IEC 62385:2007

(Main)Nuclear power plants - Instrumentation and control important to safety - Methods for assessing the performance of safety system instrument channels

Nuclear power plants - Instrumentation and control important to safety - Methods for assessing the performance of safety system instrument channels

Defines the requirements for demonstrating acceptable performance of safety system instrument channels through response time testing, calibration verification, and other means. The same requirements may be adopted for demonstrating the acceptable performance of non-safety systems and other instrument channels.

Centrales nucléaires de puissance - Instrumentation et contrôle-commande importants pour la sûreté - Méthodes d'évaluation des performances des chaînes d'instrumentation des systèmes de sûreté

Définit des exigences permettant d'assurer que les performances des chaînes d'instrumentation des systèmes de sûreté sont acceptables, sur la base d'essais relatifs aux temps de réponse, par la vérification de l'étalonnage ou d'autres moyens. Les mêmes exigences peuvent être retenues pour démontrer que les performances de systèmes non classés de sûreté ou d'autres chaînes d'instrumentation sont acceptables.

General Information

- Status

- Published

- Publication Date

- 20-Jun-2007

- Technical Committee

- SC 45A - Instrumentation, control and electrical power systems of nuclear facilities

- Drafting Committee

- WG 9 - TC 45/SC 45A/WG 9

- Current Stage

- PPUB - Publication issued

- Start Date

- 21-Jun-2007

- Completion Date

- 15-Aug-2007

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 10-Feb-2026

Overview

IEC 62385:2007 is an international standard published by the International Electrotechnical Commission (IEC) that focuses on nuclear power plant safety systems. Specifically, it defines the methods and requirements for assessing the performance of instrumentation and control (I&C) system instrument channels that are important to safety. The standard applies to safety system instrument channels measuring parameters such as temperature, pressure, differential pressure, liquid level, flow, and neutron flux.

This standard provides guidelines for demonstrating acceptable performance of safety system instrumentation through rigorous testing techniques including response time testing, calibration verification, functional tests, and channel checks. The principles and methods outlined in IEC 62385:2007 can also be applied to non-safety systems and other instrument channels within nuclear facilities.

Key Topics

- Performance Verification: IEC 62385 emphasizes methods for verifying accurate performance of safety instrument channels through response time testing, calibration checks, and performance validation to ensure reliability under operational conditions.

- Testing Environment and Procedures: The standard details the proper environment settings for testing, including test intervals, locations, and necessary calibration of measurement and test equipment.

- Response Time Testing: Specialized techniques such as ramp tests, noise analysis, plunge tests, and power interrupt tests are described for measuring the response time of pressure transmitters, temperature sensors, and neutron detectors.

- On-line Calibration Monitoring: The standard introduces on-line calibration monitoring methods enabling continuous assessment of instrument calibration without the need to disassemble or physically access instruments.

- Cross-Calibration Methods: Procedures for cross-validation of sensors, especially resistance temperature detectors (RTDs), ensuring consistent and accurate sensor outputs.

- Verification of Neutron Detectors: Methodologies tailored to the verification of neutron detector performance essential for nuclear plant safety system instrumentation.

- Qualifications of Personnel: Requirements for personnel qualifications conducting these tests to maintain accuracy and compliance.

Applications

IEC 62385:2007 is vital for nuclear power plant operators, instrumentation suppliers, and regulatory bodies involved in nuclear safety. Practical applications include:

- Nuclear Safety Compliance: Ensuring instrumentation systems critical to plant safety meet stringent international performance standards.

- On-line Monitoring: Providing test methods that allow remote, on-line verification of instrument channel functioning without reactor shutdown or physical access to containment areas, thus improving operational efficiency.

- Cost-effective Maintenance: Standardized procedures enable cost reductions through effective preventive maintenance, minimizing unexpected failures.

- Regulatory Framework Support: Supporting regulatory authorities in validating the performance and reliability of instrumentation important to nuclear safety, facilitating informed licensing and inspection processes.

- Integration with Nuclear I&C Systems: Complementing higher-level IEC SC 45A series standards, such as IEC 61513, by focusing on instrument channel performance within the broader nuclear instrumentation and control system framework.

Related Standards

IEC 62385:2007 is part of a comprehensive suite of IEC SC 45A standards designed for instrumentation and control in nuclear facilities. Related and complementary standards include:

- IEC 61513: Provides overarching requirements for instrumentation and control systems important to safety, establishing the safety life-cycle framework relevant to IEC 62385.

