IEC 62832-3:2020

(Main)Industrial-process measurement, control and automation - Digital factory framework - Part 3: Application of Digital Factory for life cycle management of production systems

Industrial-process measurement, control and automation - Digital factory framework - Part 3: Application of Digital Factory for life cycle management of production systems

IEC 62832-3:2020 specifies rules of the Digital Factory framework for managing information of a production system throughout its life cycle. It also defines how the information will be added, deleted or changed in the Digital Factory by the various activities during the life cycle of the production system.

Mesure, commande et automation dans les processus industriels - Cadre de l’usine numérique (Digital Factory) - Partie 3: Application de l'usine numérique pour la gestion du cycle de vie de systèmes de production

L'IEC 62832-3:2020 spécifie les règles pour le cadre de l’usine numérique (Digital Factory) destiné à la gestion des informations d'un système de production tout au long de son cycle de vie. Elle définit également la manière dont les informations sont ajoutées, supprimées ou modifiées dans le DigitalFactory par les différentes activités lors du cycle de vie du système de production.

General Information

- Status

- Published

- Publication Date

- 26-Oct-2020

- Technical Committee

- TC 65 - Industrial-process measurement, control and automation

- Drafting Committee

- WG 16 - TC 65/WG 16

- Current Stage

- PPUB - Publication issued

- Start Date

- 27-Oct-2020

- Completion Date

- 20-Nov-2020

Overview

IEC 62832-3:2020, published by the International Electrotechnical Commission (IEC), defines the Digital Factory framework specifically for the life cycle management of production systems in industrial-process measurement, control, and automation. This international standard establishes rules for handling information throughout the entire life cycle of a production system-from creation, modification, to deletion-within a digital factory environment.

The standard supports manufacturers and production system integrators by providing a structured approach to manage complex data related to production assets. It facilitates effective digitalization by enabling consistent information flow for optimal asset management, maintenance, and evolution, paving the way for Industry 4.0 and smart manufacturing implementations.

Key Topics

Life Cycle Management: IEC 62832-3 lays out guidelines on managing all relevant information for production systems throughout their life cycles. This includes design, operation, maintenance, and eventual decommissioning.

Digital Factory Framework Elements: The standard defines how Digital Factories should represent:

- Production system assets (DFassets) and their attributes.

- Relationships between assets using DFassetLinks.

- DataElements that can be constant or variable, representing asset-specific data.

- Filtering and viewing mechanisms (ViewElements) for discipline-specific perspectives.

Information Structure and Dictionaries: Rules for maintaining dictionaries (standardized, consortium-based, and supplier dictionaries) ensure consistent terminology and classification across the industry and supply chains.

Libraries and Repositories: Establishes methods for managing SupplierLibraries, DFLibraries, and asset class definitions to organize reusable components and information.

Access and Maintenance: Procedures for creating, managing, replicating, and controlling access to Digital Factories are detailed to ensure secure and efficient information handling.

Compatibility and Assessment: Includes methods to evaluate compatibility between different assets leveraging DataElementRelationships and DFassetClassAssociations that support interoperability and integration efforts.

Mapping to Other Technologies: The Annex A provides guidance on aligning the Digital Factory framework with other standards such as IEC 62714 (AutomationML) and IEC 62541-100 (OPC UA for devices), fostering interoperability.

Applications

IEC 62832-3:2020 is vital for organizations seeking to implement or improve digital factory solutions in manufacturing plants. Its practical applications include:

Manufacturing System Design: Facilitates digital modeling of production assets for improved system design and virtual commissioning.

Asset Lifecycle Tracking: Enables continuous monitoring and updating of production system components throughout their lifecycle.

Maintenance Management: Supports predictive maintenance by providing structured and up-to-date asset information accessible across teams.

Interdisciplinary Collaboration: Provides mechanisms to filter and present relevant data views tailored for various technical disciplines (e.g., mechanical, electrical, automation).

Supply Chain Integration: Harmonizes terminology and asset classifications across suppliers through standardized dictionaries and libraries.

