IEC 61439-1:2020

(Main)Low-voltage switchgear and controlgear assemblies - Part 1: General rules

Low-voltage switchgear and controlgear assemblies - Part 1: General rules

IEC 61439-1:2020 lays down the general definitions and service conditions, construction requirements, technical characteristics and verification requirements for low-voltage switchgear and controlgear assemblies. NOTE Throughout this document, the term assembly(s) (see 3.1.1) is used for a low-voltage switchgear and controlgear assembly(s). For the purpose of determining assembly conformity, the requirements of the relevant part of the IEC 61439 series, Part 2 onwards, apply together with the cited requirements of this document. For assemblies not covered by Part 3 onward, Part 2 applies. This third edition cancels and replaces the second edition published in 2011. It constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) clarification that power electric converter systems, switch mode power supplies, uninterruptable power supplies and adjustable speed power drive systems are tested to their particular products standard, but when they are incorporated in assemblies the incorporation is in accordance with the IEC 61439 series of standards;

b) introduction of a group rated current for circuits within a loaded assembly and the refocusing of temperature-rise verification on this new characteristic;

c) addition of requirements in respect of DC;

d) introduction of the concept of class I and class II assemblies regarding protection against electric shock.

The contents of the corrigendum 1 of December 2021 and corrigendum 2 of September 2023 have been included in this copy.

Ensembles d'appareillage à basse tension - Partie 1: Règles générales

L’IEC 61439-1:2020 formule les définitions générales et les conditions d’emploi, les exigences de construction, les caractéristiques techniques et les exigences de vérification pour les ensembles d’appareillage à basse tension. NOTE Dans le présent document, le terme ensemble(s) (voir 3.1.1) est utilisé pour désigner un ou des ensembles d’appareillage à basse tension. Dans le but de déterminer la conformité de l’ensemble, les exigences de la partie applicable de la série IEC 61439 (à partir de la Partie 2), s’appliquent, de même que les exigences citées dans le présent document. Pour les ensembles non couverts par les parties à partir de la Partie 3, la Partie 2 s’applique. Cette troisième édition annule et remplace la deuxième édition parue en 2011. Elle constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) clarification du fait que les systèmes et matériels électroniques de conversion de puissance, les alimentations à découpage, les alimentations sans interruption et les systèmes d’entraînements électriques de puissance à vitesse variable sont soumis à essai conformément à leur propre norme de produit, mais que lorsqu’ils sont incorporés dans des ensembles, l’incorporation est conforme à la série de normes IEC 61439;

b) introduction d’un courant assigné de groupe pour les circuits au sein d’un ensemble chargé et recentrage de la vérification de l’échauffement sur cette nouvelle caractéristique;

c) ajout d’exigences relatives au courant continu;

d) introduction du concept d’ensembles de classe I et de classe II en matière de protection contre les chocs électriques.

Le contenu du corrigendum 1 décembre 2021 et le corrigendum 2 de septembre 2023 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 04-May-2020

- Technical Committee

- SC 121B - Low-voltage switchgear and controlgear assemblies

- Drafting Committee

- MT 2 - TC 121/SC 121B/MT 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 05-May-2020

- Completion Date

- 15-May-2020

Relations

- Effective Date

- 15-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 61439-1:2020 - "Low‑voltage switchgear and controlgear assemblies – Part 1: General rules" - defines the general rules, terminology, service conditions, construction and technical characteristics, and verification requirements for low‑voltage switchgear and controlgear assemblies. It is the foundational document of the IEC 61439 series and is used together with the relevant product‑specific parts (Part 2 onward) to determine assembly conformity. This third edition (2020) replaces the 2011 edition and includes important technical updates and corrigenda.

Key topics and requirements

- Scope and definitions: common terms, constructional units, insulation classes and service conditions that apply across the IEC 61439 series.

- Service conditions: normal and special environmental conditions, ambient temperature, humidity, pollution degree and transport/storage conditions.

- Construction requirements: materials, mechanical strength, corrosion resistance, lifting provisions and use of insulating materials.

- Degree of protection: requirements referenced to IP (ingress protection) and IK (mechanical impact) codes for enclosures.

- Clearances and creepage: electrical separation to manage insulation and prevent breakdown.

- Protection against electric shock: requirements for basic and fault protection, including the new concept of class I and class II assemblies.

- Incorporation of devices and components: rules for fixed and removable parts, accessibility, barriers and marking.

- Internal circuits and terminals: main and auxiliary circuit rules, conductor identification and terminal requirements.

- Performance requirements: dielectric properties (power‑frequency and impulse withstand), temperature‑rise limits and the new group rated current concept (temperature‑rise verification focused on group rated current).

- Short‑circuit: coordination, rated short‑time and peak withstands, and conditional short‑circuit current information.

- EMC: electromagnetic compatibility considerations for assemblies.

- Design verification: tests and verifications required to demonstrate conformity to the standard.

Notable technical changes in the 2020 edition:

- Clarification on testing of power electronic equipment (e.g., converters, UPS) to their product standards while their incorporation into assemblies follows IEC 61439 rules.

- Introduction of group rated current and refocus of temperature‑rise verification on that characteristic.

