IEC 60282-4:2020

(Main)High-voltage fuses - Part 4: Additional testing requirements for high-voltage expulsion fuses utilizing polymeric insulators

High-voltage fuses - Part 4: Additional testing requirements for high-voltage expulsion fuses utilizing polymeric insulators

IEC 60282-4:2020 applies to expulsion fuses complying with IEC 60282-2 and specifies additional testing requirements for fuses employing a cutout fuse-base that utilizes polymeric insulators.

Fusibles à haute tension - Partie 4: Exigences d'essai supplémentaires pour les fusibles à expulsion à haute tension utilisant des isolateurs polymériques

IEC 60282-4:2020 s'applique aux fusibles à expulsion conformes à l'IEC 60282.2 et spécifie les exigences d'essai supplémentaires pour les fusibles qui comprennent un socle de déconnecteur à isolateurs polymériques.

General Information

- Status

- Published

- Publication Date

- 15-Apr-2020

- Technical Committee

- SC 32A - High-voltage fuses

- Drafting Committee

- WG 8 - TC 32/SC 32A/WG 8

- Current Stage

- PPUB - Publication issued

- Start Date

- 16-Apr-2020

- Completion Date

- 01-May-2020

Overview

IEC 60282-4:2020 sets additional testing requirements for high-voltage expulsion fuses that utilize polymeric insulators within cutout fuse-bases. This international standard supplements IEC 60282-2 and addresses the need for consistent, rigorous product testing for expulsion fuses integrated with polymeric insulators, particularly those that do not fall under existing insulator testing standards such as IEC 61592 and IEC 61109. As the application of polymeric insulators in high-voltage fuse systems grows globally, this standard formalizes comprehensive testing to ensure safety, reliability, and performance under various mechanical and environmental stresses.

Key Topics

- Scope and Application: IEC 60282-4 covers expulsion fuses compliant with IEC 60282-2 that use cutout fuse-bases containing polymeric insulators, focusing on additional testing beyond traditional methods.

- Mechanical Testing: Includes evaluation of mechanical stresses at temperature extremes, long-term deformation, and creep performance to confirm that polymeric insulators withstand physical and environmental pressures.

- Environmental Testing: Details accelerated weathering, tracking and erosion, and flammability tests to simulate real-world conditions and assess material durability and safety under various weather and electrical stress factors.

- Interface and Connection Testing: Ensures the integrity of end fittings and interface connections through water immersion pre-stressing and verification tests that simulate operational conditions.

- Breaking Tests: Incorporates dye penetration assessments to detect fissures or defects post-operation, enhancing quality control for fuse safety performance.

- Acceptance Criteria: Specifies pass/fail parameters for testing, ensuring uniformity in evaluation.

- Definitions: Clarifies terms such as polymeric insulator, cutout fuse-base, resin insulator, and composite polymeric insulator to promote consistent communication across industries.

Applications

- High-Voltage Power Distribution: Ensures expulsion fuses using polymeric insulators perform reliably in electrical grids and substations.

- Electrical Safety Assurance: Supports utilities and manufacturers in verifying the mechanical and environmental resilience of fuse components, reducing failure risks.

- Polymeric Insulator Adoption: Encourages the use of non-ceramic insulator technology in fuse cutouts by providing standardized testing benchmarks.

- Quality Control and Certification: Assists manufacturers in meeting international standards to gain market acceptance for high-voltage fuse products incorporating polymeric materials.

- Design and Development: Guides R&D teams in selecting and evaluating polymeric insulator materials suited for demanding electrical applications.

Related Standards

- IEC 60282-2: High-voltage expulsion fuses standard that IEC 60282-4 supplements with additional testing protocols for polymeric insulator applications.

- IEC 61592 and IEC 61109: Related standards covering artificial pollution testing on polymer post and suspension insulators, respectively.

- IEC 62217:2012: Provides test methods and acceptance criteria for polymeric HV insulators used indoors and outdoors.

- IEC 60060-1: Defines high-voltage test techniques relevant to the electrical testing components of IEC 60282-4.

- ISO 4287 and ISO 868: Address surface texture parameters and hardness testing that support polymeric material assessment.

- IEEE Std C37.41™: Provides guidelines for long-term deformation and creep testing in high-voltage fuse applications, influencing IEC 60282-4’s mechanical testing methods.

