IEC PAS 61076-3-104:2002

(Main)Connectors for electronic equipment - Part 3-104: Detail specification for 8-way, shielded free and fixed connectors, for data transmissions with frequencies up to 600 MHz minimum

Connectors for electronic equipment - Part 3-104: Detail specification for 8-way, shielded free and fixed connectors, for data transmissions with frequencies up to 600 MHz minimum

Establishes uniform specifications, type testing requirements and quality assessment procedures for 8 ways connectors, with up to 4 pairs, for frequencies up to 600 MHz minimum, and intended to be used at different locations within cabling for ICT, home entertainment and multimedia. Contains a choice of all test methods and sequences, severity and preferred values for dimensions and characteristics.

General Information

- Status

- Replaced

- Publication Date

- 18-Jun-2002

- Technical Committee

- SC 48B - Electrical connectors

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 03-Apr-2003

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Buy Documents

IEC PAS 61076-3-104:2002 - Connectors for electronic equipment - Part 3-104: Detail specification for 8-way, shielded free and fixed connectors, for data transmissions with frequencies up to 600 MHz minimum Released:6/19/2002

Frequently Asked Questions

IEC PAS 61076-3-104:2002 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Connectors for electronic equipment - Part 3-104: Detail specification for 8-way, shielded free and fixed connectors, for data transmissions with frequencies up to 600 MHz minimum". This standard covers: Establishes uniform specifications, type testing requirements and quality assessment procedures for 8 ways connectors, with up to 4 pairs, for frequencies up to 600 MHz minimum, and intended to be used at different locations within cabling for ICT, home entertainment and multimedia. Contains a choice of all test methods and sequences, severity and preferred values for dimensions and characteristics.

Establishes uniform specifications, type testing requirements and quality assessment procedures for 8 ways connectors, with up to 4 pairs, for frequencies up to 600 MHz minimum, and intended to be used at different locations within cabling for ICT, home entertainment and multimedia. Contains a choice of all test methods and sequences, severity and preferred values for dimensions and characteristics.

IEC PAS 61076-3-104:2002 is classified under the following ICS (International Classification for Standards) categories: 31.220.10 - Plug-and-socket devices. Connectors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC PAS 61076-3-104:2002 has the following relationships with other standards: It is inter standard links to IEC 61076-3-104:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC PAS 61076-3-104:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/PAS 61076-3-104

Edition 1.0

2002-06

Connectors for electronic equipment –

Part 3-104:

Detail specification for 8-way, shielded free

and fixed connectors for data transmissions

with frequencies up to 600 MHz minimum

PUBLICLY AVAILABLE SPECIFICATION

INTERNATIONAL Reference number

ELECTROTECHNICAL

IEC/PAS 61076-3-104

COMMISSION

IEC/PAS 61076-3-104

Edition 1.0

2002-06

Connectors for electronic equipment –

Part 3-104:

Detail specification for 8-way, shielded free

and fixed connectors for data transmissions

with frequencies up to 600 MHz minimum

PUBLICLY AVAILABLE SPECIFICATION

INTERNATIONAL Reference number

ELECTROTECHNICAL

IEC/PAS 61076-3-104

COMMISSION

– 2 – Copyright © 2002, IEC

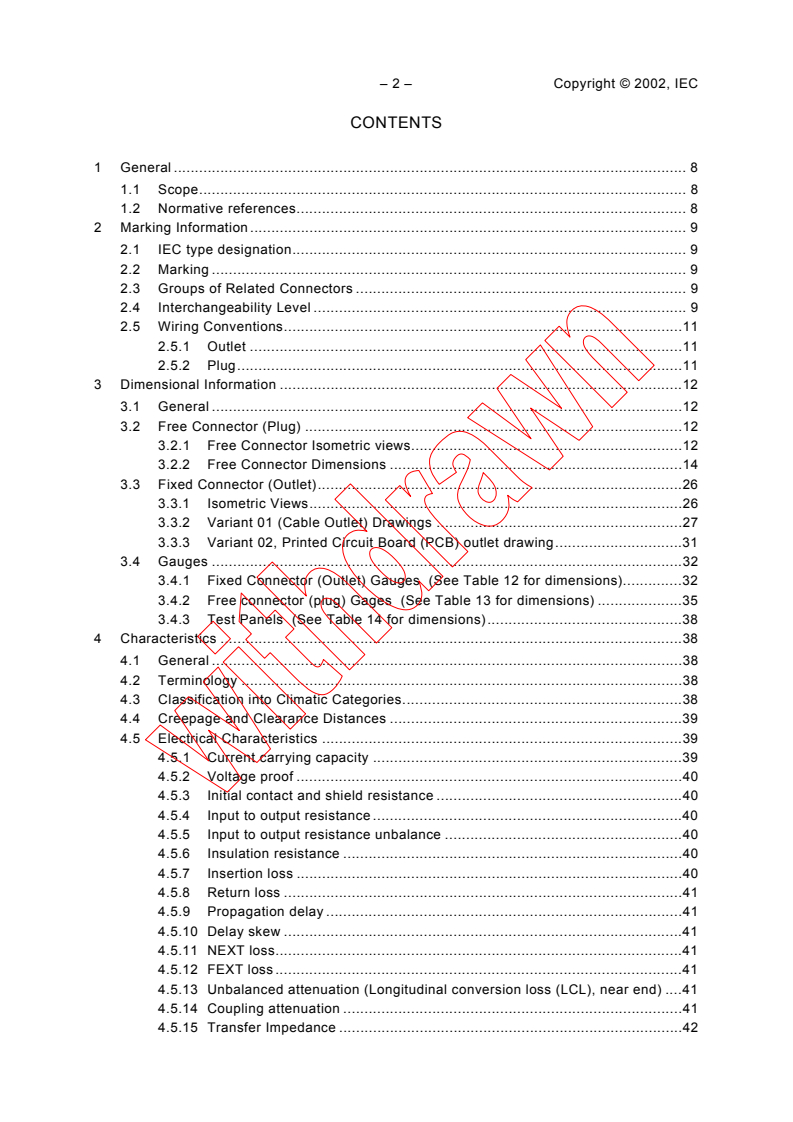

CONTENTS

1 General . 8

1.1 Scope. 8

1.2 Normative references. 8

2 Marking Information. 9

2.1 IEC type designation. 9

2.2 Marking . 9

2.3 Groups of Related Connectors . 9

2.4 Interchangeability Level . 9

2.5 Wiring Conventions.11

2.5.1 Outlet .11

2.5.2 Plug.11

3 Dimensional Information .12

3.1 General .12

3.2 Free Connector (Plug) .12

3.2.1 Free Connector Isometric views.12

3.2.2 Free Connector Dimensions .14

3.3 Fixed Connector (Outlet).26

3.3.1 Isometric Views.26

3.3.2 Variant 01 (Cable Outlet) Drawings .27

3.3.3 Variant 02, Printed Circuit Board (PCB) outlet drawing.31

3.4 Gauges .32

3.4.1 Fixed Connector (Outlet) Gauges (See Table 12 for dimensions).32

3.4.2 Free connector (plug) Gages (See Table 13 for dimensions) .35

3.4.3 Test Panels (See Table 14 for dimensions).38

4 Characteristics .38

4.1 General .38

4.2 Terminology .38

4.3 Classification into Climatic Categories.38

4.4 Creepage and Clearance Distances .39

4.5 Electrical Characteristics .39

4.5.1 Current carrying capacity .39

4.5.2 Voltage proof .40

4.5.3 Initial contact and shield resistance .40

4.5.4 Input to output resistance .40

4.5.5 Input to output resistance unbalance .40

4.5.6 Insulation resistance .40

4.5.7 Insertion loss .40

4.5.8 Return loss .41

4.5.9 Propagation delay .41

4.5.10 Delay skew .41

4.5.11 NEXT loss.41

4.5.12 FEXT loss .41

4.5.13 Unbalanced attenuation (Longitudinal conversion loss (LCL), near end) .41

4.5.14 Coupling attenuation .41

4.5.15 Transfer Impedance .42

4.6 Mechanical .42

4.6.1 Mechanical operation .42

4.6.2 Effectiveness of connector coupling devices .42

4.6.3 Insertion and Withdrawal Forces.42

5 Quality assessment procedures .42

6 Qualification Approval Test Schedule .42

6.1 General .42

6.2 Test Procedures and Measuring Methods.42

6.3 Preconditioning.43

6.4 Wiring and Mounting of Specimens .43

6.4.1 Wiring.43

6.4.2 Mounting.43

6.4.3 Basic (Minimum) Test Schedule .43

6.4.4 Full Test Schedule .43

Annex A (normative) Contact Resistance Arrangement .49

A.1 Procedure .49

Annex B (normative) Gauging Requirements .50

B.1 Fixed Connectors .50

B.2 Free Connectors.50

Annex C (normative) Locking device mechanical operation .51

C.1 Object .51

C.2 Preparation of the specimens.51

C.3 Test method .51

C.4 Final Measurements .51

Annex D (normative) Plug and Outlet interoperability Qualification .52

D.1 Object .52

D.2 Test Equipment .52

D.3 Test Procedure.53

Annex E (normative) General requirements for the measurement set-up .54

E.1 Test instrumentation .54

E.2 Coaxial cables and test leads for network analysers .54

E.3 Measurement precautions.54

E.4 Balun requirements.54

E.5 Reference components for calibration. .55

E.5.1 Reference loads for calibration .55

E.5.2 Reference cables for calibration .56

E.6 Termination loads for termination of conductor pairs.56

E.7 Termination of screens .57

E.8 Test specimen and reference planes .57

Annex F (normative) Insertion loss. .58

F.1 Object .58