Digital Twin Development: Serves as a foundation for building digital twins by structuring detailed physical and functional asset information digitally.

Compliance and Standardization: Assists enterprises in aligning their digital factory initiatives with global standards to ensure interoperability and scalability.

Related Standards

To maximize the effectiveness of IEC 62832-3:2020, it is important to also consider related international standards and frameworks:

IEC 62832-1 and IEC 62832-2 – Other parts of the Digital Factory framework series focusing on concepts, attributes, and the modeling of production systems.

IEC 62714 (AutomationML) – Standard for describing plant engineering information, with complementary modeling techniques.

IEC 62541-100 (OPC UA for Devices) – Standard for communication in automation, which supports interoperability between industrial devices.

ISO 15926 – For lifecycle data integration in process plants, useful for broader lifecycle management.

IEC 61512 (Batch Control) – Provides standards for batch process management that can integrate with lifecycle data in digital factories.

Keywords: IEC 62832-3, Digital Factory framework, production system lifecycle, industrial automation standards, asset lifecycle management, manufacturing digitalization, Industry 4.0, production asset digital twin, IEC standards, automation interoperability.

Frequently Asked Questions

IEC 62832-3:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Industrial-process measurement, control and automation - Digital factory framework - Part 3: Application of Digital Factory for life cycle management of production systems". This standard covers: IEC 62832-3:2020 specifies rules of the Digital Factory framework for managing information of a production system throughout its life cycle. It also defines how the information will be added, deleted or changed in the Digital Factory by the various activities during the life cycle of the production system.

IEC 62832-3:2020 specifies rules of the Digital Factory framework for managing information of a production system throughout its life cycle. It also defines how the information will be added, deleted or changed in the Digital Factory by the various activities during the life cycle of the production system.

IEC 62832-3:2020 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62832-3:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62832-3 ®

Edition 1.0 2020-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Industrial-process measurement, control and automation – Digital Factory

framework –

Part 3: Application of Digital Factory for life cycle management of production

systems

Mesure, commande et automation dans les processus industriels – Cadre de

l’usine numérique (Digital Factory) –

Partie 3: Application de l'usine numérique pour la gestion du cycle de vie de

systèmes de production

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62832-3 ®

Edition 1.0 2020-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Industrial-process measurement, control and automation – Digital Factory

framework –

Part 3: Application of Digital Factory for life cycle management of production

systems

Mesure, commande et automation dans les processus industriels – Cadre de

l’usine numérique (Digital Factory) –

Partie 3: Application de l'usine numérique pour la gestion du cycle de vie de

systèmes de production

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 25.040.40 ISBN 978-2-8322-8966-2

