IEC 61003-1:2004

(Main)Industrial-process control systems - Instruments with analogue inputs and two-or multi-state outputs - Part 1: Methods of evaluating performance

Industrial-process control systems - Instruments with analogue inputs and two-or multi-state outputs - Part 1: Methods of evaluating performance

IEC 61003-1:2004 is applicable to pneumatic and electric industrial-process instruments using measured values that are continuous signals in accordance with IEC 60382, or IEC 60381-1. It is intended to specify uniform testing methods for performance evaluation of industrial-process instruments with analogue measured values and two- or multi-state outputs. This second edition cancels and replaces the first edition issued in 1991 and constitutes a technical revision. It takes into account the common standardized basis specified in the IEC 61298 series. This bilingual version (2014-01) corresponds to the monolingual English version, published in 2004-01.

Systèmes de commande de processus industriels - Instruments avec entrées analogiques et sorties à deux ou plusieurs états - Partie 1: Méthodes d'évaluation des performances

La CEI 61003-1:2004 est applicable aux instruments pneumatiques et électriques pour processus industriels utilisant des valeurs mesurées qui sont des signaux continus conformément à la CEI 60382 ou à la CEI 60381-1. Elle a pour objet de spécifier des méthodes d'essai uniformes pour l'évaluation des performances des instruments pour processus industriels avec valeurs mesurées analogiques et sorties à deux ou plusieurs états. Cette deuxième édition annule et remplace la première édition parue en 1991 et constitue une révision technique. Elle tient compte de la base commune normalisée spécifiée dans la série CEI 61298. La présente version bilingue (2014-01) correspond à la version anglaise monolingue publiée en 2004-01.

General Information

- Status

- Published

- Publication Date

- 27-Jan-2004

- Technical Committee

- SC 65B - Measurement and control devices

- Drafting Committee

- WG 6 - TC 65/SC 65B/WG 6

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 14-Jun-2016

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61003-1:2004 - "Industrial-process control systems - Instruments with analogue inputs and two‑ or multi‑state outputs - Part 1: Methods of evaluating performance" - defines uniform methods of evaluating performance for pneumatic and electric process instruments that accept continuous (analogue) measured values and provide two‑state or multi‑state outputs. This second edition (2004) replaces the 1991 edition and aligns test methods with the common basis in the IEC 61298 series. The standard is intended for manufacturers, users and independent testing bodies to verify performance claims and to guide consistent test programs.

Key topics and requirements

- Scope and applicability

- Applies to instruments using continuous signals per IEC 60382 or IEC 60381‑1 (pneumatic and DC analogue signals).

- Covers devices used as controllers or as switches (alarms, interlocks) with two‑state or multi‑state outputs.

- Excludes instruments with feedback and does not address electronic security issues.

- General test conditions

- Requirements for documentary information, safety, installation and supply conditions to be considered during evaluation.

- Emphasis on manufacturer-supplied documentation (installation, commissioning, maintenance, spare parts).

- Performance test procedures

- Tests under reference conditions and tests for the effects of influence quantities (environmental and supply variations).

- Procedures for checking pre‑delivery calibration, set point determination, switching points, switching differential (Xsd), mean switching point, and, for multi‑state devices, switching range.

- Multi‑state instruments

- Definitions and methods to evaluate n‑state outputs, mutual influence between switching points and overall switching range.

- Reporting and observations

- Content and format expectations for test reports and summary of tests.

- Notes on protective finishes, design features, tools/equipment, maintenance and repair considerations.

Applications and practical value

- Provides a repeatable, internationally recognized method to:

- Verify manufacturer performance specifications for two‑state and multi‑state instruments.

- Support product development, factory acceptance testing and third‑party certification.

- Evaluate switching behavior used in alarms, safety interlocks, and on/off control loops in process plants.

- Useful in sectors such as chemical, oil & gas, power generation, water treatment and manufacturing where robust switching and alarm performance are critical.

Who should use this standard

- Instrument manufacturers designing and certifying analogue‑input, multi‑state output devices.

- Independent testing laboratories and conformity assessment bodies.

- Plant engineers, procurement specialists and system integrators who need objective performance data for selection and acceptance testing.

Related standards

- IEC 61298 series (Parts 1–4) - general methods and procedures for evaluating performance

- IEC 60381‑1, IEC 60382 - analogue signal standards for process control

- IEC 61010‑1 - safety requirements for measurement and control equipment

- IEC 61326 - EMC requirements

- IEC 60050‑351 - IEV terms for automatic control

Keywords: IEC 61003-1, industrial-process control systems, analogue inputs, two-state outputs, multi-state outputs, methods of evaluating performance, switching differential, switching point, IEC 61298.

IEC 61003-1:2004 - Industrial-process control systems - Instruments with analogue inputs and two-or multi-state outputs - Part 1: Methods of evaluating performance Released:1/28/2004 Isbn:2831873967

IEC 61003-1:2004 - Industrial-process control systems - Instruments with analogue inputs and two-or multi-state outputs - Part 1: Methods of evaluating performance Released:1/28/2004 Isbn:9782832213261

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

IEC 61003-1:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Industrial-process control systems - Instruments with analogue inputs and two-or multi-state outputs - Part 1: Methods of evaluating performance". This standard covers: IEC 61003-1:2004 is applicable to pneumatic and electric industrial-process instruments using measured values that are continuous signals in accordance with IEC 60382, or IEC 60381-1. It is intended to specify uniform testing methods for performance evaluation of industrial-process instruments with analogue measured values and two- or multi-state outputs. This second edition cancels and replaces the first edition issued in 1991 and constitutes a technical revision. It takes into account the common standardized basis specified in the IEC 61298 series. This bilingual version (2014-01) corresponds to the monolingual English version, published in 2004-01.

IEC 61003-1:2004 is applicable to pneumatic and electric industrial-process instruments using measured values that are continuous signals in accordance with IEC 60382, or IEC 60381-1. It is intended to specify uniform testing methods for performance evaluation of industrial-process instruments with analogue measured values and two- or multi-state outputs. This second edition cancels and replaces the first edition issued in 1991 and constitutes a technical revision. It takes into account the common standardized basis specified in the IEC 61298 series. This bilingual version (2014-01) corresponds to the monolingual English version, published in 2004-01.

