IEC 61709:2011

(Main)Electric components - Reliability - Reference conditions for failure rates and stress models for conversion

Electric components - Reliability - Reference conditions for failure rates and stress models for conversion

IEC 61709:2011 gives guidance on how failure rate data can be employed for reliability prediction of electric components in equipment. Reference conditions are numerical values of stresses that are typically observed by components in the majority of applications. Reference conditions are useful since they are the basis of the calculation of failure rate under any conditions by the application of stress models that take into account the actual operating conditions. This standard also gives guidance on how a database of component failure data can be constructed to provide failure rates that can be used with the included stress models. This edition includes the following significant technical changes with respect to the previous edition:

- the addition of a number of component types and the updating of models for a large number of component types;

- the addition of annexes on reliability prediction, sources of failure rate data and component classification information.

Composants électriques - Fiabilité - Conditions de référence pour les taux de défaillance et modèles de contraintes pour la conversion

La CEI 61709:2011 donne des recommandations concernant les méthodes d'utilisation des données de taux de défaillance pour les prévisions de fiabilité de composants électriques d'équipements. Les conditions de référence sont des valeurs numériques de contraintes généralement observées sur les composants dans la plupart des applications. Ces conditions de référence sont utiles dans la mesure où elles permettent de calculer le taux de défaillance dans toutes conditions, en appliquant des modèles de contrainte qui tiennent compte des conditions de fonctionnement réelles. La présente norme donne également des recommandations concernant les méthodes pour constituer une base de données de taux de défaillance des composants afin que les taux fournis puissent être employés avec les modèles de contrainte fournis. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- l'addition de plusieurs types de composants et l'actualisation des modèles pour nombreux types de composants;

- l'addition des annexes relatives aux prévisions de fiabilité, des sources des données de taux de défaillance et des informations relatives au classification des composants.

General Information

- Status

- Published

- Publication Date

- 23-Jun-2011

- Technical Committee

- TC 56 - Dependability

- Drafting Committee

- WG 2 - TC 56/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 17-Feb-2017

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61709:2011 is an essential international standard published by the International Electrotechnical Commission (IEC) that addresses the reliability of electric components. This edition provides comprehensive guidance on how failure rate data can be effectively utilized for reliability prediction of electrical components used in various equipment. It introduces reference conditions-numerical values of stresses commonly observed in most applications-as the foundation for calculating failure rates under different operating conditions through stress models.

The standard covers a wide range of component types with updated models and includes annexes offering additional insights on reliability prediction, failure rate data sources, and component classification. IEC 61709:2011 is a valuable resource for engineers, reliability specialists, and organizations aiming to improve the dependability of electrical systems by applying validated stress models and failure data.

Key Topics

Reference Conditions for Failure Rates

Defines numerical baseline conditions for environmental and mechanical stresses to standardize failure rate estimation. This includes temperature, voltage, current, and environmental application factors typical for electric components.Stress Models for Conversion

Details generic and specific stress models allowing failure rates to be adjusted from reference to actual operating conditions. Stress factors include voltage, current, temperature, and environment-related dependencies.Component Categories

Covers a broad spectrum of components such as integrated circuits (ICs), discrete semiconductors, optoelectronics, capacitors, resistors, inductors, connectors, relays, switches, and pilot lamps with corresponding stress models and reference data.Data Base Construction for Failure Rate

Guidance on developing and maintaining databases containing failure data essential for accurate reliability prediction and model calibration.Annexes for Practical Use

Normative and informative annexes provide detailed failure modes, reliability prediction methods, data source selection, and classification schemes to support practical application of the standard.

Applications

IEC 61709:2011 is widely applied in fields that demand high reliability and safety in electrical and electronic equipment, including:

Aerospace and Defense

Ensuring component reliability under extreme environmental conditions and critical mission profiles.Industrial Automation

Predictive maintenance and life assessment of industrial controllers, sensors, and actuators.Consumer Electronics

Improving product lifecycle and reducing warranty costs through realistic reliability modeling.Telecommunications

Reliability prediction for networking equipment exposed to variable environmental stresses.Automotive Electronics

Stress-based failure rate calculation for electronic control units and sensors in vehicles.

