IEC 61988-4:2007

(Main)Plasma display panels - Part 4: Climatic and mechanical testing methods

Plasma display panels - Part 4: Climatic and mechanical testing methods

Defines test methods for evaluating environmental and mechanical endurance characteristics of plasma display modules (PDP modules).

Panneaux d'affichage à plasma - Partie 4: Méthodes d'essais climatiques et mécaniques

Définit les méthodes d essai pour l évaluation des caractéristiques d endurance environnementales et mécaniques des modules d affichage à plasma (modules PDP).

General Information

- Status

- Replaced

- Publication Date

- 25-Apr-2007

- Technical Committee

- TC 110 - Electronic displays

- Drafting Committee

- WG 4 - TC 110/WG 4

- Current Stage

- WPUB - Publication withdrawn

- Start Date

- 03-Apr-2015

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Frequently Asked Questions

IEC 61988-4:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Plasma display panels - Part 4: Climatic and mechanical testing methods". This standard covers: Defines test methods for evaluating environmental and mechanical endurance characteristics of plasma display modules (PDP modules).

Defines test methods for evaluating environmental and mechanical endurance characteristics of plasma display modules (PDP modules).

IEC 61988-4:2007 is classified under the following ICS (International Classification for Standards) categories: 31.260 - Optoelectronics. Laser equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61988-4:2007 has the following relationships with other standards: It is inter standard links to IEC 61988-4-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61988-4:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

CEI

61988-4

NORME

First edition

INTERNATIONALE

Première édition

2007-04

Plasma display panels –

Part 4:

Climatic and mechanical testing methods

Panneaux d'affichage à plasma –

Partie 4:

Méthodes d’essais climatiques et mécaniques

Reference number

Numéro de référence

IEC/CEI 61988-4

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de

référence, texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou

remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

CEI

61988-4

NORME

First edition

INTERNATIONALE

Première édition

2007-04

Plasma display panels –

Part 4:

Climatic and mechanical testing methods

Panneaux d'affichage à plasma –

Partie 4:

Méthodes d’essais climatiques et mécaniques

PRICE CODE

R

CODE PRIX

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

Pour prix, voir catalogue en vigueur

– 2 – 61988-4 © IEC:2007

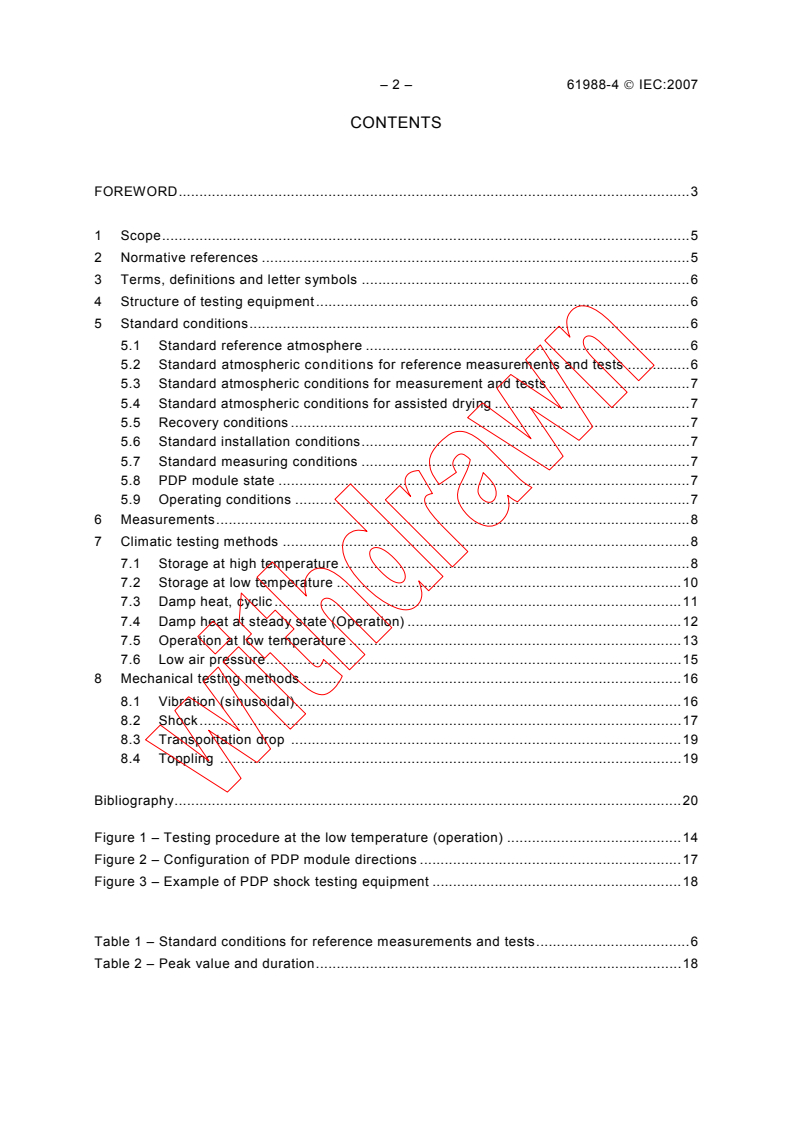

CONTENTS

FOREWORD.3

1 Scope.5

2 Normative references .5

3 Terms, definitions and letter symbols .6

4 Structure of testing equipment.6

5 Standard conditions.6

5.1 Standard reference atmosphere .6

5.2 Standard atmospheric conditions for reference measurements and tests .6

5.3 Standard atmospheric conditions for measurement and tests .7

5.4 Standard atmospheric conditions for assisted drying .7

5.5 Recovery conditions .7

5.6 Standard installation conditions.7

5.7 Standard measuring conditions .7

5.8 PDP module state .7

5.9 Operating conditions .7

6 Measurements.8

7 Climatic testing methods .8

7.1 Storage at high temperature .8

7.2 Storage at low temperature .10

7.3 Damp heat, cyclic.11

7.4 Damp heat at steady state (Operation) .12

7.5 Operation at low temperature .13

7.6 Low air pressure.15

8 Mechanical testing methods .16

8.1 Vibration (sinusoidal).16

8.2 Shock.17

8.3 Transportation drop .19

8.4 Toppling .19

Bibliography.20

Figure 1 – Testing procedure at the low temperature (operation) .14

Figure 2 – Configuration of PDP module directions .17

Figure 3 – Example of PDP shock testing equipment .18

Table 1 – Standard conditions for reference measurements and tests.6

Table 2 – Peak value and duration.18

61988-4 © IEC:2007 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

PLASMA DISPLAY PANELS –

Part 4: Climatic and mechanical testing methods

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61988-4 has been prepared by IEC technical committee 110: Flat

panel display devices.

The text of this standard is based on the following documents:

FDIS Report on voting

110/107/FDIS 110/110/RVD

Full information on the voting for the approval on this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – 61988-4 © IEC:2007

A list of all the parts in the IEC 61988 series, under the general title Plasma display panels,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

61988-4 © IEC:2007 – 5 –

PLASMA DISPLAY PANELS –

Part 4: Climatic and mechanical testing methods

1 Scope

This part of IEC 61988 defines test methods for evaluating environmental and mechanical

endurance characteristics of plasma display modules (PDP modules).

2 Normative references

The following referenced standards are indispensable for the application of this standard. For

standards with explicit dates, only the edition cited applies. For undated standards, the latest

edition of the referenced standard (including any amendments) applies.

IEC 60068-1:1988, Environmental testing – Part 1: General and guidance

IEC 60068-2-1:1990, Environmental testing – Part 2: Tests – Tests A: Cold

IEC 60068-2-2:1974, Environmental testing – Part 2: Tests – Tests B: Dry heat

IEC 60068-2-6, Environmental testing – Part 2: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-13, Environmental testing – Part 2: Tests – Test M: Low air pressure

IEC 60068-2-27:1987, Environmental testing – Part 2: Tests – Test Ea and guidance: Shock

IEC 60068-2-30, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic (12 h

+ 12 h cycle)

IEC 60068-2-78:2001, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat,

steady state

IEC 61747-5:1998, Liquid crystal and solid-state display devices – Part 5: Environmental,

endurance and mechanical test methods

IEC 61988-1, Plasma display panels – Part 1: Terminology and letter symbols

ISO 2248, Packaging – Complete, filled transport packages – Vertical impact test by dropping