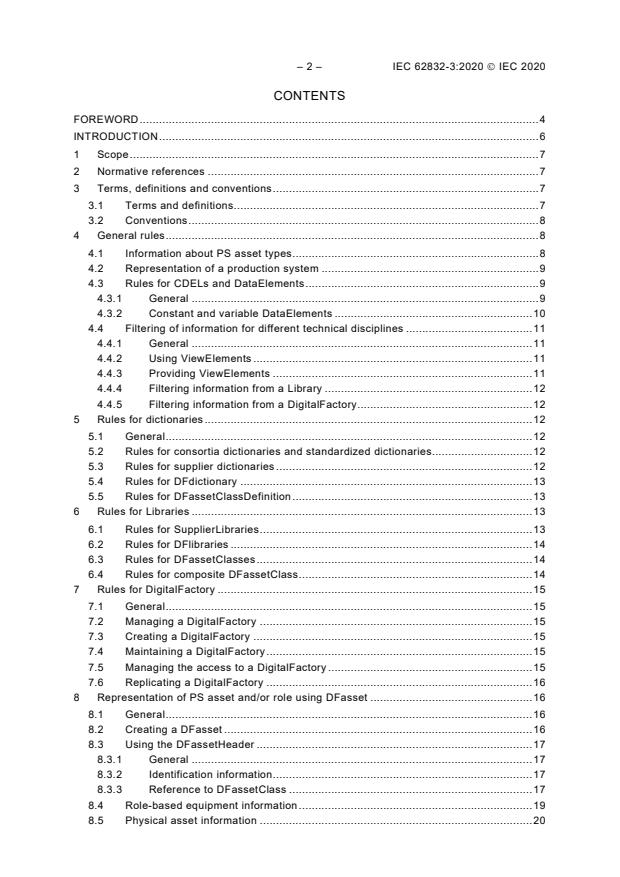

– 2 – IEC 62832-3:2020 IEC 2020

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and conventions . 7

3.1 Terms and definitions . 7

3.2 Conventions . 8

4 General rules . 8

4.1 Information about PS asset types . 8

4.2 Representation of a production system . 9

4.3 Rules for CDELs and DataElements . 9

4.3.1 General . 9

4.3.2 Constant and variable DataElements . 10

4.4 Filtering of information for different technical disciplines . 11

4.4.1 General . 11

4.4.2 Using ViewElements . 11

4.4.3 Providing ViewElements . 11

4.4.4 Filtering information from a Library . 12

4.4.5 Filtering information from a DigitalFactory. 12

5 Rules for dictionaries . 12

5.1 General . 12

5.2 Rules for consortia dictionaries and standardized dictionaries. 12

5.3 Rules for supplier dictionaries . 12

5.4 Rules for DFdictionary . 13

5.5 Rules for DFassetClassDefinition . 13

6 Rules for Libraries . 13

6.1 Rules for SupplierLibraries . 13

6.2 Rules for DFlibraries . 14

6.3 Rules for DFassetClasses . 14

6.4 Rules for composite DFassetClass . 14

7 Rules for DigitalFactory . 15

7.1 General . 15

7.2 Managing a DigitalFactory . 15

7.3 Creating a DigitalFactory . 15

7.4 Maintaining a DigitalFactory . 15

7.5 Managing the access to a DigitalFactory . 15

7.6 Replicating a DigitalFactory . 16

8 Representation of PS asset and/or role using DFasset . 16

8.1 General . 16

8.2 Creating a DFasset . 16

8.3 Using the DFassetHeader . 17

8.3.1 General . 17

8.3.2 Identification information . 17

8.3.3 Reference to DFassetClass . 17

8.4 Role-based equipment information . 19

8.5 Physical asset information . 20

8.5.1 Basic DFasset . 20

8.5.2 Composite DFasset . 20

9 Representation of PS assets relationships using DFassetLink . 20

9.1 General . 20

9.2 DFassetClassAssociation . 21

9.3 DataElementRelationship . 21

9.4 Evaluating compatibility between DFassets . 22

9.4.1 Overview . 22

9.4.2 Interpretation of compatibility . 22

9.4.3 Evaluation of compatibility . 22

Annex A (informative) Mapping of Digital Factory Framework to other technologies . 23

A.1 General: implementing DF Framework . 23

A.2 Mapping to IEC 62714 (AutomationML) . 23

A.3 Mapping to IEC 62541-100 (OPC UA for devices) . 25

Bibliography . 26

Figure 1 – Example for PS asset type description based on multiple dictionaries . 8

Figure 2 – Representation of a production system . 9

Figure 3 – Example for use of constant and variable DataElements . 10

Figure 4 – Example for DFasset created from DFassetClass . 18

Figure 5 – Example for extending DFasset with additional information . 18

Figure 6 – Development of physical asset information and role-based equipment

information . 19

Table A.1 – Mapping of DF model elements to concepts of IEC 62714 (all parts) . 24

Table A.2 – Mapping of DF model elements to concepts of IEC 62541-100 . 25

– 4 – IEC 62832-3:2020 IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INDUSTRIAL-PROCESS MEASUREMENT, CONTROL

AND AUTOMATION – DIGITAL FACTORY FRAMEWORK –

Part 3: Application of Digital Factory for

life cycle management of production systems

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62832-3 has been prepared by IEC technical committee 65:

Industrial-process measurement, control and automation.

