IEC TS 62565-5-2:2022

(Main)Nanomanufacturing - Material specifications - Part 5-2: Nano-enabled electrodes of electrochemical capacitors - Blank detail specification

Nanomanufacturing - Material specifications - Part 5-2: Nano-enabled electrodes of electrochemical capacitors - Blank detail specification

IEC 62565-5-2:2022(E) which is a Technical Specification, establishes a blank detail specification that lists the relevant key control characteristics (KCC) including chemical, physical, structural, and electrochemical characteristics of nano-enabled electrode for electrochemical capacitors. Electrodes of both electric double layer capacitors and pseudo capacitors with nano/ nanostructured materials such as nanoporous activated carbon, graphene, carbon nanotube, carbon black, carbon aerogel, carbon nanomaterial coating collector, etc., are included. For other electrodes, this document can be used for reference.

In addition, this document enables the customer to specify requirements in a standardized manner and to verify through standardized methods that the nano-enabled electrode of the electrochemical capacitors meets the required properties.

General Information

- Status

- Published

- Publication Date

- 20-Apr-2022

- Technical Committee

- TC 113 - Nanotechnology for electrotechnical products and systems

- Drafting Committee

- WG 11 - TC 113/WG 11

- Current Stage

- PPUB - Publication issued

- Start Date

- 21-Apr-2022

- Completion Date

- 13-May-2022

Overview

IEC TS 62565-5-2:2022 - Nanomanufacturing – Material specifications – Part 5-2: Nano-enabled electrodes of electrochemical capacitors – Blank detail specification provides a standardized blank detail specification for nano-enabled electrodes used in electrochemical capacitors. This Technical Specification lists the relevant key control characteristics (KCC) - chemical, physical, structural and electrochemical - for electrodes of both electric double-layer capacitors (EDLCs) and pseudocapacitors using nano/nanostructured materials (for example: nanoporous activated carbon, graphene, carbon nanotubes, carbon black, carbon aerogel, and nanomaterial coatings). It enables customers and suppliers to specify requirements consistently and to verify properties using referenced measurement methods.

Key topics and requirements

The document focuses on clear, auditable specification and testability of nano-enabled electrode materials. Major technical topics include:

- General procurement information and product description format for bilateral contracts.

- Chemical KCCs: moisture (Karl Fischer), ash content (incineration, TGA), magnetic impurities (ICP‑MS/OES/ASS), etc.

- Physical KCCs: thickness, surface and rolling density, resistivity, surface roughness.

- Structural KCCs: specific surface area, pore volume, morphological descriptors for nanoporous and nanostructured carbons.

- Electrochemical KCCs: specific capacitance (CCC, CCD), voltage maintenance, leakage current, DC resistance, cycling endurance and temperature endurance.

- Measurement methods: Annex A provides documented procedures or references for many tests (e.g., Karl Fischer titration, TGA, ICP methods, BET surface area, contact angle, capacitance and leakage test protocols).

The specification format includes tables for KCC reporting and an overview table of measurement methods to support reproducible verification.

Applications and users

This Technical Specification is valuable for:

- Manufacturers and material suppliers defining product datasheets for nano-enabled electrodes.

- OEMs and system integrators (EVs, high-speed transport, aerospace, grid storage, renewable-energy inverters) sourcing electrochemical capacitors.

- Procurement and quality teams seeking standardized acceptance criteria.

- Test laboratories and R&D groups developing or validating electrode materials and cell performance.

- Regulatory and conformity assessment bodies referencing standardized KCCs for material evaluation.

Use cases include supplier-customer contracts, incoming material inspection, product development comparisons, and qualification testing for capacitor manufacturing.

Related standards

- Part of the IEC 62565 series (Nanomanufacturing – Material specifications); consult the IEC webstore for other parts and for normative references used throughout this Technical Specification.

- The document is a Technical Specification (Edition 1.0, 2022-04) and complements existing electrochemical and materials test standards cited in its normative references.

Keywords: IEC TS 62565-5-2, nanomanufacturing, nano-enabled electrodes, electrochemical capacitors, key control characteristics, nanoporous activated carbon, graphene, carbon nanotube, measurement methods, material specification.