IEC 61003-1:2004 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control; 35.240.50 - IT applications in industry. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61003-1:2004 has the following relationships with other standards: It is inter standard links to IEC 61003-1:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61003-1:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 61003-1

Second edition

2004-01

Industrial-process control systems –

Instruments with analogue inputs and

two- or multi-state outputs –

Part 1:

Methods of evaluating performance

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 61003-1

Second edition

2004-01

Industrial-process control systems –

Instruments with analogue inputs and

two- or multi-state outputs –

Part 1:

Methods of evaluating performance

IEC 2004 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale U

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

– 2 – 61003-1 IEC:2004(E)

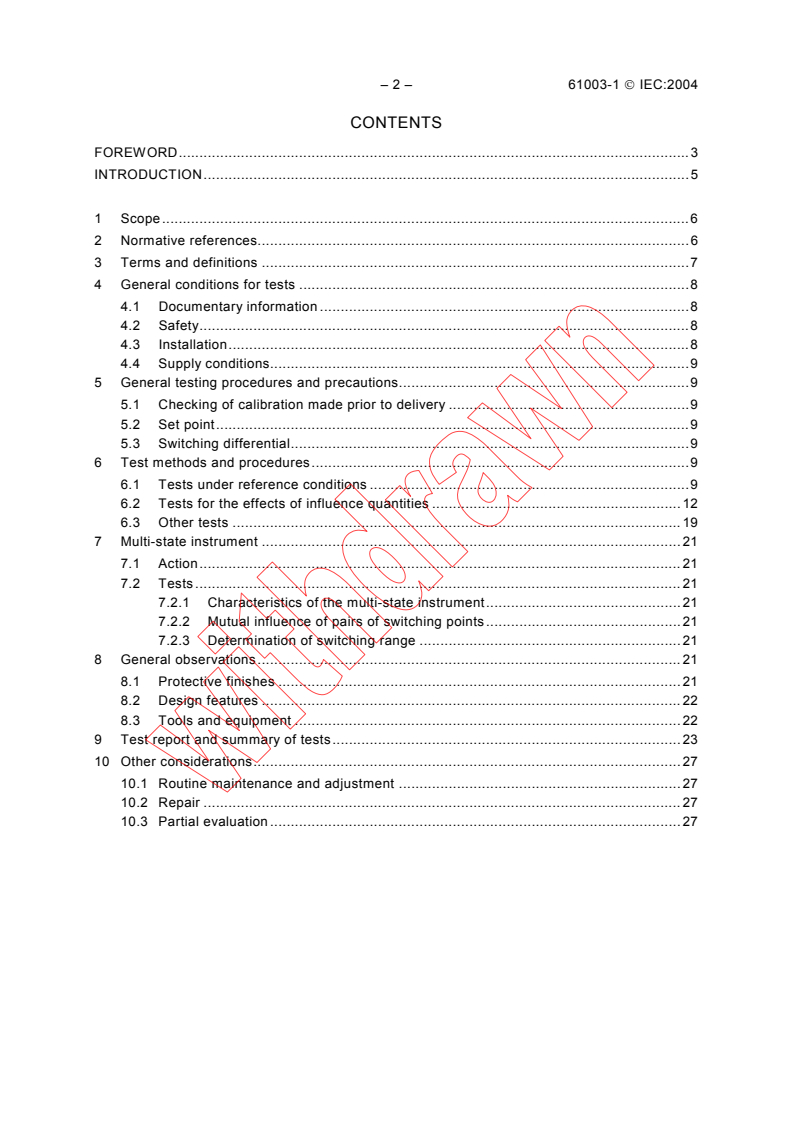

CONTENTS

FOREWORD.3

INTRODUCTION.5

1 Scope.6

2 Normative references.6

3 Terms and definitions .7

4 General conditions for tests .8

4.1 Documentary information.8

4.2 Safety.8

4.3 Installation.8

4.4 Supply conditions.9

5 General testing procedures and precautions.9

5.1 Checking of calibration made prior to delivery .9

5.2 Set point.9

5.3 Switching differential.9

6 Test methods and procedures.9

6.1 Tests under reference conditions .9

6.2 Tests for the effects of influence quantities .12

6.3 Other tests.19

7 Multi-state instrument.21

7.1 Action.21

7.2 Tests.21

7.2.1 Characteristics of the multi-state instrument.21

7.2.2 Mutual influence of pairs of switching points.21

7.2.3 Determination of switching range .21

8 General observations.21

8.1 Protective finishes.21

8.2 Design features.22

8.3 Tools and equipment .22

9 Test report and summary of tests.23

10 Other considerations.27

10.1 Routine maintenance and adjustment .27

10.2 Repair.27

10.3 Partial evaluation.27

61003-1 © IEC:2004(E) – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

INDUSTRIAL-PROCESS CONTROL SYSTEMS –

INSTRUMENTS WITH ANALOGUE INPUTS AND

TWO- OR MULTI-STATE OUTPUTS –

Part 1: Methods of evaluating performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61003-1 has been prepared by subcommittee 65B: Devices, of IEC

technical committee 65: Industrial-process measurement and control.

This second edition cancels and replaces the first edition issued in 1991 and constitutes a

technical revision. It takes into account the common standardized basis specified in the IEC

61298 series. Any test method or procedure specified and described herein is referred to the

corresponding Clause of the IEC 61298 series. Any particular method or procedure not covered

by the IEC 61298 series is developed and specified in this standard in accordance with the

criteria stated in the IEC 61298 series, as far as they are applicable.

– 4 – 61003-1 IEC:2004(E)

The text of this standard is based on the following documents:

FDIS Report on voting

65B/516/FDIS 65B/524/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

2012. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

61003-1 © IEC:2004(E) – 5 –

INTRODUCTION

The methods of evaluation specified in this part of IEC 61003 are intended for use by

manufacturers to determine the performance of their products and by users, or independent

testing establishments, to verify the manufacturer's performance specifications.

The test conditions in this standard, for example the range of ambient temperatures and power

supply, represent those, which commonly arise in use. Consequently, the values specified

herein shall be used where the manufacturer specifies no other values.

