IEC 61477:2009

(Main)Live working - Minimum requirements for the utilization of tools, devices and equipment

Live working - Minimum requirements for the utilization of tools, devices and equipment

IEC 61477:2009 gives the minimum requirements relative to specification, manufacture, selection, application and maintenance of tools, devices and equipment for live working. It provides the type of information which is useful to skilled persons in order to make the use of tools, devices and equipment safer. This type of information includes:

- the characteristics of tools, devices and equipment;

- their conditions for use;

- their conditions for maintenance;

- their conditions for storage and transportation.

Such information may be given in standards, manufacturer's instructions for use and in internal regulations set forth by companies for their own employees. Such information should be completed by work methods, which are excluded from the scope of this standard. This second edition of IEC 61477 cancels and replaces the first edition published in 2001, its Amendment 1 (2002) and Amendment 2 (2004). The contents of the corrigendum of April 2009 have been included in this copy.

Travaux sous tension - Exigences minimales pour l'utilisation des outils, dispositifs et équipements

La CEI 61477:2009 donne les exigences minimales relatives aux spécifications, à la fabrication, à la sélection, à l'emploi et à l'entretien des outils, dispositifs et équipements pour travaux sous tension. Elle fournit le type d'information utile aux personnes formées de façon à rendre plus sûre l'utilisation des outils, dispositifs et équipements pour travaux sous tension. Ce type d'information comprend:

- les caractéristiques des outils, dispositifs et équipements;

- leurs conditions d'utilisation;

- leurs conditions d'entretien;

- leurs conditions d'entreposage et de transport.

Ces informations peuvent figurer dans les normes, les instructions d'emploi des fabricants, les règlements internes établis par les entreprises pour leurs employés. Il convient que ces informations soient complétées par des méthodes de travail, lesquelles sont exclues du domaine d'application de cette norme. Cette deuxième édition de la CEI 61477 annule et remplace la première édition parue en 2001, l'Amendement 1 (2002) et l'Amendement 2 (2004). Le contenu du corrigendum d'avril 2009 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 19-Feb-2009

- Technical Committee

- TC 78 - Live working

- Drafting Committee

- WG 11 - TC 78/WG 11

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Feb-2009

- Completion Date

- 15-Mar-2009

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61477:2009 is an international standard published by the International Electrotechnical Commission (IEC) that sets the minimum requirements for the utilization of tools, devices, and equipment used in live working. It focuses on the safe specification, manufacture, selection, application, maintenance, storage, and transportation of live working tools. This standard provides essential guidance for skilled electrical workers, manufacturers, and organizations to improve safety and efficiency when working on or near energized electrical equipment.

The standard covers various critical aspects, including the characteristics of tools, conditions for their use, maintenance protocols, and proper handling during storage and transport. IEC 61477:2009 serves as a reference point in the development of national regulations and complements manufacturer instructions and company-specific safety rules.

Key Topics

Characteristics of Tools

- Marking and Symbols: Tools suitable for live working must carry clear and durable markings, such as the IEC 60417-5216 symbol (double triangle) to indicate compliance with live working requirements.

- Physical Attributes: Consideration of weight, dimensions, and the spatial arrangement of insulating and conductive parts to ensure the tool’s safety and usability during live work.

- Electrical and Mechanical Properties: Details on insulating performance, mechanical robustness, and thermal resistance, as essential factors ensuring tool reliability.

Conditions for Use

- Operating Range: Defined limits within which tools can be safely operated, considering voltage levels and environmental conditions.

- Precautions: Guidelines on verifying tools before use to identify any damage or defects that could compromise safety.

Maintenance Requirements

- Cleaning Procedures: Recommendations for non-damaging cleaning methods to maintain insulating properties.

- Periodic Checks: Regular inspections and functional verifications to detect wear or deterioration.

- Repairs: Conditions under which tools can be repaired and the necessity to maintain compliance after repair.

Storage and Transportation

- Environmental Controls: Ensuring tools are stored and transported under conditions that do not degrade their electrical or mechanical performance.

- Packaging and Protection: Suitable measures to protect tools from mechanical damage and contamination.

