IEC TS 62788-6-3:2022

(Main)Measurement procedures for materials used in photovoltaic modules - Part 6-3: Adhesion testing for PV module laminates using the single cantilevered beam (SCB) method

Measurement procedures for materials used in photovoltaic modules - Part 6-3: Adhesion testing for PV module laminates using the single cantilevered beam (SCB) method

IEC TS 62788-6-3:2022 describes the single cantilevered beam (SCB) test, useful for characterizing adhesion in photovoltaic (PV) modules. This document offers a generalized method for performing the test, with the expectation that best practices for utilizing this test method will be developed for specific applications.

This document provides a method for measuring the adhesion energy of most interfaces within the photovoltaic (PV) module laminate. This method provides a measure of adhesive energy, via the critical energy release rate, and so is more useful for comparing adhesion of different specimen types; e.g. different materials, module or coupon samples, or materials before and after stress exposure.

General Information

- Status

- Published

- Publication Date

- 18-Aug-2022

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 2 - TC 82/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 19-Aug-2022

- Completion Date

- 20-Sep-2022

Overview

IEC TS 62788-6-3:2022 specifies the single cantilevered beam (SCB) method for adhesion testing of photovoltaic (PV) module laminates. The technical specification defines a generalized procedure to quantify adhesion energy (the critical energy release rate, Gc) for interfaces inside PV modules - for example, backsheet/encapsulant, glass/encapsulant, encapsulant/interlayer and cell/encapsulant interfaces. The SCB method is designed for both coupon-level and module-level testing and is intended to be a more robust, quantitative alternative to conventional peel tests when comparing materials or measuring changes after stress exposure.

Key topics and requirements

- Test principle: A width‑tapered cantilever beam is adhered to the laminate; loading at the beam apex initiates and propagates a delamination. Measured load-displacement and debond length are used to calculate Gc.

- Apparatus: Requirements for a load frame, clevis loading connection, loading tab and beam geometry (width-tapered cantilever) are described.

- Specimen preparation: Guidance on preparing coupons and module test points to target specific interfaces.

- Measurement procedure: Step-by-step instructions for loading, recording load/displacement curves, and measuring final debond length.

- Analysis: Calculation of the critical energy release rate (Gc) and optional use of a reference compliance curve (Annex D) to determine crack length.

- Reporting: Required test data and result presentation to ensure reproducibility and comparability.

- Informative annexes: Background fracture/beam mechanics theory, use-case guidance (backsheets, encapsulants, modules), reference diagrams, calibration methods and debond-length measurement techniques (Annexes A–E).

Applications and users

- Who uses it: PV module manufacturers, materials and encapsulant suppliers, independent test laboratories, reliability engineers, R&D groups and certification bodies.

- Practical uses:

- Compare adhesion of different materials or manufacturing processes.

- Quantify adhesion degradation after environmental stress (thermal cycling, humidity, UV).

- Support material selection and module design to reduce delamination risk.

- Provide quantitative data for failure analysis and reliability qualification.

- Advantages: Produces a quantitative adhesion energy (Gc) that is less influenced by viscoelastic peel mechanics than 90° or 180° peel tests, improving sensitivity for comparative studies.

Related standards

- IEC 62788 series - Measurement procedures for materials used in photovoltaic modules (other parts).

- IEC 62788-1-1 and IEC TS 62788-2 - component-level adhesion and characterization (peel tests).

- IEC 61730-2 - PV module safety qualification (includes module-level peel/adhesion considerations).

Keywords: SCB, single cantilevered beam, adhesion testing, PV module laminates, critical energy release rate, adhesion energy, encapsulant, backsheet, photovoltaic testing.

Buy Documents

IEC TS 62788-6-3:2022 - Measurement procedures for materials used in photovoltaic modules - Part 6-3: Adhesion testing for PV module laminates using the single cantilevered beam (SCB) method Released:8/19/2022 Isbn:9782832255612

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC TS 62788-6-3:2022 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Measurement procedures for materials used in photovoltaic modules - Part 6-3: Adhesion testing for PV module laminates using the single cantilevered beam (SCB) method". This standard covers: IEC TS 62788-6-3:2022 describes the single cantilevered beam (SCB) test, useful for characterizing adhesion in photovoltaic (PV) modules. This document offers a generalized method for performing the test, with the expectation that best practices for utilizing this test method will be developed for specific applications. This document provides a method for measuring the adhesion energy of most interfaces within the photovoltaic (PV) module laminate. This method provides a measure of adhesive energy, via the critical energy release rate, and so is more useful for comparing adhesion of different specimen types; e.g. different materials, module or coupon samples, or materials before and after stress exposure.

