IEC 60034-1:2010

(Main)Rotating electrical machines - Part 1: Rating and performance

Rotating electrical machines - Part 1: Rating and performance

IEC 60034-1:2010 is applicable to all rotating electrical machines except those covered by other IEC standards, for example, IEC 60349. Machines within the scope of this standard may also be subject to superseding, modifying or additional requirements in other publications, for example, IEC 60079 and IEC 60092. The changes with respect to the previous edition are as follows:

- clarification of water coolant temperature,

- recognition of IE code,

- clarification of the term "tolerances".

Machines électriques tournantes - Partie 1: Caractéristiques assignées et caractéristiques de fonctionnement

La CEI 60034-1:2010 est applicable à toutes les machines électriques tournantes à l'exception de celles qui font l'objet d'autres normes de la CEI, par exemple la CEI 60349. Les machines comprises dans le domaine d'application de la présente norme peuvent également être soumises à des exigences nouvelles, modifiées ou complémentaires figurant dans d'autres publications - par exemple, la série CEI 60079 et la CEI 60092. Les modification par rapport à l'édition précédente sont les suivantes:

- clarification portant sur la température de l'eau de refroidissement,

- reconnaissance du code IE,

- clarification du terme " tolérances ".

General Information

- Status

- Published

- Publication Date

- 02-Feb-2010

- Technical Committee

- TC 2 - Rotating machinery

- Drafting Committee

- WG 12 - TC 2/WG 12

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 09-May-2017

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60034-1:2010 is a critical international standard published by the International Electrotechnical Commission (IEC) that establishes comprehensive guidelines for the rating and performance of rotating electrical machines. This standard applies broadly to all types of rotating electrical machines except those governed by more specialized IEC standards such as IEC 60349. It provides unified criteria for assessing machine capabilities, ensuring compatibility, reliability, and safety across diverse applications in the electrical engineering sector.

This edition introduces important clarifications on water coolant temperature, incorporates the recognition of the International Efficiency (IE) code, and refines definitions related to tolerances, thereby enhancing precision in machine rating and performance specifications.

Key Topics

Scope and Application

IEC 60034-1:2010 is applicable to a variety of rotating electrical machines, setting foundational requirements while acknowledging that machines may also be subject to additional standards for specific conditions, such as IEC 60079 for explosive atmospheres or IEC 60092 for marine applications.Duty Types and Performance Ratings

The standard defines multiple duty types (S1 to S10) to classify operational modes, including continuous, short-time, and intermittent periodic duties. This classification aids in selecting appropriate machine ratings based on usage patterns.Rating Assignments and Classes

Detailed procedures for rating assignment, selection of rating classes, and allocation of machine outputs are provided. This ensures precise evaluation of machine performance under various voltage and environmental conditions.Site Operating and Electrical Conditions

The document addresses site-specific parameters such as altitude, ambient air temperature, and coolant characteristics (including water coolant temperature), acknowledging their effect on machine performance and lifespan.Thermal Performance and Testing Procedures

Comprehensive guidelines for thermal tests-including temperature rise limits, measurement methods, and thermal class definitions-are included to verify machine resilience under operational stress.Safety and Compliance

The standard also covers essential safety aspects such as protective earthing, electromagnetic compatibility (EMC) requirements, and marking specifications on rating plates for clear identification.Tolerance Definitions

Clarifications on tolerances enable manufacturers and users to understand acceptable deviations in rated values, ensuring consistency and interoperability.

Applications

Industrial Motors and Generators

IEC 60034-1:2010 is indispensable for manufacturers and users of industrial motors, generators, and other rotating electrical equipment requiring precise rating and performance measurement.Equipment Design and Manufacturing

Engineers and designers rely on this standard to certify machines that meet international quality benchmarks, helping optimize designs for efficiency and durability under specified operating conditions.Maintenance and Testing Services

Maintenance teams use the standard’s testing protocols to assess machine health, predict failure points related to thermal limits, and ensure continued safe operation.Energy Efficiency and Regulatory Compliance

Incorporation of the IE code allows organizations to classify machines according to recognized energy efficiency levels, supporting energy-saving initiatives and compliance with global regulations.Specialized Environments

The coordination with other IEC standards makes IEC 60034-1:2010 relevant for harsh or hazardous environments such as marine installations, explosive atmospheres, and variable altitude conditions.