- Addition of explicit DC requirements.

- Introduction of class I / class II assembly classification for shock protection.

Applications

IEC 61439-1:2020 is applied when designing, manufacturing, specifying, testing or installing low‑voltage switchgear and controlgear assemblies used in:

- industrial and manufacturing plants

- commercial buildings and infrastructure

- utility distribution and substations

- data centers, renewable energy systems and EV charging installations

- OEM panel builders and switchboard manufacturers

Who should use this standard

- Electrical designers and panel builders

- Product manufacturers and integrators

- Test laboratories and conformity assessment bodies

- Specifiers, consulting engineers and asset owners

- Regulatory and certification authorities

Related standards

- IEC 61439‑2 and subsequent parts (Part 2 onward) - product‑specific requirements and verification methods that apply together with Part 1 for assembly conformity.

- Product standards for power converters, UPS and drive systems (these products are tested to their own standards but incorporated per IEC 61439 series).

Keywords: IEC 61439-1, low-voltage switchgear, controlgear assemblies, group rated current, temperature-rise verification, class I class II, DC requirements, design verification, IP code, IK code, short-circuit withstand, EMC.

REDLINE IEC 61439-1:2020 - Low-voltage switchgear and controlgear assemblies - Part 1: General rules Released:5/5/2020 Isbn:9782832283370

IEC 61439-1:2020 - Low-voltage switchgear and controlgear assemblies - Part 1: General rules

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61439-1:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Low-voltage switchgear and controlgear assemblies - Part 1: General rules". This standard covers: IEC 61439-1:2020 lays down the general definitions and service conditions, construction requirements, technical characteristics and verification requirements for low-voltage switchgear and controlgear assemblies. NOTE Throughout this document, the term assembly(s) (see 3.1.1) is used for a low-voltage switchgear and controlgear assembly(s). For the purpose of determining assembly conformity, the requirements of the relevant part of the IEC 61439 series, Part 2 onwards, apply together with the cited requirements of this document. For assemblies not covered by Part 3 onward, Part 2 applies. This third edition cancels and replaces the second edition published in 2011. It constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) clarification that power electric converter systems, switch mode power supplies, uninterruptable power supplies and adjustable speed power drive systems are tested to their particular products standard, but when they are incorporated in assemblies the incorporation is in accordance with the IEC 61439 series of standards; b) introduction of a group rated current for circuits within a loaded assembly and the refocusing of temperature-rise verification on this new characteristic; c) addition of requirements in respect of DC; d) introduction of the concept of class I and class II assemblies regarding protection against electric shock. The contents of the corrigendum 1 of December 2021 and corrigendum 2 of September 2023 have been included in this copy.

IEC 61439-1:2020 lays down the general definitions and service conditions, construction requirements, technical characteristics and verification requirements for low-voltage switchgear and controlgear assemblies. NOTE Throughout this document, the term assembly(s) (see 3.1.1) is used for a low-voltage switchgear and controlgear assembly(s). For the purpose of determining assembly conformity, the requirements of the relevant part of the IEC 61439 series, Part 2 onwards, apply together with the cited requirements of this document. For assemblies not covered by Part 3 onward, Part 2 applies. This third edition cancels and replaces the second edition published in 2011. It constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) clarification that power electric converter systems, switch mode power supplies, uninterruptable power supplies and adjustable speed power drive systems are tested to their particular products standard, but when they are incorporated in assemblies the incorporation is in accordance with the IEC 61439 series of standards; b) introduction of a group rated current for circuits within a loaded assembly and the refocusing of temperature-rise verification on this new characteristic; c) addition of requirements in respect of DC; d) introduction of the concept of class I and class II assemblies regarding protection against electric shock. The contents of the corrigendum 1 of December 2021 and corrigendum 2 of September 2023 have been included in this copy.

IEC 61439-1:2020 is classified under the following ICS (International Classification for Standards) categories: 29.130.20 - Low voltage switchgear and controlgear. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61439-1:2020 has the following relationships with other standards: It is inter standard links to IEC 61439-1:2020/COR2:2023, IEC 61439-1:2020/COR1:2021, IEC 61439-1:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61439-1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61439-1 ®

Edition 3.0 2020-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Low-voltage switchgear and controlgear assemblies –

Part 1: General rules

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61439-1 ®

Edition 3.0 2020-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Low-voltage switchgear and controlgear assemblies –

Part 1: General rules

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.130.20 ISBN 978-2-8322-8337-0

