IEC 62341-1-1:2009

(Main)Organic light emitting diode (OLED) displays - Part 1-1: Generic specifications

Organic light emitting diode (OLED) displays - Part 1-1: Generic specifications

IEC 62341-1-1:2009 is a generic specification for organic light emitting diode (OLED) displays. It defines general procedures for quality assessment to be used in the IECQ System and establishes general rules for methods of electrical and optical measurements, environmental and mechanical tests and endurance tests.

Afficheurs à diodes électroluminescentes organiques (OLED) - Partie 1-1: Spécifications génériques

La CEI 62341-1-1:2009 est une spécification générique pour les afficheurs à diodes électroluminescentes organiques (OLED; en anglais Organic Light Emitting Diode). Elle définit les procédures générales pour l'assurance de la qualité à utiliser dans le système IECQ-CECC et établit des règles générales pour les méthodes de mesures électriques et optiques, les essais d'environnement et mécaniques et les essais d'endurance.

General Information

- Status

- Published

- Publication Date

- 06-Apr-2009

- Technical Committee

- TC 110 - Electronic displays

- Drafting Committee

- WG 5 - TC 110/WG 5

- Current Stage

- PPUB - Publication issued

- Start Date

- 07-Apr-2009

- Completion Date

- 30-Apr-2009

Overview

IEC 62341-1-1:2009 is an international standard developed by the International Electrotechnical Commission (IEC) that defines generic specifications for Organic Light Emitting Diode (OLED) displays. This standard provides a comprehensive framework for quality assessment procedures within the IEC Quality Assessment System for Electronic Components (IECQ). It establishes general rules regarding electrical and optical measurement methods, environmental and mechanical testing, and endurance evaluations for OLED display devices.

Aimed at manufacturers, testers, and quality assurance professionals involved in OLED display production and evaluation, IEC 62341-1-1 ensures consistent product reliability and performance across the industry by standardizing measurement and testing processes.

Key Topics

Quality Assessment Procedures

The standard details robust quality assessment methods including qualification approvals, commercial confidentiality aspects, inspection lot formation, and subcontracting protocols. It emphasizes stringent quality conformance inspections and outlines statistical sampling plans such as Acceptable Quality Level (AQL) and Lot Tolerance Percentage Defective (LTPD).Measurement Standards

IEC 62341-1-1 specifies standard atmospheric and environmental conditions for testing to ensure repeatable and accurate results. It covers electrical and optical measurement techniques, including visual examination and physical assessments like dimensions and weight.Test Methods

The document details various test procedures:- Environmental tests simulating real-world operating conditions

- Mechanical tests for durability assessment

- Endurance tests to evaluate long-term device reliability, featuring both general and accelerated test protocols.

Marking and Traceability

The standard requires clear device identification markings and traceability coding to link devices back to production or inspection lots, supporting effective quality tracking and recall management.Order of Precedence

It defines a hierarchy for resolving conflicting requirements among related documents, prioritizing detail specifications over generic ones, and including IECQ rules, family specifications, and national standards.

Applications

OLED Display Manufacturing

Implementing IEC 62341-1-1 helps manufacturers standardize quality control processes, ensuring OLED displays meet international performance and reliability expectations.Quality Control and Inspection

Testing laboratories and quality assurance teams apply the electrical, optical, environmental, and endurance tests specified in the standard to certify OLED display batches before market release.Supply Chain Traceability

Device marking and traceability guidelines aid logistics and supply chain management to trace components through manufacturing and distribution channels, facilitating warranty and defect management.Product Development and Certification

R&D teams leverage this standard for benchmarking prototype devices against established norms, assisting in product qualification and regulatory certification processes.

Related Standards

IEC 62341 Series

The series includes related parts:- Part 1-2: Terminology and letter symbols for OLED displays

- Part 5: Environmental testing methods

- Part 6-1: Measuring methods of optical and electro-optical parameters

IEC 60410:1973 – Sampling plans and procedures for inspection by attributes, foundational for statistical quality control.

IEC 60747-1:2006 – Semiconductor devices part 1, offering general guidelines relevant to OLED devices.

IEC QC 001002 – IEC Quality Assessment System for Electronic Components (IECQ) rules of procedure, framing quality assurance protocols applicable to OLED displays.