IEC TS 62788-6-3:2022 describes the single cantilevered beam (SCB) test, useful for characterizing adhesion in photovoltaic (PV) modules. This document offers a generalized method for performing the test, with the expectation that best practices for utilizing this test method will be developed for specific applications. This document provides a method for measuring the adhesion energy of most interfaces within the photovoltaic (PV) module laminate. This method provides a measure of adhesive energy, via the critical energy release rate, and so is more useful for comparing adhesion of different specimen types; e.g. different materials, module or coupon samples, or materials before and after stress exposure.

IEC TS 62788-6-3:2022 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62788-6-3:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62788-6-3 ®

Edition 1.0 2022-08

TECHNICAL

SPECIFICATION

colour

inside

Measurement procedures for materials used in photovoltaic modules –

Part 6-3: Adhesion testing for PV module laminates using the single cantilevered

beam (SCB) method

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TS 62788-6-3 ®

Edition 1.0 2022-08

TECHNICAL

SPECIFICATION

colour

inside

Measurement procedures for materials used in photovoltaic modules –

Part 6-3: Adhesion testing for PV module laminates using the single

cantilevered beam (SCB) method

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 27.160 ISBN 978-2-8322-5561-2

– 2 – IEC TS 62788-6-3:2022 © IEC 2022

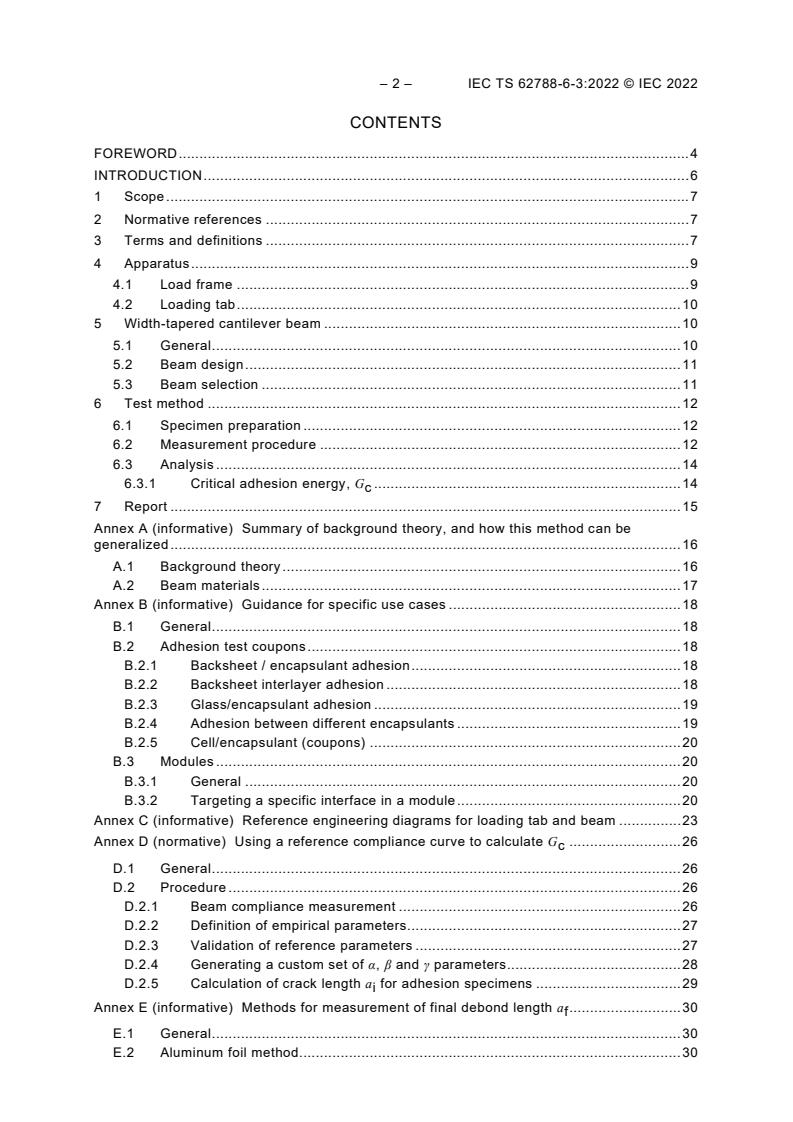

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Apparatus . 9

4.1 Load frame . 9

4.2 Loading tab . 10

5 Width-tapered cantilever beam . 10

5.1 General . 10

5.2 Beam design . 11

5.3 Beam selection . 11

6 Test method . 12

6.1 Specimen preparation . 12

6.2 Measurement procedure . 12

6.3 Analysis . 14

6.3.1 Critical adhesion energy, G . 14

c

7 Report . 15

Annex A (informative) Summary of background theory, and how this method can be

generalized . 16

A.1 Background theory . 16

A.2 Beam materials . 17

Annex B (informative) Guidance for specific use cases . 18

B.1 General . 18

B.2 Adhesion test coupons . 18

B.2.1 Backsheet / encapsulant adhesion . 18

B.2.2 Backsheet interlayer adhesion . 18

B.2.3 Glass/encapsulant adhesion . 19

B.2.4 Adhesion between different encapsulants . 19

B.2.5 Cell/encapsulant (coupons) . 20

B.3 Modules . 20