Related Standards

IEC 60349

Governs electrical machines for specific applications and is applicable when specialized machine types are involved, superseding IEC 60034-1 as appropriate.IEC 60079

Related to equipment used in explosive atmospheres; machines compliant with IEC 60034-1 may need additional certification under IEC 60079.IEC 60092

Focuses on electrical installations in ships, defining conditions that may impact machine rating and performance beyond IEC 60034-1.Energy Efficiency Standards (IE Codes)

Integrated within IEC 60034-1 for classifying machine efficiency levels, facilitating selection and compliance with global efficiency regulations.

Summary

IEC 60034-1:2010 serves as an authoritative benchmark for the rating and performance of rotating electrical machines, ensuring uniformity and high standards across the electrical industry. By addressing machine duty types, environmental conditions, thermal performance, and safety requirements, this standard supports manufacturers, designers, operators, and regulators in achieving optimal machine functionality, reliability, and energy efficiency worldwide.

Keywords: IEC 60034-1, rotating electrical machines, machine rating, performance standards, electrical motor standards, thermal performance, duty types, IEC standards, electromagnetic compatibility, machine safety, IE efficiency code.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60034-1:2010 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Rotating electrical machines - Part 1: Rating and performance". This standard covers: IEC 60034-1:2010 is applicable to all rotating electrical machines except those covered by other IEC standards, for example, IEC 60349. Machines within the scope of this standard may also be subject to superseding, modifying or additional requirements in other publications, for example, IEC 60079 and IEC 60092. The changes with respect to the previous edition are as follows: - clarification of water coolant temperature, - recognition of IE code, - clarification of the term "tolerances".

IEC 60034-1:2010 is applicable to all rotating electrical machines except those covered by other IEC standards, for example, IEC 60349. Machines within the scope of this standard may also be subject to superseding, modifying or additional requirements in other publications, for example, IEC 60079 and IEC 60092. The changes with respect to the previous edition are as follows: - clarification of water coolant temperature, - recognition of IE code, - clarification of the term "tolerances".

IEC 60034-1:2010 is classified under the following ICS (International Classification for Standards) categories: 29.160.01 - Rotating machinery in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60034-1:2010 has the following relationships with other standards: It is inter standard links to EN ISO 1680:2013, EN ISO 13631:2002, EN ISO 5801:2017, EN ISO 8528-13:2016, EN 14161:2011, EN 14161:2011+A1:2015, IEC 60034-1:2017, IEC 60034-1:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60034-1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60034-1 ®

Edition 12.0 2010-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Rotating electrical machines –

Part 1: Rating and performance

Machines électriques tournantes –

Partie 1: Caractéristiques assignées et caractéristiques de fonctionnement

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60034-1 ®

Edition 12.0 2010-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Rotating electrical machines –

