IEC 60076-12:2008

(Main)Power transformers - Part 12: Loading guide for dry-type power transformers

Power transformers - Part 12: Loading guide for dry-type power transformers

IEC 60076-12:2008 is applicable to dry-type transformers according to the scope of IEC 60076-11. It provides the means to estimate ageing rate and consumption of lifetime of the transformer insulation as a function of the operating temperature, time and the loading of the transformer.

Transformateurs de puissance - Partie 12: Guide de charge pour transformateurs de puissance de type sec

La CEI 60076-12:2008 s'applique aux transformateurs de type sec, conformément au domaine d'application de la CEI 60076-11. Elle fournit les moyens pour estimer la vitesse de vieillissement et la consommation de la durée de vie de l'isolation du transformateur en fonction de la température de fonctionnement, de la durée et de la charge du transformateur.

General Information

- Status

- Published

- Publication Date

- 04-Nov-2008

- Technical Committee

- TC 14 - Power transformers

- Drafting Committee

- MT 27 - TC 14/MT 27

- Current Stage

- PPUB - Publication issued

- Start Date

- 05-Nov-2008

- Completion Date

- 30-Nov-2008

Overview

IEC 60076-12:2008, titled Power transformers – Part 12: Loading guide for dry-type power transformers, is an international standard published by the International Electrotechnical Commission (IEC). This standard specifically addresses dry-type transformers as defined in IEC 60076-11 and provides comprehensive guidance on loading these transformers. It focuses on estimating the ageing rate and consumption of transformer insulation lifetime, considering operating temperature, duration of use, and loading conditions.

By offering mathematical models and detailed guidelines, IEC 60076-12 helps maintain optimal transformer performance and reliability while preventing premature insulation degradation due to thermal stress caused by overloading or abnormal operating conditions. This standard is essential for manufacturers, planners, and users involved in selecting and operating dry-type power transformers, ensuring safe and efficient transformer management.

Key Topics

Scope and Applicability

The standard applies to dry-type power transformers covered under IEC 60076-11. It is tailored for transformers used in general electrical power distribution and other industrial applications, excluding highly specialized cases such as certain wind turbine or welding machine transformers without additional manufacturer input.Loading Beyond Nameplate Rating

IEC 60076-12 discusses the effects of loading transformers above their rated capacity, including distinctions between:- Short-time emergency loading: Temporary and transient overloading usually due to system disturbances.

- Long-time emergency loading: Prolonged elevated loading until a new thermal steady state is established.

Thermal Ageing and Insulation Lifetime

Central to the standard is the relationship between winding hot-spot temperature and insulation ageing rate, which dictates transformer lifespan. The document provides formulas and models for calculating:- Hot-spot temperature rise-critical for estimating thermal stress.

- Ageing rate relative to reference temperature.

- Lifetime consumption as a function of temperature and load duration.

Temperature and Load Limitations

Limits on current and permissible temperatures are defined to prevent damage. The standard includes tables and guidance on maximum winding temperatures and acceptable loading boundaries, considering both continuous and emergency operating conditions.Loading Models and Calculations

The document offers detailed equations for:- Continuous load temperature rise.

- Transient load impacts and their effects on insulation ageing.

- Winding time constant determination for thermal analysis.

Additional Considerations

It addresses environmental and operational factors such as:- Magnetic leakage fields.

- Effects of transformer enclosures.

- Ambient outdoor conditions influencing transformer loading and cooling.

Applications

IEC 60076-12:2008 benefits stakeholders in power system design and operation by providing:

Transformer Specification Optimization

Helps engineers select transformers with appropriate ratings based on expected loading profiles and ambient conditions.Thermal Management for Dry-Type Transformers

Guides maintenance and operation teams in managing transformer thermal loading and monitoring insulation ageing to extend service life.Risk Assessment for Overloading Scenarios

Supports system planners evaluating short-term and long-term emergency loading options, minimizing risk of insulation failure.Lifecycle Cost Reduction

Enables utilities and industries to estimate the impact of load variations on transformer longevity, facilitating informed decisions on load management and replacement planning.Compliance and Standardization

Assures uniform assessment and communication of transformer loading capabilities globally in accordance with IEC standards, improving interoperability and safety.

Related Standards

IEC 60076-11: Dry-type Transformers

This part establishes requirements and testing related to temperature-rise limits under rated loads, serving as a foundational reference for IEC 60076-12.IEC 60216-1: Electrical Insulating Materials – Thermal Endurance

Defines ageing procedures and evaluation methods for insulating materials, directly linked to the insulation ageing models used in IEC 60076-12.IEC 61378-1: Converter Transformers for Industrial Applications

Addresses specific transformer types that may require additional guidance outside the scope of this loading guide.