Using IEC 61709 aids in standardizing reliability assessments, optimizing design for durability, and supporting risk-informed decision-making throughout the product lifecycle.

Related Standards

IEC 61709:2011 complements and integrates with other key standards, including:

IEC 60050 (Electropedia)

Provides standard terminology essential for understanding reliability definitions and parameters.IEC 61014 (Reliability Tests)

Sets the testing requirements for validating component and system reliability claims.IEC 60812 (Failure Modes and Effects Analysis)

Focuses on identifying failure modes, supporting the failure mode understanding highlighted in IEC 61709.ISO 9001 / ISO/TS 16949

Quality management standards emphasizing reliability as a key quality attribute.MIL-HDBK-217 (Military Handbook for Reliability Prediction)

Often referenced for reliability data and models in defense applications alongside IEC 61709.

By aligning with these standards, organizations can establish holistic reliability programs covering data collection, analysis, prediction, and quality management.

Keywords: IEC 61709, electric component reliability, failure rates, stress models, reliability prediction, reference conditions, electrical components, reliability standards, failure rate database, reliability modeling, integrated circuits, discrete semiconductors, reliability engineering, stress factors

Frequently Asked Questions

IEC 61709:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric components - Reliability - Reference conditions for failure rates and stress models for conversion". This standard covers: IEC 61709:2011 gives guidance on how failure rate data can be employed for reliability prediction of electric components in equipment. Reference conditions are numerical values of stresses that are typically observed by components in the majority of applications. Reference conditions are useful since they are the basis of the calculation of failure rate under any conditions by the application of stress models that take into account the actual operating conditions. This standard also gives guidance on how a database of component failure data can be constructed to provide failure rates that can be used with the included stress models. This edition includes the following significant technical changes with respect to the previous edition: - the addition of a number of component types and the updating of models for a large number of component types; - the addition of annexes on reliability prediction, sources of failure rate data and component classification information.

IEC 61709:2011 gives guidance on how failure rate data can be employed for reliability prediction of electric components in equipment. Reference conditions are numerical values of stresses that are typically observed by components in the majority of applications. Reference conditions are useful since they are the basis of the calculation of failure rate under any conditions by the application of stress models that take into account the actual operating conditions. This standard also gives guidance on how a database of component failure data can be constructed to provide failure rates that can be used with the included stress models. This edition includes the following significant technical changes with respect to the previous edition: - the addition of a number of component types and the updating of models for a large number of component types; - the addition of annexes on reliability prediction, sources of failure rate data and component classification information.

IEC 61709:2011 is classified under the following ICS (International Classification for Standards) categories: 31.020 - Electronic components in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61709:2011 has the following relationships with other standards: It is inter standard links to IEC 61709:2017, IEC 61709:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61709:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61709 ®

Edition 2.0 2011-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric components – Reliability – Reference conditions for failure rates and

stress models for conversion

Composants électriques – Fiabilité – Conditions de référence pour les taux

de défaillance et modèles de contraintes pour la conversion

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61709 ®

Edition 2.0 2011-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric components – Reliability – Reference conditions for failure rates and