ISO 2859 – Sampling procedures for inspection by attributes, supporting the statistical concepts incorporated in IEC 62341-1-1.

Keywords

Organic Light Emitting Diode, OLED displays, IEC 62341-1-1, quality assessment, electrical measurements, optical measurements, endurance tests, environmental tests, IECQ system, device traceability, OLED manufacturing standards, international OLED specifications.

Frequently Asked Questions

IEC 62341-1-1:2009 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Organic light emitting diode (OLED) displays - Part 1-1: Generic specifications". This standard covers: IEC 62341-1-1:2009 is a generic specification for organic light emitting diode (OLED) displays. It defines general procedures for quality assessment to be used in the IECQ System and establishes general rules for methods of electrical and optical measurements, environmental and mechanical tests and endurance tests.

IEC 62341-1-1:2009 is a generic specification for organic light emitting diode (OLED) displays. It defines general procedures for quality assessment to be used in the IECQ System and establishes general rules for methods of electrical and optical measurements, environmental and mechanical tests and endurance tests.

IEC 62341-1-1:2009 is classified under the following ICS (International Classification for Standards) categories: 31.260 - Optoelectronics. Laser equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62341-1-1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62341-1-1 ®

Edition 1.0 2009-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Organic light emitting diode (OLED) displays –

Part 1-1: Generic specifications

Afficheurs à diodes électroluminescentes organiques (OLED) –

Partie 1-1: Spécifications génériques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62341-1-1 ®

Edition 1.0 2009-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Organic light emitting diode (OLED) displays –

Part 1-1: Generic specifications

Afficheurs à diodes électroluminescentes organiques (OLED) –

Partie 1-1: Spécifications génériques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

