IEC 62561-3:2017

(Main)Lightning protection system components (LPSC) - Part 3: Requirements for isolating spark gaps (ISG)

Lightning protection system components (LPSC) - Part 3: Requirements for isolating spark gaps (ISG)

IEC 62561-3:2017 specifies the requirements and tests for isolating spark gaps (ISG) for lightning protection systems.

ISGs can be used to indirectly bond a lightning protection system to other nearby metalwork where a direct bond is not permissible for functional reasons.

This bilingual version (2018-11) corresponds to the monolingual English version, published in 2017-06.

This second edition cancels and replaces the first edition, published in 2012. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition.

- a new classification has been added related to ISGs location installation;

- an updated flow chart of tests has been developed.

The French version of this document has not been voted upon.

Composants des systèmes de protection contre la foudre (CSPF) - Partie 3: Exigences pour les éclateurs d'isolement

L'IEC 62561-3:2017 spécifie les exigences et les essais à appliquer aux éclateurs d'isolement liés à un système de protection contre la foudre.

Les éclateurs d'isolement peuvent être utilisés pour raccorder indirectement un système de protection contre la foudre à une partie métallique proche, lorsqu'un raccordement direct n'est pas admissible pour des raisons fonctionnelles.

La présente version bilingue (2018-11) correspond à la version anglaise monolingue publiée en 2017-06.

Cette deuxième édition annule et remplace la première édition parue en 2012. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- une nouvelle classification a été ajoutée concernant l'emplacement de l'installation des éclateurs d'isolement;

- un logigramme d'essais mis à jour a été développé.

La version française de cette norme n'a pas été soumise au vote

General Information

- Status

- Published

- Publication Date

- 14-Jun-2017

- Technical Committee

- TC 81 - Lightning protection

- Drafting Committee

- MT 14 - TC 81/MT 14

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 05-Jul-2023

- Completion Date

- 30-Jul-2021

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62561-3:2017 - part of the Lightning Protection System Components (LPSC) series - specifies the requirements and test procedures for isolating spark gaps (ISG) used in lightning protection systems (LPS). ISGs provide a controlled, indirect bond between an LPS and nearby metalwork where a direct electrical connection is not permissible for functional reasons. This second edition (2017) updates the first edition (2012) and introduces a new classification for ISG installation location plus an updated flow chart of tests.

Keywords: IEC 62561-3, isolating spark gaps, ISG requirements, lightning protection, LPSC, lightning protection standard.

Key topics and technical requirements

The standard defines performance, testing and documentation expectations for ISGs, including:

- Scope and intended use - typical applications such as earth-termination systems (power and telecom), rail earth electrodes, laboratory measuring earths, cathodic protection systems, service entry masts, and bypassing insulated flanges/couplings.

- Classification - by lightning-current carrying capability and by installation location (new in this edition).

- Environmental requirements and tests - resistance to salt mist, humid sulphurous and ammonia atmospheres, and ultraviolet (UV) exposure for outdoor ISGs.

- Mechanical tests - impact and hammer tests to verify physical robustness.

- Electrical tests - isolation resistance, rated DC and power-frequency withstand voltage, rated impulse sparkover voltage and lightning current withstand tests.

- Marking, installation instructions and EMC - required identification, packaging and guidance for correct field use; electromagnetic compatibility considerations.

- Test reporting - required structure and content of laboratory test reports; normative flow chart of test sequences is included.

Practical applications and who uses this standard

IEC 62561-3 is practical and directly applicable for:

- Manufacturers of isolating spark gaps and lightning protection components - design, type testing and compliance.

- Test labs and certification bodies - to conduct the environmental, mechanical and electrical tests and produce compliant test reports.

- Designers and consultants of lightning protection systems - specifying suitable ISGs for installations where direct bonding is not allowed.

- Installers and facility engineers - understanding installation classes, marking and performance limits to ensure safe, compliant bonding arrangements.

- Industry sectors - power utilities, telecommunications, railways, petrochemical and pipeline operators, laboratories and any facility using cathodic protection or insulated pipeline couplings.

Related standards

- IEC 62561-1 (LPSC Part 1: connection components)

- IEC 62305 series (LPS design and protection principles)

- Environmental and materials test references cited (e.g., IEC 60068-2-52, IEC 60068-2-75, ISO 4892 series)

Using IEC 62561-3 helps ensure ISGs meet internationally recognized safety, performance and testing criteria for reliable lightning protection and compliant indirect bonding.

IEC 62561-3:2017 - Lightning protection system components (LPSC) - Part 3: Requirements for isolating spark gaps (ISG) Released:6/15/2017 Isbn:9782832244555

IEC 62561-3:2017 - Lightning protection system components (LPSC) - Part 3: Requirements for isolating spark gaps (ISG)

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

IEC 62561-3:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Lightning protection system components (LPSC) - Part 3: Requirements for isolating spark gaps (ISG)". This standard covers: IEC 62561-3:2017 specifies the requirements and tests for isolating spark gaps (ISG) for lightning protection systems. ISGs can be used to indirectly bond a lightning protection system to other nearby metalwork where a direct bond is not permissible for functional reasons. This bilingual version (2018-11) corresponds to the monolingual English version, published in 2017-06. This second edition cancels and replaces the first edition, published in 2012. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition. - a new classification has been added related to ISGs location installation; - an updated flow chart of tests has been developed. The French version of this document has not been voted upon.