F.2 Test method .58

F.3 Tests set up. .58

F.4 Procedure. .58

F.4.1 Calibration. .58

F.4.2 Measurement. .58

F.5 Test report.59

– 4 – Copyright © 2002, IEC

F.6 Accuracy .59

Annex G (normative) Return loss.60

G.1 Object 60

G.2 Test method .60

G.3 Test set-up .60

G.4 Procedure .60

G.4.1 Calibration .60

G.4.2 Measurement .60

G.5 Test report.60

G.6 Accuracy .60

Annex H (normative) Near end cross talk.61

H.1 Object 61

H.2 Test method .61

H.3 Test set-up .61

H.4 Procedure .62

H.4.1 Calibration .62

H.4.2 Establishment of noise floor .62

H.4.3 Measurement .63

H.5 Test report.63

H.6 Accuracy .63

Annex I (normative) Far end cross talk .64

I.1 Object .64

I.2 Test method .64

I.3 Test set-up .64

I.4 Procedure .65

I.4.1 Calibration .65

I.4.2 Establishment of noise floor .65

I.5 Measurement.65

I.6 Test report.66

I.7 Accuracy .66

Annex J (normative) Unbalanced Attenuation .67

J.1 Object .67

J.2 Test method .67

J.3 Test set-up .67

J.4 Procedure .68

J.4.1 Calibration .68

J.4.2 Noise floor .68

J.4.3 Measurement .68

J.5 Test report.68

J.6 Accuracy .68

Annex K (normative) Transfer impedance .69

K.1 Object .69

K.2 Test method .69

K.3 Definitions .69

K.3.1 Inner and outer circuit .69

K.3.2 Coupling length.69

K.4 Test set-up .70

K.4.1 Preparation of test specimen .70

K.4.2 Triaxial set-up .70

K.4.3 Impedance of the inner circuit.71

K.4.4 Impedance matching networks .71

K.5 Procedure .72

K.5.1 Calibration .72

K.5.2 Measurement .72

K.5.3 Evaluation of test results .73

K.6 Test report.74

K.7 Accuracy .74

Annex L (normative) Coupling attenuation .75

L.1 Object .75

L.2 Test method .75

L.3 Test equipment and set-up.75

L.3.1 Equipment .75

L.3.2 Equipment set-up .75

L.3.3 Validation of the equipment set-up.75

L.4 Procedure .76

L.4.1 Calibration .76

L.4.2 Measurement .76

L.5 Test report.76

Annex M (normative) Termination of balun.77

M.1 Termination of balun with low return loss for common mode .77

M.1.1 Centre tap connected to ground.77

M.1.2 Centre tap open .77

– 6 – Copyright © 2002, IEC

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

CONNECTORS FOR ELECTRONIC EQUIPMENT –

Part 3-104: Detail specification for 8-way, shielded free

and fixed connectors for data transmissions

with frequencies up to 600 MHz minimum

FOREWORD

A PAS is a technical specification not fulfilling the requirements for a standard, but made

available to the public.

IEC-PAS 61076-3-104 has been processed by subcommittee 48B: Connectors, of IEC

technical committee 48: Electromechanical components and mechanical structures for

electronic equipment.

The text of this PAS is based on the This PAS was approved for

following document: publication by the P-members of the

committee concerned as indicated in

the following document:

Draft PAS Report on voting

48B/1167/PAS 48B/1215A/RVD

Following publication of this PAS, the technical committee or subcommittee concerned will

investigate the possibility of transforming the PAS into an International Standard.

The International Electrotechnical Commission (IEC) draws attention to the fact that it is

claimed that compliance with this PAS may involve the use of patents concerning 8-way,

shielded free and fixed connectors for data transmissions with frequencies up to 600 MHz

minimum.