Frequently Asked Questions

IEC TS 62565-5-2:2022 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Nanomanufacturing - Material specifications - Part 5-2: Nano-enabled electrodes of electrochemical capacitors - Blank detail specification". This standard covers: IEC 62565-5-2:2022(E) which is a Technical Specification, establishes a blank detail specification that lists the relevant key control characteristics (KCC) including chemical, physical, structural, and electrochemical characteristics of nano-enabled electrode for electrochemical capacitors. Electrodes of both electric double layer capacitors and pseudo capacitors with nano/ nanostructured materials such as nanoporous activated carbon, graphene, carbon nanotube, carbon black, carbon aerogel, carbon nanomaterial coating collector, etc., are included. For other electrodes, this document can be used for reference. In addition, this document enables the customer to specify requirements in a standardized manner and to verify through standardized methods that the nano-enabled electrode of the electrochemical capacitors meets the required properties.

IEC 62565-5-2:2022(E) which is a Technical Specification, establishes a blank detail specification that lists the relevant key control characteristics (KCC) including chemical, physical, structural, and electrochemical characteristics of nano-enabled electrode for electrochemical capacitors. Electrodes of both electric double layer capacitors and pseudo capacitors with nano/ nanostructured materials such as nanoporous activated carbon, graphene, carbon nanotube, carbon black, carbon aerogel, carbon nanomaterial coating collector, etc., are included. For other electrodes, this document can be used for reference. In addition, this document enables the customer to specify requirements in a standardized manner and to verify through standardized methods that the nano-enabled electrode of the electrochemical capacitors meets the required properties.

IEC TS 62565-5-2:2022 is classified under the following ICS (International Classification for Standards) categories: 07.120 - Nanotechnologies. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62565-5-2:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC TS 62565-5-2 ®

Edition 1.0 2022-04

TECHNICAL

SPECIFICATION

Nanomanufacturing – Material specifications –

Part 5-2: Nano-enabled electrodes of electrochemical capacitors – Blank detail

specification

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC TS 62565-5-2 ®

Edition 1.0 2022-04

TECHNICAL

SPECIFICATION

Nanomanufacturing – Material specifications –

Part 5-2: Nano-enabled electrodes of electrochemical capacitors – Blank detail

specification

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 07.120 ISBN 978-2-8322-1099-1