The text of this International Standard is based on the following documents:

FDIS Report on voting

65/831/FDIS 65/842/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 62832 series, published under the general title, Industrial-process

measurement, control and automation – Digital Factory framework, can be found on the IEC

website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 6 – IEC 62832-3:2020 IEC 2020

INTRODUCTION

IEC 62832 provides a framework used for establishing and maintaining the digital

representations of production systems, including the representation of the elements of the

production systems and of the relationships between these elements. The framework is

intended also to support the exchange of information about these elements.

The framework aims at reducing the interoperability barriers for exchange of information for the

various activities related to production systems. The main advantages of this method are that

all information related to a production system is described in a standardized manner, and it can

be used and modified through its entire life cycle. The method defined in IEC 62832 is kept as

generic as possible in order to enable its use in several industrial sectors.

Manufacturers and suppliers provide information about available PS asset types by using

electronic catalogues, which are based on commonly agreed data definitions (for instance

1 2

IEC CDD, eCl@ss and eOTD ). Such data definitions can be provided by standard

organizations (like IEC CDD), by consortia (like eCl@ss e.V.) or by companies (like eOTD

dictionaries).

The DF Framework provides a standardized approach, by defining the concepts of Libraries

(i.e. SupplierLibraries and DFlibraries) and by defining basic rules for such Libraries.

The intention of this document is to provide a common base for implementation of the DF

framework using different technologies (for example different engineering data formats).

Proposals for such implementations are provided in Annex A.

IEC 62832-1 describes the general principles of the DF reference model together with its most

important model elements. IEC 62832-2 specifies detailed requirements for model elements of

the DF reference model. This part of IEC 62832 specifies the rules for using the DF framework.

_____________

eCl@ss® is the registered trademark of a product supplied by the eCl@ss e.V. association. This information is

given for the convenience of users of this document and does not constitute an endorsement by IEC of the product

named.

eOTD® is the registered trademark of a product supplied by ECCMA (Electronic Commerce Code Management

Association). This information is given for the convenience of users of this document and does not constitute an

endorsement by IEC of the product named.

INDUSTRIAL-PROCESS MEASUREMENT, CONTROL

AND AUTOMATION – DIGITAL FACTORY FRAMEWORK –

Part 3: Application of Digital Factory for

life cycle management of production systems

1 Scope

This part of IEC 62832 specifies rules of the Digital Factory framework for managing information

of a production system throughout its life cycle. It also defines how information will be added,

deleted or changed in the DigitalFactory by the various activities during the life cycle of the

production system.

These rules include:

– rules to represent a production system with a DigitalFactory;

– rules to represent a PS asset or a role with a DFasset;

– rules to represent a relationship between PS assets with a DFassetLink;

– rules to represent a relationship between roles with a DFassetLink;

– rules to represent the hierarchy of PS assets in a production system;

– rules to check the compatibility between associated PS assets.

NOTE 1 "PS" and "DF" are used in IEC 62832 (all parts) as qualifiers, they are part of the concept names. See

IEC 62832-1:2020, Clause 3.

NOTE 2 Common rules are the base for the exchange of data between and within enterprises, between engineering

tools, and between departments.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62832-1:2020, Industrial-process measurement, control and automation – Digital Factory

framework – Part 1: General principles

IEC 62832-2:2020, Industrial-process measurement, control and automation – Digital Factory

framework – Part 2: Model elements

ISO/IEC 6523 (all parts), Information technology – Structure for the identification of

organizations and organization parts

3 Terms, definitions and conventions

3.1 Terms and definitions

For the purposes of this document, the terms and definitions as well as the abbreviated terms

given in IEC 62832-1, IEC 62832-2 and the following apply.

– 8 – IEC 62832-3:2020 IEC 2020

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• ISO Online browsing platform: available at http://www.iso.org/obp

• IEC Electropedia: available at http://www.electropedia.org/

3.2 Conventions

While IEC 62832-1 is using general names for describing the concepts, IEC 62832-2 and

IEC 62832-3 define more formal requirements. In order to clearly identify the names of the

model elements, IEC 62832-2 and IEC 62832-3 use ‘PascalCase’ for names.

