does not

exceed 85 dB(A).

A combination of product safety labels, such as eye, ear, dust and head protection, is allowed.

8.2.101 Tools capable of only contact actuation or contact actuation with automatic

reversion actuation modes in accordance with 19.102 and 19.104 shall be visibly marked with

the product safety label specified in Figure AA.1 of Annex AA. This subclause is not applicable

to tools with selective actuation.

Compliance is checked by inspection.

8.11 Addition:

For tools with the ability to select different actuation modes selective actuation, markings

indicating which actuation mode is enabled.

8.14.1 Addition:

The additional safety instructions as specified in 8.14.1.101 or 8.14.1.102 (as applicable) shall

be given. The term "tool" in these warnings may be replaced by a specific tool designation, such

as fastener driving tool, nailer, pinner, stapler, tacker, etc. The term "fastener(s)" in these

warnings may be replaced by a specific fastener designation such as nail(s), pin(s), staple(s),

tack(s), etc. This part may be printed separately from the "General Power Tool Safety

Warnings".

8.14.1.101 Fastener driving tool safety warnings (except for multi-blow tools)

a) Always assume that the tool contains fasteners. Careless handling of the tool may result

in unexpected firing of fasteners and personal injury.

b) Disconnect the tool from the power source when loading and unloading fasteners,

making adjustments or changing accessories. The tool may be accidentally activated if

it is connected to the power source, which may result in personal injury.

c) Be careful when handling fasteners, especially when loading and unloading. The

fasteners have sharp points which may result in personal injury.

d) Do not point the tool towards yourself or anyone nearby. Unexpected triggering will

discharge a fastener, which may result in personal injury.

e) Keep fingers away from the trigger when not operating the tool and when moving from

one operating position to another. Unexpected triggering will discharge a fastener, which

may result in personal injury.

f) Hold the tool by insulated gripping surfaces, when performing an operation where the

fastener may contact hidden wiring or its own cord. A fastener contacting a "live" wire

may make exposed metal parts of the tool "live" and could give the operator an electric

shock.

g) Hold the tool with a firm grasp during operation. Uncontrolled recoil of the tool may result

in unintended activation, which may result in personal injury.

h) Keep all body parts such as hands and legs, etc. away from the firing direction of the

tool. The fastener may penetrate the workpiece as well as any object behind it, which may

result in personal injury.

i) When using the tool, keep all body parts such as hands and legs, etc. away from the

area where the fastener is driven into the workpiece. The fastener could deflect and exit

the workpiece, which may result in personal injury.

j) Do not actuate the tool unless the tool is placed firmly against the workpiece. If the

tool is not in contact with the workpiece, the fastener may be deflected away from the

workpiece, which may result in personal injury.

k) When fastening electrical cables, make sure the cables are not energized. Hold the

tool only by insulated gripping surfaces. Use only fasteners designed for electrical

cable installations. Inspect that the fastener has not damaged the insulation of the

electrical cables. A fastener that damages the insulation of electric cables can lead to

electric shock and fire hazards.

NOTE 101 The warning in item k) above is omitted for tools that are not intended to fasten electrical cables.

l) Do not use this tool for fastening electrical cables. It is not designed for electric cable

installation and may damage the insulation of electric cables, thereby causing electric shock

or fire hazards.

NOTE 102 The warning in item l) above is omitted for tools intended to fasten electric cables in accordance

with 8.14.2 b) 106).

m) Disconnect the tool from the power source if a fastener jams in the tool. While removing

a jammed fastener, the tool may be accidentally activated if it is connected to the power

source, which may result in personal injury.

n) Use caution while removing a jammed fastener. The mechanism may be under

compression and the fastener may be forcefully discharged, which may result in personal

injury.

NOTE 103 The warning in item n) above is omitted for tools that do not utilize a stored potential energy to drive

the fasteners.

8.14.1.102 Multi-blow tool safety warnings

a) Hold the tool by insulated gripping surfaces, when performing an operation where the

fastener may contact hidden wiring or its own cord. A fastener contacting a "live" wire