ISO 4180-1, Complete, filled transport packages – General rules for the compilation of

performance test schedules – Part 1: General principles

ISO 4180-2, Complete, filled transport packages – General rules for the compilation of

performance test schedules – Part 2: Quantitative data

– 6 – 61988-4 © IEC:2007

ISO 10531, Packaging – Complete, filled transport packages – Stability testing of unit loads

3 Terms, definitions and letter symbols

For the purposes of this document, most of the definitions used in this standard comply with

IEC 60068-1 and IEC 61988-1. The following symbols are used in addition to those defined in

IEC 61988-1.

3.1

P

op

air pressure at which the PDP module is operated during the tests

3.2

P

st

air pressure at which the PDP module is stored in a non-operating state during the tests

4 Structure of testing equipment

The system diagrams and/or driving conditions of the testing equipment shall comply with the

structure specified in each item.

5 Standard conditions

5.1 Standard reference atmosphere

Temperature: 25 °C

Air pressure: 101,3 kPa

NOTE No requirement for relative humidity is given because correction by calculation is generally not possible.

If the parameters to be measured depend on temperature and/or pressure and the law of

dependence is known, the values shall be measured in the conditions specified in 5.3 and,

if necessary, be corrected by calculation to the standard reference atmospheric conditions

above.

5.2 Standard atmospheric conditions for reference measurements and tests

If the parameters to be measured depend on temperature, pressure and humidity and the law

of dependence is unknown, the atmospheric conditions to be specified shall be selected from

the following values, as shown in Table 1.

Table 1 – Standard conditions for reference measurements and tests

a a

Temperature Relative humidity Air pressure

°C % RH kPa

20 ± 3 45 to 75 86 to 106

25 ± 3

30 ± 3

35 ± 3

a

Inclusive values.

61988-4 © IEC:2007 – 7 –

5.3 Standard atmospheric conditions for measurement and tests

Unless otherwise specified, all tests and measurements shall be carried out under standard

atmospheric conditions:

− temperature: 15 °C to 35 °C;

− relative humidity: 25 % to 85 %, where appropriate;

− air pressure: 86 kPa to 106 kPa.

The absolute humidity of the atmosphere shall not exceed 22 g/m .

5.4 Standard atmospheric conditions for assisted drying

Where assisted drying is required before commencing a series of measurements, the

conditions listed below shall be used on the PDP module for at least 2 h, unless otherwise

prescribed by the relevant specification:

− temperature: (55 ± 3) °C;

− relative humidity: not exceeding 20 %;

− air pressure: 86 kPa to 106 kPa.

When the specified temperature for the dry heat test is lower than 55 °C, assisted drying shall

be carried out at that lower temperature.

5.5 Recovery conditions

The recovery shall be carried out in the conditions specified in 5.3 of IEC 60068-1:

− temperature: 15 °C to 35 °C;

− relative humidity: 25 % to 75 %;

− air pressure: 86 kPa to 106 kPa.

5.6 Standard installation conditions

Unless otherwise specified in the relevant specification, stand the PDP module keeping

adequate clearance to avoid airflow disturbance. The mounting structure of the PDP module

shall be specified in the relevant specification.

5.7 Standard measuring conditions

The standard measuring conditions described in IEC 61988-2 shall be applied.

5.8 PDP module state

For the non-operating test, the PDP module shall be either unpacked and turned off, or as

otherwise specified in the relevant specification.

For the operating test, the PDP module shall be either in the unpacked, turned off and

ready-for-use state, or as otherwise specified in the relevant specification.

5.9 Operating conditions

Full screen: The signal input sets at (15 ± 1) % of white level without gamma correction or

equivalent input level when gamma correction is used.

In case a different signal input is used, it shall be noted in the report.

NOTE The 15 % signal input level is a typical value for video.

– 8 – 61988-4 © IEC:2007

6 Measurements

The following items shall be evaluated on initial, intermediate and final measurements:

a) visual and optical performance (refer to IEC 61988-2-1 and IEC 61988-2-2);

b) electrical performance (refer to IEC 61988-2-1 and IEC 61988-2-2);

c) mechanical performance.