Applications

IEC 61477:2009 is crucial for multiple applications within the electrical maintenance and live working sectors:

- Live Electrical Maintenance: Ensures that tools used for work on energized equipment meet safety criteria, reducing the risk of electrical hazards.

- Tool Manufacturing and Testing: Provides manufacturers specific requirements and testing procedures to design and certify live working tools.

- Company Safety Protocols: Assists employers in establishing internal regulations and guidelines that align with international safety standards.

- Training and Competency Development: Serves as a reference for educators and trainers to enhance the knowledge of electrically skilled persons about tool selection and safe live working practices.

Related Standards

- IEC 60050-651: International Electrotechnical Vocabulary – Part 651: Live Working, for terminology related to electrical safety and tools.

- IEC 60417: Graphical Symbols for Use on Equipment, which defines symbols such as the double triangle marking.

- IEC 60743: Live Working – Terminology for Tools, Equipment, and Devices, providing standard definitions.

- IEC 61230: Portable Equipment for Earthing or Earthing and Short-circuiting, complementing requirements for grounding devices.

- IEC 60895: Conductive Clothing suitable for live working environments.

- IEC 61482-2: Arc Protective Clothing standards relevant to live working situations.

By adhering to IEC 61477:2009, electrical professionals and organizations can ensure the safe use of live working tools while complying with internationally recognized safety practices. This standard supports risk reduction, operational efficiency, and industry consistency in high-risk electrical work environments.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 61477:2009 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Live working - Minimum requirements for the utilization of tools, devices and equipment". This standard covers: IEC 61477:2009 gives the minimum requirements relative to specification, manufacture, selection, application and maintenance of tools, devices and equipment for live working. It provides the type of information which is useful to skilled persons in order to make the use of tools, devices and equipment safer. This type of information includes: - the characteristics of tools, devices and equipment; - their conditions for use; - their conditions for maintenance; - their conditions for storage and transportation. Such information may be given in standards, manufacturer's instructions for use and in internal regulations set forth by companies for their own employees. Such information should be completed by work methods, which are excluded from the scope of this standard. This second edition of IEC 61477 cancels and replaces the first edition published in 2001, its Amendment 1 (2002) and Amendment 2 (2004). The contents of the corrigendum of April 2009 have been included in this copy.

IEC 61477:2009 gives the minimum requirements relative to specification, manufacture, selection, application and maintenance of tools, devices and equipment for live working. It provides the type of information which is useful to skilled persons in order to make the use of tools, devices and equipment safer. This type of information includes: - the characteristics of tools, devices and equipment; - their conditions for use; - their conditions for maintenance; - their conditions for storage and transportation. Such information may be given in standards, manufacturer's instructions for use and in internal regulations set forth by companies for their own employees. Such information should be completed by work methods, which are excluded from the scope of this standard. This second edition of IEC 61477 cancels and replaces the first edition published in 2001, its Amendment 1 (2002) and Amendment 2 (2004). The contents of the corrigendum of April 2009 have been included in this copy.

IEC 61477:2009 is classified under the following ICS (International Classification for Standards) categories: 13.260 - Protection against electric shock. Live working; 29.240.20 - Power transmission and distribution lines; 29.260.99 - Other electrical equipment for working in special conditions. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61477:2009 has the following relationships with other standards: It is inter standard links to IEC 61477:2009/COR1:2009, IEC 61477:2001/AMD2:2004, IEC 61477:2001/AMD1:2002, IEC 61477:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61477:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61477 ®

Edition 2.0 2009-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Minimum requirements for the utilization of tools, devices and

equipment

Travaux sous tension – Exigences minimales pour l’utilisation des outils,

dispositifs et équipements

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61477 ®

Edition 2.0 2009-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Live working – Minimum requirements for the utilization of tools, devices and