By adopting IEC 60282-4:2020, manufacturers, utilities, and testing laboratories ensure that high-voltage expulsion fuses with polymeric insulators meet rigorous international safety and reliability standards, facilitating the broader acceptance and deployment of advanced polymer-based electrical components in critical power infrastructure.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60282-4:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "High-voltage fuses - Part 4: Additional testing requirements for high-voltage expulsion fuses utilizing polymeric insulators". This standard covers: IEC 60282-4:2020 applies to expulsion fuses complying with IEC 60282-2 and specifies additional testing requirements for fuses employing a cutout fuse-base that utilizes polymeric insulators.

IEC 60282-4:2020 applies to expulsion fuses complying with IEC 60282-2 and specifies additional testing requirements for fuses employing a cutout fuse-base that utilizes polymeric insulators.

IEC 60282-4:2020 is classified under the following ICS (International Classification for Standards) categories: 29.120.50 - Fuses and other overcurrent protection devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60282-4:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60282-4 ®

Edition 1.0 2020-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

High-voltage fuses –

Part 4: Additional testing requirements for high-voltage expulsion fuses utilizing

polymeric insulators

Fusibles à haute tension –

Partie 4: Exigences d'essai supplémentaires pour les fusibles à expulsion à

haute tension utilisant des isolateurs polymériques

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60282-4 ®

Edition 1.0 2020-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

High-voltage fuses –

Part 4: Additional testing requirements for high-voltage expulsion fuses utilizing

polymeric insulators

Fusibles à haute tension –

Partie 4: Exigences d'essai supplémentaires pour les fusibles à expulsion à

haute tension utilisant des isolateurs polymériques

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.120.50 ISBN 978-2-8322-8089-8