stress models for conversion

Composants électriques – Fiabilité – Conditions de référence pour les taux

de défaillance et modèles de contraintes pour la conversion

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX XD

ICS 31.020 ISBN 978-2-88912-551-7

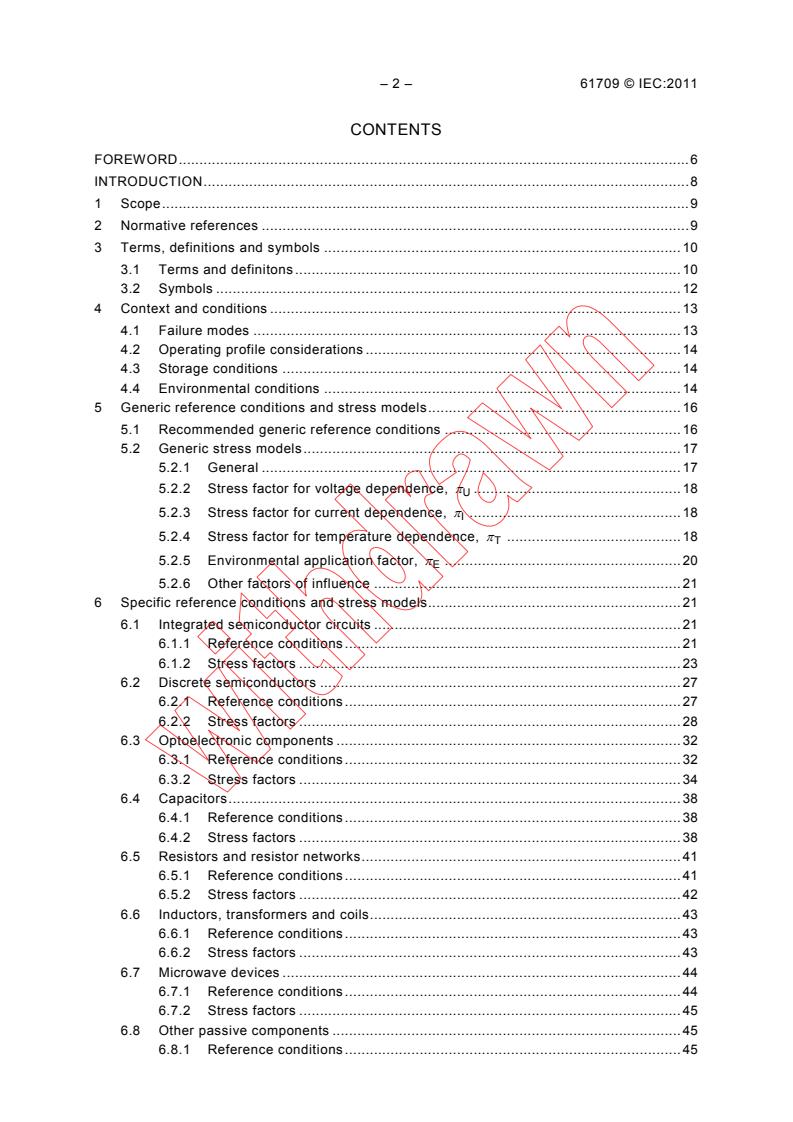

– 2 – 61709 © IEC:2011

CONTENTS

FOREWORD . 6

INTRODUCTION . 8

1 Scope . 9

2 Normative references . 9

3 Terms, definitions and symbols . 10

3.1 Terms and definitons . 10

3.2 Symbols . 12

4 Context and conditions . 13

4.1 Failure modes . 13

4.2 Operating profile considerations . 14

4.3 Storage conditions . 14

4.4 Environmental conditions . 14

5 Generic reference conditions and stress models . 16

5.1 Recommended generic reference conditions . 16

5.2 Generic stress models . 17

5.2.1 General . 17

5.2.2 Stress factor for voltage dependence, π . 18

U

5.2.3 Stress factor for current dependence, π . 18

I

5.2.4 Stress factor for temperature dependence, π . 18

T

5.2.5 Environmental application factor, π . 20

E

5.2.6 Other factors of influence . 21

6 Specific reference conditions and stress models. 21

6.1 Integrated semiconductor circuits . 21

6.1.1 Reference conditions . 21

6.1.2 Stress factors . 23

6.2 Discrete semiconductors . 27

6.2.1 Reference conditions . 27

6.2.2 Stress factors . 28

6.3 Optoelectronic components . 32

6.3.1 Reference conditions . 32

6.3.2 Stress factors . 34

6.4 Capacitors . 38

6.4.1 Reference conditions . 38

6.4.2 Stress factors . 38

6.5 Resistors and resistor networks . 41

6.5.1 Reference conditions . 41

6.5.2 Stress factors . 42

6.6 Inductors, transformers and coils . 43

6.6.1 Reference conditions . 43

6.6.2 Stress factors . 43

6.7 Microwave devices . 44

6.7.1 Reference conditions . 44

6.7.2 Stress factors . 45

6.8 Other passive components . 45

6.8.1 Reference conditions . 45

61709 © IEC:2011 – 3 –

6.8.2 Stress factors . 45

6.9 Electrical connections. 45

6.9.1 Reference conditions . 45

6.9.2 Stress factors . 46

6.10 Connectors and sockets . 46

6.10.1 Reference conditions . 46

6.10.2 Stress factors . 46

6.11 Relays . 46

6.11.1 Reference conditions . 46

6.11.2 Stress factors . 47

6.12 Switches and push-buttons . 49

6.12.1 Reference conditions . 49

6.12.2 Stress factors . 50

6.13 Signal and pilot lamps . 51

6.13.1 Reference conditions . 51

6.13.2 Stress factors . 51

Annex A (normative) Failure modes of components . 53

Annex B (informative) Failure rate prediction . 55

Annex C (informative) Considerations for the design of a data base on failure rates . 65