equipment

Travaux sous tension – Exigences minimales pour l’utilisation des outils,

dispositifs et équipements

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

N

CODE PRIX

ICS 13.260; 29.240.20; 29.260.99 ISBN 978-2-88910-519-9

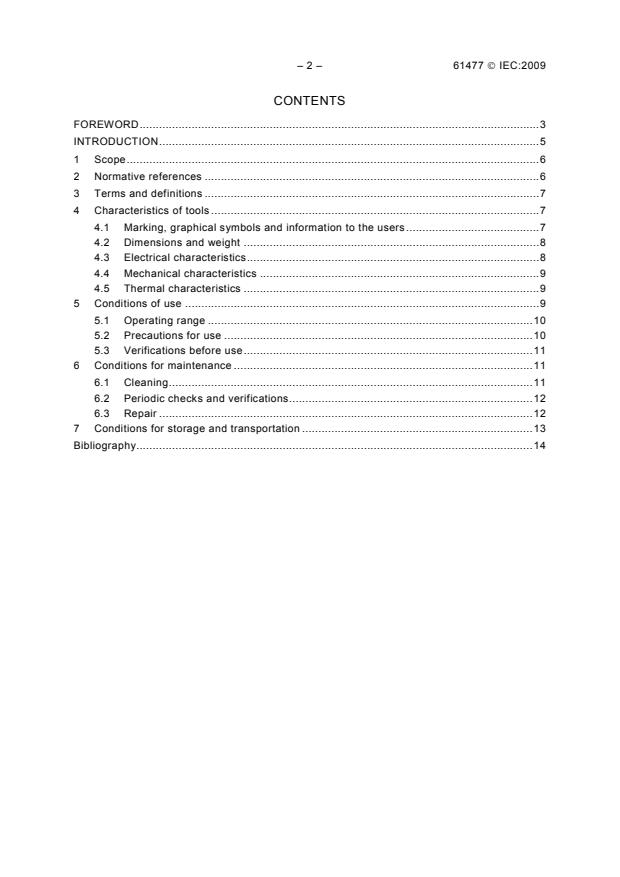

– 2 – 61477 © IEC:2009

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references .6

3 Terms and definitions .7

4 Characteristics of tools .7

4.1 Marking, graphical symbols and information to the users.7

4.2 Dimensions and weight .8

4.3 Electrical characteristics.8

4.4 Mechanical characteristics .9

4.5 Thermal characteristics .9

5 Conditions of use .9

5.1 Operating range .10

5.2 Precautions for use .10

5.3 Verifications before use.11

6 Conditions for maintenance .11

6.1 Cleaning.11

6.2 Periodic checks and verifications.12

6.3 Repair .12

7 Conditions for storage and transportation .13

Bibliography.14

61477 © IEC:2009 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LIVE WORKING –

MINIMUM REQUIREMENTS FOR THE UTILIZATION

OF TOOLS, DEVICES AND EQUIPMENT

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61477 has been prepared by IEC technical committee 78: Live

working.

This second edition of IEC 61477 cancels and replaces the first edition published in 2001, its

Amendment 1 (2002) and Amendment 2 (2004).

The document 78/772/FDIS, circulated to the National Committees as Amendment 3, led to

the publication of the new edition.

The text of this standard is based on the first edition, Amendment 1, Amendment 2 and the

following documents:

FDIS Report on voting

78/772/FDIS 78/786/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

– 4 – 61477 © IEC:2009

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of April 2009 have been included in this copy.

61477 © IEC:2009 – 5 –

INTRODUCTION

This International Standard does not replace national regulations but it can be regarded as a

reference for the development of national regulations. Where National regulations are in force

to dictate the conditions of utilization of tools, devices and equipment for live working, these

can be more stringent than the minimum requirements of this standard.

– 6 – 61477 © IEC:2009

LIVE WORKING –

MINIMUM REQUIREMENTS FOR THE UTILIZATION

OF TOOLS, DEVICES AND EQUIPMENT

1 Scope

This International Standard gives the minimum requirements relative to specification,

manufacture, selection, application and maintenance of tools, devices and equipment for live

working.

It provides the type of information which is useful to skilled persons in order to make the use

of tools, devices and equipment safer.

This type of information includes:

• the characteristics of tools, devices and equipment;

• their conditions for use;

• their conditions for maintenance;

• their conditions for storage and transportation.

Such information may be given in standards, manufacturer’s instructions for use and in

internal regulations set forth by companies for their own employees.

Such information should be completed by work methods, which are excluded from the scope

of this standard.