- IEC 60880 and IEC 62138: Specify hardware and software requirements for computer-based systems in nuclear applications, referenced indirectly by IEC 62385.

- IAEA Safety Standards: Including IAEA NS-R-1 (Safety Requirements for Nuclear Power Plant Design) and NS-G-1.3 (Instrumentation and Control Systems Important to Safety), which align closely with IEC methodologies.

- IEC 61508: International functional safety standard which IEC 61513 and related nuclear standards interpret for nuclear applications, supporting overall safety integrity.

- Other IEC SC 45A Documents: Covering device qualifications, fault tolerance, common cause failure mitigation, and control room design, providing complementary safety requirements.

By adhering to IEC 62385:2007, nuclear facilities ensure their safety-related instrumentation channels perform reliably under all conditions, contributing critically to plant safety and operational excellence. This standard embodies industry best practices for measurement accuracy, timely response, and robust performance verification essential to nuclear safety instrumentation and control systems.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 62385:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Nuclear power plants - Instrumentation and control important to safety - Methods for assessing the performance of safety system instrument channels". This standard covers: Defines the requirements for demonstrating acceptable performance of safety system instrument channels through response time testing, calibration verification, and other means. The same requirements may be adopted for demonstrating the acceptable performance of non-safety systems and other instrument channels.

Defines the requirements for demonstrating acceptable performance of safety system instrument channels through response time testing, calibration verification, and other means. The same requirements may be adopted for demonstrating the acceptable performance of non-safety systems and other instrument channels.

IEC 62385:2007 is classified under the following ICS (International Classification for Standards) categories: 27.120.20 - Nuclear power plants. Safety. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62385:2007 has the following relationships with other standards: It is inter standard links to EN IEC 62465:2019, EN 62765-1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62385:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

