IEC 62305-3:2024

(Main)Protection against lightning - Part 3: Physical damage to structures and life hazard

Protection against lightning - Part 3: Physical damage to structures and life hazard

IEC 62305-3:2024 provides the requirements for protection of a structure against physical damage by means of a lightning protection system (LPS), and for protection against injury to human beings due to touch and step voltages in the vicinity of an LPS (see IEC 62305-1).

This document is applicable to the:

a) design, installation, inspection and maintenance of an LPS for structures without limitation of their height,

b) establishment of measures for protection against injury to human beings primarily due to touch and step voltages.

This third edition cancels and replaces the second edition published in 2010. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

a) Minimum thicknesses of metal sheets or metal pipes are given in Table 4 for air-termination systems where it is necessary to prevent hot-spot problems. Maximum temperature rises ΔT (K) and time duration t50 (s) for different thicknesses and long strokes are also given.

b) Cross-reference to the IEC 62561 series is made for the use of reliable, stable, safe and appropriate LPS components.

c) The application of two methods – general and simplified – for separation distance calculation is clarified.

d) Some changes to the requirements for continuity of steel reinforcement are made.

e) Annex C is revised to address comments from IEC subcommittee 31J.

f) Revision of positioning of air-termination conductors are modified according to the three accepted methods. A more precise description of the methods for positioning of the air-termination systems are made according to the complexity of structures to be protected. The main text has been simplified, Annex A has been deleted and all detailed information has been moved to Annex D.

g) Information on the protection of green roofs is introduced in Annex D.

h) Information on the protection of protruding parts on facades of tall buildings is introduced in Annex D.

i) a new definition of “electrically insulated LPS” has been introduced to distinguish it from an LPS both electrically and physically isolated from the structure, with a slight modification of the other LPS definitions.

Protection contre la foudre - Partie 3: Dommages physiques sur les structures et risques humains

L'IEC 62305-3:2024 spécifie les exigences pour la protection d'une structure contre les dommages physiques par un système de protection contre la foudre (SPF) et pour la protection contre les blessures d'êtres humains dues aux tensions de contact et de pas à proximité d'un SPF (voir l'IEC 62305-1).

Le présent document s'applique:

a) à la conception, l'installation, l'inspection et la maintenance d'un SPF pour des structures, sans limitation de leur hauteur;

b) à la mise en œuvre de mesures pour la protection contre les blessures d'êtres humains essentiellement dues aux tensions de contact et de pas.

Cette troisième édition annule et remplace la deuxième édition parue en 2010. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) les épaisseurs minimales des tôles ou canalisations métalliques sont indiquées dans le Tableau 4 pour les dispositifs de capture à utiliser si des mesures de prévention contre les problèmes de points chauds se révèlent nécessaires. Les échauffements maximaux ΔT (K) et la durée t50 (s) pour différentes épaisseurs et pour des coups de longue durée sont également donnés;

b) un renvoi à la série IEC 62561 est établi en ce qui concerne l'utilisation de composants appropriés fiables, stables et sûrs du système de protection contre la foudre (SPF);

c) l'application de deux méthodes (générale et simplifiée) de calcul de la distance de séparation est clarifiée;

d) certaines exigences relatives à la continuité des armatures en acier ont été modifiées;

e) l'Annexe C est révisée pour tenir compte des remarques formulées par le sous-comité 31J de l'IEC;

f) Le positionnement des conducteurs de capture a été révisé en fonction des trois méthodes admises. Les méthodes de positionnement des dispositifs de capture sont décrites avec davantage de précision compte tenu de la complexité des structures à protéger. Le texte principal a été simplifié, l'Annexe A a été supprimée et toutes les informations supplémentaires ont été déplacées à l'Annexe D;

g) des informations relatives à la protection de toitures végétalisées ont été ajoutées à l'Annexe D;

h) des informations relatives à la protection des parties saillantes sur les façades de bâtiments hauts ont été ajoutées à l'Annexe D;

i) une nouvelle définition de la “SPF isolée électriquement” a été introduite pour la distinguer de la SPF isolée électriquement et physiquement de la structure, avec une légère modification des autres définitions de la SPF.

Guidance concerning the permissible temperature rise for parts of electrical equipment, in particular for terminals

General Information

- Status

- Published

- Publication Date

- 11-Sep-2024

- Technical Committee

- TC 81 - Lightning protection

- Drafting Committee

- MT 21 - TC 81/MT 21

- Current Stage

- PPUB - Publication issued

- Start Date

- 12-Sep-2024

- Completion Date

- 21-Jun-2024

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62305-3:2024 - Protection against lightning: Part 3: Physical damage to structures and life hazard sets requirements for protecting buildings and people from lightning-induced physical damage and from injury due to touch and step voltages around a lightning protection system (LPS). Applicable to the design, installation, inspection and maintenance of LPS for structures of any height, this third edition (technical revision) replaces the 2010 edition and clarifies methods, component requirements and new protective measures.

Key Topics and Requirements

- Scope and applicability: LPS design and measures to prevent injury from touch/step voltages for all structure heights.

- Air-termination systems: Minimum metal sheet/pipe thicknesses (see Table 4) to avoid hot-spot problems; maximum temperature rises (ΔT) and time durations (t50) for long strokes.

- Separation distance: Clarification and application of two calculation approaches - general and simplified methods for determining safe separation distances between LPS conductors and conductive parts of a structure.

- LPS components: Cross-reference to the IEC 62561 series to ensure use of reliable, standardized components.

- Air-termination conductor positioning: Revised positioning rules based on three accepted methods; detailed guidance moved to Annex D to match structural complexity.

- Continuity of steel reinforcement: Updated requirements affecting bonding and continuity in reinforced structures.

- New definitions: Introduction of “electrically insulated LPS” to distinguish from systems electrically and physically isolated from the structure.

- Annex updates: Annex C revised per subcommittee comments; Annex D now includes detailed methods, plus new guidance on green roofs and protection of protruding facade parts on tall buildings.

Applications and Who Uses It

IEC 62305-3:2024 is essential for professionals and organizations involved in lightning protection and building safety:

- Electrical and lightning protection engineers - LPS design and risk assessment.

- Architects and structural engineers - integrating LPS and ensuring continuity of reinforcement and conductor routing.

- Installers and contractors - following installation, testing, inspection and maintenance requirements.

- Facility and building managers - ensuring occupant safety from touch/step voltages and meeting compliance.

- Inspection bodies and authorities having jurisdiction (AHJs) - verifying conformity with updated technical rules and component standards.

Practical uses include designing complete LPS, choosing compliant components (IEC 62561), calculating separation distances, specifying air-termination layouts for complex and tall structures, protecting green roofs and facade projections, and preventing thermal/hot-spot damage in conductors.

Related Standards

- IEC 62305-1 (general principles of lightning protection) - referenced for overall risk management.

- IEC 62561 series - for LPS components and their performance and testing requirements.