B.3.1 General . 20

B.3.2 Targeting a specific interface in a module . 20

Annex C (informative) Reference engineering diagrams for loading tab and beam . 23

Annex D (normative) Using a reference compliance curve to calculate G . 26

c

D.1 General . 26

D.2 Procedure . 26

D.2.1 Beam compliance measurement . 26

D.2.2 Definition of empirical parameters . 27

D.2.3 Validation of reference parameters . 27

D.2.4 Generating a custom set of α, β and γ parameters . 28

D.2.5 Calculation of crack length a for adhesion specimens . 29

i

Annex E (informative) Methods for measurement of final debond length a . 30

f

E.1 General . 30

E.2 Aluminum foil method. 30

E.3 Light method . 30

E.4 Pull-apart method . 30

Bibliography . 32

Figure 1 – Diagram of the loading connection using a clevis grip . 9

Figure 2 – Schematic of load frame with a) a platen for securing test coupon, and b)

modified to sit on top of a PV module . 10

Figure 3 – Photos of the loading tab alone, and attached to the beam . 10

Figure 4 – Width-tapered beam . 11

Figure 5 – Typical width-tapered cantilever beam load/displacement curve . 13

Figure 6 – Example of an a measurement on glass/encapsulant/cell specimens . 14

f

Figure B.1 – Top view of backsheet and encapsulant beam coupons . 21

Figure B.2 – Cross-sectional view of backsheet and encapsulant beam coupons . 22

Figure C.1 – Schematics of loading tab . 24

Figure C.2 – Schematics of beam . 25

Figure D.1 – Photo of a beam prior to start of the calibration measurement . 26

Figure D.2 – Photo of a beam at the end of the calibration measurement . 27

Figure D.3 – Plot used for generating beam calibration curves with the empirical fits

according to Formula (D.2) using values from Table D.1 . 29

Figure E.1 – Illustration of debond length measurement with a cohesive zone . 31

Table 1 – Typical adhesion strengths . 12

Table D.1 – Reference empirical fit parameters . 27

Table D.2 – Example read points for fit evaluation . 28

– 4 – IEC TS 62788-6-3:2022 © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MEASUREMENT PROCEDURES FOR MATERIALS

USED IN PHOTOVOLTAIC MODULES –

Part 6-3: Adhesion testing for PV module laminates

using the single cantilevered beam (SCB) method

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC TS 62788-6-3 has been prepared by IEC technical committee 82: Solar photovoltaic energy

systems. It is a Technical Specification.