Part 1: Rating and performance

Machines électriques tournantes –

Partie 1: Caractéristiques assignées et caractéristiques de fonctionnement

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XB

CODE PRIX

ICS 29.160 ISBN 978-2-88910-016-3

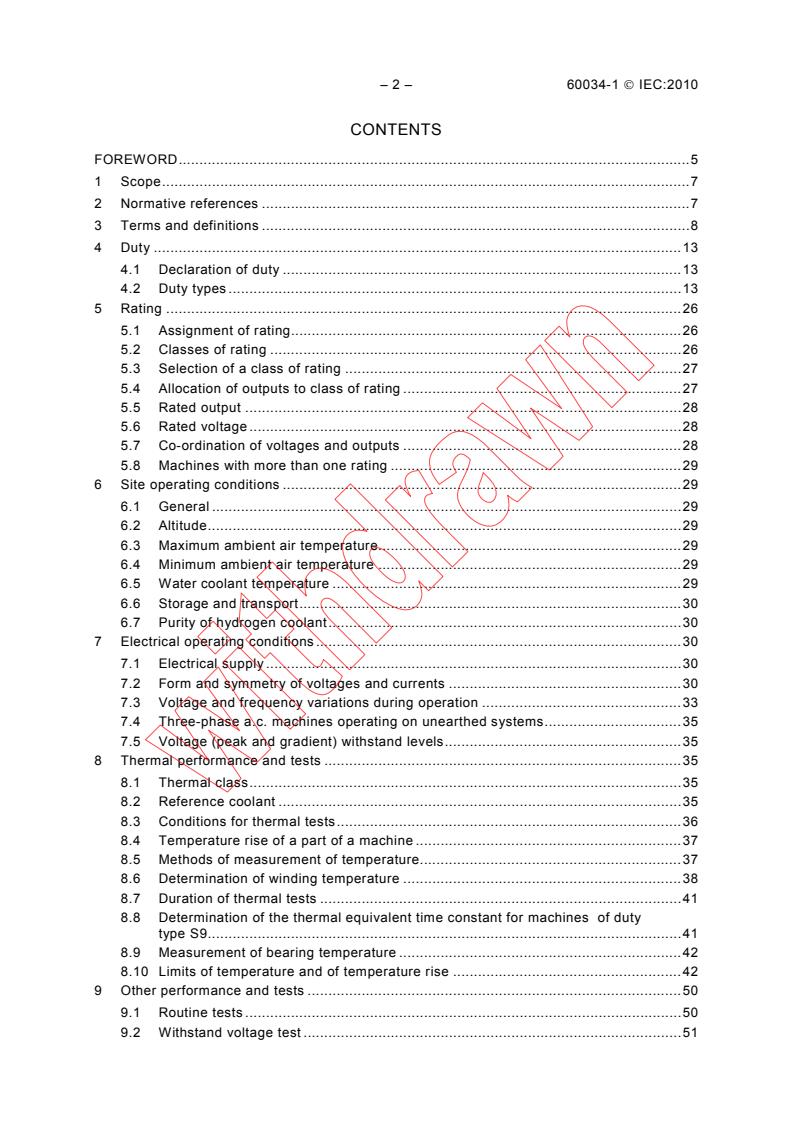

– 2 – 60034-1 © IEC:2010

CONTENTS

FOREWORD.5

1 Scope.7

2 Normative references .7

3 Terms and definitions .8

4 Duty .13

4.1 Declaration of duty .13

4.2 Duty types .13

5 Rating .26

5.1 Assignment of rating.26

5.2 Classes of rating .26

5.3 Selection of a class of rating .27

5.4 Allocation of outputs to class of rating .27

5.5 Rated output .28

5.6 Rated voltage.28

5.7 Co-ordination of voltages and outputs .28

5.8 Machines with more than one rating .29

6 Site operating conditions .29

6.1 General .29

6.2 Altitude.29

6.3 Maximum ambient air temperature.29

6.4 Minimum ambient air temperature .29

6.5 Water coolant temperature .29

6.6 Storage and transport.30

6.7 Purity of hydrogen coolant.30

7 Electrical operating conditions.30

7.1 Electrical supply .30

7.2 Form and symmetry of voltages and currents .30

7.3 Voltage and frequency variations during operation .33

7.4 Three-phase a.c. machines operating on unearthed systems.35

7.5 Voltage (peak and gradient) withstand levels.35

8 Thermal performance and tests .35

8.1 Thermal class.35

8.2 Reference coolant .35

8.3 Conditions for thermal tests.36

8.4 Temperature rise of a part of a machine .37

8.5 Methods of measurement of temperature.37

8.6 Determination of winding temperature .38

8.7 Duration of thermal tests .41

8.8 Determination of the thermal equivalent time constant for machines of duty

type S9.41

8.9 Measurement of bearing temperature .42

8.10 Limits of temperature and of temperature rise .42

9 Other performance and tests .50

9.1 Routine tests .50

9.2 Withstand voltage test .51

60034-1 © IEC:2010 – 3 –

9.3 Occasional excess current.53

9.4 Momentary excess torque for motors.54

9.5 Pull-up torque.55

9.6 Safe operating speed of cage induction motors .55

9.7 Overspeed .56

9.8 Short-circuit current for synchronous machines .57

9.9 Short-circuit withstand test for synchronous machines.57

9.10 Commutation test for commutator machines .58

9.11 Total harmonic distortion (THD) for synchronous machines .58

10 Rating plates .58

10.1 General .58

10.2 Marking .59

11 Miscellaneous requirements .60

11.1 Protective earthing of machines .60

11.2 Shaft-end key(s).62

12 Tolerances .62

12.1 General .62

12.2 Tolerances on values of quantities .62

13 Electromagnetic compatibility (EMC) .64

13.1 General .64

13.2 Immunity .64

13.3 Emission .65

13.4 Immunity tests.65

13.5 Emission tests.65

14 Safety.65

Annex A (informative) Guidance for the application of duty type S10 and for

establishing the value of relative thermal life expectancy TL .67

Annex B (informative) Electromagnetic compatibility (EMC) limits .68

Bibliography.69

Figure 1 – Continuous running duty – Duty type S1.14

Figure 2 – Short-time duty – Duty type S2.15

Figure 3 – Intermittent periodic duty – Duty type S3.16

Figure 4 – Intermittent periodic duty with starting – Duty type S4 .17

Figure 5 – Intermittent periodic duty with electric braking – Duty type S5 .18

Figure 6 – Continuous operation periodic duty – Duty type S6 .19

Figure 7 – Continuous operation periodic duty with electric braking – Duty type S7 .20