Keywords: IEC 62305-3:2024, lightning protection, LPS, touch and step voltages, air-termination system, separation distance, IEC 62561, protection of structures, green roofs, façade protection.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

Intertek Testing Services NA Inc.

Intertek certification services in North America.

QAI Laboratories

Building and construction product testing and certification.

Sponsored listings

Frequently Asked Questions

IEC 62305-3:2024 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Protection against lightning - Part 3: Physical damage to structures and life hazard". This standard covers: IEC 62305-3:2024 provides the requirements for protection of a structure against physical damage by means of a lightning protection system (LPS), and for protection against injury to human beings due to touch and step voltages in the vicinity of an LPS (see IEC 62305-1). This document is applicable to the: a) design, installation, inspection and maintenance of an LPS for structures without limitation of their height, b) establishment of measures for protection against injury to human beings primarily due to touch and step voltages. This third edition cancels and replaces the second edition published in 2010. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Minimum thicknesses of metal sheets or metal pipes are given in Table 4 for air-termination systems where it is necessary to prevent hot-spot problems. Maximum temperature rises ΔT (K) and time duration t50 (s) for different thicknesses and long strokes are also given. b) Cross-reference to the IEC 62561 series is made for the use of reliable, stable, safe and appropriate LPS components. c) The application of two methods – general and simplified – for separation distance calculation is clarified. d) Some changes to the requirements for continuity of steel reinforcement are made. e) Annex C is revised to address comments from IEC subcommittee 31J. f) Revision of positioning of air-termination conductors are modified according to the three accepted methods. A more precise description of the methods for positioning of the air-termination systems are made according to the complexity of structures to be protected. The main text has been simplified, Annex A has been deleted and all detailed information has been moved to Annex D. g) Information on the protection of green roofs is introduced in Annex D. h) Information on the protection of protruding parts on facades of tall buildings is introduced in Annex D. i) a new definition of “electrically insulated LPS” has been introduced to distinguish it from an LPS both electrically and physically isolated from the structure, with a slight modification of the other LPS definitions.

IEC 62305-3:2024 provides the requirements for protection of a structure against physical damage by means of a lightning protection system (LPS), and for protection against injury to human beings due to touch and step voltages in the vicinity of an LPS (see IEC 62305-1). This document is applicable to the: a) design, installation, inspection and maintenance of an LPS for structures without limitation of their height, b) establishment of measures for protection against injury to human beings primarily due to touch and step voltages. This third edition cancels and replaces the second edition published in 2010. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) Minimum thicknesses of metal sheets or metal pipes are given in Table 4 for air-termination systems where it is necessary to prevent hot-spot problems. Maximum temperature rises ΔT (K) and time duration t50 (s) for different thicknesses and long strokes are also given. b) Cross-reference to the IEC 62561 series is made for the use of reliable, stable, safe and appropriate LPS components. c) The application of two methods – general and simplified – for separation distance calculation is clarified. d) Some changes to the requirements for continuity of steel reinforcement are made. e) Annex C is revised to address comments from IEC subcommittee 31J. f) Revision of positioning of air-termination conductors are modified according to the three accepted methods. A more precise description of the methods for positioning of the air-termination systems are made according to the complexity of structures to be protected. The main text has been simplified, Annex A has been deleted and all detailed information has been moved to Annex D. g) Information on the protection of green roofs is introduced in Annex D. h) Information on the protection of protruding parts on facades of tall buildings is introduced in Annex D. i) a new definition of “electrically insulated LPS” has been introduced to distinguish it from an LPS both electrically and physically isolated from the structure, with a slight modification of the other LPS definitions.

IEC 62305-3:2024 is classified under the following ICS (International Classification for Standards) categories: 29.020 - Electrical engineering in general; 91.120.40 - Lightning protection. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62305-3:2024 has the following relationships with other standards: It is inter standard links to IEC 62305-3:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62305-3:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62305-3 ®

Edition 3.0 2024-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Protection against lightning –

Part 3: Physical damage to structures and life hazard

Protection contre la foudre –

Partie 3: Dommages physiques sur les structures et risques humains

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications, symboles

en utilisant différents critères (numéro de référence, texte, graphiques et le glossaire. Avec un abonnement, vous aurez

comité d’études, …). Elle donne aussi des informations sur les toujours accès à un contenu à jour adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 500 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 25 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62305-3 ®

Edition 3.0 2024-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Protection against lightning –

Part 3: Physical damage to structures and life hazard

Protection contre la foudre –

Partie 3: Dommages physiques sur les structures et risques humains

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.020, 91.120.40 ISBN 978-2-8322-9059-0