Annex D (informative) Potential sources of failure rate data and methods of selection . 68

Annex E (informative) Overview of component classification . 74

Annex F (informative) Examples . 86

Bibliography . 88

Figure 1 – Selection of stress regions in accordance with current and voltage-operating

conditions . 48

Figure 2 – Selection of stress regions in accordance with current and voltage-operating

conditions . 50

Figure B.1 – Stress profile . 59

Figure B.2 – Averaging failure rates . 60

Table 1 – Basic environments . 15

Table 2 – Values of environmental parameters for basic environments . 15

Table 3 – Recommended reference conditions for environmental and mechanical

stresses . 17

Table 4 – Environmental application factor, π . 20

E

Table 5 – Memory . 21

Table 6 – Microprocessors and peripherals, microcontrollers and signal processors . 22

Table 8 – Analog integrated circuits (IC) . 23

Table 9 – Application-specific ICs (ASICs) . 23

Table 10 – Constants for voltage dependence . 24

Table 11– Factor π for digital CMOS-family ICs . 24

U

Table 12 – Factor π for bipolar analog ICs . 24

U

Table 13 – Constants for temperature dependence . 24

– 4 – 61709 © IEC:2011

for ICs (without EPROM; FLASH-EPROM; OTPROM; EEPROM;

Table 14 – Factor π

T

EAROM) . 26

Table 15 – Factor π for EPROM, FLASH-EPROM, OTPROM, EEPROM, EAROM. 26

T

Table 16 – Transistors common, low frequency. 27

Table 17 – Transistors, microwave, e.g. RF >800 MHz. 27

Table 18 – Diodes . 28

Table 19 – Power semiconductors . 28

Table 20 − Constants for voltage dependence of transistors . 29

Table 21 – Factor π for transistors . 29

U

Table 22 – Constants for temperature dependence of discrete semiconductors . 29

Table 23 – Factor π for transistors, reference and microwave diodes . 31

T

Table 24 – Factor for diodes (without reference and microwave diodes) and power

π

T

semiconductors . 31

Table 25 – Optoelectronic semiconductor signal receivers . 32

Table 26 – LEDs, IREDs, laser diodes and transmitter components . 33

Table 27 – Optocouplers and light barriers. 33

Table 28 – Passive optical components . 34

Table 29 – Transceiver, transponder and optical sub-equipment . 34

Table 30 – Constants for voltage dependence of phototransistors . 35

Table 31 – Factor π for phototransistors . 35

U

Table 32 – Constants for current dependence of LEDs and IREDs . 35

Table 33 – Factor π for LEDs and IREDs . 35

I

Table 34 – Constants for temperature dependence of optoelectronic components . 36