The text of this Technical Specification is based on the following documents:

Draft Report on voting

82/2012/DTS 82/2057A/RVDTS

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Specification is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at http://www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 62788 series, published under the general title Measurement

procedures for materials used in photovoltaic modules, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC TS 62788-6-3:2022 © IEC 2022

INTRODUCTION

This document describes the single cantilevered beam (SCB) test, useful for characterizing

adhesion in photovoltaic (PV) modules. This method is grounded in fundamental concepts of

beam and fracture mechanics [1] , [4], and allows for a quantitative measurement of adhesion

strength. A method for calculating the debond length, a has been developed as an option to

f,

physical measurement.

PV modules are multi-layer structures that depend on adequate adhesion between each layer

to ensure their reliable operation. Adhesion testing is described in current IEC PV standards for

module safety qualification (IEC 61730-2) and component characterization (IEC 62788 series).

The most commonly used tests are peel tests at either 180° for components (IEC TS 62788-2

test and IEC 62788-1-1), or at 90° for modules (IEC 61730-2 MST 35).

Peel tests are in practice simple to carry out, and provide a peel strength value, different from

adhesion strength. Viscoelastic properties of the polymeric material and the mechanics of the

pull tab have a strong influence on the result, making these tests of limited value in comparing

either different materials, or the same material after stress exposures.

In the SCB method, an elastic width-tapered cantilever beam is adhered to the sample. When

the beam is loaded at its apex, delamination will initiate at the weakest interface and advance

upon continued loading. This measurement allows for calculation of the critical value of the

, which is the adhesion property for a given material interface. The value

energy release rate, G

c

defined by this method is less dependent of the viscoelastic properties of the polymeric material,

and so more useful for measuring differences or changes in adhesive strength.

The SCB method can be conducted at either the coupon or module level. Because it does not

require using the backsheet as a pull tab, it is more likely to able to test the adhesion of a thin

outer layer of the backsheet. These considerations give this test method good flexibility to use

in applications related to PV modules. Examples for several specific use cases are provided.

This document offers a generalized method for performing the test, with the expectation that

best practices for utilizing this test method will be developed for specific applications.

Examples of this method being employed to quantify and define the threshold values of

encapsulant and backsheet adhesion for PV module reliability may be found in the literature [1]

through [5].

___________

Numbers in square brackets refer to the Bibliography.

MEASUREMENT PROCEDURES FOR MATERIALS

USED IN PHOTOVOLTAIC MODULES –

Part 6-3: Adhesion testing for PV module laminates

using the single cantilevered beam (SCB) method

1 Scope

This part of IEC TS 62788 provides a method for measuring the adhesion energy of most

interfaces within the photovoltaic (PV) module laminate.

In contrast to other adhesion tests in general use, this method provides a measure of adhesive

energy, via the critical energy release rate, and so is more useful for comparing adhesion of

different specimen types; e.g. different materials, module or coupon samples, or materials

before and after stress exposure.

This is a “weakest link” test, meaning that the weakest interface is the one most likely to fail in

a given test. Adhesion of a specific layer may be difficult to intentionally measure if there is a

weaker interface in the system.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC TS 61836, Solar photovoltaic energy systems – Terms, definitions and symbols

ISO 7500-1, Metallic materials – Calibration and verification of static uniaxial testing machines

– Part 1: Tension/compression testing machines – Calibration and verification of the force-

measuring system

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC TS 61836 apply, as

well as the following.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

cantilevered beam

beam supported at only one end such that the slope and deflection of that end is ideally zero

– 8 – IEC TS 62788-6-3:2022 © IEC 2022

3.2

mechanical compliance

measure of the extent of deformation due to the action of external forces (reciprocal of stiffness)

Note 1 to entry: Unit (preferred): m/N.

3.3

adhesive failure

de-bonding occurring between the adhesive and the adherent, to be differentiated from

cohesive failure within the adhesive material

3.4

cohesive failure

crack propagating within the adhesive during adhesion test, e.g. peel test

3.5

adhesive energy

G

specific energy (in J/m ) released during separation of two material layers

3.6

critical adhesive energy

G

c

critical strain energy release rate necessary to promote crack growth

3.7

debond length

a

measured length of specimen from the apex of the tapered beam to the end of the debonded

area

3.8

load-line displacement

Δ

displacement measured along the loading axis of a load frame

3.9

unfixed beam length

L

b

length of the beam between the clamp and the tip, used to determine the compliance calibration

of the beam

3.10

compliance calibration method

method used to calculate the debond length based on the measured compliance at various

crack lengths for a specific beam

3.11

plastic deformation

permanent, non-recoverable deformation

3.12

cohesive zone

trailing area adjacent to the debond edge that may consist of cavitation, voids and ligaments

within the adhesive

4 Apparatus

4.1 Load frame

A properly calibrated load frame shall be used that can be operated in a displacement control

mode with a constant rate of 10,0 µm/s. A load cell with a capacity of 200 N is recommended.