If additional measurements are carried out, they shall be noted in the report.

Data about initial, intermediate and final measurements shall be recorded in the report.

7 Climatic testing methods

The testing equipment used shall be noted in the relevant specification.

NOTE Make sure that the actual value, such as temperature, is within the specified value and a report on the

actual value is made.

7.1 Storage at high temperature

7.1.1 Purpose

The purpose of this test is to evaluate the performance of the PDP module after high

temperature storage.

7.1.2 Storage conditions

Test Bb of IEC 60068-2-2 shall be applied with the following specific conditions.

Test Bb: Dry heat for non heat-dissipating specimen with gradual change of temperature.

a) Temperature

The temperature shall be selected from the values given below:

(100 ± 3) °C

(95 ± 3) °C

(90 ± 3) °C

(85 ± 3) °C

(80 ± 3) °C

(75 ± 3) °C

(70 ± 3) °C

(65 ± 3) °C

(60 ± 3) °C

(55 ± 3) °C

(50 ± 3) °C

(45 ± 3) °C

(40 ± 3) °C

(35 ± 3) °C

(30 ± 3) °C

61988-4 © IEC:2007 – 9 –

The temperature selected shall be noted in the report.

b) Duration

The duration shall be selected from the values given below:

2 h, 16 h, 24 h, 48 h, 72 h, 96 h, 120 h, 192 h, 240 h, 300 h, 500 h and 1 000 h.

The duration selected shall be noted in the report.

c) Humidity

The absolute humidity of the atmosphere should not exceed 20 g/m (corresponding

approximately to 50 % relative humidity at 35 °C).

7.1.3 Testing procedures

a) The chamber shall be at the temperature of the laboratory. The PDP module, while being

at the ambient temperature of the laboratory, shall be introduced into the chamber in

accordance with 5.6 or as otherwise specified.

b) The temperature in the chamber shall then be adjusted to the temperature appropriate to

the degree of severity and time shall be allowed for the chamber to reach temperature

stability. (Temperature stability is defined in 4.8 of IEC 60068-1.) The rate of change of

temperature in the chamber shall not exceed 3 °C/min, averaged over a period of not

more than 5 min. The test temperature shall be measured in accordance with 4.6 of

IEC 60068-1.

c) The PDP module shall then be exposed to the high temperature conditions for the duration

as specified in the relevant specification. The duration shall be measured from the moment

temperature stability has been reached.

d) If required by the relevant specification, intermediate measurements shall be performed in

accordance with 7.1.4.

e) At the end of this period, the PDP module shall remain in the chamber and the temperature

shall be gradually lowered to a value lying within the limits of standard atmospheric

conditions for testing. The rate of change of temperature in the chamber shall not exceed

3 °C/min, averaged over a period of not more than 5 min. At the end of this period, the

PDP module shall be subject to the recovery procedure in the chamber or otherwise as

appropriate.

7.1.4 Intermediate measurements

The relevant specification may require functional tests during the conditioning programme.

When intermediate measurements are required, the relevant specification shall define the

measuring items and the period(s) during the conditioning, and the results shall be noted in

the report.

7.1.5 Recovery

a) The PDP module shall then remain under standard atmospheric conditions for recovery for

a period adequate for the attainment of temperature stability.

b) If required by the relevant specification, the PDP module shall be measured during the

recovery period.

– 10 – 61988-4 © IEC:2007

7.2 Storage at low temperature

7.2.1 Purpose

The purpose of this test is to evaluate the performance of the PDP module after low

temperature storage.

7.2.2 Storage conditions

Test Ab of IEC 60068-2-1 shall be applied with the following specific conditions.

Test Ab: Cold for non heat-dissipating specimen with gradual change of temperature.

a) Temperature

The temperature shall be selected from the values given below:

(–50 ± 3) °C

(–45 ± 3) °C

(–40 ± 3) °C

(–35 ± 3) °C

(–30 ± 3) °C

(–25 ± 3) °C

(–20 ± 3) °C

(–15 ± 3) °C

(–10 ± 3) °C

(–5 ± 3) °C

(0 ± 3) °C

The temperature selected shall be noted in the report.

b) Duration

The duration shall be selected from the values given below:

2 h, 16 h, 24 h, 48 h, 72 h, 96 h, 120 h, 192 h, 240 h, 300 h, 500 h and 1 000 h.