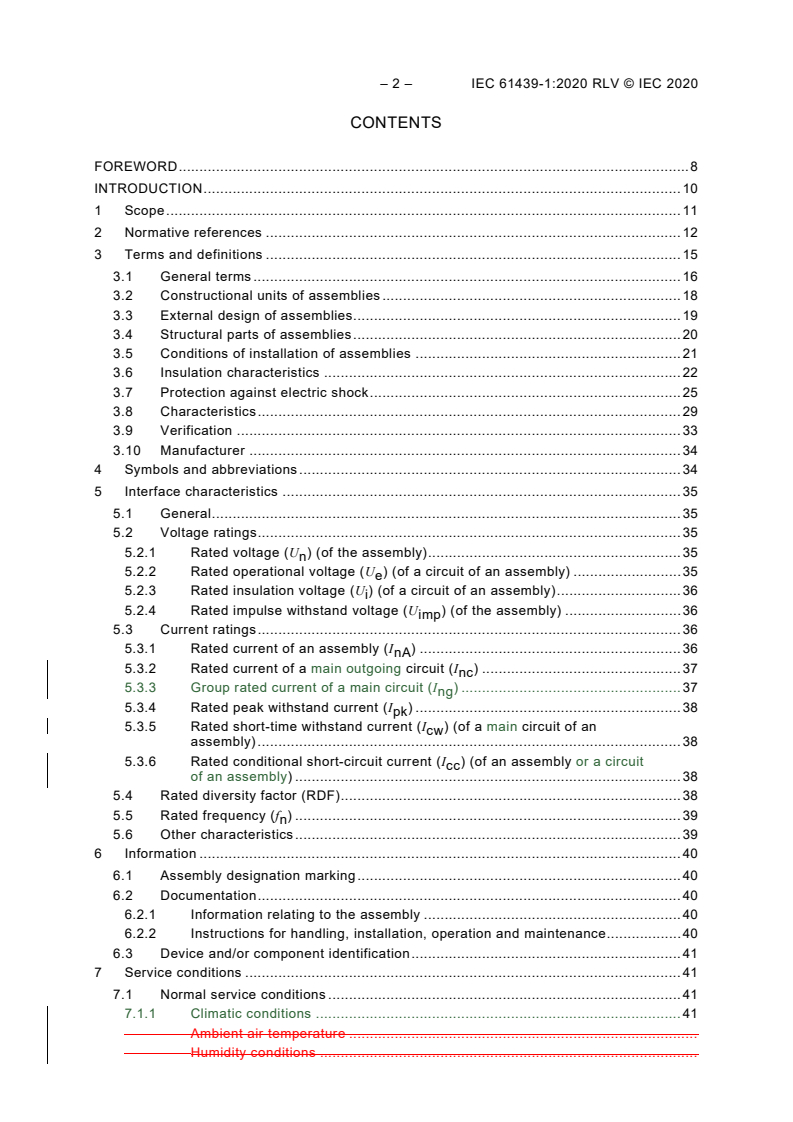

– 2 – IEC 61439-1:2020 RLV © IEC 2020

CONTENTS

FOREWORD . 8

INTRODUCTION . 10

1 Scope . 11

2 Normative references . 12

3 Terms and definitions . 15

3.1 General terms . 16

3.2 Constructional units of assemblies . 18

3.3 External design of assemblies . 19

3.4 Structural parts of assemblies . 20

3.5 Conditions of installation of assemblies . 21

3.6 Insulation characteristics . 22

3.7 Protection against electric shock . 25

3.8 Characteristics . 29

3.9 Verification . 33

3.10 Manufacturer . 34

4 Symbols and abbreviations . 34

5 Interface characteristics . 35

5.1 General . 35

5.2 Voltage ratings . 35

5.2.1 Rated voltage (U ) (of the assembly) . 35

n

5.2.2 Rated operational voltage (U ) (of a circuit of an assembly) . 35

e

5.2.3 Rated insulation voltage (U ) (of a circuit of an assembly) . 36

i

5.2.4 Rated impulse withstand voltage (U ) (of the assembly) . 36

imp

5.3 Current ratings . 36

5.3.1 Rated current of an assembly (I ) . 36

nA

5.3.2 Rated current of a main outgoing circuit (I ) . 37

nc

5.3.3 Group rated current of a main circuit (I ) . 37

ng

5.3.4 Rated peak withstand current (I ) . 38

pk

5.3.5 Rated short-time withstand current (I ) (of a main circuit of an

cw

assembly) . 38

5.3.6 Rated conditional short-circuit current (I ) (of an assembly or a circuit

cc

of an assembly) . 38

5.4 Rated diversity factor (RDF) . 38

5.5 Rated frequency (f ) . 39

n

5.6 Other characteristics . 39

6 Information . 40

6.1 Assembly designation marking . 40

6.2 Documentation . 40

6.2.1 Information relating to the assembly . 40

6.2.2 Instructions for handling, installation, operation and maintenance . 40

6.3 Device and/or component identification . 41

7 Service conditions . 41

7.1 Normal service conditions . 41

7.1.1 Climatic conditions . 41

Ambient air temperature .

Humidity conditions .

7.1.2 Pollution degree . 42

Altitude .