The tests specified in this standard are not necessarily sufficient for instruments specifically

designed for unusually arduous duties. Conversely, a restricted series of tests may be suitable

for instruments designed to perform within a more limited range of conditions.

It will be appreciated that the closest communication should be maintained between the

evaluating body and the manufacturer. Note shall be taken of the manufacturer's specifications

for the instrument, when the test programme is being decided, and the manufacturer should be

invited to comment on both the test programme and the results. His comments on the results

should be included in any report produced by the testing organisation.

– 6 – 61003-1 IEC:2004(E)

INDUSTRIAL-PROCESS CONTROL SYSTEMS –

INSTRUMENTS WITH ANALOGUE INPUTS AND

TWO- OR MULTI-STATE OUTPUTS –

Part 1: Methods of evaluating performance

1 Scope

This part of IEC 61003 is applicable to pneumatic and electric industrial-process instruments

using measured values that are continuous signals in accordance with IEC 60382, or IEC

60381-1. The other input value (i.e. the set point value) may be either a mechanical (position,

force, etc.) or a standard signal.

It should be noted that tests specified herein may be applied to instruments which have other

continuous measured values, provided that due allowance is made for such differences.

These instruments may be used as controllers or as switches for alarm and other similar

purposes.

Instruments with feedback are not covered by this standard.

Electronic security issues may impact only a few products covered by this document.

Consequently this document does not address such security issues.

This standard is intended to specify uniform testing methods for performance evaluation of

industrial-process instruments with analogue measured values and two- or multi-state outputs.

Considerations other than the performances are listed in Clause 10.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60050-351:1998, International Electrotechnical Vocabulary (IEV) – Part 351 Automatic

control

IEC 60381-1:1982, Analogue signals for process control systems – Part 1: Direct current

signals

IEC 60382:1991, Analogue pneumatic signals for process control systems

IEC 61010-1:2001, Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

IEC 61298-1:1995, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 1: General considerations

IEC 61298-2:1995, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 2: Tests under reference conditions

61003-1 © IEC:2004(E) – 7 –

IEC 61298-3:1998, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 3: Tests for the effects of influence quantities

IEC 61298-4:1995, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 4: Evaluation report content

IEC 61326:2002, Electrical equipment for measurement, control and laboratory use – EMC

requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-351 and in

IEC 61298-1, IEC 61298-2, IEC 61298-3, IEC 61298-4, together with the following definitions

apply.

3.1

, x

switching point x

1 2

measured value (with the input moving either upscale or downscale), at which the output (y)

changes from one state to another

3.2

two-state instrument

action illustrated in Figure 1, where x is the value of the input variable and y is the value of the

output signal.

The two-state instrument, having one pair of switching points x and x (x greater than x ) has

1 2 2 1

the relationships:

for x < x

y = y

1 1

y = y for x > x

2 2

For x < x < x y may be either y or y .

1 2, 1 2

It is y if the last switching point crossed by x was x .

1 1

It is y if the last switching point crossed by x was x .

2 2

3.3

multi-state instrument

a multi-state instrument (see Clause 7 and Figure 4) has n possible output values and n-1 pairs

of switching points. Each pair of switching points may be investigated by the procedure given

for the two-state instrument.

3.4

switching differential X

sd

difference between the switching point x with the measured value moving upscale and the

switching point x with the measured value moving downscale

3.5

instrument with no switching differential

this is considered to be a special case where the switching differential approaches zero

3.6

mean switching point x

m

the mean of the values of upscale and downscale switching points

– 8 – 61003-1 IEC:2004(E)

3.7

switching range X

sr

in a multi-state instrument the range of measured values corresponding to the extreme

switching points

3.8

set point w (reference input variable)

the point (value) at which it is desired that switching (at x or x as specified) should occur

2 1

4 General conditions for tests

For the purpose of this standard the general test conditions (e.g. environmental test conditions,

supply conditions, load conditions, mounting position, externally induced vibrations, external

mechanical constraints, delivery of the instrument) specified in IEC 61298-1, Clause 6 apply,

together with the additional information below.

4.1 Documentary information

The manufacturer shall supply to the evaluating body information for installation,

commissioning, operation, routine maintenance and repair of the instrument. A spare parts list,

together with a recommendation of the spare parts to be held in stock, shall be supplied. The

language of written information for installation should be the language of the local user.

All the relevant publications supplied by the manufacturer, automatically and on request, should

be listed.

If they do not contain a clear description, with adequate diagrams, of the operation of the

instrument, or if they do not contain an adequate spare parts and specifications list, the nature

of the inadequacy should be noted.

Additionally, any certificates indicating the degree of intrinsic safety and flameproofing, etc. of

electrically powered instruments should be listed. This information should give details of the

certificate numbers and the degree of protection provided.

Procedures for installation, routine maintenance and adjustment, repairs and overhaul should

be examined by the actual performance of the required operation. This should be performed in

accordance with the manufacturer's instructions, so that an evaluation of the instructions can

be carried out concurrently.

4.2 Safety

Electrically powered instruments should be examined to determine the degree to which their

design protects them against accidental electric shock.

4.3 Installation

The instrument should be installed and set to work according to the manufacturer's

instructions, taking account of the various applications which may be met in practice and which

require different procedures.

The method of mounting specified by the manufacturer should be reported. Any restrictions on

the use of the instrument caused by this method of mounting shall be noted with explanations.

Any other aspects that may seem relevant to the ease or difficulty of installation should be

noted with explanations.

61003-1 © IEC:2004(E) – 9 –

4.4 Supply conditions

Tolerances on supply conditions for mains supplied equipment are given in 6.2.2 of IEC 61298-1.

For instruments with self-contained power supplies (e.g. battery-powered) the tolerances are

different and shall be agreed.

NOTE For pneumatic instrument care should be taken to ensure that pneumatic connections are leak tight.

5 General testing procedures and precautions

For the purpose of this standard, the general testing procedures and precautions, specified in

Clause 7 of IEC 61298-1, shall be applied, together with the additional information below.

5.1 Checking of calibration made prior to delivery

The input-output characteristic that shall be checked (see 7.6 of IEC 61298-1) is the values of

the switching points x and x found during the calibration (if any) made prior to delivery.

1 2

5.2 Set point

Except where otherwise specified, the set point shall be set to the midscale value or, where no

scale is provided, to the middle of the effective range of adjustment.