For further information or procurement of the IEC 60076-12:2008 standard, visit the official IEC website at www.iec.ch. Utilizing this standard ensures effective and safe operation of dry-type power transformers, contributing to the reliability and efficiency of electrical power systems worldwide.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60076-12:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Power transformers - Part 12: Loading guide for dry-type power transformers". This standard covers: IEC 60076-12:2008 is applicable to dry-type transformers according to the scope of IEC 60076-11. It provides the means to estimate ageing rate and consumption of lifetime of the transformer insulation as a function of the operating temperature, time and the loading of the transformer.

IEC 60076-12:2008 is applicable to dry-type transformers according to the scope of IEC 60076-11. It provides the means to estimate ageing rate and consumption of lifetime of the transformer insulation as a function of the operating temperature, time and the loading of the transformer.

IEC 60076-12:2008 is classified under the following ICS (International Classification for Standards) categories: 29.180 - Transformers. Reactors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60076-12:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60076-12

Edition 1.0 2008-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Power transformers –

Part 12: Loading guide for dry-type power transformers

Transformateurs de puissance –

Partie 12: Guide de charge pour transformateurs de puissance de type sec

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60076-12

Edition 1.0 2008-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Power transformers –

Part 12: Loading guide for dry-type power transformers

Transformateurs de puissance –

Partie 12: Guide de charge pour transformateurs de puissance de type sec

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

V

CODE PRIX

ICS 29.180 ISBN 978-2-88910-041-5

– 2 – 60076-12 © IEC:2008

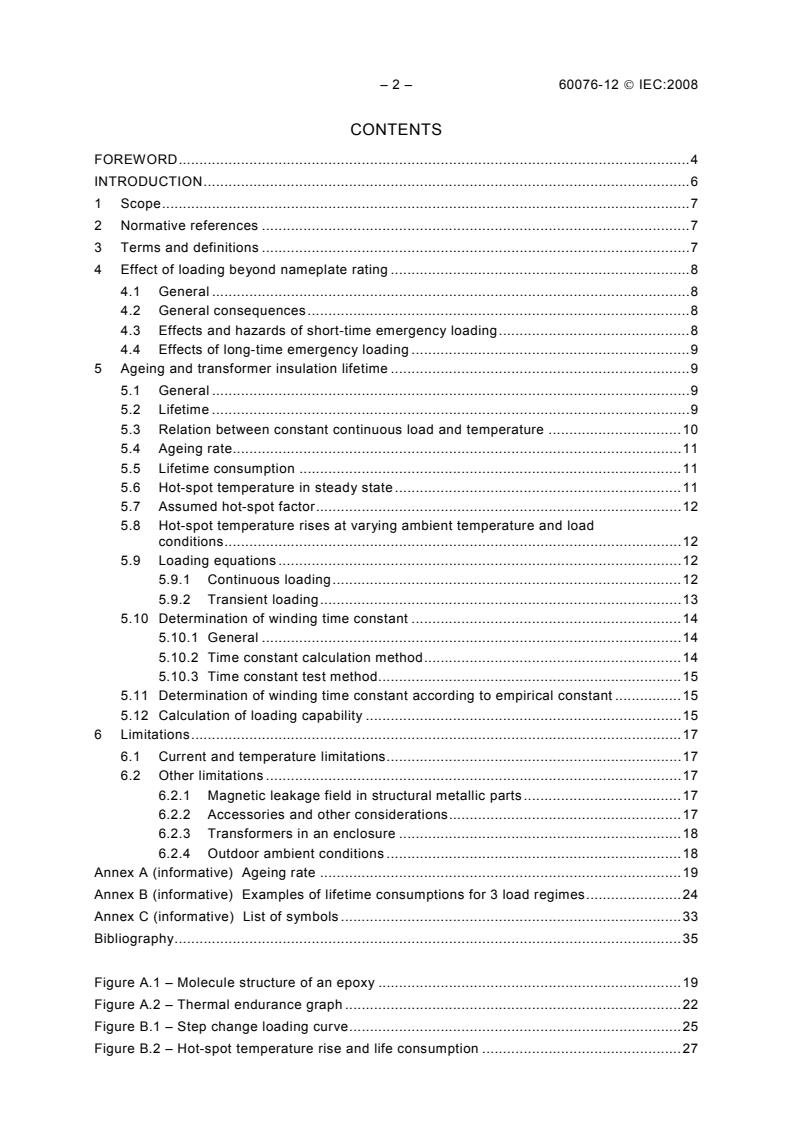

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references .7

3 Terms and definitions .7

4 Effect of loading beyond nameplate rating .8

4.1 General .8

4.2 General consequences.8

4.3 Effects and hazards of short-time emergency loading.8

4.4 Effects of long-time emergency loading .9

5 Ageing and transformer insulation lifetime .9

5.1 General .9

5.2 Lifetime .9

5.3 Relation between constant continuous load and temperature .10

5.4 Ageing rate.11

5.5 Lifetime consumption .11

5.6 Hot-spot temperature in steady state.11

5.7 Assumed hot-spot factor.12

5.8 Hot-spot temperature rises at varying ambient temperature and load

conditions.12

5.9 Loading equations .12

5.9.1 Continuous loading.12

5.9.2 Transient loading.13

5.10 Determination of winding time constant .14

5.10.1 General .14

5.10.2 Time constant calculation method.14

5.10.3 Time constant test method.15

5.11 Determination of winding time constant according to empirical constant .15

5.12 Calculation of loading capability .15

6 Limitations.17

6.1 Current and temperature limitations.17

6.2 Other limitations .17

6.2.1 Magnetic leakage field in structural metallic parts.17

6.2.2 Accessories and other considerations.17

6.2.3 Transformers in an enclosure .18

6.2.4 Outdoor ambient conditions .18

Annex A (informative) Ageing rate .19

Annex B (informative) Examples of lifetime consumptions for 3 load regimes.24