The IEC takes no position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured the IEC that he is willing to give free licences with

applicants throughout the world. In this respect, the statement of the holder of this patent right

is registered with the IEC

Information may be obtained from:

The Siemon Company

Siemon Business Park

76 Westbury Park Road

Watertown, CT 06795-0400

USA

Attention is drawn to the possibility that some of the elements of this International Standard

may be the subject of patent rights other than those identified above. IEC shall not be held

responsible for identifying any or all such patent rights.

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

– 8 – Copyright © 2002, IEC

CONNECTORS FOR ELECTRONIC EQUIPMENT –

Part 3-104: Detail specification for 8-way, shielded free

and fixed connectors for data transmissions

with frequencies up to 600 MHz minimum

1 General

1.1 Scope

This part of IEC 61076 establishes uniform specifications, type testing requirements and

quality assessment procedures for 8 ways connectors, with up to 4 pairs, for frequencies up to

600 MHz minimum, and intended to be used at different locations within cabling for ICT, home

entertainment and multimedia. It contains a choice of all test methods and sequences,

severity and preferred values for dimensions and characteristics.

1.2 Normative references

The following normative documents contain provisions that, through reference in this text,

constitute provisions of this part of IEC 61076. At the time of publication, the editions

indicated were valid. All normative documents are subject to revision, and parties to

agreements based on this part of IEC 61076 are encouraged to investigate the possibility of

applying the most recent editions of the normative documents listed below. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60352-2:1990, Solderless connections – Part 2: Solderless crimped connections –

General requirements, test methods and practical guidance

IEC 60352-3:1993, Solderless connections – Part 3: Solderless accessible insulation

displacement connections – General requirements, test methods and practical guidance.

IEC 60352-4:1994, Solderless connections – Part 4: Solderless non-accessible insulation

displacement connections – General requirements, test methods and practical guidance

IEC 60352-6:1994, Solderless connections – Part 6: Insulation piercing connections –

General requirements, test methods and practical guidance

IEC 61076-1:1995, Connectors with assessed quality, for use in d.c., low frequency analogue

applications and in digital high speed data application – Part 1: Generic specifications –

Capability approval

ISO/IEC 11801 Information technology – Generic cabling for customer premises

IEC 60068-1 Environmental testing. Part 1: General and guidance

IEC 60603-7 Connectors for frequencies below 3 MHz for use with printed boards – Part 7:

Detail specification for connectors, 8-way, including fixed and free connectors with common

mating features, with assessed quality

IEC 60512-1 Electromechanical components for electronic equipment, Basic testing

procedures and measuring methods – Part 1: General

IEC 60512-2 Electromechanical components for electronic equipment, basic testing

procedures and measuring methods – Part 2: General examination, electrical continuity and

contact resistance tests, insulation tests and voltage stress tests

IEC 60512-3 Electromechanical components for electronic equipment; basic testing

procedures and measuring methods – Part 3: Current-carrying capacity tests

IEC 60512-4 Electromechanical components for electronic equipment; basic testing

procedures and measuring methods – Part 4: Dynamic stress tests

IEC 60512-5 Electromechanical components for electronic equipment; basic testing

procedures and measuring methods – Part 5: Impact tests (free components), static load tests

(fixed components), endurance tests and overload tests

IEC 60512-6 Electromechanical components for electronic equipment; basic testing

procedures and measuring methods – Part 6: Climatic tests and soldering tests

IEC 60512-7 Electromechanical components for electronic equipment; basic testing

procedures and measuring methods – Part 7: Mechanical operating tests and sealing tests

IEC 60512-8 Electromechanical components for electronic equipment; basic testing

procedures and measuring methods – Part 8: Connector tests (mechanical) and mechanical

tests on contacts and terminations

ISO 1302 Technical Drawings – Method of indicating surface texture

2 Marking Information

2.1 IEC type designation

Connectors, connector bodies and connectors with pre-inserted contacts according to this

standard shall be designated by the following system.

Connectors conforming to this standard shall be identified by the following indications and in

the order given:

The letters “IEC”.

The number denoting this sectional specification.

The number of the detail specification (without dashes), being nine characters (e.g.

610764100).

A letter denoting the style of the connector (the system shall be specified in the detail

specification

2.2 Marking

Each connector and its associated package shall be marked in accordance with the

requirements specified in 2.6 of IEC 61076-1.