CEI

NORME

First edition

INTERNATIONALE

Première édition

2007-06

Nuclear power plants –

Instrumentation and control important to safety –

Methods for assessing the performance of

safety system instrument channels

Centrales nucléaires de puissance –

Instrumentation et contrôle-commande

importants pour la sûreté –

Méthodes d’évaluation des performances

des chaînes d’instrumentation

des systèmes de sûreté

Reference number

Numéro de référence

IEC/CEI 62385:2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de

référence, texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou

remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD

CEI

NORME

First edition

INTERNATIONALE

Première édition

2007-06

Nuclear power plants –

Instrumentation and control important to safety –

Methods for assessing the performance of

safety system instrument channels

Centrales nucléaires de puissance –

Instrumentation et contrôle-commande

importants pour la sûreté –

Méthodes d’évaluation des performances

des chaînes d’instrumentation

des systèmes de sûreté

PRICE CODE

W

CODE PRIX

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

Pour prix, voir catalogue en vigueur

– 2 – 62385 © IEC:2007

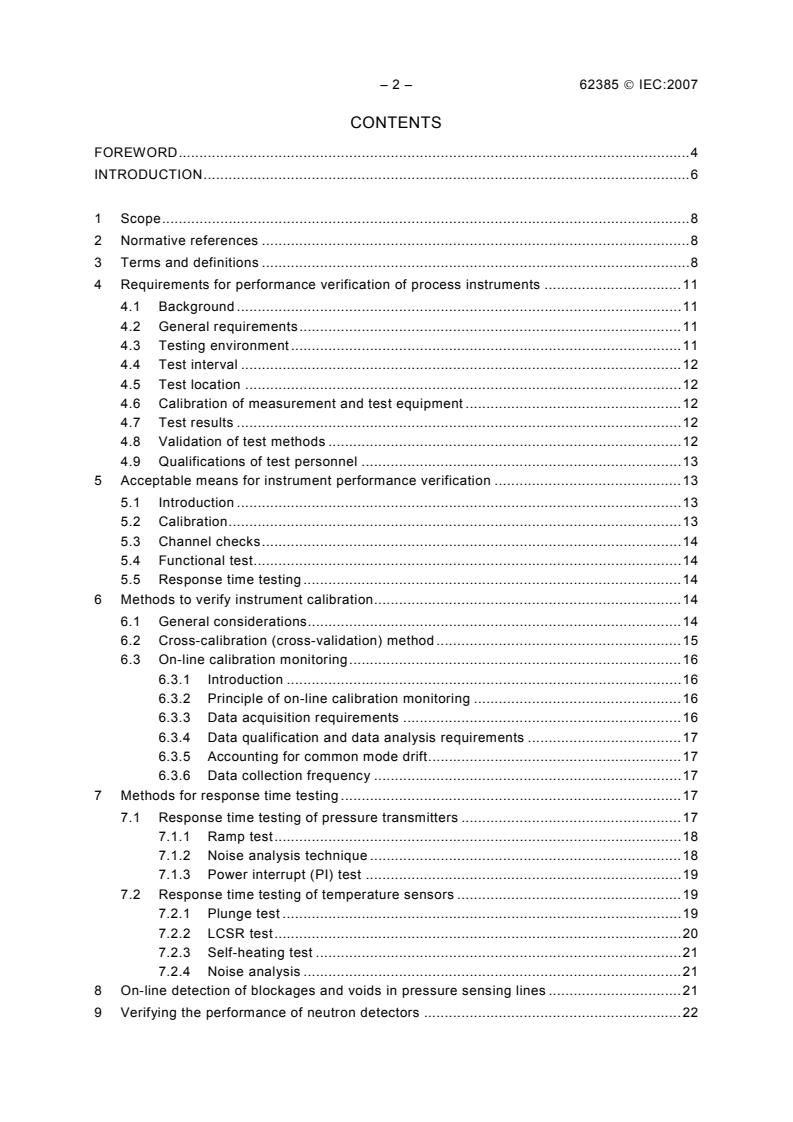

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.8

2 Normative references .8

3 Terms and definitions .8

4 Requirements for performance verification of process instruments .11

4.1 Background .11

4.2 General requirements.11

4.3 Testing environment.11

4.4 Test interval .12

4.5 Test location .12

4.6 Calibration of measurement and test equipment .12

4.7 Test results .12

4.8 Validation of test methods .12

4.9 Qualifications of test personnel .13

5 Acceptable means for instrument performance verification .13

5.1 Introduction .13

5.2 Calibration.13

5.3 Channel checks.14

5.4 Functional test.14

5.5 Response time testing .14

6 Methods to verify instrument calibration.14

6.1 General considerations.14

6.2 Cross-calibration (cross-validation) method .15

6.3 On-line calibration monitoring.16

6.3.1 Introduction .16

6.3.2 Principle of on-line calibration monitoring .16

6.3.3 Data acquisition requirements .16

6.3.4 Data qualification and data analysis requirements .17

6.3.5 Accounting for common mode drift.17

6.3.6 Data collection frequency .17

7 Methods for response time testing .17

7.1 Response time testing of pressure transmitters .17

7.1.1 Ramp test.18

7.1.2 Noise analysis technique .18

7.1.3 Power interrupt (PI) test .19

7.2 Response time testing of temperature sensors .19

7.2.1 Plunge test .19

7.2.2 LCSR test.20

7.2.3 Self-heating test .21

7.2.4 Noise analysis .21

8 On-line detection of blockages and voids in pressure sensing lines .21

9 Verifying the performance of neutron detectors .22

62385 © IEC:2007 – 3 –

Annex A (informative) RTD cross-calibration/cross-validation .23

Annex B (informative) On-line calibration monitoring.28

Annex C (informative) Response time testing techniques for pressure transmitters and

neutron detectors.30

Annex D (informative) Response time testing techniques for RTDs .33

Bibliography.37

– 4 – 62385 © IEC:2007

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

NUCLEAR POWER PLANTS –

INSTRUMENTATION AND CONTROL IMPORTANT TO SAFETY –

METHODS FOR ASSESSING THE PERFORMANCE

OF SAFETY SYSTEM INSTRUMENT CHANNELS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62385 has been prepared by subcommittee 45A: Instrumentation

and control of nuclear facilities, of IEC technical committee 45: Nuclear instrumentation.

The text of this standard is based on the following documents:

FDIS Report on voting

45A/653/FDIS 45A/661/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

62385 © IEC:2007 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 62385 © IEC:2007

INTRODUCTION

a) Technical background, main issues and organisation of the Standard

This International Standard describes test methods for ensuring that safety system instrument

channels in nuclear power plants comply with specifications for accuracy, response time and

other performance characteristics. This Standard applies to those instruments whose primary

sensors measure temperature, pressure, differential pressure, liquid level, flow and neutron

flux. The focus of this Standard is on test methods that can be used remotely while the plant

is on-line without a need to enter the reactor containment or physically access the

instruments.

b) Situation of the current Standard in the structure of the SC 45A standard series

IEC 62385 is the third level SC 45A document tackling the issue of assessing methods of

performance of safety systems instrument channels.

