IEC 60034-1:2004

(Main)Rotating electrical machines - Part 1: Rating and performance

Rotating electrical machines - Part 1: Rating and performance

Is applicable to all rotating electrical machines except those covered by other IEC standards (for example, IEC 60349). Machines within the scope of this standard may also be subject to superseding, modifying or additional requirements in other IEC standards.

Machines électriques tournantes - Partie 1: Caractéristiques assignées et caractéristiques de fonctionnement

Est applicable à toutes les machines électriques tournantes à l'exception de celles qui font l'objet d'autres normes de la CEI, par exemple la CEI 60349. Les machines comprises dans le domaine d'application de la présente norme peuvent également être soumises à des exigences nouvelles, modifiées ou complémentaires figurant dans d'autres normes de la CEI.

General Information

- Status

- Published

- Publication Date

- 20-Apr-2004

- Technical Committee

- TC 2 - Rotating machinery

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 03-Feb-2010

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60034-1:2004 - Rotating electrical machines - Part 1: Rating and performance (Eleventh edition, 2004) is an international standard that defines general requirements for the rating, performance and testing of rotating electrical machines (motors and generators). The standard applies to all rotating electrical machines except those specifically covered by other IEC standards (for example, IEC 60349) and may be supplemented by other parts of IEC 60034 or by product-specific standards. Users should confirm they have the latest edition or amendments via the IEC catalogue.

Key topics and technical requirements

The standard addresses fundamental technical and test requirements that determine machine performance and suitability for service, including:

- Scope and definitions - common terms and machine classification.

- Duty and duty declaration - duty types (S1–S10), continuous, intermittent and non‑periodic duties and how they affect rating and thermal limits.

- Rating and nameplate data - assignment of rated output, rated voltage, coordination of voltage/output and multiple ratings.

- Site operating conditions - altitude, ambient temperature limits, coolant temperatures (air, hydrogen), storage and transport conditions.

- Electrical operating conditions - supply characteristics, voltage/frequency variation limits, unbalanced operation and peak/gradient withstand levels.

- Thermal performance and tests - thermal class, reference coolant, temperature-rise measurement methods, thermal test conditions and limits.

- Other performance and tests - routine tests, dielectric (withstand) tests, excess current and torque tests, pull-up torque, overspeed and short‑circuit testing.

- Electromagnetic compatibility (EMC) - emission and immunity considerations and limits (with informative Annex B).

- Safety, earthing and mechanical details - protective earthing, shaft keying, marking and rating plates.

- Tolerances and documentation - permitted tolerances on specified values and required declarations.

(The standard contains informative annexes including guidance on duty type S10 and EMC limits.)

Practical applications

IEC 60034-1 is used to:

- Specify machine performance and acceptance criteria in procurement contracts.

- Guide motor/generator design decisions (thermal management, insulation class, cooling).

- Define factory and site test procedures for verification and certification.

- Establish rating plates and marking information for installed equipment.

- Inform engineering decisions on installation environment (altitude, ambient, supply variations).

Who should use this standard

- Electrical machine manufacturers and design engineers

- Test laboratories and quality assurance teams

- Specifiers, procurement and commissioning engineers

- Plant engineers and asset managers ensuring machine performance and compliance

Related standards

- IEC 60349 (example of a standard covering specific rotating machines)

- Other parts of the IEC 60034 series for machine-specific requirements and tests

For the latest status, editions and amendments consult the IEC catalogue or IEC Web Site.

IEC 60034-1:2004 - Rotating electrical machines - Part 1: Rating and performance Released:4/21/2004

IEC 60034-1:2004 - Machines électriques tournantes - Partie 1: Caractéristiques assignées et caractéristiques de fonctionnement Released:4/21/2004

IEC 60034-1:2004 - Rotating electrical machines - Part 1: Rating and performance Released:4/21/2004 Isbn:2831874556

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60034-1:2004 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Rotating electrical machines - Part 1: Rating and performance". This standard covers: Is applicable to all rotating electrical machines except those covered by other IEC standards (for example, IEC 60349). Machines within the scope of this standard may also be subject to superseding, modifying or additional requirements in other IEC standards.

Is applicable to all rotating electrical machines except those covered by other IEC standards (for example, IEC 60349). Machines within the scope of this standard may also be subject to superseding, modifying or additional requirements in other IEC standards.

IEC 60034-1:2004 is classified under the following ICS (International Classification for Standards) categories: 29.160.01 - Rotating machinery in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60034-1:2004 has the following relationships with other standards: It is inter standard links to IEC 60034-1:1996/AMD1:1997, IEC 60034-1:1996, IEC 60034-1:1996/AMD2:1999, IEC 60034-1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60034-1:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60034-1

Eleventh edition

2004-04

Rotating electrical machines –

Part 1:

Rating and performance

This English-language version is derived from the original

bilingual publication by leaving out all French-language

pages. Missing page numbers correspond to the French-

language pages.

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (http://www.iec.ch/searchpub/cur_fut.htm)

enables you to search by a variety of criteria including text searches, technical

committees and date of publication. On-line information is also available on

recently issued publications, withdrawn and replaced publications, as well as

corrigenda.

• IEC Just Published

This summary of recently issued publications (http://www.iec.ch/online_news/

justpub/jp_entry.htm) is also available by email. Please contact the Customer

Service Centre (see below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 60034-1

Eleventh edition

2004-04

Rotating electrical machines –

Part 1:

Rating and performance

IEC 2004 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical,

including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

XB

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

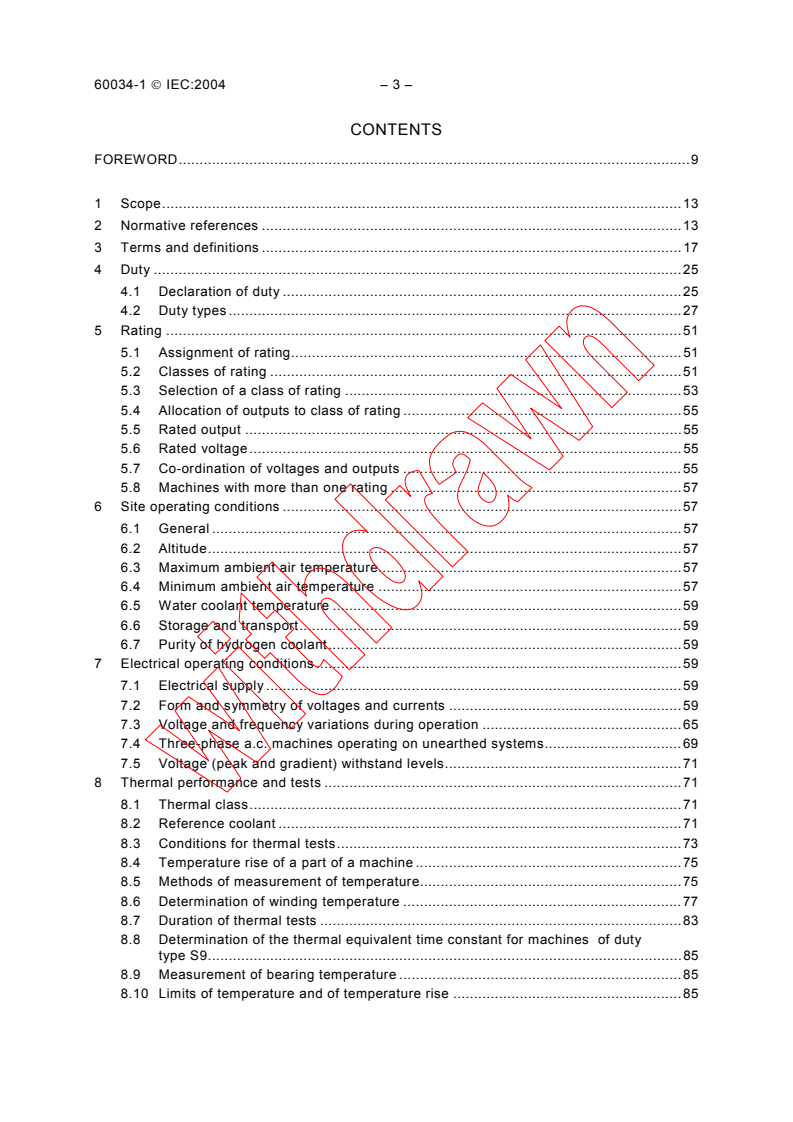

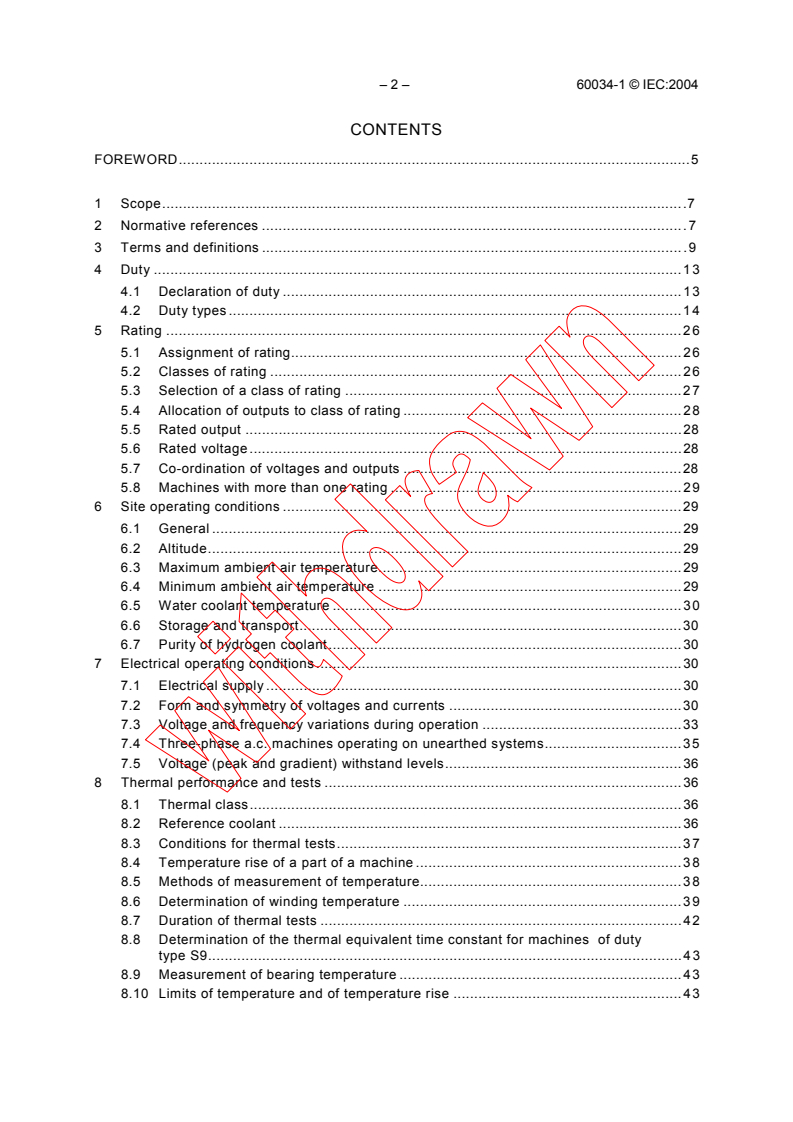

60034-1 IEC:2004 – 3 –

CONTENTS

FOREWORD.9

1 Scope.13

2 Normative references.13

3 Terms and definitions .17

4 Duty.25

4.1 Declaration of duty.25

4.2 Duty types.27

5 Rating.51

5.1 Assignment of rating.51

5.2 Classes of rating.51

5.3 Selection of a class of rating .53

5.4 Allocation of outputs to class of rating .55

5.5 Rated output.55

5.6 Rated voltage.55

5.7 Co-ordination of voltages and outputs .55

5.8 Machines with more than one rating .57

6 Site operating conditions.57

6.1 General.57

6.2 Altitude.57

6.3 Maximum ambient air temperature.57

6.4 Minimum ambient air temperature .57

6.5 Water coolant temperature .59

6.6 Storage and transport.59

6.7 Purity of hydrogen coolant.59

7 Electrical operating conditions.59

7.1 Electrical supply.59

7.2 Form and symmetry of voltages and currents .59

7.3 Voltage and frequency variations during operation .65

7.4 Three-phase a.c. machines operating on unearthed systems.69

7.5 Voltage (peak and gradient) withstand levels.71

8 Thermal performance and tests .71

8.1 Thermal class.71

8.2 Reference coolant.71

8.3 Conditions for thermal tests.73

8.4 Temperature rise of a part of a machine .75

8.5 Methods of measurement of temperature.75

8.6 Determination of winding temperature .77

8.7 Duration of thermal tests .83

8.8 Determination of the thermal equivalent time constant for machines of duty

type S9.85

8.9 Measurement of bearing temperature .85

8.10 Limits of temperature and of temperature rise .85

60034-1 IEC:2004 – 5 –

9 Other performance and tests .103

9.1 Routine tests.103

9.2 Withstand voltage test.105

9.3 Occasional excess current.109

9.4 Momentary excess torque for motors.111

9.5 Pull-up torque.113

9.6 Safe operating speed of cage induction motors .113

9.7 Overspeed.115

9.8 Short-circuit current for synchronous machines .117

9.9 Short-circuit withstand test for synchronous machines.117

9.10 Commutation test for commutator machines .117

9.11 Total Harmonic Distortion (THD) for synchronous machines .117

10 Rating plates.119

10.1 General.119

10.2 Marking.119

11 Miscellaneous requirements.123

11.1 Protective earthing of machines .123

11.2 Shaft-end key(s).125

12 Tolerances.127

12.1 General.127

13 Electromagnetic compatibility (EMC) .131

13.1 General.131

13.2 Immunity.131

13.3 Emission.131

13.4 Immunity tests.131

13.5 Emission tests.133

14 Safety.133

Annex A (informative) Guidance for the application of duty type S10 and for

establishing the value of relative thermal life expectancy TL .135

Annex B (informative) Electromagnetic compatibility (EMC) limits .137

Figure 1 – Continuous running duty – Duty type S1.27

Figure 2 – Short-time duty – Duty type S2.29

Figure 3 – Intermittent periodic duty – Duty type S3.31

Figure 4 – Intermittent periodic duty with starting – Duty type S4 .33

Figure 5 – Intermittent periodic duty with electric braking – Duty type S5 .35

Figure 6 – Continuous operation periodic duty – Duty type S6 .37

Figure 7 – Continuous operation periodic duty with electric braking – Duty type S7 .39

Figure 8 – Continuous operation periodic duty with related load/speed changes –

Duty type S8 .43

Figure 9 – Duty with non-periodic load and speed variations – Duty type S9 .45

Figure 10 – Duty with discrete constant loads – Duty type S10 .49

Figure 11 – Voltage and frequency limits for generators.69

Figure 12 – Voltage and frequency limits for motors.69

60034-1 IEC:2004 – 7 –

Table 1 – Preferred voltage ratings .57

Table 2− Unbalanced operating conditions for synchronous machines .63

Table 3 − Primary functions of machines.67

Table 4 – Reference coolant (see also Table 10) .71

Table 5 – Time interval .81

Table 6 – Measuring points.85

Table 7 – Limits of temperature rise of windings indirectly cooled by air .89

Table 8 − Limits of temperature rise of windings indirectly cooled by hydrogen .91

Table 9 – Adjustments to limits of temperature rise at the operating site of indirect

cooled windings to take account of non-reference operating conditions and ratings .91

Table 10 – Assumed maximum ambient temperature .95

Table 11 – Adjusted limits of temperature rise at the test site (Δθ ) for windings

T

indirectly cooled by air to take account of test site operating conditions .97

Table 12 – Limits of temperature of directly cooled windings and their coolants .99

Table 13 – Adjustments to limits of temperature at the operating site for windings

directly cooled by air or hydrogen to take account of non-reference operating

conditions and ratings.101

Table 14 – Adjusted limits of temperature at the test site θ for windings directly cooled

T

by air to take account of test site operating conditions .101

Table 15 – Minimum schedule of routine tests .103

Table 16 – Withstand voltage tests .107

−1

Table 17 – Maximum safe operating speed (min ) of three-phase single-speed cage

induction motors for voltages up to and including 1 000 V.113

Table 18 – Overspeeds.115

Table 19 – Cross-sectional areas of earthing conductors .125

Table 20 – Schedule of tolerances on values of quantities .127

Table B.1 – Electromagnetic emission limits for machines without brushes .137

Table B.2 – Electromagnetic emission limits for machines with brushes.137

60034-1 IEC:2004 – 9 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ROTATING ELECTRICAL MACHINES –

Part 1: Rating and performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60034-1 has been prepared IEC technical committee 2: Rotating

machinery.