In this standard, the word tool(s) is used for "tools, devices and equipment for live working"

unless otherwise specified.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050-651:1999, International Electrotechnical Vocabulary (IEV) – Part 651: Live working

IEC 60417, Graphical symbols for use on equipment

IEC 60743, Live working – Terminology for tools, equipment and devices

61477 © IEC:2009 – 7 –

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

(electrically) skilled person

(electrically) qualified person (US)

person with relevant education and experience to enable him or her to perceive risks and to

avoid hazards which electricity can create

[IEV 651-01-33]

3.2

required insulation level for live working (RILL)

statistical impulse withstand voltage of the insulation at the work location necessary to reduce

the risk of breakdown of this insulation to an acceptable low level

NOTE It is generally considered that an acceptable low level is reached when the value of the statistical impulse

withstand voltage is greater than or equal to the overvoltage having a probability of being exceeded by no more

than 2 %.

[IEV 651-01-17]

3.3

live working zone

space around live parts where prevention of electrical hazard is assured by suitable means

such as limiting access to skilled persons, maintaining the appropriate air distances to

energized parts and using tools for live working

NOTE 1 The distance from the live parts to the outer boundary of a live working zone is greater or equal to the

minimum working distance.

NOTE 2 The live working zone and the specific precautions that apply are generally defined by national or

company regulations.

NOTE 3 In some countries the term "danger zone" is used instead of "live working zone".

[IEV 651-01-06]

3.4

tools (for live working)

tools, devices and equipment particularly designed or adapted, tested and maintained for live

working

[IEV 651-01-24]

4 Characteristics of tools

The selection of tools to carry out the work to be performed requires a combination of both the

advice and guidance from the manufacturer of the tools and the knowledge and experience of

the user. This information enables the user to select tools that are not only the easiest to use

but also ensures that tools are not used beyond their capabilities.

Those persons using the tools should be informed of the correct use of the tools and any

particular safety issues that need to be observed or recognized.

4.1 Marking, graphical symbols and information to the users

It is essential for the safety of the user to have a clear meaning of the marking, including

graphical symbols.

– 8 – 61477 © IEC:2009

The items of marking shall be clearly and durably legible. They shall not impair the

performance of the tool, particularly its insulating properties, if any.

This subclause applies to the tools considered as final products, and not to the raw material

they are made of. According to that, it is considered inappropriate to mark the raw material

with the double triangle.

Tools for which compliance with any IEC standard dealing with live working is claimed, shall

be indicated by the following marking, as a minimum:

– symbol IEC 60417-5216 (2002-10) – Suitable for live working; double triangle;

– number of the relevant IEC standard immediately adjacent to the symbol (IEC 6XXXX).

NOTE 1 The symbol indicates a suitability for live working (see IEV 651-01-01) and then is not to be associated

only with insulating tools. Conductive clothing (IEC 60895) and arc protective clothing (IEC 61482-2) are suitable

for live working.

NOTE 2 Portable equipment and separate components for earthing or earthing and short-circuiting (IEC 61230)

are not marked with this symbol.

Limit or rated values, such as the working load of any lifting equipment, and special properties

or categories shall also be clearly indicated, where these values or indications are needed for

a proper selection of the tool.

Identification of the tools can be completed through other means than marking, such as coded

information (bar codes, microchips, etc.), or be associated to its packaging. It shall be

particularly the case of characteristics or information not needed on the work location.

4.2 Dimensions and weight

The physical characteristics of the tools shall be assessed in order to take account of the

implications for safety when in use. These characteristics are as follows:

• the weight of the tools to be handled by the workers, in particular those tools likely to be

used at a distance during work, such as universal tool attachments, insulating poles,

blankets and protective covers (see IEC 60743);

• the dimension(s) of the parts providing the required insulation level (for example, the

distance between the handling zone and the active end of the tool, the boundaries of

surface on protective covers which provide the required protection);

• the dimension(s) of the conductive parts which may enter the live working zone.

The last item is particularly useful because it has an influence on the air gap strength.

4.3 Electrical characteristics

The user of tools needs to know and understand the electrical characteristics of the various

parts comprising the tools being used. This is especially important for parts which provide

insulating, insulated or conductive characteristics.

In this regard, it is necessary to distinguish between:

• the insulating or insulated parts of a tool;

• the conductive parts of a tool.