The duration selected shall be noted in the report.

7.2.3 Testing procedures

a) The chamber shall be at the temperature of the laboratory. The PDP module, while being

at the ambient temperature of the laboratory, shall be introduced into the chamber in

accordance with 5.6, or as otherwise specified.

b) The temperature in the chamber shall then be adjusted to the temperature appropriate to

the degree of severity and time shall be allowed for the chamber to reach temperature

stability. (Temperature stability is defined in 4.8 of IEC 60068-1.) The rate of change of

temperature in the chamber shall not exceed 3 °C/min, averaged over a period of not

more than 5 min. The test temperature shall be measured in accordance with 4.6 of

IEC 60068-1.

c) The PDP module shall then be exposed to the low temperature conditions for the duration

as specified in the relevant specification. The duration shall be measured from the moment

temperature stability has been reached.

d) If required by the relevant specification, intermediate measurements shall be performed in

accordance with 7.2.4.

61988-4 © IEC:2007 – 11 –

e) At the end of this period, the PDP module shall remain in the chamber and the temperature

shall be gradually raised to a value lying within the limits of standard atmospheric

conditions for testing. The rate of change of temperature in the chamber shall not exceed

3 °C/min, averaged over a period of not more than 5 min. At the end of this period, the

PDP module shall be subject to the recovery procedure in the chamber, or otherwise as

appropriate.

7.2.4 Intermediate measurements

The relevant specification may require functional tests during the conditioning programme.

When intermediate measurements are required, the relevant specification shall define the

measuring items and the period(s) during the conditioning, and the results shall be noted in

the report.

7.2.5 Recovery

a) The droplets of water may be removed.

b) The PDP module shall then remain under standard atmospheric conditions for recovery for

a period until the dew condensation is removed, with a minimum of 5 h.

c) If required by the relevant specification, the PDP module shall be measured during the

recovery period.

7.3 Damp heat, cyclic

7.3.1 Purpose

The purpose of this test is to evaluate the performance of the PDP module after damp heat,

cyclic test.

IEC 60068-2-30 shall be applied with the following specific conditions.

7.3.2 PDP module installation

The PDP module shall be introduced into the chamber in accordance with 5.6 or as

otherwise specified in the relevant specification.

7.3.3 Intermediate measurements

The relevant specification may require functional tests during the conditioning programme.

When intermediate measurements are required, the relevant specification shall define the

measuring items and the period(s) during the conditioning, and the results shall be noted in

the report.

7.3.4 Recovery

The PDP module shall be placed under the standard atmospheric conditions for assisted

drying, or shall remain under standard atmospheric conditions for recovery for a period until

the dew condensation is removed, with a minimum of 5 h.

– 12 – 61988-4 © IEC:2007

When the PDP module is placed under the standard atmospheric conditions for assisted

drying, placing the PDP module under the standard atmospheric conditions (at least 2 h)

shall follow.

7.4 Damp heat at steady state (operation)

7.4.1 Purpose

The purpose of this test is to evaluate the performance of the PDP module after exposure to

damp heat operating conditions.

7.4.2 Test conditions

This test shall be executed in a chamber or a room in which constant temperature and

humidity can be maintained. Water drop condensation should be avoided.

IEC 60068-2-78 shall be applied with the following specific conditions.

a) Temperature and humidity

The temperature and humidity shall be selected from the values given below:

Temperature: (40 ± 3) °C

(45 ± 3) °C

(50 ± 3) °C

(55 ± 3) °C

(60 ± 3) °C

Humidity: (85 ± 3) % RH

(93 ± 3) % RH

The temperature and humidity selected shall be noted in the report.

b) Time before PDP module power-on

After the specified temperature and humidity have been reached, the time before the

PDP module power-on shall be selected from the values given below:

2 h, 4 h, 8 h, 12 h and 24 h.