IEC 62561-3:2017 specifies the requirements and tests for isolating spark gaps (ISG) for lightning protection systems. ISGs can be used to indirectly bond a lightning protection system to other nearby metalwork where a direct bond is not permissible for functional reasons. This bilingual version (2018-11) corresponds to the monolingual English version, published in 2017-06. This second edition cancels and replaces the first edition, published in 2012. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition. - a new classification has been added related to ISGs location installation; - an updated flow chart of tests has been developed. The French version of this document has not been voted upon.

IEC 62561-3:2017 is classified under the following ICS (International Classification for Standards) categories: 91.120.40 - Lightning protection. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62561-3:2017 has the following relationships with other standards: It is inter standard links to IEC 62561-3:2023, IEC 62561-3:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62561-3:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62561-3 ®

Edition 2.0 2017-06

INTERNATIONAL

STANDARD

Lightning protection system components (LPSC) –

Part 3: Requirements for isolating spark gaps (ISG)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 62561-3 ®

Edition 2.0 2017-06

INTERNATIONAL

STANDARD

Lightning protection system components (LPSC) –

Part 3: Requirements for isolating spark gaps (ISG)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 91.120.40 ISBN 978-2-8322-4455-5

– 2 – IEC 62561-3:2017 © IEC 2017

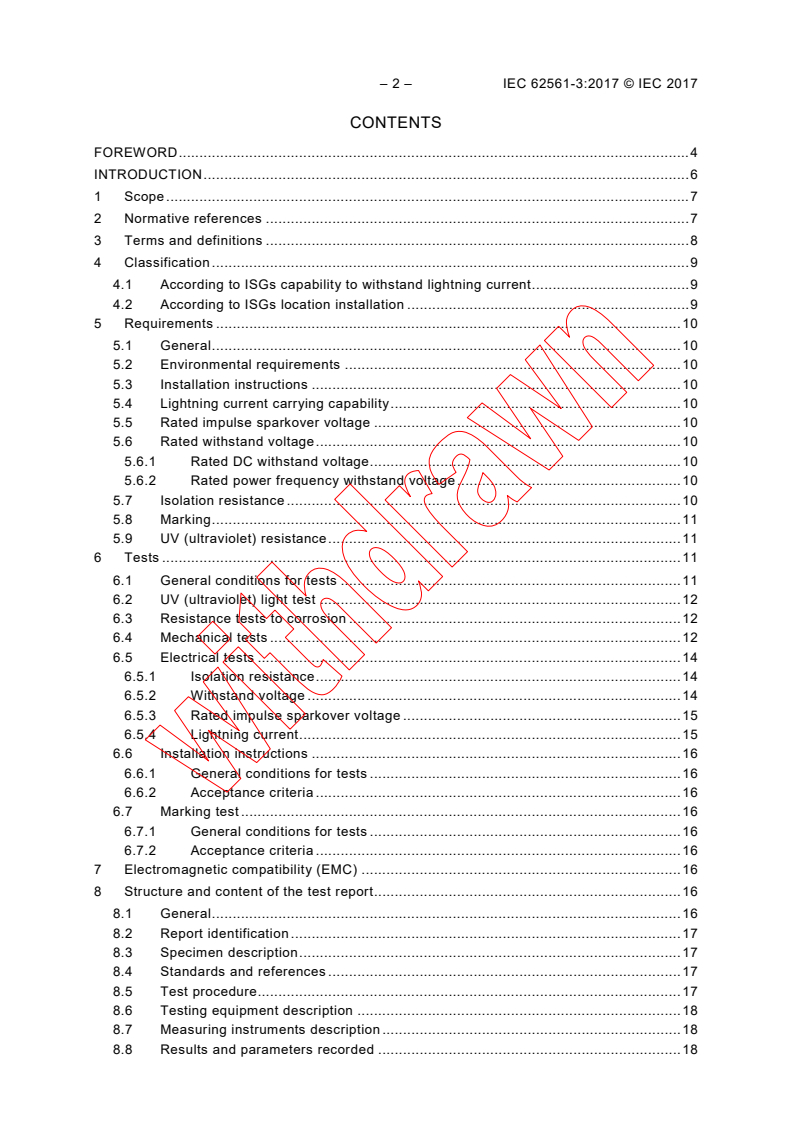

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Classification . 9

4.1 According to ISGs capability to withstand lightning current . 9

4.2 According to ISGs location installation . 9

5 Requirements . 10

5.1 General . 10

5.2 Environmental requirements . 10

5.3 Installation instructions . 10

5.4 Lightning current carrying capability . 10

5.5 Rated impulse sparkover voltage . 10

5.6 Rated withstand voltage . 10

5.6.1 Rated DC withstand voltage . 10

5.6.2 Rated power frequency withstand voltage . 10

5.7 Isolation resistance . 10

5.8 Marking . 11

5.9 UV (ultraviolet) resistance . 11

6 Tests . 11

6.1 General conditions for tests . 11

6.2 UV (ultraviolet) light test . 12

6.3 Resistance tests to corrosion . 12

6.4 Mechanical tests . 12

6.5 Electrical tests . 14

6.5.1 Isolation resistance . 14

6.5.2 Withstand voltage . 14

6.5.3 Rated impulse sparkover voltage . 15

6.5.4 Lightning current . 15

6.6 Installation instructions . 16

6.6.1 General conditions for tests . 16

6.6.2 Acceptance criteria . 16

6.7 Marking test . 16

6.7.1 General conditions for tests . 16

6.7.2 Acceptance criteria . 16

7 Electromagnetic compatibility (EMC) . 16

8 Structure and content of the test report . 16

8.1 General . 16

8.2 Report identification . 17

8.3 Specimen description . 17

8.4 Standards and references . 17

8.5 Test procedure . 17

8.6 Testing equipment description . 18

8.7 Measuring instruments description . 18

8.8 Results and parameters recorded . 18

8.9 Statement of pass/fail . 18

Annex A (normative) Flow chart of tests . 19

Annex B (normative) Environmental test for isolating spark gaps . 21

B.1 General . 21

B.2 Salt mist treatment . 21

B.3 Humid sulphurous atmosphere treatment . 21

B.4 Ammonia atmosphere treatment. 21

Annex C (normative) Environmental test for outdoor isolating spark gaps –

Resistance to ultraviolet light . 22

C.1 General . 22

C.2 The tests . 22

C.3 First alternative test to C.2 . 22

C.4 Second alternative test to C.2 . 22

Bibliography . 23

Figure 1 – Pendulum hammer test apparatus . 13

Figure A.1 – Flow chart of the sequence of tests for ISGs . 20

Table 1 – Lightning impulse current (I ) parameters . 15

imp

– 4 – IEC 62561-3:2017 © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIGHTNING PROTECTION SYSTEM COMPONENTS (LPSC) –

Part 3: Requirements for isolating spark gaps (ISG)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62561-3 has been prepared by IEC technical committee 81:

Lightning protection.

This second edition cancels and replaces the first edition, published in 2012. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition.

a) a new classification has been added related to ISGs location installation;