Annex C (informative) List of symbols .33

Bibliography.35

Figure A.1 – Molecule structure of an epoxy .19

Figure A.2 – Thermal endurance graph .22

Figure B.1 – Step change loading curve.25

Figure B.2 – Hot-spot temperature rise and life consumption .27

60076-12 © IEC:2008 – 3 –

Figure B.3 – Load current and winding hot-spot temperature rise.30

Figure B.4 – Ageing rate versus time .30

Table 1 – Constants for lifetime equation .10

Table 2 – Maximum hot-spot winding temperature .16

Table 3 – Current and temperature limits applicable to loading beyond nameplate rating .17

Table B.1 – Lifetime consumption calculations.26

Table B.2 – Life consumption calculations for varying load .29

Table B.3 – Life consumption calculation .31

– 4 – 60076-12 © IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POWER TRANSFORMERS –

Part 12: Loading guide for dry-type power transformers

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60076-12 has been prepared by IEC technical committee 14:

Power transformers.

This standards cancels and replaces IEC 60905 (1987). This first edition constitutes a

technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

14/584/FDIS 14/590/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

60076-12 © IEC:2008 – 5 –

A list of all parts of IEC 60076 series, under the general title Power transformers, can be

found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn:

• replaced by a revised edition; or

• amended.

– 6 – 60076-12 © IEC:2008

INTRODUCTION

This part of IEC 60076 provides guidance for the specification and loading of dry type power

transformers from the point of view of operating temperatures and thermal ageing. It provides

the consequence of loading above the nameplate rating and guidance for the planner to

choose appropriate rated quantities and loading conditions for new installations.

IEC 60076-11 is the basis for contractual agreements and it contains the requirements and

tests relating to temperature-rise figures for dry type power transformers during continuous

rated loading. It should be noted that IEC 60076-11 refers to the average winding temperature

rise while this part of IEC 60076 refers mainly to the hot-spot temperature and the latter

stated values are provided only for guidance.

This part of IEC 60076 gives mathematical models for judging the consequence of different

loading, with different temperatures of the cooling medium, and with transient or cyclical

variation with time. The models provide for the calculation of operating temperatures in the

transformer, particularly the temperature of the hottest part of the winding. This hot-spot

temperature is used for estimation of the number of hours of life time consumed during a

particular time period.

This part of IEC 60076 further presents recommendations for limitations of permissible

loading according to the results of temperature calculations or measurements. These

recommendations refer to different types of loading duty – continuous loading, short-time and

long time emergency loading. An explanation of ageing fundamentals is given in Annex A.

60076-12 © IEC:2008 – 7 –

POWER TRANSFORMERS –

Part 12: Loading guide for dry-type power transformers

1 Scope

This part of IEC 60076 is applicable to dry-type transformers according to the scope of

IEC 60076-11. It provides the means to estimate ageing rate and consumption of lifetime of

the transformer insulation as a function of the operating temperature, time and the loading of

the transformer.

