IEC 60811-511:2012

(Main)Electric and optical fibre cables - Test methods for non-metallic materials - Part 511: Mechanical tests - Measurement of the melt flow index of polyethylene compounds

Electric and optical fibre cables - Test methods for non-metallic materials - Part 511: Mechanical tests - Measurement of the melt flow index of polyethylene compounds

IEC 60811-511:2012 describes the procedure for the measurement of the melt flow index for polyethylene compounds. IEC 60811-511:2012 cancels and replaces Clause 10 of IEC 60811-4-1:2004, which is withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012. There are no specific technical changes with respect to the previous edition, but see the Foreword to IEC 60811-100:2012.

This publication is to be read in conjunction with IEC 60811-100:2012.

Câbles électriques et à fibres optiques - Méthodes d'essai pour les matériaux non-métalliques - Partie 511: Essais mécaniques - Mesure de l'indice de fluidité à chaud des mélanges polyéthylène

La CEI 60811-511:2012 décrit la méthode de calcul de l'indice de fluidité à chaud pour les mélanges polyéthylène. La CEI 60811-511:2012 annule et remplace l'Article 10 de la CEI 60811-4-1:2004, qui est supprimée. L'ensemble des informations relatives aux remplacements figure dans l'Annexe A de la CEI 60811-100:2012. Aucune modification technique n'a été effectuée par rapport à l'édition précédente; voir cependant l'avant-propos de la CEI 60811-100:2012.

Cette publication doit être lue conjointement avec la CEI 60811-100:2012.

General Information

- Status

- Published

- Publication Date

- 12-Mar-2012

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 17 - TC 20/WG 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 13-Mar-2012

- Completion Date

- 31-Mar-2012

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60811-511:2012 is an international standard published by the International Electrotechnical Commission (IEC) that specifies test methods for the mechanical characterization of non-metallic materials used in electric and optical fibre cables. Specifically, Part 511 of this standard focuses on the measurement of the melt flow index (MFI) of polyethylene and polypropylene compounds. This test is vital for assessing the processability and consistency of polymer compounds applied in cable insulation, sheathing, and other protective layers.

The standard updates and replaces Clause 10 of the withdrawn IEC 60811-4-1:2004, maintaining technical continuity while providing consolidated guidance for cable manufacturers and material testers.

Key Topics

- Scope: Defines the procedures for measuring the melt flow index of polyethylene and polypropylene compounds, which reflects the extrusion behavior of these polymers under heat and pressure.

- Material Classification: Differentiates polyethylene types by density - low-density (LDPE), medium-density (MDPE), and high-density polyethylene (HDPE), which influences melt flow behavior.

- Test Methods: Details three methods (A, B, and C) for melt flow index determination, including sample preparation, apparatus, and test execution.

- Temperature and Load Parameters:

- Polyethylene compounds are tested at 190 °C.

- Polypropylene compounds are tested at 230 °C.

- Apparatus Specification: Includes a heated cylinder, piston, and specific dies to ensure standardized extrusion conditions.

- Complementary Standards: Requires use in conjunction with IEC 60811-100:2012 for general requirements and IEC 60811-606 for density determination of materials.

- Reporting: Specifies the format and essential details to be included in the test report for reproducibility and quality control.

Applications

IEC 60811-511:2012 is critical for quality assurance in the manufacturing of electrical and optical fibre cables with non-metallic materials. Key practical applications include:

- Material Qualification: Ensuring the polyethylene and polypropylene compounds used in cable jackets, insulation, or bedding meet required melt flow parameters to optimize extrusion processes.

- Process Control: Monitoring melt flow index to detect variations in polymer batch quality or formulation that may affect cable performance and durability.

- Research and Development: Supporting development of new cable materials with optimized flow characteristics for improved manufacturability and mechanical properties.

- Compliance: Assisting manufacturers and testing laboratories to comply with international standards for cable materials, facilitating global market acceptance.

- Failure Analysis: Using melt flow index data to investigate material-related faults such as poor extrusion, cracking, or reduced mechanical strength in cables.

Related Standards

- IEC 60811-100:2012: General provisions for test methods applied to non-metallic materials in cables.

- IEC 60811-606: Methods for determining the density of non-metallic cable materials, crucial for material classification in melt flow index testing.

- ISO 1133: International standard for melt mass-flow rate (MFR) testing, equivalent in methodology to IEC 60811-511.

- IEC 60811 Series: A comprehensive suite of test methods covering various mechanical, physical, electrical, and environmental characteristics of cable materials.

Summary

IEC 60811-511:2012 defines a standardized procedure to measure the melt flow index (MFI) of polyethylene and polypropylene compounds, key polymers widely used in insulation and protective layers of electrical and optical fibre cables. By ensuring reliable and repeatable measurement of melt flow properties, this standard supports consistent material quality and optimized cable manufacturing. It is indispensable for cable producers, material suppliers, and testing laboratories focused on meeting international quality and performance benchmarks. Through its detailed test methods and harmonization with related standards, IEC 60811-511 helps promote enhanced process control, product innovation, and global compliance in cable industry materials testing.

Buy Documents

IEC 60811-511:2012 - Electric and optical fibre cables - Test methods for non-metallic materials - Part 511: Mechanical tests - Measurement of the melt flow index of polyethylene compounds

IEC 60811-511:2012+AMD1:2017 CSV - Electric and optical fibre cables - Test methods for non-metallic materials - Part 511: Mechanical tests - Measurement of the melt flow index of polyethylene and polypropylene compounds Released:7/21/2017 Isbn:9782832246313

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60811-511:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric and optical fibre cables - Test methods for non-metallic materials - Part 511: Mechanical tests - Measurement of the melt flow index of polyethylene compounds". This standard covers: IEC 60811-511:2012 describes the procedure for the measurement of the melt flow index for polyethylene compounds. IEC 60811-511:2012 cancels and replaces Clause 10 of IEC 60811-4-1:2004, which is withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012. There are no specific technical changes with respect to the previous edition, but see the Foreword to IEC 60811-100:2012. This publication is to be read in conjunction with IEC 60811-100:2012.