For more details on the structure of the SC 45A standard series, see item d) of this

introduction.

c) Recommendations and limitations regarding the application of this Standard

The main interests to benefit from this international Standard are nuclear utilities that use on-

line performance testing, suppliers who develop and install such systems, and regulatory

authorities seeking documented industry consensus on successful practices. These users will

benefit from the awareness of methods and practices considered appropriate by IEC experts

and from the cost savings associated with the standardization of methods and practices.

d) Description of the structure of the IEC SC 45A standard series and relationships with

other IEC documents and other bodies documents (IAEA, ISO)

The top-level document of the IEC SC 45A standard series is IEC 61513. It provides general

requirements for I&C systems and equipment that are used to perform functions important to

safety in NPPs. IEC 61513 structures the IEC SC 45A standard series.

IEC 61513 refers directly to other IEC SC 45A standards for general topics related to

categorization of functions and classification of systems, qualification, separation of systems,

defence against common cause failure, software aspects of computer-based systems,

hardware aspects of computer-based systems, and control room design. The standards

referenced directly at this second level should be considered together with IEC 61513 as a

consistent document set.

At a third level, IEC SC 45A standards not directly referenced by IEC 61513 are standards

related to specific equipment, technical methods, or specific activities. Usually these

documents, which make reference to second-level documents for general topics, can be used

on their own.

A fourth level extending the IEC SC 45A standard series, corresponds to the Technical

Reports which are not normative.

62385 © IEC:2007 – 7 –

IEC 61513 has adopted a presentation format similar to the basic safety publication

IEC 61508 with an overall safety life-cycle framework and a system life-cycle framework and

provides an interpretation of the general requirements of IEC 61508-1, IEC 61508-2 and

IEC 61508-4, for the nuclear application sector. Compliance with IEC 61513 will facilitate

consistency with the requirements of IEC 61508 as they have been interpreted for the nuclear

industry. In this framework IEC 60880 and IEC 62138 correspond to IEC 61508-3 for the

nuclear application sector.

IEC 61513 refers to ISO as well as to IAEA 50-C-QA (now replaced by IAEA 50-C/SG-Q) for

topics related to quality assurance (QA).

The IEC SC 45A standards series consistently implements and details the principles and

basic safety aspects provided in the IAEA code on the safety of NPPs and in the IAEA safety

series, in particular the Requirements NS-R-1, establishing safety requirements related to the

design of Nuclear Power Plants, and the Safety Guide NS-G-1.3 dealing with instrumentation

and control systems important to safety in Nuclear Power Plants. The terminology and

definitions used by SC 45A standards are consistent with those used by the IAEA.

– 8 – 62385 © IEC:2007

NUCLEAR POWER PLANTS –

INSTRUMENTATION AND CONTROL IMPORTANT TO SAFETY –

METHODS FOR ASSESSING THE PERFORMANCE

OF SAFETY SYSTEM INSTRUMENT CHANNELS

1 Scope

The purpose of this International Standard is to define the requirements for demonstrating

acceptable performance of safety system instrument channels through response time testing,

calibration verification, and other means. The same requirements may be adopted for

demonstrating the acceptable performance of non-safety systems and other instrument

channels. This Standard contains the main topics in its body and includes annexes to provide

further information. The annexes are for information only and contain a selection of the

available methods.

The methods described in this Standard are used to check instrument calibration for accuracy

and time response. It covers direct methods used to set calibration within required tolerances

and indirect methods to indicate a need for a direct calibration. The use of the indirect

methods allows for longer periods between the routine direct calibrations.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 61224:1993, Nuclear reactors – Response time in resistance temperature detectors

(RTD) – In-situ measurements

IEC 62397, Nuclear power plants – Instrumentation and control important for safety –

Resistance Temperature Detectors

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

accuracy of measurement

closeness of the agreement between the result of a measurement and the conventionally true

value of the measurand

[IEV 394-40-35]

3.2

blockage

narrowing of a tube (e.g., pressure sensing line) due to accumulation of contaminants in the

reactor water, solidification of boron, valves that are left partially open, etc. A blockage can

cause a delay in measurement of dynamic pressure information.