The time before the PDP module power-on selected shall be noted in the report.

c) Duration

The duration shall be selected from the values given below:

24 h, 48 h, 72 h, 96 h, 120 h, 240 h, 500 h and 1 000 h.

The duration selected shall be noted in the report.

7.4.3 Testing procedures

The PDP module shall be introduced into the chamber in accordance with 5.6 or as otherwise

specified.

For testing procedures other than described above, refer to Clause 7 of IEC 60068-2-78.

61988-4 © IEC:2007 – 13 –

7.4.4 Recovery

The PDP module shall be placed under the standard atmospheric conditions for assisted

drying, or shall remain under standard atmospheric conditions for recovery for a period until

the dew condensation is removed, with a minimum of 5 h.

When the PDP module is placed under the standard atmospheric conditions for assisted

drying, placing the PDP module under the standard atmospheric conditions (at least 2 h)

shall follow.

7.5 Operation at low temperature

7.5.1 Purpose

The purpose of this test is to evaluate the performance of the PDP module at low temperature

operating conditions.

7.5.2 Test chamber

a) The chamber shall be capable of maintaining the specified temperature in the working

space within the tolerances given in 7.5.3, taking into account the effect of the PDP

module under test on chamber conditions. Forced air circulation may be used to maintain

homogeneous conditions.

b) In order to limit radiation problems, the temperature of the walls of the chamber, after

temperature stability has been reached, shall not differ by more than 8 % of the specified

ambient temperature of the test, expressed in K. This requirement applies to all parts of the

chamber walls and the PDP modules shall be unable to “see” any heating or cooling

elements which do not comply with this requirement.

c) The temperature tolerances given in 7.5.3 are intended to take account of absolute errors

in measurements and slow changes of temperature. For heat-dissipating PDP modules,

the temperature near the PDP module is influenced by the effect of heat dissipation of the

PDP module itself and can be different from the values measured in the positions

defined in IEC 60068-1.

7.5.3 Test conditions

a) Temperature

The temperature shall be selected from the values given below:

(–20 ± 3) °C

(–15 ± 3) °C

(–10 ± 3) °C

(–5 ± 3) °C

(0 ± 3) °C

The temperature selected shall be noted in the report.

b) Time before PDP module power-on

After the specified temperature has been reached, the time before the PDP module

power-on shall be selected from the values given below:

2 h, 4 h, 8 h, 12 h and 24 h.

The time before the PDP module power-on selected shall be noted in the report.

– 14 – 61988-4 © IEC:2007

c) Duration

The duration shall be 4 h as shown in Figure 1 or longer. In case it is longer it shall be

noted in the report.

7.5.4 Initial measurements

Initial measurements shall be carried out as specified by the relevant specification.

7.5.5 Testing procedures

a) The PDP module shall be introduced into the chamber in the ready-for-use state.

b) Adjust the temperature in the chamber to the prescribed temperature and maintain at the

temperature for the prescribed duration. The temperature and time before the PDP module

power-on shall be selected from the values given in 7.5.3.

c) Operate the PDP module. See 5.9 for the operating condition.

d) Measure the PDP module 5 min after the PDP module has been turned on (low

temperature, first measurement on Figure 1).

e) Keep the PDP module operated for 4 h.

f) Measure the PDP module (low temperature second measurement on Figure 1).

g) Turn off the PDP module and adjust the chamber to the standard atmospheric conditions.

The PDP module shall not show condensation.

Figure 1 shows the testing procedure at the low temperature operation mentioned above.

Temperature °C Final measurement

Standard atmospheric

condition: (25 ± 3) °C

Time before PDP

module power-on

4 h

5min

Temperature: (0 ± 3) °C

(Example)

Time h

st

nd

Low temperature 1

Power on Low temperature 2

Introduce PDP module

PDP module measurement measurement

into the chamber

IEC 588/07

Figure 1 – Testing procedure at the low temperature (operation)

7.5.6 Final measurements

Final measurements shall be carried out as specified by the relevant specification.

61988-4 © IEC:2007 – 15 –

7.5.7 Information to be given in the relevant specification

When this test is included in the relevant specification, the following details shall be given as

far as they are applicable:

a) initial measurements;

b) temperature and time before PDP module power-on;

st nd

c) low temperature 1 and 2 measurements;

d) final measurements.