A help for matching the names is provided in IEC 62832-2:2020, Table B.1.

4 General rules

4.1 Information about PS asset types

The description of a PS asset type is provided in a Library by means of a DFassetClass, which

is derived from a DFassetClassDefinition in a ConceptDictionary. This relationship is

documented by the "DFassetClassDefinition" reference in the header of the DFassetClass. The

product characteristics are described by DataElements and CDELs, which commonly also are

based on definitions from the same ConceptDictionary as the DFassetClassDefinition. If the

used dictionary does not support description of all relevant product characteristics, additional

DataElements and CDELs may be provided based on definitions from a different

ConceptDictionary (e.g. from a different consortium or from the vendor) (see for example

Figure 1).

Figure 1 – Example for PS asset type description based on multiple dictionaries

4.2 Representation of a production system

A DigitalFactory shall be used to represent a production system (see Figure 2). The production

system represented by a DigitalFactory may be a planned production system or an existing

production system.

The granularity of the digital representation of the production system may vary depending on

the intended purpose.

EXAMPLE For initial planning purposes, the DigitalFactory can contain DFassets representing the main components

of the production systems, while for operation purposes the DFassets can describe sub-structures down to single

devices or depending on criticality minor mechanical components (such as bolts and screws).

During the life cycle of the production system, the information in the DigitalFactory should

change according to the changing production system.

Figure 2 – Representation of a production system

4.3 Rules for CDELs and DataElements

4.3.1 General

A DFasset shall be used to represent a specific PS asset, a specific role or a specific PS asset

with an assigned role. The particular aspects or features of a PS asset or role should be

described with CDELs. Each CDEL collects all DataElements describing a specific feature (for

example an interface, a part, an aspect) of the PS asset.

A DataElement shall contain the actual information describing a characteristic of a PS asset or

of a role. DataElements shall be created based on DETs and CDELs shall be created based on

CDELdefinitions.

– 10 – IEC 62832-3:2020 IEC 2020

A CDEL may contain at the same time DataElements with defined DataValues and

DataElements with undefined DataValues. The method to leave DataValues of DataElements

undefined shall be specified for each Library as well as for each DigitalFactory.

EXAMPLE Examples for methods to assign an undefined DataValue are: to keep the value empty; to define an

invalid value; or to eliminate the value space from the DataElement.

4.3.2 Constant and variable DataElements

Depending on the intended use of a specific DataElement, it can be necessary to provide

additional information together with the DataValue of the DataElement. In order to specify such

requirements, a DataElementType shall be categorized by using DET category. The possible

values of DET categories are "variable" and "constant". If a DET does not have a defined DET

category, the value of DET category shall be considered as "constant".

DET that have a DET category of "constant" are called in this document "constant DET" and

DET that have a DET category of "variable" are called "variable DET". DataElements that are

derived from "variable DET" are called "variable DataElements", all other DataElements are

called "constant DataElements".

If DataElements are ‘variable’, thenTimeStamp and ValueQuality shall be provided for the

DataValue.

EXAMPLE Figure 3 shows an example for a constant DataElement ("max. temperature") and a variable

DataElement ("measured temperature"). The "max. temperature" is defined for a PS asset type "temperature sensor".

The DataValue does not change for the life time of the actual temperature sensor (PS asset). On the other hand, the

actually measured temperature can change. This is why the DataElement is classified as variable DataElement.

Figure 3 – Example for use of constant and variable DataElements

4.4 Filtering of information for different technical disciplines

4.4.1 General

A view is a set of information extracted from a search space. Different views of the information

about the PS assets or roles reduce the complexity that is presented to the user. These views

support operational activities to access, manage, and update the information. A given

operational activity typically does not use all of the PS asset information.

It is possible to filter the information for a particular technical discipline or for a particular

application aspect.

A technical discipline is defined as an area of technical expertise applied to a specific set of

activities. A particular view may be provided for multiple technical disciplines, because activities

which belong to different technical disciplines need to exchange the same common information.