– 2 – IEC 62305-3:2024 © IEC 2024

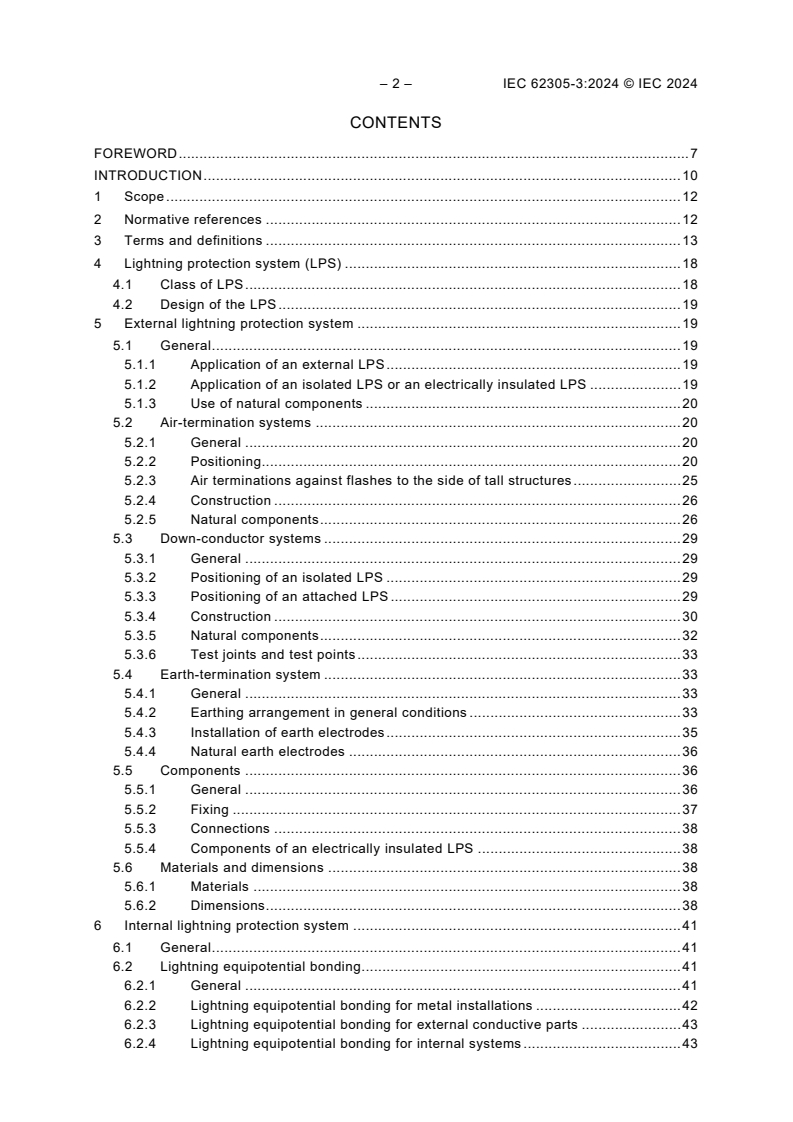

CONTENTS

FOREWORD . 7

INTRODUCTION . 10

1 Scope . 12

2 Normative references . 12

3 Terms and definitions . 13

4 Lightning protection system (LPS) . 18

4.1 Class of LPS . 18

4.2 Design of the LPS . 19

5 External lightning protection system . 19

5.1 General . 19

5.1.1 Application of an external LPS . 19

5.1.2 Application of an isolated LPS or an electrically insulated LPS . 19

5.1.3 Use of natural components . 20

5.2 Air-termination systems . 20

5.2.1 General . 20

5.2.2 Positioning . 20

5.2.3 Air terminations against flashes to the side of tall structures . 25

5.2.4 Construction . 26

5.2.5 Natural components . 26

5.3 Down-conductor systems . 29

5.3.1 General . 29

5.3.2 Positioning of an isolated LPS . 29

5.3.3 Positioning of an attached LPS . 29

5.3.4 Construction . 30

5.3.5 Natural components . 32

5.3.6 Test joints and test points . 33

5.4 Earth-termination system . 33

5.4.1 General . 33

5.4.2 Earthing arrangement in general conditions . 33

5.4.3 Installation of earth electrodes . 35

5.4.4 Natural earth electrodes . 36

5.5 Components . 36

5.5.1 General . 36

5.5.2 Fixing . 37

5.5.3 Connections . 38

5.5.4 Components of an electrically insulated LPS . 38

5.6 Materials and dimensions . 38

5.6.1 Materials . 38

5.6.2 Dimensions . 38

6 Internal lightning protection system . 41

6.1 General . 41

6.2 Lightning equipotential bonding . 41

6.2.1 General . 41

6.2.2 Lightning equipotential bonding for metal installations . 42

6.2.3 Lightning equipotential bonding for external conductive parts . 43

6.2.4 Lightning equipotential bonding for internal systems . 43

6.2.5 Lightning equipotential bonding for lines connected to the structure to

be protected . 44

6.3 Separation distance . 45

6.3.1 General approach . 45

6.3.2 Simplified approach . 46

7 Maintenance and inspection of an LPS . 47

7.1 General . 47

7.2 Maintenance . 47

7.3 Objective of inspections . 47

7.4 Need for inspection . 48

8 Protection measures against injury to human beings due to touch and step

voltages . 48

8.1 Protection measures against touch voltages . 48

8.2 Protection measures against step voltages . 49

Annex A (normative) Minimum cross-section of the entering cable screen to avoid

dangerous sparking . 50

Annex B (informative) Evaluation of the separation distance s . 51

Annex C (normative) Additional requirements for LPSs in the case of structures with a

risk of explosion . 56

C.1 General . 56

C.2 Basic requirements . 56

C.2.1 General . 56

C.2.2 Required information . 56

C.2.3 Earthing . 56

C.3 Structures containing solid explosive material . 57

C.4 Structures with hazardous areas . 57

C.4.1 General . 57

C.4.2 Structures with Zones 2 and 22 . 58

C.4.3 Structures with Zones 1 and 21 . 58

C.4.4 Structures with Zones 0 and 20 . 58

C.4.5 Specific applications . 58

C.5 Maintenance and inspection . 59

Annex D (informative) Explanatory text concerning the design, construction,

maintenance and inspection of lightning protection systems . 60

D.1 General . 60

D.2 Structure of Annex D . 60

D.3 Additional information . 60

D.4 Design of lightning protection systems (LPSs) . 60

D.4.1 General remarks . 60

D.4.2 Design of the LPS . 62

D.5 External lightning protection system . 66

D.5.1 General . 66

D.5.2 Air-termination systems . 67

D.5.3 Down-conductor systems . 87

D.5.4 Earth-termination systems . 108

D.5.5 Components . 117

D.5.6 Materials and dimensions . 117

D.6 Internal lightning protection system . 122

D.6.1 General . 122

– 4 – IEC 62305-3:2024 © IEC 2024

D.6.2 Lightning equipotential bonding (EB) . 122

D.6.3 Electrical isolation of the external LPS . 128

D.6.4 Protection against effects of induced currents in internal systems . 132

D.7 Maintenance and inspection of the LPS . 132

D.7.1 General . 132

D.7.2 Inspection . 132

D.7.3 Testing . 134

D.7.4 Maintenance . 135

Bibliography . 136

Figure 1 – Protection angle corresponding to the class of LPS . 22

Figure 2 – Contacting the rolling sphere with the structure to be protected. 23

Figure 3 – Application of the protection angle method . 24

Figure 4 – Loop in a down conductor . 31

Figure 5 – Minimum length l of each earth electrode according to the class of LPS . 34

Figure B.1 – Values of coefficient k in the case of a wire air-termination system . 51

c

Figure B.2 – Values of coefficient k in the case of a multiple down-conductor system . 52

c

Figure B.3 – Values of coefficients k in the case of multiple down conductors with an

c

interconnecting ring of down conductors at each level . 53

Figure B.4 – Values of coefficient k in the case of a meshed air-termination system,

c

with a multiple down-conductor system . 54

Figure D.1 – LPS design flow diagram . 61

Figure D.2 – Space protected by two parallel air-termination horizontal wires or two

air-termination rods (r > d/2) . 69

Figure D.3 – Designing the protection volume of catenary wire . 70

Figure D.4 – Horizontal section of the protected area at a given height . 71

Figure D.5 – Three examples of design of attached LPS air termination according to

the mesh method air-termination design . 73

Figure D.6 – Lateral protected volume constructed from the rolling sphere and the

lateral protection angle methods near the height equal to the radius of the sphere . 74

Figure D.7 – Application of the protection angle method for lateral impact with heights

up to 60 m . 75

Figure D.8 – Air termination and visually concealed conductors for buildings less than

20 m high with sloping roofs. 76

Figure D.9 – Construction of an LPS using natural components on the roof of the

structure . 78

Figure D.10 – Positioning of the external LPS on a structure made of insulating

material (e.g. wood or bricks) with a height up to 60 m with flat roof and with roof

fixtures . 79

Figure D.11 – Connection of natural air-termination rod to air-termination conductor . 81