b) an updated flow chart of tests has been developed.

The text of this International Standard is based on the following documents:

FDIS Report on voting

81/561/FDIS 81/566/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62561 series, published under the general title Lightning

protection system components (LPSC), can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC 62561-3:2017 © IEC 2017

INTRODUCTION

This part of IEC 62561 deals with the requirements and tests for lightning protection system

components (LPSC), specifically isolating spark gaps (ISG) used for the installation of a

lightning protection system (LPS) designed and implemented according to the IEC 62305

series.

LIGHTNING PROTECTION SYSTEM COMPONENTS (LPSC) –

Part 3: Requirements for isolating spark gaps (ISG)

1 Scope

This part of IEC 62561 specifies the requirements and tests for isolating spark gaps (ISG) for

lightning protection systems.

ISGs can be used to indirectly bond a lightning protection system to other nearby metalwork

where a direct bond is not permissible for functional reasons.

Typical applications include the connection to

• earth-termination systems of power installations,

• earth-termination systems of telecommunication systems,

• auxiliary earth electrodes of voltage-operated, earth fault circuit breakers,

• rail earth electrode of power and DC railways,

• measuring earth electrodes for laboratories,

• installations with cathodic protection and stray current systems,

• service entry masts for low-voltage overhead cables,

• bypassing insulated flanges and insulated couplings of pipelines.

This does not cover applications where follow currents occur.

NOTE Lightning protection system components (LPSC) can also be suitable for use in hazardous conditions such

as fire and explosive atmosphere. Due regard will be taken of the extra requirements necessary for the

components to be installed in such conditions.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-52:1996, Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

IEC 60068-2-75:1997, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

_____________

nd rd

2 edition (1996). A 3 edition IEC 60068-2-52: Environmental testing – Part 2-52: Tests – Test Kb: Salt mist,

cyclic (sodium chloride solution) is under preparation. Stage at the time of publication:

IEC PRVC 60068-2-52:2017.

st

st nd

1 edition (1997). This 1 edition was replaced in 2014 by a 2 edition IEC 60068-2-75:2014, Environmental

testing – Part 2-75: Tests – Test Eh: Hammer tests.

– 8 – IEC 62561-3:2017 © IEC 2017

ISO 4892-2:2006, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-

arc lamps

IEC 62561-1, Lightning protection system components (LPSC) – Part 1: Requirements for

connection components

ISO 4892-3:2006, Plastics – Methods of exposure to laboratory light sources – Part 3:

Fluorescent UV lamps

ISO 4892-4, Plastics – Methods of exposure to laboratory light sources – Part 4: Open-flame

carbon-arc lamps

ISO 6957:1988, Copper alloys – Ammonia test for stress corrosion resistance

ISO 6988:1985, Metallic and other non-organic coatings – Sulphur dioxide test with general

condensation of moisture

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

isolating spark gap

ISG

component with discharge distance for isolating electrically conductive installation sections

Note 1 to entry: In the event of a lightning strike, the isolated sections are temporarily connected conductively as

the result of response to the discharge.

3.2

sparkover voltage

maximum voltage value before disruptive discharge between the electrodes of the ISG

3.3

withstand voltage

value of the test voltage to be applied under specified conditions in a withstand test, during

which a specified number of disruptive discharges is tolerated

3.4

power frequency withstand voltage

r.m.s value of a sinusoidal power frequency voltage that the ISG can withstand

3.5

DC withstand voltage

value of a DC voltage that the ISG can withstand

_____________

nd nd rd

edition (2006). This 2 edition was replaced in 2013 by a 3 edition ISO 4892-2:2013, Plastics – Methods

of exposure to laboratory light sources – Part 2: Xenon-arc lamps.

nd rd

nd

2 edition (2006). This 2 edition was replaced in 2016 by a 3 edition: ISO 4892-3: 2016, Plastics – Methods

of exposure to laboratory light sources – Part 3: Fluorescent UV lamps.