NOTE For special applications such as wind turbine application transformers, furnace transformers, welding

machine transformers, and others, the manufacturer should be consulted regarding the particular loading profile.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60076-11, Power transformers – Part 11: Dry-type transformers

IEC 60216-1, Electrical insulating materials – Properties of thermal endurance –

Part 1: Ageing procedures and evaluation of test results

IEC 61378-1:1997, Convertor transformers – Part 1: Transformers for industrial applications

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

long-time emergency loading

loading resulting from the prolonged outage of some system elements that will not be

reconnected before the transformer reaches a new and higher steady state temperature

3.2

short-time emergency loading

unusually heavy loading of a transient nature (less than one time constant of the coil) due to

the occurrence of one or more unlikely events which seriously disturb normal system loading

3.3

hot-spot

if not specifically defined, “hot-spot” means the hottest-spot of the winding

3.4

relative thermal ageing rate

for a given hot-spot temperature, the rate at which transformer insulation ageing is reduced or

accelerated compared with the ageing rate at a reference hot-spot temperature

– 8 – 60076-12 © IEC:2008

3.5

transformer insulation life time

the total time between the initial state for which the normal transformer insulation life time is

considered new and the final state when due to thermal ageing, dielectric stress, short-circuit

stress, or mechanical movement, which could occur in normal service and result in a high risk

of electrical failure

3.6

AN cooling

cooling by natural air ventilation

3.7

AF cooling

method of cooling to increase the rated power of the transformer with fan cooling

4 Effect of loading beyond nameplate rating

4.1 General

Normal life expectancy is a conventional reference basis for continuous duty under design

ambient temperature and rated operating conditions. The application of a load in excess of

nameplate rating and/or an ambient temperature higher than specified ambient temperatures

involves a degree of risk and accelerated ageing. It is the purpose of this part of IEC 60076 to

identify such risks and to indicate how, within limitations, transformers may be loaded in

excess of the nameplate rating.

4.2 General consequences

The consequences of loading a transformer beyond its nameplate rating are as follows:

– the temperatures of windings, terminals, leads, tap changer and insulation increase, and

can reach unacceptable levels;

– enclosure cooling is more sensitive to overload leading to a more rapid increase in

insulation temperature to unacceptable levels;

– as a consequence, there will be a risk of premature failure associated with the increased

currents and temperatures. This risk may be of an immediate short-term character or may

come from the cumulative effect of thermal ageing of the insulation in the transformer over

many years.

NOTE Another consequence of overload is an increased voltage drop in the transformer.

4.3 Effects and hazards of short-time emergency loading

The main risks, for short-time emergency loading over the specified limits, are

– critical mechanical stresses due to increased temperature, which can reach an

unacceptable level causing cracks in the insulation of a cast resin transformer;

– mechanical damage in the winding due to short and repetitive current above rated current;

– mechanical damage in the winding due to short and repetitive current combined with

ambient temperature higher than specified;

– deterioration of mechanical properties at higher temperature could reduce the short-circuit

strength;

– reduction of dielectric strength due to elevated temperature.

As a result the maximum overcurrent is limited to 50 % over the rated nominal current.

60076-12 © IEC:2008 – 9 –

The agreement of the manufacturer is necessary in case of overloading in excess of 50 % to

assess the consequences of such overloading. In any case the duration of such overloading

should be kept as short as possible.

4.4 Effects of long-time emergency loading

The effects of long-time emergency loading are the following:

– cumulative thermal deterioration of the mechanical and dielectric properties of the

conductor insulation will accelerate at higher temperatures. If this deterioration proceeds

far enough, it reduces the lifetime of the transformer, particularly if the apparatus is

subjected to system short-circuits;

– other insulation materials, as well as structural parts and the conductors, suffer increased

ageing rate at higher temperature;

– the calculation rules for ageing rate and consumption of lifetime are based on

considerations of loading.

5 Ageing and transformer insulation lifetime

5.1 General

Experience indicates that the normal lifetime of a transformer is some tens of years. It cannot

be stated more precisely, because it may vary even between identical units, owing in

particular to operating factors, which may differ from one transformer to another. With few

exceptions a transformer rarely operates at 100 % of rated current throughout its lifetime.

Other heating factors such as insufficient cooling, harmonics, over fluxing and/or unusual

conditions as described in 60076-11 could also affect the life of the transformer.

When heat, which is mainly due to the transformer losses, is transferred to the insulation

system, a chemical process begins. This process changes the molecular structure of the

materials which form the insulation system. The ageing rate increases with the amount of heat

transferred to the system. This process is cumulative and irreversible, which means that the

materials do not regain their original molecular structure when the heat supply stops and the

temperature decreases. The thermal index of the insulation system is stated in the

manufacturer’s documentation and is also written on the rating plate. It is assumed that failing

insulation due to ageing is one of the causes of end of lifetime of the transformer.