62385 © IEC:2007 – 9 –

3.3

calibration

set of operations that establish, under specified conditions, the relationship between values of

quantities indicated by measuring instrument or measuring system, or values represented by

a material measure or a reference material, and the corresponding values realized by

standards

[IEV 394-40-43]

3.4

channel

an arrangement of interconnected components within a system that initiates a single output. A

channel loses its identity where the single-output signals are combined with signals from an-

other channels (e.g. from a monitoring channel or a safety actuation channel).

[IAEA Safety Glossary, Version 2.0, 2006]

3.5

channel check

process by which a plant operator compares the reading of redundant instrument channels on

a regular basis to verify that these are in good agreement according to predefined criteria

3.6

cross-calibration (cross-validation)

a procedure of intercomparing the indications of redundant instruments (e.g., temperature

sensors) to identify outlier sensors as a means of verifying calibration or identifying calibration

changes. A more appropriate term for this definition is “cross-validation,” but, cross-calibration

is more commonly used.

3.7

drift

variation in sensor or instrument channel output that may occur between calibrations that

cannot be related to changes in the process variable or environmental conditions

3.8

impulse line (sensing line)

piping or tubing connecting the process to the sensor; impulse lines/sensing lines are usually

used to connect pressure, level, and flow transmitters to the process. They vary in length from

a few metres to a few hundred metres. Sensing lines may also include isolation and root

valves and other piping hardware along their length.

3.9

in-situ test

test of a sensor or a transmitter that is performed without removing the sensor or transmitter

from its normal installed position in the system

3.10

noise analysis technique

method for in-situ response time testing of sensors, detectors, and transmitters and for on-line

detection of blockages, voids, and leaks in pressure sensing lines

– 10 – 62385 © IEC:2007

3.11

on-line monitoring

continuous or periodic measurement and recording of output of installed instrumentation

3.12

outlier

a sensor such as an RTD that has exceeded a prespecified deviation

3.13

performance monitoring (performance verification)

process of demonstrating that an installed instrument channel continues to perform its

intended function of monitoring the process variable with the expected accuracy, response

time, and stability

3.14

pressure transmitters

pressure, level, and flow transmitters that are based on the principle of pressure or differential

pressure measurement, and are collectively referred to in this Standard as pressure

transmitters, pressure sensors, or just transmitters

3.15

redundancy

provision of alternative (identical or diverse) structures, systems or components, so that any

one can perform the required function regardless of the state of operation or failure of any

other

[IAEA Safety Glossary, Version 2.0, 2006]

3.16

Resistance Temperature Detector (RTD)

detector generally made up of a stainless steel cylindrical barrel protecting a platinum resistor

whose resistance varies with temperature. This detector is placed in the piping containing the

fluid whose temperature is measured in this way. It can be directly immersed in the fluid or

protected by an intermediate casing called the thermowell.

[IEC 62397]

3.17

response time

the period of time necessary for a component to achieve a specified output state from the time

that it receives a signal requiring it to assume that output state

[IAEA Safety Glossary, Version 2.0, 2006]

3.18

test interval

the elapsed time between the initiation of identical tests on the same sensor and signal

processing device, logic assembly or final actuation device

[IEC 60671]

3.19

thermowell

protective jacket for RTDs, thermocouples, and other temperature sensors. The thermowell is

also used to facilitate replacement of the temperature sensor.

62385 © IEC:2007 – 11 –

3.20

time constant

in the case of a first order system, the time required for the output signal of a system to reach

63,2 % of its final variation after a step change of its input signal.

If the system is not first order system, the term "time constant" is not appropriate. For a

system of a higher order, the term "response time" should be used.

[IEC 62397]

4 Requirements for performance verification of process instruments

4.1 Background

The control and safety systems of nuclear power plants depend on process instrumentation

which must provide reliable information to ensure plant safety and efficiency. Therefore, the

performance of this instrumentation should be verified at predefined intervals during the plant

life time. For this purpose, test methods have been developed, validated, and used in nuclear

power plants. These methods include means to perform the tests in-situ and while the plant is

operating (on-line testing).

This clause gives the requirements for in-situ and on-line testing to verify that process

instrumentation provides accurate and timely data and to identify faulty instruments. The

focus of the Standard is on the process sensors that measure temperature, pressure, liquid

level, flow, and neutron flux.