This eleventh edition cancels and replaces the tenth edition published in 1996, its

amendments 1 (1997) and 2 (1999). It constitutes a technical revision.

60034-1 IEC:2004 – 11 –

The major changes introduced in this edition are:

Clause or

Change

subclause

7.2.2 New requirements for a.c. generators to supply non-linear circuits

8 Major changes to Tables 4, 7 and 9

9.1 New requirements for routine tests

9.2 Table 16 Test voltage of auxiliaries

9.11 Total harmonic distortion for synchronous machines

11.1 Protective earthing of machines

12.1 Table 20 Tolerance on efficiency

13 Electromagnetic compatibility

The text of this standard is based on the following documents:

FDIS Report on voting

2/1278/FDIS 2/1294/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

2005. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

60034-1 IEC:2004 – 13 –

ROTATING ELECTRICAL MACHINES –

Part 1: Rating and performance

1 Scope

This part of IEC 60034 is applicable to all rotating electrical machines except those covered

by other IEC standards, for example, IEC 60349.

Machines within the scope of this standard may also be subject to superseding, modifying or

additional requirements in other publications, for example, IEC 60079, and IEC 60092.

NOTE If particular clauses of this standard are modified to meet special applications, for example machines

subject to radioactivity or machines for aerospace, all other clauses apply insofar as they are compatible.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60027-1, Letter symbols to be used in electrical technology − Part 1: General

IEC 60027-4, Letter symbols to be used in electrical technology − Part 4: Symbols for

quantities to be used for rotating electrical machines

IEC 60034-2, Rotating electrical machines − Part 2: Methods for determining losses and

efficiency of rotating electrical machinery from tests (excluding machines for traction vehicles)

IEC 60034-3, Rotating electrical machines − Part 3: Specific requirements for turbine-type

synchronous machines

IEC 60034-5, Rotating electrical machines − Part 5: Degrees of protection provided by the

integral design of rotating electrical machines (IP code)- Classification

IEC 60034-6, Rotating electrical machines − Part 6: Methods of cooling (IC code)

IEC 60034-8, Rotating electrical machines – Part 8: Terminal markings and direction of

rotation

IEC 60034-12, Rotating electrical machines − Part 12: Starting performance of single-speed

three-phase cage induction motors

IEC 60034-15, Rotating electrical machines − Part 15: Impulse voltage withstand levels of

rotating a.c. machines with form-wound stator coils

− Part 17: Cage induction motors when fed from

IEC 60034-17, Rotating electrical machines

converters – Application guide

60034-1 IEC:2004 – 15 –

IEC 60034-18 (all parts), Rotating electrical machines – Functional evaluation of insulating

systems

IEC 60038, IEC standard voltages

IEC 60050(411):1996, International Electrotechnical Vocabulary (IEV) − Chapter 411:

Rotating machines

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60072 (all parts), Dimensions and output series for rotating electrical machines

IEC 60204-1, Safety of machinery – Electrical equipment of machines – Part 1: General

requirements

IEC 60204-11, Safety of machinery – Electrical equipment of machines – Part 11:

Requirements for HV equipment for voltages above 1 000 V a.c. or 1 500 V d.c. and not

exceeding 36 kV

IEC 60279, Measurement of the winding resistance of an a.c. machine during operation at

alternating voltage

IEC 60335-1, Household and similar electrical appliances – Safety – Part 1: General

requirements

IEC 60445, Basic and safety principles for man-machine interface, marking and identification

– Identification of equipment terminals and of terminations of certain designated conductors,

including general rules for an alphanumeric system

IEC 60971, Semiconductor convertors. Identification code for convertor connections

IEC 61293, Marking of electrical equipment with ratings related to electrical supply – Safety

requirements

IEC 61986, Rotating electrical machines – Equivalent loading and super-position techniques –

Indirect testing to determine temperature rise

IEC 62114, Electrical insulation systems – Thermal classification

CISPR 11, Industrial, scientific and medical (ISM) radio-frequency equipment –

Electromagnetic disturbance characteristics – Limits and methods of measurement

CISPR 14, Electromagnetic compatibility – Requirements for household appliances, electric

tools and similar apparatus

CISPR 16, Specification for radio disturbance and immunity measuring apparatus and

methods

60034-1 IEC:2004 – 17 –

3 Terms and definitions

For the purposes of this document, the definitions in IEC 60050(411) and the following

definitions apply.

For definitions concerning cooling and coolants, other than those in 3.17 to 3.22, reference

should be made to IEC 60034-6.

For the purposes of this standard, the term ‘agreement’ means ‘agreement between the

manufacturer and purchaser’.

3.1

rated value

a quantity value assigned, generally by a manufacturer, for a specified operating condition of

a machine

[IEV 411-51-23]

NOTE The rated voltage or voltage range is the rated voltage or voltage range between lines at the terminals.

3.2

rating

the set of rated values and operating conditions

[IEV 411-51-24]

3.3

rated output

the value of the output included in the rating

3.4

load

all the values of the electrical and mechanical quantities that signify the demand made on a

rotating machine by an electrical circuit or a mechanism at a given instant

[IEV 411-51-01]

3.5

no-load (operation)

the state of a machine rotating with zero output power (but under otherwise normal operating

conditions)

[IEV 411-51-02, modified]

3.6

full load

the load which causes a machine to operate at its rating

[IEV 411-51-10]

3.7

full load value

a quantity value for a machine operating at full load

[IEV 411-51-11]

NOTE This concept applies to power, torque, current, speed, etc.

60034-1 IEC:2004 – 19 –

3.8

de-energized and rest

the complete absence of all movement and of all electrical supply or mechanical drive

[IEV 411-51-03]

3.9

duty

the statement of the load(s) to which the machine is subjected, including, if applicable,

starting, electric braking, no-load and rest and de-energized periods, and including their

durations and sequence in time

[IEV 411-51-06]

3.10

duty type

a continuous, short-time or periodic duty, comprising one or more loads remaining constant

for the duration specified, or a non-periodic duty in which generally load and speed vary

within the permissible operating range

[IEV 411-51-13]

3.11

cyclic duration factor

the ratio between the period of loading, including starting and electric braking, and the

duration of the duty cycle, expressed as a percentage

[IEV 411-51-09]

3.12

locked-rotor torque

the smallest measured torque the motor develops at its shaft and with the rotor locked, over

all its angular positions at rated voltage and frequency

[IEV 411-48-06]

3.13

locked rotor current

the greatest steady-state r.m.s. current taken from the line with the motor held at rest, over all

angular positions of its rotor, at rated voltage and frequency

[IEV 411-48-16]

3.14

pull-up torque (of an a.c. motor)

the smallest steady-state asynchronous torque which the motor develops between zero speed

and the speed which corresponds to the breakdown torque, when the motor is supplied at the

rated voltage and frequency

This definition does not apply to those asynchronous motors of which the torque continually

decreases with increase in speed.

NOTE In addition to the steady-state asynchronous torques, harmonic synchronous torques, which are a function

of rotor load angle, will be present at specific speeds.

At such speeds, the accelerating torque may be negative for some rotor load angles.