Figure 8 – Continuous operation periodic duty with related load/speed changes – Duty

type S8 .22

Figure 9 – Duty with non-periodic load and speed variations – Duty type S9 .23

Figure 10 – Duty with discrete constant loads – Duty type S10 .25

Figure 11 – Voltage and frequency limits for generators.34

Figure 12 – Voltage and frequency limits for motors.34

Table 1 – Preferred voltage ratings .29

Table 2 − Unbalanced operating conditions for synchronous machines .32

– 4 – 60034-1 © IEC:2010

Table 3 − Primary functions of machines.34

Table 4 – Reference coolant (see also Table 10) .36

Table 5 – Time interval .40

Table 6 – Measuring points.42

Table 7 – Limits of temperature rise of windings indirectly cooled by air .44

Table 8 − Limits of temperature rise of windings indirectly cooled by hydrogen .45

Table 9 – Adjustments to limits of temperature rise at the operating site of indirect

cooled windings to take account of non-reference operating conditions and ratings .45

Table 10 – Assumed maximum ambient temperature .47

Table 11 – Adjusted limits of temperature rise at the test site (Δθ ) for windings

T

indirectly cooled by air to take account of test site operating conditions .48

Table 12 – Limits of temperature of directly cooled windings and their coolants .49

Table 13 – Adjustments to limits of temperature at the operating site for windings

directly cooled by air or hydrogen to take account of non-reference operating

conditions and ratings.50

Table 14 – Adjusted limits of temperature at the test site θ for windings directly cooled

T

by air to take account of test site operating conditions .50

Table 15 – Minimum schedule of routine tests .51

Table 16 – Withstand voltage tests .52

−1

Table 17 – Maximum safe operating speed (min ) of three-phase single-speed cage

induction motors for voltages up to and including 1 000 V.56

Table 18 – Overspeeds.57

Table 19 – Cross-sectional areas of earthing conductors .62

Table 20 – Schedule of tolerances on values of quantities .63

Table B.1 – Electromagnetic emission limits for machines without brushes .68

Table B.2 – Electromagnetic emission limits for machines with brushes.68

60034-1 © IEC:2010 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ROTATING ELECTRICAL MACHINES –

Part 1: Rating and performance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60034-1 has been prepared by IEC technical committee 2:

Rotating machinery.

This twelfth edition cancels and replaces the eleventh edition published in 2004. It constitutes

a technical revision.

Major changes were not introduced in this edition. The corrections, clarifications and

improvements include:

– 6 – 60034-1 © IEC:2010

Clause or

Change

subclause

6.5 Clarification of water coolant temperature

8.10.2 Minor change to Table 12

10.2 Recognition of IE code, of open circuit voltage of synchronous machines

excited by permanent magnets and of maximum operation speed of machines

specifically designed for converter supply

Clarification of the term ‘tolerances’

The text of this standard is based on the following documents:

FDIS Report on voting

2/1579/FDIS 2/1587/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 60034 series, published under the general title Rotating electrical

machines, can be found on the IEC website.

NOTE A table of cross-references of all IEC TC 2 publications can be found in the IEC TC 2 dashboard on the

IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60034-1 © IEC:2010 – 7 –

ROTATING ELECTRICAL MACHINES –

Part 1: Rating and performance

1 Scope

This part of IEC 60034 is applicable to all rotating electrical machines except those covered

1)

by other IEC standards, for example, IEC 60349 [10] .

Machines within the scope of this standard may also be subject to superseding, modifying or

additional requirements in other publications, for example, IEC 60079 [8] and IEC 60092 [9].