4.2 General requirements

Performance monitoring shall be conducted to verify that the safety system instrument

channels in nuclear power plants are functioning within their performance specification limits.

The tests that verify performance characteristics shall be conducted in accordance with

written procedures, and the test results shall be documented. The instrument channel should

be tested in a single test. When the total channel is not tested in a single test, separate tests

on groups of components or on single components encompassing the total instrument channel

shall be combined to verify total channel performance. Performance monitoring encompasses

the instrument channel portion of the overall safety system. Test boundaries shall include

sensors and transmitters, sensing lines (impulse lines), thermowells, cables, and all other

active and passive components that affect the overall instrument channel performance.

If a performance index such as response cannot be identified exactly, a conservative estimate

of the index shall be made by measurement and analysis and compared against the pertinent

performance requirements to ensure that the performance is acceptable.

4.3 Testing environment

In general, abnormal environmental conditions such as seismic events, radiation fields,

extreme pressures, temperatures, and moisture conditions are covered by design qualification

tests. As such, testing of equipment for such environments is not within the scope of this

Standard. However, the performance testing described in this Standard should be carried out

within the bounds of the instrument’s environmental conditions (e.g., temperature, pressure,

humidity, flow, etc.) If the test conditions vary widely, appropriate corrections shall be made

for comparison or trending of data to compensate for performance due to variation in the

environmental conditions or the effect of the environmental conditions on performance.

– 12 – 62385 © IEC:2007

In some cases, such as response time testing of temperature sensors, process operating

conditions can have a strong influence on the result. In these cases, the tests shall be

performed at or near normal operating conditions to provide the actual “in-service”

performance of the sensors. Extrapolation from laboratory conditions to plant conditions

should not be performed in cases where the extrapolation results can have large and

unquantifiable uncertainties.

4.4 Test interval

The test intervals shall be established to detect unacceptable performance. The following

factors should be considered in determining the test interval:

a) technical specification requirements;

b) regulatory requirements;

c) manufacturer’s recommendation and industry standards;

d) margin between measured performance characteristics and allowable performance limits;

e) rate-of-change of performance characteristics with time; and

f) component failure rates and target reliability.

4.5 Test location

Testing should be performed in-situ to the extent practicable. Instrument removal for testing is

acceptable only if such removal does not affect test results. In most cases of concern in this

Standard, in-situ tests are performed remotely from the instrument cabinet in the control room

area. Procedures shall be implemented to confirm that equipment status is restored after

testing.

4.6 Calibration of measurement and test equipment

The calibration of measurement and test equipment used in verifying equipment performance

characteristics shall be traceable to national standards and/or accepted values of natural

physical phenomena. Written procedures shall be used to perform the calibration and the

results of the calibration shall be documented.

4.7 Test results

The test results shall be compared to the allowable performance limits. Allowances for

uncertainties associated with the performance monitoring test shall be included in the test

results or the establishment of performance limits. If the results are found to exceed the limit,

or the rate of change in the performance characteristics are such that the allowable

performance limits may be exceeded prior to the next test, predetermined action should be

taken to correct the problem.

The accuracy of test results should be stated in terms of a percentage of the reported value or

a ± band around the reported value. This accuracy should be determined from not only the

equipment uncertainties, but also from the uncertainties of the test and analysis techniques

involved. If uncertainties cannot be identified objectively, it should be demonstrated that the

test results are conservative.

4.8 Validation of test methods

All performance monitoring test methods shall be validated. This validation shall be

documented and should address the following considerations:

62385 © IEC:2007 – 13 –

a) Comparison of the test method with suitable laboratory tests, in-situ tests, or both tests to

establish the validity of the method and quantify the accuracy of its results. The accuracy

of the test method and results should be established by theoretical or experimental

means, or both. The accuracy determination should consider all sources of error in the

test method.

b) Theoretical justification for the test method.

c) That the assumptions and conditions to ensure validity of the test method are satisfied.

Furthermore, if the test assumptions are not fully satisfied, it should be demonstrated that

the results that are obtained will nevertheless be conservative.

d) Any software used for data acquisition, data qualification, or data analysis should be

designed and developed using a systematic approach according to accepted industry

standards for software development for nuclear power plants. All software packages

should go through comprehensive verification and validation (V&V) testing. The basis for

the V&V tests and the results of the V&V work should be documented. The V&V tests

should be designed to reveal any problem that can produce invalid or non-conservative

results.