IEC 60811-511:2012 describes the procedure for the measurement of the melt flow index for polyethylene compounds. IEC 60811-511:2012 cancels and replaces Clause 10 of IEC 60811-4-1:2004, which is withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012. There are no specific technical changes with respect to the previous edition, but see the Foreword to IEC 60811-100:2012. This publication is to be read in conjunction with IEC 60811-100:2012.

IEC 60811-511:2012 is classified under the following ICS (International Classification for Standards) categories: 29.035.01 - Insulating materials in general; 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60811-511:2012 has the following relationships with other standards: It is inter standard links to IEC 60811-4-1:2004, IEC 60811-511:2012/AMD1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60811-511:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60811-511 ®

Edition 1.0 2012-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 511: Mechanical tests – Measurement of the melt flow index of polyethylene

compounds

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 511: Essais mécaniques – Mesure de l’indice de fluidité à chaud des

mélanges polyéthylène

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60811-511 ®

Edition 1.0 2012-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 511: Mechanical tests – Measurement of the melt flow index of polyethylene

compounds

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 511: Essais mécaniques – Mesure de l’indice de fluidité à chaud des

mélanges polyéthylène

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX M

ICS 29.035.01; 29.060.20 ISBN 978-2-88912-988-1

– 2 – 60811-511 IEC:2012

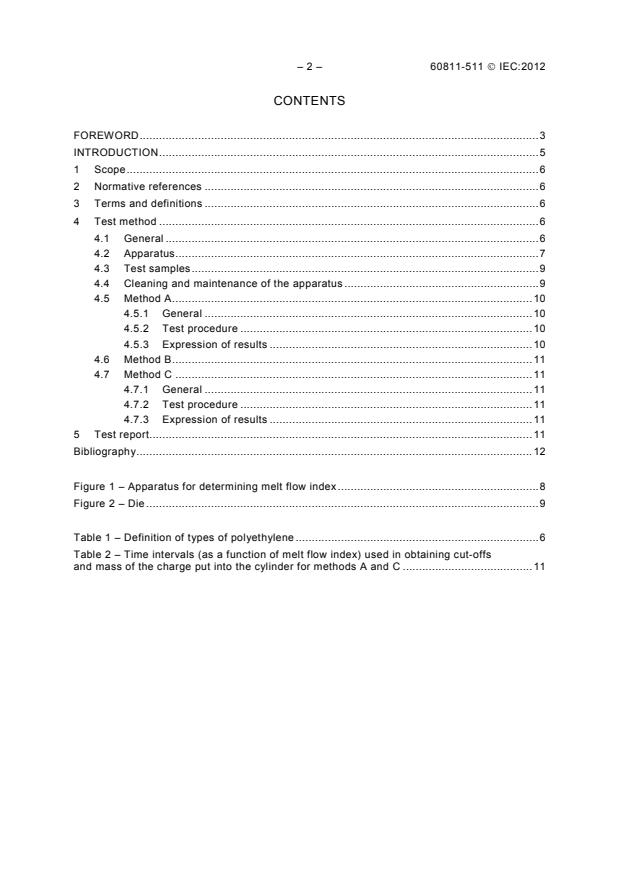

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test method . 6

4.1 General . 6

4.2 Apparatus . 7

4.3 Test samples . 9

4.4 Cleaning and maintenance of the apparatus . 9

4.5 Method A . 10

4.5.1 General . 10

4.5.2 Test procedure . 10

4.5.3 Expression of results . 10

4.6 Method B . 11

4.7 Method C . 11

4.7.1 General . 11

4.7.2 Test procedure . 11

4.7.3 Expression of results . 11

5 Test report. 11

Bibliography . 12

Figure 1 – Apparatus for determining melt flow index . 8

Figure 2 – Die . 9

Table 1 – Definition of types of polyethylene . 6

Table 2 – Time intervals (as a function of melt flow index) used in obtaining cut-offs

and mass of the charge put into the cylinder for methods A and C . 11

60811-511 IEC:2012 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 511: Mechanical tests –

Measurement of the melt flow index of polyethylene compounds

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60811-511 has been prepared by IEC technical committee 20:

Electric cables.

This Part 511 of IEC 60811 cancels and replaces Clause 10 of IEC 60811-4-1:2004, which is

withdrawn. Full details of the replacements are shown in Annex A of IEC 60811-100:2012.

There are no specific technical changes with respect to the previous edition, but see the

Foreword to IEC 60811-100:2012.

– 4 – 60811-511 IEC:2012

The text of this standard is based on the following documents:

FDIS Report on voting

20/1307/FDIS 20/1356/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part of IEC 60811 shall be used in conjunction with IEC 60811-100.

A list of all the parts in the IEC 60811 series, published under the general title Electric and

optical fibre cables – Test methods for non-metallic materials, can be found on the IEC

website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60811-511 IEC:2012 – 5 –

INTRODUCTION

The IEC 60811 series specifies the test methods to be used for testing non-metallic materials

of all types of cables. These test methods are intended to be referenced in standards for

cable construction and for cable materials.

NOTE 1 Non-metallic materials are typically used for insulating, sheathing, bedding, filling or taping within cables.