NOTE If particular clauses of this standard are modified to meet special applications, for example machines

subject to radioactivity or machines for aerospace, all other clauses apply insofar as they are compatible.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60027-1, Letter symbols to be used in electrical technology − Part 1: General

IEC 60027-4, Letter symbols to be used in electrical technology − Part 4: Rotating electrical

machines

IEC 60034-2 (all parts), Rotating electrical machines − Part 2: Standard methods for

determining losses and efficiency from tests (excluding machines for traction vehicles)

IEC 60034-3, Rotating electrical machines − Part 3: Specific requirements for synchronous

generators driven by steam turbines or combustion gas turbines

IEC 60034-5, Rotating electrical machines − Part 5: Degrees of protection provided by the

integral design of rotating electrical machines (IP code) – Classification

IEC 60034-8, Rotating electrical machines – Part 8: Terminal markings and direction of

rotation

IEC 60034-12, Rotating electrical machines − Part 12: Starting performance of single-speed

three-phase cage induction motors

IEC 60034-15, Rotating electrical machines − Part 15: Impulse voltage withstand levels of

form-wound stator coils for rotating a.c. machines

IEC 60034-17, Rotating electrical machines − Part 17: Cage induction motors when fed from

converters – Application guide

IEC 60034-18 (all parts), Rotating electrical machines – Part 18: Functional evaluation of

insulating systems

___________

1)

Figures in square brackets refer to the Bibliography.

– 8 – 60034-1 © IEC:2010

IEC 60034-30, Rotating electrical machines – Part 30: Efficiency classes of single-speed,

three-phase, cage-induction motors (IE-code)

IEC 60038, IEC standard voltages

IEC 60050-411:1996, International Electrotechnical Vocabulary (IEV) − Chapter 411: Rotating

machines

IEC 60060-1, High-voltage test techniques – Part 1: General definitions and test requirements

IEC 60072 (all parts), Dimensions and output series for rotating electrical machines

IEC 60085, Electrical insulation – Thermal evaluation and designation

IEC 60204-1, Safety of machinery – Electrical equipment of machines – Part 1: General

requirements

IEC 60204-11, Safety of machinery – Electrical equipment of machines – Part 11:

Requirements for HV equipment for voltages above 1 000 V a.c. or 1 500 V d.c. and not

exceeding 36 kV

IEC 60335-1, Household and similar electrical appliances – Safety – Part 1: General

requirements

IEC 60445, Basic and safety principles for man-machine interface, marking and identification

– Identification of equipment terminals and conductor terminals

IEC 60664-1, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

2)

IEC 60971, Semiconductor convertors. Identification code for convertor connections

IEC 61293, Marking of electrical equipment with ratings related to electrical supply – Safety

requirements

CISPR 11, Industrial, scientific and medical equipment – Radiofrequency disturbance

characteristics – Limits and methods of measurement

CISPR 14 (all parts), Electromagnetic compatibility – Requirements for household appliances,

electric tools and similar apparatus

CISPR 16 (all parts), Specification for radio disturbance and immunity measuring apparatus

and methods

3 Terms and definitions

For the purposes of this document, the terms and definitions in IEC 60050-411, some of which

are repeated here for convenience, and the following terms and definitions apply.

NOTE 1 For definitions concerning cooling and coolants, other than those in 3.17 to 3.22, reference should be

made to IEC 60034-6 [1].

___________

2)

IEC 60971 was withdrawn (and not replaced) in 2004.

60034-1 © IEC:2010 – 9 –

NOTE 2 For the purposes of this standard, the term ‘agreement’ means ‘agreement between the manufacturer

and purchaser’.

3.1

rated value

a quantity value assigned, generally by a manufacturer, for a specified operating condition of

a machine

[IEV 411-51-23]

NOTE The rated voltage or voltage range is the rated voltage or voltage range between lines at the terminals.

3.2

rating

the set of rated values and operating conditions

[IEV 411-51-24]

3.3

rated output

the value of the output included in the rating

3.4

load

all the values of the electrical and mechanical quantities that signify the demand made on a

rotating machine by an electrical circuit or a mechanism at a given instant

[IEV 411-51-01]

3.5

no-load (operation)

the state of a machine rotating with zero output power (but under otherwise normal operating

conditions)

[IEV 411-51-02, modified]

3.6

full load

the load which causes a machine to operate at its rating

[IEV 411-51-10]

3.7

full load value

a quantity value for a machine operating at full load

[IEV 411-51-11]

NOTE This concept applies to power, torque, current, speed, etc.