5.3 Switching differential

Except where otherwise specified, if the switching differential X is adjustable, it shall be set

sd

to the midscale value or, where no scale is provided, to the middle of the effective range of

adjustment.

6 Test methods and procedures

For the purpose of this standard, the tests general methods and procedures – if any – specified

in IEC 61298-2 and IEC 61298-3 apply, together with the additional information stated below.

6.1 Tests under reference conditions

Methods and procedures for each test are described in the last column of the following table.

In the others column are indicated:

– Clause N° and designation of test;

– Clause number of the reference where the general procedures are specified.

– 10 – 61003-1 IEC:2004(E)

Clause and Designation Reference Test methods and procedures description

6.1.1 Switching accuracy IEC 61298-2 The input measured value x shall be varied

related factors slowly at least five times in each direction

4.1.7

through its entire range. By observation of the

output, the values of points x and x and their

1 2

average shall be determined.

For each cycle, the switching differential (x –

x ) shall be noted.

6.1.1.1 Inaccuracy of IEC 61298-2 Switching point inaccuracy is determined by

selecting the greatest positive and negative

switching points

4.1.7.1

deviations of any measured value of x and x ,

1 2

of any cycle, from the set point w for increasing

and decreasing inputs and reporting this in

percent of nominal span of measured value.

6.1.1.2 Non-repeatability of IEC 61298-2 Non-repeatability shall be computed observing

the maximum difference, in percent of nominal

switching points

4.1.7.6

span of measured value, among all x values

and among all x values.

The maximum value, from either the x

maximum difference or the x maximum

difference, is reported as non-repeatability.

6.1.1.3 Inaccuracy of IEC 61298-2 The switching differential X is calculated by

sd

subtracting the average value of x from the

switching

4.1.7.1

average value of x (see 6.1.1).

differential

Switching differential inaccuracy is determined

by selecting the greatest positive and negative

deviations of any measured value of the

switching differentials – calculated in each of

the five cycles – from the X value and

sd

reporting this in percent of the nominal span of

measured value.

6.1.1.4 Non-repeatability of IEC 61298-2 Non-repeatability shall be computed calculating

the differences, in percent of the nominal span

switching

4.1.7.6

of measured value, among all switching

differential

differential values noted in 6.1.1.

The maximum of those values is reported as

non-repeatability of switching differential.

6.1.2 Mean switching Mean switching point x is calculated as the

m

mean of the average values of x and x (see

point

1 2

6.1.1).

For the adjustment of set point value w, four

6.1.3 Set point

cases shall be considered:

1. a) w is an adjustable and directly

measurable value;

b) w is adjustable at the instrument and an

adjusting scale for w is provided;

2. w is adjustable at the instrument, but there

is no adjusting scale;

3. w is a pre-selected fixed value.

61003-1 © IEC:2004(E) – 11 –

Clause and Designation Reference Test methods and procedures description

6.1.3.1 Set point adjustable IEC 61298-2 Determine values of x x and X , and their

1, 2 sd

and measurable or accuracy-related factors, in accordance with

4.1.7.1 and

the test procedures in subclause 6.1.1, at least

indicated

4.1.7.6

for values of w of 10 %, 50 % and 90 %, the

50 % value being taken last.

Determine values of x , in accordance with the

m

test procedures in 6.1.2.

The inaccuracy of set point setting is

determined by selecting the greatest positive

and negative deviations of any measured value

of x from the ideal set-point value for each

m

cycle and for each set-point and reporting this

in percent of the nominal span of measured

value.

6.1.3.2 Set point adjustable IEC 61298-2 Determine values of x x and X , and their

1, 2 sd

accuracy-related factors, in accordance with

but not indicated

4.1.7.1 and

the test procedures in 6.1.1 and 6.1.2, and

4.1.7.6

values of x , in accordance with the test

m

procedures in 6.1.2.

Make this test, for at least three values of w,

approximately evenly spaced over the effective

range of adjustment, the approximately mid

value being taken last.

No determination of x -w is possible in this

m

case.

6.1.3.3 Set point not IEC 61298-2 Determine values of x x and X , and their

1, 2 sd

adjustable accuracy-related factors, in accordance with

4.1.7.1 and

the test procedures in 6.1.1 and 6.1.2, and

4.1.7.6

values of x , in accordance with the test

m

procedures in 6.1.2.

The inaccuracy of set point setting is

determined by selecting the greatest positive

and negative deviations of any measured value

of x from the value of w declared by the

m

manufacturer and reporting that in percent of

the nominal span of measured value.

NOTE For two-state instruments with non-symmetrically

adjustable switching differential (e.g. instruments where

x or x instead of x is intended to be equal to w) the

1 2 m

value of x – w or x – w instead of x -w should be taken

1 2 m

into account.

– 12 – 61003-1 IEC:2004(E)

6.2 Tests for the effects of influence quantities

Methods and procedures for each test are described in the last column of the following table.

In the others column are indicated:

– Clause N° and designation of test;

– Clause number of the reference where the general procedures are specified.

Clause and Designation Reference Test methods and procedures description

6.2.1 Ambient IEC 61298-3 The change in switching points shall be

determined at each test temperature

temperature

Clause 5

specified in 5.2 of IEC 61298-3. For example:

+20 °C (reference), +40 °C, +55 °C, +20 °C,

0 °C, –20 °C, +20 °C. After the first cycle, a

second temperature cycle, identical to the

first, shall be performed without readjustment

of the instrument.

For instruments with a pneumatic output the

air supply temperature shall be the same as

the instrument temperature.

6.2.2 Humidity IEC 61298-3 The test shall be performed for electrical

instruments only.

Clause 6

This test shall be performed according to the

methods and procedures stated in Clause 6

of IEC 61298-3, together with what is stated

below.

After the stabilisation at the reference relative

humidity and temperature, a set of reference

measurements shall be taken.

The power supply to the instrument shall be

switched off and the relative humidity shall be

increased as specified in Clause 6 of IEC

61298-3.

The instrument shall be switched on for the

final 4 h of the period in stable conditions and

the change in switching points shall be

measured immediately after this period.