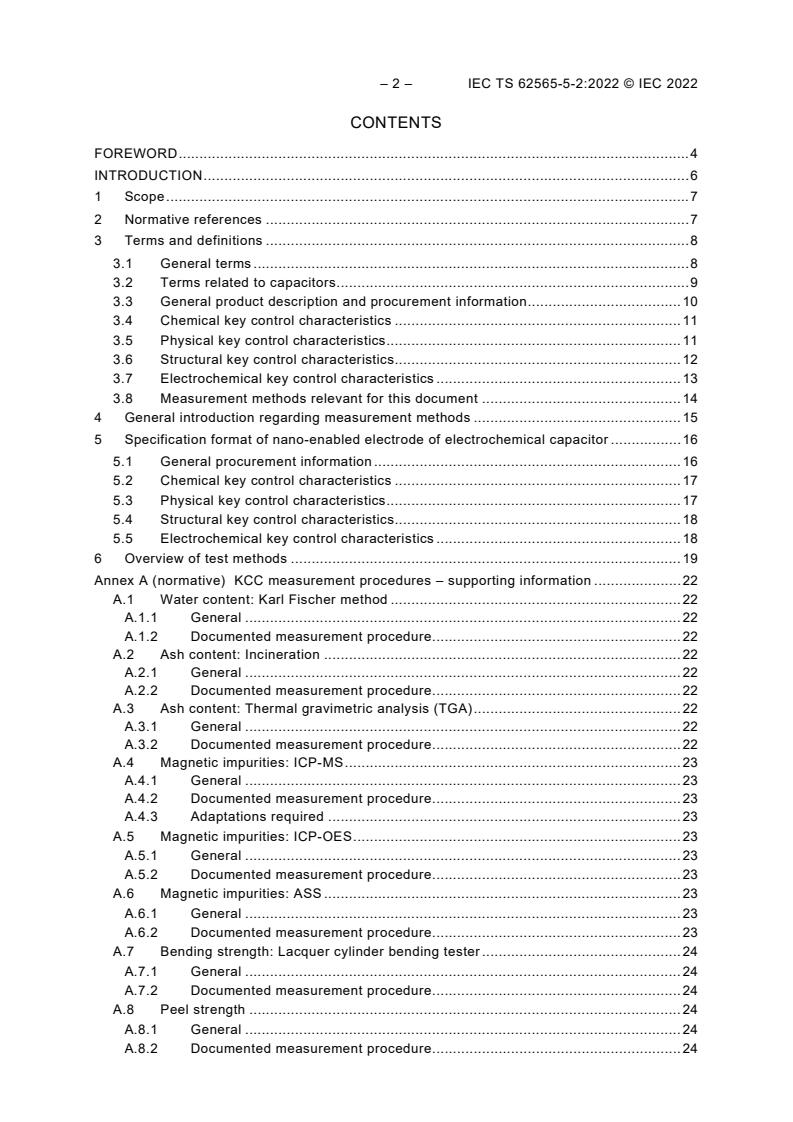

– 2 – IEC TS 62565-5-2:2022 © IEC 2022

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

3.1 General terms . 8

3.2 Terms related to capacitors . 9

3.3 General product description and procurement information . 10

3.4 Chemical key control characteristics . 11

3.5 Physical key control characteristics . 11

3.6 Structural key control characteristics. 12

3.7 Electrochemical key control characteristics . 13

3.8 Measurement methods relevant for this document . 14

4 General introduction regarding measurement methods . 15

5 Specification format of nano-enabled electrode of electrochemical capacitor . 16

5.1 General procurement information . 16

5.2 Chemical key control characteristics . 17

5.3 Physical key control characteristics . 17

5.4 Structural key control characteristics. 18

5.5 Electrochemical key control characteristics . 18

6 Overview of test methods . 19

Annex A (normative) KCC measurement procedures – supporting information . 22

A.1 Water content: Karl Fischer method . 22

A.1.1 General . 22

A.1.2 Documented measurement procedure. 22

A.2 Ash content: Incineration . 22

A.2.1 General . 22

A.2.2 Documented measurement procedure. 22

A.3 Ash content: Thermal gravimetric analysis (TGA) . 22

A.3.1 General . 22

A.3.2 Documented measurement procedure. 22

A.4 Magnetic impurities: ICP-MS . 23

A.4.1 General . 23

A.4.2 Documented measurement procedure. 23

A.4.3 Adaptations required . 23

A.5 Magnetic impurities: ICP-OES . 23

A.5.1 General . 23

A.5.2 Documented measurement procedure. 23

A.6 Magnetic impurities: ASS . 23

A.6.1 General . 23

A.6.2 Documented measurement procedure. 23

A.7 Bending strength: Lacquer cylinder bending tester . 24

A.7.1 General . 24

A.7.2 Documented measurement procedure. 24

A.8 Peel strength . 24

A.8.1 General . 24

A.8.2 Documented measurement procedure. 24

A.9 Rebound rate . 24

A.9.1 General . 24

A.9.2 Documented measurement procedure. 24

A.10 Electrolyte adsorption capacity . 24

A.10.1 General . 24

A.10.2 Documented measurement procedure. 25

A.11 Contact angle . 25

A.11.1 General . 25

A.11.2 Documented measurement procedure. 25

A.12 Resistivity . 25

A.12.1 General . 25

A.12.2 Documented measurement procedure. 25

A.12.3 Adaptations required . 25

A.13 Thickness . 25

A.14 Surface and rolling density . 25

A.14.1 General . 25

A.14.2 Documented measurement procedure. 26

A.14.3 Adaptations required . 26

A.15 Specific surface area and pore volume . 26

A.15.1 General . 26

A.15.2 Documented measurement procedure. 26

A.16 Surface roughness . 26

A.17 Specific capacitance: CCC, CCD . 26

A.17.1 General . 26

A.17.2 Documented measurement procedure. 27

A.18 Voltage maintenance rate . 27

A.18.1 General . 27

A.18.2 Documented measurement procedure. 27

A.19 Leakage current: CCC, CCD, CVD . 27

A.19.1 General . 27

A.19.2 Documented measurement procedure. 27

A.20 Endurance in cycling . 27

A.20.1 General . 27

A.20.2 Documented measurement procedure. 28

A.21 Temperature endurance . 28

A.21.1 General . 28

A.21.2 Documented measurement procedure. 28

A.22 DC resistance: CCC, CCD . 28

A.22.1 General . 28

A.22.2 Documented measurement procedure. 28

Bibliography . 29

Table 1 – Format for general product description and procurement information . 16

Table 2 – Format for chemical key control characteristics . 17

Table 3 – Format for physical key control characteristics . 17

Table 4 – Format for structural key control characteristics . 18

Table 5 – Format for electrochemical key control characteristics . 18

Table 6 – Overview of measurement methods . 20

– 4 – IEC TS 62565-5-2:2022 © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

NANOMANUFACTURING – MATERIAL SPECIFICATIONS –

Part 5-2: Nano-enabled electrodes of electrochemical capacitor –

Blank detail specification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC TS 62565-5-2 has been prepared by IEC technical committee 113: Nanotechnology for

electrotechnical products and systems. It is a Technical Specification.