NOTE 2 These test methods are accepted as basic and fundamental and have been developed and used over

many years principally for the materials in all energy cables. They have also been widely accepted and used for

other cables, in particular optical fibre cables, communication and control cables and cables for ships and offshore

applications.

– 6 – 60811-511 IEC:2012

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 511: Mechanical tests –

Measurement of the melt flow index of polyethylene compounds

1 Scope

This Part 511 of IEC 60811 describes the procedure for the measurement of the melt flow

index for polyethylene compounds.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60811-100:2012, Electric and optical fibre cables – Test methods for non-metallic

materials – Part 100: General

IEC 60811-606, Electric and optical fibre cables – Test methods for non-metallic materials-

Part 606: Physical tests – Methods for determining the density

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60811-100 apply.

Additionally, for the purposes of this standard, a distinction is made between low-density,

medium-density and high-density PE as shown in Table 1.

Table 1 – Definition of types of polyethylene

a

Density at 23 °C

Type of polyethylene

g/cm

Low-density polyethylene ≤ 0,925

Medium-density polyethylene

> 0,925 ≤ 0,940

High-density polyethylene

> 0,940

a

These densities refer to unfilled resins as determined by the method specified in IEC 60811-606.

4 Test method

4.1 General

This part of IEC 60811 shall be used in conjunction with Part 100: General

All the tests shall be carried out not less than 16 h after the extrusion of the insulating or

sheathing compounds.

60811-511 IEC:2012 – 7 –

The melt flow index (MFI) of polyethylene and polyethylene compounds is the quantity of

material extruded in 1,5 min or 10 min at 190 °C through a specified die under the action of a

load determined by the method used.

NOTE 1 The same method is also specified in ISO 1133.

NOTE 2 The melt flow index is not applicable to flame retarding polyethylene. Flame retardant PE is defined as

PE containing additives intended to reduce flame propagation.

4.2 Apparatus

The apparatus consists basically of an extrusion plastometer, the general design being as

shown in Figure 1. The compound, which is contained in a vertical cylinder, is extruded

through a die by a loaded piston under controlled temperature conditions. All surfaces of the

apparatus in contact with the material under test shall have a high polish.

The apparatus consists of the following parts:

a) Steel cylinder

A steel cylinder fixed in a vertical position and thermally insulated for operation at 190 °C.

The cylinder shall be at least 115 mm long with an internal diameter of between 9,5 mm

and 10 mm and complying with the requirements in item b) below. The base of the cylinder

shall be thermally insulated if the area of the exposed metal exceeds 4 cm and it is

recommended that the insulating material used be polytetrafluoroethylene (thickness

about 3 mm) in order to avoid the extruded material from sticking.

b) Steel hollow piston

A steel hollow piston with a length at least the same as that of the cylinder. The axes of

the cylinder and of the piston shall coincide and the effective length of the piston shall be

a maximum of 135 mm. There is a head of length (6,35 ± 0,10) mm. The diameter of the

head shall be less than the internal diameter of the cylinder at all points along the working

length of the cylinder by (0,075 ± 0,015) mm. In addition, for calculating the load (see item

c) this diameter should be known within ± 0,025 mm. The lower edge of the head shall

have a radius of 0,4 mm and the upper edge has its sharp edge removed. Above the head,

the piston has a diameter of about 9 mm. A stud may be added at the top of the piston to

support the removable load, but the piston is thermally insulated from this load.

c) Removable load on top of the piston

The combined masses of the load and the piston shall be such that the force P applied is:

– P = 21,2 N in the case of method A (see 4.5);

– P = 49,1 N in the case of method C (see 4.7);

d) Heater

A heater to maintain the polyethylene in the cylinder at a temperature of (190 ± 0,5) °C.

An automatic temperature control is strongly recommended.

e) Temperature measuring device

A temperature measuring device located as closely as possible to the die, but situated

within the body of the cylinder. The measuring device shall be calibrated to permit

temperature measurement to an accuracy of ± 0,1 °C.

f) Die

A die of length (8,000 ± 0,025) mm made of hardened steel, the mean internal diameter

being between 2,090 mm and 2,100 mm and uniform along its length to within ± 0,005 mm

(see Figure 2). The die shall not project beyond the base of the cylinder.

g) Balance

A balance accurate to ± 0,000 5 g.

– 8 – 60811-511 IEC:2012

Dimensions in millimeters

NOTE The figure shows the large external diameter cylinder, die-retaining plate A and insulating plate B.

Key

1 guide collar

Figure 1 – Apparatus for determining melt flow index

60811-511 IEC:2012 – 9 –

Dimensions in millimetres

NOTE The figure shows the small external diameter cylinder with an example method of retaining the die.

Figure 2 – Die

4.3 Test samples

A sample of insulation or sheath of sufficient mass shall be taken from one end of the cable or

wire. The sample shall be cut in pieces, the dimension of which shall not exceed 3 mm in any

direction.

It is permitted to take material from different cores of the same cable.

4.4 Cleaning and maintenance of the apparatus

The apparatus shall be cleaned after each test.

On no account should abrasives or materials likely to damage the surfaces of the piston,

cylinder or die be used in removing superficial polyethylene or in manipulating any part of the

apparatus.

Suitable solvents for cleaning the apparatus are xylene, tetrahydronaphthalene or odourless

kerosene. The piston shall be cleaned while still hot with a cloth dipped in the solvent;

likewise, the cylinder shall also be cleaned while still hot, with a swab dipped in the solvent.

The die shall be cleaned with a closely-fitting brass reamer or wooden peg and then

immersed in boiling solvent.