3.6

rated withstand voltage

value of a withstand voltage declared by the manufacturer to characterize the isolating

behavior of an ISG

3.7

rated power frequency withstand voltage

U

W AC

value of a power frequency withstand voltage declared by the manufacturer to characterize

the isolating behavior of an ISG

3.8

rated DC withstand voltage

U

W DC

value of a DC withstand voltage declared by the manufacturer to characterize the isolating

behavior of an ISG

3.9

impulse sparkover voltage

impulse voltage of the waveshape 1,2/50 to classify the sparkover behavior of the ISG

3.10

rated impulse sparkover voltage

U

imp

manufacturer’s declaration of the ISG sparkover voltage

3.11

isolation resistance

ohmic resistance of the ISG between the active parts

3.12

lightning impulse current

I

imp

impulse current that classifies an ISG

Note 1 to entry: Five parameters are to be considered: the peak value, the charge, the duration, the specific

energy and the rate of rise of the impulse current.

4 Classification

4.1 According to ISGs capability to withstand lightning current

The following classes apply, as per Table 1:

a) class H for heavy duty;

b) class N for normal duty;

c) class 1L for light duty;

d) class 2L for light duty;

e) class 3L for light duty.

4.2 According to ISGs location installation

The following classes apply:

a) indoor installation;

b) outdoor installation.

– 10 – IEC 62561-3:2017 © IEC 2017

5 Requirements

5.1 General

ISGs shall be designed in such a manner that when they are installed in accordance with the

manufacturer’s instructions, their performance shall be reliable, stable and safe to persons

and surrounding equipment.

5.2 Environmental requirements

ISGs shall be designed in such way that they operate satisfactorily under the environmental

conditions given by the normal service conditions. Outdoor ISGs shall be contained in a

weather shield of glass-glazed ceramic, or other acceptable material, that is resistant to UV

(ultraviolet) light, corrosion and erosion.

Compliance is checked by testing. In accordance with 6.2 and 6.3.

5.3 Installation instructions

The manufacturer of the ISG shall provide adequate instructions in their literature to ensure

that the installer of the ISG can select and install them in a suitable and safe manner.

Compliance is checked by review as per 6.6.

5.4 Lightning current carrying capability

ISGs shall have sufficient lightning current carrying capability.

Compliance is checked in accordance with Clause 6 following the manufacturer’s declaration

for the class of the ISG in accordance with Clause 4.

5.5 Rated impulse sparkover voltage

The ISG shall always spark over at this value during the tests.

The ISG may e

...

IEC 62561-3 ®

Edition 2.0 2017-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Lightning protection system components (LPSC) –

Part 3: Requirements for isolating spark gaps (ISG)

Composants des systèmes de protection contre la foudre (CSPF) –

Partie 3: Exigences pour les éclateurs d'isolement

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 21 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC -

Glossaire IEC - std.iec.ch/glossary

webstore.iec.ch/advsearchform

67 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC et en français, extraites des articles Termes et Définitions des

en utilisant différents critères (numéro de référence, texte, publications IEC parues depuis 2002. Plus certaines entrées

comité d’études,…). Elle donne aussi des informations sur les antérieures extraites des publications des CE 37, 77, 86 et

projets et les publications remplacées ou retirées. CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just Si vous désirez nous donner des commentaires sur cette

Published détaille les nouvelles publications parues. publication ou si vous avez des questions contactez-nous:

Disponible en ligne et aussi une fois par mois par email. sales@iec.ch.

IEC 62561-3 ®

Edition 2.0 2017-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Lightning protection system components (LPSC) –

Part 3: Requirements for isolating spark gaps (ISG)

Composants des systèmes de protection contre la foudre (CSPF) –

Partie 3: Exigences pour les éclateurs d'isolement

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 91.120.40 ISBN 978-2-8322-6202-3

