IEC 62817:2014

(Main)Photovoltaic systems - Design qualification of solar trackers

Photovoltaic systems - Design qualification of solar trackers

IEC 62817:2014 is a design qualification standard applicable to solar trackers for photovoltaic systems, but may be used for trackers in other solar applications. The standard defines test procedures for both key components and for the complete tracker system. In some cases, test procedures describe methods to measure and/or calculate parameters to be reported in the defined tracker specification sheet. In other cases, the test procedure results in a pass/fail criterion. This standard ensures the user of the said tracker that parameters reported in the specification sheet were measured by consistent and accepted industry procedures. The tests with pass/fail criteria are engineered with the purpose of separating tracker designs that are likely to have early failures from those designs that are sound and suitable for use as specified by the manufacturer.

Systèmes photovoltaïques - Qualification de conception des suiveurs solaires

L'IEC 62817:2014 est une norme de qualification de conception applicable aux suiveurs solaires pour systèmes photovoltaïques, mais peut servir aux suiveurs dans d'autres applications solaires. La norme définit les procédures d'essai destinées aussi bien aux composants clés qu'au système suiveur complet. Dans certains cas, les procédures d'essai décrivent des procédés servant à mesurer et/ou calculer des paramètres à rapporter dans la feuille de spécification définie pour le suiveur. Dans d'autres cas, le mode opératoire d'essai se conclut par des critères d'acceptation et de refus. Cette norme donne à l'utilisateur dudit suiveur la garantie que les paramètres rapportés dans la feuille de spécification ont été mesurés par des procédures industrielles cohérentes et acceptées. Les essais basés sur des critères d'acceptation et de rejet ont pour objet de distinguer les conceptions de suiveur susceptibles de présenter des défaillances prématurément de celles présentant la robustesse nécessaire et correspondant à l'usage spécifié par le fabricant.

General Information

- Status

- Published

- Publication Date

- 24-Aug-2014

- Technical Committee

- TC 82 - Solar photovoltaic energy systems

- Drafting Committee

- WG 7 - TC 82/WG 7

- Current Stage

- PPUB - Publication issued

- Start Date

- 25-Aug-2014

- Completion Date

- 15-Sep-2014

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62817:2014 is an international standard developed by the International Electrotechnical Commission (IEC) that focuses on the design qualification of solar trackers used in photovoltaic (PV) systems. Solar trackers play a critical role in optimizing the efficiency of solar power generation by adjusting the orientation of PV modules to follow the sun's position. This standard specifies test procedures for both individual solar tracker components and complete tracker systems. It ensures consistent, reliable, and industry-accepted methods for verifying the parameters reported in solar tracker specifications.

IEC 62817 serves as a benchmark for manufacturers, designers, and users of solar trackers, aiming to separate robust tracker designs from those prone to early failure. The standard enhances the reliability and performance of solar tracking solutions applied not only in PV systems but potentially in other solar technologies.

Key Topics

Scope and Objectives

IEC 62817 addresses design qualification needed to validate solar tracker functionality, durability, and safety in real-world PV operations. It includes procedures to measure or calculate key performance parameters and criteria to determine design suitability.Solar Tracker Taxonomy and Definitions

The standard outlines classifications including single-axis and dual-axis trackers, types of payloads (standard PV or concentrator PV modules), and key structural components. It clarifies terminology such as backtracking and actuation/control architectures for uniform understanding.Performance and Mechanical Testing

Tests cover pointing accuracy, tracker positioning precision, control and drive train reliability, and mechanical robustness under static and extreme dynamic loads such as wind and snow. Methods to measure repeatability, stiffness, torque, and backlash are detailed.Functional Validation

Validation includes operational tests like manual operation, emergency stops, feedback sensor functionality, and power outage recovery to ensure safe and continuous operation under varied conditions.Energy Consumption and Environmental Testing

The standard requires the assessment of daily and stow energy consumption, stow time, and power usage to optimize energy efficiency. Environmental resilience tests verify tracker survival under temperature extremes, wind speeds, and snow loads.Reporting and Specification Consistency

IEC 62817 mandates standardized reporting, ensuring that specification data provided by manufacturers correspond to measured values, offering users trustworthy performance information.

Applications

Photovoltaic System Design

Enables engineers and system integrators to select trackers that are verified for reliable, long-term operation, increasing overall PV system yield and lifespan.Solar Tracker Manufacturing

Provides manufacturers with standardized testing protocols to validate designs before market release, reducing warranty claims and improving product quality.Solar Project Development

Assists project developers and investors in assessing the technical performance and reliability of tracker systems, supporting informed procurement decisions.Research and Innovation

Researchers developing new solar tracker designs or control algorithms can use IEC 62817 guidelines to benchmark performance against industry standards.Quality Assurance and Compliance

Facilitates compliance with international norms, aiding regulatory approvals and certification processes for solar tracker equipment.

Related Standards

- IEC 61215 – Design qualification and type approval for crystalline silicon terrestrial photovoltaic modules.

- IEC 61730 – Photovoltaic module safety qualification.

- IEC 61724 – Photovoltaic system performance monitoring guidelines.

- IEC 62919 – Photovoltaics – Design and installation of photovoltaic systems.

- Other relevant IEC standards addressing PV module testing, system integration, and safety requirements complement IEC 62817 for comprehensive solar energy system standardization.

By conforming to IEC 62817:2014, stakeholders in the solar energy industry can ensure solar trackers meet rigorous design, performance, and durability criteria, fostering increased adoption of reliable solar tracking technology and enhancing the efficiency of photovoltaic power generation worldwide.

IEC 62817:2014+AMD1:2017 CSV - Photovoltaic systems - Design qualification of solar trackers Released:7/28/2017 Isbn:9782832246757

IEC 62817:2014 - Photovoltaic systems - Design qualification of solar trackers

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 62817:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Photovoltaic systems - Design qualification of solar trackers". This standard covers: IEC 62817:2014 is a design qualification standard applicable to solar trackers for photovoltaic systems, but may be used for trackers in other solar applications. The standard defines test procedures for both key components and for the complete tracker system. In some cases, test procedures describe methods to measure and/or calculate parameters to be reported in the defined tracker specification sheet. In other cases, the test procedure results in a pass/fail criterion. This standard ensures the user of the said tracker that parameters reported in the specification sheet were measured by consistent and accepted industry procedures. The tests with pass/fail criteria are engineered with the purpose of separating tracker designs that are likely to have early failures from those designs that are sound and suitable for use as specified by the manufacturer.