S

CODE PRIX

ICS 31.260 ISBN 978-2-88910-675-2

– 2 – 62341-1-1 © IEC:2009

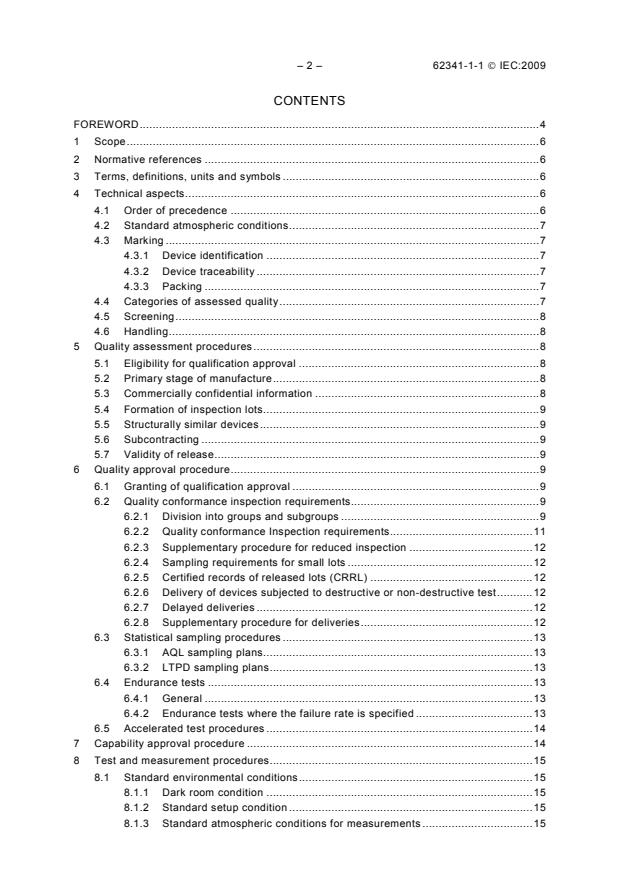

CONTENTS

FOREWORD.4

1 Scope.6

2 Normative references .6

3 Terms, definitions, units and symbols .6

4 Technical aspects.6

4.1 Order of precedence .6

4.2 Standard atmospheric conditions.7

4.3 Marking .7

4.3.1 Device identification .7

4.3.2 Device traceability .7

4.3.3 Packing .7

4.4 Categories of assessed quality.7

4.5 Screening.8

4.6 Handling.8

5 Quality assessment procedures.8

5.1 Eligibility for qualification approval .8

5.2 Primary stage of manufacture.8

5.3 Commercially confidential information .8

5.4 Formation of inspection lots.9

5.5 Structurally similar devices.9

5.6 Subcontracting .9

5.7 Validity of release.9

6 Quality approval procedure.9

6.1 Granting of qualification approval .9

6.2 Quality conformance inspection requirements.9

6.2.1 Division into groups and subgroups .9

6.2.2 Quality conformance Inspection requirements.11

6.2.3 Supplementary procedure for reduced inspection .12

6.2.4 Sampling requirements for small lots .12

6.2.5 Certified records of released lots (CRRL) .12

6.2.6 Delivery of devices subjected to destructive or non-destructive test.12

6.2.7 Delayed deliveries .12

6.2.8 Supplementary procedure for deliveries.12

6.3 Statistical sampling procedures .13

6.3.1 AQL sampling plans.13

6.3.2 LTPD sampling plans.13

6.4 Endurance tests .13

6.4.1 General .13

6.4.2 Endurance tests where the failure rate is specified .13

6.5 Accelerated test procedures .14

7 Capability approval procedure .14

8 Test and measurement procedures.15

8.1 Standard environmental conditions.15

8.1.1 Dark room condition .15

8.1.2 Standard setup condition .15

8.1.3 Standard atmospheric conditions for measurements .15

62341-1-1 © IEC:2009 – 3 –

8.2 Physical examination.15

8.2.1 Visual examination .15

8.2.2 Dimensions .15

8.2.3 Weight.15

8.2.4 Permanence of marking.15

8.3 Electrical and optical measurement .15

8.3.1 General conditions and precautions.16

8.4 Environmental test .16

8.5 Endurance test .16

Annex A (informative) Lot tolerance percentage defective (LTPD) sampling plans .17

Bibliography.22

Table A.1 – LTPD sampling plans .19

Table A.2 – Hypergeometric sampling plans for small lot sizes of 200 or less .20

Table A.3 – AQL and LTPD sampling plans.21

– 4 – 62341-1-1 © IEC:2009

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

ORGANIC LIGHT EMITTING DIODE (OLED) DISPLAYS –

Part 1-1: Generic specifications

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62341-1-1 has been prepared by IEC technical committee 110:

Flat panel display devices.

The text of this standard is based on the following documents:

FDIS Report on voting

110/168/FDIS 110/176/RVD

Full information on the voting for the approval on this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 62341 series, under the general title Organic light emitting diode

(OLED) displays can be found on the IEC website.

62341-1-1 © IEC:2009 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 62341-1-1 © IEC:2009

ORGANIC LIGHT EMITTING DIODE (OLED) DISPLAYS –

Part 1-1: Generic specifications

1 Scope

This part of IEC 62341 is a generic specification for organic light emitting diode (OLED)

displays. It defines general procedures for quality assessment to be used in the IECQ-CECC

system and establishes general rules for methods of electrical and optical measurements,

environmental and mechanical tests and endurance tests.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60410:1973, Sampling plans and procedures for inspection by attributes

IEC 60747-1:2006, Semiconductor devices – Part 1: General

IEC 62341-1-2, Organic light emitting diode displays – Part 1-2: Terminology and letter

symbols

IEC 62341-5 , Organic light emitting diode (OLED) displays – Part 5: Environmental testing

methods

IEC 62341-6-1 , Organic light emitting diode (OLED) displays – Part 6-1: Measuring methods

of optical and electro-optical parameters

IEC QC 001002 (all parts), IEC Quality Assessment System for Electronic components (IECQ)

– Rules of Procedure

ISO 2859 (all parts), Sampling procedures for inspection by attributes

3 Terms, definitions, units and symbols

For the purposes of this document, the terms, definitions, units and symbols given in

IEC 62341-1-2 apply.

4 Technical aspects

4.1 Order of precedence

Where there are conflicting requirements, documents shall rank in the following order of

authority:

a) the detail specification;

b) the blank detail specification;

———————

In preparation.

In preparation.

62341-1-1 © IEC:2009 – 7 –

c) the family specification, if any;

d) the sectional specification;

e) the generic specification;

f) the basic specification;

g) the IECQ rules of procedure;

h) any other international (e.g. IEC) documents to which reference is made;

i) a national document.