7.2 Special service conditions . 43

7.3 Conditions during transport, storage and installation . 43

8 Constructional requirements . 43

8.1 Strength of materials and parts . 43

8.1.1 General . 43

8.1.2 Protection against corrosion . 44

8.1.3 Properties of insulating materials . 44

8.1.4 Resistance to ultra-violet (UV) radiation . 45

8.1.5 Mechanical strength . 45

8.1.6 Lifting provision . 45

8.2 Degree of protection provided by an assembly enclosure . 45

8.2.1 Protection against mechanical impact (IK code) . 45

8.2.2 Protection against contact with live parts, ingress of solid foreign bodies

and water (IP code) . 46

8.2.3 Assembly with removable parts. 46

8.3 Clearances and creepage distances. 47

8.3.1 General . 47

8.3.2 Clearances . 47

8.3.3 Creepage distances . 48

8.4 Protection against electric shock . 48

8.4.1 General . 48

8.4.2 Basic protection . 48

8.4.3 Fault protection . 49

8.4.4 Protection by total insulation Additional requirements for class II

assemblies . 52

8.4.5 Limitation of steady-state touch currents and charge . 54

8.4.6 Operating and servicing conditions . 54

8.5 Incorporation of switching devices and components . 56

8.5.1 Fixed parts . 56

8.5.2 Removable parts . 56

8.5.3 Selection of switching devices and components . 56

8.5.4 Installation of switching devices and components . 57

8.5.5 Accessibility . 57

8.5.6 Barriers . 58

8.5.7 Direction of operation and indication of switching positions . 58

8.5.8 Indicator lights and push-buttons . 58

8.5.9 Power factor correction banks . 58

8.6 Internal electrical circuits and connections . 58

8.6.1 Main circuits . 58

8.6.2 Auxiliary circuits . 59

8.6.3 Bare and insulated conductors . 59

8.6.4 Selection and installation of non-protected live conductors to reduce the

possibility of short-circuits . 60

8.6.5 Identification of the conductors of main and auxiliary circuits . 60

8.6.6 Identification of the protective conductor (PE, PEL, PEM, PEN) and of

the neutral conductor (N) and the mid-point conductor (M) of the main

circuits . 60

– 4 – IEC 61439-1:2020 RLV © IEC 2020

8.6.7 Conductors in AC circuits passing through ferromagnetic enclosures or

plates . 61

8.7 Cooling . 61

8.8 Terminals for external conductors cables . 61

9 Performance requirements . 63

9.1 Dielectric properties . 63

9.1.1 General . 63

9.1.2 Power-frequency withstand voltage . 63

9.1.3 Impulse withstand voltage . 63

9.1.4 Protection of surge protective devices . 64

9.2 Temperature-rise limits . 64

9.2.1 General . 64

9.2.2 Adjustment of rated currents for alternative ambient air temperatures . 64

9.3 Short-circuit protection and short-circuit withstand strength . 65

9.3.1 General . 65

9.3.2 Information concerning short-circuit withstand strength . 65

9.3.3 Relationship between peak current and short-time current . 66

9.3.4 Coordination of protective devices . 66

9.4 Electromagnetic compatibility (EMC) . 66

10 Design verification . 67

10.1 General . 67

10.2 Strength of materials and parts . 68

10.2.1 General . 68

10.2.2 Resistance to corrosion . 68

10.2.3 Properties of insulating materials . 70

10.2.4 Resistance to ultraviolet (UV) radiation . 72

10.2.5 Lifting . 73

10.2.6 Verification of protection against mechanical impact (IK code) . 74

10.2.7 Marking . 74

10.2.8 Mechanical operation . 74

10.3 Degree of protection of assemblies (IP Code) . 75

10.4 Clearances and creepage distances. 76

10.5 Protection against electric shock and integrity of protective circuits . 76

10.5.1 Effectiveness of the protective circuit General . 76

10.5.2 Effective earth continuity between the exposed-conductive-parts of the

class I assembly and the protective circuit . 76

10.5.3 Short-circuit withstand strength of the protective circuit . 76

10.6 Incorporation of switching devices and components . 77

10.6.1 General . 77

10.6.2 Electromagnetic compatibility . 77

10.7 Internal electrical circuits and connections . 77

10.8 Terminals for external conductors . 77

10.9 Dielectric properties . 78

10.9.1 General . 78

10.9.2 Power-frequency withstand voltage . 78

10.9.3 Impulse withstand voltage . 79

10.9.4 Testing of enclosures made of insulating material . 81

10.9.5 External door or cover mounted operating handles of insulating material . 81

10.9.6 Testing of conductors and hazardous live parts covered by insulating

material to provide protection against electric shock . 81

10.10 Verification of Temperature-rise . 82

10.10.1 General . 82

10.10.2 Verification by testing . 82

10.10.3 Derivation of ratings for similar variants Verification by comparison . 89

10.10.4 Verification assessment . 92

10.11 Short-circuit withstand strength . 96

10.11.1 General . 96

10.11.2 Circuits of assemblies which are exempted from the verification of the

short-circuit withstand strength . 97

10.11.3 Verification by comparison with a reference design – Using a checklist . 97

10.11.4 Verification by comparison with a reference design(s) – Using

calculation . 97

10.11.5 Verification by test . 98

10.12 Electromagnetic compatibility (EMC) . 104

Mechanical operation .