IEC 62817:2014 is a design qualification standard applicable to solar trackers for photovoltaic systems, but may be used for trackers in other solar applications. The standard defines test procedures for both key components and for the complete tracker system. In some cases, test procedures describe methods to measure and/or calculate parameters to be reported in the defined tracker specification sheet. In other cases, the test procedure results in a pass/fail criterion. This standard ensures the user of the said tracker that parameters reported in the specification sheet were measured by consistent and accepted industry procedures. The tests with pass/fail criteria are engineered with the purpose of separating tracker designs that are likely to have early failures from those designs that are sound and suitable for use as specified by the manufacturer.

IEC 62817:2014 is classified under the following ICS (International Classification for Standards) categories: 27.160 - Solar energy engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62817:2014 has the following relationships with other standards: It is inter standard links to IEC 62817:2014/AMD1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62817:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62817 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic systems – Design qualification of solar trackers

Systèmes photovoltaïques – Qualification de conception des suiveurs solaires

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC

65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte,

et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les

publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées.

antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Restez informé sur les nouvelles publications IEC. Just Service Clients - webstore.iec.ch/csc

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62817 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic systems – Design qualification of solar trackers

Systèmes photovoltaïques – Qualification de conception des suiveurs solaires

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.160 ISBN 978-2-8322-4675-7

IEC 62817 ®

Edition 1.1 2017-07

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Photovoltaic systems – Design qualification of solar trackers

Systèmes photovoltaïques – Qualification de conception des suiveurs solaires

– 2 – IEC 62817:2014+AMD1:2017 CSV

© IEC 2017

CONTENTS

FOREWORD . 6

1 Scope and object . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Specifications for solar trackers for PV applications . 9