2.3 Groups of Related Connectors

Groups of connectors within a subfamily having common features. Typical examples are

same type and range but different style. A group of related connectors is covered by a single

detail specification.

• Type: Connectors within a particular subfamily such as a multicontact connector with one,

two or four pairs.

• Range: The housing (shell) sizes and contacts arrangements within a type. For example

a housing containing one, two or four pairs.

• Style: A particular connector within a type, for example fixed panel, PCB or free connector.

• Variant: Variations within a type, style or range.

2.4 Interchangeability Level

These connectors shall be fully interchangeable and intermateable. The mechanical and

electrical characteristics shall be met whatever is the source of the connector. Moreover it is

desirable that the mechanical and electrical compatibility with lower performance connecting

hardware as defined in ISO/IEC 11801 and IEC 60603-7 is ensured when connected to

this connector.

This can be achieved through the use of an adapter cord. Elements of connecting hardware,

e.g. plugs, sockets that terminate more than one cable are permitted.

The plug/socket interface may be constructed so as to permit the use of multiple modules

e.g. 2 × 2 pairs or 4 × 1 pair plugs mated directly with a single 4 pairs socket.

– 10 – Copyright © 2002, IEC

IEC-61076-3-104 L N N N

L N N L L N

L N N L L

Reference to

this standard

Number denoting

performance level (PL)

750 operations

Letters denoting connector

2500 operations

type

Free Version A

Number denoting variant

01 Cable outlet

Fixed Version B

02 PCB outlet

03 Four pair plug

04 Two pair plug

Note: “L” stands for letter

05 1 pair plug

“N” stands for number

Number of contacts

Number denoting contact finish

1 Gold, gold-alloy

2 Palladium/nickel

Letter denoting type of contact

Female F

Male M

Letter denoting type of conductor

accommodation, or cable

Letter denoting type of termination

A Tinsel wire

Screw terminal A

B Stranded wire

Crimp C

C Solid wire

Insulation displacement D

D Tinsel or stranded wire

Insulation piercing P

E Stranded or solid wire

Solder S

F Tinsel, stranded or solid wire

Compliant pin T

X Customer specific req. for cables

2.5 Wiring Conventions

2.5.1 Outlet

Figure 1

2.5.2 Plug

Figure 2

– 12 – Copyright © 2002, IEC

3 Dimensional Information

3.1 General

Original dimensions are in millimetres except where noted.

3.2 Free Connector (Plug)

3.2.1 Free Connector Isometric views

Figure 3 – Variant 03, 4-pair plug

Figure 4 – Variant 04, 2-pair plug

Figure 5 – Variant 05, 1-pair plug

– 14 – Copyright © 2002, IEC

3.2.2 Free Connector Dimensions

3.2.2.1 Variant 03, 4-pair plug drawings

Figure 6 – Variant 03 drawing 1

Table 1 – Variant 03 drawing 1 dimensions

Nominal Maximum Minimum

D 0,76 0,81 0,71

F 14,73 14,99 14,48

K 1,78 1,88 1,68

L 5,33 5,54 5,13

P 14,22 14,35 14,10

W 4,27 4,39 4,14

X 10,67 10,74 10,59

Y 11,86 11,91 11,81

Z 1,96 2,08 1,83

AA 2,59 2,72 2,46

AB 11,18 11,43 10,92

AC 45° 46° 44°

AD 5,08 5,21 4,95

Dimension D is the same as ES in figure 8 and GS in figure 11.