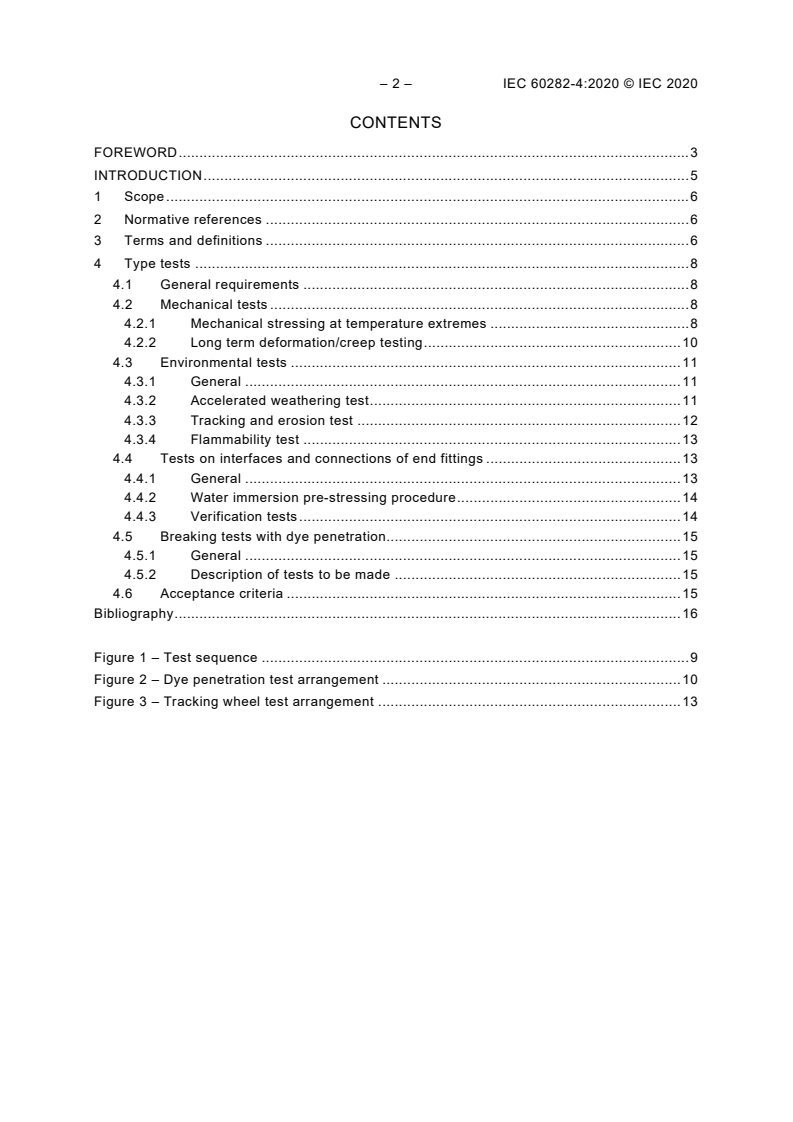

– 2 – IEC 60282-4:2020 © IEC 2020

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Type tests . 8

4.1 General requirements . 8

4.2 Mechanical tests . 8

4.2.1 Mechanical stressing at temperature extremes . 8

4.2.2 Long term deformation/creep testing . 10

4.3 Environmental tests . 11

4.3.1 General . 11

4.3.2 Accelerated weathering test . 11

4.3.3 Tracking and erosion test . 12

4.3.4 Flammability test . 13

4.4 Tests on interfaces and connections of end fittings . 13

4.4.1 General . 13

4.4.2 Water immersion pre-stressing procedure . 14

4.4.3 Verification tests . 14

4.5 Breaking tests with dye penetration. 15

4.5.1 General . 15

4.5.2 Description of tests to be made . 15

4.6 Acceptance criteria . 15

Bibliography . 16

Figure 1 – Test sequence . 9

Figure 2 – Dye penetration test arrangement . 10

Figure 3 – Tracking wheel test arrangement . 13

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HIGH-VOLTAGE FUSES –

Part 4: Additional testing requirements for high-voltage

expulsion fuses utilizing polymeric insulators

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60282-4 has been prepared by subcommittee 32A: High-voltage

fuses, of IEC technical committee 32: Fuses.

The text of this International Standard is based on the following documents:

FDIS Report on voting

32A/346/FDIS 32A/348/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – IEC 60282-4:2020 © IEC 2020

A list of all parts in the IEC 60282 series, published under the general title High-voltage fuses,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

High-voltage expulsion fuses are tested according to IEC 60282-2 which recognizes that fuse-

bases may use polymer (non-ceramic) insulators. However, very little additional testing is

specified for fuses using such insulators. In the case of polymer post insulators and

suspension insulators, only artificial pollution tests are required in accordance with IEC 61592

and IEC 61109, respectively. However, for fuses that use insulators not covered by these

International Standards, such as certain fuse-cutouts, the additional testing required is by

agreement between manufacturer and user. Fuses that need such "additional testing" are

expulsion fuses that utilize polymer insulators in which a single mounting bracket is used,

either at the centre of an insulator or connected to two insulators (a "cutout fuse-base"). As

the market for expulsion fuses using polymer insulators has grown, manufacturers have

introduced many tests in addition to artificial pollution tests, covering other aspects of a fuse's

performance. This document formalises such testing and provides standardisation and

consistency. It should be noted that the document focusses on product testing as opposed to

material testing. In addition to drawing on test procedures covered by IEC 62217:2012,

Polymeric HV insulators for indoor and outdoor use – General definitions, test methods and

acceptance criteria, material from IEEE Std C37.41™:2016 (primarily 18.1.2 Long-term

deformation/creep testing) is also used, with the permission of IEEE.

– 6 – IEC 60282-4:2020 © IEC 2020

HIGH-VOLTAGE FUSES –

Part 4: Additional testing requirements for high-voltage

expulsion fuses utilizing polymeric insulators

1 Scope

This part of IEC 60282 applies to expulsion fuses complying with IEC 60282-2 and specifies

additional testing requirements for fuses employing a cutout fuse-base that utilizes polymeric

insulators.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60060-1:2010, High-voltage test techniques – Part 1: General definitions and test

requirements

IEC 60282-2:2008, High-voltage fuses – Part 2: Expulsion fuses

ISO 4287, Geometrical Product Specifications (GPS) – Surface Texture: Profile method –

Terms, definitions and surface texture parameters

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 868, Plastics and ebonite – Determination of indentation hardness by means of a

durometer (Shore hardness)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

polymeric insulator

insulator whose insulating body consists of at least one organic based material

Note 1 to entry: Polymeric insulators are also known as non-ceramic insulators.

Note 2 to entry: Coupling devices may be attached to the ends of the insulating body.

[SOURCE: IEC 60050-471:2007, 471-01-13]

3.2

composite polymeric insulator

polymeric insulator made of at least two polymeric insulating parts, namely a core and a

housing equipped with end fittings

[SOURCE: IEC 60050-471:2007, 471-01-02, modified – the term "polymeric" added and the

note to entry deleted.]