The text of this Technical Specification is based on the following documents:

Draft Report on voting

113/628/DTS 113/643/RVDTS

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this Technical Specification is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

A list of all parts in the IEC 62565 series, published under the general title Nanomanufacturing –

Material specifications, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC TS 62565-5-2:2022 © IEC 2022

INTRODUCTION

This Technical Specification specifies how to report the various characteristics of electrodes for

industrial use in electrotechnical products, and how to incorporate these into a bilateral detail

specification between vendor and user.

Electrochemical capacitors are widely used in the fields of electric vehicles, high speed trains,

aircraft, photovoltaic, wind power and electronics, due to their ultra-fast charge/discharge

capability, long cycle life, wide working temperature range, high security reliability and low

maintenance cost [1] . In the manufacture process of electrochemical capacitor, the electrode

is a bridge between raw material and device. Therefore, the performance of the electrode is

very critical in the whole electrochemical capacitor industry chain because the properties of

electrodes not only reflect the performance of upstream raw material but also determine the

performance of electrochemical capacitor [2][3][4][5][6][7][8][9].

For the purposes of development and commercialization of raw nanomaterials for electrodes

and the electrochemical capacitor and assembly produced therefrom, the product

characteristics and characterization methods need to be specified in a standardized way. This

blank detail specification will benefit different stakeholders as follows: for material suppliers, it

provides necessary feedback from the manufacturers to guide the design and production of raw

materials; for the end-product manufacturers, it provides a toolbox for evaluating product quality

so as to manage and improve process control, yield of products; for commercialization and

trade, it provides a guidance on referred test methods for electrode classification; in addition,

it will strengthen the links between material manufacture and down-stream user.

In this blank detail specification, the key chemical, physical, structural and electrochemical

characteristics that will significantly influence the performance of electrochemical capacitors

and their measurement methods are listed. These characteristics and characterization methods

are not limited only to nano-enabled electrodes but also can be reference for other electrodes

which are constructed by coating electrode materials on a current collector.

_____________

Numbers in square brackets refer to the Bibliography.

NANOMANUFACTURING – MATERIAL SPECIFICATIONS –

Part 5-2: Nano-enabled electrodes of electrochemical capacitor –

Blank detail specification

1 Scope

This part of IEC 62565, which is a Technical Specification, establishes a blank detail

specification that lists the relevant key control characteristics (KCC) including chemical,

physical, structural, and electrochemical characteristics of nano-enabled electrode for

electrochemical capacitors. Electrodes of both electric double layer capacitors and pseudo

capacitors with nano/ nanostructured materials such as nanoporous activated carbon, graphene,

carbon nanotube, carbon black, carbon aerogel, carbon nanomaterial coating collector, etc.,

are included. For other electrodes, this document can be used for reference.

In addition, this document enables the customer to specify requirements in a standardized

manner and to verify through standardized methods that the nano-enabled electrode of the

electrochemical capacitors meets the required properties.

Numeric values to be specified for the characteristics in this document are intentionally left

blank and are determined by agreement between customer and electrochemical capacitor

supplier. Properties and characteristics deemed by the customer or supplier as not relevant to

a specific application are classified as "not applicable" or "not specified".

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC TS 62607-4-2, Nanomanufacturing – Key control characteristics – Part 4-2: Nano-enabled

electrical energy storage – Physical characterization of cathode nanomaterials, density

measurement

IEC TS 62607-4-3, Nanomanufacturing – Key control characteristics – Part 4-3: Nano-enabled

electrical energy storage – Contact and coating resistivity measurements for nanomaterials

IEC TS 62607-4-8, Nanomanufacturing – Key control characteristics – Part 4-8: Nano-enabled

electrical energy storage – Determination of water content in electrode nanomaterials, Karl

Fischer method

IEC TS 62607-6-20, Nanomanufacturing – Key control characteristics – Part 6-20: Graphene-

based material – Metallic impurity content: ICP-MS

ISO 9277, Determination of the specific surface area of solids by gas adsorption – BET method

ISO 15901-2, Pore size distribution and porosity of solid materials by mercury porosimetry and

gas adsorption – Part 2: Analysis of nanopores by gas adsorption

_____________

Under preparation. Stage at the time of publication: IEC DTS 62607-6-20:2021.