3.8

de-energized and rest

the complete absence of all movement and of all electrical supply or mechanical drive

[IEV 411-51-03]

3.9

duty

the statement of the load(s) to which the machine is subjected, including, if applicable,

starting, electric braking, no-load and rest and de-energized periods, and including their

durations and sequence in time

– 10 – 60034-1 © IEC:2010

[IEV 411-51-06]

3.10

duty type

a continuous, short-time or periodic duty, comprising one or more loads remaining constant

for the duration specified, or a non-periodic duty in which generally load and speed vary

within the permissible operating range

[IEV 411-51-13]

3.11

cyclic duration factor

the ratio between the period of loading, including starting and electric braking, and the

duration of the duty cycle, expressed as a percentage

[IEV 411-51-09]

3.12

locked-rotor torque

the smallest measured torque the motor develops at its shaft and with the rotor locked, over

all its angular positions, at rated voltage and frequency

[IEV 411-48-06]

3.13

locked-rotor current

the greatest steady-state r.m.s. current taken from the line with the motor held at rest, over all

angular positions of its rotor, at rated voltage and frequency

[IEV 411-48-16]

3.14

pull-up torque (of an a.c. motor)

the smallest steady-state asynchronous torque which the motor develops between zero speed

and the speed which corresponds to the breakdown torque, when the motor is supplied at the

rated voltage and frequency

This definition does not apply to those asynchronous motors of which the torque continually

decreases with increase in speed.

NOTE In addition to the steady-state asynchronous torques, harmonic synchronous torques, which are a function

of rotor load angle, will be present at specific speeds.

At such speeds, the accelerating torque may be negative for some rotor load angles.

Experience and calculation show this to be an unstable operating condition and therefore harmonic synchronous

torques do not prevent motor acceleration and are excluded from this definition.

3.15

breakdown torque (of an a.c. motor)

the maximum steady-state asynchronous torque which the motor develops without an abrupt

drop in speed, when the motor is supplied at the rated voltage and frequency

This definition does not apply to motors with torques that continually decrease with increase

in speed.

3.16

pull-out torque (of a synchronous motor)

the maximum torque which the synchronous motor develops at synchronous speed with rated

voltage, frequency and field current

60034-1 © IEC:2010 – 11 –

3.17

cooling

a procedure by means of which heat resulting from losses occurring in a machine is given up

to a primary coolant, which may be continuously replaced or may itself be cooled by a

secondary coolant in a heat exchanger

[IEV 411-44-01]

3.18

coolant

a medium, liquid or gas, by means of which heat is transferred

[IEV 411-44-02]

3.19

primary coolant

a medium, liquid or gas, which, being at a lower temperature than a part of a machine and in

contact with it, removes heat from that part

[IEV 411-44-03]

3.20

secondary coolant

a medium, liquid or gas, which, being at a lower temperature than the primary coolant,

removes the heat given up by this primary coolant by means of a heat exchanger or through

the external surface of the machine

[IEV 411-44-04]

3.21

direct cooled winding

inner cooled winding

a winding mainly cooled by coolant flowing in direct contact with the cooled part through

hollow conductors, tubes, ducts or channels which, regardless of their orientation, form an

integral part of the winding inside the main insulation

[IEV 411-44-08]

NOTE In all cases when ‘indirect’ or ‘direct’ is not stated, an indirect cooled winding is implied.

3.22

indirect cooled winding

any winding other than a direct cooled winding

NOTE In all cases when ‘indirect’ or ‘direct’ is not stated, an indirect cooled winding is implied.

[IEV 411-44-09]

3.23

supplementary insulation

an independent insulation applied in addition to the main insulation in order to ensure

protection against electric shock in the event of failure of the main insulation

3.24

moment of inertia

the sum (integral) of the products of the mass elements of a body and the squares of their

distances (radii) from a given axis

– 12 – 60034-1 © IEC:2010

3.25

thermal equilibrium

the state reached when the temperature rises of the several parts of the machine do not vary

by more than a gradient of 2 K per hour

[IEV 411-51-08]

NOTE Thermal equilibrium may be determined from the time-temperature rise plot when the straight lines

between points at the beginning and end of two successive reasonable intervals each have a gradient of less than

2 K per hour.

3.26

thermal equivalent time constant

the time constant, replacing several individual time constants, which determines

approximately the temperature course in a winding after a step-wise current change

3.27

encapsulated winding

a winding which is completely enclosed or sealed by moulded insulation

[IEV 411-39-06]

3.28

rated form factor of direct current supplied to a d.c. motor armature from a static power

converter

the ratio of the r.m.s. maximum permissible value of the current I to its average value

rms,maxN

I (mean value integrated over one period) at rated conditions:

avN

I

rms, maxN

k =

fN

I

avN

3.29

current ripple factor

the ratio of the difference between the maximum value I and the minimum value I of an

max min

undulating current to two times the average value I (mean value integrated over one

av

period):

I − I

max min

q =

i

2 × I

av

NOTE For small values of current ripple, the ripple factor may be approximated by the following expression:

I – I

max min

q =

i

I + I

max min

The above expression may be used as an approximation if the resulting calculated value of q

i

is equal to or less than 0,4.