Some tools may also comprise parts made of non-conductive material which do not comply

with the requirements applicable to insulating material for live working. In this case, the

corresponding tool shall ensure the required insulation level and consequently shall not affect

adversely the electrical insulation at work location.

61477 © IEC:2009 – 9 –

The tools shall be selected on the basis of its electrical characteristics. The electrical

characteristics of a tool are generally related to the maximum system voltage taking into

account the required insulation level. These characteristics may be used to allocate the tool to

a particular electrical classification, according to the live working product standards.

NOTE Long insulating tools such as insulating poles are generally selected in order to maintain suitable air

distances to live parts; therefore, they do not need the kind of classification as explained above.

Limit values for the maximum levels of voltage to which tools should be exposed shall be

given in clear terms in the instructions for use accompanying the tools or be clearly marked

on the tools.

4.4 Mechanical characteristics

The following mechanical characteristics are particularly important for tools with primarily a

mechanical function.

These characteristics represent the maximum mechanical stress and strain values which can

be either transmitted by these tools or to which they can be subjected. These stresses and

strains can arise from one or more of the following:

• traction;

• compression;

• bending;

• torsion;

• tightening torque;

• shearing.

For other categories of tools, protective equipment in particular, the characteristics of

mechanical strength such as

• puncture resistance;

• cutting resistance;

• tear resistance;

• tensile strength and elongation at break;

• abrasive resistance, etc.

are also important.

4.5 Thermal characteristics

Live working tools are used in an electrical environment where thermal risks may arise, for

instance:

• due to proximity of workers where electrical arcing in air can occur; or

• from melting of protective equipment when subjected to abnormal current conditions in the

system.

When appropriate, tools shall comply with flame retardancy requirements, they shall guaranty

that they do not aggravate the consequence of electrical arcs or comply with other kinds of

thermal requirements.

5 Conditions of use

The following information is essential for anyone who uses live working tools:

– 10 – 61477 © IEC:2009

• the operating range, characterized by the type of electrical installations on which it can be

used or the limits of use related to the environment or the method of work;

• the verifications before use to ensure the integrity (electrical and mechanical) of the tool;

• the precautions to be observed during use.

5.1 Operating range

5.1.1 Type of installations and limits of use

The characterization of the electrical installations can be very general:

• overhead lines;

• substations;

• underground networks;

• power generation facilities.

A much more detailed description is needed in many cases. This may include for example:

• type of live parts to be worked on (for instance, use of protective covers);

• type of support (for instance, use of saddles);

• type of insulator (porcelain, toughened glass, composite).

Where tools have been designed to be only used either at a distance, at potential or in

contact, it is vital that these limitations and constraints be clearly explained to the users.

Where tools using special techniques are used (e.g. sprayed-water cleaning, work from a

helicopter, etc.), the limits and constraints of use shall be clearly explained to the users.

5.1.2 Environment

Where the characteristics of the tools are either limited or adversely influenced by the

environmental conditions during use, such limitations and influences shall be explained to the

users. The following points shall be taken into consideration (this listing is neither exhaustive

nor in order of priority):

• precipitation;

• temperature (some materials suffer adverse mechanical change with very low or very high

temperatures);

• altitude;

• fog.

5.2 Precautions for use

It is important that the user be familiar with the following points:

• the instructions for assembly and installation;

• the instructions for operation where necessary;

• the particular limits to be observed in use to prevent danger.

When the tool is a diagnostic device, it is important that the user be informed of:

• the functioning principle;

• the possible limitations of use due to this principle;

• ways to confirm the diagnostic, where necessary.

61477 © IEC:2009 – 11 –

5.3 Verifications before use

Each time the tools are used, they shall first be subjected to a verification check in order to

assure the user of their required electrical and mechanical integrity. This verification shall

include the following features:

• that they have suffered no damage when being put into storage or transported (e.g.

insulating surfaces are not damaged by holes, flaking, scratches and cracks);

• that they are clean;

• that they are complete where assembled from separated or detachable parts;

• that they work correctly (e.g. mechanisms are free without restriction or seizure, latches

function correctly, etc.).

In the case of diagnostic devices, a built-in testing unit shall be supplied in order to verify the

device before and after use.