5 Report . 12

6 Tracker definitions and taxonomy . 13

6.1 General . 13

6.2 Payload types . 13

6.2.1 Standard photovoltaic (PV) module trackers . 13

6.2.2 Concentrator photovoltaic (CPV) module trackers . 13

6.3 Rotational axes . 14

6.3.1 General . 14

6.3.2 Single-axis trackers . 14

6.3.3 Dual-axis trackers . 15

6.4 Actuation and control . 17

6.4.1 Architecture . 17

6.4.2 Drive train . 17

6.4.3 Drive types . 17

6.4.4 Drive train torque . 18

6.5 Types of tracker control . 18

6.5.1 Passive control . 18

6.5.2 Active control . 18

6.5.3 Backtracking . 19

6.6 Structural characteristics . 19

6.6.1 Vertical supports . 19

6.6.2 Foundation types . 20

6.6.3 Tracker positions . 20

6.6.4 Stow time . 21

6.7 Energy consumption . 21

6.7.1 Daily energy consumption . 21

6.7.2 Stow energy consumption . 21

6.8 External elements and interfaces . 21

6.8.1 Foundation . 21

6.8.2 Foundation interface . 21

6.8.3 Payload . 21

6.8.4 Payload interface . 22

6.8.5 Payload mechanical interface . 22

6.8.6 Payload electrical interface . 22

6.8.7 Grounding interface . 22

6.8.8 Installation effort . 22

6.8.9 Control interface . 22

6.9 Internal tolerances . 23

6.9.1 Primary-axis tolerance . 23

6.9.2 Secondary axis tolerance. 23

6.9.3 Backlash . 23

© IEC 2017

6.9.4 Stiffness . 23

6.10 Tracker system elements . 24

6.10.1 Mechanical structure . 24

6.10.2 Tracker controller . 24

6.10.3 Sensors . 24

6.11 Reliability terminology . 24

6.11.1 General . 24

6.11.2 Mean time between failures (MTBF) . 24

6.11.3 Mean time between critical failures (MTBCF) . 25

6.11.4 Mean time to repair (MTTR) . 25

6.12 Environmental conditions . 25

6.12.1 Operating temperature range . 25

6.12.2 Survival temperature range . 25

6.12.3 Wind speed . 25

6.12.4 Maximum wind during operation . 26

6.12.5 Maximum wind during stow . 26

6.12.6 Snow load . 26

7 Tracker accuracy characterization . 26

7.1 Overview . 26

7.2 Pointing error (instantaneous) . 26

7.3 Measurement . 27

7.3.1 Overview . 27

7.3.2 Example of experimental method to measure pointing error . 27

7.3.3 Calibration of pointing error measurement tool . 28

7.4 Calculation of tracker accuracy . 29

7.4.1 Overview . 29

7.4.2 Data collection . 29

7.4.3 Data binning by wind speed . 31

7.4.4 Data filtering . 31

7.4.5 Data quantity . 31

7.4.6 Accuracy calculations . 31

8 Tracker test procedures . 32

8.1 Visual inspection . 32

8.1.1 Purpose . 32

8.1.2 Procedure . 32

8.1.3 Requirements . 33

8.2 Functional validation tests. 33

8.2.1 Purpose . 33

8.2.2 Tracking limits verification . 33

8.2.3 Hard limit switch operation. 33

8.2.4 Automatic sun tracking after power outage and feedback sensor

shadowing . 33

8.2.5 Manual operation . 34

8.2.6 Emergency stop . 34

8.2.7 Maintenance mode . 34

8.2.8 Operational temperature range . 34

8.2.9 Wind stow . 34

8.3 Performance tests . 34

8.3.1 Purpose . 34

– 4 – IEC 62817:2014+AMD1:2017 CSV

© IEC 2017

8.3.2 Daily energy and peak power consumption . 34

8.3.3 Stow time and stow energy and power consumption . 35

8.4 Mechanical testing . 35

8.4.1 Purpose . 35

8.4.2 Control/drive train pointing repeatability test . 36

8.4.3 Deflection under static load test . 37

8.4.4 Torsional stiffness, mechanical drift, drive torque, and backlash testing . 39

8.4.5 Moment testing under extreme wind loading . 43

8.5 Environmental testing . 45

8.5.1 Purpose . 45

8.5.2 Procedure . 45

8.5.3 Requirements . 47

8.6 Accelerated mechanical cycling . 47

8.6.1 Purpose . 47

8.6.2 Procedure . 48

8.6.3 Requirements . 50

9 Design qualification testing specific to tracker electronic equipment . 50

9.1 General purpose . 50

9.2 Sequential testing for electronic components . 50

9.2.1 General . 50

9.2.2 Visual inspection of electronic components . 51

9.2.3 Functioning test . 52

9.2.4 Protection against dust, water, and foreign bodies (IP code) . 53

9.2.5 Protection against mechanical impacts (IK code) . 53

9.2.6 Robustness of terminals test . 54

9.2.7 Surge immunity test . 55

9.2.8 Shipping vibration test . 55

9.2.9 Shock test . 56

9.2.10 UV test . 56

9.2.11 Thermal cycling test. 57

9.2.12 Humidity-freeze test. 58

9.2.13 Damp heat . 59

10 Additional optional accuracy calculations . 59

10.1 Typical tracking accuracy range . 59

10.2 Tracking error histogram . 59

10.3 Percent of available irradiance as a function of pointing error . 60

Figure 1 – Convention for elevation angle . 16

Figure 2 – Illustration of primary-axis tolerance for VPDAT . 23

Figure 3 – General illustration of pointing error . 27

Figure 4 – Example of experimental method to measure pointing error . 27

Figure 5 – Example measurement locations for structural deflection . 38

Figure 6 – Load configurations while the payload is in the horizontal position . 38

Figure 7 – Load configuration when the payload is in the vertical position . 38

Figure 8 – Moment load applied to an elevation axis . 40

Figure 9 – Angular displacement versus applied torque to axis of rotation . 41

Figure 10 – Examples of characteristic length for (a) elevation torque, (b) azimuth

torque . 42

© IEC 2017

Figure 11 – Two configurations for extreme wind moment loading. 44

Figure 12 – Representation of a tracker’s discrete-movement profile . 48

Figure 13 – Representation of an accelerated discrete-movement profile for testing . 49

Figure 14 – Test sequence for electronic components. 51

Figure 15 – Electronic component thermal cycling test . 57

Figure 16 – Electronic component humidity-freeze test . 58

Figure 17 – Pointing-error frequency distribution for the entire test period . 60

Figure 18 – Available irradiance as a function of pointing error . 60

Figure 19 – Available irradiance as a function of pointing error with binning by wind

speed . 61

Table 1 – Tracker specification template . 10

Table 2 – Alternate tracking-accuracy reporting template . 32

– 6 – IEC 62817:2014+AMD1:2017 CSV

© IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PHOTOVOLTAIC SYSTEMS –

DESIGN QUALIFICATION OF SOLAR TRACKERS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 62817 edition 1.1 contains the first edition (2014-08) [documents 82/853/FDIS and 82/877/

RVD] and its amendment 1 (2017-07) [documents 82/1018/CDV and 82/1097/RVC].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions are in green text, deletions are in strikethrough red text. A

separate Final version with all changes accepted is available in this publication.

© IEC 2017

International Standard IEC 62817 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 8 – IEC 62817:2014+AMD1:2017 CSV

© IEC 2017

PHOTOVOLTAIC SYSTEMS –

DESIGN QUALIFICATION OF SOLAR TRACKERS

1 Scope and object

This International Standard is a design qualification standard applicable to solar trackers for

photovoltaic systems, but may be used for trackers in other solar applications. The standard

defines test procedures for both key components and for the complete tracker system. In

some cases, test procedures describe methods to measure and/or calculate parameters to be

reported in the defined tracker specification sheet. In other cases, the test procedure results

in a pass/fail criterion.

The objective of this design qualification standard is twofold.

First, this standard ensures the user of the said tracker that parameters reported in the

specification sheet were measured by consistent and accepted industry procedures. This

provides customers with a sound basis for comparing and selecting a tracker appropriate to

their specific needs. This standard provides industry-wide definitions and parameters for solar

trackers. Each vendor can design, build, and specify the functionality and accuracy with

uniform definition. This allows consistency in specifying the requirements for purchasing,

comparing the products from different vendors, and verifying the quality of the products.

Second, the tests with pass/fail criteria are engineered with the purpose of separating tracker

designs that are likely to have early failures from those designs that are sound and suitable

for use as specified by the manufacturer. Mechanical and environmental testing in this

standard is designed to gauge the tracker’s ability to perform under varying operating

conditions, as well as to survive extreme conditions. Mechanical testing is not intended to

certify structural and foundational designs, because this type of certification is specific to local

jurisdictions, soil types, and other local requirements.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-6, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-21, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-27, Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock

IEC 60068-2-75, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60904-3:2008, Photovoltaic devices – Part 3: Measurement principles for terrestrial

photovoltaic (PV) solar devices with reference spectral irradiance data

IEC 61000-4-5:2005, Electromagnetic compatibility (EMC) – Part 4-5: Testing and

measurement techniques – Surge immunity test

© IEC 2017

IEC 62262:2002, Degrees of protection provided by enclosures for electrical equipment

against external mechanical impacts (IK code)

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories

ISO 12103-1, Road vehicles – Test dust for filter evaluation – Part 1: Arizona test dust

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply. For additional

tracker-specific terminology, see Clause 6.

3.1

photovoltaics

PV

devices that use solar radiation to directly generate electrical energy

3.2

concentrator photovoltaics

CPV

devices that focus magnified sunlight on photovoltaics to generate electrical energy. The

sunlight could be magnified by various different methods, such as reflective or refractive

optics, in dish, trough, lens, or other configurations

3.3

concentrator module

CPV module

group of receivers (PV cells mounted in some way), optics, and other related components,

such as interconnections and mechanical enclosures, integrated together into a modular

package. The module is typically assembled in a factory and shipped to an installation site to

be installed along with other modules on a solar tracker

Note 1 to entry: The module is typically assembled in a factory and shipped to an installation site to be installed

along with other modules on a solar tracker.

Note 2 to entry: A CPV module typically does not have a field-adjustable focus point. In addition, a module could

be made of several sub-modules. The sub-module is a smaller, modular portion of the full-size module, which might

be assembled into the full module either in a factory or in the field.

3.4

concentrator assembly

concentrator assembly consisting of receivers, optics, and other related components that have

a field-adjustable focus point and are typically assembled and aligned in the field

EXAMPLE: A system that combines a single large dish with a receiver unit that is aligned with the focal point of the

disk.