The load frame shall conform to the requirements of ISO 7500-1.

The load frame shall be equipped with the following:

• a clevis grip link that couples the load train to the loading tab attached to the specimen,

Figure 1. The link should be ≥ 30 mm between the centres of the connection points, and

each end of the link shall be able to rotate freely about the clevis pin orthogonal to the

specimen plane. The clevis pin should be 1,0 mm steel or material of equal or greater elastic

modulus.

• a platen opposite the loading grip to which the test specimen is secured, Figure 2a); or, the

load frame may be modified to sit on the specimen (e.g., PV module) Figure 2b).

• a displacement indicator capable of monitoring and recording load-line displacement. The

displacement indicator shall indicate the load-line displacement within an accuracy of

10 μm.

• a load-sensing device capable of monitoring and recording the total load carried by the

specimen. This device shall indicate the load with an accuracy over the load range(s) of

interest within 0,1 N.

Dimensions in millimetres

Figure 1 – Diagram of the loading connection using a clevis grip

– 10 – IEC TS 62788-6-3:2022 © IEC 2022

a) b)

Figure 2 – Schematic of load frame with a) a platen for securing test coupon, and b)

modified to sit on top of a PV module

4.2 Loading tab

The loading tab connects to the beam and to the loading pin of the Clevis joint. The preferred

material for the loading tab is stainless steel, although aluminium may also be used. To provide

a low friction surface, a sapphire jewel bearing is recommended for the contact with the loading

pin. This should be inspected for damage prior to each test, and cracked bearings shall be

replaced. Photos of a loading tab are shown in Figure 3. A reference engineering design is

provided in Annex C.

Figure 3 – Photos of the loading tab alone, and attached to the beam

5 Width-tapered cantilever beam

5.1 General

The beam is usually considered disposable and used only once. After cleaning, it may be reused

if evaluated to ensure no permanent deformation has occurred. Recovering a deformed beam

is not recommended.

Design parameters for the beam include both physical dimensions and material properties.

Annex A describes a range of beams which may be used in the context of this document. Two

specific designs are included in this specification, with the selection to be made based on the

maximum expected adhesion energy, G , of the system to be measured.

max

5.2 Beam design

A variety of materials and beam designs can be used according to theory as described in

Annex A. For simplicity, this document specifies a single material, Grade 5 Ti-6Al04V, and

specific design parameters as given in Figure 4. Thickness shall be either 0,8 mm or 1,6 mm,

as appropriate for different adhesion strengths (5.3).

A reference engineering diagram is provided in Figure C.1.

NOTE Annex A describes considerations for other materials, in particular for situations where very low adhesion

energy measurements are targeted, or when adhesion to both beam and specimen is problematic with a titanium

beam.

Dimensions in millimetres

Figure 4 – Width-tapered beam

5.3 Beam selection

The optimum beam thickness is based on the expected adhesion strength value, with typical

adhesion strengths for some PV interfaces shown in Table 1. The 0,8 mm titanium beam has

2 2

been found useful for a range from ~20 J/m to 1 200 J/m , and the 1,6 mm beam for a range

2 2

from 100 J/m to 2 500 J/m . For measurement of very low adhesion energies, a different beam

material should be used; see Annex A.

Adhesion energy of an interface after environmental exposures can vary significantly, to near

zero. For comparison of adhesion energy before and after environmental exposures, the same

beam is recommended to be used for both, even for very low adhesion energies.

Highest sensitivity will be obtained with the most compliant beam which does not permanently

deform during the measurement, so the titanium beam with thickness of 0,8 mm is a useful

starting point. If the thin beam is used and visibly deformed after the test, the thicker beam

should be used. If the thick beam is pulled off the substrate without elastically bending, this

indicates a lower adhesion energy, and the thinner beam should be used.