3.3

core (of a composite polymeric insulator)

central insulating part of a composite polymeric insulator which provides the primary

mechanical characteristics of the insulator

[SOURCE: IEC 60050-471:2007, 471-01-03, modified – addition of "composite polymeric";

addition of "primary" and "of the insulator"; note to entry deleted.]

3.4

housing

external insulating part(s) of a composite polymeric insulator that provides the necessary

creepage distance, other dielectric characteristics of the insulator, and protects the core from

the environment

[SOURCE: IEC 60050-471:2007, 471-01-09, modified – "of a composite polymeric insulator"

and "other dielectric characteristics of the insulator" added.]

3.5

insulating body

insulating assembly that contains the insulator and permanent fittings

3.6

insulator trunk

central insulating part of an insulator from which the sheds project

Note 1 to entry: Also known as shank on smaller insulators.

[SOURCE: IEC 60050-471:2007, 471-01-11]

3.7

shed (of an insulator)

insulating part, projecting from the insulator trunk, intended to increase the creepage distance

Note 1 to entry: The shed can be with or without ribs.

[SOURCE: IEC 60050-471:2007, 471-01-15]

3.8

cutout fuse-base

fuse-base that uses an insulator or insulators having a single point mounting bracket

Note 1 to entry: The mounting bracket is generally located centrally between the terminals that are mounted at

the outer ends of the insulator(s).

3.9

resin insulator

polymeric insulator whose insulating body consists of a solid shank and sheds protruding from

the shank made from only one organic based housing material (e.g. cycloaliphatic epoxy)

– 8 – IEC 60282-4:2020 © IEC 2020

3.10

interface

surface between the different materials

Note 1 to entry: Various interfaces occur in most composite insulators, for example:

– between housing and fixing devices;

– between core and housing.

4 Type tests

4.1 General requirements

Fuses according to this document shall comply with the requirements of IEC 60282-2, except

for those that are specifically replaced with requirements specified in this document for the

following type tests.

4.2 Mechanical tests

4.2.1 Mechanical stressing at temperature extremes

4.2.1.1 General

When conducting this test with a fuse using a polymeric insulator(s), it is not necessary to

perform the mechanical tests outlined in 8.8.1 of IEC 60282-2:2008. The testing covered

in 4.2.1 only applies to devices that can be opened and closed manually.

4.2.1.2 Test procedure

Three new fuses shall be used for this test. The test samples shall consist of the fuse-base,

fuse-carrier, and end fittings. The fuse carriers should contain fuse-links of sufficiently high

current rating, or dummy links, so that the fuse-links are not subjected to the same endurance

test as the fuse-bases and fuse-carriers.

All samples shall be cycled between −30 °C (+0 °C, −5 °C) and +40 °C (+5 °C, −0 °C). The

samples shall remain at each temperature extreme for a minimum of 8 h per cycle. The cycle

time from one temperature extreme to the other shall be any convenient value, however the

sample rate of temperature change should be no more than 0,5 °C/min to avoid thermal shock.

All samples shall complete 4 cycles (a cycle includes both temperature extremes) resulting in

a minimum total test time of approximately 83 h. See Figure 1 for a representation of the

preferred test sequence. If the specified minimum ambient air temperature for the fuse is

other than −30 °C (see IEC 60282-2:2008, 4.1 a)) then this value (+0 °C, −5 °C) shall be used

for the minimum temperature of the cycle.

Once per cycle, manual open/close operations shall be performed, using a device approved

by the manufacturer. At the end of an eight-hour cold or hot period, each sample is subjected

to 50 open/close operations. All operations shall be performed at a minimum 30° angle from

centreline with 25 on the right and 25 on the left. The closing force should simulate typical

service conditions as recommended by the manufacturer. Tests shall alternate with each

cycle such that over the four cycles, a total of 100 open/close operations are performed hot

and 100 open/close operations cold. The four-cycle sequence can start with a hot period or

cold period, but a cold period is the preferred sequence.

Figure 1 – Test sequence

4.2.1.3 Acceptance criteria

4.2.1.3.1 Initial acceptance criteria

The following are the initial criteria for successful completion of this test:

a) Overall length of fuse-base shall comply with manufacturer's specification.

b) No loose or deformed parts, cracks or other obvious visual deformation in any of the

assemblies shall occur.

c) Each sample shall perform its intended function as demonstrated by 4.2.1.3.2.