As specified in Clause 6 of IEC 61298-3, the

relative humidity shall be reduced to the

original reference value and, after

stabilisation, the effect of this test on the

switching points shall be determined.

After this test, a visual inspection shall be

conducted to check for effects of flashover,

accumulation of condensation, deterioration

of components.

61003-1 © IEC:2004(E) – 13 –

Clause and Designation Reference Test methods and procedures description

6.2.3 Vibrations IEC 61298-3 a) During the frequency sweeping,

frequencies shall be noted, which cause

Clause 7

significant changes in the switching points or

spurious operation such as contact bounce.

NOTE In order to measure the effect of vibrations on

the switching behaviour, the sweeping shall be

performed with the measured variable input set above

the switching point x , or below the switching point x

2 1

to a distance that is twice the value of the switching

differential X , but not less than 1 % of nominal span

sd

of measured value.

If, during the sweeping, switching occurs, the

test shall be repeated with a larger difference

between measured value input and switching

point (at 0 Hz) until no switching is induced by

vibration.

The largest difference and the frequency, at

which the last switching occurred, are to be

noted.

b) Endurance conditioning by sweeping

7.3 of IEC 61298-3

The instrument shall be subjected to vibration

for ½ h in each of three mutually perpen-

dicular planes, one of which shall be the

vertical direction. In each plane, the test shall

be run at that frequency which resulted in the

largest mechanical resonance during the

initial resonance search, or if a resonance

was not detected, the vibration frequency

shall be swept continuously through the

whole frequency range being considered.

c) Final resonance search

7.4 of IEC 61298-3

The resonance frequencies and the

frequencies which cause significant changes

in the switching points found in the initial

resonance search and the final resonance

search shall be compared. Difference can be

caused by non-elastic deformation, which

may lead to the origination of cracks in the

mechanical construction.

d) Final measurement

7.5 of IEC 61298-3

The satisfactory mechanical condition of the

instrument shall be verified at the end of the

test. Any change of switching points shall be

noted. If the instrument has a mechanical set

point, determine whether vibration has shifted

the set point.

– 14 – 61003-1 IEC:2004(E)

Clause and Designation Reference Test methods and procedures description

6.2.4 Shock, drop and IEC 61298-3 This test shall be performed according to the

methods and procedures stated in Clause 8

topple

Clause 8

of IEC 61298-3, together with what is stated

below.

Before the test, a reference measurement of

switching points shall be recorded.

After the test any change in switching points

shall be recorded.

6.2.5 Mounting position IEC 61298-3 The change in switching points caused by

±10° inclinations from the reference position

Clause 9

of the instrument shall be determine

...

IEC 61003-1 ®

Edition 2.0 2004-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Industrial-process control systems – Instruments with analogue inputs and two-

or multi-state outputs –

Part 1: Methods of evaluating performance

Systèmes de commande de processus industriels – Instruments avec entrées

analogiques et sorties à deux ou plusieurs états –

Partie 1: Méthodes d’évaluation des performances

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61003-1 ®

Edition 2.0 2004-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Industrial-process control systems – Instruments with analogue inputs and two-

or multi-state outputs –

Part 1: Methods of evaluating performance

Systèmes de commande de processus industriels – Instruments avec entrées

analogiques et sorties à deux ou plusieurs états –

Partie 1: Méthodes d’évaluation des performances

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

V

CODE PRIX

ICS 25.040.40; 35.240.50 ISBN 978-2-8322-1326-1

– 2 – 61003-1 IEC:2004

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references. 6

3 Terms and definitions . 7

4 General conditions for tests . 8

4.1 Documentary information . 8

4.2 Safety . 8

4.3 Installation . 8

4.4 Supply conditions. 9

5 General testing procedures and precautions. 9

5.1 Checking of calibration made prior to delivery . 9

5.2 Set point . 9

5.3 Switching differential . 9

6 Test methods and procedures . 9

6.1 Tests under reference conditions . 9

6.2 Tests for the effects of influence quantities . 12

6.3 Other tests . 19

7 Multi-state instrument . 21

7.1 Action . 21

7.2 Tests . 21

7.2.1 Characteristics of the multi-state instrument . 21

7.2.2 Mutual influence of pairs of switching points . 21

7.2.3 Determination of switching range . 21

8 General observations . 21

8.1 Protective finishes . 21

8.2 Design features . 22

8.3 Tools and equipment . 22

9 Test report and summary of tests . 23

10 Other considerations . 27

10.1 Routine maintenance and adjustment . 27

10.2 Repair . 27

10.3 Partial evaluation . 27

61003-1 © IEC:2004 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

INDUSTRIAL-PROCESS CONTROL SYSTEMS –

INSTRUMENTS WITH ANALOGUE INPUTS AND

TWO- OR MULTI-STATE OUTPUTS –

Part 1: Methods of evaluating performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61003-1 has been prepared by subcommittee 65B: Devices, of IEC

technical committee 65: Industrial-process measurement and control.

This second edition cancels and replaces the first edition issued in 1991 and constitutes a

technical revision. It takes into account the common standardized basis specified in the IEC

61298 series. Any test method or procedure specified and described herein is referred to the

corresponding Clause of the IEC 61298 series. Any particular method or procedure not covered

by the IEC 61298 series is developed and specified in this standard in accordance with the

criteria stated in the IEC 61298 series, as far as they are applicable.

This bilingual version (2014-01) corresponds to the monolingual English version, published in

2004-01.

– 4 – 61003-1 IEC:2004

The text of this standard is based on the following documents:

FDIS Report on voting

65B/516/FDIS 65B/524/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

2012. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

61003-1 © IEC:2004 – 5 –

INTRODUCTION

The methods of evaluation specified in this part of IEC 61003 are intended for use by

manufacturers to determine the performance of their products and by users, or independent

testing establishments, to verify the manufacturer's performance specifications.

The test conditions in this standard, for example the range of ambient temperatures and power

supply, represent those, which commonly arise in use. Consequently, the values specified

herein shall be used where the manufacturer specifies no other values.

The tests specified in this standard are not necessarily sufficient for instruments specifically

designed for unusually arduous duties. Conversely, a restricted series of tests may be suitable

for instruments designed to perform within a more limited range of conditions.