– 10 – 60811-511 IEC:2012

It is recommended that, at fairly frequent intervals, for example once a week for apparatus in

constant use, the insulating plate and the die-retaining plate, if fitted (see Figure 1), be

removed and the cylinder cleaned thoroughly.

4.5 Method A

4.5.1 General

Method A is suitable for determining the melt flow index (MFI) of a sample of compound

whose MFI is unknown.

The MFI of a compound may be affected by previous thermal and mechanical treatments, and

in particular oxidation will tend to reduce the MFI. Oxidation occurring during the test will

usually cause a systematic reduction in the masses of successive cut-offs. This phenomenon

is not exhibited by compounds containing an anti-oxidant.

4.5.2 Test procedure

The apparatus shall be cleaned (see 4.4). Before beginning a series of tests, the temperature

of the cylinder and piston shall be at (190 ± 0,5) °C for 15 min and this temperature

maintained during the extrusion of the polyethylene.

It is recommended that the temperature measuring device (see item e) of 4.2 be a mercury-in-

glass thermometer located permanently within the mass of the cylinder (see note below).

A low melting-point alloy, such as Wood's metal, improves the thermal contact and its use is

recommended.

NOTE If any other temperature measuring device is used, it should be calibrated at (190 ± 0,5) °C before the

beginning of each series of tests in comparison with a mercury-in-glass thermometer, conforming to item e) of 4.2),

placed within the cylinder and immersed in polyethylene to its appropriate depth of immersion.

The cylinder shall then be charged with a portion of the sample (see Table 2) and the

unloaded piston reinserted into the top of the cylinder.

Four minutes after introducing the sample, during which time the temperature of the cylinder

shall have returned to (190 ± 0,5) °C, the load is placed on the piston to extrude the

polyethylene through the die. The rate of extrusion shall be measured by cutting the extruded

material at regular intervals of time at the die with a suitable sharp-edged instrument to give

short lengths of extruded material referred to as "cut-offs". The time intervals at which each

cut-off is taken are given in Table 2.

Several cut-offs shall be taken within 20 min of the introduction of the sample into the

cylinder. The first cut-off and any containing air bubbles shall be ignored. The remaining

successive cut-offs, of which there shall be at least three, shall be weighed individually to the

nearest milligram and the average mass determined. If the difference between the maximum

and the minimum values of the individual weightings exceeds 10 % of the average, the test

results shall be discarded and the test repeated on a fresh portion of the sample.

4.5.3 Expression of results

The melt flow index (MFI) shall be reported to two significant figures and expressed in g/600 s

as MFI.190.20.A (see NOTE):

600 × m

MFI.190.20.A =

t

where

MFI is expressed in grams per 10 min;

m is the average mass of cut-offs, expressed in grams;

60811-511 IEC:2012 – 11 –

t is the time interval of cut-offs, expressed in seconds.

NOTE 190 = temperature of tests, expressed in degrees Celsius; 20 (or 50 for method C) = approximate load,

expressed in Newtons applied to the melt.

4.6 Method B

Not used.

NOTE This heading is included only for clarity, as it appears in ISO 1133.

4.7 Method C

4.7.1 General

Method C is suitable for determining the MFI of a sample of polyethylene whose MFI,

measured in accordance with method A, is below 1.

4.7.2 Test procedure

The test procedure is the same as for method A.

The time intervals used in obtaining the cut-offs and the mass of the charge put into the

cylinder are given in Table 2.

Table 2 – Time intervals (as a function of melt flow index) used in obtaining cut-offs

and mass of the charge put into the cylinder for methods A and C

Melt flow index Mass of the charge Time

MFI put into the cyl

...

IEC 60811-511 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 511: Mechanical tests – Measurement of the melt flow index of polyethylene

and polypropylene compounds

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 511: Essais mécaniques – Mesure de l’indice de fluidité à chaud des

mélanges polyéthylène et polypropylène

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC

65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte,

et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les

publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées.

antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Restez informé sur les nouvelles publications IEC. Just Service Clients - webstore.iec.ch/csc

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60811-511 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 511: Mechanical tests – Measurement of the melt flow index of polyethylene

and polypropylene compounds

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 511: Essais mécaniques – Mesure de l’indice de fluidité à chaud des

mélanges polyéthylène et polypropylène

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.035.01; 29.060.20 ISBN 978-2-8322-4631-3

IEC 60811-511 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Electric and optical fibre cables – Test methods for non-metallic materials –

Part 511: Mechanical tests – Measurement of the melt flow index of polyethylene

and polypropylene compounds

Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques –

Partie 511: Essais mécaniques – Mesure de l’indice de fluidité à chaud des

mélanges polyéthylène et polypropylène

– 2 – IEC 60811-511:2012+AMD1:2017 CSV

IEC 2017

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test method . 6

4.1 General . 6

4.2 Apparatus . 7

4.3 Test samples . 9

4.4 Cleaning and maintenance of the apparatus . 9

4.5 Method A . 10

4.5.1 General . 10

4.5.2 Test procedure . 10

4.5.3 Expression of results . 10

4.6 Method B . 11

4.7 Method C . 11

4.7.1 General . 11

4.7.2 Test procedure . 11

4.7.3 Expression of results . 11

5 Test report. 11

Bibliography . 12

Figure 1 – Apparatus for determining melt flow index . 8

Figure 2 – Die . 9

Table 1 – Definition of types of polyethylene .