Note 1 to entry: This term is used to differentiate certain CPV designs from the CPV modules mentioned above.

4 Specifications for solar trackers for PV applications

The manufacturer shall provide the test lab, as part of its product marking and documentation,

a table in the form specified below (see Table 1). The third column of Table 1 is for

information purposes regarding this standard and is not intended to be part of an actual

specification template provided to the test lab. See later clauses/subclauses of this standard

for further explanation of individual specifications.

– 10 – IEC 62817:2014+AMD1:2017 CSV

© IEC 2017

Some of the specifications within Table 1 are required to be provided by the manufacturer and

verified by the test lab, whereas others are the sole responsibility of the test lab. Still other

specifications in Table 1 are optional; however, if a tracker manufacturer chooses to include

optional information, it shall be reported and measured in the specific way shown in Table 1

(and in some cases, reporting requirements are further described in the appropriate clause of

this standard). Refer to the third column of Table 1 to determine the responsibility of the

specification or optional status (“T” indicates test lab responsibility, “M” indicates

manufacturer responsibility, and “O” indicates an optional parameter).

Table 1 – Tracker specification template

Characteristic Example Responsibility/Clause/Subclause

Manufacturer The XYZ Company (M)

Model number XX1090 (M)

Type of tracker CPV Tracker, Dual Axis (M) 6.2, 6.3

Payload characteristics

Minimum/maximum mass 100 kg/1 025 kg (M) 6.8.3

supported

Payload center of mass 0 m to 0,3 m distance perpendicular (M) 6.8.3

restrictions to mounting surface

Maximum payload surface area 30 m (M) 6.8.3

Nominal payload surface area 28 m (M)

Maximum dynamic torques Azimuth (Θ ):10 kN m (M) 8.4.5

z

allowed while moving

Θ , Θ : 5 kN m

x y

[ shall provide a set of diagrams to

clarify torques and which axes they

are relative to ]

Maximum static torques allowed [ shall provide a set of diagrams ] (M) 8.4.4, 8.4.5

while in stow position

Installation characteristics

Allowable foundation Reinforced concrete (M ) 6.6.2

Foundation tolerance in primary (O) 6.9

± 0,5°

axis

Foundation tolerance in ( O) 6.9

± 0,5°

secondary axis

Installation effort 5 man-hours, 40 metric ton crane (O) 6.8.8

Payload interface flexibility The interface can be configured to (O)

mount modules from manufacturers

“A”, “B”, and “C”. Bolting

configurations “X”, “Y”, and “Z” are

allowable.

Electrical characteristics

Includes backup power? No (M) N/A

Daily energy consumption 1,5 kWh (T) 6.7.1

Stow energy consumption 1 kWh (T) 6.7.2

Input power requirements AC, 100 V to 240 V, 50 Hz to 60 Hz, (M) No specifics defined

5 A

Effective (and apparent) peak 500 W (550 VA) (T) 8.3.2

power consumption tracking

Effective (and apparent) peak 50 W (55 VA) (T) 8.3.2

power consumption non-tracking

Effective (and apparent) peak 1 000 W (1 100 VA) (T) 8.3.3

power consumption stow

positioning.

© IEC 2017

Characteristic Example Responsibility/Clause/Subclause

Tracking accuracy

Accuracy, typical 0,1° (T) 7.4.6

(low wind, min deflect point)

Accuracy, typical 0,3° (T) 7.4.6

(low wind, max deflect point)

th

Accuracy, 95 percentile 0,5° (T) 7.4.6

(low wind, min deflect point)

th

Accuracy, 95 percentile 0,8° (T) 7.4.6

(low wind, max deflect point)

Mean wind speed during the “low 3,1 m/s (T) 7.4.6

wind” test conditions

Accuracy, typical 0,7° (T) 7.4.6

(high wind, min deflect point)

Accuracy, typical 1,0° (T) 7.4.6

(high wind, max deflect point)

th

Accuracy, 95 percentile 1,1° (T) 7.4.6

(high wind, min deflect point)

th

Accuracy, 95 percentile 1,6° (T) 7.4.6

(high wind, max deflect point)

Mean wind speed during the “high 5,2 m/s (T) 7.4.6

wind” test conditions

Weight and area of payload 500 kg payload evenly distributed (T) 7.4.2.1

installed during testing over a 50 m area

Payload center of mass installed Payload center of mass 0,2 m above (T) 7.4.2.1

during testing the module mounting surface

Control characteristics

Control algorithm Hybrid (M) 6.5

Control interface None (M) 6.8.9

External communication interface Ethernet/TCP-IP (M) No specific description

Emergency stow provided? Yes, at wind speeds 14 m/s (M) 6.6.3.1

Stow time 4 min (M) 6.6.4

Clock accuracy 1 s per year (M) N/A

Hard limit switches Not included (M) 7.2.3

Mechanical design

Actuation type Distributed (M) 6.4.1

Drive type Electric (M) 6.4.3

Actuators DC motor, 185 W (M) No specific description

Range of motion, primary axis ± 160° azimuth (M) 6.6.3.3

Range of motion, secondary axis 10° to 90° elevation (M) 6.6.3.3

System stiffness See test lab report on measurement (T),(O) 6.9.4, 8.4.3

locations, applied loads, and

measured deflections

Drive train torsional stiffness See plot of angular displacement (T) 8.4.4, Figure 9

versus applied torque

Backlash 0,1° maximum (T) 6.9.3, 8.4.4

Environmental conditions

Maximum allowable wind speed 14 m/s (M) 6.12.4

during tracking

– 12 – IEC 62817:2014+AMD1:2017 CSV

© IEC 2017

Characteristic Example Responsibility/Clause/Subclause

Maximum allowable wind speed in 40 m/s (M) 6.12.5

stow

Temperature operational range –20 °C to +50 °C (M) 6.12.1

Temperature survival range (M) 6.12.2

–40 °C to +60 °C

Snow rating Up to 20 kg/m of snow load allowed (M) 6.12.6

Maintenance and Reliability

Maintenance schedule Grease application every 12 months (O)

(0,75 man-hours required)

Drive train fluid change every 3 years

(1,25 man-hours required)

MTBF 3,5 years (O) 6.11.2

MTTR 2 h (azimuth or elevation motor) (O) 6.11.4

(list components that are expected to

need repair or replacement within a

10-year period)

For an alternate template for the presentation of accuracy specifications, see Table 2.