– 8 – IEC TS 62565-5-2:2022 © IEC 2022

ISO 25178 (all parts), Geometrical product specifications (GPS) – Surface texture: Areal

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 General terms

3.1.1

nanomaterial

material with any external dimension in the nanoscale or having internal structure or surface

structure in the nanoscale

[SOURCE: ISO/TS 80004-1:2015, 2.4, modified – The two notes have been removed.]

3.1.2

nanostructured material

material having internal nanostructure or surface nanostructure

Note 1 to entry: This definition does not exclude the possibility for a nano-object to have internal structure or surface

structure. If external dimension(s) are in the nanoscale, the term nano-object is recommended.

[SOURCE: ISO/TS 80004-1:2015, 2.7]

3.1.3

nano-enabled device

device in which the material elements or assembly of such elements exhibit performance or

function only possible with nanotechnology

Note 1 to entry: The material element is a nanomaterial.

Note 2 to entry: The performance or function exhibited is measurable and significant for the application of the nano-

enabled device.

Note 3 to entry: Applications of nano-enabled devices can include, but are not limited to, energy storage devices

(capacitors, materials for lithium ion battery, fuel cell membrane, etc.), photovoltaic, organic electronics, and electro-

optical devices.

[SOURCE: IEC 80004-9:2017, 3.1.5, modified – Notes 1 and 2 have been modified.]

3.1.4

key control characteristic

KCC

key performance indicator

material property or intermediate product characteristic which can affect safety or compliance

with regulations, fit, function, performance, quality, reliability or subsequent processing of the

final product

Note 1 to entry: The measurement of a key control characteristic is described in a standardized measurement

procedure with known accuracy and precision.

Note 2 to entry: It is possible to define more than one measurement method for a key control characteristic if the

correlation of the results is well-defined and known.

3.1.5

blank detail specification

BDS

structured generic specification of the set of key control characteristics which are needed to

describe a specific nano-enabled product without assigning specific values and/or attributes

Note 1 to entry: The templates defined in a blank detail specification list the key control characteristics for the nano-

enabled material or product without assigning specific values to it.

Note 2 to entry: Examples of nano-enabled products are: nanomaterials, nanocomposites and nano-subassemblies.

Note 3 to entry: Blank detail specifications are intended to be used by industrial users to prepare their detail

specifications used in bilateral procurement contracts. A blank detail specification facilitates the comparison and

benchmarking of different materials. Furthermore, a standardized format makes procurement more efficient and more

error robust.

3.2 Terms related to capacitors

3.2.1

electrochemical capacitor

supercapacitor

device that stores electrical energy using a double layer in an electrochemical cell

Note 1 to entry: The electrochemical capacitor is not to be confused with electrolytic capacitors.

[SOURCE: IEC 60050-114:2014, 114-03-03]

3.2.2

electrode

conductive part in electric contact with a medium of lower conductivity and intended to perform

one or more of the functions of emitting charge carriers to or receiving charge carriers from that

medium or to establish an electric field in that medium

[SOURCE: IEC 60050-151:2001, 151-13-01]

3.2.3

electrode type

classification of the electrode of an electrochemical capacitor according to the charge-storage

mechanism

Note 1 to entry: There are two electrochemical capacitor types: electric double layer capacitor and pseudo

capacitor.

3.2.4

electric double layer capacitor

EDLC

device for electrostatic storage of electrical energy achieved by separation of charge in a double

layer

[SOURCE: ISO 18300:2016, 3.8]

3.2.5

pseudo capacitor

Faraday capacitor

device for storage of electrical energy achieved by rapid oxidation-reduction reaction near the

surface of electrode

– 10 – IEC TS 62565-5-2:2022 © IEC 2022

3.3 General product description and procurement information

3.3.1

active material

material that can be used to store energy by electrochemical double-layer or pseudo

capacitance effect

Note 1 to entry: Typically, nonreactive carbon materials are electric double-layer capacitance active material,

including activated carbon, pure carbon nanotube and pure graphene.

Note 2 to entry: Typically, carbon composites and carbons embedded with heteroatoms are pseudo capacitance

active material.