6 Conditions for maintenance

During their working life, tools undergo wear and tear which may alter their design

characteristics. Designers and manufacturers of these tools shall provide information to users

concerning the measures necessary to maintain and, where necessary, restore these

characteristics to the design and manufacturing values. The measures to be taken will

strongly depend upon the construction features and materials used and cannot be described

in the present standard. Nevertheless, some general guidance can be given concerning

cleaning and repair.

In addition, conditions for maintenance includes the periodic checks and verifications that are

carried out to ensure that the electrical and mechanical characteristics are maintained or

properly restored.

6.1 Cleaning

Insulating characteristics and, in some cases, the mechanical functioning of tools, can be

adversely affected by contamination and soiling. Users shall be instructed in the use of

appropriate cleaning materials and techniques.

The cleaning materials shall ensure a correct removal of dirt, grime and contamination

deposits commonly encountered during use. Such dirt, grime and contamination is mainly

composed of greasy products and solid particles (including sand, soil and metallic dusts),

some of which are likely to be conductive.

These cleaning products shall not cause deterioration of the tools nor adversely affect the

insulating surfaces and shall comply with the applicable environmental protection

requirements.

The cleaning procedures shall include the following:

• a full description of the cleaning operation which may include, where necessary, rinsing

and drying operations;

• recommended frequency of cleaning operations (all insulating or insulated tools shall be

cleaned after each use and before being put into storage).

A practice is to cover the insulating surfaces of tools, after cleaning, with a water-repellent

coating; in this case, users shall be instructed in the use of this practice, in compliance with

the first paragraph of 6.1.

– 12 – 61477 © IEC:2009

6.2 Periodic checks and verifications

Periodic checks and verifications provide an assurance of the effectiveness of the

maintenance procedures being implemented for tools used for live working.

These checks and verifications generally include visual, electrical and mechanical inspections

and tests.

These checks and verifications shall be derived from the tests set out in the relevant

standards for the tools concerned. It may be necessary to modify some of these test values

as these are drafted to take account of degradation due to ageing and use. The advice and

guidance of the manufacturer should be sought concerning the appropriate test values.

As visual inspections are subjective by nature, its is recommended that examples of typical

and unacceptable deterioration be given to the inspecting staff in the suitable form, for

comparison purposes with the tools being inspected.

The periodicity of inspections shall be defined in conjunction with the advice and guidance

from the manufacturer of the tool. The following factors shall also be taken into account when

deciding on periodicity:

• ageing of the tool, depending on the constructional features and materials used;

• wear and tear taking place in normal use;

• frequency of use.

It is acknowledged that tools used for live working on low-voltage installations (below

1 kV r.m.s.) do not need regular electrical testing to verify their insulating properties, unless

otherwise specified. This is because of the margins provided by the levels of dielectric

strength employed in their design. Visual inspections of these tools provide a sufficient

verification of their characteristics.

6.3 Repair

It is important that users be familiar with the kinds of repair which may need to be carried out.

These repairs are generally carried out to restore required characteristics and may be

effected:

• by the manufacturer (or the supplier); or

• by the user.

In the latter case, it is recommended that instructions be provided by the manufacturer, to

ensure that repair operations are carried out under the correct conditions.

Such instructions shall include the following:

• details of products to be used for repair work;

• details of storage conditions, in particular temperature limits and maximum storage

periods for the products;

• how the products shall be used, in particular the methods for preparation and application;

• environmental conditions in which the repair shall take place;

• repair procedures, specifying the various steps, preparation, application and verification.

NOTE The decision-making process whether or not to repair tools takes into account regulatory, economical and

technical factors. These factors are specific to each tool so that it is not possible in this standard to give guidance

or general criteria for this process.

When decision is not to repair, recycling and disposal shall be processed in environmentally

safe conditions.

61477 © IEC:2009 – 13 –

7 Conditions for storage and transportation

The required characteristics of the tools can be adversely affected by incorrect storage and

transportation.

When deciding how and where to store tools, account shall be taken of all the factors,

including environmental factors, which may adversely affect them. Such factors, depending on

the constructional features and material used, can include:

• relative humidity, temperature (hot and cold), thermal radiation, ultra-violet radiation,

aggressive products including ozone;

• method of storage (long flexible objects, such as mats and blankets, deteriorate when

stored for a long time, either folded or compressed b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...