The same order of precedence shall apply to equivalent national documents.

4.2 Standard atmospheric conditions

Preferred values of temperature, humidity and pressure for the measurement characteristics

and tests, for operating condition, are specified in 8.1.3. Unless otherwise specified, all

measurement and tests shall be carried out under the condition described in 8.1.3.

4.3 Marking

4.3.1 Device identification

The marking on the device shall enable clear identification of the device. The order of priority

for marking on small products shall be specified in the detail specification.

4.3.2 Device traceability

The device shall be provided with a traceability code, which enables back-tracing of the

device to certain production or inspection lot.

4.3.3 Packing

Marking on the packing shall state:

a) the device identification code;

b) the traceability code(s) of the enclosed devices;

c) the number of enclosed devices;

d) the required precautions, if any.

This marking shall be in accordance with custom regulations.

4.4 Categories of assessed quality

This generic specification provides three categories of assessed quality. The devices are

grouped in an identified inspection lot in accordance with IEC QC 001002-3, 3.3, which is

tested to the specified quality categories. The AQL (acceptance quality levels) or LTPD (lot

tolerance percentage defective) associated with the same inspection group may vary for each

category and shall be as specified in the detail specification.

The minimum requirements of the categories are as follows:

Category I The type shall meet the requirements of qualification approval of categories II

or III. Each lot shall meet the inspection requirements of group A, which

includes functional tests. Every three months, one lot shall meet the

inspection requirements for interconnection ability. Annually, one lot shall

meet the group B and group C inspection requirements (see 6.2.1)

– 8 – 62341-1-1 © IEC:2009

Category II The type shall meet the requirements of group A, group B, group C and group

D if needed, for qualification approval. The lot shall meet the inspection

requirements of group A and group B on a lot-by-lot basis, and of group C on

a periodic basis.

Category III The type shall meet the requirements of group A, group B, group C and group

D if needed, for qualification approval. The lot is 100 % screened and shall

meet the inspection requirements of group A and group B on a lot-by-lot basis,

and of group C on a periodic basis.

The sectional or blank detail specification shall define the minimum requirements for each

category. A detail specification may contain requirements, including screening requirements,

additional to those given in the generic, sectional or blank or any other relevant detail

specification.

4.5 Screening

A screening is an examination or test applied to all devices in a lot.

When required by the detail specification, all devices in the lot shall be screened by

submitting them to one of the sequences given in the relevant sectional or blank detail

specification, and all defectives shall be removed. Other sequences not specified in this

standard are applicable only where the above sequences are not correlated or are in

contradiction with failure mechanisms. When a part of the screening process as given in the

sectional or blank detail specification forms part of the manufacturing process in the

prescribed sequence, these procedures need not be repeated.

4.6 Handling

See IEC 60747-1, Clause 8.

Adequate warning shall be displayed in the case of harmful products.

5 Quality assessment procedures

Quality assessment comprises the procedure for obtaining qualification approval followed by

quality conformance inspection on a lot-by-lot basis (including screening if required) and on a

periodic basis as qualified in the detail specification. The quality assessment tests are

subdivided into group A, B and C tests; these are performed lot by lot or periodically, group D

(see 6.2.1.5) tests may also be specified, for example, for qualification approval.

5.1 Eligibility for qualification approval

A type of device becomes eligible for qualification approval when the rules of procedure of

IEC QC 001002-3, Clause 3, are satisfied.

5.2 Primary stage of manufacture

The primary stage of manufacture is defined in the sectional or blank detail specification.

5.3 Commercially confidential information

If any part of the manufacturing process is commercially confidential, this shall be suitably

identified, and the designated management representative (DMR) shall demonstrate to the

satisfaction of the National Supervising Inspectorate (NSI) that the requirements of the rules

of procedure given in 2.3.3.1 of IEC QC 001002-3, have been complied with.

62341-1-1 © IEC:2009 – 9 –

5.4 Formation of inspection lots

See the rules of procedure given in IEC QC 001002-3, 3.3.1.

5.5 Structurally similar devices

See the rules of procedure given in IEC QC 001002-3, 3.3.2.

Details concerning grouping are given in the relevant sectional or blank detail specification.