11 Routine verification . 105

11.1 General . 105

11.2 Degree of protection against contact with hazardous live parts, ingress of

solid foreign bodies and water of enclosures . 105

11.3 Clearances and creepage distances. 105

11.4 Protection against electric shock and integrity of protective circuits . 106

11.5 Incorporation of built-in components . 106

11.6 Internal electrical circuits and connections . 106

11.7 Terminals for external conductors . 106

11.8 Mechanical operation . 106

11.9 Dielectric properties . 106

11.10 Wiring, operational performance and function . 107

Annex A (normative) Minimum and maximum cross-section of copper conductors

cables suitable for connection to terminals for external conductors cables (see 8.8) . 117

Annex B (normative) Method of calculating the cross-sectional area of protective

conductors with regard to thermal stresses due to currents of short duration . 118

Annex C (informative) User information template . 119

Annex D (informative) Design verification . 123

Annex E (informative) Rated diversity factor . 125

Annex F (normative) Measurement of clearances and creepage distances . 138

Annex G (normative) Correlation between the nominal voltage of the supply system

and the rated impulse withstand voltage of the equipment . 143

Annex H (informative) Operating current and power loss of copper conductors cables . 145

Annex I (informative) Thermal equivalent of an intermittent current . 149

Annex K (normative) Protection by electrical separation.

Annex L (informative) Clearances and creepage distances for North American region .

Annex M (informative) North American temperature rise limits .

Annex J (normative) Electromagnetic compatibility (EMC). 150

Annex K (normative) Operating current and power loss of bare copper bars . 163

Annex L (informative) Guidance on verification of temperature-rise . 166

– 6 – IEC 61439-1:2020 RLV © IEC 2020

Annex M (normative) Verification of the short-circuit withstand strength of busbar

structures by comparison with a tested reference design by calculation . 173

Annex N (informative) List of notes concerning certain countries . 178

Bibliography . 184

Figure E.1 – Typical assembly . 134

Figure E.2 – Example 1: Table E.1 – Functional unit loading for an assembly

with a rated diversity factor of 0,68 . 136

Figure E.3 – Example 2: Table E.1 – Functional unit loading for an assembly with a

rated diversity factor of 0,6 in Section B and 0,68 in Section C . 137

Figure F.1 – Measurement of ribs clearance and creepage distances . 142

Figure I.1 – Example of average heating effect calculation . 149

Figure J.1 – Examples of ports . 150

Figure L.1 – Verification of temperature-rise . 172

Figure M.1 – Tested busbar structure (TS) . 174

Figure M.2 – Non tested busbar structure (NTS) . 175

Figure M.3 – Angular busbar configuration with supports at the corners . 176

Table 1 – Minimum clearances in air (8.3.2) . 107

Table 2 – Minimum creepage distances (8.3.3) . 108

Table 3 – Cross-sectional area of a copper protective conductor (8.4.3.2.2) . 109

Table 4 – Conductor selection and installation requirements (8.6.4) . 109

Table 5 – Minimum terminal capacity for copper protective conductors (PE, PEN (8.8) . 110

Table 6 – Temperature-rise limits (9.2) . 110

a

Table 7 – Values for the factor n (9.3.3) . 111

Table 8 – Power-frequency withstand voltage for main circuits (10.9.2) . 112

Table 9 – Power-frequency withstand voltage for auxiliary and control circuits (10.9.2) . 112

Table 10 – Impulse withstand test voltages (10.9.3) . 112

Table 11 – Copper test conductors for rated currents up to 400 A inclusive

(10.10.2.3.2) . 113

Table 12 – Copper test conductors for rated currents from 400 A to 4 000 7 000 A

(10.10.2.3.2) . 114

Table 13 – Short-circuit verification by comparison with reference designs: checklist

(10.5.3.3, 10.11.3 and 10.11.4) . 115

Table 14 – Relationship between prospective fault current and diameter of copper wire . 116

Table 15 – Climatic conditions . 116

Table A.1 – Cross-section of copper conductors cables suitable for connection

to terminals for external conductors cables . 117

Table B.1 – Values of k for insulated protective conductors not incorporated in cables

or bare protective conductors in contact with cable covering . 118

Table C.1 – User information template . 119

Table D.1 – List of design verifications to be performed . 123

Table E.1 – Examples of loading for an assembly . 135

Table F.1 – Minimum width of grooves . 138

Table G.1 – Correspondence between the nominal voltage of the supply system and

the equipment rated impulse withstand voltage . 144

Table H.1 – Operating current and power loss of single-core copper cables with a

permissible conductor temperature of 70 °C (ambient temperature inside the assembly:

55 °C) . 145

Table H.2 – Reduction factor k for cables with a permissible conductor temperature

of 70 °C (extract from IEC 60364-5-52:2009, Table B.52.14). 146

Table J.1 – Tests for EMC immunity for environment A (see J.10.12.2) . 154

Table J.2 – Tests for EMC immunity for environment B (see J.10.12.2) . 155

Table J.3 – Acceptance criteria when electromagnetic disturbances are present . 157

Table K.1 – Operating current and power loss of bare copper bars with rectangular

cross-section, run horizontally and arranged with their largest face vertical, frequency

50 Hz to 60 Hz (ambient air temperature inside the assembly: 55 °C, temperature of

the conductor 70 °C) . 163

Table K.2 – Factor k for different temperatures of the air inside the assembly and/or

for the conductors . 164

– 8 – IEC 61439-1:2020 RLV © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LOW-VOLTAGE SWITCHGEAR AND CONTROLGEAR ASSEMBLIES –

Part 1: General rules

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 61439-1 has been prepared by subcommittee 121B: Low-voltage

switchgear and controlgear assemblies, of IEC technical committee 121: Switchgear and

controlgear and their assemblies for low voltage.