For a particular activity, the view should be provided based on two aspects. The first aspect is

what kinds of elements of information are shown in the view, and the second aspect is how

those elements are associated in the view.

The first aspect is provided by filtering, and the second aspect is provided by supporting multiple

views with different hierarchies. The DF framework provides support for the first aspect

(filtering) but does not support the second aspect (organization of filtering results into views).

A particular application might be related to a tool processing information from a Library or from

a DigitalFactory for a specific purpose.

If views are used to select only the relevant information, subsequent processing of this

information can be executed more efficiently. This may be implemented by using a combination

of multiple ViewElements.

4.4.2 Using ViewElements

ViewElements may be used to filter information from Libraries or in DigitalFactories (depending

on the defined search space). This allows filtering information specific for a TechnicalDiscipline.

ViewElements may be used to select

– DFassetClasses,

– DFassetClassAssociations,

– DFassets,

– DFassetLinks,

– CDELs, and

– DataElements.

4.4.3 Providing ViewElements

ViewElements may be provided by data suppliers in SupplierLibraries or by the enterprise in

DFlibraries.

The enterprise may provide ViewElements in a DFlibrary by

• importing them from SupplierLibraries, or

• creating them as filters for similar queries (e.g. for specific purposes or for a specific

technical discipline).

– 12 – IEC 62832-3:2020 IEC 2020

When a ViewElement is provided, technical disciplines shall be used to specify the purpose of

filtering.

4.4.4 Filtering information from a Library

In order to find a specific DFassetClass in a Library, a ViewElement shall be used. The Library

can be filtered to find a DFassetClass derived from a specific DFassetClassDefinition, which

has certain DataElements with specific values.

A ViewElement shall be used to define which information from the DFassetClasses is filtered

from the Library. This helps comparing DFassetClasses.

EXAMPLE Selection of replacement for a failed asset.

To select assets replacing an existing asset, the replacement needs to fulfil all necessary requirements, even if the

same PS asset type is no longer available on the market. Therefore, the new part needs to be selected by its technical

parameters. The ViewElement is used to define the technical parameters for selection.

4.4.5 Filtering information from a DigitalFactory

A ViewElement shall be used to find a specific DFasset, DFassetLink or DFassetAssignment in

a DigitalFactory.

A DFasset can be found, if it is derived from a specific DFassetClass and has certain

DataElements with specific DataValues.

A DFassetLink can be found if it is derived from a specific DFassetClassAssociation.

5 Rules for dictionaries

5.1 General

ConceptDictionaries may have different structural organization and contents. A

ConceptDictionaryEntry may define a DET, a CDELdefinition, or a DFassetClassDefinition.

The rules for defining DETs of a ConceptDictionary shall be specified by a data specification.

Such a data specification defines for example the data types to be used in definition of the

DETs.

Concept dictionaries should provide information regarding physical assets and information

regarding roles.

EXAMPLE The IEC CDD is a repository of different dictionaries with different rules. The dictionary for IEC 61987

(all parts) provides DFassetClassDefinitions for role-based equipment information (as part of the OLOP). Other

dictionaries in the IEC CDD do not provide such DFassetClassDefinitions.

Concept dictionaries may be owned and managed by a standardization body, a consortium, a

data supplier or an enterprise.

5.2 Rules for consortia dictionaries and standardized dictionaries

Standardization bodies and classification consortia providing concept dictionaries shall be

registered as a registration authority by registration authority identifiers defined by

ISO/IEC 6523.

5.3 Rules for supplier dictionaries

If content of a SupplierLibrary cannot be interpreted based on standardized dictionaries or

consortium dictionaries only, then a supplier dictionary that supports interpretation of the

content of the SupplierLibrary shall be provided.

Every concept that is used in the SupplierLibrary and is not defined by existing concept

dictionaries shall be defined by a ConceptDictionaryEntry in a corresponding supplier

dictionary.