4.9 Qualifications of test personnel

Testing to verify the performance of nuclear power plant instruments shall be performed by

test personnel who have been properly trained by experienced experts with documented

qualification to perform the training. The training of the test personnel shall be documented

and updated periodically. Examples of training topics to qualify the test personnel are:

a) principles of performance verification tests;

b) review of performance test procedures;

c) equipment preparation for data acquisition;

d) training on data acquisition and data analysis software; and

e) interpretation and documentation of results.

5 Acceptable means for instrument performance verification

5.1 Introduction

This clause gives the requirements for calibration, channel checks, functional tests, and

response time testing of process instruments. It is followed by descriptions of methods to

perform instrument calibration and response time testing.

The performance of instruments in nuclear power plants may be established in a laboratory or

by bench testing. The means for laboratory or bench calibration of instruments are well

established and are not addressed in this Standard. Rather, the means for in-situ/on-line

calibration verification of sensors and transmitters are described. Regarding response time

performance of sensors and transmitters, both laboratory/bench testing methods as well as in-

situ/on-line testing methods are described in this Standard.

5.2 Calibration

Instrument calibration utilizes known precision inputs to verify that the instrument produces

the required outputs over the required operational range within specified limits. When

calibration is used for instrument performance verification, the calibration shall be

accomplished or verified through individual application or combination of the following taking

into account previous experience:

– 14 – 62385 © IEC:2007

a) perturbation of the monitored variable;

b) simulation of the monitored variable (this is sometimes referred to as conventional

calibration);

c) on-line monitoring (by redundant and/or diverse parameter comparison); and

d) cross-calibration (also called cross-validation) of redundant sensors.

The focus of this Standard is on the on-line monitoring and cross-calibration/cross-validation

methods.

5.3 Channel checks

Channel checks involving comparison of two or more instrument channels' indications are

intended to verify the continued operability of instrument channels between calibrations.

Consequently, these checks shall be conducted more frequently than calibration. They

generally require no hardware interaction beyond observing or recording the given channel

indication(s).

5.4 Functional test

Functional testing shall be performed to verify that the instrument channel performs its

intended function.

5.5 Response time testing

Response time testing shall be performed at predefined intervals. It may be performed with

the instrumentation either in or out of service. Acceptable methods for response time testing

are identified later in this Standard and further information about these methods is provided in

the annexes. These methods include in-situ tests that can be performed while the plant is on-

line.

Examples of in-situ response time testing methods are the loop current step response (LCSR)

test for RTDs and the noise analysis technique for pressure transmitters and neutron

detectors. For response time testing of thermocouples, either the LCSR test or the noise

analysis technique is used. The noise analysis technique can also be used to monitor for RTD

response time degradation. If response time degradation is identified, then the LCSR test

shall be performed to establish if the RTD response time is acceptable. Detailed requirements

concerning RTD are to be found in IEC 61224 and IEC 62397.

Response time testing of the rest of the instrument channel should also be performed as

required.

Examples of laboratory or bench testing methods are the plunge test for temperature sensors

and the ramp test for pressure sensors.

6 Methods to verify instrument calibration

6.1 General considerations

This Clause is concerned with in-situ/on-line calibration verification of sensors and

transmitters.

62385 © IEC:2007 – 15 –

The calibration of redundant instruments such as primary coolant RTDs in a pressurized water

reactor (PWR) plant can be verified using a method referred to as cross-calibration or cross-

validation. For non-redundant instruments or where redundancy is limited to only a few

instruments, the on-line calibration monitoring approach is used. The requirements for the

cross-calibration method and the on-line calibration monitoring approach are outlined below.

6.2 Cross-calibration (cross-validation) method

The cross-calibration method is typically used for RTDs. Once a group of RTDs is properly

calibrated and installed in a plant, cross-calibration tests shall be performed periodically (e.g.,

once every maintenance cycle) to ensure that the RTD calibrations have not changed beyond

an acceptable limit.