Further it is assumed that the ageing rate varies with temperature according to the Arrhenius’

equation. See Annex A for additional background information. The two constants in Arrhenius’

equation should ideally be determined by means of thermal endurance testing. In cases where

data from such testing is missing, this guide provides estimated constants, which are

calculated on the basis of the following assumptions:

– a temperature increase of 6 K doubles the ageing rate. 6 K is an estimated value for the

whole winding linked with the value of specific materials used in the winding;

– another value for this doubling rate should be used when supported by thermal endurance

tests on the complete electrical insulation system (EIS), according to IEC 60216-1;

– insulation failures are the cause of end of life of the transformer.

5.2 Lifetime

The expected lifetime L of a transformer at a constant hot-spot thermodynamic temperature T

in Kelvin (K) can be calculated by means of the equation:

b

T

L = a × e (1)

This equation can be written more conveniently as:

– 10 – 60076-12 © IEC:2008

b

L = a × exp( ) (2)

T

Although any time unit may be used in these formulas, the hour is used in this guide. The

constant a, given in Table 1 for the different insulation system temperatures, is based on this

time unit.

NOTE 1 The expected lifetime calculated according to this equation should not be perceived in a too literal sense.

The ability of the transformer to withstand high over-currents due to short-circuits in the power system and over-

voltages is, after this theoretically calculated lifetime, certainly weakened compared to a new transformer. In the

absence of such disturbances the transformer may still operate satisfactorily for many years. Taking precaution to

avoid short-circuit and installing adequate over-voltage protection may extend the transformer lifetime.

Table 1 – Constants for lifetime equation

Rated hot spot

Arrhenius' equation

Insulation

winding

constants

system

temperature

temperature

(thermal class ) a b ϑ

HS,r

°C h K °C

105 (A) 3,10E-14 15 900 95

120 (E) 5,48E-15 17 212 110

130 (B) 1,72E-15 18 115 120

155 (F) 9,60E-17 20 475 145

180 (H) 5,35E-18 22 979 170

200 5,31E-19 25 086 190

220 5,26E-20 27 285 210

NOTE 2 The following formulas are used to determine the coefficients a and b for the rated hot-spot temperature

in the winding:

b

ln (180 000) = + ln (a)

ϑ + 273

HS,r

b

ln (90 000) = + ln (a)

ϑ + 6 + 273

HS,r

ϑ is the winding rated hot-spot temperature;

HS,r

Ti is insulation system temperature (thermal index Ti ).

The Table 1 is calculated by doubling the ageing for each 6 K.

NOTE 3 Most power transformers operate well below full load most of their actual lifetime. Since a hot-spot

temperature of as little as 6 °C below rated values results in half the rated loss of life, the actual lifetime of a

transformer typically exceeds 20 years. Accordingly, the constants in Table 1 were developed based on 180 000 h

using a halving constant of 6 K.

5.3 Relation between constant continuous load and temperature

The constant hot-spot thermodynamic temperature T, in Kelvin (K), of the winding is given by:

T = 273 + ϑ + Δϑ (3)

a HSn

where

ϑ is the ambient temperature in degrees Celsius (°C);

a

60076-12 © IEC:2008 – 11 –

Δϑ is the winding hot-spot temperature rise above the ambient temperature at the

HSn

considered load.

Note that the ambient temperature may not be independent of the loading, but may be a

function of the loading :

ϑ = f(current) (4)

a

This function may vary from one site to another. Knowledge of this correlation for the

particular site is necessary to make relevant estimates of the ageing rate and consumption of

lifetime. The correlation may be found by measurement at the specific site. If no such

information is available, indications regarding ageing rate and lifetime consumption can be

obtained by making alternative calculations at different ambient temperatures, for example

within the range 10 °C to 40 °C.

The formulas given in this standard consider eddy losses as ohmic losses in the windings.

Test data indicates that the formulas show higher loss of lifetime than expected. If harmonic

currents are present, the increased eddy losses during overloading may need additional

consideration in accordance with Annex A of IEC 61378-1.

5.4 Ageing rate

The normal lifetime of a transformer is in practice at least 180 000 h. In order to express the

ageing rate k as consumption of lifetime-hours per hour of operation time at a temperature T

in Kelvins (K), 180 000 h is used as a conservative reference in the following equation:

−b

−1

k = 180 000 × a × exp( ) (5)

T

The relative ageing rate kr at constant hot-spot temperature T, in Kelvins (K), expressed as a

percentage of the ageing rate that gives 180 000 h lifetime is calculated according to the

equation:

−b

−1

kr = 100 × t × a × exp( ) (6)

T

a and b are be to taken from Table 1.

5.5 Lifetime consumption

The lifetime consumption L , expressed in hours (h), at a constant hot-spot temperature T, in

c

Kelvins (K), during a time t in hours (h) is calculated according to the equation:

−

b

−1

L = 180 000 × t × a × exp( ) (7)

c

T

a and b are taken from Table 1.