It will be appreciated that the closest communication should be maintained between the

evaluating body and the manufacturer. Note shall be taken of the manufacturer's specifications

for the instrument, when the test programme is being decided, and the manufacturer should be

invited to comment on both the test programme and the results. His comments on the results

should be included in any report produced by the testing organisation.

– 6 – 61003-1 IEC:2004

INDUSTRIAL-PROCESS CONTROL SYSTEMS –

INSTRUMENTS WITH ANALOGUE INPUTS AND

TWO- OR MULTI-STATE OUTPUTS –

Part 1: Methods of evaluating performance

1 Scope

This part of IEC 61003 is applicable to pneumatic and electric industrial-process instruments

using measured values that are continuous signals in accordance with IEC 60382, or IEC

60381-1. The other input value (i.e. the set point value) may be either a mechanical (position,

force, etc.) or a standard signal.

It should be noted that tests specified herein may be applied to instruments which have other

continuous measured values, provided that due allowance is made for such differences.

These instruments may be used as controllers or as switches for alarm and other similar

purposes.

Instruments with feedback are not covered by this standard.

Electronic security issues may impact only a few products covered by this document.

Consequently this document does not address such security issues.

This standard is intended to specify uniform testing methods for performance evaluation of

industrial-process instruments with analogue measured values and two- or multi-state outputs.

Considerations other than the performances are listed in Clause 10.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60050-351:1998, International Electrotechnical Vocabulary (IEV) – Part 351 Automatic

control

IEC 60381-1:1982, Analogue signals for process control systems – Part 1: Direct current

signals

IEC 60382:1991, Analogue pneumatic signals for process control systems

IEC 61010-1:2001, Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

IEC 61298-1:1995, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 1: General considerations

IEC 61298-2:1995, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 2: Tests under reference conditions

61003-1 © IEC:2004 – 7 –

IEC 61298-3:1998, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 3: Tests for the effects of influence quantities

IEC 61298-4:1995, Process measurement and control devices – General methods and

procedures for evaluating performance – Part 4: Evaluation report content

IEC 61326:2002, Electrical equipment for measurement, control and laboratory use – EMC

requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-351 and in

IEC 61298-1, IEC 61298-2, IEC 61298-3, IEC 61298-4, together with the following definitions

apply.

3.1

switching point x , x

1 2

measured value (with the input moving either upscale or downscale), at which the output (y)

changes from one state to another

3.2

two-state instrument

action illustrated in Figure 1, where x is the value of the input variable and y is the value of the

output signal.

The two-state instrument, having one pair of switching points x and x (x greater than x ) has

1 2 2 1

the relationships:

y = y for x < x

1 1

y = y for x > x

2 2

< x < x y may be either y or y .

For x

1 2, 1 2

It is y if the last switching point crossed by x was x .

1 1

It is y if the last switching point crossed by x was x .

2 2

3.3

multi-state instrument

a multi-state instrument (see Clause 7 and Figure 4) has n possible output values and n-1 pairs

of switching points. Each pair of switching points may be investigated by the procedure given

for the two-state instrument.

3.4

switching differential X

sd

difference between the switching point x with the measured value moving upscale and the

switching point x with the measured value moving downscale

3.5

instrument with no switching differential

this is considered to be a special case where the switching differential approaches zero

3.6

mean switching point x

m

the mean of the values of upscale and downscale switching points

– 8 – 61003-1 IEC:2004

3.7

switching range X

sr

in a multi-state instrument the range of measured values corresponding to the extreme

switching points

3.8

set point w (reference input variable)

the point (value) at which it is desired that switching (at x or x as specified) should occur

2 1

4 General conditions for tests

For the purpose of this standard the general test conditions (e.g. environmental test conditions,

supply conditions, load conditions, mounting position, externally induced vibrations, external

mechanical constraints, delivery of the instrument) specified in IEC 61298-1, Clause 6 apply,

together with the additional information below.

4.1 Documentary information

The manufacturer shall supply to the evaluating body information for installation,

commissioning, operation, routine maintenance and repair of the instrument. A spare parts list,

together with a recommendation of the spare parts to be held in stock, shall be supplied. The

language of written information for installation should be the language of the local user.

All the relevant publications supplied by the manufacturer, automatically and on request, should

be listed.

If they do not contain a clear description, with adequate diagrams, of the operation of the

instrument, or if they do not contain an adequate spare parts and specifications list, the nature

of the inadequacy should be noted.

Additionally, any certificates indicating the degree of intrinsic safety and flameproofing, etc. of

electrically powered instruments should be listed. This information should give details of the

certificate numbers and the degree of protection provided.

Procedures for installation, routine maintenance and adjustment, repairs and overhaul should

be examined by the actual performance of the required operation. This should be performed in

accordance with the manufacturer's instructions, so that an evaluation of the instructions can

be carried out concurrently.

4.2 Safety

Electrically powered instruments should be examined to determine the degree to which their

design protects them against accidental electric shock.

4.3 Installation

The instrument should be installed and set to work according to the manufacturer's

instructions, taking account of the various applications which may be met in practice and which

require different procedures.

The method of mounting specified by the manufacturer should be reported. Any restrictions on

the use of the instrument caused by this method of mounting shall be noted with explanations.

Any other aspects that may seem relevant to the ease or difficulty of installation should be

noted with explanations.

61003-1 © IEC:2004 – 9 –

4.4 Supply conditions

Tolerances on supply conditions for mains supplied equipment are given in 6.2.2 of IEC 61298-1.

For instruments with self-contained power supplies (e.g. battery-powered) the tolerances are

different and shall be agreed.

NOTE For pneumatic instrument care should be taken to ensure that pneumatic connections are leak tight.

5 General testing procedures and precautions

For the purpose of this standard, the general testing procedures and precautions, specified in

Clause 7 of IEC 61298-1, shall be applied, together with the additional information below.

5.1 Checking of calibration made prior to delivery

The input-output characteristic that shall be checked (see 7.6 of IEC 61298-1) is the values of

and x found during the calibration (if any) made prior to delivery.

the switching points x

1 2

5.2 Set point

Except where otherwise specified, the set point shall be set to the midscale value or, where no

scale is provided, to the middle of the effective range of adjustment.

5.3 Switching differential

Except where otherwise specified, if the switching differential X is adjustable, it shall be set

sd

to the midscale value or, where no scale is provided, to the middle of the effective range of

adjustment.