– 2 – IEC 62561-3:2017 © IEC 2017

CONTENTS

CONTENTS . 2

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Classification . 9

4.1 According to ISGs capability to withstand lightning current . 9

4.2 According to ISGs location installation . 9

5 Requirements . 10

5.1 General . 10

5.2 Environmental requirements . 10

5.3 Installation instructions . 10

5.4 Lightning current carrying capability . 10

5.5 Rated impulse sparkover voltage . 10

5.6 Rated withstand voltage . 10

5.6.1 Rated DC withstand voltage . 10

5.6.2 Rated power frequency withstand voltage . 10

5.7 Isolation resistance . 10

5.8 Marking . 11

5.9 UV (ultraviolet) resistance . 11

6 Tests . 11

6.1 General conditions for tests . 11

6.2 UV (ultraviolet) light test . 12

6.3 Resistance tests to corrosion . 12

6.4 Mechanical tests . 12

6.5 Electrical tests . 14

6.5.1 Isolation resistance . 14

6.5.2 Withstand voltage . 14

6.5.3 Rated impulse sparkover voltage . 15

6.5.4 Lightning current . 15

6.6 Installation instructions . 16

6.6.1 General conditions for tests . 16

6.6.2 Acceptance criteria . 16

6.7 Marking test . 16

6.7.1 General conditions for tests . 16

6.7.2 Acceptance criteria . 16

7 Electromagnetic compatibility (EMC) . 16

8 Structure and content of the test report . 16

8.1 General . 16

8.2 Report identification . 17

8.3 Specimen description . 17

8.4 Standards and references . 17

8.5 Test procedure . 17

8.6 Testing equipment description . 18

8.7 Measuring instruments description . 18

8.8 Results and parameters recorded . 18

8.9 Statement of pass/fail . 18

Annex A (normative) Flow chart of tests . 19

Annex B (normative) Environmental test for isolating spark gaps . 21

B.1 General . 21

B.2 Salt mist treatment . 21

B.3 Humid sulphurous atmosphere treatment . 21

B.4 Ammonia atmosphere treatment. 21

Annex C (normative) Environmental test for outdoor isolating spark gaps –

Resistance to ultraviolet light . 22

C.1 General . 22

C.2 The tests . 22

C.3 First alternative test to C.2 . 22

C.4 Second alternative test to C.2 . 22

Bibliography . 23

Figure 1 – Pendulum hammer test apparatus . 13

Figure A.1 – Flow chart of the sequence of tests for ISGs . 20

Table 1 – Lightning impulse current (I ) parameters . 15

imp

– 4 – IEC 62561-3:2017 © IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIGHTNING PROTECTION SYSTEM COMPONENTS (LPSC) –

Part 3: Requirements for isolating spark gaps (ISG)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62561-3 has been prepared by IEC technical committee 81:

Lightning protection.

This bilingual version (2018-11) corresponds to the monolingual English version, published in

2017-06.

This second edition cancels and replaces the first edition, published in 2012. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition.

a) a new classification has been added related to ISGs location installation;

b) an updated flow chart of tests has been developed.

The text of this International Standard is based on the following documents:

FDIS Report on voting

81/561/FDIS 81/566/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

The French version of this document has not been voted upon.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62561 series, published under the general title Lightning

protection system components (LPSC), can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 62561-3:2017 © IEC 2017

INTRODUCTION

This part of IEC 62561 deals with the requirements and tests for lightning protection system

components (LPSC), specifically isolating spark gaps (ISG) used for the installation of a

lightning protection system (LPS) designed and implemented according to the IEC 62305

series.

LIGHTNING PROTECTION SYSTEM COMPONENTS (LPSC) –

Part 3: Requirements for isolating spark gaps (ISG)

1 Scope

This part of IEC 62561 specifies the requirements and tests for isolating spark gaps (ISG) for

lightning protection systems.

ISGs can be used to indirectly bond a lightning protection system to other nearby metalwork

where a direct bond is not permissible for functional reasons.

Typical applications include the connection to

• earth-termination systems of power installations,

• earth-termination systems of telecommunication systems,

• auxiliary earth electrodes of voltage-operated, earth fault circuit breakers,

• rail earth electrode of power and DC railways,

• measuring earth electrodes for laboratories,

• installations with cathodic protection and stray current systems,

• service entry masts for low-voltage overhead cables,

• bypassing insulated flanges and insulated couplings of pipelines.

This does not cover applications where follow currents occur.

NOTE Lightning protection system components (LPSC) can also be suitable for use in hazardous conditions such

as fire and explosive atmosphere. Due regard will be taken of the extra requirements necessary for the

components to be installed in such conditions.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-52:1996, Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

IEC 60068-2-75:1997, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

_____________

nd rd

2 edition (1996). A 3 edition IEC 60068-2-52: Environmental testing – Part 2-52: Tests – Test Kb: Salt mist,

cyclic (sodium chloride solution) is under preparation. Stage at the time of publication:

IEC PRVC 60068-2-52:2017.

st st nd

1 edition (1997). This 1 edition was replaced in 2014 by a 2 edition IEC 60068-2-75:2014, Environmental

testing – Part 2-75: Tests – Test Eh: Hammer tests.

– 8 – IEC 62561-3:2017 © IEC 2017

ISO 4892-2:2006, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-

arc lamps

IEC 62561-1, Lightning protection system components (LPSC) – Part 1: Requirements for

connection components

ISO 4892-3:2006, Plastics – Methods of exposure to laboratory light sources – Part 3:

Fluorescent UV lamps

ISO 4892-4, Plastics – Methods of exposure to laboratory light sources – Part 4: Open-flame

carbon-arc lamps

ISO 6957:1988, Copper alloys – Ammonia test for stress corrosion resistance

ISO 6988:1985, Metallic and other non-organic coatings – Sulphur dioxide test with general

condensation of moisture

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

isolating spark gap

ISG

component with discharge distance for isolating electrically conductive installation sections

Note 1 to entry: In the event of a lightning strike, the isolated sections are temporarily connected conductively as

the result of response to the discharge.

3.2

sparkover voltage

maximum voltage value before disruptive discharge between the electrodes of the ISG

3.3

withstand voltage

value of the test voltage to be applied under specified conditions in a withstand test, during

which a specified number of disruptive discharges is tolerated

3.4

power frequency withstand voltage

r.m.s value of a sinusoidal power frequency voltage that the ISG can withstand

3.5

DC withstand voltage

value of a DC voltage that the ISG can withstand

_____________

nd nd rd

2 edition (2006). This 2 edition was replaced in 2013 by a 3 edition ISO 4892-2:2013, Plastics – Methods

of exposure to laboratory light sources – Part 2: Xenon-arc lamps.

nd nd rd

2 edition (2006). This 2 edition was replaced in 2016 by a 3 edition: ISO 4892-3: 2016, Plastics – Methods

of exposure to laboratory light sources – Part 3: Fluorescent UV lamps.