Table 35 – Factor π for optical components . 37

T

Table 36 – Capacitors . 38

Table 37 – Constants for voltage dependence of capacitors . 39

Table 38 – Factor π for capacitors . 39

U

Table 39 – Constants for temperature dependence of capacitors . 40

Table 40 – Factor π for capacitors . 41

T

Table 41 – Resistors and resistor networks . 42

Table 42 – Constants for temperature dependence of resistors . 42

Table 43 – Factor π for resistors . 43

Τ

Table 44 – Inductors, transformers and coils . 43

Table 45 – Constants for temperature dependence of inductors, transformers and coils . 43

Table 46 – Factor π for inductors, transformers and coils . 44

Τ

Table 47 – Microwave devices . 44

Table 48 – Other passive components . 45

Table 49 – Electrical connections. 46

Table 50 – Connectors and sockets . 46

Table 51 – Relays . 47

Table 52 – Factor π for low current relays. 48

ES

61709 © IEC:2011 – 5 –

Table 53 – Factor π for general purpose relays . 48

ES

Table 54 – Factor π for automotive relays . 49

ES

Table 55 – Constants for temperature dependence of relays . 49

Table 56 – Facteur π for relays . 49

T

Table 57 – Switches and push-buttons . 50

Table 58 – Factor π for switches and push-buttons for low electrical stress . 51

ES

Table 59 – Factor π for switches and push-buttons for higher electrical stress . 51

ES

Table 60 – Signal and pilot lamps . 51

Table 61 – Factor π for signal and pilot lamps . 52

U

Table A.1 – Failure modes – Integrated circuits (ICs)(digital) . 53

Table A.2 – Failure modes – Transistors, diodes, optocouplers . 53

Table A.3 – Failure modes – Capacitors . 54

Table A.4 – Failure modes – Resistors, inductive devices, relays . 54

Table C.1 – Reliability prediction database attributes . 66

Table D.1 – Sources of reliability data (in alphabetical order) . 70

Table E.1 – Classification tree (IEC 61360). 75

– 6 – 61709 © IEC:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC COMPONENTS –

RELIABILITY –

REFERENCE CONDITIONS FOR FAILURE RATES

AND STRESS MODELS FOR CONVERSION

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61709 has been prepared by IEC technical committee 56:

Dependability.

This second edition cancels and replaces the first edition, published in 1996 and constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

– the addition of a number of component types and the updating of models for a large

number of component types;

– the addition of annexes on reliability prediction, sources of failure rate data and

component classification information.

61709 © IEC:2011 – 7 –

The text of this standard is based on the following documents:

FDIS Report on voting

56/1422/FDIS 56/1431/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 8 – 61709 © IEC:2011

INTRODUCTION

This International Standard is intended for the reliability prediction of components as used in

equipment and is aimed at organizations that have their own data and describes how to state

and use that data in order to perform reliability predictions.

It can also be used to allow an organization to set up a failure rate database and describes

the reference conditions for which field failure rates should be stated. The reference

conditions adopted in this standard are typical of the majority of applications of components in

equipment however when components operate under other conditions the users may consider

stating these conditions as their reference conditions.

Using the presented stress models allows extrapolation of failure rates to other operating

conditions which in turn permits the prediction of failure rates at assembly level. This allows

estimation of the effect of design changes or changes in the environmental conditions on

component reliability. Reliability prediction is most useful in the early design phase of

electrical equipment. It can be used, for example, to identify potential reliability problems, the

planning of logistic support strategies and the evaluation of designs.

The stress models contained herein are generic and are as simple as possible while still being

comparable with more complex equations contained in other models.

This standard does not contain failure rates, but it describes how they can be stated and

used. This approach allows a user to select the most relevant and up to date failure rates for

the prediction from a source that they select. This standard also contains information on how

to select the data that can be used in the presented models.