Figure D.12 – Construction of the bridging between the segments of the metallic

facade plates . 82

Figure D.13 – Air-termination rod used for protection of a metallic roof fixture with

electric power installations which are not bonded to the air-termination system . 83

Figure D.14 – Method of achieving electrical continuity on metallic parapet capping . 84

Figure D.15 – Examples of air termination for a house with an antenna using an

attached LPS . 86

Figure D.16 – Installation of external LPS on a structure of insulating material with

different roof levels . 90

Figure D.17 – LPS design for a cantilevered part of a structure . 91

Figure D.18 – Use of a metallic facade covering as a natural down-conductor system

on a structure of steel-reinforced concrete . 93

Figure D.19 – Use of metallic facade as natural down-conductor system and

connection of facade supports . 94

Figure D.20 – Connection of the continuous strip windows to a metal facade covering . 95

Figure D.21 – Measuring the overall electrical resistance of steel reinforcement . 96

Figure D.22 – Equipotential bonding in a structure with a steel reinforcement . 98

Figure D.23 – Typical methods of joining reinforcing rods in concrete (where permitted) . 99

Figure D.24 – Examples of clamps used as joints between reinforcing rods and

conductors . 100

Figure D.25 – Examples of connection points to the reinforcement in a reinforced

concrete wall . 101

Figure D.26 – Internal down conductors in industrial structures . 104

Figure D.27 – Installation of bonding conductors on plate-like prefabricated reinforced

concrete parts by means of bolted or welded conductor links . 106

Figure D.28 – Installation of bonding conductors in reinforced concrete structures and

flexible bonds between two reinforced concrete parts . 107

Figure D.29 – Combined foundation earth electrode . 112

Figure D.30 – Construction of foundation earth ring for structures of different

foundation design . 113

Figure D.31 – Example of a Type A earthing arrangement with a vertical conductor

type electrode . 114

Figure D.32 – Example of a Type A earthing arrangement with a vertical rod type

electrode . 115

Figure D.33 – Meshed earth-termination system of a plant . 118

Figure D.34 – Example of an equipotential bonding arrangement . 124

Figure D.35 – Example of bonding arrangement in a structure with multiple entry points

of external conductive parts using a ring electrode for interconnection of bonding bars . 125

Figure D.36 – Example of bonding in the case of multiple entry points of external

conductive parts and an electric power or communication line, using an internal ring

conductor for interconnection of the bonding bars . 126

Figure D.37 – Example of bonding arrangement in a structure with multiple entry points

of external conductive parts entering the structure above ground level. 127

Figure D.38 – Directions for calculations of the separation distance, s, for a worse case

lightning interception point at a distance, l, from the reference point according to 6.3 . 130

Table 1 – Relation between lightning protection levels (LPL) and class of LPS (see

IEC 62305-1) . 18

Table 2 – Values of rolling sphere radius, mesh size and protection angle

corresponding to the class of LPS . 21

Table 3 – Minimum thickness of metal sheets or metal pipes in air-termination systems . 27

Table 4 – Maximum temperature rises ∆T (K) of inner surface and time duration t (s)

for different thickness t’’ (mm) and long strokes according to LPL I (Q = 200 C) . 28

LONG

Table 5 – Preferred values of the distance between down conductors by LPS according

to the class of LPS . 30

– 6 – IEC 62305-3:2024 © IEC 2024

Table 6 – LPS materials and conditions of use . 37

Table 7 – Material, configuration and minimum cross-sectional area of air-termination

conductors, air-termination rods, earth lead-in conductors and down conductors . 39

Table 8 – Material, configuration and minimum dimensions of earth electrodes . 40

Table 9 – Minimum dimensions of conductors connecting different bonding bars or

connecting bonding bars to the earth-termination system . 42

Table 10 – Minimum dimensions of conductors connecting internal metal installations

to the bonding bar . 42

Table 11 – Separation distance – Values of coefficient k . 45

i

Table 12 – Separation distance – Values of coefficient k . 45

m

Table 13 – Separation distance – Approximated values of coefficient k . 47

c

Table A.1 – Cable length to be considered according to the condition of the screen . 50

Table D.1 – Suggested fixing centres . 75

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PROTECTION AGAINST LIGHTNING –

Part 3: Physical damage to structures and life hazard

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 62305-3 has been prepared by IEC technical committee 81: Lightning protection. It is an

International Standard.

This third edition cancels and replaces the second edition published in 2010. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Minimum thicknesses of metal sheets or metal pipes are given in Table 4 for air-termination

systems where it is necessary to prevent hot-spot problems. Maximum temperature rises

ΔT (K) and time duration t (s) for different thicknesses and long strokes are also given.

b) Cross-reference to the IEC 62561 series is made for the use of reliable, stable, safe and

appropriate LPS components.

– 8 – IEC 62305-3:2024 © IEC 2024

c) The application of two methods – general and simplified – for separation distance calculation

is clarified.

d) Some changes to the requirements for continuity of steel reinforcement are made.

e) Annex C is revised to address comments from IEC subcommittee 31J.

f) Revision of positioning of air-termination conductors are modified according to the three

accepted methods. A more precise description of the methods for positioning of the air-

termination systems is made according to the complexity of structures to be protected. The

main text has been simplified, Annex A has been deleted and all detailed information has

been moved to Annex D.

g) Information on the protection of green roofs is introduced in Annex D.

h) Information on the protection of protruding parts on facades of tall buildings is introduced in

Annex D;

i) a new definition of “electrically insulated LPS” has been introduced to distinguish it from an

LPS both electrically and physically isolated from the structure, with a slight modification of

the other LPS definitions.

The text of this International Standard is based on the following documents:

Draft Report on voting

81/764/FDIS 81/767/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 62305 series, published under the general title Protection against

lightning, can be found on the IEC website.

The following differing practices of a less permanent nature exist in the countries indicated

below.

In Austria, Annex C shall not be applied and is replaced by the National standard ÖVE/ÖNORM

EN 62305-3 Beiblatt 1:2013-11-01 Blitzschutz – Teil 3: Schutz von baulichen Anlagen und

Personen – Beiblatt 1: Zusätzliche Informationen für bauliche Anlagen mit

explosionsgefährdeten Bereichen. In Austria, Annex C shall be classified as "Informative".

In Germany, the need for lightning protection is determined by, and the class of required LPS

shall be selected according to, a national annex to the third edition of IEC 62305-1 (including

an option for a risk assessment following the third edition of IEC 62305-2).

In Germany, for a metallic or electrically-continuous connected reinforced concrete framework,

in addition, DIN EN 62305-3 Beiblatt 1 shall be applied.

In Germany, 8.1 condition b) is not applied – see DIN EN 62305-3 Beiblatt 1. Instead, the

alternate measures, as described in DIN EN 62305-3 Beiblatt 1, shall be applied.

In Germany, for 8.2, the alternate measures, as described in DIN EN 62305-3 Beiblatt 1, shall

be applied.