Experience and calculation show this to be an unstable operating condition and therefore harmonic synchronous

torques do not prevent motor acceleration and are excluded from this definition.

60034-1 IEC:2004 – 21 –

3.15

breakdown torque (of an a.c. motor)

the maximum steady-state asynchronous torque which the motor develops without an abrupt

drop in speed, when the motor is supplied at the rated voltage and frequency

This definition does not apply to motors with torques that continually decrease with increase

in speed.

3.16

pull-out torque (of a synchronous motor)

the maximum torque which the synchronous motor develops at synchronous speed with rated

voltage, frequency and field current

3.17

cooling

a procedure by means of which heat resulting from losses occurring in a machine is given up

to a primary coolant, which may be continuously replaced or may itself be cooled by a

secondary coolant in a heat exchanger

[IEV 411-44-01]

3.18

coolant

a medium, liquid or gas, by means of which heat is transferred

[IEV 411-44-02]

3.19

primary coolant

a medium, liquid or gas, which, being at a lower temperature than a part of a machine and in

contact with it, removes heat from that part

[IEV 411-44-03]

3.20

secondary coolant

a medium, liquid or gas, which, being at a lower temperature than the primary coolant,

removes the heat given up by this primary coolant by means of a heat exchanger or through

the external surface of the machine

[IEV 411-44-04]

3.21

direct cooled (inner cooled) winding

a winding mainly cooled by coolant flowing in direct contact with the cooled part through

hollow conductors, tubes, ducts or channels which, regardless of their orientation, form an

integral part of the winding inside the main insulation

[IEV 411-44-08]

3.22

indirect cooled winding

any winding other than a direct cooled winding

[IEV 411-44-09]

___________

1)

In all cases when ‘indirect’ or ‘direct’ is not stated, an indirect cooled winding is implied.

60034-1 IEC:2004 – 23 –

3.23

supplementary insulation

an independent insulation applied in addition to the main insulation in order to ensure

protection against electric shock in the event of failure of the main insulation

3.24

moment of inertia

the sum (integral) of the products of the mass elements of a body and the squares of their

distances (radii) from a given axis

3.25

thermal equilibrium

the state reached when the temperature rises of the several parts of the machine do not vary

by more than a gradient of 2 K per hour

[IEV 411-51-08]

NOTE Thermal equilibrium may be determined from the time-temperature rise plot when the straight lines

between points at the beginning and end of two successive reasonable intervals each have a gradient of less than

2 K per hour.

3.26

thermal equivalent time constant

the time constant, replacing several individual time constants, which determines

approximately the temperature course in a winding after a step-wise current change

3.27

encapsulated winding

a winding which is completely enclosed or sealed by moulded insulation

[IEV 411-39-06]

3.28

rated form factor of direct current supplied to a d.c. motor armature from a static power

converter

the ratio of the r.m.s. maximum permissible value of the current I to its average value

rms,maxN

I (mean value integrated over one period) at rated conditions:

avN

I

rms, maxN

k =

fN

I

avN

3.29

current ripple factor

the ratio of the difference between the maximum value I and the minimum value I of an

max min

undulating current to two times the average value I (mean value integrated over one

av

period):

I − I

max min

q =

i

2 × I

av

NOTE For small values of current ripple, the ripple factor may be approximated by the following expression:

I − I

max min

q =

i

I + I

max min

The above expression may be used as an approximation if the resulting calculated value of q

i

is equal to or less than 0,4.

60034-1 IEC:2004 – 25 –

3.30

tolerance

the permitted deviation between the declared value of a quantity and the measured value

3.31

type test

a test of one or more machines made to a certain design to show that the design meets

certain specifications

[IEV 411-53-01]

NOTE The type test may also be considered valid if it is made on a machine which has minor deviations of rating

or other characteristics. These deviations should be subject to agreement.

3.32

routine test

a test to which each individual machine is subjected during or after manufacture to ascertain

whether it complies with certain criteria

[IEV 411-53-02]

4 Duty

4.1 Declaration of duty

It is the responsibility of the purchaser to declare the duty. The purchaser may describe the

duty by one of the following:

a) numerically, where the load does not vary or where it varies in a known manner;

b) as a time sequence graph of the variable quantities;

c) by selecting one of the duty types S1 to S10 that is no less onerous than the expected

duty.

The duty type shall be designated by the appropriate abbreviation, specified in 4.2, written

after the value of the load.

An expression for the cyclic duration factor is given in the relevant duty type figure.

The purchaser normally cannot provide values for the moment of inertia of the motor (J ) or

M

the relative thermal life expectancy (TL), see Annex A. These values are provided by the

manufacturer.

Where the purchaser does not declare a duty, the manufacturer shall assume that duty type

S1 (continuous running duty) applies.

60034-1 IEC:2004 – 27 –

4.2 Duty types

4.2.1 Duty type S1 – Continuous running duty

Operation at a constant load maintained for sufficient time to allow the machine to reach

thermal equilibrium, see Figure 1.

The appropriate abbreviation is S1.

P

t

P

V

t

Θ

Θ

max

t

IEC 326/04

Key

P load

P electrical losses

V

temperature

Θ

maximum temperature attained

Θ

max

t time

Figure 1 – Continuous running duty – Duty type S1

60034-1 IEC:2004 – 29 –

4.2.2 Duty type S2 – Short-time duty

Operation at constant load for a given time, less than that required to reach thermal

equilibrium, followed by a time de-energized and at rest of sufficient duration to re-establish

machine temperatures within 2 K of the coolant temperature, see Figure 2.

The appropriate abbreviation is S2, followed by an indication of the duration of the duty,

Example: S2 60 min.

P

t

P

V

t

Θ

Θ

max

Δt

P

t

IEC 327/04

Key

P load

P electrical losses

V

Θ temperature

maximum temperature attained

Θ

max

t time

operation time at constant load

Δt

P

Figure 2 – Short-time duty – Duty type S2

60034-1 IEC:2004 – 31 –

4.2.3 Duty type S3 – Intermittent periodic duty

A sequence of identical duty cycles, each including a time of operation at constant load and a

time de-energized and at rest, see Figure 3. In this duty, the cycle is such that the starting

current does not significantly affect the temperature rise.

The appropriate abbreviation is S3, followed by the cyclic duration factor.

Example: S3 25 %

P

T

C

Δt Δt

P R

t

P

V

t

Θ

Θ

max

t

IEC 328/04

Key

P load

P electrical losses

V

temperature

Θ

maximum temperature attained

Θ

max

t time

T time of one load cycle

C

operation time at constant load

Δt

P

time de-energized and at rest

Δt

R

Cyclic duration factor = Δt /T

P C

Figure 3 – Intermittent periodic duty – Duty type S3

___________

2)

Periodic duty implies that thermal equilibrium is not reached during the time on load.

60034-1 IEC:2004 – 33 –

4.2.4 Duty type S4 – Intermittent periodic duty with starting

A sequence of identical duty cycles, each cycle including a significant starting time, a time of

operation at constant load and a time de-energized and at rest, see Figure 4.

The appropriate abbreviation is S4, followed by the cyclic duration factor, the moment of

inertia of the motor (J ) and the moment of inertia of the load (J ), both referred to the motor

M ext

shaft.

2 2

Example: S4 25 % J = 0,15 kg × m J = 0,7 kg × m

M ext

P

T

C

t

Δt Δt

P R

P

V

Δt

D

t

Θ

Θ

max

t

IEC 329/04

Key

P load t time

P electrical losses T time of one load cycle

V C

temperature starting/accelerating time

Θ Δt

D

maximum temperature attained operation time at constant load

Θ Δt

max P

time de-energized and at rest

Δt

R

Cyclic duration factor = (Δt + Δt )/T

D P C

Figure 4 – Intermittent periodic duty with starting – Duty type S4

___________

Periodic duty implies that thermal equilibrium is not reached during the time on load.

60034-1 IEC:2004 – 35 –

4.2.5 Duty type S5 – Intermittent periodic duty with electric braking

A sequence of identical duty cycles, each cycle consisting of a starting time, a time of

operation at constant load, a time of electric braking and a time de-energized and at rest, see

Figure 5.