– 16 – Copyright © 2002, IEC

Figure 7 – Variant 03 drawing 2

Table 2 – Variant 03 drawing 2 dimensions

Nominal Maximum Minimum

B 5,99 6,05 5,94

C

60° 61° 59°

G 11,68 11,81 11,56

H 2,29 2,36 2,21

J 2,08 2,21 1,96

N 4,70 4,83 4,57

DN

15° 18° 12°

DP 2,57 2,69 2,44

DR

45° 46° 44°

DS 45° 46° 44°

DT 0,64 0,76 0,51

DU 0,64 0,76 0,51

DV 2,29 2,41 2,16

DW 0,51 0,64 0,38

DX 3,25 3,38 3,12

DY 7° 8° 6°

DZ 30° 31° 29°

EA R0,51 R0,58 R0,43

EB 8,13 8,26 8,00

EC 1,14 1,27 1,01

– 18 – Copyright © 2002, IEC

Figure 8 – Variant 03 drawing 3

Table 3 – Variant 03 drawing 3 dimensions

Nominal Maximum Minimum

A 13,11 13,16 13,06

E 0,81 0,86 0,76

M 5,41 5,46 5,36

T 0,81 0,86 0,76

U 4,06 4,14 3,99

V 0,53 0,58 0,48

AV 6,20 6,25 6,15

AW 13,31 13,36 13,26

AY 3,05 3,12 2,97

AZ R2,03 R2,11 R1,96

BA 2,26 2,34 2,19

BB 1,27 1,52 1,19

3.2.2.2 Variant 04, 2-Pair Plug Drawings

Figure 9 – Variant 04 drawing 1

Table 4 – Variant 04 drawing 1 dimensions

Nominal Maximum Minimum

DA 7,01 7,09 6,93

DB 11,18 11,43 10,92

DC 14,73 14,99 14,48

DD 5,08 5,21 4,95

DE 1,78 1,88 1,68

DF R0,38 R0,46 R0,30

DG 10,67 10,74 10,59

DH 11,86 11,91 11,81

DJ 5,99 6,05 5,94

DK

60° 61° 59°

DL 6,20 6,25 6,15

DM 0,25 0,30 0,20

– 20 – Copyright © 2002, IEC

Figure 10 – Variant 04 drawing 2

Table 5 – Variant 04 drawing 2 dimensions

Nominal Maximum Minimum

EE 0,81 0,86 0,76

EF 1,57 1,65 1,50

EG 4,06 4,14 3,99

EH 0,53 0,58 0,48

EJ 5,41 5,46 5,36

EK 2,84 2,92 2,77

EL 5,64 5,69 5,61

EM 5,23 5,28 5,18

EN 3,35 3,43 3,28

EP 1,57 1,65 1,50

ER 4,27 4,39 4,14

ES 0,76 0,81 0,71

ET 45°X0,25 45°X0.33 45°X0.18

EU R2,03 R2,16 R1,91

Dimension ES is the same as D in figure 4 and GS in figure 11

3.2.2.3 Variant 05,1-Pair Plug Drawings

Figure 11 – Variant 05 drawing 1

– 22 – Copyright © 2002, IEC

Table 6 – Variant 05 drawing 1 dimensions

Nominal Maximum Minimum

FA 7,01 7,09 6,93

FB 1,75 1,83 1,67

FC 7,37 7,45 7,29

FD 5,08 5,16 5,00

FE 1,78 1,86 1,70

FF R0,38 R0,46 R0,30

FG 10,67 10,74 10,59

FH 12,01 12,07 11,96

FJ 13,72 13,80 13,64

FK

45° 46° 44°

FL 1,14 1,22 1,06

FM 5,72 5,80 5,64

FN R0,23 R0,31 R0,15

FP 5,29 5,37 5,21

FR R0,38 R0,46 R0,30

FS 6,20 6,28 6,12

FU 6,02 6,10 5,94

FV 60,00 61 59

FW 2,34 2,46 2,21

Figure 12 – Variant 05 drawing 2

Table 7 – Variant 05 drawing 2 dimensions

Nominal Maximum Minimum

FT R0,15 0,23 0,07

FX R0,76 0,84 0,68

FY 0,18 0,26 0,10

FZ

25° 26° 24°

GA 0,51 0,59 0,43

GB R0,51 R0,59 R0,43

GC 30° 31° 29°

GD 1,63 1,71 1,55

GE

3° 4° 2°

GF 1,02 1,10 0,94

GG 0,38° 0,46° 0,30°

GH 2,29 2,37 2,21

– 24 – Copyright © 2002, IEC

3.2.2.4 1-Pair Plug Drawing 3 (See Table 8 for dimensions)

Figure 13 – Variant 05 drawing 3

Table 8 – Variant 05 drawing 3 dimensions

Nominal Maximum Minimum

GJ

45°X0,25 45°X0,33 45°X0,33

GK 0,89 0,97 0,81

GL 2,41 2,54 2,29

GM 5,49 5,57 5,41

GP 3,35 3,43 3,28

GR 1,57 1,65 1,50

GS 0,76 0,81 0,71

GT 2,13 2,21 2,05

GU 2,84 2,92 2,77

GV R2,03 R2,11 R1,96

Dimension GS is the same as D in figure 4 and ES in figure 8.