7.6 Low air pressure

7.6.1 Purpose

The purpose of this test is to evaluate the influence of air pressure on the assumption that the

PDP module is used at high altitude area.

7.6.2 Test conditions

IEC 60068-2-13 shall be applied with the following specific conditions.

7.6.2.1 Operating test

This test starts at ambient conditions.

Air pressure shall be reduced 1 kPa/min or slower, starting from atmospheric pressure

(86 kPa to106 kPa) down to P .

op

Air pressure, P , shall be selected from the values given below:

op

(60 ± 5) kPa;

(70 ± 5) kPa;

(80 ± 5) kPa.

The pressure selected shall be noted in the report.

7.6.2.2 Non-operating test

Air pressure shall be reduced 4 kPa/min or slower, starting from atmospheric pressure

(86 kPa to106 kPa) down to P .

st

Air pressure, P shall be selected from the values given below:

st ,

(20 ± 5) kPa

(30 ± 5) kPa

(40 ± 5) kPa

(50 ± 5) kPa

The pressure selected shall be noted in the report.

7.6.3 Duration

The duration shall be selected from the values given below:

5 min, 30 min and 2 h.

– 16 – 61988-4 © IEC:2007

The duration selected shall be noted in the report.

7.6.4 Testing procedures

a) The chamber shall be within the temperature range specified by the standard atmospheric

conditions for testing. For non-operating tests, the PDP module shall be introduced into the

chamber in accordance with 5.6 or as otherwise specified.

b) The pressure in the chamber shall then be reduced to the value appropriate to severity.

c) When operating tests are required, the PDP module shall be switched on or be electrically

loaded. Checks shall be made to ascertain whether the PDP module is capable of

functioning in accordance with the relevant specification. The PDP module may remain

under operating conditions for the specified duration, or be switched off as prescribed in

the relevant specification. For heat-dissipating PDP modules, the relevant specification

may require that the PDP module is switched on and adequate time allowed for it to reach

thermal stability before or after the air pressure is reduced and functional tests and/or

measurements are made.

d) The air pressure shall be maintained for the specified duration.

e) The air pressure shall be restored to the standard atmospheric conditions at the end of the

tests and measurements. Even if required by the relevant specification, the rate of change

of air pressure shall not exceed 10 kPa/min.

8 Mechanical testing methods

The testing equipment used shall be noted in the relevant specification.

NOTE Make sure that the actual value, such as acceleration, is within the specified value and a report on the

actual value is made.

8.1 Vibration (sinusoidal)

IEC 60068-2-6 and 2.3 of IEC 61747-5 shall be applied with the following specific conditions.

In case of contradiction between these standards, 2.3 of IEC 61747-5 shall govern.

8.1.1 Purpose

The purpose of this test is to evaluate the assurance of mechanical endurance in a vibration

environment.

8.1.2 Equipment

The equipment, including vibration table and mounting jig, shall be capable of maintaining the

test conditions specified in 8.1.3. It should not resonate in the vibration frequency range.

8.1.3 Test conditions

a) Vibration frequency: continuously swept from (10 ± 1) Hz to (55 ± 1) Hz, swept back to

(10 ± 1) Hz and repeat.

b) Duration: 20 min. each axis

c) Vibration axes: Figure 2 shows the axes of the PDP module.

61988-4 © IEC:2007 – 17 –

d) Acceleration: The acceleration shall be selected from the values given below:

2 2 2 2 2 2 2

10,0 m/s , 10,5 m/s , 11,0 m/s , 11,5 m/s , 12,0 m/s , 12,5 m/s and 13,0 m/s .

The acceleration selected shall be noted in the report.

e) Sweep rate: 1 octave/min with a tolerance of ±10 %.

f) The PDP module shall be mounted on a testing table.

Positive Y-axis

Positive

Positive

Y-axis

Z-axis

Positive X-axis

Screen

Screen centre

centre on

the front

surface of

the panel

IEC 589/07

Figure 2 – Configuration of PDP module directions

8.2 Shock

8.2.1 Purpose

The purpose of this test is to evaluate the assurance of mechanical endurance after

mechanical shocks.