Data suppliers providing concept dictionaries shall be registered as a registration authority by

registration authority identifiers defined by ISO/IEC 6523.

5.4 Rules for DFdictionary

A DFdictionary shall contain all ConceptDictionaryEntries necessary to interpret contents of the

associated DFlibraries.

DFdictionaries shall be created by integrating copies of ConceptDictionaryEntries or by

referencing to ConceptDictionaryEntries from standardized dictionaries, from consortium

dictionaries or from supplier dictionaries.

When integrating a LibraryEntry (for example a DFassetClass) of a SupplierLibrary into a

DFlibrary, it should be made sure that every concept used in the LibraryEntry is defined in the

DFdictionary.

ConceptDictionaryEntries from multiple concept dictionaries specific to different domains or

owned by different organizations may be integrated into or referenced from a DF dictionary, as

long as the ConceptDictionaryEntries conform to the definitions of ConceptDictionaryEntries in

IEC 62832-2. If a ConceptDictionaryEntry from a different ConceptDictionary is integrated into

a DFdictionary, the ConceptIdentifier is not changed.

The enterprise providing concept dictionaries may or may not be registered as a registration

authority by a registration authority identifier defined by ISO/IEC 6523.

5.5 Rules for DFassetClassDefinition

DFassetClassDefinitions including physical asset information and DFassetClassDefinitions for

role-based equipment information should be provided in a concept dictionary.

A DFassetClassDefinition may define rules and/or structures for describing the physical asset

information of a PS asset type, role-based equipment information, or both.

6 Rules for Libraries

6.1 Rules for SupplierLibraries

SupplierLibraries shall be used to provide information from the data supplier to the enterprise,

including information about PS asset types that are used for production systems.

LibraryEntries in a SupplierLibrary shall be based on ConceptDictionaryEntries defined in

concept dictionaries.

Information about a PS asset type shall be provided as a DFassetClass, based on a

DFassetClassDefinition defined by a ConceptDictionary. The general rules defined in 6.3 apply

to all DFassetClasses in SupplierLibraries.

EXAMPLE Examples for information about a PS asset type are information about the characteristics and structure

of a PS asset type.

In order to provide information from the data supplier to the enterprise, ViewElements,

DFassetClassAssociations, GenericAssociations and DataElementRelationships may be

provided in SupplierLibraries.

– 14 – IEC 62832-3:2020 IEC 2020

6.2 Rules for DFlibraries

Each enterprise shall have one or more DFlibraries. Exactly one DFlibrary shall be used for

creating and maintaining a DigitalFactory. A DFlibrary may be used for multiple Digital Factories

in an enterprise.

Enterprises shall integrate relevant LibraryEntries into a DFlibrary by selecting them from

relevant SupplierLibraries. LibraryEntries in a DFlibrary may also be created by the enterprise.

LibraryEntries within a DFlibrary shall be based on ConceptDictionaryEntries in the

DFdictionary only.

6.3 Rules for DFassetClasses

Every DFassetClass shall be identified uniquely in a Library by the identification information of

its DFassetClassHeader.

The ElementIdentifier of LibraryEntries is defined by the owner of the Library. When a

LibraryEntry is integrated from a SupplierLibrary into a DFlibrary, if the original identifier is not

sufficiently unique (e.g. if different data suppliers use the same identifiers) it might be necessary

to change its ElementIdentifier.

A DFassetClass in a Library shall be derived either from one DFassetClassDefinition in a

dictionary or from one or more DFassetClasses.

A DFassetClass may be derived

– from a DFassetClassDefinition that describes only physical asset information, or

– from a DFassetClassDefinition that describes only role-based equipment information.

If a DFassetClass is derived from a DFassetClassDefinition,

– its DFassetClassHeader shall provide the reference to the DFassetClassDefinition,

– its DFassetClassBody shall be derived from this DFassetClassDefinition. This means the

DFassetClassBody shall include relevant DataElements for description of the product type.

The DataElements correspond to DataElementTypes included in the

DFassetClassDefinition,

– it is not required that the DFassetClassBody includes all CDELs or DataElements that have

corresponding definitions in the DFassetClassDefinition.