6 Test methods and procedures

For the purpose of this standard, the tests general methods and procedures – if any – specified

in IEC 61298-2 and IEC 61298-3 apply, together with the additional information stated below.

6.1 Tests under reference conditions

Methods and procedures for each test are described in the last column of the following table.

In the others column are indicated:

– Clause N° and designation of test;

– Clause number of the reference where the general procedures are specified.

– 10 – 61003-1 IEC:2004

Clause and Designation Reference Test methods and procedures description

6.1.1 Switching accuracy IEC 61298-2 The input measured value x shall be varied

related factors slowly at least five times in each direction

4.1.7

through its entire range. By observation of the

output, the values of points x and x and their

1 2

average shall be determined.

For each cycle, the switching differential (x –

x ) shall be noted.

6.1.1.1 Inaccuracy of IEC 61298-2 Switching point inaccuracy is determined by

selecting the greatest positive and negative

switching points

4.1.7.1

deviations of any measured value of x and x ,

1 2

of any cycle, from the set point w for increasing

and decreasing inputs and reporting this in

percent of nominal span of measured value.

6.1.1.2 Non-repeatability of IEC 61298-2 Non-repeatability shall be computed observing

the maximum difference, in percent of nominal

switching points

4.1.7.6

span of measured value, among all x values

and among all x values.

The maximum value, from either the x

maximum difference or the x maximum

difference, is reported as non-repeatability.

6.1.1.3 Inaccuracy of IEC 61298-2 The switching differential X is calculated by

sd

subtracting the average value of x from the

switching

4.1.7.1

average value of x (see 6.1.1).

differential

Switching differential inaccuracy is determined

by selecting the greatest positive and negative

deviations of any measured value of the

switching differentials – calculated in each of

the five cycles – from the X value and

sd

reporting this in percent of the nominal span of

measured value.

6.1.1.4 Non-repeatability of IEC 61298-2 Non-repeatability shall be computed calculating

the differences, in percent of the nominal span

switching

4.1.7.6

of measured value, among all switching

differential

differential values noted in 6.1.1.

The maximum of those values is reported as

non-repeatability of switching differential.

is calculated as the

6.1.2 Mean switching Mean switching point x

m

mean of the average values of x and x (see

point

1 2

6.1.1).

For the adjustment of set point value w, four

6.1.3 Set point

cases shall be considered:

1. a) w is an adjustable and directly

measurable value;

b) w is adjustable at the instrument and an

adjusting scale for w is provided;

2. w is adjustable at the instrument, but there

is no adjusting scale;

3. w is a pre-selected fixed value.

61003-1 © IEC:2004 – 11 –

Clause and Designation Reference Test methods and procedures description

6.1.3.1 Set point adjustable IEC 61298-2 Determine values of x x and X , and their

1, 2 sd

and measurable or accuracy-related factors, in accordance with

4.1.7.1 and

the test procedures in subclause 6.1.1, at least

indicated

4.1.7.6

for values of w of 10 %, 50 % and 90 %, the

50 % value being taken last.

Determine values of x , in accordance with the

m

test procedures in 6.1.2.

The inaccuracy of set point setting is

determined by selecting the greatest positive

and negative deviations of any measured value

of x from the ideal set-point value for each

m

cycle and for each set-point and reporting this

in percent of the nominal span of measured

value.

6.1.3.2 Set point adjustable IEC 61298-2 Determine values of x x and X , and their

1, 2 sd

accuracy-related factors, in accordance with

but not indicated

4.1.7.1 and

the test procedures in 6.1.1 and 6.1.2, and

4.1.7.6

values of x , in accordance with the test

m

procedures in 6.1.2.

Make this test, for at least three values of w,

approximately evenly spaced over the effective

range of adjustment, the approximately mid

value being taken last.

No determination of x -w is possible in this

m

case.

6.1.3.3 Set point not IEC 61298-2 Determine values of x x and X , and their

1, 2 sd

accuracy-related factors, in accordance with

adjustable

4.1.7.1 and

the test procedures in 6.1.1 and 6.1.2, and

4.1.7.6

values of x , in accordance with the test

m

procedures in 6.1.2.

The inaccuracy of set point setting is

determined by selecting the greatest positive

and negative deviations of any measured value

of x from the value of w declared by the

m

manufacturer and reporting that in percent of

the nominal span of measured value.

NOTE For two-state instruments with non-symmetrically

adjustable switching differential (e.g. instruments where

x or x instead of x is intended to be equal to w) the

1 2 m

value of x – w or x – w instead of x -w should be taken

1 2 m

into account.

– 12 – 61003-1 IEC:2004

6.2 Tests for the effects of influence quantities

Methods and procedures for each test are described in the last column of the following table.

In the others column are indicated:

– Clause N° and designation of test;

– Clause number of the reference where the general procedures are specified.

Clause and Designation Reference Test methods and procedures description

6.2.1 Ambient IEC 61298-3 The change in switching points shall be

determined at each test temperature

temperature

Clause 5

specified in 5.2 of IEC 61298-3. For example:

+20 °C (reference), +40 °C, +55 °C, +20 °C,

0 °C, –20 °C, +20 °C. After the first cycle, a

second temperature cycle, identical to the

first, shall be performed without readjustment

of the instrument.

For instruments with a pneumatic output the

air supply temperature shall be the same as

the instrument temperature.

6.2.2 Humidity IEC 61298-3 The test shall be performed for electrical

instruments only.

Clause 6

This test shall be performed according to the

methods and procedures stated in Clause 6

of IEC 61298-3, together with what is stated

below.

After the stabilisation at the reference relative

humidity and temperature, a set of reference

measurements shall be taken.

The power supply to the instrument shall be

switched off and the relative humidity shall be

increased as specified in Clause 6 of IEC

61298-3.

The instrument shall be switched on for the

final 4 h of the period in stable conditions and

the change in switching points shall be

measured immediately after this period.

3, the

As specified in Clause 6 of IEC 61298-

relative humidity shall be reduced to the

original reference value and, after

stabilisation, the effect of this test on the

switching points shall be determined.

After this test, a visual inspection shall be

conducted to check for effects of flashover,

accumulation of condensation, deterioration

of components.