3.3.2

additive

material added in small quantities to a liquid or granular material to produce some desired

modification to its characteristics

[SOURCE: ISO 6707-1:2020, 3.4.4.1]

3.3.3

nano-additive

additive that is nanomaterial or nano-structured material

3.3.4

graphene

graphene layer

single-layer graphene

monolayer graphene

1LG

single layer of carbon atoms with each atom bound to three neighbours in a honeycomb

structure

Note 1 to entry: It is an important building block of many carbon nano-objects.

Note 2 to entry: As graphene is a single layer, it is also sometimes called monolayer graphene or single-layer

graphene and abbreviated as 1LG to distinguish it from bilayer graphene (2LG) and few-layered graphene (FLG).

Note 3 to entry: Graphene has edges and can have defects and grain boundaries where the bonding is disrupted.

[SOURCE: ISO/TS 80004-13:2017, 3.1.2.1]

3.3.5

nanofibre

nano-object with two similar external dimensions in the nanoscale and the third dimension

significantly larger

Note 1 to entry: The largest external dimension is not necessarily in the nanoscale.

Note 2 to entry: The terms nanofibril and nanofilament can also be used.

[SOURCE: ISO/TS 80004-2:2015, 4.5]

3.3.6

nanotube

hollow nanofibre

[SOURCE: ISO/TS 80004-2:2015, 4.8]

3.3.7

carbon nanotube

nanotube composed of carbon

[SOURCE: ISO/TS 80004-3:2020, 3.3.3, modified – Note 1 has been removed.]

3.3.8

carbon black

compounding ingredient consisting essentially of more than 95 % elemental carbon in the form

of near-spherical particles with major diameters less than 1 µm, generally coalesced into

aggregates

[SOURCE: ISO 1382:2020, 3.75, modified – Note 1 has been removed.]

3.3.9

current collector

conductive material in a fuel cell that collects electrons from the anode side or conducts

electrons to the cathode side

[SOURCE: IEC 60050-485:2020, 485-06-07]

3.3.10

aluminium foil

sheet of aluminium metal, usually less than 150 μm thick, that may be laminated to other

materials such as kraft paper or polyethylene

[SOURCE: ISO 9229:2020, 3.5.7]

3.3.11

carbonaceous coating aluminium foil

aluminium foil coated with carbon nanomaterial

3.4 Chemical key control characteristics

3.4.1

water content

ratio, expressed in percent, between the mass of water contained in the material as received

and the corresponding dry residue of the material

[SOURCE: ISO/TS 21268-2:2019, 3.6]

3.4.2

ash content

percent by mass of carbon-free residue on combustion and pyrolysis

[SOURCE: ISO 1998-2:1998, 2.10.120]

3.4.3

metallic impurities

metallic elements, such as Fe, Co, Ni, present but not intentionally added to a material, and the

minimum content of which is not controlled

3.5 Physical key control characteristics

3.5.1

bending strength

maximum bending radius of the device or assembly at which the coating layer of electrode

begins to crack or exfoliate from the current collector after applying the electrode to a film-

bending tester

– 12 – IEC TS 62565-5-2:2022 © IEC 2022

3.5.2

peel strength

force per unit effective width required to separate the electrode materials from the substrate

current collector under the specified conditions of test

3.5.3

rebound rate

after calendaring, thickness change ratio of the electrode at different time points

3.5.4

volume resistivity

ρ

v

measured volume resistance calculated to apply to a cube of unit side

Note 1 to entry: It is expressed in ohm metres (Ω·m).

[SOURCE: ISO 14309:2019, 3.3]

3.5.5

electrolyte adsorption capacity

ability of electrode to adsorb electrolyte, which can be determined by the time when a certain

amount of electrolyte is absorbed by electrode with a certain area.

3.6 Structural key control characteristics

3.6.1

thickness

shortest distance between two surfaces limiting a layer, when this distance can be considered

to be a constant over a region of a finite size

[SOURCE IEC 60050-113:2011, 113-01-24]

3.6.2

surface density

areic mass

surface mass density

at a given point on a two-dimensional domain of quasi-infinitesimal area dA, scalar quantity

equal to the mass dm within the domain divided by the area dA, thus ρ = dm/dA

A

[SOURCE: IEC 60050-113:2011, 113-03-10, modified – The note has been removed.]