The appropriate abbreviation is S5, followed by the cyclic duration factor, the moment of inertia of

the motor (J ) and the moment of inertia of the load (J ), both referred to the motor shaft.

M ext

2 2

Example: S5 25 % J = 0,15 kg × m J = 0,7 kg × m

M ext

P

T

C

t

Δt

F

P

V

Δt

P Δt

R

Δt

D

t

Θ

Θ

max

t

IEC 330/04

Key

P T

load time of one load cycle

C

P electrical losses Δt starting/accelerating time

V D

Θ temperature Δt operation time at constant load

P

maximum temperature attained time of electric braking

Θ Δt

max F

t time time de-energized and at rest

Δt

R

Cyclic duration factor = (Δt + Δt + Δt )/T

D P F C

Figure 5 – Intermittent periodic duty with electric braking – Duty type S5

___________

Periodic duty implies that thermal equilibrium is not reached during the time on load.

60034-1 IEC:2004 – 37 –

4.2.6 Duty type S6 – Continuous-operation periodic duty

A sequence of identical duty cycles, each cycle consisting of a time of operation at constant

load and a time of operation at no-load. There is no time de-energized and at rest, see

Figure 6.

The appropriate abbreviation is S6, followed by the cyclic duration factor.

Example: S6 40 %

P

T

C

Δt Δt

P V

t

P

V

t

Θ

Θ

max

t

IEC 331/04

Key

P load t time

P electrical losses T time of one load cycle

V C

temperature operation time at constant load

Θ Δt

P

maximum temperature attained operation time at no-load

Θ Δt

max V

Cyclic duration factor = Δt /T

P C

Figure 6 – Continuous operation periodic duty – Duty type S6

___________

Periodic duty implies that thermal equilibrium is not reached during the time on load.

60034-1 IEC:2004 – 39 –

4.2.7 Duty type S7 – Continuous-operation periodic duty with electric braking

A sequence of identical duty cycles, each cycle consisting of a starting time, a time of

operation at constant load and a time of electric braking. There is no time de-energized and at

rest, see Figure 7.

The appropriate abbreviation is S7, followed by the moment of inertia of the motor (J ) and

M

the moment of inertia of the load (J ), both referred to the motor shaft.

ext

2 2

Example: S7 J = 0,4 kg × m J = 7,5 kg × m

M ext

T

C

P

t

Δt Δt

Δt P F

D

P

V

t

Θ

Θ

max

t

IEC 332/04

Key

P load t time

P electrical losses T time of one load cycle

V C

temperature starting/accelerating time

Θ Δt

D

maximum temperature attained operation time at constant load

Θ Δt

max P

Cyclic duration factor = 1 Δt time of electric braking

F

Figure 7 – Continuous operation periodic duty with electric braking – Duty type S7

___________

Periodic duty implies that thermal equilibrium is not reached during the time on load.

60034-1 IEC:2004 – 41 –

4.2.8 Duty type S8 – Continuous-operation periodic duty with related load/speed

changes

A sequence of identical duty cycles, each cycle consisting of a time of operation at constant

load corresponding to a predetermined speed of rotation, followed by one or more times of

operation at other constant loads corresponding to different speeds of rotation (carried out, for

example, by means of a change in the number of poles in the case of induction motors).

There is no time de-energized and at rest (see Figure 8).

The appropriate abbreviation is S8, followed by the moment of inertia of the motor (J ) and

M

the moment of inertia of the load (J ), both referred to the motor shaft, together with the

ext

load, speed and cyclic duration factor for each speed condition.

2 2 −1

Example: S8 J = 0,5 kg × m J = 6 kg × m 16 kW 740 min 30 %

M ext

−1

40 kW 1 460 min 30 %

−1

25 kW 980 min 40 %

___________

Periodic duty implies that thermal equilibrium is not reached during the time on load.

60034-1 IEC:2004 – 43 –

T

C

P

t

Δt Δt

P2 P3

Δt Δt Δt

D P1 F1

P Δt

V

F2

t

Θ

Θ

max

t

n

t

IEC 333/04

Key

P load t time

P electrical losses T time of one load cycle

V C

temperature starting/accelerating time

Θ Δt

D

maximum temperature attained operation time at constant load (P1, P2, P3)

Θ Δt

max P

n speed Δt time of electric braking (F1, F2)

F

Cyclic duration factor = (Δt +Δt )/T ; (Δt +Δt )/T ; (Δt +Δt )/T

D P1 C F1 P2 C F2 P3 C

Figure 8 – Continuous operation periodic duty with related

load/speed changes – Duty type S8

60034-1 IEC:2004 – 45 –

4.2.9 Duty type S9 – Duty with non-periodic load and speed variations

A duty in which generally load and speed vary non-periodically within the permissible

operating range. This duty includes frequently applied overloads that may greatly exceed the

reference load (see Figure 9).

The appropriate abbreviation is S9.

For this duty type, a constant load appropriately selected and based on duty type S1 is taken

as the reference value ("P " in Figure 9) for the overload concept.

ref

Δt

P

n

Δt

F

Δt

D

Δt

R

t

P

Δt

S

P

ref

t

P

V

t

Θ

Θ

max

t

IEC 334/04

Key

P load t time

P reference load starting/accelerating time

Δt

ref

D

P electrical losses operation time at constant load

Δt

V

P

temperature Δt time of electric braking

Θ

F

Θ maximum temperature attained Δt time de-energized and at rest

max R

n speed time under overload

Δt

S

Figure 9 – Duty with non-periodic load and speed variations – Duty type S9

60034-1 IEC:2004 – 47 –

4.2.10 Duty type S10 – Duty with discrete constant loads and speeds

A duty consisting of a specific number of discrete values of load (or equivalent loading) and if

applicable, speed, each load/speed combination being maintained for sufficient time to allow

the machine to reach thermal equilibrium, see Figure 10. The minimum load within a duty

cycle may have the value zero (no-load or de-energized and at rest).

Th

...

NORME CEI

INTERNATIONALE 60034-1

Onzième édition

2004-04

Machines électriques tournantes –

Partie 1:

Caractéristiques assignées

et caractéristiques de fonctionnement

Cette version française découle de la publication d’origine

bilingue dont les pages anglaises ont été supprimées.

Les numéros de page manquants sont ceux des pages

supprimées.

Numéro de référence

CEI 60034-1:2004(F)

Numérotation des publications

Depuis le 1er janvier 1997, les publications de la CEI sont numérotées à partir de

60000. Ainsi, la CEI 34-1 devient la CEI 60034-1.

Editions consolidées

Les versions consolidées de certaines publications de la CEI incorporant les

amendements sont disponibles. Par exemple, les numéros d’édition 1.0, 1.1 et 1.2

indiquent respectivement la publication de base, la publication de base incorporant

l’amendement 1, et la publication de base incorporant les amendements 1 et 2

Informations supplémentaires sur les publications de la CEI

Le contenu technique des publications de la CEI est constamment revu par la CEI

afin qu'il reflète l'état actuel de la technique. Des renseignements relatifs à cette

publication, y compris sa validité, sont disponibles dans le Catalogue des

publications de la CEI (voir ci-dessous) en plus des nouvelles éditions, amende-

ments et corrigenda. Des informations sur les sujets à l’étude et l’avancement des

travaux entrepris par le comité d’études qui a élaboré cette publication, ainsi que la

liste des publications parues, sont également disponibles par l’intermédiaire de:

• Site web de la CEI (www.iec.ch)

• Catalogue des publications de la CEI

Le catalogue en ligne sur le site web de la CEI (www.iec.ch/searchpub) vous permet

de faire des recherches en utilisant de nombreux critères, comprenant des

recherches textuelles, par comité d’études ou date de publication. Des informations

en ligne sont également disponibles sur les nouvelles publications, les publications

remplacées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published

Ce résumé des dernières publications parues (www.iec.ch/online_news/justpub)

est aussi disponible par courrier électronique. Veuillez prendre contact avec le

Service client (voir ci-dessous) pour plus d’informations.