5.6 Subcontracting

The use of subcontracting is permitted for quality assessments procedures. To use the

subcontracting, see the rules of procedure given in IEC QC 001002-3, Annex B to Clause 2

and 3.1.2.

5.7 Validity of release

See the rules of procedure given in IEC QC 001002-3, 3.2.2.

6 Quality approval procedure

6.1 Granting of qualification approval

See the rules of procedure given in IEC QC 001002-3, 3.1.4 and 3.1.5. Method a), b) or c) of

the rules of procedure may be used at the manufacture’s discretion in accordance with the

inspection requirements given in the sectional or blank detail specification. Samples may be

composed of appropriate structurally similar devices. In some cases, group D tests are

required for qualification approval. The qualification report shall include a summary of all the

test results for each group and subgroup, including number of devices tested and number of

devices failed. This summary shall be derived from variables and/or attributes data.

The manufacturer shall retain all data for submission to the NSI on demand.

6.2 Quality conformance inspection requirements

Quality conformance inspection shall consist of the examinations and tests of groups A, B, C

and D, as specified. For group B and C inspection, samples may be composed of structurally

similar devices. Samples for periodic tests shall be drawn from one or more lots which have

passed group A and B inspection. Individual devices shall have passed the group A

measurements called for in the detail specification.

6.2.1 Division into groups and subgroups

The following grouping shall be used in the preparation of detail specification.

6.2.1.1 Group A inspection (lot-by-lot)

This group prescribes the visual inspection and the electrical measurements to be made on a

lot-by-lot basis to assess the principal properties of a device. Unless otherwise specified,

structural similarity grouping is not permitted.

Group A inspection is divided into appropriate subgroups as follows:

Subgroup A1 This subgroup comprises a visual examination as specified in 8.2.1.

Subgroup A2 This subgroup comprises measurements of primary characteristics of the

device.

– 10 – 62341-1-1 © IEC:2009

Subgroup A3/A4 These subgroups may not be required. They comprise measurements of

secondary characteristics of the device. The correct requirements for each

device category are given in the sectional or blank detail specification. The

choice between subgroup A3 or A4 for given measurements is essentially

governed by the desirability of performing them at a given quality level.

6.2.1.2 Group B inspection (lot-by-lot, except for category I)

This group prescribes the procedure to be used to assess certain additional properties of the

device, and includes mechanical, environmental and endurance tests that can normally be

performed in one week or as specified in the relevant sectional or blank detail specification.

6.2.1.3 Group C inspection (periodic)

This group prescribes the procedures to be used on a periodic basis to assess certain

additional properties of the devices, and includes electrical and optical measurements,

mechanical, environmental and endurance tests appropriate for checking at intervals of either

three months (categories II and III) or one year (category I), or as specified in the relevant

sectional or blank detail specification.

6.2.1.4 Division of group B and group C into subgroups

To enable comparison and to facilitate change from group B to group C and vice versa when

necessary tests in these groups have been divided among subgroups bearing the same

number for corresponding tests.

The division is as given below.

Subgroup B1/C1 Comprise measurements that assess visual and dimensional properties

of the devices.

Subgroup B2a/C2a Comprise measurements that assess electrical and optical properties of

the devices of a design nature.

Subgroup B2b/C2b Comprise measurements that further assess some of the electrical and

optical characteristics of the device already measured in group A by

measurement under different voltage, current, temperature of optical

condition.

Subgroup B2c/C2c Comprise verification of ratings of the device, where appropriate.

Subgroup B3/C3 Comprise tests intended to assess mechanical robustness of the

devices.

Subgroup B4/C4 Comprise tests intended to assess interconnection ability of the devices.

Subgroup B5/C5 Comprise tests intended to assess the ability of the device to withstand

climate stresses, for example change of temperature, sealing.

Subgroup B6/C6 Comprise tests intended to assess the ability of the device to withstand

mechanical stresses, for example vibration, shock.

Subgroup B7/C7 Comprise tests intended to assess the ability of the device to withstand

long-term humidity.

Subgroup B8/C8 Comprise tests intended to assess failure characteristics of the device

under endurance testing.

62341-1-1 © IEC:2009 – 11 –

Subgroup B9/C9 Comprise tests intended to assess electrical and optical properties of

the device under storage conditions at extremes of temperature.