In Japan, when using country-specific lightning protection components, the manufacturer and/or

lightning protection designer shall explain that the component will withstand the electromagnetic

effects of lightning currents and possible accidental stresses without damage.

In Italy, a separation distance is not required in structures with metallic or electrically-

continuous connected reinforced concrete framework according to 5.3.5.

In Italy, in reinforced concrete structures, the reinforcement may be used for equipotential

bonding. In this case, if a ring electrode is not yet installed and connected to the reinforcement

steels, a ring conductor welded or bolted to the steel reinforcement will be installed, to which

the bonding bars should be connected via welded conductors.

In the Netherlands, in some situations, special fasteners which are necessary and which are

not available on the commercial market and are not tested according to IEC 62561-4 (because

of a small number of required special fasteners), must comply with the lateral and axial test

mentioned in IEC 62561-4. A written statement of passing these lateral and axial tests must be

issued by the designer and/or the installer of the LPS and must be a part of the commissioning

documents.

In South Africa, the class of required LPS shall be selected on the basis of a risk assessment

of either the second edition of IEC 62305-2 or the third edition of IEC 62305-2 . This note

applies also for D.4.1 and D.4.2.1.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

– 10 – IEC 62305-3:2024 © IEC 2024

INTRODUCTION

This part of IEC 62305 deals with the protection, in and around a structure, against physical

damage and injury to human beings due to touch and step voltages.

The main and most effective measure for protection of structures and its content against

physical damage is considered to be a lightning protection system (LPS). It usually consists of

both external and internal lightning protection measures.

An external LPS is intended to

a) intercept a lightning flash to the structure (with an air-termination system),

b) conduct the lightning current safely towards earth (using a down-conductor system),

c) disperse the lightning current into the earth (using an earth-termination system).

NOTE The purpose of the external LPS is to protect the structure from a direct lightning strike by providing the

preferred attachment points, conducting and dispersing the lightning current. It will not significantly influence the

attachment process between the structure and the lightning to increase or reduce the number of direct lightning

strikes (S1) to the structure.

An internal LPS prevents dangerous sparking within the structure using either equipotential

bonding or a separation distance (and hence isolation) between the external LPS (as defined

in 3.2) and other electrically conducting elements internal to the structure.

Main protection measures against injury to human beings due to touch and step voltages are

intended to:

1) reduce dangerous current flowing through bodies by either insulating exposed conductive

parts, or by increasing the surface soil resistivity, or both,

2) reduce the occurrence of dangerous touch and step voltages by either physical restrictions

or warning notices, or both.

The type and location of an LPS should be carefully considered in the initial design of a new

structure, thereby enabling maximum advantage to be taken of the electrically conductive parts

of the structure. By so doing, design and construction of an integrated installation is made

easier, the overall aesthetic aspects can be improved, and the effectiveness of the LPS can be

increased at minimum cost and effort.

Access to the ground and the proper use of foundation steelwork for the purpose of forming an

effective earth termination may well be impossible once construction work on a site has

commenced. Therefore, soil resistivity and the nature of the earth should be considered at the

earliest possible stage of a project. This information is fundamental to the design of an earth-

termination system and can influence the foundation design work for the structure.

Regular consultation between LPS designers and installers, architects and builders is essential

in order to achieve the best result at minimum cost.

If lightning protection is to be added to an existing structure, every effort should be made to

ensure that it conforms to the principles of this document. The design of the type and location

of an LPS should take into account the features of the existing structure.

When safety is involved and significant changes are made to the structure or its use changes,

consideration of updating the lightning protection installation to the present edition of this

document is recommended.

National or local laws and regulations can provide guidance or minimum requirements on the

application of this document. This includes specifying the class of a required LPS for specific

applications without a risk assessment, the conditions of separation and bonding of other earth-

termination systems, the additional information given in Annex C for LPSs in case of structures

with a risk of explosion, and the mandatory requirements for inspection, testing and

maintenance of LPSs given in Clause 7.

– 12 – IEC 62305-3:2024 © IEC 2024

PROTECTION AGAINST LIGHTNING –

Part 3: Physical damage to structures and life hazard

1 Scope

This part of IEC 62305 provides the requirements for protection of a structure against physical

damage by means of a lightning protection system (LPS), and for protection against injury to

human beings due to touch and step voltages in the vicinity of an LPS (see IEC 62305-1).

This document is applicable to the:

a) design, installation, inspection and maintenance of an LPS for structures without limitation

of their height,

b) establishment of measures for protection against injury to human beings primarily due to

touch and step voltages.

NOTE 1 Specific requirements for an LPS in structures dangerous to their surroundings due to the risk of explosion

are provided in Annex C.

NOTE 2 This document is not intended to provide protection against failures of electrical and electronic systems

due to overvoltages. Specific requirements for such cases are provided in IEC 62305-4.

NOTE 3 Specific requirements for the protection against lightning of wind turbines are reported in IEC 61400-24

[1] .

NOTE 4 Specific requirements for the protection against overvoltage of photovoltaic systems are reported in

IEC 61643-32 [2] and in IEC 62305-4:2024, Annex F.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60079-10-1:2020, Explosive atmospheres – Part 10-1: Classification of areas – Explosive

gas atmospheres

IEC 60079-10-2:2015, Explosive atmospheres – Part 10-2: Classification of areas – Explosive

dust atmospheres

IEC 60079-14, Explosive atmospheres – Part 14: Electrical installations design, selection and

erection

IEC 60364-5-53, Low-voltage electrical installations – Part 5-53: Sel

...

SLOVENSKI STANDARD

01-april-2000

Guidance concerning the permissible temperature rise for parts of electrical

equipment, in particular for terminals

Guidance concerning the permissible temperature rise for parts of electrical equipment,

in particular for terminals

Guide concernant l'échauffement admissible des parties des matériels électriques, en

particulier les bornes de raccordement

Ta slovenski standard je istoveten z: IEC/TR 60943

ICS:

29.020 Elektrotehnika na splošno Electrical engineering in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

RAPPORT

CEI

TECHNIQUE – TYPE 3

IEC

TECHNICAL

Deuxième édition

REPORT – TYPE 3

Second edition

1998-01

Guide concernant l’échauffement admissible

des parties des matériels électriques,

en particulier les bornes de raccordement

Guidance concerning the permissible

temperature rise for parts of electrical equipment,

in particular for terminals

IEC 1998 Droits de reproduction réservés Copyright - all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in

utilisée sous quelque forme que ce soit et par aucun any form or by any means, electronic or mechanical,

procédé, électronique ou mécanique, y compris la photo- including photocopying and microfilm, without permission in

copie et les microfilms, sans l'accord écrit de l'éditeur. writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http: //www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale

PRICE CODE XA

International Electrotechnical Commission

Pour prix, voir catalogue en vigueur

For price, see current catalogue

60943 © IEC:1998 – 3 –

CONTENTS

Page

FOREWORD . 7

INTRODUCTION . 11

Clause

Section 1: General

1 General. 15

1.1 Scope and object . 15

1.2 Reference documents. 15

1.3 Definitions. 17

1.4 Symbols. 17

Section 2: Theory

2 General considerations concerning the nature of electric contact and the calculation

and measurement of the ohmic resistance of contacts . 19

2.1 Electric contacts and connection terminals . 19

2.2 Nature of electrical contact. 19

2.3 Calculation of contact resistance . 23

3 Ageing mechanisms of contacts and connection terminals . 31

3.1 General. 31

3.2 Contacts of dissimilar metals. 33

3.3 Oxidation ageing mechanisms. 37

3.4 Results concerning ageing of copper contacts . 41

3.5 Usage and precautions to be taken in the use of copper contact materials . 47

4 Calculation of temperature rise of conductors, contacts and connection terminals . 49

4.1 Symbolic representation. 49

4.2 Temperature rise ΔT of a conductor with respect to the temperature T of the

s e

surrounding medium. 53

4.3 Temperature rise ΔT in the vicinity of the contact: temperature rise

o

of connection terminals . 55

4.4 Temperature rise of the elementary contact points. 55

Section 3: Application

5 Permissible temperature and temperature rise values. 57

5.1 Ambient air temperature Θ . 57

a

5.2 Temperature and temperature rise of various equipment components . 59

5.3 Temperature and temperature rise of conductors connecting electrical

equipment. 75

5.4 Temperature and temperature rise of connection terminals for electrical

equipment – Influence on connected conductors. 77

60943 © IEC:1998 – 5 –

Clause Page

6 General procedure to be followed for determining permissible temperature and

temperature rise. 79

6.1 Basic parameters. 79

6.2 Method to be followed for determining maximum permissible temperature

and temperature rise . 79

Annexes

A Numerical examples of the application of the theory and other data . 83

B Physical characteristics of selected metals and alloys. 89

C Physical characteristics of fluid dielectrics . 91

D Information on the reaction of contact metals with substances in the atmosphere. 93

E Temperature rise of a conductor cooled by radiation and convection

in the vicinity of a terminal . 95

F List of symbols used in this report. 113

G Bibliography . 117

60943 © IEC:1998 – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

__________

GUIDANCE CONCERNING THE PERMISSIBLE TEMPERATURE RISE

FOR PARTS OF ELECTRICAL EQUIPMENT,

IN PARTICULAR FOR TERMINALS

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical reports or guides and they are accepted by the National Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

report of one of the following types:

• type 1, when the required support cannot be obtained for the publication of an

International Standard, despite repeated efforts;

• type 2, when the subject is still under technical development or where for any other

reason there is the future but no immediate possibility of an agreement on an International

Standard;

• type 3, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard, for example "state of the art".

Technical reports of types 1 and 2 are subject to review within three years of publication to

decide whether they can be transformed into International Standards. Technical reports of

type 3 do not necessarily have to be reviewed until the data they provide are considered to be

no longer valid or useful.

IEC 60943, which is a technical report of type 3, has been prepared by IEC technical

committee 32: Fuses.

This second edition cancels and replace the first edition which was issued in 1989.

60943 © IEC:1998 – 9 –

The text of this technical report is based on the following documents:

Committee draft Report on voting

32/142/CDV 32/148/RVC

Full information on the voting for the approval of this technical report can be found in the report

on voting indicated in the above table.

Annexes are for information only.

60943 © IEC:1998 – 11 –

INTRODUCTION

a) The temperature rise encountered in electrical assemblies as a result of the various losses

in the conductors, contacts, magnetic circuits, etc. is of growing importance as a result of

the development of new techniques of construction and operation of equipment.

This development has been particularly significant in the field of assemblies, where

numerous components dissipating energy (contactors, fuses, resistors, etc.), in particular

modular devices are found within enclosures of synthetic materials which are somewhat

impermeable to heat.

This temperature rise results in a relatively high temperature of the basic elements

constituting the electric contacts: a high temperature favours oxidation at the contact

interface, increases its resistance and thereby leads to further heating, and thus to an even

higher temperature. If the component material of the contact is unsuitable or insufficiently

protected, the contact may be irreparably damaged before the calculated useful life of the

equipment has expired.

Such temperature rises also affect connection terminals and the connected conductors, and

their effects should be limited in order to ensure that the insulation of the conductors

remains satisfactory throughout the life of the installation.

b) In view of these problems, this report has been prepared with the following objectives:

– to analyze the various heating and oxidation phenomena to which the contacts, the

connection terminals and the conductors leading to them are subjected, depending on

their environment and their arrangement;

– to provide elementary rules to product committees to enable them to specify permissible

temperatures and temperature rises.

c) Attention is drawn to the precautions to be taken for sets of components when parts are

grouped together in the same enclosure.

The attention of users should be drawn particularly to the fact that the temperature rise of

terminals permitted by particular switchgear standards results from conventional situations

during type tests; these can differ appreciably from the situations met with in practice, which

have to be taken into account, particularly because of the temperatures permitted by the

insulation of the conductors which may be connected to the terminals under normal

conditions.

d) Attention is drawn to the fact that in the relevant product standards, the permissible

temperature and temperature rise for the external terminals are measured during

conventional type tests and therefore they may not reflect the actual situation likely to occur

in normal use.

Suitable precautions should then be adopted to avoid exposure to temperatures that may

affect the life of materials adjacent to the terminals of components.

In this case, it is essential to distinguish the concept of "external ambient temperature"

which prevails outside the enclosure from that of "the temperature of the fluid surrounding a

part" which comprises the external ambient temperature plus the internal temperature rise

due to the parts. These concepts, as well as other complementary concepts such as the

thermal resistance of an enclosure, are dealt with in clause 5 and explained by means of

numerical examples.

In order to facilitate complete calculation, this report links up the temperature of the fluid

surrounding a component to the external ambient temperature by the introduction of the

concept of "coefficient of filling" and gives a numerical example (5.2.3.2) which specifies the

values of the coefficient of filling to be used in several practical cases.

60943 © IEC:1998 – 13 –

The quantities involved in calculating contact constriction resistance are subject to wide

variations due to the physical conditions and degree of contamination of the surface in

contact. By calculation alone, therefore, the contact resistance can be estimated to an

accuracy of no better than an order of magnitude.

More precise and more accurate values should be obtained by direct measurement on given

items of electrical equipment, because in practice it is often the case that other incalculable

degradation mechanisms predominate.

This report is not meant to give guidance on the derating of components.

It is strongly advised that the reference literature quoted at the end of this report be studied

before attempting to apply the data to a practical problem.