• Service clients

Si vous avez des questions au sujet de cette publication ou avez besoin de

renseignements supplémentaires, prenez contact avec le Service clients:

Email: custserv@iec.ch

Tél: +41 22 919 02 11

Fax: +41 22 919 03 00

NORME CEI

INTERNATIONALE 60034-1

Onzième édition

2004-04

Machines électriques tournantes –

Partie 1:

Caractéristiques assignées

et caractéristiques de fonctionnement

IEC 2004 Droits de reproduction réservés

Aucune partie de cette publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun

procédé, électronique ou mécanique, y compris la photocopie et les microfilms, sans l'accord écrit de l'éditeur.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

XB

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

Pour prix, voir catalogue en vigueur

− 2 − 60034-1 CEI:2004

SOMMAIRE

AVANT-PROPOS .8

1 Domaine d'application.12

2 Références normatives.12

3 Définitions.16

4 Services.24

4.1 Spécification du service .24

4.2 Services types.26

5 Caractéristiques assignées.50

5.1 Attribution des caractéristiques assignées.50

5.2 Classes de caractéristiques assignées.50

5.3 Choix d'une classe de caractéristiques assignées .52

5.4 Attribution de la puissance à une classe de caractéristiques assignées .54

5.5 Puissance assignée.54

5.6 Tension assignée.54

5.7 Coordination des tensions et des puissances .54

5.8 Machines à plus d'un ensemble de caractéristiques assignées .56

6 Conditions de fonctionnement sur site.56

6.1 Généralités.56

6.2 Altitude.56

6.3 Température maximale de l'air ambiant.56

6.4 Température minimale de l'air ambiant.56

6.5 Température de l'eau de refroidissement .58

6.6 Stockage et transport.58

6.7 Pureté de l'hydrogène de refroidissement.58

7 Conditions de fonctionnement électriques .58

7.1 Alimentation électrique.58

7.2 Forme et symétrie des tensions et des courants.58

7.3 Variations de tension et de fréquence en fonctionnement .64

7.4 Machines triphasées à courant alternatif fonctionnant sur réseaux isolés.68

7.5 Niveaux de tenue en tension (crête et gradient) .70

8 Caractéristiques thermiques de fonctionnement et essais thermiques.70

8.1 Classification thermique.70

8.2 Fluide de refroidissement de référence .70

8.3 Conditions des essais thermiques.72

8.4 Echauffement d'un élément de machine.74

8.5 Méthodes de mesurage de la température .74

8.6 Détermination de la température d'enroulement .76

8.7 Durée des essais thermiques.82

8.8 Détermination de la constante de temps thermique équivalente des machines

pour service type S9 .84

8.9 Mesurage de la température des paliers.84

8.10 Limites d'échauffement et de température.84

− 4 − 60034-1 CEI:2004

9 Autres caractéristiques de fonctionnement et essais . 102

9.1 Essais individuels.102

9.2 Essais de tension de tenue . 104

9.3 Surintensité occasionnelle.108

9.4 Excès momentané de couple des moteurs . 110

9.5 Couple minimal pendant le démarrage . 112

9.6 Vitesse de sécurité en fonctionnement des moteurs à induction à cage . 112

9.7 Survitesse.114

9.8 Courant de court-circuit des machines synchrones. 116

9.9 Epreuve de tenue au court-circuit des machines synchrones . 116

9.10 Essai de commutation pour machines à collecteur . 116

9.11 Distorsion harmonique totale (DHT) pour machines synchrones . 116

10 Plaques signalétiques.118

10.1 Généralités.118

10.2 Marquage.118

11 Exigences diverses.122

11.1 Mise à la terre de protection des machines . 122

11.2 Clavette(s) de bout d'arbre. 124

12 Tolérances. 126

12.1 Généralités.126

13 Compatibilité électromagnétique (CEM) . 130

13.1 Généralités.130

13.2 Immunité.130

13.3 Emission.130

13.4 Essais d’immunité.130

13.5 Essais d’émission.132

14 Sécurité. 132

Annexe A (informative) Guide pour l'application du service type S10 et pour l'obtention

de la valeur relative de l'espérance de vie thermique TL . 134

Annexe B (informative) Limites de Compatibilité Electromagnétique (CEM). 136

Figure 1 – Service continu – Service type S1 .26

Figure 2 – Service temporaire – Service type S2.28

Figure 3 – Service intermittent périodique – Service type S3.30

Figure 4 – Service intermittent périodique à démarrage – Service type S4 .32

Figure 5 – Service intermittent périodique à freinage électrique – Service type S5.34

Figure 6 – Service ininterrompu périodique à charge intermittente – Service type S6 .36

Figure 7 – Service ininterrompu périodique à freinage électrique – Service type S7.38

Figure 8 – Service ininterrompu périodique à changements liés de charge et de vitesse

– Service type S8 .42

Figure 9 – Service à variations non périodique de charge et de vitesse – Service type S9 .44

Figure 10 – Service avec charges constantes distinctes – Service type S10.48

Figure 11 – Valeurs limites de tension et fréquence pour les alternateurs .68

Figure 12 – Valeurs limites de tension et fréquence pour les moteurs .68

− 6 − 60034-1 CEI:2004

Tableau 1 – Tensions assignées préférables .56

Tableau 2 – Conditions de fonctionnement déséquilibrées pour les machines synchrones.62

Tableau 3 – Fonctions principales des machines .66

Tableau 4 – Fluide de refroidissement de référence (voir aussi Tableau 10) .70

Tableau 5 – Délai.80

Tableau 6 – Points de mesure .84

Tableau 7 – Limites d’échauffement des enroulements à refroidissement indirect par l’air.88

Tableau 8 – Limites d’échauffement des enroulements à refroidissement indirect

par hydrogène.90

Tableau 9 – Corrections aux limites des échauffements sur le site de fonctionnement

des enroulements à refroidissement indirect pour tenir compte de conditions de

fonctionnement et de caractéristiques assignées qui ne sont pas les conditions de

référence .90

Tableau 10 – Températures ambiantes maximales présumées .94

Tableau 11 – Limites corrigées des échauffements sur le site d'essai (Δθ ) des

T

enroulements à refroidissement indirect par air pour tenir compte des conditions de

fonctionnement sur le site d'essai.96

Tableau 12 – Limites des températures des enroulements à refroidissement direct

et de leurs fluides de refroidissement .98

Tableau 13 – Corrections aux limites de température sur le site de fonctionnement

pour les enroulements à refroidissement direct par air ou hydrogène pour tenir compte

de conditions de fonctionnement et de caractéristiques assignées qui ne sont pas les

conditions de référence . 100

Tableau 14 – Limites corrigées de température sur le site d'essai θ pour les

T

enroulement à refroidissement direct par air pour tenir compte des conditions de

fonctionnement sur le site d'essai. 100

Tableau 15 – Liste minimale des essais individuels . 102

Tableau 16 − Essais de tension de tenue. 106

−1

Tableau 17 – Vitesse maximale de sécurité en fonctionnement (min ) des moteurs

triphasés à induction à cage, à une seule vitesse, pour des tensions d’alimentation

inférieures ou égales à 1 000 V . 112

Tableau 18 − Survitesses . 114

Tableau 19 − Section des conducteurs de terre . 124

Tableau 20 − Nomenclature des tolérances sur les valeurs des grandeurs. 126

Tableau B.1 – Limites d’émission électromagnétique pour les machines sans balais. 136

Tableau B.2 – Limites d’émission électromagnétique pour les machines avec balais. 136

− 8 − 60034-1 CEI:2004

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

MACHINES ÉLECTRIQUES TOURNANTES –

Partie 1: Caractéristiques assignées et caractéristiques

de fonctionnement

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation composée

de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a pour objet de

favoriser la coopération internationale pour toutes les questions de normalisation dans les domaines de

l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes internationales,

des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au public (PAS) et des

Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des comités d'études,

aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les organisations

internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent également aux

travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO), selon des

conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable de

l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60034-1 a été établie par le comité d'études 2 de la CEI:

Machines tournantes.