4.2.1.3.2 Acceptance testing

After the samples have passed the initial acceptance criteria listed in 4.2.1.3.1, further tests

are performed to determine that the fuse has not received damage to impair its current

carrying capability and drop-out capability.

a) Each sample shall be subjected to a temperature rise test as specified in IEC 60282-2.

The temperature rise of individual components may exceed the temperature rise limits

specified in IEC 60282-2, provided that all temperature measurements demonstrate that

the fuse has reached temperature stability, without thermal runaway occurring.

b) Each sample shall demonstrate it is capable of full mechanical performance when a fuse

element melts. For drop-out devices, capability can be verified by the following process.

Each sample shall have a fuse-carrier mounted in the fuse-support with an appropriately

sized fuse-link. Sufficient current shall be passed through the fuse to cause the element to

melt. The sample shall operate and move to the proper open condition.

4.2.1.4 Dye penetration test for composite polymeric insulators

After the testing detailed in 4.2.1.3.1 and 4.2.1.3.2 a dye penetration test is performed to

verify that no damage to the core material occurred during the mechanical tests. Four

samples shall be cut from each tested insulator making the cut approximately 90° to the long

axis of the insulator. Using a diamond-coated circular saw blade under running cold water is

the preferred method, however other cutting methods may be used with agreement from the

manufacturer. The length of the samples shall be 10 mm ± 1,0 mm. The cut surfaces shall be

smoothed by means of fine abrasive cloth (grain size 180). The cut ends shall be clean and

parallel. The specimens shall be placed (long axis of the insulator vertical) on a layer of steel

or glass balls of the same diameter (1 mm to 2 mm) in a vessel or tray. A solution of 1 % (by

– 10 – IEC 60282-4:2020 © IEC 2020

weight) of Astrazon BR 200 in methanol shall be poured into the vessel, its level being 2 mm

to 3 mm higher than the level of the balls. See Figure 2 for a representation of this test

arrangement. The specimens shall be observed for 15 min. Other, equivalent, products to

Astrazon BR 200 may be used.

Dimensions in millimetres

Figure 2 – Dye penetration test arrangement

4.2.1.5 Dye penetration test acceptance criteria

No dye shall rise through the specimens before the 15 min have elapsed. Steps may be taken

to prevent dye wicking up the outside surface of the samples.

4.2.2 Long term deformation/creep testing

4.2.2.1 General

This test is for fuses that incorporate composite and/or resin type polymeric insulators.

4.2.2.2 Number of devices to be tested

Three new test samples shall be used for this test, consisting of a fuse-base and a

disconnecting blade, or a fuse-base, fuse-carrier and fuse-link. The test procedure is:

a) The distance between the upper contact and lower hinge on all three fuse-bases shall be

measured.

b) The test samples shall be placed into an oven at 75 °C (+5 °C, −0 °C) until all components

have reached thermal equilibrium.

c) Once all components have reached the proper temperature, the three disconnecting

blades or fuse-carriers and fuse-links shall be installed into the three fuse-bases in the

closed position.

d) After 8 h have passed, the first device is removed and placed in a water bath, at ambient

temperature, for one minute. After one minute, the disconnecting blade or fuse-carrier and

fuse-link is removed and the distance between the upper contact and lower hinge is

measured.

_____________

Astrazon BR 200 is an example of a suitable product available commercially. This information is given for the

convenience of users of this document and does not constitute an endorsement by the IEC of this product.

Reproduced from IEEE Std C37.41:2016, with the permission of IEEE.

e) After 24 h have passed, the second device is removed and placed in a water bath, at

ambient temperature, for one minute. After one minute, the disconnecting blade or fuse-

carrier and fuse-link is removed and the distance between the upper contact and lower

hinge is measured.

f) After 168 h, the final device is removed and placed in a water bath, at ambient

temperature, for one minute. After one minute, the disconnecting blade or fuse-carrier and

fuse-link is removed and the distance between the upper contact and lower hinge is

measured.

4.2.2.3 Acceptance criteria

a) The final measured length of all samples shall be within the limits defined by the

manufacturer.

b) Each sample shall be subjected to a temperature rise test at rated current of the fuse-base

or fuse-carrier, whichever is lower. The temperature rise of individual components may

exceed the temperature rise limits specified in IEC 60282-2, provided that all

measurements demonstrate that temperature stability, without thermal runaway, has

occurred.

c) The samples shall demonstrate that they remain capable of proper mechanical

performance. For dropout devices, performance shall be verified by the following process.