The test involves a systematic comparison of a group of redundant RTDs that are measuring

the same temperature. To perform the test, the resistance of the RTDs should be measured

sequentially and converted to equivalent temperatures using the most recent RTD calibration

tables. Alternatively, the temperature readings of the RTDs should be obtained from the plant

computer or by using a suitable data acquisition system. The temperatures shall then be

averaged and the deviation of each RTD from the average shall be calculated. Any RTD that

has exceeded a prespecified deviation should be called an outlier, flagged and/or removed

from the average, and the process shall be repeated as necessary to identify all outliers.

The test should be performed at several temperatures at isothermal conditions during plant

heat up or cool down periods. With data collected at three or more widely spaced

temperatures, a new calibration table may be generated for an outlier. This approach

essentially amounts to an in-situ calibration of the outlier. For more information, refer to

Annex A.

In performing the cross-calibration/cross-validation tests, a number of factors shall be

accounted for:

a) The test data shall be examined for plant temperature stability to ensure that there are no

excessive temperature fluctuations involved. If excessive plant temperature fluctuations

are involved, analytical corrections shall be applied to the data to minimize fluctuation

effects on the test results.

b) The test data shall be examined for plant temperature uniformity to ensure that various

loops are at the same temperature and redundant sensors are exposed to essentially

equal temperatures. If this is not the case, analytical corrections shall be used to account

for any temperature differences that can affect the results.

c) The uncertainty of the test results shall be determined by combining uncertainties of the

measurement and test equipment as well as the uncertainties due to plant temperature

fluctuations, plant temperature non-uniformity, and any precision error that may be

involved.

The cross-calibration method described above can also be used to verify the calibration of

thermocouples. For this application, the reading of each thermocouple shall be compared with

the average of RTDs. Thermocouples should not be cross calibrated together. They should be

cross-calibrated against the average reading of redundant RTDs that measure the same

temperature.

– 16 – 62385 © IEC:2007

The acceptance criteria for an RTD to pass the cross-calibration test depends on the plant.

The plant procedure shall identify the acceptance criteria based on the plant accuracy

requirements for temperature sensors. Typically, an RTD is accepted if its deviation is less

than ± 0,3 ºC from the average temperature. For thermocouples, typical acceptance criteria is

± 1,0 ºC.

6.3 On-line calibration monitoring

6.3.1 Introduction

The cross-calibration technique described above may be used when there are redundant

instruments (e.g., six or more). When there are not enough redundant instruments, on-line

calibration monitoring should be used to verify the calibration of instruments.

The principle of on-line calibration monitoring is described below and the details are covered

in Annex B. On-line calibration monitoring is applicable to most instruments and can be used

to verify the calibration of sensors and transmitters or an entire instrument channel. In

particular, on-line calibration monitoring is useful for pressure, level, and flow transmitters. As

such, the requirements for on-line calibration monitoring in this Standard are provided based

on pressure, level, and flow transmitters. Pressure, level, and flow transmitters are

collectively referred to as pressure transmitters or just transmitters.

6.3.2 Principle of on-line calibration monitoring

The calibration of nuclear power plant pressure transmitters typically involves two steps:

a) Determine if calibration is needed. This step is performed by providing the instrument with

a series of known inputs covering the operating range of the instrument. The output is

recorded for each input and compared with the acceptance criteria.

b) Calibrate if needed. If the instrument does not meet its acceptance criteria, it is calibrated

by making necessary adjustments.

The first step can be automated and performed while the plant is operating. This approach

may be used to verify instrument calibration or extend the calibration interval of instruments. It

is referred to as on-line calibration monitoring, on-line calibration testing, or on-line drift

monitoring.

6.3.3 Data acquisition requirements

To perform on-line calibration monitoring, the output of instruments should be recorded

continuously or periodically to identify drift, bias errors, noise, and other anomalies. The data

for on-line calibration monitoring may be obtained from the plant computer, a dedicated data

acquisition system, or other means. Data should be collected during plant startup and/or

shutdown periods to allow the calibration of instruments to be verified throughout their

operating range. The calibration of the data acquisition equipment shall be established and

documented. This calibration shall be traceable to applicable quality assurance requirements.

62385 © IEC:2007 – 17 –

6.3.4 Data qualification and data analysis requirements

The on-line monitoring data should be screened (qualified) to ensure that extraneous

information is not used for calibration verification of instruments. Examples of data screening

methods are filtering and amplitude probability density (APD) tests. Following data

qualification, an analysis shall be performed involving averaging and/or modeling techniques

as necessary to estimate the value of the process that is being monitored. The estimated

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...