3.6

rated withstand voltage

value of a withstand voltage declared by the manufacturer to characterize the isolating

behavior of an ISG

3.7

rated power frequency withstand voltage

U

W AC

value of a power frequency withstand voltage declared by the manufacturer to characterize

the isolating behavior of an ISG

3.8

rated DC withstand voltage

U

W DC

value of a DC withstand voltage declared by the manufacturer to characterize the isolating

behavior of an ISG

3.9

impulse sparkover voltage

impulse voltage of the waveshape 1,2/50 to classify the sparkover behavior of the ISG

3.10

rated impulse sparkover voltage

U

imp

manufacturer’s declaration of the ISG sparkover voltage

3.11

isolation resistance

ohmic resistance of the ISG between the active parts

3.12

lightning impulse current

I

imp

impulse current that classifies an ISG

Note 1 to entry: Five parameters are to be considered: the peak value, the charge, the duration, the specific

energy and the rate of rise of the impulse current.

4 Classification

4.1 According to ISGs capability to withstand lightning current

The following classes apply, as per Table 1:

a) class H for heavy duty;

b) class N for normal duty;

c) class 1L for light duty;

d) class 2L for light duty;

e) class 3L for light duty.

4.2 According to ISGs location installation

The following classes apply:

a) indoor installation;

b) outdoor installation.

– 10 – IEC 62561-3:2017 © IEC 2017

5 Requirements

5.1 General

ISGs shall be designed in such a manner that when they are installed in accordance with the

manufacturer’s instructions, their performance shall be reliable, stable and safe to persons

and surrounding equipment.

5.2 Environmental requirements

ISGs shall be designed in such way that they operate satisfactorily under the environmental

conditions given by the normal service conditions. Outdoor ISGs shall be contained in a

weather shield of glass-glazed ceramic, or other acceptable material, that is resistant to UV

(ultraviolet) light, corrosion and erosion.

Compliance is checked by testing. In accordance with 6.2 and 6.3.

5.3 Installation instructions

The manufacturer of the ISG shall provide adequate instructions in their literature to ensure

that the installer of the ISG can select and install them in a suitable and safe manner.

Compliance is checked by review as per 6.6.

5.4 Lightning current carrying capability

ISGs shall have sufficient lightning current carrying capability.

Compliance is checked in accordance with Clause 6 following the manufacturer’s declaration

for the class of the ISG in accordance with Clause 4.

5.5 Rated impulse sparkover voltage

The ISG shall always spark over at this value during the tests.

The ISG may experience some variation of sparkover characteristics before and after the

lightning current test. This shall be included in the rated impulse sparkover voltage defined by

the manufacturer.

5.6 Rated withstand voltage

5.6.1 Rated DC withstand voltage

The ISG shall never spark over at this value during the tests even after performing the

lightning current test.

5.6.2 Rated power frequency withstand voltage

The ISG shall never spark over at this value during the tests even after performing the

lightning current test.

5.7 Isolation resistance

Before the lightning current test the isolation resistance shall be higher than 500 kΩ and after

the lightning current test isolation resistance shall not be lower than 500 kΩ.

Compliance is checked in accordance with 6.5.1.

5.8 Marking

All products complying with this document shall be marked at least with the following:

a) manufacturer’s or responsible vendor’s name or trade mark or identifying symbol;

b) part number;

c) the classification in accordance with Clause 4.

If the marking in accordance with b) is not practical it may be given on the smallest packaging

unit. The marking shall be durable and legible.

Compliance is checked in accordance with 6.7.

NOTE Marking can be applied for example by moulding, pressing, engraving, printing adhesive labels or water

slide transfers.

5.9 UV (ultraviolet) resistance

ISG housings for outdoor installation shall be made of UV resistant material.

Compliance is checked by tests as per 6.2.

6 Tests

6.1 General conditions for tests

The tests in accordance with this document are type tests and performed in a sequence

according to Annex A.

These tests are of such a nature that, after they have been performed, they need not be

repeated unless changes are made to the materials, design or type of manufacturing process,

which might change the performance characteristics of the product.

a) Unless otherwise specified, tests are carried out with the specimens assembled and

installed as in normal use according to the manufacturer's or supplier's instructions.

b) Unless otherwise specified, three specimens are subjected to the tests and the

requirements are satisfied if all the tests are met.

c) If only one of the specimens does not satisfy a test due to an assembly or a manufacturing

fault, that test and any preceding one which may have influenced the results of the test

shall be repeated and also the tests which follow shall be carried out in the required

sequence on another full set of specimens, all of which shall comply with the

requirements.

d) If the ISG has an integral connection component part with its design, it shall be subjected

to the testing regime of IEC 62561-1 using the appropriate lightning current given in

Table 1 of this document.

The applicant, when submitting a set of specimens, may also submit an additional set of

specimens which may be necessary should one specimen fail. The testing laboratory will

then, without further request, test the additional set of specimens and will reject the sets only

if a further failure occurs. If the additional set of specimens is not submitted at the same time,

the failure of one specimen will entail rejection.

Prior to the testing of the ISG and clamp assembly, suitable protection measures should be

employed to ensure that the housing is not exposed to the conditioning treatment.

– 12 – IEC 62561-3:2017 © IEC 2017

6.2 UV (ultraviolet) light test

This test is necessary for ISGs designed to be installed outdoors or in specific environments.

ISG housings for outdoor application shall withstand UV light effects.

One set of three new specimens shall be assembled and mounted rigidly on an insulating

plate (e.g. brick, polytetrafluoroethylene (PTFE)) in accordance with the manufacturer’s

installation instructions.