Table 2 – Time intervals (as a function of melt flow index) used in obtaining cut-offs

and mass of the charge put into the cylinder for methods A and C . 11

IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 511: Mechanical tests –

Measurement of the melt flow index

of polyethylene and polypropylene compounds

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 60811-511 edition 1.1 contains the first edition (2012-03) [documents 20/1307/FDIS and

20/1356/RVD] and its amendment 1 (2017-07) [documents 20/1736/FDIS and 20/1741/RVD].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions are in green text, deletions are in strikethrough red text. A

separate Final version with all changes accepted is available in this publication.

– 4 – IEC 60811-511:2012+AMD1:2017 CSV

IEC 2017

International Standard IEC 60811-511 has been prepared by IEC technical committee 20:

Electric cables.

There are no specific technical changes with respect to the previous edition, but see

the Foreword to IEC 60811-100:2012.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part of IEC 60811 shall be used in conjunction with IEC 60811-100.

A list of all the parts in the IEC 60811 series, published under the general title Electric and

optical fibre cables – Test methods for non-metallic materials, can be found on the IEC

website.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date,

the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

IEC 2017

INTRODUCTION

The IEC 60811 series specifies the test methods to be used for testing non-metallic materials

of all types of cables. These test methods are intended to be referenced in standards for

cable construction and for cable materials.

NOTE 1 Non-metallic materials are typically used for insulating, sheathing, bedding, filling or taping within cables.

NOTE 2 These test methods are accepted as basic and fundamental and have been developed and used over

many years principally for the materials in all energy cables. They have also been widely accepted and used for

other cables, in particular optical fibre cables, communication and control cables and cables for ships and offshore

applications.

– 6 – IEC 60811-511:2012+AMD1:2017 CSV

IEC 2017

ELECTRIC AND OPTICAL FIBRE CABLES –

TEST METHODS FOR NON-METALLIC MATERIALS –

Part 511: Mechanical tests –

Measurement of the melt flow index

of polyethylene and polypropylene compounds

1 Scope

This Part 511 of IEC 60811 describes the procedure for the measurement of the melt flow

index for polyethylene and polypropylene compounds.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60811-100:2012, Electric and optical fibre cables – Test methods for non-metallic

materials – Part 100: General

IEC 60811-606, Electric and optical fibre cables – Test methods for non-metallic materials-

Part 606: Physical tests – Methods for determining the density

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60811-100 apply.

Additionally, for the purposes of this standard, a distinction is made between low-density,

medium-density and high-density PE as shown in Table 1.

Table 1 – Definition of types of polyethylene

a

Density at 23 °C

Type of polyethylene

g/cm

Low-density polyethylene

≤ 0,925

Medium-density polyethylene > 0,925 ≤ 0,940

High-density polyethylene

> 0,940

a

These densities refer to unfilled resins as determined by the method specified in IEC 60811-606.

4 Test method

4.1 General

This part of IEC 60811 shall be used in conjunction with Part100: General IEC 60811-100.

All the tests shall be carried out not less than 16 h after the extrusion of the insulating or

sheathing compounds.

IEC 2017

The melt flow index (MFI) of polyethylene and polyethylene polypropylene compounds is the

quantity of material extruded in 1,5 min or 10 min at 190 °C a given temperature through a

specified die under the action of a load determined by the method used.

The temperature for polyethylene compounds is 190 °C and for polypropylene compounds it is

230 °C.

NOTE 1 The same method is also specified in ISO 1133 as melt mass-flow rate (MFR) procedure.

NOTE 2 The melt flow index is not applicable to flame retarding polyethylene. Flame retardant PE polyethylene is

defined as PE polyethylene containing additives intended to reduce flame propagation.

4.2 Apparatus

The apparatus consists basically of an extrusion plastometer, the general design being as

shown in Figure 1. The compound, which is contained in a vertical cylinder, is extruded

through a die by a loaded piston under controlled temperature conditions. All surfaces of the

apparatus in contact with the material under test shall have a high polish.

The apparatus consists of the following parts:

a) Steel cylinder

A steel cylinder fixed in a vertical position and thermally insulated for operation at 190 °C.

The cylinder shall be at least 115 mm long with an internal diameter of between 9,5 mm

and 10 mm and complying with the requirements in item b) below. The base of the cylinder

shall be thermally insulated if the area of the exposed metal exceeds 4 cm and it is

recommended that the insulating material used be polytetrafluoroethylene (thickness

about 3 mm) in order to avoid the extruded material from sticking.

b) Steel hollow piston

A steel hollow piston with a length at least the same as that of the cylinder. The axes of

the cylinder and of the piston shall coincide and the effective length of the piston shall be

a maximum of 135 mm. There is a head of length (6,35 ± 0,10) mm. The diameter of the

head shall be less than the internal diameter of the cylinder at all points along the working

length of the cylinder by (0,075 ± 0,015) mm. In addition, for calculating the load (see item

c) this diameter should be known within ± 0,025 mm. The lower edge of the head shall

have a radius of 0,4 mm and the upper edge has its sharp edge removed. Above the head,

the piston has a diameter of about 9 mm. A stud may be added at the top of the piston to

support the removable load, but the piston is thermally insulated from this load.

c) Removable load on top of the piston

The combined masses of the load and the piston shall be such that the force P applied is:

– P = 21,2 N in the case of method A (see 4.5);

– P = 49,1 N in the case of method C (see 4.7);

d) Heater

A heater to maintain the polyethylene compound in the cylinder at a the given temperature

of (190 ± 0,5) °C for polyethylene and of (230 ± 0,5) °C for polypropylene. An automatic

temperature control is strongly recommended.

e) Temperature measuring device

A temperature measuring device located as closely as possible to the die, but situated

within the body of the cylinder. The measuring device shall be calibrated to permit

temperature measurement to an accuracy of ± 0,1 °C.

f) Die

A die of length (8,000 ± 0,025) mm made of hardened steel, the mean internal diameter

being between 2,090 mm and 2,100 mm and uniform along its length to within ± 0,005 mm

(see Figure 2). The die shall not project beyond the base of the cylinder.