5.6 Hot-spot temperature in steady state

For most transformers in service, the hot-spot temperature inside a winding is not precisely

known. For most of these units, the hot-spot temperature can be assessed by calculation.

The calculation rules in this document are based on the following:

– 12 – 60076-12 © IEC:2008

ϑ is the hot-spot temperature, in degrees Celsius (°C), at rated conditions (rated current,

HS

rated ambient temperature, rated voltage, rated frequency…).

The parameter ϑ can be found by calculation method or by test.

HS

NOTE Although there is no standard test to determine the hot-spot temperature, if the manufacturer demonstrates

other values by test, the manufacturer can use these values to carry out calculation of the life consumption of the

transformer.

5.7 Assumed hot-spot factor

For the following consideration, the assumed hot-spot factor Z is 1,25:

Δϑ = Z × Δϑ (8)

HS,r Wr

where

Δϑ is the hot-spot temperature rise, in Kelvin (K);

HS,r

Δϑ is average winding temperature rise at rated load, in Kelvin (K).

Wr

5.8 Hot-spot temperature rises at varying ambient temperature and load conditions

The basic value required for calculating the life consumption is the temperature at the hot-

spot. For this purpose, it is necessary to know the temperature rise at this position for each

load condition as well as the ambient temperature.

q

Δϑ = Z × Δϑ × I (9)

HSn n

Wr

where

Δϑ is the hot-spot temperature rise at the considered load;

HSn

I is the loading factor per unit;

n

q is equal to 1,6 for air natural cooling (AN) ; or

is equal to 2 for AF cooled transformers (AF);

Z is assumed to be 1,25.

Whenever possible it is preferable to use test results for Δϑ , to limit the uncertainty

Wr

regarding the validity of the factor Z and the value of q. Experience shows that q and Z

assume different values depending on the type of transformer and the level of the load current

at which it operates.

NOTE With some types of winding constructions, determination of Δϑ may be possible only on prototype

Wr

transformers.

5.9 Loading equations

5.9.1 Continuous loading

The hot-spot temperature ϑ as a function of load for steady-state conditions should be

HS

calculated by the following equations:

ϑ = ϑ + Δϑ (10)

HS a HS

60076-12 © IEC:2008 – 13 –

For AN cooling the following equation applies:

2m

Δϑ = Δϑ []I (11)

HS HS,r

For AF cooling the following equation applies:

X

Δϑ = Δϑ []I C (12)

HS HS,r T

T + ϑ

k HS

C = (13)

T

T + ϑ

k HS,r

where

Δϑ is the hot-spot temperature rise at per unit load I, in Kelvins (K);

HS

ϑ is the rated or tested hot-spot temperature at 1,0 per unit load, in degrees Celsius

HS,r

(°C) [tested values for self-cooled operation for use in Equation (11) may be different

than tested values for fan-cooled operation for use in Equation (12)] ;

I is loading factor per unit (ratio between load current and rated current);

C is the temperature correction for resistance change with temperature;

T

m is an empirical constant, which is equal to 0,8 (suggested unless test data is

available);

ϑ is the ambient temperature, in degrees Celsius (°C);

a

ϑ is the hot-spot temperature at load I, in degrees Celsius (°C);

HS

T is the temperature constant for conductor, which is 225 for aluminium and 235 for

k

copper;

X is an empirical constant used in forced-air calculation, which is 1 (suggested unless

test data available).

Test data indicates that the above equations should result in conservative predictions of the

hot-spot temperature.

The m exponent of 0,8 for self-cooled operation and the X exponent of 1 for forced-air

operation are derived from heat transfer correlation for natural and forced convection. Test

data indicates that a temperature correction for resistance given by Equation (13) is required

to predict hot-spot temperatures rise during forced-air loading due to the higher losses

present at forced-cooled operation.

Equation (11) and Equation (12) ignore eddy losses in the windings, which vary inversely with

temperature. The formula provides a conservative result since Eddy losses are usually low

unless harmonic currents are present.

Equation (11) and Equation (12) require an iterative calculation procedure. Using the

suggested exponents and considering the resistance change with temperature for fan-cooled

operation should result in conservative calculations of the hot-spot temperature rise, even

when eddy losses are ignored. If harmonic currents are present, the increased eddy losses

during overloading may need consideration in accordance with Annex A of IEC 61378-1.