Subgroup B10/C10 Comprise tests intended to assess performance of the device during

vibration of air pressure.

Subgroup B11/C11 Comprise tests on the permanence of marking.

Subgroup CRRL Lists a selection of tests and/or measurements made in the preceding

subgroups, the results of which shall be presented in the certified

record of released lots (CRRL).

These subgroups may not all be required.

6.2.1.5 Group D inspection

This group prescribes the procedures to be carried out at intervals of 12 months or for

qualification approval only.

6.2.2 Quality conformance Inspection requirements

The Statistical sampling procedures described in 6.3 shall be used.

6.2.2.1 Criteria for lot rejection

Lots failing to meet the quality conformance inspection of either group A or group B inspection

shall not be accepted. If, during conformance inspection, devices fail a test in a subgroup

which would result in the lot being rejected, the quality conformance inspection can be

terminated, and the lot shall be considered a rejected lot in group A and B. If a lot is

withdrawn in a state of failing to meet quality conformance requirements and is not

resubmitted, it shall be considered a rejected lot.

6.2.2.2 Re-submitted lots

Failing lots, those have been reworked when technically possible and are resubmitted for

quality conformance inspection, shall contain only devices that were included in the original

lot and shall be kept separate from new lots and shall be clearly identified as re-submitted lots.

Re-submitted lots shall be randomly re-sampled and inspected for all the inspection criteria of

group A.

6.2.2.3 Procedure in case of test equipment failure or operator error

If any devices are believed to have failed as a result of faulty test equipment or operator error,

the failure shall be entered in the test record (but may be excluded from CRRL by agreement

with the NSI) and shall be submitted along with a complete explanation of why the failures are

believed to be invalid to the NSI.

The chief inspector shall decide whether replacement devices from the same inspection lot

may be added to the sample. Replacement devices shall be subjected to the same tests to

which the discarded devices were subjected prior to failure and to any remaining specified

tests to which the discarded devices were not subjected prior to failure.

6.2.2.4 Procedure in case of failure in periodic tests

When a group B failure occurs, the corresponding group C tests are invalid. In the event of

failing periodic inspection tests for causes other than faults or an operator error, see the rules

of procedure given in IEC QC 001002-3, 3.1.8.

– 12 – 62341-1-1 © IEC:2009

6.2.3 Supplementary procedure for reduced inspection

6.2.3.1 Group B

A special reduced inspection procedure may be used which allows the manufacturer to carry

out the appropriate group B tests at normal inspection on every fourth lot with a maximum

interval of three months instead of on a lot-by-lot basis for the tests in all subgroups of group

B. This special procedure applies to each subgroup, which has fulfilled the required conditions.

The condition for this change shall be that 10 successive lots have passed group B inspection.

Reversion to normal inspection in group B shall all be made when a sample has failed to meet

a subgroup inspection under the reduced inspection procedure.

6.2.3.2 Group C

When a three-month interval is specified for periodic tests, the test period may be extended to

six months provided that three successive periodic tests have been passed at three-month

intervals. Reversion to the normal three-month interval shaII be made when a sample has

failed to meet a subgroup inspection under the extended interval procedure (see also 6.2.2.4).

6.2.4 Sampling requirements for small lots

Where a lot size is 200 or less, the following procedures, complying with the appropriate

requirements of Annex A, shall be used. (Where the AQL system is specified, the equivalent

LTPD shall first be selected from Table A.3 of Annex A.) In the case of not complying with this

requirement, the sampling requirement shall be specified in the detail specification.

a) Non-destructive testing:

1) 100 % of the OLED modules shall be inspected for any test indicated as non-

destructive; or,

2) any appropriate LTPD single sampling plan selected from Table A.2 of Annex A; or,

3) any appropriate LTPD double sampling plan.

b) Destructive testing:

1) any appropriate LTPD single sampling plan selected from Table A.2 of Annex A; or,

2) any appropriate LTPD double sampling plan.

6.2.5 Certified records of released lots (CRRL)

See the rules of procedure given in 1.5 and Annex B of IEC QC 001002-2.

6.2.6 Delivery of devices subjected to destructive or non-destructive test

Tests considered as destructive are marked (D) in the sectional or blank detail specification.