3.6.3

rolling density

ratio of the mass of the rolled active material to its volume after being coated on a substrate

[SOURCE: IEC TS 62607-4-2, 3.1.3]

3.6.4

specific surface area

absolute surface area of the sample divided by sample mass

[SOURCE: ISO/TS 11931:2012, 3.3]

3.6.5

pore volume

volume of open pores unless otherwise stated

[SOURCE: ISO 15901-1:2016, 3.14]

3.6.6

surface roughness

surface topology of an area of surface, qualified in the International Standards by reference to

various resolution determinants and methods of calculation

[SOURCE ISO/IEC 10373-2:2015, 3.7]

3.7 Electrochemical key control characteristics

3.7.1

capacitance

ability of a capacitor to store electrical charge

Note 1 to entry: Unit: farad (F).

[SOURCE: IEC 62576:2018, 3.5]

3.7.2

specific capacitance of electrode

capacitance of capacitor divided by the mass or volume of electrode

Note 1 to entry: Unit: farad per gram (F/g) or farad per cubic centimetre (F/cm ).

3.7.3

leakage current

value of the current that flows through a capacitor after a charge for a fixed period of time

Note 1 to entry: Leakage current is given in amperes (A).

Note 2 to entry: Leakage current is caused by an unwanted conductive path other than a short circuit.

[SOURCE: IEC 62391-1:2015, 3.28, modified – Note 2 to entry has been added.]

3.7.4

voltage maintenance rate

ratio of voltage maintenance

ratio of the voltage at the open-ended terminals to the charge voltage after a specified time

period subsequent to the charging of a capacitor

[SOURCE: IEC 62576:2018, 3.25]

3.7.5

endurance in cycling

number of charge and discharge cycles when the measured capacitance or internal resistance

value reaches a specified degree of its initial value under a certain temperature and a certain

rate of charge current

3.7.6

temperature endurance

ratio of the capacitance or internal resistance to its initial value after a specified charging time

at constant voltage under a specific temperature

3.7.7

internal resistance

combined resistance of constituent material specific resistance and inside connection

resistance of a capacitor

– 14 – IEC TS 62565-5-2:2022 © IEC 2022

Note 1 to entry: Unit: ohm (Ω).

[SOURCE: IEC 62576:2018, 3.15]

3.8 Measurement methods relevant for this document

3.8.1

inductively coupled plasma mass spectroscopy

ICP-MS

analytical method for qualitative determination and quantitative evaluation of element

concentrations by measuring the ions produced by a radiofrequency inductively coupled plasma

Note 1 to entry: In the mass spectrometer the ions are separated and the elements identified according to their

mass-to-charge ratio m/z, while the concentration of the elements is proportional to the numbers of ions.

[SOURCE: ISO 7086-1:2019, 3.5]

3.8.2

inductively coupled plasma optical emission spectroscopy

ICP-OES

trace-level, elemental analysis technique that uses the emission spectra of a sample to identify

and quantify the elements present

[SOURCE: ISO 7086-1:2019, 3.6]

3.8.3

atomic absorption spectrometry

AAS

spectroanalytical method for qualitative determination and quantitative evaluation of element

concentrations wherein the technique determines these concentrations by measuring the

atomic absorption of free atoms

[ISO 7086-1:2019, 3.2]

3.8.4

thermal gravimetric analysis

TGA

method in which the change in the mass of a sample is measured as a function of temperature

while the sample is subjected to a controlled temperature programme

[SOURCE: ISO/TS 80004-6:2021, 6.1.2]

3.8.5

constant current discharge

CCD

discharge during which the electric current is maintained at a constant value regardless of the

battery voltage or temperature

3.8.6

constant current charge

CCC

charge during which the electric current is maintained at a constant value regardless of the

battery voltage or temperature

[SOURCE: IEC 60050-482:2004, 482-05-38]

3.8.7

constant voltage charge

CVC

charge during which the voltage is maintained at a constant value regardless of charge current

or temperature

[SOURCE: IEC 60050-482:2004, 482-05-49]

4 General introduction regarding measurement methods

For reasons of practicality for industrial use in manufacturing of nano-enabled electrotechnical

products, this document recommends appropriate measurement methods for each material

parameter. The specification of some KCCs of nano-enabled electrodes of electrochemical

capacitors refer to measurement procedures for which

– no standards currently exist, or

– standards are under development but have not yet been published, or

– standards were developed for other use cases but can be adopted with modifications.

In other cases, industrial users of this document shall fall back to methods which are used in

the scientific community. As they are not established as documented measurement procedures,

users of this document shall agree bilaterally on it. For the KCCs in this document, Clause 6

provides a general overview.