– 8 – IEC 60811-511:2012+AMD1:2017 CSV

IEC 2017

g) Balance

A balance accurate to ± 0,000 5 g.

Dimensions in millimeters

NOTE The figure shows the large external diameter cylinder, die-retaining plate A and insulating plate B.

Key

1 guide collar

Figure 1 – Apparatus for determining melt flow index

IEC 2017

Dimensions in millimetres

NOTE The figure shows the small external diameter cylinder with an example method of retaining the die.

Figure 2 – Die

4.3 Test samples

The test shall be carried out on granules or a sample section of insulation or sheath of

sufficient mass shall be taken from one end of the cable or wire. In the latter case, the sample

shall be cut into pieces, the dimension of which shall not exceed 3 mm in any direction.

It is permitted to take material from different cores of the same cable.

4.4 Cleaning and maintenance of the apparatus

The apparatus shall be cleaned after each test.

On no account should abrasives or materials likely to damage the surfaces of the piston,

cylinder or die be used in removing superficial polyethylene compound or in manipulating any

part of the apparatus.

Suitable solvents for cleaning the apparatus are xylene, tetrahydronaphthalene or odourless

kerosene. The piston shall be cleaned while still hot with a cloth dipped in the solvent;

likewise, the cylinder shall also be cleaned while still hot, with a swab dipped in the solvent.

The die shall be cleaned with a closely-fitting brass reamer or wooden peg and then

immersed in boiling solvent.

– 10 – IEC 60811-511:2012+AMD1:2017 CSV

IEC 2017

It is recommended that, at fairly frequent intervals, for example once a week for apparatus in

constant use, the insulating plate and the die-retaining plate, if fitted (see Figure 1), be

removed and the cylinder cleaned thoroughly.

4.5 Method A

4.5.1 General

Method A is suitable for determining the melt flow index (MFI) of a sample of compound

whose MFI is unknown.

The MFI of a compound may be affected by previous thermal and mechanical treatments, and

in particular oxidation will tend to reduce the MFI. Oxidation occurring during the test will

usually cause a systematic reduction in the masses of successive cut-offs. This phenomenon

is not exhibited by compounds containing an anti-oxidant.

4.5.2 Test procedure

The apparatus shall be cleaned (see 4.4). Before beginning a series of tests, the temperature

of the cylinder and piston shall be at (190 ± 0,5) °C for polyethylene or (230 ± 0,5) °C for

polypropylene for 15 min and this temperature maintained during the extrusion of the

polyethylene compound.

It is recommended that the temperature measuring device (see item e) of 4.2 be a mercury-in-

glass thermometer located permanently within the mass of the cylinder (see note below).

A low melting-point alloy, such as Wood's metal, improves the thermal contact and its use is

recommended.

NOTE If any other temperature measuring device is used, it should be calibrated at (190 ±

0,5) °C for polyethylene or (230 ± 0,5) ºC for polypropylene before the beginning of each

series of tests in comparison with a mercury-in-glass thermometer, conforming to item e) of

4.2), placed within the cylinder and immersed in polyethylene the compound to its appropriate

depth of immersion.

The cylinder shall then be charged with a portion of the sample (see Table 2) and the

unloaded piston reinserted into the top of the cylinder.

Four minutes after introducing the sample, during which time the temperature of the cylinder

shall have returned to (190 ± 0,5) °C for polyethylene or (230 ± 0,5) °C for polypropylene, the

load is placed on the piston to extrude the polyethylene compound through the die. The rate

of extrusion shall be measured by cutting the extruded material at regular intervals of time at

the die with a suitable sharp-edged instrument to give short lengths of extruded material

referred to as "cut-offs". The time intervals at which each cut-off is taken are given in Table 2.

Several cut-offs shall be taken within 20 min of the introduction of the sample into the

cylinder. The first cut-off and any containing air bubbles shall be ignored. The remaining

successive cut-offs, of which there shall be at least three, shall be weighed individually to the

nearest milligram and the average mass determined. If the difference between the maximum

and the minimum values of the individual weightings exceeds 10 % of the average, the test

results shall be discarded and the test repeated on a fresh portion of the sample.

4.5.3 Expression of results

The melt flow index (MFI) shall be reported to two significant figures and expressed in g/600 s

as MFI.190.20.A MFI.T.20.A (see NOTE):

600 × m

MFI.190.20.A MFI.T.20.A =

t

where

IEC 2017

MFI is expressed in grams per 10 min;

m is the average mass of cut-offs, expressed in grams;

t is the time interval of cut-offs, expressed in seconds.

NOTE 190 T = temperature of tests, expressed in degrees Celsius; 20 (or 50 for method C) = approximate load,

expressed in newtons applied to the melt.

4.6 Method B

Not used.

NOTE This heading is included only for clarity, as it appears in ISO 1133 as melt volume-flow rate (MVR)

procedure.

4.7 Method C

4.7.1 General

Method C is suitable for determining the MFI of a sample of polyethylene compound whose

MFI, measured in accordance with method A, is below 1.

4.7.2 Test procedure

The test procedure is the same as for method A.

The time intervals used in obtaining the cut-offs and the mass of the charge put into the

cylinder are given in Table 2.