Cette onzième édition annule et remplace la dixième édition, parue en 1996, ainsi que ses

amendements 1 (1997) et 2 (1999); elle constitue une révision technique.

− 10 − 60034-1 CEI:2004

Les principales modifications apportées par cette édition sont les suivantes:

Article ou

Modifications

Paragraphe

7.2.2 Nouvelles spécifications pour les alternateurs qui alimentent des circuits non

linéaires

8 Modifications importantes dans les Tableaux 4, 7 et 9

9.1 Nouvelles spécifications pour les essais individuels

9.2 Tableau 16 Essais de tension des auxiliaires

9.11 Distorsion harmonique totale (DHT) pour machines synchrones

11.1 Mise à la terre de protection des machines

12.1 Tableau 20 Tolérance sur le rendement

13 Compatibilité électromagnétique

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

2/1278/FDIS 2/1294/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2005. A cette

date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

− 12 − 60034-1 CEI:2004

MACHINES ÉLECTRIQUES TOURNANTES –

Partie 1: Caractéristiques assignées et caractéristiques

de fonctionnement

1 Domaine d'application

La présente partie de la CEI 60034 est applicable à toutes les machines électriques tournantes

à l'exception de celles qui font l'objet d'autres normes de la CEI, par exemple la CEI 60349.

Les machines comprises dans le domaine d'application de la présente norme peuvent

également être soumises à des exigences nouvelles, modifiées ou complémentaires figurant

dans d'autres publications – par exemple, la CEI 60079 et la CEI 60092.

NOTE S'il est nécessaire de modifier certains articles de la présente norme afin de permettre des applications

spéciales, par exemple pour les matériels soumis à des rayonnements ou les matériels aérospatiaux, tous les

autres articles restent valables, pour autant qu'ils ne soient pas en contradiction avec ces spécifications

particulières.

2 Références normatives

Les documents normatifs suivants sont indispensables pour l’application de la présente norme.

Pour les références datées, seule l’édition citée s’applique. Pour les références non datées, la

dernière édition du document référencé s’applique (y compris les amendements).

CEI 60027-1, Symboles littéraux à utiliser en électrotechnique − Partie 1: Généralités

CEI 60027-4, Symboles littéraux à utiliser en électrotechnique − Partie 4: Symboles des

grandeurs relatives aux machines électriques tournantes

CEI 60034-2, Machines électriques tournantes − Partie 2: Méthodes pour la détermination des

pertes et du rendement des machines électriques tournantes à partir d'essais (à l'exclusion des

machines électriques de traction)

CEI 60034-3, Machines électriques tournantes − Partie 3: Règles spécifiques pour les

turbomachines synchrones

CEI 60034-5, Machines électriques tournantes − Partie 5: Degrés de protection procurés par la

conception intégrale des machines électriques tournantes (code IP). Classification

CEI 60034-6, Machines électriques tournantes − Partie 6: Modes de refroidissement (code IC)

CEI 60034-8, Machines électriques tournantes – Partie 8: Marques d’extrémité et sens de

rotation

CEI 60034-12, Machines électriques tournantes − Partie 12: Caractéristiques de démarrage

des moteurs triphasés à induction à cage à une seule vitesse

CEI 60034-15, Machines électriques tournantes − Partie 15: Niveaux de tension de tenue au

choc des machines tournantes à courant alternatif à bobines stator préformées

CEI 60034-17, Machines électriques tournantes − Partie 17: Moteurs à induction à cage

alimentés par convertisseurs – Guide d’application

− 14 − 60034-1 CEI:2004

CEI 60034-18 (toutes les parties), Machines électriques tournantes – Evaluation fonctionnelle

des systèmes d’isolation

CEI 60038, Tensions normales de la CEI

CEI 60050(411):1996, Vocabulaire Electrotechnique International (VEI) − Chapitre 411:

Machines tournantes

CEI 60060-1, Techniques des essais à haute tension – Partie 1: Définitions et prescriptions

générales relatives aux essais

CEI 60072 (toutes les parties), Dimensions et séries de puissances des machines électriques

tournantes

CEI 60204-1, Sécurité des machines – Equipement électrique des machines – Partie 1: Règles

générales

CEI 60204-11, Sécurité des machines – Equipement électrique des machines – Partie 11:

Prescriptions pour les équipements HT fonctionnant à des tensions supérieures à 1 000 V c.a.

ou 1 500 V c.c. et ne dépassant pas 36 kV

CEI 60279, Mesure de la résistance des enroulements d'une machine à courant alternatif en

fonctionnement sous tension alternative

CEI 60335-1, Appareils électrodomestiques et analogues – Sécurité – Partie 1: Prescriptions

générales

CEI 60445, Principes fondamentaux et de sécurité pour les interfaces hommes-machines, le

marquage et l’identification – Identification des bornes de matériels et des extrémités de

certains conducteurs désignés et règles générales pour un système alphanumérique

CEI 60971, Convertisseurs à semi-conducteurs – Code d'identification pour montages

convertisseurs

CEI 61293, Marquage des matériels électriques avec des caractéristiques assignées relatives

à l'alimentation électrique – Prescriptions de sécurité

CEI 61986, Machines électriques tournantes – Charge équivalente et techniques par super-

position – Essais indirects pour déterminer l’échauffement

CEI 62114, Systèmes d’isolation électrique (SIE) – Classification thermique

CISPR 11, Appareils industriels, scientifiques et médicaux (ISM) à fréquence radioélectrique –

Caractéristiques de perturbations électromagnétiques – Limites et méthodes de mesure

CISPR 14, Compatibilité électromagnétique – Exigences pour les appareils électro-

domestiques, outillages électriques et appareils analogues

CISPR 16, Spécifications des méthodes et des appareils de mesure des perturbations

radioélectriques et de l'immunité aux perturbations radioélectriques

− 16 − 60034-1 CEI:2004

3 Termes et définitions

Pour les besoins du présent document, les définitions de la CEI 60050(411) s’appliquent ainsi

que les définitions suivantes.

Pour des définitions autres que celles de 3.17 à 3.22 concernant les modes et les fluides de

refroidissement, se référer à la CEI 60034-6.

Au sens de la présente norme, le terme «accord» signifie «accord entre le constructeur et

l’acheteur».

3.1

valeur assignée

valeur d'une grandeur fixée, généralement par le constructeur, pour un fonctionnement spécifié

d'une machine

[VEI 411-51-23]

NOTE La tension assignée ou plage de tensions assignées est la tension assignée ou plage de tensions

assignées entre phases aux bornes.

3.2

caractéristiques assignées

ensemble des valeurs assignées et des conditions de fonctionnement

[VEI 411-51-24]

3.3

puissance assignée

valeur de la puissance incluse dans les caractéristiques assignées

3.4

charge

ensemble des valeurs des grandeurs électriques et mécaniques qui caractérisent les

exigences imposées à une machine tournante par un circuit électrique ou un dispositif

mécanique, à un instant donné

[VEI 411-51-01]

3.5

fonctionnement à vide

état de fonctionnement d'une machine tournant à puissance nulle (mais les autres conditions

étant les conditions normales de fonctionnement)

[VEI 411-51-02 modifiée]

3.6

pleine charge

charge amenant une machine à fonctionner à ses caractéristiques assignées

[VEI 411-51-10]

3.7

valeur de pleine charge

valeur d'une grandeur pour une machine fonctionnant à pleine charge

[VEI 411-51-11]

NOTE Cette notion est applicable à la puissance, au couple, au courant, à la vitesse, etc.