Each sample shall have a fuse-carrier mounted in the fuse-support and current passed

through the fuse element sufficient to melt it. The sample shall be verified to have

operated and moved to the proper open state.

4.3 Environmental tests

4.3.1 General

These tests are for fuses that incorporate composite and/or resin type polymeric insulators.

4.3.2 Accelerated weathering test

4.3.2.1 Test procedure

Three new fuse-bases shall be selected with labels/markings included, if applicable.

The new fuse-bases shall be subjected to a 1 000 h UV light test using the following test

method. Markings on the housing, if any, shall be directly exposed to UV light:

Xenon-arc methods: ISO 4892-2, using cycle 1 with a dark period of 8 h

NOTE More information on accelerated weathering tests can be found in CIGRE Technical Brochure No. 488.

4.3.2.2 Acceptance criteria

After the test, markings on shed or housing material shall still be legible; cracks, blisters, and

crumbling are not permitted. General surface degradation shall be measured using the

following method.

Two surface roughness measurements shall be made on each of the three specimens. The

roughness, Rz as defined in ISO 4287, shall be measured along a sampling length of at least

2,5 mm. Rz shall not exceed 0,1 mm.

A 1 min dry power frequency withstand voltage test shall be performed on each sample (fitted

with a disconnecting blade, or a fuse-carrier and fuse-link) as specified in IEC 60060-1. Each

sample shall withstand its rated short-duration power frequency withstand voltage. If flashover

or puncture occurs, the fuse shall be considered to have failed the test.

– 12 – IEC 60282-4:2020 © IEC 2020

4.3.3 Tracking and erosion test

4.3.3.1 General

These tests are for fuses that incorporate composite and/or resin type polymeric insulators.

Three samples shall be selected for the test procedure in 4.3.3.2, and for acceptance criteria

testing in 4.3.3.3. A fourth sample shall be selected for acceptance criteria testing in 4.2.2.3.

This forth reference sample shall not be tested in accordance with 4.3.3.2.

The devices shall be mounting on a tracking wheel. The tracking wheel cycles each device

through 4 periods: submersion, drip, energized, and cooling, see Figure 3 for reference. The

saline solution in the tank shall contain deionized water and 1,40 ± 0,06g/l of NaCl.

4.3.3.2 Test procedure

a) Set up and energize the circuit. The test voltage shall be no less than 58 % of the device's

maximum rated voltage. The test circuit, when loaded with a resistive current of 250 mA

(RMS) on the high-voltage side, shall experience a maximum drop of 5 %.

b) Each sample shall be exposed to 30 000 cycles. One cycle shall consist of one insulator

rotating through each period. Each cycle shall be completed in 200 s ± 25 s, with the

insulator being stationary no less than 80 % of the cycle time. Each of the 4 periods shall

be approximately equal in duration. Several interruptions of the test for inspection

purposes, each of these not exceeding 15 min, are permissible. Interruption periods shall

not be counted in the test duration.

c) The test samples shall be given a 24-hour recovery period after each 96 h test period.

During this period, the test procedure remains unchanged, except that the saline solution

is removed from the dip tank.

The 24 h recovery period may be omitted upon agreement with the manufacturer and test

station.

d) Upon completion of all 30 000 cycles. The samples shall be removed and evaluated within

a 48 h period.

The tracking and erosion test shall be regarded as passed if all samples met the following

criteria and the acceptance testing according to 4.3.3.3:

• Each sample shall complete all 30 000 cycles without the leakage current rising

above 250 mA.

• No punctures of a shed, housing or interface.

• For composite insulators: tracking/erosion shall not reach the core.

• For resin insulators: erosion depth is less than 3 mm.

4.3.3.3 Acceptance testing procedure

Each aged sample and reference sample shall be subjected to the following tests. The

procedures shall be completed in the following order.

a) Rinse all samples with deionized water.

b) Measure the resistance using a mega-ohm meter with a test voltage not less than 1 kV.