This third edition cancels and replaces the second edition published in 2011. It constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) clarification that power electric converter systems, switch mode power supplies,

uninterruptable power supplies and adjustable speed power drive systems are tested to

their particular products standard, but when they are incorporated in assemblies the

incorporation is in accordance with the IEC 61439 series of standards;

b) introduction of a group rated current for circuits within a loaded assembly and the

refocusing of temperature-rise verification on this new characteristic;

c) addition of requirements in respect of DC;

d) introduction of the concept of class I and class II assemblies regarding protection against

electric shock.

The text of this International Standard is based on the following documents:

FDIS Report on voting

121B/99/FDIS 121B/103/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

The reader’s attention is drawn to the fact that Annex N lists all the “in-some-countries”

clauses on differing practices of a less permanent nature regarding this document.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61439 series, under the general title Low-voltage switchgear and

controlgear assemblies, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

The contents of the corrigendum of December 2021 have been included in this copy.

The contents of the corrigendum 2 of September 2023 only applies to the French version.

– 10 – IEC 61439-1:2020 RLV © IEC 2020

INTRODUCTION

The purpose of this document is to harmonize as far as practicable all rules and requirements

of a general nature applicable to low-voltage switchgear and controlgear assemblies

(ASSEMBLIES), in order to obtain uniformity of requirements and verification for assemblies and

to avoid the need for verification in other standards. All those requirements for the various

assembly standards which can be considered as general have therefore been gathered in this

document together with specific subjects of wide interest and application, e.g. temperature-

rise, dielectric properties, etc.

For each type of low-voltage switchgear and controlgear assembly, only two main standards

are necessary to determine all requirements and the corresponding methods of verification:

– the basic standard, (this document) referred to as “IEC 61439-1” in the specific standards,

covering the various types of low-voltage switchgear and controlgear assemblies;

– the specific assembly standard hereinafter also referred to as the relevant assembly

standard.

For a general rule to apply to a specific assembly standard, it should be explicitly referred to

by quoting this document followed by the relevant clause or subclause number e.g.

“IEC 61439-1:2020, 9.1.3”.

A specific assembly standard may not require, and hence need not call up, a general rule

where it is not applicable, or it may can add requirements if the general rule is deemed

inadequate in the particular case, but it may not deviate from it unless there is substantial

technical justification detailed in the specific assembly standard.

Where, in this document, a cross-reference is made to another clause, the reference is to be

taken to apply to that clause as amended by the specific assembly standard, where applicable.

Requirements in this document that are subject to agreement between the assembly

manufacturer and the user are summarized in Annex C (informative). This schedule also

facilitates the supply of information on basic conditions and additional user specifications to

enable proper design, application and utilization of the assembly.

For the new re-structured IEC 61439 series, the following parts are envisaged published:

a) IEC 61439-1: General rules

b) IEC 61439-2: Power switchgear and controlgear assemblies (PSC-assemblies)

c) IEC 61439-3: Distribution boards (to supersede IEC 60439-3) intended to be operated by

ordinary persons (DBO)

d) IEC 61439-4: ASSEMBLIES for construction sites (to supersede IEC 60439-4) Particular

requirements for assemblies for construction sites (ACS)

e) IEC 61439-5: Assemblies for power distribution (to supersede IEC 60439-5) in public

networks

f) IEC 61439-6: Busbar trunking systems (to supersede IEC 60439-2) (busways)

f) IEC 61439-7: Assemblies for specific applications such as marinas, camping sites, market

squares, electric vehicle charging stations

g) IEC TR 61439-0: Guidance to specifying assemblies.

This list is not exhaustive; additional parts may can be developed as the need arises.

___________

IEC 61439-2 includes requirements for assemblies for use in photovoltaic installations.

LOW-VOLTAGE SWITCHGEAR AND CONTROLGEAR ASSEMBLIES –

Part 1: General rules

1 Scope

NOTE 1 Throughout this standard, the term ASSEMBLY (see 3.1.1) is used for a low-voltage switchgear and

controlgear assembly.

This part of IEC 61439 lays down the general definitions and states the service conditions,

construction requirements, technical characteristics and verification requirements for low-

voltage switchgear and controlgear assemblies.

This standard cannot be used alone to specify an ASSEMBLY or used for a purpose of

determining conformity. ASSEMBLIES shall comply with the relevant part of the IEC 61439

series; Parts 2 onwards.

NOTE Throughout this document, the term assembly(s) (see 3.1.1) is used for a low-voltage switchgear and

controlgear assembly(s).

For the purpose of determining assembly conformity, the requirements of the relevant part of

the IEC 61439 series, Part 2 onwards, apply together with the cited requirements of this

document. For assemblies not covered by Part 3 onward, Part 2 applies.