− 18 − 60034-1 CEI:2004

3.8

repos

absence complète de tout mouvement et de toute alimentation électrique ou de tout entraî-

nement mécanique

[VEI 411-51-03]

3.9

service

stipulation de la charge (des charges) à laquelle (auxquelles) la machine est soumise,

y compris, le cas échéant, les périodes de démarrage, de freinage électrique, de fonction-

nement à vide et de repos, ainsi que leurs durées et leur ordre de succession dans le temps

[VEI 411-51-06]

3.10

service type

service continu, temporaire ou périodique comprenant une ou plusieurs charges qui restent

constantes pendant la durée spécifiée ou service non périodique pendant lequel généralement

la charge et la vitesse varient dans la plage de fonctionnement admissible

[VEI 411-51-13]

3.11

facteur de marche

rapport entre la période de fonctionnement en charge, y compris le démarrage et le freinage

électrique, à la durée du cycle de service, exprimé en pourcentage

[VEI 411-51-09]

3.12

couple à rotor bloqué

couple mesuré le plus faible que développe le moteur sur son bout d'arbre d'entraînement,

quand son rotor est maintenu bloqué quelle que soit sa position angulaire et qu'il est alimenté à

tension et fréquence assignées

[VEI 411-48-06]

3.13

courant à rotor bloqué

valeur efficace la plus élevée du courant en régime établi, absorbé par le moteur lorsqu'il est

alimenté aux tension et fréquence assignées et que son rotor est maintenu bloqué quelle que

soit sa position angulaire

[VEI 411-48-16]

3.14

couple minimal pendant le démarrage (d'un moteur à courant alternatif)

valeur la plus faible du couple asynchrone en régime établi, que le moteur développe entre la

vitesse nulle et la vitesse qui correspond au couple maximal (couple de décrochage) lorsque le

moteur est alimenté à la tension et à la fréquence assignées

Cette définition ne s'applique pas au cas de moteurs asynchrones dont le couple décroît

continuellement lorsque la vitesse augmente.

NOTE En plus des couples asynchrones en régime établi, il existe, à des vitesses spécifiques, des couples

harmoniques synchrones qui sont fonction de l'angle de charge du rotor.

A de telles vitesses, le couple d'accélération peut être négatif pour certains angles de charge du rotor.

L'expérience et le calcul montrent que c'est une condition de fonctionnement instable et qu'en conséquence les

couples harmoniques synchrones n'empêchent pas l'accélération du moteur et sont exclus de cette définition.

− 20 − 60034-1 CEI:2004

3.15

couple maximal (couple de décrochage) (d'un moteur à courant alternatif)

valeur maximale en régime établi du couple asynchrone que le moteur développe sans chute

brutale de vitesse, lorsqu'il est alimenté à tension et fréquence assignées

Cette définition ne s'applique pas au cas des moteurs asynchrones dont le couple décroît

continuellement lorsque la vitesse augmente.

3.16

couple de décrochage synchrone (d'un moteur)

couple le plus élevé que développe un moteur synchrone à sa température de fonctionnement

et à la vitesse de synchronisme, à tension, fréquence et excitation assignées

3.17

refroidissement

opération par laquelle de la chaleur provenant des pertes produites dans une machine est

cédée à un fluide de refroidissement primaire qui peut être continûment remplacé ou être

lui-même refroidi dans un échangeur de chaleur par un fluide de refroidissement secondaire

[VEI 411-44-01]

3.18

fluide de refroidissement

fluide, liquide ou gaz, par l'intermédiaire duquel la chaleur est transférée

[VEI 411-44-02]

3.19

fluide de refroidissement primaire

fluide, liquide ou gaz, qui, se trouvant à une température inférieure à celle des pièces de la

machine et en contact avec celles-ci, transporte la chaleur cédée par ces pièces

[VEI 411-44-03]

3.20

fluide de refroidissement secondaire

fluide, liquide ou gaz, qui, se trouvant à une température inférieure à celle du fluide de

refroidissement primaire, transporte la chaleur cédée par ce fluide primaire au moyen d'un

échangeur de chaleur ou à travers la surface extérieure de la machine

[VEI 411-44-04]

3.21

enroulement à refroidissement direct (refroidissement interne)

enroulement refroidi principalement par un fluide de refroidissement s'écoulant en contact

direct avec la partie refroidie à travers des passages creux, tubes, conduits ou canaux qui,

quelle que soit leur orientation, forment partie intégrante de l'enroulement à l'intérieur de

l'isolation principale

[VEI 411-44-08]

3.22

enroulement à refroidissement indirect

tout enroulement autre qu’un enroulement à refroidissement direct

[VEI 411-44-09]

___________

Dans tous les cas où «indirect» ou «direct» n’est pas indiqué, il s’agit d’un enroulement à refroidissement

indirect.

− 22 − 60034-1 CEI:2004

3.23

isolation supplémentaire

isolation indépendante prévue en plus de l'isolation principale, en vue d'assurer la protection

contre les chocs électriques en cas de défaut survenant dans l'isolation principale

3.24

moment d'inertie

somme (intégrale) des produits des masses élémentaires d'un corps par le carré de leurs

distances (radiales) par rapport à un axe donné

3.25

équilibre thermique

état atteint lorsque les échauffements des diverses parties de la machine ne varient pas de

plus d’un gradient de 2 K par heure

[VEI 411-51-08]

NOTE On peut déterminer l'équilibre thermique à partir d'un tracé de l’échauffement en fonction du temps, lorsque

les droites entre points pris en début et fin de chacun de deux intervalles de temps raisonnables successifs ont une

pente de moins de 2 K par heure.

3.26

constante de temps thermique équivalente

constante de temps qui, en remplaçant plusieurs constantes de temps individuelles, détermine

approximativement l'évolution de la température dans un enroulement après une variation de

courant en échelon

3.27

enroulement enrobé

enroulement complètement enfermé ou noyé dans un isolant moulé

[VEI 411-39-06]

3.28

valeur assignée du facteur de forme du courant continu fourni à l'induit d'un moteur à

courant continu par un convertisseur statique de puissance

rapport de la valeur efficace maximale admissible du courant I à sa valeur moyenne

eff, maxN

I (valeur moyenne intégrée sur une période) aux conditions assignées:

moyN

I

eff,maxN

k =

fN

I

moyN

3.29

facteur d'ondulation du courant

rapport de la différence entre la valeur maximale I et la valeur minimale I d'un courant

max min

ondulé au double de sa valeur moyenne I (valeur moyenne intégrée sur une période):

moy

II−

max min

q =

i

2 × I

moy

NOTE Pour de faibles valeurs d'ondulation du courant, le facteur d'ondulation peut être approché par la formule

suivante:

I − I

max min

q =

i

I + I

max min

La formule ci-dessus peut être utilisée en tant qu'approximation si la valeur calculée résultante

de q est inférieure ou égale à 0,4.

i

− 24 − 60034-1 CEI:2004

3.30

tolérance

déviation permise entre la valeur déclarée et la valeur mesurée

3.31

essai de type

essai effectué sur une ou plusieurs machines réalisées selon une conception donnée pour

vérifier que cette conception répond à certaines spécifications

[VEI 411-53-01]

NOTE L'essai type peut être aussi considéré comme valide s'il a été réalisé sur une machine ayant des déviations

mineures en caractéristiques assignées ou autres. Il convient que ces déviations fassent l'objet d'un accord.

3.32

essai de routine

essai auquel est soumise chaque machine en cours ou en fin de fabrication pour vérifier qu'elle

satisfait à certains critères définis

[VEI 411-53-02]

4 Services

4.1 Spécification du service

C'est à l'acheteur qu'incombe la responsabilité de spécifier le service. L'acheteur peut décrire

le service par l'une des méthodes suivantes:

a) numériquement, si la charge ne varie pas ou varie de façon connue;

b) graphiquement, par une représentation des grandeurs variables en fonction du temps;

c) en choisissant l'un des services types S1 à S10 qui est au moins aussi sévère que le

service prévu.

Le service type doit être désigné par l’abréviation appropriée spécifiée en 4.2, à la suite de la

valeur de la charge.

Une formulation du facteur de marche est indiquée sous chaque figure appropriée de service

type.

Normalement l'acheteur ne peut pas fournir une valeur au moment d'inertie du moteur (J ) ni à

M

l'espérance de vie thermique en valeur relative (TL), voir Annexe A. Ces valeurs sont fournies

par le constructeur.