The resistance shall not be less than 3 MΩ. Three measurements shall be taken: end

fitting to end fitting and each end fitting to the centre fitting.

c) Steep-front impulse voltage test and acceptance criteria according to 4.4.3.2.

d) Dry power frequency withstand voltage test and acceptance criteria according to 4.4.3.3.

e) Lightning impulse voltage dry test according to IEC 60060-1. Impulse wave shape shall be

the standard 1,2/50 µs. Each sample shall withstand 80 % of its rated lightning impulse

withstand voltage.

Figure 3 – Tracking wheel test arrangement

4.3.4 Flammability test

No flammability tests are required for any type of polymeric insulator being part of cut out fuse

bases. However, if required by the customer, further information on flammability testing

associated with polymer insulators can be found in IEC 62217.

4.4 Tests on interfaces and connections of end fittings

4.4.1 General

This testing is for fuses that incorporate composite and/or resin type polymeric insulators. A

test sample shall consist of a fuse-base and a disconnecting blade, or a fuse-base, fuse-

carrier, and fuse-link.

Fuses using composite polymeric insulators are subject to pre-stressing. For pre-stressing,

three samples shall be selected. A fourth sample shall be selected for verification tests (4.4.3)

but this reference sample shall not be pre-stressed.

Fuses that do not require pre-stressing (i.e. those that use resin insulators) before the

verification tests do not require the use of a reference sample as the tested fuses are used to

determine the reference flashover voltage. Three samples shall be tested.

– 14 – IEC 60282-4:2020 © IEC 2020

4.4.2 Water immersion pre-stressing procedure

Pre-stressing only applies to fuses using composite polymeric insulators. Only the fuse-base

is required to undergo the pre-stressing procedure.

a) The hardness of the insulator housing shall be measured for each sample. Measurement

shall be in accordance with ISO 868 using a Shore A Durometer.

b) Each sample shall be boiled for 100 h in water having 0,1 % by weight of NaCl.

c) After boiling, each insulator sample shall be allowed to cool and rinsed with deionized

water.

d) The hardness shall be re-measured. The hardness shall not have changed by more than

20 %.

e) The verification tests (4.4.3) shall be completed within 48 h of the samples being removed

from the boiling water.

4.4.3 Verification tests

4.4.3.1 General

The following verification tests apply to fuses that incorporate composite and/or resin type

polymeric insulators. Tests in 4.4.3.2 shall be performed before tests in 4.4.3.3. Additionally,

for composite polymeric insulators, the procedure in 4.4.2 shall be performed prior to tests in

4.4.3.2.

4.4.3.2 Steep-front impulse voltage test

Each sample, and the reference sample if necessary, shall be subjected to steep-front

impulse flashovers resulting from ten positive and ten negative voltage waves. The voltage

shall rise at a minimum of 1 000 kV/μs. For an example of these waves see IEC 60060-1:2010,

Figure 12. The samples shall be mounted per the manufacturer's specification with fuse-

carriers or disconnecting blades installed in the fuse-base. The fuse-base shall be earthed

and both terminals energised. The test shall be regarded as passed if all samples met the

following criteria:

• Each impulse shall cause an external flashover.

• For composite insulators: there are no punctures that expose the core.

• For resin insulators: there are no punctures to any potted fittings.

NOTE The typical industry perspective is that punctures of any kind are not allowed. However, the intent of this

test is to significantly stress the interface between core and housing, or fitting and resin insulator, by subjecting the

cutout to a "failure" mode (flashover). Based on the typical construction of composite polymer cutouts, punctures to

the centrally located mounting bracket may not impact the rated dielectric strength of some designs. To test this,

additional, subsequent, tests are specified. These are a dry power frequency test in 4.4.3.3, and in the case of the

tracking and erosion test (4.3.3), after the testing performed in accordance with 4.4.3.2 and 4.4.3.3 a lightning

impulse test is performed (see 4.3.3.3). Note that for these tests, any (additional) punctures are not allowed.

4.4.3.3 Dry power frequency test

The dry power frequency voltage (reference flashover voltage) shall be determined by

averaging five flashover voltages on each sample. If a reference sample is being used, the

average flashover voltage for this sample is the reference flashover voltage. The reference

flashover voltage shall be corrected to normal standard atmospheric conditions in accordance

with IEC 60060-1. The flashover voltage shall be obtained by increasing the voltage linearly

from zero within 1 min.

Before commencing the following test, the shank temperature on all test samples, including

the reference sample if applicable, shall be determined by averaging three values measured

between the sheds along the length of the insulator(s) (reference temperature).