61709 © IEC:2011 – 9 –

ELECTRIC COMPONENTS –

RELIABILITY –

REFERENCE CONDITIONS FOR FAILURE RATES

AND STRESS MODELS FOR CONVERSION

1 Scope

This International Standard gives guidance on how failure rate data can be employed for

reliability prediction of electric components in equipment.

Reference conditions are numerical values of stresses that are typically observed by

components in the majority of applications. Reference conditions are useful since they are the

basis of the calculation of failure rate under any conditions by the application of stress models

that take into account the actual operating conditions. Failure rates stated at reference

conditions allow realistic reliability predictions to be made in the early design phase.

The stress models described herein are generic and can be used as a basis for conversion of

the failure rate data at these reference conditions to actual operating conditions when needed

and this simplifies the prediction approach. Conversion of failure rate data is only permissible

within the specified functional limits of the components.

This standard also gives guidance on how a database of component failure data can be

constructed to provide failure rates that can be used with the included stress models.

Reference conditions for failure rate data are specified, so that data from different sources

can be compared on a uniform basis. If failure rate data are given in accordance with this

International Standard then no additional information on the specified conditions is required.

This standard does not provide base failure rates for components – rather it provides models

that allow failure rates obtained by other means to be converted from one operating condition

to another operating condition.

The prediction methodology described in this standard assumes that the parts are being used

within its useful life. The methods in this standard have a general application but are

specifically applied to a selection of component types as defined in Clause 6 and Clause E.2.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-191, International Electrotechnical Vocabulary – Part 191: Dependability and

quality of service

IEC 60605-6, Equipment reliability testing – Part 6: Tests for the validity and estimation of the

constant failure rate and constant failure intensity

IEC 60721-3-3, Classification of environmental conditions – Part 3: Classification of groups of

environmental parameters and their severities – Section 3: Stationary use at weather

protected locations

– 10 – 61709 © IEC:2011

IEC 60721-3-4, Classification of environmental conditions – Part 3: Classification of groups of

environmental parameters and their severities – Section 4: Stationary use at non-

weatherprotected locations

IEC 60721-3-5, Classification of environmental conditions – Part 3: Classification of groups of

environmental parameters and their severities – Section 4: Ground vehicle installations

IEC 60721-3-7, Classification of environmental conditions – Part 3: Classification of groups of

environmental parameters and their severities – Section 7: Portable and non-stationary use

3 Terms, definitions and symbols

3.1 Terms and definitons

For the purpose of this document, the terms and definitions of IEC 60050-191, as well as the

following terms and definitions apply.

3.1.1

electric component

component with conductive terminals through which voltages or currents may be applied or

delivered

[IEC 61360-1:2009, 2.18]

NOTE The term electric component includes the commonly used terms “electronic component”, “electrical

component” and “electro-mechanical component”.

3.1.2

failure (of an item)

loss of ability to perform as required

NOTE 1 When the loss of ability is caused by a pre-existing latent fault, the failure occurs when a particular set of

circumstances is encountered.

NOTE 2 A failure of an item is an event that results in a fault in that item, which is a state.

3.1.3

failure mode

manner in which failure occurs

NOTE A failure mode may be defined by the function lost or the state transition that occurred.

3.1.4

instantaneous failure rate

failure rate

limit, if it exists, of the ratio of the conditional probability that the instant of a failure of a non-

repairable item occurs within time interval (t, t + ∆t) to ∆t when ∆t tends to zero, given that it

has not failed within time interval (0,t)

NOTE 1 The instantaneous failure rate, λ(t), is expressed by the formula:

1 F(t + ∆t)− F(t) f (t)

λ(t) = lim =

∆t R(t) R(t)

∆t→0

where F(t) and f(t) are respectively the distribution function and the probability density of the failure instant, and

where R(t) is the reliability function, related to the reliability R(t , t ) by R(t) = R(0, t).

1 2

NOTE 2 See IEC 61703.

61709 © IEC:2011 – 11 –

NOTE 3 Other terms used for instantaneous failure rate are “hazard function”, “hazard rate” and “force of

mortality” (abbreviation FOM).