The specimens shall be subjected to an environmental test consisting of an ultraviolet light

test as specified in Annex C.

The specimens are deemed to have passed this part of the test if there are no signs of

disintegration and no cracks visible to normal or corrected vision.

Ensure that the surface of the mounting plate is suitable to resist UV radiation.

6.3 Resistance tests to corrosion

This test is necessary for ISGs having metallic parts designed to be installed outdoors or in

specific environments.

The specimens used in and complying with the test in 6.2, shall be subjected to corrosion

tests as per Annex B.

After the parts have been dried during 10 min in a drying oven at a temperature of

100 ºC ± 5 ºC, they shall not present any trace of rust on surfaces.

Traces of rust on the edges or a yellowish stain removed by rubbing are not taken into

account. White rust, patina and other surface oxidations are not considered as corrosive

deterioration.

6.4 Mechanical tests

All specimens complying with 6.2 and 6.3 shall be stressed three times by mechanical

impacts.

The impacts are carried out on the accessible parts of the ISG, which may be mechanically

stressed accidentally.

The specimens are assembled under their normal operating conditions specified in the

manufacturer’s documentation.

The ISG is mounted on a pendulum hammer test apparatus according to

IEC 60068-2-75:1997, Clause 4, as shown in Figure 1. The striking element material shall be

polyamide as per IEC 60068-2-75:1997, Table 1, and its mass shall be 200 g as per

IEC 60068-2-75:1997, Table 2.

Dimensions in millimetres

IEC

Key

1 pendulum

2 frame

3 height of fall

4 specimen

5 mounting fixture

Figure 1 – Pendulum hammer test apparatus

The hammer shall fall from a height of 200 mm so that one impact on each side is applied, as

far as possible perpendicular to the length of the arrangement. The drop height is the vertical

distance between the position of the point of control, when the pendulum is released, and the

position of this point at the time of the impact.

The point of control is located on the surface of the striking part where the line passing

through the point of intersection of the axes of the steel tube of the pendulum and the part of

striking, perpendicular to the plane crossing the two axes, comes into contact with the

surface.

The impacts are not applied to the connectors.

NOTE In theory, the centre of gravity of the striking part should be the point of control. As, in practice, it is

difficult to determine the centre of gravity, the point of control has been chosen as described above.

– 14 – IEC 62561-3:2017 © IEC 2017

After the test, the ISG shall show no cracks or similar damage visible to normal or corrected

vision without magnification and shall not present damage which can potentially affect its later

use.

6.5 Electrical tests

6.5.1 Isolation resistance

The test is conducted with a DC voltage of 0,5 times the rated withstand voltage up to a

maximum of 500 V.

The resistance shall be measured after 30 s of applying the test voltage.

The specimen is deemed to have passed the test if the resistance is equal or greater than

500 kΩ.

6.5.2 Withstand voltage

6.5.2.1 General

The rated withstand voltages shall be tested according to the value declared by the

manufacturer in accordance with 5.3.

6.5.2.2 Power frequency withstand voltage

6.5.2.2.1 General conditions for tests

The rated power frequency withstand voltage is tested by applying an AC voltage at the

terminals of the ISG. The voltage is increased continuously at a rate of 100 V/s with a nominal

frequency of 50 Hz or 60 Hz until the r.m.s. value as declared by the manufacturer is reached

and this is maintained for a time of 60 s ± 1 s.

The prospective short-circuit current of the source may be limited to a minimum value of

5 mA.

6.5.2.2.2 Acceptance criteria

The specimens are deemed to have passed the test if during the application of the test

voltage the ISG does not spark over, or conduct a leakage current exceeding 1 mA.

6.5.2.3 DC withstand voltage

6.5.2.3.1 General conditions for tests

The rated DC withstand voltage shall be tested by applying a DC voltage at the terminals of

the ISG. The voltage shall be increased continuously at a rate of 100 V/s until the value as

declared by the manufacturer is reached and this is maintained for a time of 60 s ± 1 s.

The prospective short circuit current of the source may be limited to a minimum value of

5 mA.

6.5.2.3.2 Acceptance criteria

The specimens are deemed to have passed the test if during the application of the test

voltage the ISG does not spark over, or conduct a leakage current exceeding 1 mA.

6.5.3 Rated impulse sparkover voltage

6.5.3.1 General conditions for tests

An impulse voltage 1,2/50 μs with a peak value of the declared impulse sparkover voltage

shall be applied at the terminals of the ISG. The test is performed with five surges of positive

and negative polarity and the ISG has to spark over at each test impulse.

6.5.3.2 Acceptance criteria

The specimens are deemed to have passed the test if they have operated at each test

impulse and no signs of cracks or punctures appear on the enclosures.

6.5.4 Lightning current

6.5.4.1 General conditions for tests

After 6.5.3 and the conditioning according to Annex B, the specimens shall be pre-stressed

with a test current of 0,5 I , followed by a second test current of I after the ISG has

imp imp

cooled down close to ambient temperature.

The impulse discharge current passing through the device under test is defined by the crest

value I , the charge Q and the specific energy W/R. The impulse current shall show no

imp

reversal and reach I within 50 µs. The transfer of the charge Q shall occur within 5 ms and

imp

the specific energy W/R shall be dissipated within 5 ms.

All the parameters are given in Table 1.

a

Table 1 – Lightning impulse current (I ) parameters

imp

I Q W/R

imp

ISG classification

kA ± 10 %

+20 +45

As % kJ/Ω %

−10 −10

H 100 2 500

N 50 625

12,5

1L 25 156

2L 10 25

2.5

3L 5 6,25

a rd

The parameters are derived from the 3 edition of IEC 62305-1 which is under preparation.