5 Report

A certified report of the qualification tests, with measured performance characteristics and

details of any failures and re-tests, shall be prepared by the test agency in accordance with

ISO/IEC 17025. The report shall contain the specification sheet per Table 1. Each certificate or

test report shall include at least the following information:

a) a title;

b) name and address of the test laboratory and location where the tests were carried out;

c) unique identification of the certification or report and of each page;

d) name and address of client, where appropriate;

e) description and identification of the item tested;

f) characterization and condition of the test item;

g) date of receipt of test item and date(s) of test, where appropriate;

h) identification of test method used;

i) reference to sampling procedure, where relevant;

j) any deviations from, additions to, or exclusions from, the test method and any other

information relevant to a specific test;

k) measurements, examinations and derived results supported by tables, graphs,

sketches, and photographs as appropriate, and any failures observed;

l) a statement of the estimated uncertainty of the test results (where relevant);

m) a signature and title, or equivalent identification of the person(s) accepting

responsibility for the content of the certificate or report, and the date of issue;

n) where relevant, a statement to the effect that the results relate only to the items tested;

o) a statement that the certificate or report shall not be reproduced except in full, without

the written approval of the laboratory.

A copy of this report shall be kept by the manufacturer for reference purposes.

© IEC 2017

6 Tracker definitions and taxonomy

6.1 General

Solar trackers are mechanical devices used to track or follow the sun across the sky on a

daily basis. Although a solar tracker can be used for many purposes, the scope of this

standard is focused on solar trackers for photovoltaic (PV) applications. In PV applications,

the primary purpose of the tracker is to enhance the capture of available solar irradiance to be

converted to electricity. Photovoltaic trackers can be classified into two types: standard PV

trackers and concentrator photovoltaic (CPV) trackers. Each of these tracker types can be

further categorized by the number and orientation of their axes, their actuation architecture

and drive type, their intended applications, and their vertical supports and foundation type.

6.2 Payload types

6.2.1 Standard photovoltaic (PV) module trackers

6.2.1.1 Uses

Standard PV trackers are used to minimize the angle of incidence between incoming light and

a PV module. This increases the amount of energy produced from a fixed amount of power-

generating capacity.

6.2.1.2 Type of light accepted

Photovoltaic modules accept both direct and diffuse light from all angles. This means that

systems implementing standard PV trackers produce energy even when not dir

...

IEC 62817 ®

Edition 1.0 2014-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic systems – Design qualification of solar trackers

Systèmes photovoltaïques – Qualification de conception des suiveurs solaires

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC Plus de 55 000 entrées terminologiques électrotechniques, en

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62817 ®

Edition 1.0 2014-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Photovoltaic systems – Design qualification of solar trackers