5.9.2 Transient loading

The hot-spot temperature rise due to transient overloading should be determined by the

following equations:

– 14 – 60076-12 © IEC:2008

−t

⎡ ⎤

⎢ τ ⎥

Δϑ = (Δϑ − Δϑ ) 1− exp + Δϑ (14)

t U i i

⎢ ⎥

⎣ ⎦

ϑ = Δϑ + ϑ (15)

HS t a

where

Δϑ is the initial hot-spot temperature rise at some prior load I , expressed in Kelvins

i

n

(K);

Δϑ is the hot-spot temperature rise in Kelvins (K) at time t after changing the load;

t

Δϑ is the ultimate hot-spot temperature rise in Kelvins (K) if the per unit overload I

U U

continued until the hot-spot temperature rise stabilised;

t is the time, in minutes (min);

τ is the time constant in minutes (min) for the transformer at rated load;

R

τ is the time constant in minutes (min) for the transformer at a given load;

ϑ is the hot-spot temperature in degrees Celsius (°C);

HS

ϑ is the ambient temperature in degrees Celsius (°C).

a

5.10 Determination of winding time constant

5.10.1 General

The concept of a transformer time constant is based on the assumption that a single heat

source supplies heat to a single heat sink and that the temperature rise of the sink is an

exponential function of the heat input. The time constant is defined as the time for the

temperature rise over ambient to change 63,2 % after a step change in load. Typically the

temperature stabilises after 5 time constants. Hot-spot temperature calculations for loading

should be made on both the low-voltage and high-voltage windings since published test data

indicates that the time constants may be different. Insulation system temperature classes for

the two windings may also be different.

The time constant should be calculated or determined by test on the transformer after

agreement between supplier and purchaser.

5.10.2 Time constant calculation method

The time constant of a winding at rated load, τ , is:

R

C(Δϑ −ϑ )

HS,r e

τ = (16)

R

P

r

where

C is the effective thermal capacity of winding, in watt-minutes per K (Wmin/K),

= (15,0 × mass of aluminium conductor in kilograms (kg)) + (24,5 × mass of epoxy and

other winding insulation in kilograms (kg)), or

= (6,42 × mass of copper conductor in kilograms (kg)) + (24,5 × mass of epoxy and other

winding insulation in kilograms (kg));

or

60076-12 © IEC:2008 – 15 –

C is the effective thermal capacity of winding, in watt-hours per K (Wh/K),

= (0,25 × mass of aluminium conductor in kilograms (kg)) + (0,408 × mass of epoxy and

other winding insulation in kilograms (kg)), or

= (0,107 × mass of copper conductor in kilograms (kg)) + (0,408 × mass of epoxy and

other winding insulation in kilograms (kg));

P is the winding total losses (resistive losses + eddy losses) at rated load and rated

r

temperature rise, in watts (W);

Δϑ is the winding hot-spot temperature rise at rated load, in Kelvin (K);

HS,r

ϑ is the core contribution to winding hot-spot temperature rise at no load. This value

e

should be the value given below or the value measured by the manufacturer during the

temperature rise test on the transformer.

= 5 K for outer winding (usually HV)

= 25 K for inner winding (usually LV less than 1 kV).

NOTE 1 The core contribution values above are based on manufacturers’ experience.

NOTE 2 Other winding insulation material and kind of epoxy material can be used. For such transformers the

correspondent specific heat values of 24,5 Wmin/K and /kg (or 0,408 Wh/K and per kg) can be replaced by the

values based on the manufacturer’s experience.

5.10.3 Time constant test method

Time constants may also be estimated from the hot resistance cooling curve obtained during

thermal tests.

5.11 Determination of winding time constant according to empirical constant

When the temperature rise changes, the time constant varies according to the empirical

constant m.

C(Δϑ −ϑ )

HS,r e

τ = (17)

R

P

r

If m is equal to 1, Equation (17) is correct for any load and any starting temperature. If m is

not equal to 1, the time constant for any load and for any starting temperature for either a

heating cycle or a cooling cycle is given by Equation (18).

⎛ ⎞ ⎛

⎞

Δϑ Δϑ

U i

⎜ ⎟ ⎜ ⎟

−

⎜ ⎟ ⎜ ⎟

Δϑ Δϑ

HS,r HS,r

⎝ ⎠ ⎝ ⎠

= (18)

τ τ

R

1 1

⎛ ⎞ m ⎛ ⎞ m

Δϑ Δϑ

U i

⎜ ⎟ ⎜ ⎟

−

⎜ ⎟ ⎜ ⎟

Δϑ Δϑ

HS,r HS,r

⎝ ⎠ ⎝ ⎠

5.12 Calculation of loading capability

Equations (10) through (18) should be used to determine hot-spot temperatures during a load

cycle. They should also be used to determine the short-time or continuous loading, which

results in the maximum temperatures given in Table 1 or any other limiting temperatures.