NOTE When a lightning current flows in an arc, a shock wave is produced. The severity of the shock is dependent

upon the peak current and the rate of rise of the current. The shorter the rise time, the greater the severity. In

general, the acoustic shock wave can cause damage to the surrounding components, such as the enclosure of the

ISG.

6.5.4.2 Acceptance criteria

The specimens are deemed to have passed the test if no signs of cracks or punctures appear

on the enclosures.

After the current test, the tests according to 6.5.1, 6.5.2 and 6.5.3 shall be carried out.

– 16 – IEC 62561-3:2017 © IEC 2017

6.6 Installation instructions

6.6.1 General conditions for tests

The content of the installation instructions is checked as per its completeness by review.

6.6.2 Acceptance criteria

Installation instructions are deemed to have passed the test if they contain at least the

following:

a) classification and lightning current capability (I );

imp

b) rated withstand voltage;

c) rated power frequency withstand voltage (U );

W AC

d) rated DC withstand voltage (U );

W DC

e) assembly instructions with installation location (if crucial to the function);

f) appropriate connection components for the installation if not part of the ISG.

6.7 Marking test

6.7.1 General conditions for tests

The marking is checked by inspection and by rubbing it by hand for 15 s with a piece of cloth

soaked with water and again for 15 s with a piece of cloth soaked with white spirit/mineral

spirit.

Marking made by moulding, pressing or engraving is not subjected to this test.

6.7.2 Acceptance criteria

The specimen is deemed to have passed the test if the marking remains legible.

7 Electromagnetic compatibility (EMC)

Products covered by this document are, in normal use, passive in respect of electromagnetic

influences (emission and immunity).

8 Structure and content of the test report

8.1 General

The purpose of Clause 8 is to provide general requirements for laboratory test reports. It is

intended to promote clear, complete reporting procedures for laboratories submitting test

reports.

The results of each test carried out by the testing laboratory shall be reported accurately,

clearly, unambiguously and objectively, in accordance with any instructions in the test

methods. The results shall be reported in a test report and shall include all the information

necessary for the interpretation of the test results and all information required by the method

used.

Particular care and attention shall be paid to the arrangement of the report, especially with

regard to presentation of the test data and ease of assimilation by the reader. The format

shall be carefully and specifically designed for each type of test carried out, but the headings

shall be standardized as indicated below.

The structure of each report shall include at least information specified in 8.2 to 8.9.

8.2 Report identification

The following information shall be included :

a) A title or subject of the report.

b) Name and email address or telephone number of the testing laboratory.

c) Name, address and telephone number of the sub-testing laboratory where the test

was carried out, if different from the company which has been assigned to perform

the test.

d) Unique identification number (or serial number) of the test report.

e) Name and address of the vendor.

f) Report shall be paginated and the total number of pages indicated on each page,

including appendices or annexes.

g) Date of issue of the report.

h) Date(s) test(s) was (were) performed.

i) Signature and title, or an equivalent identification of the person(s) authorized to

sign by the testing laboratory for the content of the report.

j) Signature and title of person(s) conducting the test(s).

8.3 Specimen description

a) Sample description.

b) Detailed description and unambiguous identification of the test sample and/or test

assembly, for example part number, type, classification, material, dimensions.

c) Characterization and condition of the test sample and/or test assembly.

d) Sampling procedure, where relevant.

e) Date of receipt of test samples.

f) Photographs, drawings or any other visual documentation, if available.

8.4 Standards and references

a) Identification of the test standard used and the date of issue of the standard.

b) Reference to this document may only be made if the full set of tests is performed

and reported, except where the deviations are clearly justified in 8.5 b).

c) Other relevant documentation with the documentation date.

8.5 Test procedure

a) Description of the test procedure.

b) Justification for any deviations from, additions to or exclusions from the referenced

standard.

c) Any other information relevant to a specific test such as environmental conditions.

d) Configuration of testing assembly and measuring set up.

e) Location of the arrangement in the testing area and measuring techniques.

_____________

It is suggested to insert in the test report a specific declaration to avoid its misuse. A declaration example is:

“This type test report may not be reproduced other than in full, except with the prior written approval of the

issuing testing laboratory. This type test report only covers the samples submitted for test and does not

produce evidence of the quality for series production.”

– 18 – IEC 62561-3:2017 © IEC 2017

8.6 Testing equipment description

Description of equipment used for every test conducted, for example generators,

conditioning/ageing devices.

8.7 Measuring instruments description

Characteristics and calibration dates of all instruments used for measuring the values

specified in this document, for example shunts, oscilloscopes, ohmmeters, torque meters.

8.8 Results and parameters recorded

a) The required passing criteria for each test, defined in the standard.

b) The measured, observed or derived results shall be clearly identified at least for:

• isolation resistance,

• withstand voltage (power frequency withstand voltage, DC withstand voltage),

• rated spark over voltage,

• lightning current carrying capability (current, charge, specific energy, duration),

• connection component test results as per 6.1 d) (ohmic resistance, tightening and

loosening torques),

• marking,

• statement of UV resistance.

The above shall be presented by means of tables, graphs, drawings, photographs or other

documentation of visual observations as appropriate.

8.9 Statement of pass/fail

A statement of pass/fail is necessary, identifying the part of the test for which the specimen

has faile

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...