Within a DFassetClass, multiple CDELs may be provided. A CDEL shall be used to describe a

set of characteristics that belong to a particular aspect, feature of the described PS asset type,

or describe role-based equipment information.

A DFassetClass may include additional DataElements and CDELs other than those of the

referenced DFassetClassDefinition (see Figure 1). These additional model elements may be

based on definitions from different ConceptDictionaries.

DataElements in DFassetClasses may have undefined DataValue.

6.4 Rules for composite DFassetClass

A composite DFassetClass contains constituent DFassets and DFassetLinks.

For a composite DFassetClass

– the constituent DFassets shall be identified uniquely within the scope of the composite

DFassetClass by their RoleBasedEquipmentIdentifier (in addition to their ElementIdentifier),

– the PSassetIdentifier of every constituent DFasset shall be undefined,

– the DFassetLinks shall be identified within the scope of the composite DFassetClass.

Multiple constituent DFassets within one composite DFassetClass may be derived from the

same DFassetClass.

Relationships between constituent DFassets in a composite DFassetClass shall be represented

by using DFassetLinks. The DFassetLinkEndPoints shall be identified by the identification of

the respective constituent DFassets and identification of the respective interfaces (CDELs) in

the constituent DFasset.

7 Rules for DigitalFactory

7.1 General

The use of a DigitalFactory may include:

– managing a DigitalFactory;

– creating a DigitalFactory;

– browsing a representation of a production system in a DigitalFactory;

– extracting a representation of a production system in a DigitalFactory;

– filtering information from a representation of a production system in a DigitalFactory;

– modifying a representation of a production system in of a DigitalFactory;

– replicating a DigitalFactory.

7.2 Managing a DigitalFactory

A DigitalFactory shall be managed by using the content of the DFassetHeader of the

DigitalFactory.

7.3 Creating a DigitalFactory

A DigitalFactory provides a digital representation of a production system. This digital

representation may be created for a specific purpose such as for representation of a specific

life cycle stage of the production system.

EXAMPLE A DigitalFactory can represent a planned production system or can represent a production system in

operation.

7.4 Maintaining a DigitalFactory

Depending on the intended purpose, the representation of the production system in a

DigitalFactory should be maintained up to date during the life cycle of the production system.

All information necessary to manage the production system should be added to, deleted from,

or changed in the DFassetBody of a DigitalFactory by the various activities during the life cycle

phases, throughout the life cycle of the production system.

7.5 Managing the access to a DigitalFactory

If a DigitalFactory is used and updated by various users, it shall be possible to manage the

access to the DigitalFactory and the revision information (e.g. the revision number) shall be

maintained. The rules for managing the access and for maintaining the revision information

shall be defined by the enterprise according to their requirements.

– 16 – IEC 62832-3:2020 IEC 2020

7.6 Replicating a DigitalFactory

A DigitalFactory provides the description of a specific production system. If such an existing

production system needs to be replicated, it is possible to use the existing description of the

production system (e.g. the original DigitalFactory) as a blueprint for planning the new

production system.

In such a case, a copy of the original DigitalFactory is created (e.g. as replicate DigitalFactory).

The identification and management information for the replicated DigitalFactory is not copied

from the original DigitalFactory, but shall be provided specifically for the replicated

DigitalFactory.

If the structure of the DigitalFactory is replicated, the identifiers of all physical asset information

shall be updated.

When a DigitalFactory is replicated, the correct handling of all other identification information

shall be considered. A redesign of the replicated DigitalFactory might be necessary.

8 Representation of PS asset and/or role using DFasset

8.1 General

A DFasset shall be used to represent a specific PS asset, a specific role or a specific PS asset

with an assigned role.

The DFassetHeader shall be used to identify and to manage a DFasset in a DigitalFactory.

Every DFasset shall be identified by the ElementIdentifier in its DFassetHeader.

The elements in the DFassetBody shall be used to represent

– the requirements of the corresponding role (rol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...