Systèmes photovoltaïques – Qualification de conception des suiveurs solaires

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XB

CODE PRIX

ICS 27.160 ISBN 978-2-8322-1826-6

– 2 – IEC 62817:2014 © IEC 2014

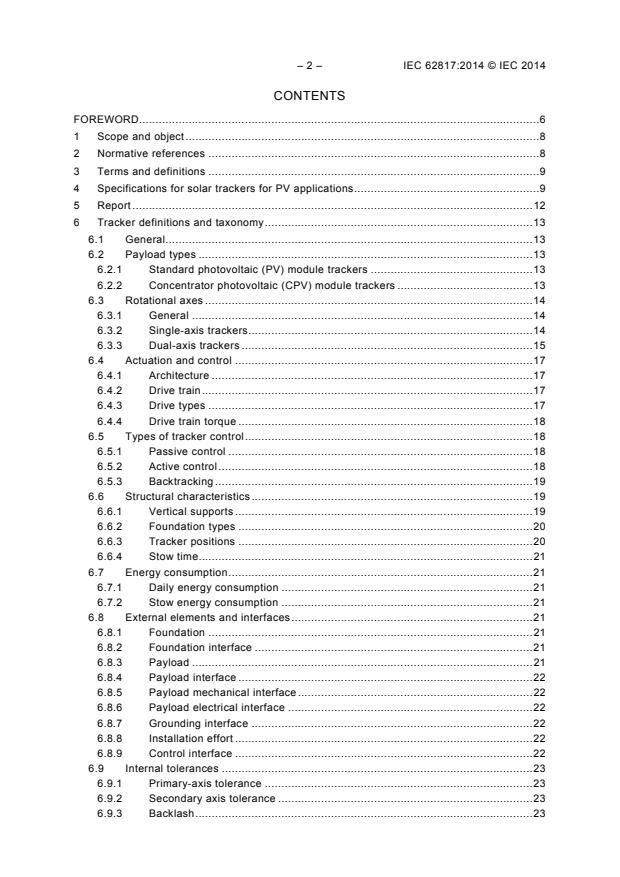

CONTENTS

FOREWORD. 6

1 Scope and object . 8

2 Normative references . 8

3 Terms and definitions . 9

4 Specifications for solar trackers for PV applications . 9

5 Report . 12

6 Tracker definitions and taxonomy . 13

6.1 General . 13

6.2 Payload types . 13

6.2.1 Standard photovoltaic (PV) module trackers . 13

6.2.2 Concentrator photovoltaic (CPV) module trackers . 13

6.3 Rotational axes . 14

6.3.1 General . 14

6.3.2 Single-axis trackers . 14

6.3.3 Dual-axis trackers . 15

6.4 Actuation and control . 17

6.4.1 Architecture . 17

6.4.2 Drive train . 17

6.4.3 Drive types . 17

6.4.4 Drive train torque . 18

6.5 Types of tracker control . 18

6.5.1 Passive control . 18

6.5.2 Active control . 18

6.5.3 Backtracking . 19

6.6 Structural characteristics . 19

6.6.1 Vertical supports . 19

6.6.2 Foundation types . 20

6.6.3 Tracker positions . 20

6.6.4 Stow time . 21

6.7 Energy consumption . 21

6.7.1 Daily energy consumption . 21

6.7.2 Stow energy consumption . 21

6.8 External elements and interfaces . 21

6.8.1 Foundation . 21

6.8.2 Foundation interface . 21

6.8.3 Payload . 21

6.8.4 Payload interface . 22

6.8.5 Payload mechanical interface . 22

6.8.6 Payload electrical interface . 22

6.8.7 Grounding interface . 22

6.8.8 Installation effort . 22

6.8.9 Control interface . 22

6.9 Internal tolerances . 23

6.9.1 Primary-axis tolerance . 23

6.9.2 Secondary axis tolerance . 23

6.9.3 Backlash . 23

6.9.4 Stiffness . 23

6.10 Tracker system elements . 24

6.10.1 Mechanical structure . 24

6.10.2 Tracker controller . 24

6.10.3 Sensors . 24

6.11 Reliability terminology . 24

6.11.1 General . 24

6.11.2 Mean time between failures (MTBF) . 24

6.11.3 Mean time between critical failures (MTBCF) . 25

6.11.4 Mean time to repair (MTTR) . 25

6.12 Environmental conditions . 25

6.12.1 Operating temperature range . 25

6.12.2 Survival temperature range . 25

6.12.3 Wind speed . 25

6.12.4 Maximum wind during operation . 26

6.12.5 Maximum wind during stow . 26

6.12.6 Snow load . 26

7 Tracker accuracy characterization . 26

7.1 Overview . 26

7.2 Pointing error (instantaneous) . 26

7.3 Measurement . 27

7.3.1 Overview . 27

7.3.2 Example of experimental method to measure pointing error . 27

7.3.3 Calibration of pointing error measurement tool . 28

7.4 Calculation of tracker accuracy . 28

7.4.1 Overview . 28

7.4.2 Data collection . 28

7.4.3 Data binning by wind speed . 29

7.4.4 Data filtering . 30

7.4.5 Data quantity . 30

7.4.6 Accuracy calculations . 30

8 Tracker test procedures . 31

8.1 Visual inspection . 31

8.1.1 Purpose . 31

8.1.2 Procedure . 31

8.1.3 Requirements . 31

8.2 Functional validation tests . 32

8.2.1 Purpose . 32

8.2.2 Tracking limits verification . 32

8.2.3 Hard limit switch operation . 32

8.2.4 Automatic sun tracking after power outage and feedback sensor

shadowing . 32

8.2.5 Manual operation . 33

8.2.6 Emergency stop . 33

8.2.7 Maintenance mode . 33

8.2.8 Operational temperature range . 33

8.2.9 Wind stow . 33

8.3 Performance tests . 33

8.3.1 Purpose . 33

– 4 – IEC 62817:2014 © IEC 2014

8.3.2 Daily energy and peak power consumption . 33

8.3.3 Stow time and stow energy and power consumption . 34

8.4 Mechanical testing . 34

8.4.1 Purpose . 34

8.4.2 Control/drive train pointing repeatability test . 35

8.4.3 Deflection under static load test . 36

8.4.4 Torsional stiffness, mechanical drift, drive torque, and backlash testing . 38

8.4.5 Moment testing under extreme wind loading . 41

8.5 Environmental testing . 43

8.5.1 Purpose . 43

8.5.2 Procedure . 43

8.5.3 Requirements . 45

8.6 Accelerated mechanical cycling . 46

8.6.1 Purpose . 46

8.6.2 Procedure . 46

8.6.3 Requirements . 48

9 Design qualification testing specific to tracker electronic equipment . 48

9.1 General purpose . 48

9.2 Sequential testing for electronic components . 48

9.2.1 General . 48

9.2.2 Visual inspection of electronic components . 49

9.2.3 Functioning test . 50

9.2.4 Protection against dust, water, and foreign bodies (IP code) . 51

9.2.5 Protection against mechanical impacts (IK code) . 51

9.2.6 Robustness of terminals test . 52

9.2.7 Surge immunity test . 53

9.2.8 Shipping vibration test . 53

9.2.9 Shock test . 54

9.2.10 UV test . 54

9.2.11 Thermal cycling test . 55

9.2.12 Humidity-freeze test . 56

9.2.13 Damp heat . 57

10 Additional optional accuracy calculations . 57

10.1 Typical tracking accuracy range . 57

10.2 Tracking error histogram . 57

10.3 Percent of available irradiance as a function of pointing error . 58

Figure 1 – Convention for elevation angle . 16

Figure 2 – Illustration of primary-axis tolerance for VPDAT . 23

Figure 3 – General illustration of pointing error . 27

Figure 4 – Example of experimental method to measure pointing error . 27

Figure 5 – Example measurement locations for structural deflection . 37

Figure 6 – Load configurations while the payload is in the horizontal position . 37

Figure 7 – Load configuration when the payload is in the vertical position . 37

Figure 8 – Moment load applied to an elevation axis . 39

Figure 9 – Angular displacement versus applied torque to axis of rotation . 39

Figure 10 – Examples of characteristic length for (a) elevation torque, (b) azimuth

torque . 41

Figure 11 – Two configurations for extreme wind moment loading . 42

Figure 12 – Representation of a tracker’s discrete-movement profile . 46

Figure 13 – Representation of an accelerated discrete-movement profile for testing . 47

Figure 14 – Test sequence for electronic components. 49

Figure 15 – Electronic component thermal cycling test . 55

Figure 16 – Electronic component humidity-freeze test . 56

Figure 17 – Pointing-error frequency distribution for the entire test period . 58

Figure 18 – Available irradiance as a function of pointing error . 58

Figure 19 – Available irradiance as a function of pointing error with binning by wind

speed . 59

Table 1 – Tracker specification template . 10

Table 2 – Alternate tracking-accuracy reporting template . 31

– 6 – IEC 62817:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

PHOTOVOLTAIC SYSTEMS –

DESIGN QUALIFICATION OF SOLAR TRACKERS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62817 has been prepared by IEC technical committee 82: Solar

photovoltaic energy systems.

The text of this design qualification standard is based on the following documents:

FDIS Report on voting

82/853/FDIS 82/877/RVD

Full information on the voting for the approval of this international standard can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 8 – IEC 62817:2014 © IEC 2014

PHOTOVOLTAIC SYSTEMS –

DESIGN QUALIFICATION OF SOLAR TRACKERS

1 Scope and object

This International Standard is a design qualification standard applicable to solar trackers for

photovoltaic systems, but may be used for trackers in other solar applications. The standard

defines test procedures for both key components and for the complete tracker system. In

some cases, test procedures describe methods to measure and/or calculate parameters to be

reported in the defined tracker specification sheet. In other cases, the test procedure results

in a pass/fail criterion.