This document applies to low-voltage switchgear and controlgear assemblies (ASSEMBLIES)

only when required by the relevant assembly standard as follows:

– assemblies for which the rated voltage does not exceed 1 000 V in case of AC or

1 500 V in case of DC;

– assemblies designed for a nominal frequency of the incoming supply or supplies not

exceeding 1 000 Hz;

– assemblies intended for indoor and outdoor applications;

– stationary or movable assemblies with or without an enclosure;

– assemblies intended for use in connection with the generation, transmission, distribution

and conversion of electric energy, and for the control of electrical energy consuming

equipment.

– ASSEMBLIES designed for use under special service conditions, for example in ships

and in rail vehicles provided that the other relevant specific requirements are complied

with;

NOTE 2 Supplementary requirements for ASSEMBLIES in ships are covered by IEC 60092-302.

– ASSEMBLIES designed for electrical equipment of machines provided that the other

relevant specific requirements are complied with.

NOTE 3 Supplementary requirements for ASSEMBLIES forming part of a machine are covered by the

IEC 60204 series.

This standard applies to all ASSEMBLIES whether they are designed, manufactured and verified

on a one-off basis or fully standardised and manufactured in quantity.

The manufacture and/or assembly may be carried out other than by the original manufacturer

(see 3.10.1).

This document does not apply to individual devices and self-contained components such as

motor starters, fuse switches, power electronic converter systems and equipment (PECS),

switch mode power supplies (SMPS), uninterruptable power supplies (UPS), basic drive

– 12 – IEC 61439-1:2020 RLV © IEC 2020

modules (BDM), complete drive modules (CDM), adjustable speed power drives systems

(PDS), and other electronic equipment, etc. which will comply with their relevant product

standards. This document describes the integration of devices and self-contained components

into an assembly or into an empty enclosure forming an assembly.

For some applications involving, for example, explosive atmospheres, functional safety, there

can be a need to comply with the requirements of other standards or legislation in addition to

those specified in the IEC 61439 series.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undate

...

IEC 61439-1 ®

Edition 3.0 2020-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Low-voltage switchgear and controlgear assemblies –

Part 1: General rules

Ensembles d’appareillage à basse tension –

Partie 1: Règles générales

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61439-1 ®

Edition 3.0 2020-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Low-voltage switchgear and controlgear assemblies –

Part 1: General rules

Ensembles d’appareillage à basse tension –

Partie 1: Règles générales

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.130.20 ISBN 978-2-8322-8154-3