Devices subjected to destructive tests shall not be included in the lot for delivery. Devices

subjected to non-destructive environmental tests may be delivered provided they are re-tested

according to group A requirements and satisfy them.

6.2.7 Delayed deliveries

Before delivery of lots in store for a period and in conditions specified in the sectional or blank

detail specification, the lots or the quantities to be delivered shall undergo the specified group

A inspection and the group B interconnection ability tests. Once this has been done the

complete lot, no further re-testing is required for another period.

6.2.8 Supplementary procedure for deliveries

The manufacturer may, at his discretion, supply devices that have met a more severe

assessment level than that required.

62341-1-1 © IEC:2009 – 13 –

6.3 Statistical sampling procedures

For group A, B and C inspections, either the AQL sampling procedure or the LTPD sampling

procedure shall be used. The detail specification shall specify which of the procedures is to

be used. In the case of not complying with this procedure, the sampling procedure shall be

specified in the detail specification.

6.3.1 AQL sampling plans

See Clause 4 of IEC 60410. There are three types of sampling plans: single, double and

multiple. When several types of plans are available for a given AQL and code letter, any one

may be used.

6.3.2 LTPD sampling plans

See Annex A.

6.4 Endurance tests

6.4.1 General

Endurance tests performed on devices at, or within, their maximum rating shall be considered

non-destructive. If the LTPD sampling procedure isn’t complied with sampling requirement,

test time, acceptance criteria and the procedure to be used shall be specified in the detail

specification. Endurance tests shall be specified in the relevant specification.

6.4.2 Endurance tests where the failure rate is specified

Failure rate as used in this standard is defined as LTPD expressed as a percentage per

thousand hours.

6.4.2.1 Selection of samples

Samples for endurance tests shall be selected at random from the inspection lot (see Annex

A). The sample size for a 1 000 h test shall be chosen by the manufacturer from the column

under the specified failure rate (see Table A.1) or the actual lot size (see Table A.2).

The acceptance number shall be the one associated with the particular sample size chosen.

6.4.2.2 Failure

A device, which fails at one or more of the end-point limits specified for endurance tests at

any specified reading interval shall be considered a failure and be considered as such at any

subsequent reading interval. If the sample fails, the test may be terminated at the discretion of

the manufacturer.

6.4.2.3 Endurance test time

Whenever the failure rate is specified, the endurance test time should be preferably 1 000 h

initially. Once a lot has passed the 1 000 h test, endurance tests can be reduced to a certain

period, as specified in the detail specification. If the initial test time other than 1 000 h is

applied, the time shall be specified in the detail specification.

6.4.2.4 Procedure to be used if the number of observed failures exceeds the

acceptance number

In the event that the number of failures observed on endurance tests exceeds the acceptance

number, the manufacturer shall choose one of the following options:

a) withdraw the entire lot;

– 14 – 62341-1-1 © IEC:2009

b) add additional samples in accordance with 6.4.2.4.1.

c) extend the test time to 1 000 h in accordance with 6.4.2.4.2, if a time less than 1 000 h

was originally chosen;

d) screen the lot and re-submit in accordance with 6.2.2.2.

After applying one of the preceding options, the procedure of 6.2.2.4 shall apply.

If the manufacturer chooses an option other than a) through d), the procedure shall be

specified in the detail specification.

6.4.2.4.1 Additional samples

This option shall be used only once for each submission. When this option is chosen, a new

total sample size (initial plus added) shall be chosen, by the manufacturer from Tables A.1 or

A.2 from the column specifying the failure rate (Table A.1) or the actual lot size (Table A.2). A

quantity of additional units sufficient to increase the sample to the newly chosen total sample

size shall be selected from the lot. The new acceptance number shall be the one associated

with the new total sample size chosen. The added sample shall be subjected to the same

endurance test conditions and time period as the initial sample. If the total observed number

of defectives (initial plus added) does not exceed the acceptance number for the total sample,

the lot shall be accepted; if the observed number of defectives exceeds the new acceptance

number, the lot shall be rejected.