– 26 – Copyright © 2002, IEC

3.3 Fixed Connector (Outlet)

3.3.1 Isometric Views

Figure 14 – Isometric view of variant 01 (cable outlet)

3.3.2 Variant 01 (Cable Outlet) Drawings

Figure 15 – Variant 01, Cable outlet drawing 1

– 28 – Copyright © 2002, IEC

Table 9 – Variant 01 drawing 1 dimensions

Nominal Maximum Minimum

AX 1,91 2,03 1,78

BC 14,48 14,61 14,35

BD 2,29 2,41 2,16

BE 19,05 19,30 18,80

BF 1,78 1,85 1,70

BG 1,65 1,78 1,52

BH 2,03 2,16 1,91

BJ 2,29 2,36 2,21

BK

70° 71° 67°

BL 63° 66° 60°

BM 11,73 11,79 11,68

BN 10,92 11,00 10,85

BP 6,60 6,73 6,48

BR 0,64 0,71 0,61

BS 20° 23° 17°

BT 4,57 4,70 4,45

BU 1,07 1,12 1,02

BW 1,78 1,85 0,00

BX 0,76 0,90 0,64

BY 1,02 1,14 0,89

BZ 5,16 5,28 5,03

CA 2,29 2,36 2,21

CB 0,61 0,69 0,53

CC 1,61 1,66 1,56

CD 4,24 4,29 4,19

CE 7° 8° 6°

CF 0,51 0,56 0,46

CG 0,51 0,58 0,43

CH 1,52 1,65 1,40

CJ

23° 28° 18°

CK 2,21 2,34 2,08

CL 1,19 1,24 1,14

Figure 16 – Variant 01 cable outlet drawing 2

– 30 – Copyright © 2002, IEC

Table 10 – Variant 01 cable outlet drawing 2 dimensions

Nominal Maximum Minimum

CK 2,21 2,34 2,08

CL 1,78 1,88 1,68

CM 5,33 5,54 5,13

CN 12,45 12,57 12,32

CP 0,76 1,02 0,69

CR 13,18 13,26 13,10

CS 6,09 6,17 6,01

CT 5,33 5,41 5,25

CU 5,49 5,51 5,46

CV 6,26 6,34 6,18

CW 13,37 13,45 13,29

CX 13,21 13,29 13,13

CY 6,10 6,18 6,02

CZ 6,26 6,34 6,18

3.3.3 Variant 02, Printed Circuit Board (PCB) outlet drawing

Figure 17 – Variant 02 drawing

Table 11 – Variant 02 drawing dimensions

Nominal Maximum Minimum

A 14,48 14,55 14,40

B 15,75 15,88 15,62

C 20,78 20,85 20,70

D 13,72 13,84 13,59

E 5,84 5,97 5,72

F 6,60 6,73 6,48

G 8,46 8,53 8,38

NOTE See Figure 13 for internal dimensions.

– 32 – Copyright © 2002, IEC

3.4 Gauges

Gauges shall be made according to the following requirements:

Material: tool steel, hardened.

√ = Surface roughness, according to ISO 1302

Ra = 0,25 µm max. (10 µin max.)

A 0,01 mm (0,0004 in) wear tolerance shall be applied.

Clearance shall be provided for connector contacts.

Annex A and B have additional information about using the gauges.