– 12 – IEC TS 62788-6-3:2022 © IEC 2022

Table 1 – Typical adhesion strengths

Interface G

max

J/m

Backsheet – encapsulant (initial) 200 to 800

Backsheet interlayers (initial) 200 to 2 300

Encapsulant glass (initial) 1 200 to 2 500

Encapsulant – cell (initial) 1 200 to 2 000

6 Test method

6.1 Specimen preparation

A general procedure is provided below, with examples for specific use cases provided in

Annex B.

a) Prepare the test material

1) If the interface of interest is in the form of two different materials, laminate them in a

manner which replicates the bonding in the application.

2) If a flexible substrate is used (e.g. for backsheet interlayer, or backsheet to-

encapsulant), or a weak rigid substrate (e.g. a silicon cell) fix it to a strong rigid substrate

(e.g. thick glass).

• The size shall be large enough to completely hold the beam, with width greater than

h, and length greater than b.

• It may improve beam-specimen adhesion if the surface to be attached to the beam

is abraded. Then, clean the surface with isopropyl alcohol and allow to dry.

b) Abrade the surface of the selected beam to be bonded with a 150 grit sandpaper or similar,

and clean with isopropyl alcohol.

c) Adhere the tapered-width portion of beam to the top layer of the test specimen using a thin

layer of adhesive, leaving the rectangular portion unattached. A two-part structural adhesive

is recommended, using manufacturer’s instructions for mixing and shelf life. A weight (1 kg

to 5 kg) should be placed on top of each beam specimen to ensure even adhesive coverage

and a thin bond line. Care should be taken to ensure uniform weight distribution along the

length of the beam. Use of silica spheres in the epoxy can help to assure a minimum

thickness across the interface. Remove any excess adhesive from around the beam while

tacky but before it is fully cured.

NOTE 1 One example is 3M DP4M epoxy adhesive. This information is provided for the convenience of users

of this document and does not constitute an endorsement by IEC of this products.

d) Once the adhesive is fully cured, cut through the material around the beam down to the rigid

substrate using a sharp razor blade or scalpel (e.g. for a backsheet), or a sharp carbide or

diamond scribe (e.g. for a silicon cell). A leading-edge laser cutting device may also be

useful.

e) Condition the specimen at 23 °C ± 2 °C and 50 % ± 10 % RH for at least 24 h prior to test.

NOTE 2 Achieving equilibrium at standard conditions may take longer and can affect the results.

NOTE 3 Adhesive curing and sample conditioning can take place at the same time.

6.2 Measurement procedure

a) Attach the loading tab to the beam.

b) Attach the clevis link to the loading tab and clamp the sample to the platen. Orient the

sample so that the clevis link is vertical and in-line with the loading direction, and the centre

of the beam is aligned with the loading direction.

c) With zero applied load on the sample, initiate the test at a constant displacement rate of

10 µm/s and continue until the debond has propagated approximately 1/3 to 1/2 of the

sample length.

NOTE 1 With a constant displacement rate of 10 µm/s, test time may range between 5 min and 15 min depending

on the amount of deflection required to achieve an adequate debond length.

d) Check the beam and sample; the following conditions shall be met to result in a valid

measurement:

• The width-tapered beam shall not show any indication that it has plastically deformed

during the measurement. If the beam demonstrates any indication of permanent

deformation following the measurement, e.g. does not lie flat, the measurement is not

valid. If this occurs, repeat the measurement with a stiffer or thicker beam.

• In the sample, debonding shall exist at only one interface. If the debond switches

interfaces during the measurement or propagates at more than one interface

simultaneously, the measurement is not valid.

NOTE 2 Analysis for mixed mode debonding is beyond the current scope of this document.

e) Define the portion of the curve where the load, P, is reasonably stable as shown in Figure 5,

and note the average and standard deviation over that range. Some software will do this

automatically.

Inset figures demonstrate the increasing debond length throughout the test

Figure 5 – Typical width-tapered cantilever beam load/displacement curve

f) If using Method 2 (6.3) to calculate the critical adhesion energy G

c:

• Note the final load li

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...