61003-1 © IEC:2004 – 13 –

Clause and Designation Reference Test methods and procedures description

6.2.3 Vibrations IEC 61298-3 a) During the frequency sweeping,

frequencies shall be noted, which cause

Clause 7

significant changes in the switching points or

spurious operation such as contact bounce.

NOTE In order to measure the effect of vibrations on

the switching behaviour, the sweeping shall be

performed with the measured variable input set above

the switching point x , or below the switching point x

2 1

to a distance that is twice the value of the switching

differential X , but not less than 1 % of nominal span

sd

of measured value.

If, during the sweeping, switching occurs, the

test shall be repeated with a larger difference

between measured value input and switching

point (at 0 Hz) until no switching is induced by

vibration.

The largest difference and the frequency, at

which the last switching occurred, are to be

noted.

b) Endurance conditioning by sweeping

7.3 of IEC 61298-3

The instrument shall be subjected to vibration

for ½ h in each of three mutually perpen-

dicular planes, one of which shall be the

vertical direction. In each plane, the test shall

be run at that frequency which resulted in the

largest mechanical resonance during the

initial resonance search, or if a resonance

was not detected, the vibration frequency

shall be swept continuously through the

whole frequency range being considered.

c) Final resonance search

7.4 of IEC 61298-3

The resonance frequencies and the

frequencies which cause significant changes

in the switching points found in the initial

resonance search and the final resonance

search shall be compared. Difference can be

caused by non-elastic deformation, which

may lead to the origination of cracks in the

mechanical construction.

d) Final measurement

7.5 of IEC 61298-3

The satisfactory mechanical condition of the

instrument shall be verified at the end of the

test. Any change of switching points shall be

noted. If the instrument has a mechanical set

point, determine whether vibration has shifted

the set point.

– 14 – 61003-1 IEC:2004

Clause and Designation Reference Test methods and procedures description

6.2.4 Shock, drop and IEC 61298-3 This test shall be performed according to the

methods and procedures stated in Clause 8

topple

Clause 8

of IEC 61298-3, together with what is stated

below.

Before the test, a reference measurement of

switching points shall be recorded.

After the test any change in switching points

shall be recorded.

6.2.5 Mounting position IEC 61298-3 The change in switching points caused by

±10° inclinations from the reference position

Clause 9

of the instrument shall be determined.

IEC 61298-3 This test shall be performed according to the

6.2.6 Over-range

methods and procedures stated in Clause 10

Clause 10

of IEC 61298-3, together with what is stated

below.

Under reference conditions, with set point at

50 % (if possible), set the measured value

signal to 50 % overload (i.e. to a value equal

to 150 % of upper range values) for 1 min.

The measured value signal shall then be set

to 50 % of span and, after 5 min, the change

in switching points shall be measured. For

instruments using elevated zero signals (e.g.

0,2 bar to 1,0 bar, 4 mA to 20 mA), the test

shall be repeated with measured value

signals set to 0 (actual zero, not lower range

values).

IEC 61298-3 The effect of the load on the instrument being

6.2.7 Output load effects

changed is determined by changing the value

Clause 11

of the energy source (voltage, frequency,

etc.) and changing the load of the instrument

within the permissible limits. Combinations of

values are to be selected, which provide the

largest and smallest loading for the switch.

6.2.8 Supply voltage and IEC 61298-3 This test shall be performed on instruments

with electrical power supply for internal

frequency

12.1

operations.

variations

The effect on switching points of the

variations in the electrical power supply,

indicated in 12.1 of IEC 61298-3, shall be

measured, the load impedance being as

specified in 6.3 of IEC 61298-1.

61003-1 © IEC:2004 – 15 –

Clause and Designation Reference Test methods and procedures description

6.2.9 Short-term supply IEC 61298-3 The test shall be performed as in 12.4 of IEC

61298-3, with the following additional

voltage

12.4

procedures.

interruptions

The set point will be set to a value as

specified in the NOTE to item a) in 6.2.3.

The test shall be carried out with the output

energised and repeated with the output de-

energised.

Any spurious operations such as contact

bounce shall be noted.

In order to assess the repeatability of these

results, this test shall be repeated 10 times at

each interruption duration, the period of time

between two tests being at least equal to

10 times the duration of the interruption.

6.2.10 Power supply IEC 61298-3 Voltage spikes shall be superimposed on the

mains supply. The spike energy shall be 0,1 J

transient

12.5

and the spike amplitudes shall be 100 %,

overvoltages

200 %, 300 % and 500 % overvoltage

(percentage of nominal mains r.m.s. voltage).

The power supply lines shall be protected by

a suitable suppression filter, consisting of at

least a choke of 500 µH, capable of carrying

the line current.

Two pulses of each amplitude phased to

mains peak voltage shall be applied or

alternatively at least 10 pulses randomly

phased with respect to the mains supply.

Use the same input conditions as in the

NOTE to item a) in 6.2.3.

Any change in switching points shall be

noted.

6.2.11 Supply pressure IEC 61298-3 The effect on switching points shall be

determined when tests, as in 12.8 of IEC

variations

Clause 12.8

61298-3, are performed.

NOTE If the manufacturer's specified limits are less

than the preferred test values indicated above, this fact

shall be reported with the test results.

– 16 – 61003-1 IEC:2004

Clause and Designation Reference Test methods and procedures description

6.2.12 Common mode IEC 61298-3 This test shall be performed according to the

methods and procedures stated in 13.1 of

interference

Clause 13.1

IEC 61298-3 and in IEC 61326, together with

what is stated below.

This test shall be carried out by measurement

of the changes in switching points caused by

the superposition of an a.c. signal of 250 V

r.m.s. at mains frequency between earth and

each input terminal in turn (Figure 2 – Detail a).

The test shall then be repeated using a direct

instead of an alternating voltage (Figure 2 –

Detail b).

Whichever common mode condition is chosen,

the tests shall be performed with the measured

variable input set above the switching point x ,

or below the switching point x to a distance

that is twice the value of the switching

differential X , but not less than 1 % of

sd

nominal span of measured value.

IEC 61298-3 This test shall be performed according to the

6.2.13 Normal mode

methods and procedures stated in 13.2 of IEC

interference (series