The test samples, and the reference test sample if applicable, shall then be continuously

subjected for 30 min to 80 % of the reference flashover voltage.

Measurement of the shank temperature on all test specimens, and of the reference sample if

applicable, shall be repeated immediately after the removal of the test voltage.

The test shall be regarded as passed if all samples meet the following criteria:

• The average flashover voltage of a pre-stressed sample shall be greater than or equal to

90 % of the reference flashover voltage.

• There are no additional punctures of the shed, housing or interface.

• The difference between the temperature rise of the pre-stressed samples and the

reference sample shall be less than 10 K.

• In cases where there is no reference sample, then the maximum temperature rise shall be

less than 20 K compared to the reference temperature determined prior to the power

frequency tests.

4.5 Breaking tests with dye penetration

4.5.1 General

This test applies to fuses that use composite and/or resin type polymeric insulators. The

purpose of the test is to assess the interrupting performance of fuse-bases incorporating

polymeric insulators.

4.5.2 Description of tests to be made

The breaking tests shall be made with single-phase alternating current.

Tests shall be made in accordance with IEC 60282-2:2008, 8.6, Test Duty 1: Verification of

operation with the rated maximum breaking current I .

It is not necessary to perform additional Test Duty 1 tests to those specified in

IEC 60282-2:2008. Fuse-supports from tests performed in accordance with Test Duty 1 of

IEC 60282-2:2008, 8.6 may be used to evaluate the requirements of 4.5.

4.6 Acceptance criteria

a) There shall be no visible damage to the polymeric insulator(s) and test samples shall meet

the requirements of IEC 60282-2:2008, 7.2.

b) For fuses that use composite polymeric insulators, samples cut from each tested insulator

shall be subjected to a dye penetration test in accordance to the requirements of 4.2.1.4 in

order to verify that no damage to the core material has occurred. The fuses are

considered to have passed the tests if all samples meet the requirements in 4.2.1.5.

– 16 – IEC 60282-4:2020 © IEC 2020

Bibliography

IEC 62217:2012, Polymeric HV insulators for indoor and outdoor use – General definitions,

test methods and acceptance criteria

IEEE C37.41™-2016, IEEE Standard Design Tests for High-Voltage (>1000 V) Fuses and

Accessories

CIGRE Technical Brochure No. 488, Resistance to Weathering and UV Radiation of Polymeric

Materials for Outdoor Insulation

_____________

– 18 – IEC 60282-4:2020 © IEC 2020

SOMMAIRE

AVANT-PROPOS . 19

INTRODUCTION . 21

1 Domaine d'application . 22

2 Références normatives . 22

3 Termes et définitions . 22

4 Essais de type . 24

4.1 Exigences générales . 24

4.2 Essais mécaniques . 24

4.2.1 Contraintes mécaniques à des températures extrêmes . 24

4.2.2 Essais de déformation/fluage à long terme . 26

4.3 Essais d'environnement . 27

4.3.1 Généralités . 27

4.3.2 Essai accéléré de résistance aux intempéries . 27

4.3.3 Essai de cheminement et d'érosion . 28

4.3.4 Essai d'inflammabilité . 30

4.4 Essais sur les interfaces et connexions d'armatures d'extrémité . 30

4.4.1 Généralités . 30

4.4.2 Modalités de précontrainte par immersion dans l'eau . 31

4.4.3 Essais de vérification . 31

4.5 Essais de coupure avec pénétration de colorant . 32

4.5.1 Généralités . 32

4.5.2 Description des essais à effectuer . 32

4.6 Critères d'acceptation . 32

Bibliographie . 33

Figure 1 – Séquence d'essais . 25

Figure 2 – Montage de l'essai de pénétration de colorant . 26

Figure 3 – Montage d'essai pour la roue d'endurance . 30

COMMISSION ÉLECTRONIQUE INTERNATIONALE

____________

FUSIBLES À HAUTE TENSION –

Partie 4: Exigences d'essai supplémentaires pour

les fusibles à expulsion à haute tension

utilisant des isolateurs polymériques

AVANT-PROPOS

1) La Commission Électrotechnique Internationale (IEC) est une organisation mondiale de normalisation composée

de l'ensemble des comités électrotechniques nationaux (Comités nationaux de l'IEC). L'IEC a pour objet de

favoriser la coopération internationale pour toutes les questions de normalisation dans les doma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...