60943 © IEC:1998 – 15 –

GUIDANCE CONCERNING THE PERMISSIBLE TEMPERATURE RISE

FOR PARTS OF ELECTRICAL EQUIPMENT,

IN PARTICULAR FOR TERMINALS

Section 1: General

1 General

1.1 Scope and object

This report is intended for guidance in estimating the permissible values for temperature and

temperature rise of component parts of electrical equipment carrying current under steady

state conditions.

This report applies to electrical power connections and materials adjacent to them.

This report is concerned with the thermal effects of currents passing through connections,

therefore there are no voltage limits to its application.

This report is only applicable when referred to in the appropriate product standard.

The extent and manner to which the contents of this report are used in standards is the

responsibility of individual Technical Committees.

Whenever "permissible" values are stated in this report, they mean values permitted by the

relevant product standard.

The present report is intended to supply:

– general data on the structure of electric contacts and the calculation of their ohmic

resistance;

– the basic ageing mechanisms of contacts;

– the calculation of the temperature rise of contacts and connection terminals;

– the maximum “permissible” temperature and temperature rise for various components, in

particular the contacts, the connection terminals and the conductors connected to them;

– the general procedure to be followed by product committees for specifying the permissible

temperature and temperature rise.

1.2 Reference documents

IEC 60050(441):1984, International Electrotechnical Vocabulary (IEV) – Chapter 441: Switch-

gear and controlgear and fuses

IEC 60085:1984, Thermal evaluation and classification of electrical insulation

60943 © IEC:1998 – 17 –

IEC 60216-1:1990, Guide for the determination of thermal endurance properties of electrical

insulating materials – Part 1: general guidelines for ageing procedures and evaluation of the

test results

IEC 60364-4-42:1980, Electrical installations of buildings – Part 4: Protection for safety -

Chapter 42: Protection against thermal effects

IEC 60694:1996, Common specifications for high-voltage switchgear and controlgear standards

IEC 60721-2-1:1982, Classification of environmental conditions – Part 2: environmental

conditions appearing in nature. Temperature and humidity

IEC 60890:1987, A method of temperature-rise assessment by extrapolation for partially type-

tested assemblies (PTTA) of low voltage switchgear and controlgear

IEC 60947-1:1988, Low-voltage switchgear and controlgear – Part 1: General rules

1.3 Definitions

Definitions of terms used in this report may be found in the International Electrotechnical

Vocabulary. For the purposes of this technical report, the following terms also apply:

1.3.1

ambient air temperature ΘΘ

a

the temperature, determined under prescribed conditions, of the air surrounding the complete

device [IEV 441-11-13]

NOTE – For devices installed inside an enclosure, it is the temperature of the air outside the enclosure.

1.3.2

contact (of a mechanical switching device)

conductive parts designed to establish circuit continuity when they touch and which, due to

their relative motion during an operation, open or close a circuit or, in the case of hinged or

sliding contacts, maintain circuit continuity [IEV 441-15-05]

NOTE – Do not confuse with "IEV 441-15-06 Contact (piece): one of the conductive parts forming a contact."

1.3.3

connection (bolted or the equivalent)

two or more conductors designed to ensure permanent circuit continuity when forced together

by means of screws, bolts, or the equivalent [3.5.10 of IEC 60694]

1.4 Symbols

A list of symbols used in this report is given in annex F.

60943 © IEC:1998 – 19 –

Section 2: Theory

NOTE – This theory applies to both "contacts" and "connections" as defined in 1.3.2 and 1.3.3. For convenience,

only the word "contact" only is used in this section to cover both applications.

2 General considerations concerning the nature of electric contact and

the calculation and measurement of the ohmic resistance of contacts

2.1 Electric contacts and connection terminals

Electric contact, in its simplest and most general configuration, results from contact

established between two pieces of (usually metallic) conducting material. In the case of

connection terminals, these are the terminal itself and the conductor which is connected to it.

The active zone is the contact "interface" which is the region where the current passes from

one piece to the other. It is in this area that the contact resistance occurs, causing heating by

Joule effect, and it is also where ageing occurs through chemical reaction with the surrounding

atmosphere.

2.2 Nature of electric contact

When one piece of metal is applied to another, contact is not made over the whole apparent

contact area, but only at a certain number of points called "elementary contacts".

The effective total cross-sectional area of these contacts is equal to the effective contact area

)

S if the possible presence of impurities is ignored (dust, etc.) at the contact interface.

a

There is also a fine layer of air or of oxide normally present, the effect of which upon the

contact resistance will be examined later (see 2.3).

In the following, for ease of calculation and for a better understanding of the contact

mechanisms, the simplifying assumption is made that there are n elementary contacts on the

apparent contact area, uniformly distributed, of average constant radius a (see figure 1). The

average distance between these elementary contacts is l.

The effective contact area is then:

S = n π a

a

¶¶¶¶¶¶¶¶¶¶

)

For an explanation of the symbols used in this report, see annex F.

60943 © IEC:1998 – 21 –

IEC 1 286/97

Figure 1 – Illustration of apparent contact and effective contact areas

The contact area S depends upon how hard the contacts are pressed against each other, i.e.

a

upon the force applied, the surface state of the contacts, and the hardness of the material

used.

For the forces normally found in electrical technology, the contact area is, in practice, the area

over which the force applied reaches the ultimate strength of the contact material characterised

by the "hardness" of that material.

In fact, the asperities on each of the two surfaces before they are brought into contact and

which are due to previous preparation of the surface are of small dimension (of the order of

1/100 mm) and are crushed even by small forces of the order of 0,1 N.

Assuming that the pressure exerted upon the contact area is equal to the contact hardness of

the metal (H), then the following equation is obtained:

F

= ξ H

S

a

However, this equation applies only for a contact force of F ≥ 50 N, in fact:

F

Sn==πa²

a

ξ H

where ξ is a dimensionless "coefficient of flatness" dependent upon the state of the surfaces in

contact, usually having a value of between 0,3 and 0,6 for normal forces, but which can be

much smaller after extensive polishing of the contact surfaces against each other.

As a result, the elementary contact radius a is given by the equation:

F

a =

(1)

nHπξ

60943 © IEC:1998 – 23 –

The number n of elementary contacts can be worked out approximately by the formula:

0,625 0,2

nn= H F (2)

k

–5

where n ≈ 2,5 × 10 (SI units)

k

The above expression gives only the order of magnitude of the number of elementary contacts.

–5

Values of n can differ significantly from the value estimated, for example between 0,5 × 10

k

–5

and 30 × 10 (SI units).

2.3 Calculation of contact resistance

Contact resistance is made up of two components:

a) constriction resistance, due to the drawing together of the lines of current as they pass

through the elementary contacts;

b) film resistance, corresponding to the film of oxide or of adsorbed molecules at the interface.

2.3.1 Calculation of the constriction resistance

Consider (see figure 2) an idealised elementary contact of radius a. If the electrical conductors

are large in relation to the elementary contact, the lines of current are hyperbolae with foci

located at the ends of the elementary contact diameter and the equipotential surfaces are

flattened ellipsoids of the same foci.