3.30

tolerance

the permitted deviation between the declared value of a quantity and the measured value

3.31

type test

a test of one or more machines made to a certain design to show that the design meets

certain specifications

[IEV 411-53-01]

60034-1 © IEC:2010 – 13 –

NOTE The type test may also be considered valid if it is made on a machine which has minor deviations of rating

or other characteristics. These deviations should be subject to agreement.

3.32

routine test

a test to which each individual machine is subjected during or after manufacture to ascertain

whether it complies with certain criteria

[IEV 411-53-02]

3.33

runaway speed

the maximum speed attained by the engine/generator set after removal of the full load of the

generator if the speed regulator does not function

[IEV 811-17-23]

NOTE For motors, the maximum overspeed at loss of supply is meant that a motor might reach driven by the

coupled equipment

4 Duty

4.1 Declaration of duty

It is the responsibility of the purchaser to declare the duty. The purchaser may describe the

duty by one of the following:

a) numerically, where the load does not vary or where it varies in a known manner;

b) as a time sequence graph of the variable quantities;

c) by selecting one of the duty types S1 to S10 that is no less onerous than the expected

duty.

The duty type shall be designated by the appropriate abbreviation, specified in 4.2, written

after the value of the load.

An expression for the cyclic duration factor is given in the relevant duty type figure.

The purchaser normally cannot provide values for the moment of inertia of the motor (J ) or

M

the relative thermal life expectancy (TL), see Annex A. These values are provided by the

manufacturer.

Where the purchaser does not declare a duty, the manufacturer shall assume that duty type

S1 (continuous running duty) applies.

4.2 Duty types

4.2.1 Duty type S1 – Continuous running duty

Operation at a constant load maintained for sufficient time to allow the machine to reach

thermal equilibrium, see Figure 1.

The appropriate abbreviation is S1.

– 14 – 60034-1 © IEC:2010

P

t

P

V

t

Θ

Θ

max

t

IEC 326/04

Key

P load

P electrical losses

V

temperature

Θ

maximum temperature attained

Θ

max

t time

Figure 1 – Continuous running duty – Duty type S1

60034-1 © IEC:2010 – 15 –

4.2.2 Duty type S2 – Short-time duty

Operation at constant load for a given time, less than that required to reach thermal

equilibrium, followed by a time de-energized and at rest of sufficient duration to re-establish

machine temperatures within 2 K of the coolant temperature, see Figure 2.

The appropriate abbreviation is S2, followed by an indication of the duration of the duty,

Example: S2 60 min.

P

t

P

V

t

Θ

Θ

max

Δt

P

t

IEC 327/04

Key

P load

P electrical losses

V

Θ temperature

maximum temperature attained

Θ

max

t time

operation time at constant load

Δt

P

Figure 2 – Short-time duty – Duty type S2

– 16 – 60034-1 © IEC:2010

4.2.3 Duty type S3 – Intermittent periodic duty

NOTE Periodic duty implies that thermal equilibrium is not reached during the time on load.

A sequence of identical duty cycles, each including a time of operation at constant load and a

time de-energized and at rest, see Figure 3. In this duty, the cycle is such that the starting

current does not significantly affect the temperature rise.

The appropriate abbreviation is S3, followed by the cyclic duration factor.

Example: S3 25 %

P

T

C

Δt Δt

P R

t

P

V

t

Θ

Θ

max

t

IEC 328/04

Key

P load

P electrical losses

V

temperature

Θ

maximum temperature attained

Θ

max

t time

T time of one load cycle

C

operation time at constant load

Δt

P

time de-energized and at rest

Δt

R

Cyclic duration factor = Δt /T

P C

Figure 3 – Intermittent periodic duty – Duty type S3

60034-1 © IEC:2010 – 17 –

4.2.4 Duty type S4 – Intermittent periodic duty with starting

NOTE Periodic duty implies that thermal equilibrium is not reached during the time on load.