To fulfil the requirements of quality assessment management strategies this requires careful

documentation of the measurement procedure. The document describing the method used shall

have an identification number and include the following topics:

a) Measurement principle:

– basic scientific background;

– measurement configuration if there are different experimental setups available which

perform from a physical point of view the same measurement;

– measurement mode if there are measurement modes possible with the experimental

setup which deliver different kinds of information.

b) Measurement system:

– measurement equipment / apparatus;

– materials;

– calibration standards;

– ambient conditions;

– sample preparation method.

c) Measurement procedure:

– calibration of measurement equipment;

– detailed protocol of the measurement procedure;

– measurement accuracy.

d) Data analysis / interpretation of results:

– description of the method to derive the key control characteristics out of the

measurement data including the used key formulas.

e) Results to be reported:

– description of the test sample including a sketch, drawing or photograph;

– identification of the test sample, e.g. batch or serial number;

– quantitative description of the accuracy of the measurement;

– 16 – IEC TS 62565-5-2:2022 © IEC 2022

– measured key control characteristics listed in tables, plotted in figures, maps created by

scanning methods.

As this document is intended to be updated regularly, there will be a standardized method for

each KCC in the future, including supplementing, revising and replacing the reference

standards. Nevertheless, for special applications supplier and customer may deviate from the

recommendations and agree on other than the recommended standards or define a specific

method for their application.

5 Specification format of nano-enabled electrode of electrochemical capacitor

5.1 General procurement information

General procurement information about nano-enabled electrode for electrochemical capacitors

as well as a supplier-neutral technical description to classify the product should be provided by

the manufacturer or product supplier according to Table 1.

Table 1 – Format for general product description and procurement information

Item No ITEM INFORMATION

1.1 Supplier

1.2 Product

1.3 Trade name

1.4 Electrode type

1.5 Active material

1.6 ID number

Description of the No

1.7 manufacturing process

Yes Reference

available

Mass [kg]

1.8 Typical batch quantity

Volume [l]

Batch number

Serial number

Traceability

1.9 Others, specify

requirements

………………………….

Manufacturing date

Number

1.10 Specification Revision level

Date of issue

1.11 Packaging requirements

No

Material Safety Data

1.12

Sheet (MSDS) available

Yes Reference

NOTE Nanotechnology-based manufacturing processes are sometimes not mature enough that it can be excluded

that there are hidden parameters with significant influence on the product performance. Therefore, a detailed

description of the manufacturing process will help to control those parameters.

5.2 Chemical key control characteristics

Chemical characteristics as detailed in Table 2 shall be agreed between manufacturer and user.

Characteristics not of relevance for the application may be classified as not applicable or not

specified.

Table 2 – Format for chemical key control characteristics

ITEM MEASUREMENT MEASUREMENT

KCC SPECIFICATION

NO. METHOD PROCEDURE

IEC TS 62607-4-8

2.1 Water content Less than [ ] % Karl Fischer method

(Clause A.1)

Not available

Incineration

(Clause A.2)

2.2 Ash content Less than [ ] %

Not available

Thermal gravimetric

analysis (TGA)

(Clause A.3)

IEC TS 62607-6-20

ICP-MS

(Clause A.4)

Fe: Less than [ ] ppm

Not available

Magnetic impurities

2.3 Co: Less than [ ] ppm ICP-OES

content

(Clause A.5)

Ni: Less than [ ] ppm

Not available

AAS

(Clause A.6)

5.3 Physical key control characteristics

Physical characteristics as detailed in Table 3 shall be agreed between manufacturer and user.

Characteristics not of relevance for the application may be classified as not applicable or not

specified.

Table 3 – Format for physical key control characteristics

ITEM MEASUREMENT

MEASUREMENT

KCC SPECIFICATION

PROCEDURE

METHOD

NO.

Not available

Nominal [ ] ± Tolerance [ ]

3.1 Bending strength Film bending tester

mm

(Clause A.7)

Not available

Nominal [ ] ± Tolerance [ ]

3.2 Peel strength Peel method

N/m

(Clause A.8)

Not available

Nominal [ ] ± Tolerance [ ]

3.3 Rebound rate Thickness variation

mm

(Clause A.9)

Not available

Electrolyte adsorption Nominal [ ] ± Tolerance [ ]

3.5 Time measurement

capacity S/mL

(Clause A.10)

Not available

3.6 Contact angle Nominal [ ] ± Tolerance [ ] ° Image method

(Clause A.11)

IEC TS 62607-4-3

Nominal [ ] ± Tolerance [ ] Four-point probe

3.7 Resistivity

Ω∙cm resistivity tester

(Clause A.12)

---

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...