3.4.1 Fixed Connector (Outlet) Gauges (See Table 12 for dimensions)

3.4.1.1 Fixed Connector Location Go-Gauge

Figure 18

3.4.1.2 Fixed connector Location No Go Gauge

Figure 19

3.4.1.3 Fixed connector Size Go Gauge

Figure 20

– 34 – Copyright © 2002, IEC

3.4.1.4 Fixed connector Size No Go Gauge

Figure 21

Table 12

Nominal Maximum Minimum

HA 10,16 10,211 10,109

HB 12,19 12,241 12,139

HC 1,603 1,6043 1,6017

HD 4,11 4,161 4,059

HE 10,16 10,211 10,109

HF 12,19 12,241 12,139

HG 1,395 1,3963 1,3937

HH 4,11 4,161 4,059

HI 10,16 10,211 10,109

HJ 5,281 5,2823 5,2797

HK 1,003 1,016 0,99

HL 6,043 6,094 5,992

HM 4,11 4,161 4,059

HN 10,16 10,211 10,109

HO 5,387 5,3883 5,3857

HP 1,003 1,016 0,99

HQ 6,043 6,094 5,992

HR 4,11 4,161 4,059

3.4.2 Free connector (plug) Gages (See Table 13 for dimensions)

3.4.2.1 Free connector Location Go Gauge

Figure 22

3.4.2.2 Free connector location No Go Gauge

Figure 23

– 36 – Copyright © 2002, IEC

3.4.2.3 Free connector Plug Size Go Gauge

Figure 24

3.4.2.4 Free connector Size No Go Gauge

Figure 25

Table 14

Nominal Maximum Minimum

HS 13,97 13,985 13,955

HT 5,26 5,273 5,247

HU 4,219 4,234 4,204

HV 1,547 1,5753 1,5727

HW 0,759 0,774 0,744

HX 0,638 0,653 0,623

HY 1,791 1,806 1,776

HZ 13,97 13,985 13,955

IA 5,26 5,273 5,247

IB 4,219 4,234 4,204

IC 1,755 1,7563 1,7537

ID 0,759 0,774 0,744

IE 0,638 0,653 0,623

IF 1,791 1,806 1,776

IG 9,53 9,545 9,515

IH 12,7 12,715 12,685

II 4,117 4,1183 4,1157

IJ 6,251 6,2523 6,2497

IK 0,762 0,777 0,747

IL 9,53 9,545 9,515

IM 12,7 12,715 12,685

IN 5,565 5,5800 5,5500

IO 4,117 4,1183 4,1157

IP 6,144 6,1453 6,1427

IQ 0,762 0,777 0,747

IR 0,866 0,881 0,851

IS 1,036 1,051 1,021

– 38 – Copyright © 2002, IEC

3.4.3 Test Panels (See Table 14 for dimensions)

Test panels for panel mounted fixed connectors shall be as defined below,

Figure 26

Table 14

Nominal Maximum Minimum

IT 14,732 14,808 14,656

IU 1,524 1,6 1,448

IV 19,304 19,38 19,228

4 Characteristics

4.1 General

Compliance to the test schedules is intended to ensure the reliability of all performance parameters,

including transmission parameters. Stable and compliant contact resistance is a good indication of the

stability of transmission performance.

4.2 Terminology

The terminology used in and applicable to this specification is stated in 2.1 of IEC 61076-1.

IEC 60512-1 also contains applicable terms.

4.3 Classification into Climatic Categories

The lower and upper temperatures and the duration of the damp heat, steady state test

should, unless otherwise impractical, be selected from the preferred values stated in 2.2 of

IEC 61076-1. The connectors are classified into climatic categories in accordance with the

general rules given in IEC 60068-1. The following preferred temperature range and severity of

the damp heat steady state test has been selected.

Table 15 – Climatic categories – selected values

Climatic Category Lower Temperature UpperTemperature Damp heat Steady state

days

°C °C

40/070/21 –40 70 21

4.4 Creepage and Clearance Distances

The permissible operating voltages depend on the application and on the applicable or

specified safety requirements.

Insulation co-ordination is not required for this connector; therefore, the creepage and

clearance distances in IEC 60664-1 are reduced and covered by overall performance

requirements.

Therefore, the creepage and clearance distances are given as operating characteristics of

mated connectors.

In practice, reductions in creepage or clearance distances may occur due to the conductive

pattern of the printed board or the wiring used, and shall duly be taken into account.

Table 16

Minimum distance between contacts Minimum distance between adjacent contacts

and chassis

Type Creepage Clearance Creepage Clearance

mm in mm in mm in mm in

A, B, C 1,40 0,055 0,51 0,020 0,36 0,014 0,36 0,014

4.5 Electrical Characteristics

4.5.1 Current carrying capacity

The current carrying capacity of connectors in accordance with the requirements of 2.4 of

IEC 61076-1 shall be greater or equal to 1 A at 20 °C.

– 40 – Copyright © 2002, IEC

Figure 26

4.5.2 Voltage proof

Conditions:

IEC 60512-2, Test 4a, Method A

Mated connectors

All variants:

1 000 V d.c. or a.c. peak, contact-to-contact

1 500 V d.c. or a.c. peak, contact-to-test panel or shield

4.5.3 Initial contact and shield resistance

Conditions:

IEC 60512-2, Test 2a

Mated connectors

All types: 20 mΩ max.

4.5.4 Input to output resistance

Conditions:

IEC 60512-2, Test 2a

Mated connectors

All types: 200 mΩ max.

4.5.5 Input to output resistance unbalance

Conditions:

IEC 60512-2, Test 2a

Mated connectors

All types: 50 mΩ max.

4.5.6 Insulation resistance

Conditions:

IEC 60512-2, Test 3a, Method A

Mated connectors

Test voltage: 100 V d.c.

All types: 500 MΩ min.

4.5.7 Insertion loss

Conditions:

Annex F, Insertion loss

Mated connectors, a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...