Table 2 – Time intervals (as a function of melt flow index) used in obtaining cut-offs

and mass of the charge put into the cylinder for methods A and C

Melt flow index Mass of the charge Time

MFI put into the cylinder intervals

g s

0,1 to 0,5 4 to 5 240

0,5 to 1 4 to 5 120

1 to 3,5 4 to 5 60

4.7.3 Expression of results

The MFI shall be reported to two significant figures (see NOTE of 4.5.3) and expressed in

g/150 s as MFI.190.50.C MFI.T.50.C):

150 × m

MFI.190.50.C MFI.T.50.C =

t

NOTE The use of a shorter reference time (150 s) with a heavier load (50 N) gives results quoted on scale C

which agree approximately with results that would have been obtained had method A and scale A been used.

There is, however, no direct correlation between scales A and C.

5 Test report

The test report shall be in accordance with that given in IEC 60811-100.

– 12 – IEC 60811-511:2012+AMD1:2017 CSV

IEC 2017

Bibliography

IEC 60811-4-1:2004, Insulating and sheathing materials of electric and optical cables –

Common test methods – Part 4-1: Methods specific to polyethylene and polypropylene

compounds – Resistance to environmental stress cracking – Measurement of the melt flow

index – Carbon black and/or mineral filler content measurement in polyethylene by direct

combustion – Measurement of carbon black content by thermogravimetric analysis (TGA) –

Assessment of carbon black dispersion in polyethylene using a microscope

(withdrawn)

ISO 1133, Plastics – Determination of the melt mass-flow rate (MFR) and the melt volume-

flow rate (MVR) of thermoplastics

___________

– 14 – IEC 60811-511:2012+AMD1:2017 CSV

IEC 2017

SOMMAIRE

AVANT-PROPOS . 15

INTRODUCTION . 17

1 Domaine d’application . 18

2 Références normatives . 18

3 Termes et définitions . 18

4 Méthode d’essai . 19

4.1 Généralités. 19

4.2 Appareillage . 19

4.3 Echantillons d’essai . 22

4.4 Nettoyage et entretien de l’appareil . 22

4.5 Méthode A . 23

4.5.1 Généralités . 23

4.5.2 Méthode d’essai . 23

4.5.3 Expression des résultats. 23

4.6 Méthode B . 24

4.7 Méthode C . 24

4.7.1 Généralités . 24

4.7.2 Mode opératoire . 24

4.7.3 Expression des résultats. 25

5 Rapport d’essai . 25

Bibliographie . 26

Figure 1 – Appareil pour la détermination de l’indice de fluidité à chaud . 21

Figure 2 – Filière . 22

Tableau 1 – Distinction entre les différents niveaux de polyéthylene .

Tableau 2 – Intervalles de temps (en fonction de l’indice de fluidité) utilisés pour

obtenir les extrudats et masse d’échantillon à introduire dans le cylindre, pour les

méthodes A et C . 24

IEC 2017

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

CÂBLES ÉLECTRIQUES ET À FIBRES OPTIQUES –

MÉTHODES D’ESSAI POUR LES MATÉRIAUX NON-MÉTALLIQUES –

Partie 511: Essais mécaniques –

Mesure de l’indice de fluidité à chaud des mélanges

polyéthylène et polypropylène

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (IEC) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de l’IEC). L’IEC a pour

objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines

de l'électricité et de l'électronique. A cet effet, l’IEC – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de l’IEC"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec l’IEC, participent

également aux travaux. L’IEC collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de l’IEC concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de l’IEC

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de l’IEC se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de l’IEC. Tous les efforts raisonnables sont entrepris afin que l’IEC

s'assure de l'exactitude du contenu technique de ses publications; l’IEC ne peut pas être tenue responsable de

l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de l’IEC s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de l’IEC dans leurs publications nationales

et régionales. Toutes divergences entre toutes Publications de l’IEC et toutes publications nationales ou

régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) L’IEC elle-même ne fournit aucune attestation de conformité. Des organismes de certification indépendants

fournissent des services d'évaluation de conformité et, dans certains secteurs, accèdent aux marques de

conformité de l’IEC. L’IEC n'est responsable d'aucun des services effectués par les organismes de certification

indépendants.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à l’IEC, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de l’IEC, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de l’IEC ou de

toute autre Publication de l’IEC, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de l’IEC peuvent faire

l’objet de droits de brevet. L’IEC ne saurait être tenue pour responsable de ne pas avoir identifié de tels droits

de brevets et de ne pas avoir signalé leur existence.

Cette version consolidée de la Norme IEC officielle et de son amendement a été préparée pour

la commodité de l'utilisateur.

L'IEC 60811-511 édition 1.1 contient la première édition (2012-03) [documents 20/1307/FDIS et

20/1356/RVD] et son amendement 1 (2017-07) [documents 20/1736/FDIS et 20/1741/RVD].

Dans cette version Redline, une ligne verticale dans la marge indique où le contenu technique

est modifié par l’amendement 1. Les ajouts sont en vert, les suppressions sont en rouge,

barrées. Une version Finale avec toutes les modifications acceptées est disponible dans cette

publication.

– 16 – IEC 60811-511:2012+AMD1:2017 CSV

IEC 2017

La Norme internationale IEC 60811-511 a été établie par le comité d’études 20 de l’IEC:

Câbles électriques.

Aucune modification technique n’a été effectuée par rapport à l’édition précédente;

voir cependant l’avant-propos de l’IEC 60811-100:2012.

Cette publication a été rédigée selon les Directives ISO/IEC, Partie 2.

La présente partie de l’IEC 60811 doit être utilisée conjointement avec l’IEC 60811-100.