A sequence of identical duty cycles, each cycle including a significant starting time, a time of

operation at constant load and a time de-energized and at rest, see Figure 4.

The appropriate abbreviation is S4, followed by the cyclic duration factor, the moment of

inertia of the motor (J ) and the moment of inertia of the load (J ), both referred to the motor

M ext

shaft.

2 2

Example: S4 25 % J = 0,15 kg × m J = 0,7 kg × m

M ext

P

T

C

t

Δt Δt

P R

P

V

Δt

D

t

Θ

Θ

max

t

IEC 329/04

Key

P load t time

P T

electrical losses time of one load cycle

V C

Θ temperature Δt starting/accelerating time

D

maximum temperature attained operation time at constant load

Θ Δt

max P

time de-energized and at rest

Δt

R

Cyclic duration factor = (Δt + Δt )/T

D P C

Figure 4 – Intermittent periodic duty with starting – Duty type S4

– 18 – 60034-1 © IEC:2010

4.2.5 Duty type S5 – Intermittent periodic duty with electric braking

NOTE Periodic duty implies that thermal equilibrium is not reached during the time on load.

A sequence of identical duty cycles, each cycle consisting of a starting time, a time of

operation at constant load, a time of electric braking and a time de-energized and at rest, see

Figure 5.

The appropriate abbreviation is S5, followed by the cyclic duration factor, the moment of

inertia of the motor (J ) and the moment of inertia of the load (J ), both referred to the motor

M ext

shaft.

2 2

Example: S5 25 % J = 0,15 kg × m J = 0,7 kg × m

M ext

P

T

C

t

Δt

F

P

V

Δt

P Δt

R

Δt

D

t

Θ

Θ

max

t

IEC 330/04

Key

P load T time of one load cycle

C

P electrical losses starting/accelerating time

Δt

V

D

temperature operation time at constant load

Θ Δt

P

maximum temperature attained time of electric braking

Θ Δt

max F

t time Δt time de-energized and at rest

R

Cyclic duration factor = (Δt + Δt + Δt )/T

D P F C

Figure 5 – Intermittent periodic duty with electric braking – Duty type S5

60034-1 © IEC:2010 – 19 –

4.2.6 Duty type S6 – Continuous operation periodic duty

NOTE Periodic duty implies that thermal equilibrium is not reached during the time on load.

A sequence of identical duty cycles, each cycle consisting of a time of operation at constant

load and a time of operation at no-load. There is no time de-energized and at rest, see

Figure 6.

The appropriate abbreviation is S6, followed by the cyclic duration factor.

Example: S6 40 %

P

T

C

Δt Δt

P V

t

P

V

t

Θ

Θ

max

t

IEC 331/04

Key

P load t time

P electrical losses T time of one load cycle

V C

temperature operation time at constant load

Θ Δt

P

maximum temperature attained operation time at no-load

Θ Δt

max V

Cyclic duration factor = Δt /T

P C

Figure 6 – Continuous operation periodic duty – Duty type S6

– 20 – 60034-1 © IEC:2010

4.2.7 Duty type S7 – Continuous operation periodic duty with electric braking

NOTE Periodic duty implies that thermal equilibrium is not reached during the time on load.

A sequence of identical duty cycles, each cycle consisting of a starting time, a time of

operation at constant load and a time of electric braking. There is no time de-energized and at

rest, see Figure 7.

The appropriate abbreviation is S7, followed by the moment of inertia of the motor (J ) and

M

the moment of inertia of the load (J ), both referred to the motor shaft.

ext

2 2

Example: S7 J = 0,4 kg × m J = 7,5 kg × m

M ext

T

C

P

t

Δt Δt

Δt P F

D

P

V

t

Θ

Θ

max

t

IEC 332/04

Key

P load t time

P electrical losses T time of one load cycle

V C

temperature starting/accelerating time

Θ Δt

D

maximum temperature attained operation time at constant load

Θ Δt

max P

Cyclic duration factor = 1 time of electric braking

Δt

F

Figure 7 – Continuous operation periodic duty with electric braking – Duty type S7

60034-1 © IEC:2010 – 21 –

4.2.8 Duty type S8 – Continuous operation periodic duty with related load/speed

changes

NOTE Periodic duty implies that thermal equilibrium is not reached during the time on load.

A sequence of identical duty cycles, each cycle consisting of a time of operation at constant

load corresponding to a predetermi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...