6.4.2.4.2 Extension of endurance test period

If an endurance test time periods less than 1 000 h is used and the number of failures

observed in the initial sample exceeds the acceptance number, the manufacturer may, instead

of adding additional samples, choose to extend the test time of the entire initial sample to

1 000 h and determine a new acceptance number from Tables A.1 or A.2. The new

acceptance number shall be one associated with the largest sampling size in the specified

column which is less than, or equal to, the sample size being tested. A device, which is a

failure at the initial reading interval, shall be considered as such at the 1 000 h reading

interval. If the observed number of defectives exceeds this acceptance number, the lot shall

not be accepted.

6.5 Accelerated test procedures

Accelerated test procedures may, when eligible, be used to obtain test results in a time period

shorter than would be required for a non-accelerated test. They shall be given the equivalent

quality assessment. The detail specification shall indicate whether or not the accelerated test

is considered as destructive.

The accelerating factor for OLED displays might be temperature, humidity, voltage, current

and luminance. The method for accelerated test shall be defined in the detail specification.

7 Capability approval procedure

Components released under the capability approval procedure have the same status within

the IECQ system as those released under the qualification approval procedure. The

requirements on capability approval procedure supplement those of IEC QC 001002-3, 4.2

Detail procedure for capability approval shall be specified in detail specification.

62341-1-1 © IEC:2009 – 15 –

8 Test and measurement procedures

8.1 Standard environmental conditions

8.1.1 Dark room condition

Illuminance over the full screen shall be less than 0,3 lx anywhere on the screen of the OLED

module. When different illuminance is used, it shall be noted on the test report.

8.1.2 Standard setup condition

Standard atmospheric conditions are given as 8.1.3. Each condition shall be noted on each

specification form whenever any measurement is made under a different condition from the

standard set up condition. Measurements shall be made after sufficient warm-up time under

the standard environmental conditions.

8.1.3 Standard atmospheric conditions for measurements

Temperature : 25 °C ± 3 °C

Humidity : 25 %RH – 85 %RH

Pressure : 86 kPa – 106 kPa.

When a different atmospheric condition is used, it shall be noted on the report.

8.2 Physical examination

8.2.1 Visual examination

Examination shall be made for correctness of the following elements, in accordance with

detail specification:

a) marking and legibility;

b) terminal identification;

c) appearance of the device.

8.2.2 Dimensions

Precise size and thickness of OLED modules (or products) shall be measured to check if they

match to application set. The measurement shall be checked in accordance with the specified

drawing of detail specification.

8.2.3 Weight

Precise weight of OLED modules (or products) shall be measured to check if it matches to

application set.

8.2.4 Permanence of marking

The purpose of this test is to determine the permanence of marking following handling and

use of typical cleaning on the device. The conditions for this test shall be specified in the

detail specification.

8.3 Electrical and optical measurement

Methods for electrical and optical measurements shall be in accordance with IEC 62341-6.

Methods for electrical and optical measurements not included in IEC 62341-6 shall be

described in the detail specification.

– 16 – 62341-1-1 © IEC:2009

8.3.1 General conditions and precautions

8.3.1.1 Alternative methods

Measurements may be carried out by using the methods specified or any other method giving

equivalent results but, in case of dispute, only the specified method shall be used.

NOTE By “equivalent” it is meant that the value of the characteristic established by such other methods is within

the specified limits when measured by the specified method.

8.3.1.2 Precision of measurement

The limits quoted in the detail specification are absolute. Measurement inaccuracies shall be

taken into account when determining the actual measurement limits.

8.3.1.3 General precautions

Usual precautions should be taken to reduce measurement errors to a minimum and to avoid

damage to the device. The most important of these are given in 6.4 of IEC 60747-1.

8.4 Environmental test

See the methods given in IEC 62341-5.

8.5 Endurance test

Under consideration.

62341-1-1 © IEC:2009 – 17 –

Annex A

(informative)

Lot tolerance percentage defective (LTPD) sampling plans

A.1 General

The following specified procedures are suitable for all quality conformance requirements.

A.1.1 Selection of samples

Samples shall be randomly selected from the inspection lot. For continuous production, the

manufacturer, at his option, may select samples in a regular periodic manner during

manufacture, provided that the lot meets the requirements for the formation of lots.

A.1.2 Failures

Failure of a unit for one or more tests of a subgroup shall be char

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...