IEC 1 287/97

Figure 2 – Equipotentials and lines of current at an elementary contact point

60943 © IEC:1998 – 25 –

The resistance R between the point of contact (heavy broken line in figure 2) and the semi-

(a,l)

ellipsoid of major semi-axis l (l being the average distance between neighbouring elementary

contacts and ρ the resistivity of the metal) is equal to half the contact resistance, and is written:

ρ −

la

R = arctan

(a,l )

2.π a a

If l is large compared with a, which is the more common case:

ρ

=

R

(a,ll)( /a→∞)

4a

since the constriction resistance is the sum of both halves

ρ

R = (3)

()e

2a

For an actual contact comprising n relatively widely spread elementary contact points, the

constriction resistance is thus:

ρ

R = (4)

e

2na

2.3.2 Calculation of the film resistance

The elementary contact points generally do not have a corrosion-free interface. Indeed, any

initially pure metal surface becomes covered with a molecular layer of oxygen, leading in a few

minutes to the formation of a homogeneous layer of oxide a few nanometres thick. If this layer

is sufficiently compact and uniform, it protects the metal to some extent, the oxidation can then

stop and the metal is "passivated"; this is particularly the case with aluminium and stainless

steel at ordinary temperatures.

For other metals (copper, nickel and tin in the presence of oxygen; silver in the presence of

sulphurous gases), the formation of this first layer of reaction product produced by oxidation or

corrosion slows up the subsequent reaction which nevertheless continues, but more and more

slowly.

For certain other metals (iron), the "oxidation" speed is more or less constant because the

surface is not protected by the layer formed.

The main formulae for surface chemical reactions giving the thickness s formed as a function

of time t and thermodynamic temperature T are contained in annex D for different metals.

They are derived from the general formula:

w

sX=⋅exp− ⋅ t (5)

2kT

If the activation energy w is expressed in electronvolts, it is necessary to multiply w by 1,6021 ×

–19

10 J/eV. X is a constant and k is the Boltzmann constant.

60943 © IEC:1998 – 27 –

This thin layer of oxide does not present a purely ohmic resistance to the passage of the

current, such as could be evaluated by the formula:

ρ × length

cross-sectional area

The electrons can in fact pass through it by a "tunnel-effect" mechanism.

The "tunnel resistivity" σ (surface resistivity), which is used to characterize the conductive

o

properties of this layer, is expressed in Ωm (see table 1 for typical values). Tunnel resistivity

depends on the nature of the oxide (or other products of reaction with the atmosphere) and its

thickness. Its thickness generally does not exceed 10 nm.

If the layer of "oxide" covers the actual contact area S uniformly, the apparent resistance R

a

i

between the two faces is written:

σ

o

R =

i

S

a

In the case of n elementary contacts of radius a, the resistance R , due to the layer of oxide at

i

the interface, is expressed by the equation:

σσ

oo

R== (6)

i

total area in contact

n π a

Table 1 – Typical values of tunnel resistivity

σ

Metal State o

Ω m

–12 –11

Copper New 2 10 to 3 10

× ×

–10

Oxidised

–12 –11

10 to 4 × 10

Tinned

–13 –12

Silver

4,6 × 10 to 4 × 10

–11

exceptionally up to 2,5 × 10

–11 –9

Aluminium 7 × 10 to 10

–13

The values obtained are low for new contacts. The minimum value of 4,6 × 10 for silver

corresponds to the limit thickness of two adsorbed mono-molecular layers of oxygen, i.e.

2 × 0,272 nm = 0,54 nm.

2.3.3 Expression of the total contact resistance

The contact resistance R is the sum of the constriction resistance R (equation (4)) and the

c e

film resistance R (equation (6)), i.e:

i

60943 © IEC:1998 – 29 –

σ

ρ

R=+ (7)

c

2na

naπ

If n and a in this equation are replaced by their values:

06,,25 02

–5

nn= H F with n ≈ 2,5 × 10 (SI units)

k k

F

a= with ξ = 0,45

nHπξ

we obtain the following expression for R :

c

ρπξ

01,,875−−0 6 1

R=+HF σξHF

c o

2 n

k

This formula, applied to the different contact metals, gives the values of k and k shown in

1 2

table 2.

If one metal is thinly plated onto another, the hardness must be taken as that of the plating and

the resistivity as that of the base metal.

In the case of contacts of dissimilar metals, the overall resistance is the average of the

resistance calculated using the constants for each metal.

Table 2 – Typical values of contact resistance constants, calculated for relatively clean

–0,6 –1

surfaces (For substitution in: R = k F + k σ F )

c 1 2 0

Constriction resistance k Film resistance k

1 2

Metal

–6 6

× 10 × 10

Copper 90 247

Brass 360 450

Aluminium 130 135

Almelec 150 135

Silver 81 225

Tin 400 22,5

Nickel 420 585

Silvered copper 88 225

Tinned copper 57 22,5

Tinned aluminium 93 22,5

Silvered brass 310 225

Tinned brass 200 22,5

60943 © IEC:1998 – 31 –

2.3.4 Electrical resistance of contacts when new

Tinned copper contacts theoretically show the lowest resistance compared with other kinds of

contacts. However, this is only true provided two conditions are met: the layer of tin must be

sufficiently thin to prevent its resistivity from being involved, and sufficiently thick for the

hardness involved to actually be that of the tin. In practice, the resistivity obtained in the case

of new tinned contacts is comparable with that of silvered copper and slightly less than that of

copper. However, in the case of tinned contacts of the flexible type or those subject to

vibration, account must be taken of "fretting corrosion" phenomena on the layer of tin,

mentioned in 3.5.

Constriction resistance is particularly high in the case of tin and nickel, which rules out the use

of these materials in the solid state.

Film resistance is high in the case of nickel and nickel-plated copper, which may be admissible

in certain cases, bearing in mind the good corrosion resistance of nickel in corrosive

atmospheres (battery rooms, atmospheres containing H S etc.).

2.3.5 Measurement of contact resistance

Contact resistance measurement is useful either for development tests or as routine tests to

check production by comparison with a specimen which passed the temperature-rise test.

Contact resistance is usually measured by injecting a d.c. current through the junction (so as to

avoid effects of inductance), and measuring the resulting voltage drop across the junction.

For comparison purposes, it is important to measure the voltage drop at a defined location.

Measuring the contact resistance with a current much smaller than the normal current in

service could give incorrect values, in particular when spring-loaded contacts have been

operating on “no-load”.

In addition, the voltage of the test supply should be sufficient to break down any possible

surface layer, without exceeding the working voltage of the equipment under test. Care should

be taken to avoid errors due to thermo-electric effects.

3 Ageing mechanisms of contacts and connection terminals

3.1 General

The ageing of closed electric contacts not subjected to arc erosion (the case with terminals in

particular) is essentially due to the reaction of the metals with the surrounding environment at