Une liste de toutes les parties de la série IEC 60811, publiées sous le titre général Câbles

électriques et à fibres optiques – Méthodes d’essai pour les matériaux non-métalliques, peut

être consultée sur le site web de l’IEC.

Le comité a décidé que le contenu de la publication de base et de son amendement ne sera

pas modifié avant la date de stabilité indiquée sur le site web de l’IEC sous

"http://webstore.iec.ch" dans les données relatives à la publication recherchée. A cette date,

la publication sera

• reconduite,

• supprimée,

• remplacée par une édition révisée, ou

• amendée.

IMPORTANT – Le logo "colour inside" qui se trouve sur la page de couverture de cette

publication indique qu'elle contient des couleurs qui sont considérées comme utiles à

une bonne compréhension de son contenu. Les utilisateurs devraient, par conséquent,

imprimer cette publication en utilisant une imprimante couleur.

IEC 2017

INTRODUCTION

La série IEC 60811 précise les méthodes à employer pour les essais des matériaux non-

métalliques sur tous les types de câbles. Ces méthodes d’essai seront citées en référence

dans les normes relatives à la construction des câbles et aux matériaux des câbles.

NOTE 1 Les matériaux non-métalliques sont généralement utilisés pour l’isolation, le gainage, le matelassage, le

remplissage ou le rubanage des câbles.

NOTE 2 Ces méthodes d’essai sont reconnues comme fondamentales; elles ont été développées et utilisées

durant de nombreuses années, principalement pour les matériaux dans tous les câbles de distribution d’énergie.

Elles ont aussi été largement reconnues et utilisées pour d’autres types de câbles, en particulier les câbles à fibres

optiques, les câbles de communication et de commande, ainsi que les câbles utilisés à bord des navires et dans

les applications offshore.

– 18 – IEC 60811-511:2012+AMD1:2017 CSV

IEC 2017

CÂBLES ÉLECTRIQUES ET À FIBRES OPTIQUES –

MÉTHODES D’ESSAI POUR LES MATÉRIAUX NON-MÉTALLIQUES –

Partie 511: Essais mécaniques –

Mesure de l’indice de fluidité à chaud des mélanges

polyéthylène et polypropylène

1 Domaine d’application

La présente Partie 511 de l’IEC 60811 décrit la méthode de calcul de l’indice de fluidité à

chaud pour les mélanges polyéthylène et polypropylène.

2 Références normatives

Les documents suivants sont cités en référence de manière normative, en intégralité ou en

partie, dans le présent document et sont indispensables pour son application. Pour les

références datées, seule l’édition citée s’applique. Pour les références non datées, la

dernière édition du document de référence s’applique (y compris les éventuels

amendements).

IEC 60811-100:2012, Câbles électriques et à fibres optiques – Méthodes d’essai pour les

matériaux non-métalliques – Partie 100: Généralités

IEC 60811-606, Câbles électriques et à fibres optiques – Méthodes d’essai pour les matériaux

non-métalliques – Partie 606: Essais physiques – Méthodes de détermination de la masse

volumique

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions donnés dans la

IEC 60811-100 s’appliquent.

De plus, pour les besoins de la présente norme, la distinction entre le polyéthylène basse

densité, moyenne densité et haute densité est faite selon les explications présentées au

Tableau 1.

Tableau 1 – Distinction entre les différents niveaux de polyéthylene

a

Densité à 23 °C

Type de polyéthylène

g/cm

Polyéthylène basse densité

≤ 0,925

Polyéthylène moyenne densité > 0,925 ≤ 0,940

Polyéthylène haute densité

> 0,940

a

Les densités se rapportent aux résines non chargées et sont déterminées au moyen de la méthode spécifiée

dans l’IEC 60811-606.

IEC 2017

4 Méthode d’essai

4.1 Généralités

La présente partie de l’IEC 60811 doit être utilisée conjointement avec l’IEC 60811-100.

Tous les essais doivent être réalisés au moins 16 h après l’extrusion ou la réticulation, s’il y a

lieu, des mélanges d’isolation et de gainage.

L’indice de fluidité à chaud (IFC) du polyéthylène et des mélanges à base de polyéthylène et

polypropylène correspond à la masse de matériau extrudé en 1,5 min ou 10 min à 190 °C à

une température donnée à travers une filière déterminée, sous l’action d’une charge spécifiée

par la méthode utilisée.

La température pour les mélanges polyéthylène est de 190 °C et pour les mélanges

polypropylène, elle est de 230 °C.

NOTE 1 La même méthode est spécifiée également dans l’ISO 1133 comme mode opératoire pour l’indice de

fluidité à chaud en masse (MFR, mass-flow rate).

NOTE 2 L’indice de fluidité à chaud n’est pas appliqué au polyéthylène retardateur de flamme. Le PE

polyéthylène retardateur de flamme est défini comme un PE polyéthylène contenant des additifs destinés à limiter

la propagation des flammes.

4.2 Appareillage

L'appareillage est basé sur une extrusion plastomère, le schéma étant présenté à la Figure 1.

Le mélange contenu dans le cylindre vertical est extrudé à travers une filière sous la poussée

de la charge d'un piston dans les conditions de température contrôlées. Toutes les surfaces

de l'appareillage en contact avec le matériau en essai doivent être bien polies.

L'appareillage comporte les parties suivantes:

a) Un cylindre en acier

Un cylindre en acier fixé verticalement et isolé thermiquement afin de pouvoir opérer à

190 °C. Le cylindre doit avoir au moins 115 mm de longueur, avec un diamètre intérieur

compris entre 9,5 mm et 10 mm et doit satisfaire aux exigences du point b) ci-dessous.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...