NOTE 4 In this standard λ(t) is assumed to be constant over time.

3.1.5

reference conditions

stresses selected so as to correspond to the majority of applications and usage of

components in equipment

NOTE Stresses include electrical stress, temperature and environmental conditions

3.1.6

reference failure rate

failure rate stated under reference conditions given in this standard

NOTE The reference failure rate is specific to the component, i.e. it includes the effect of complexity, technology

of the casing, dependence on manufacturers and the manufacturing process, etc.

3.1.7

duty cycle

specified sequence of operating condition

[IEC 60050-151:2001, 151-16-02]

NOTE The duty cycle states whether components are continuously or intermittently stressed during their

operation. Continuous duty means operation for a long duration with constant or changing loads (e.g. process

controls, telephone switch). Intermittent duty means operation with constant or changing loads during up state (e.g.

numerical controls for machinery, road traffic signals).

3.1.8

prediction

computation process used to obtain the predicted value of a quantity

NOTE The term "prediction" may also be used to denote the predicted value of a quantity.

3.1.9

component

constituent part of a device which cannot be physically divided into smaller parts without

losing its particular function

[IEC 60050:2001, 151-11-21]

3.1.10

equipment

single apparatus or set of devices or apparatuses, or the set of main devices of an

installation, or all devices necessary to perform a specific task

NOTE Examples of equipment are a power transformer, the equipment of a substation, or measuring equipment.

[IEC 60050-151:2001, 151-11-25]

3.1.11

useful life

time interval, from first use until user requirements are no longer met, due to economics or

obsolescence

3.1.12

drift

difference between the final value of a characteristic at the end of a specified period and the

initial value, all other operating conditions being held constant

– 12 – 61709 © IEC:2011

NOTE The use of the term "drift" to refer to the immediate change of a characteristic in direct response to

changed operating conditions (for example, temperature) is deprecated.

[IEC 60747-1:2006, 3.6.1, modified]

3.1.13

virtual temperature

internal equivalent temperature (of a semiconductor device)

theoretical temperature which is based on a simplified representation of the thermal and

electrical behaviour of the semiconductor device

[IEC 60050-521: 2002, 521-05-14, modified]

3.1.14

virtual (equivalent) junction temperature

virtual temperature of the junction of a semiconductor device

[IEC 60050-521:2002, 521-05-15]

NOTE The virtual temperature is not necessarily the highest temperature in the device.

3.2 Symbols

In this standard, the following symbols are used:

S number of operating cycles per hour

E activation energy of a failure process

a

I operating current

op

I rated current

rat

I reference current

ref

P operating power dissipation

op

P rated power dissipation

rat

P reference power dissipation

ref

R(t ,t ) reliability between two times t and t

1 2 1 2

R thermal resistance

th

R thermal resistance (to the environment)

th,amb

S reference number of operating cycle per hour

ref

T ambient temperature in Kelvin

amb

T reference ambient temperature in Kelvin

T reference temperature in Kelvin

ref

U operating voltage

op

U rated voltage

rat

U reference voltage

ref

t fraction of time with part stress for an assembly

p

t fraction of time spent idle for an assembly

i

t fraction of time with full stress for an assembly

f

β shape parameter of the Weibull distribution

∆T actual self-heating in degrees Celsius

reference self-heating in degrees Celsius

∆T

ref

ambient temperature in degrees Celsius

θ

amb

– for capacitors the actual capacitor temperature;

– for discrete semiconductors and optoelectronic components the actual junction

61709 © IEC:2011 – 13 –

temperature;

– for inductors the actual winding temperature;

– for integrated circuits (ICs) the actual virtual (equivalent) junction temperature;

– for other electric components the actual ambient temperature;

– for resistors the actual resistor element temperature;

operating temperature in degrees Celsius

θ

op

θ reference ambient temperature in degrees Celsius

θ reference temperature in degrees Celsius

ref

– for capacitors the reference temperature of the capacitor;

– for discrete semiconductors and optoelectronic components the reference

junction temperature;

– for inductors the reference temperature of the winding;

– for ICs the reference virtual (equivalent) junction temperature;

– for other electric components the reference temperature of the component;

– for resistors the reference temperature of the resistor element.