The initial hot-spot temperature rise for the initial loading factor I should be obtained from

i

Equation (11) and is determined as follows:

2m

Δϑ = Δϑ []I (19)

i HS,r i

where

– 16 – 60076-12 © IEC:2008

I is the initial loading factor (ratio between load current and rated current).

i

From Table 2, select the limiting hot-spot temperature ϑ . For the ambient temperature,

HS

determine the permissible hot-spot temperature rise at time t from Equation (10).

Table 2 – Maximum hot-spot winding temperature

Insulation system temperature Maximum hot-spot winding

(IEC 60076-11) temperature

°C °C

105 (A) 130

120 (E) 145

130 (B) 155

155 (F) 180

180 (H) 205

200 225

220 245

Calculation of the lifetime is not practical for hot-spot temperature over the maximum hot-spot

winding temperature indicated in the Table 2 because the winding material composition may

change. Transformer loading that results in temperatures that exceed the limits in Table 2

risks transformer failures in an unpredictably short period of time.

ϑ = Δϑ + ϑ (20)

HS HS a

where

ϑ is the hot-spot temperature in degrees Celsius (°C);

HS

Δϑ is the hot-spot temperature rise in Kelvin (K);

HS

ϑ is the ambient temperature in degrees Celsius (°C).

a

Δϑ = ϑ −ϑ (21)

t HS a

where

Δϑ is the hot-spot temperature rise in Kelvin (K) at time t after changing the load.

t

Determine the ultimate hot-spot temperature rise from Equation (14).

⎡ Δϑ − Δϑ ⎤

t i

Δϑ = + Δϑ (22)

U ⎢ ⎥ i

1− exp(−t τ )

⎣ ⎦

where

Δϑ is the ultimate hot spot temperature rise in Kelvin (K).

U

The time constant τ should be obtained from 5.9. Select a time t for the duration of the load

cycle to substitute in the above equation. From Equation (11) the overload corresponding to

these conditions may be obtained as follows:

60076-12 © IEC:2008 – 17 –

⎡ ⎤ 2m

Δϑ

U

I = (23)

⎢ ⎥

U

Δϑ

⎢ ⎥

HS,r

⎣ ⎦

where

I is the ultimate loading factor.

U

The determination of the time constant should be done by an iteration process.

6 Limitations

6.1 Current and temperature limitations

With loading values beyond the nameplate rating, the hot-spot winding temperature shown in

Table 3 shall not be exceeded and the specific limitations given in 4.3 and 5.12 shall be taken

into account.

The current magnitude is limited to 1,5 I especially when the cycle is short and repeated to

r

avoid mechanical damage in the winding. Values over 1,5 I shall be specified at the enquiry

r

stage and shall be agreed upon between purchaser and manufacturer. For all other types of

cycles the current is limited to 1,5 I .

r

Table 3 – Current and temperature limits applicable to loading

beyond nameplate rating

Insulation system temperature (°C) 105 120 130 155 180 200 220

(A) (E) (B) (F) (H)

Maximum current (p.u.) 1,5 1,5 1,5 1,5 1,5 1,5 1,5

Highest temperature for hot-spot (°C) 130 145 155 180 205 225 245

NOTE 1 The temperature and current limits are not intended to be valid simultaneously. The current may be

limited to a lower value than shown in order to meet the temperature limitation requirement. Conversely, the

temperature may be limited to a lower value than shown in order to meet the current limitation requirement.

NOTE 2 The calculation shows that at the highest hot-spot temperature shown in the table the lifetime of a

new transformer is only few thousand hours.

6.2 Other limitations

6.2.1 Magnetic leakage field in structural metallic parts

The magnetic leakage field increases with increasing current. This field may cause excessive

temperatures in structural metallic parts that may restrict the overloading. The limits on load

current, hot-spot temperature and temperature of structural metallic parts other than windings

and leads stated in Table 2 should not be exceeded. It should be noted that when the hot-spot

temperature exceeds the highest temperature in Table 2 according to the insulation classes of

the transformer, the characteristics of the insulation system decrease to a level below the

minimum value for the dielectric withstand of the transformer.

6.2.2 Accessories and other considerations

Aside from the windings, other parts of the transformer, such as bushings, cable-end

connections, tap-changing devices, tap changer, temperature measurement devices, surge

arresters and leads may restrict the operation at 1,5 times the rated current.

– 18 – 60076-12 © IEC:2008

6.2.3 Transformers in an enclosure

Consumption of life time due to overload is higher when the transformer is in an enclosure.

When transformers are used indoors, a correction should be made to the rated hot-spot

temperature rise to account for the enclosure.

6.2.4 Outdoor ambient conditions

In many parts of the world, direct sunshine may increase the transformer temperature

drastically, which should be taken into account when loading beyond rated current is

considered.

Wind may improve the cooling of the transformer, but its unpredictable natur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...