The objective of this design qualification standard is twofold.

First, this standard ensures the user of the said tracker that parameters reported in the

specification sheet were measured by consistent and accepted industry procedures. This

provides customers with a sound basis for comparing and selecting a tracker appropriate to

their specific needs. This standard provides industry-wide definitions and parameters for solar

trackers. Each vendor can design, build, and specify the functionality and accuracy with

uniform definition. This allows consistency in specifying the requirements for purchasing,

comparing the products from different vendors, and verifying the quality of the products.

Second, the tests with pass/fail criteria are engineered with the purpose of separating tracker

designs that are likely to have early failures from those designs that are sound and suitable

for use as specified by the manufacturer. Mechanical and environmental testing in this

standard is designed to gauge the tracker’s ability to perform under varying operating

conditions, as well as to survive extreme conditions. Mechanical testing is not intended to

certify structural and foundational designs, because this type of certification is specific to local

jurisdictions, soil types, and other local requirements.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-6, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-21, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-27, Environmental testing – Part 2-27: Tests – Test Ea and guidance: Shock

IEC 60068-2-75, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60904-3:2008, Photovoltaic devices – Part 3: Measurement principles for terrestrial

photovoltaic (PV) solar devices with reference spectral irradiance data

IEC 61000-4-5:2005, Electromagnetic compatibility (EMC) – Part 4-5: Testing and

measurement techniques – Surge immunity test

IEC 62262:2002, Degrees of protection provided by enclosures for electrical equipment

against external mechanical impacts (IK code)

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories

ISO 12103-1, Road vehicles – Test dust for filter evaluation – Part 1: Arizona test dust

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply. For additional

tracker-specific terminology, see Clause 6.

3.1

photovoltaics

PV

devices that use solar radiation to directly generate electrical energy

3.2

concentrator photovoltaics

CPV

devices that focus magnified sunlight on photovoltaics to generate electrical energy. The

sunlight could be magnified by various different methods, such as reflective or refractive

optics, in dish, trough, lens, or other configurations

3.3

concentrator module

CPV module

group of receivers (PV cells mounted in some way), optics, and other related components,

such as interconnections and mechanical enclosures, integrated together into a modular

package. The module is typically assembled in a factory and shipped to an installation site to

be installed along with other modules on a solar tracker

Note 1 to entry: The module is typically assembled in a factory and shipped to an installation site to be installed

along with other modules on a solar tracker.

Note 2 to entry: A CPV module typically does not have a field-adjustable focus point. In addition, a module could

be made of several sub-modules. The sub-module is a smaller, modular portion of the full-size module, which might

be assembled into the full module either in a factory or in the field.

3.4

concentrator assembly

concentrator assembly consisting of receivers, optics, and other related components that have

a field-adjustable focus point and are typically assembled and aligned in the field

EXAMPLE: A system that combines a single large dish with a receiver unit that is aligned with the focal point of the

disk.

Note 1 to entry: This term is used to differentiate certain CPV designs from the CPV modules mentioned above.

4 Specifications for solar trackers for PV applications

The manufacturer shall provide the test lab, as part of its product marking and documentation,

a table in the form specified below (see Table 1). The third column of Table 1 is for

information purposes regarding this standard and is not intended to be part of an actual

specification template provided to the test lab. See later clauses/subclauses of this standard

for further explanation of individual specifications.

– 10 – IEC 62817:2014 © IEC 2014

Some of the specifications within Table 1 are required to be provided by the manufacturer and

verified by the test lab, whereas others are the sole responsibility of the test lab. Still other

specifications in Table 1 are optional; however, if a tracker manufacturer chooses to include

optional information, it shall be reported and measured in the specific way shown in Table 1

(and in some cases, reporting requirements are further described in the appropriate clause of

this standard). Refer to the third column of Table 1 to determine the responsibility of the

specification or optional status (“T” indicates test lab responsibility, “M” indicates

manufacturer responsibility, and “O” indicates an optional parameter).

Table 1 – Tracker specification template

Characteristic Example Responsibility/Clause/Subclause

Manufacturer The XYZ Company (M)

Model number XX1090 (M)

Type of tracker CPV Tracker, Dual Axis (M) 6.2, 6.3

Payload characteristics

Minimum/maximum mass 100 kg/1 025 kg (M) 6.8.3

supported

Payload center of mass 0 m to 0,3 m distance perpendicular (M) 6.8.3

restrictions to mounting surface

Maximum payload surface area 30 m (M) 6.8.3

Nominal payload surface area 28 m (M)

Maximum dynamic torques Azimuth (Θ ):10 kN m (M) 8.4.5

z

allowed while moving

Θ , Θ : 5 kN m

x y

[ shall provide a set of diagrams to

clarify torques and which axes they

are relative to ]

Maximum static torques allowed [ shall provide a set of diagrams ] (M) 8.4.4, 8.4.5

while in stow position

Installation characteristics

Allowable foundation Reinforced concrete (M ) 6.6.2

Foundation tolerance in primary (O) 6.9

± 0,5°

axis

Foundation tolerance in ( O) 6.9

± 0,5°

secondary axis

Installation effort 5 man-hours, 40 metric ton crane (O) 6.8.8

Payload interface flexibility The interface can be configured to (O)

mount modules from manufacturers

“A”, “B”, and “C”. Bolting

configurations “X”, “Y”, and “Z” are

allowable.

Electrical characteristics

Includes backup power? No (M) N/A

Daily energy consumption 1,5 kWh (T) 6.7.1

Stow energy consumption 1 kWh (T) 6.7.2

Input power requirements AC, 100 V to 240 V, 50 Hz to 60 Hz, (M) No specifics defined

5 A

Effective (and apparent) peak 500 W (550 VA) (T) 8.3.2

power consumption tracking

Effective (and apparent) peak 50 W (55 VA) (T) 8.3.2

power consumption non-tracking

Effective (and apparent) peak 1 000 W (1 100 VA) (T) 8.3.3

power consumption stow

positioning.