λ failure rate at full stress for an assembly:

f

λ failure rate at part stress for an assembly;

p

failure rate during time spent idle for an assembly;

λ

i

failure rate of a component;

λ

component

failure rate of a components failure mode;

λ

mode

failure rate of a system;

λ

S

failure rate under operating conditions;

λ

failure rate under reference conditions;

λ

ref

π current dependence factor;

I

π electrical stress dependence factor;

ES

environmental application factor;

π

E

stress factor for operating profile;

π

op

π switching rate dependence factor;

S

π temperature dependence factor;

T

voltage dependence factor.

π

U

4 Context and conditions

4.1 Failure modes

The characteristic preferred for reliability data of electric components is the (instantaneous)

failure rate. It is to be noted that, although it is often generically defined as failure, the exact

observed event that is measured is a failure mode.

In equipment a failure (mode) or functional loss is caused by a component failure mode where

that component failure mode is relevant to the application being carried out by the equipment.

It should be noted that a component has many features and only some may be used in the

specific application. A function loss at the equipment level occurs only when there is a loss of

the component feature that is used to support that function.

Furthermore a circuit requires the presence of component features according to what was

defined by the designer; this may not encompass the total feature set of the component and

– 14 – 61709 © IEC:2011

may not use a particular feature to its full capacity as defined by the data sheet in terms of

functional characteristics and ratings.

Handbooks usually define failure rate as an overall value, which includes all failure modes.

This implies that component failure rate can be considered as the sum of the failure rates of

all the modes, as follows:

n

λ = (λ )

(1)

component mode i

∑

i=1

where (λ ) is the component failure rate in which the failure mode i occurs and n is the

mode

i

number of failure modes.

Failure modes are listed in Annex A and more details about failures are contained in Annex B.

4.2 Operating profile considerations

One of the major factors affecting component reliability is operating profile. This will vary

according to the type of operation that is undertaken. This operation may be continuous over

time at a fixed level, continuous over time at a variable level or sporadic over time at either a

fixed level or a variable level. In some cases switch on and switch off could be significant and

of more importance than the steady state operational conditions. Careful consideration of the

operating profile is needed in order to fully understand how it affects the component reliability.

The operating profile can be considered to be based on calendar time or on the time of actual

operation or it can be cycle based (e.g. how many times an item is used).

4.3 Storage conditions

Components that are under storage conditions are not immune from failure. However the

stress models for environmental application factors in this standard may not apply since they

only deal with operating conditions. Different failure mechanisms may exist under storage

conditions that have not been considered in the models.

Storage conditions should be treated separately from operating conditions. They may affect

the components’ failure behaviour in later life.

4.4 Environmental conditions

The environment contributes to failure that occurs in the life of the equipment. As a

consequence the duration and intensity of environmental stresses should be included in the

operational model of the equipment.

A more severe environment may cause the failures to occur more frequently than one that is

less severe. There will usually be several aspects of the environment that will be pertinent to

a specific failure and all may need to be understood. The locality of the environment is also

important, for example on an aircraft the in-cabin and on-engine environments are very

different.

The environment may be described in terms of several types of parameters. IEC 60721-3-3

describes the environment in terms of

– climatic conditions,

– special climatic conditions,

– biological conditions,

– chemically active substances,

61709 © IEC:2011 – 15 –

– mechanically active substances,

– mechanical conditions (both static and dynamic).

All the above listed conditions are in general relevant to the equipment’s reliability (failure

rate) and it is reasonable to consider that the reliability of components, and therefore of the

equipment, decreases as the environmental stress increases (see the IEC 60721 series for a

detailed quantitative descriptions of the environmental parameters for each environment).

In this standard it is assumed that the climatic and mechanical conditions are the most

significant

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...