8.2.2 Equipment

The equipment, including shock generator and mounting jig, shall be capable of maintaining

the test conditions specified in 8.2.3. It should not produce unnecessary vibration.

Figure 3 shows an example of shock testing equipment. The PDP module shall be clamped

during the test.

– 18 – 61988-4 © IEC:2007

Mounting jig

PDP module

Mounting table

Shock generator

Shock direction

IEC 590/07

Figure 3 – Example of PDP shock testing equipment

8.2.3 Test conditions

IEC 60068-2-27 and 2.4 of IEC 61747-5 shall be applied with the following specific conditions.

In case of contradiction between these standards, 2.4 of IEC 61747-5 shall govern.

The waveform to be used for acceleration is half sine as shown in Figure 2 of IEC 60068-2-27.

Peak value of acceleration for each direction shall be selected from Table 2. Refer to Figure 2

for X, Y and Z.

Table 2 – Peak value and duration

X Y Z Duration

2 2 2

m/s m/s m/s ms

Condition 1 100 100 30 30

Condition 2 150 150 50 11

NOTE Gravitational acceleration at the earth’s surface is approximately 10 m/s .

PDP module with a screen diagonal of equal to or larger than 1,25 m (50-inch-type) is

recommended to be tested at condition 1.

61988-4 © IEC:2007 – 19 –

PDP module with a screen diagonal of smaller than 1,25 m (50-inch-type) is recommended to

be tested at condition 2.

The condition selected shall be noted in the report.

Application of shocks:

The PDP module shall be subjected to three successive shocks in both positive and negative

directions of three mutually perpendicular axes chosen so that faults are most likely to be

revealed, i.e. a total of 18 shocks.

8.3 Transportation drop

Refer to the following standards: ISO 2248, ISO 4180-1 and ISO 4180-2.

8.4 Toppling

Refer to the following standard: ISO 10531.

– 20 – 61988-4 © IEC:2007

Bibliography

IEC 61988-2-1:2002, Plasma display panels – Part 2-1: Measuring methods – Optical

IEC 61988-2-2:2003, Plasma display panels – Part 2-2: Measuring methods – Optoelectrical

___________

– 22 – 61988-4 © CEI:2007

SOMMAIRE

AVANT-PROPOS.23

1 Domaine d'application .25

2 Références normatives.25

3 Termes, définitions et symboles littéraux .26

4 Structure de l’équipement de mesure .26

5 Conditions normales.26

5.1 Atmosphère de référence normale .26

5.2 Conditions atmosphériques normales pour les mesures et les essais de

référence.26

5.3 Conditions atmosphériques normales pour la mesure et les essais.27

5.4 Conditions atmosphériques normales pour séchage assisté .27

5.5 Conditions de reprise .27

5.6 Conditions d’installation normales .27

5.7 Conditions normales de mesure .27

5.8 Etat du module PDP .27

5.9 Conditions de fonctionnement .27

6 Mesures .28

7 Méthodes d’essais climatiques .28

7.1 Stockage à haute température.28

7.2 Stockage à basse température .29

7.3 Chaleur humide (cyclique) .31

7.4 Chaleur humide (en fonctionnement) en essai continu.31

7.5 Fonctionnement à basse température.33

7.6 Basse pression atmosphérique.35

8 Méthodes d’essais mécaniques .36

8.1 Vibrations (sinusoïdales) .36

8.2 Chocs.37

8.3 Chute au cours du transport .39

8.4 Basculement .39

Bibliographie.40

Figure 1 – Procédure d’essai (en fonctionnement) à basse température .34

Figure 2 – Configuration des directions du module PDP.37

Figure 3 – Exemple d’appareil d’essai de chocs du PDP.38

Tableau 1 – Conditions normales pour les mesures et les essais de référence .26

Tableau 2 – Valeur de crête et durée .38

61988-4 © CEI:2007 – 23 –

COMMISSION ELECTROTECHNIQUE INTERNATIONALE

___________

PANNEAUX D'AFFICHAGE A PLASMA –

Partie 4: Méthodes d’essais climatiques et mécaniques

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...