Characteristic Example Responsibility/Clause/Subclause

Tracking accuracy

Accuracy, typical 0,1° (T) 7.4.6

(low wind, min deflect point)

Accuracy, typical 0,3° (T) 7.4.6

(low wind, max deflect point)

th

Accuracy, 95 percentile 0,5° (T) 7.4.6

(low wind, min deflect point)

th

Accuracy, 95 percentile 0,8° (T) 7.4.6

(low wind, max deflect point)

Mean wind speed during the “low 3,1 m/s (T) 7.4.6

wind” test conditions

Accuracy, typical 0,7° (T) 7.4.6

(high wind, min deflect point)

Accuracy, typical 1,0° (T) 7.4.6

(high wind, max deflect point)

th

Accuracy, 95 percentile 1,1° (T) 7.4.6

(high wind, min deflect point)

th

Accuracy, 95 percentile 1,6° (T) 7.4.6

(high wind, max deflect point)

Mean wind speed during the “high 5,2 m/s (T) 7.4.6

wind” test conditions

Weight and area of payload 500 kg payload evenly distributed (T) 7.4.2.1

installed during testing over a 50 m area

Payload center of mass installed Payload center of mass 0,2 m above (T) 7.4.2.1

during testing the module mounting surface

Control characteristics

Control algorithm Hybrid (M) 6.5

Control interface None (M) 6.8.9

External communication interface Ethernet/TCP-IP (M) No specific description

Emergency stow provided? Yes, at wind speeds 14 m/s (M) 6.6.3.1

Stow time 4 min (M) 6.6.4

Clock accuracy 1 s per year (M) N/A

Hard limit switches Not included (M) 7.2.3

Mechanical design

Actuation type Distributed (M) 6.4.1

Drive type Electric (M) 6.4.3

Actuators DC motor, 185 W (M) No specific description

Range of motion, primary axis (M) 6.6.3.3

± 160° azimuth

Range of motion, secondary axis 10° to 90° elevation (M) 6.6.3.3

System stiffness See test lab report on measurement (T),(O) 6.9.4, 8.4.3

locations, applied loads, and

measured deflections

Drive train torsional stiffness See plot of angular displacement (T) 8.4.4, Figure 9

versus applied torque

Backlash 0,1° maximum (T) 6.9.3, 8.4.4

Environmental conditions

Maximum allowable wind speed 14 m/s (M) 6.12.4

during tracking

– 12 – IEC 62817:2014 © IEC 2014

Characteristic Example Responsibility/Clause/Subclause

Maximum allowable wind speed in 40 m/s (M) 6.12.5

stow

Temperature operational range –20 °C to +50 °C (M) 6.12.1

Temperature survival range (M) 6.12.2

–40 °C to +60 °C

Snow rating Up to 20 kg/m of snow load allowed (M) 6.12.6

Maintenance and Reliability

Maintenance schedule Grease application every 12 months (O)

(0,75 man-hours required)

Drive train fluid change every 3 years

(1,25 man-hours required)

MTBF 3,5 years (O) 6.11.2

MTTR 2 h (azimuth or elevation motor) (O) 6.11.4

(list components that are expected to

need repair or replacement within a

10-year period)

For an alternate template for the presentation of accuracy specifications, see Table 2.

5 Report

A certified report of the qualification tests, with measured performance characteristics and

details of any failures and re-tests, shall be prepared by the test agency in accordance with

ISO/IEC 17025. The report shall contain the specification sheet per Table 1. Each certificate or

test report shall include at least the following information:

a) a title;

b) name and address of the test laboratory and location where the tests were carried out;

c) unique identification of the certification or report and of each page;

d) name and address of client, where appropriate;

e) description and identification of the item tested;

f) characterization and condition of the test item;

g) date of receipt of test item and date(s) of test, where appropriate;

h) identification of test method used;

i) reference to sampling procedure, where relevant;

j) any deviations from, additions to, or exclusions from, the test method and any other

information relevant to a specific test;

k) measurements, examinations and derived results supported by tables, graphs, sketches,

and photographs as appropriate, and any failures observed;

l) a statement of the estimated uncertainty of the test results (where relevant);

m) a signature and title, or equivalent identification of the person(s) accepting responsibility

for the content of the certificate or report, and the date of issue;

n) where relevant, a statement to the effect that the results relate only to the items tested;

o) a statement that the certificate or report shall not be reproduced except in full, without the

written approval of the laboratory.

A copy of this report shall be kept by the manufacturer for reference purposes.

6 Tracker definitions and taxonomy

6.1 General

Solar trackers are mechanical devices used to track or follow the sun across the sky on a

daily basis. Although a solar tracker can be used for many purposes, the scope of this

standard is focused on solar trackers for photovoltaic (PV) applications. In PV applications,

the primary purpose of the tracker is to enhance the capture of available solar irradiance to be

converted to electricity. Photovoltaic trackers can be classified into two types: standard PV

trackers and concentrator photovoltaic (CPV) trackers. Each of these tracker types can be

further categorized by the number and orientation of their axes, their actuation architecture

and drive type, their intended applications, and their vertical supports and foundation type.

6.2 Payload types

6.2.1 Standard photovoltaic (PV) module trackers

6.2.1.1 Uses

Standard PV trackers are used to minimize the angle of incidence between incoming light and

a PV module. This increases the amount of energy produced from a fixed amount of power-

generating capacity.

6.2.1.2 Type of light accepted

Photovoltaic modules accept both direct and diffuse light from all angles. This means that

systems implementing standard PV trackers produce energy even when not directly pointed at

the sun. Tracking in standard PV systems is used to increase the amount of energy produced

by the direct component of the incoming light.

6.2.1.3 Accuracy requirements

In standard PV systems, the energy contributed by the direct beam drops off with the cosine

of the angle between the incoming light and the module. Thus, trackers that have accuracies

of ± 5° can deliver 99,6 % of the energy supplied by the direct beam. As a result, high-

accuracy tracking is not typically used.

6.2.2 Concentrator photovoltaic (CPV) module trackers

6.2.2.1 Uses

Concentrator photovoltaic trackers are used to enable the optics used in CPV systems. These

trackers typically align CPV optical elements with the sun’s direct beam with a higher degree

of accuracy than standard PV trackers.

6.2.2.2 Type of light accepted

Direct solar radiation, as opposed to diffuse solar radiation, is the primary energy source for

CPV modules. Optics are designed specifically to focus the direct radiation on PV cells. If this

focus is not

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...