– 2 – IEC 61439-1:2020 © IEC 2020

CONTENTS

FOREWORD . 8

INTRODUCTION . 10

1 Scope . 11

2 Normative references . 11

3 Terms and definitions . 14

3.1 General terms . 14

3.2 Constructional units of assemblies . 16

3.3 External design of assemblies . 18

3.4 Structural parts of assemblies . 19

3.5 Conditions of installation of assemblies . 20

3.6 Insulation characteristics . 20

3.7 Protection against electric shock . 23

3.8 Characteristics . 27

3.9 Verification . 31

3.10 Manufacturer . 32

3.11 User . 32

4 Symbols and abbreviations . 32

5 Interface characteristics . 33

5.1 General . 33

5.2 Voltage ratings . 33

5.2.1 Rated voltage (U ) (of the assembly) . 33

n

5.2.2 Rated operational voltage (U ) (of a circuit of an assembly). 34

e

5.2.3 Rated insulation voltage (U ) (of a circuit of an assembly) . 34

i

5.2.4 Rated impulse withstand voltage (U ) (of the assembly) . 34

imp

5.3 Current ratings . 34

5.3.1 Rated current of an assembly (I ) . 34

nA

5.3.2 Rated current of a main outgoing circuit (I ) . 34

nc

5.3.3 Group rated current of a main circuit (I ) . 35

ng

5.3.4 Rated peak withstand current (I ) . 35

pk

5.3.5 Rated short-time withstand current (I ) (of a main circuit of an

cw

assembly) . 36

5.3.6 Rated conditional short-circuit current (I ) (of an assembly or a circuit

cc

of an assembly) . 36

5.4 Rated diversity factor (RDF) . 36

5.5 Rated frequency (f ) . 36

n

5.6 Other characteristics . 37

6 Information . 37

6.1 Assembly designation marking . 37

6.2 Documentation . 37

6.2.1 Information relating to the assembly . 37

6.2.2 Instructions for handling, installation, operation and maintenance . 38

6.3 Device and/or component identification . 38

7 Service conditions . 38

7.1 Normal service conditions . 38

7.1.1 Climatic conditions . 38

7.1.2 Pollution degree . 39

7.2 Special service conditions . 39

7.3 Conditions during transport, storage and installation . 40

8 Constructional requirements . 40

8.1 Strength of materials and parts . 40

8.1.1 General . 40

8.1.2 Protection against corrosion . 41

8.1.3 Properties of insulating materials . 41

8.1.4 Resistance to ultra-violet (UV) radiation . 41

8.1.5 Mechanical strength . 41

8.1.6 Lifting provision . 42

8.2 Degree of protection provided by an assembly enclosure . 42

8.2.1 Protection against mechanical impact (IK code) . 42

8.2.2 Protection against contact with live parts, ingress of solid foreign bodies

and water (IP code) . 42

8.2.3 Assembly with removable parts. 43

8.3 Clearances and creepage distances. 43

8.3.1 General . 43

8.3.2 Clearances . 43

8.3.3 Creepage distances . 44

8.4 Protection against electric shock . 44

8.4.1 General . 44

8.4.2 Basic protection . 44

8.4.3 Fault protection . 45

8.4.4 Additional requirements for class II assemblies . 48

8.4.5 Limitation of steady-state touch currents and charge . 49

8.4.6 Operating and servicing conditions . 49

8.5 Incorporation of switching devices and components . 50

8.5.1 Fixed parts . 50

8.5.2 Removable parts . 51

8.5.3 Selection of switching devices and components . 51

8.5.4 Installation of switching devices and components . 51

8.5.5 Accessibility . 52

8.5.6 Barriers . 52

8.5.7 Direction of operation and indication of switching positions . 52

8.5.8 Indicator lights and push-buttons . 52

8.5.9 Power factor correction banks . 52

8.6 Internal electrical circuits and connections . 52

8.6.1 Main circuits . 52

8.6.2 Auxiliary circuits . 53

8.6.3 Bare and insulated conductors . 53

8.6.4 Selection and installation of non-protected live conductors to reduce the

possibility of short-circuits . 55

8.6.5 Identification of the conductors of main and auxiliary circuits . 55

8.6.6 Identification of the protective conductor (PE, PEL, PEM, PEN) and of

the neutral conductor (N) and the mid-point conductor (M) of the main

circuits . 55

8.6.7 Conductors in AC circuits passing through ferromagnetic enclosures or

plates . 55

8.7 Cooling . 55

8.8 Terminals for external cables . 55

– 4 – IEC 61439-1:2020 © IEC 2020

9 Performance requirements . 57

9.1 Dielectric properties . 57

9.1.1 General . 57

9.1.2 Power-frequency withstand voltage . 57

9.1.3 Impulse withstand voltage . 57

9.1.4 Protection of surge protective devices . 58

9.2 Temperature-rise limits . 58

9.2.1 General . 58

9.2.2 Adjustment of rated currents for alternative ambient air temperatures . 58

9.3 Short-circuit protection and short-circuit withstand strength . 59

9.3.1 General . 59

9.3.2 Information concerning short-circuit withstand strength . 59

9.3.3 Relationship between peak current and short-time current . 60

9.3.4 Coordination of protective devices . 60

9.4 Electromagnetic compatibility (EMC) . 60

10 Design verification . 60

10.1 General . 60

10.2 Strength of materials and parts . 62

10.2.1 General . 62

10.2.2 Resistance to corrosion . 62

10.2.3 Properties of insulating materials . 64

10.2.4 Resistance to ultraviolet (UV) radiation . 65

10.2.5 Lifting . 66

10.2.6 Verification of protection against mechanical impact (IK code) . 67

10.2.7 Marking . 67

10.2.8 Mechanical operation . 67

10.3 Degree of protection of assemblies (IP Code) . 68

10.4 Clearances and creepage distances. 69

10.5 Protection against electric shock and integrity of protective circuits . 69

10.5.1 General . 69

10.5.2 Effective earth continuity between the exposed-conductive-parts of the

class I assembly and the protective circuit . 69

10.5.3 Short-circuit withstand strength of the protective circuit . 69

10.6 Incorporation of switching devices and components . 70

10.6.1 General . 70

10.6.2 Electromagnetic compatibility . 70

10.7 Internal electrical circuits and connections . 70

10.8 Terminals for external conductors . 70

10.9 Dielectric properties . 71

10.9.1 General . 71

10.9.2 Power-frequency withstand voltage . 71

10.9.3 Impulse withstand voltage . 72

10.9.4 Testing of enclosures made of insulating material . 74

10.9.5 External door or cover mounted operating handles of insulating material . 74

10.9.6 Testing of conductors and hazardous live parts covered by insulating

material to provide protection against electric shock . 74

10.10 Temperature-rise . 74

10.10.1 General . 74

10.10.2 Verification by testing . 75

10.10.3 Verification by comparison . 81

10.10.4 Verification assessment . 84

10.11 Short-circuit withstand strength . 86

10.11.1 General . 86

10.11.2 Circuits of assemblies which are exempted from the verification of the

short-circuit withstand strength . 86

10.11.3 Verification by comparison with a reference design – Using a checklist . 87

10.11.4 Verification by comparison with a reference design(s) – Using

calculation . 87

10.11.5 Verification by test . 87

10.12 Electromagnetic compatibility (EMC) . 93

11 Routine verification . 93

11.1 General . 93

11.2 Degree of protection against contact with hazardous live parts, ingress of

solid foreign bodies and water of enclosures . 94

11.3 Clearances and creepage distances. 94

11.4 Protection against electric shock and integrity of protective circuits . 94

11.5 Incorporation of built-in components . 95

11.6 Internal electrical circuits and connections . 95

11.7 Terminals for external conductors . 95

11.8 Mechanical operation . 95

11.9 Dielectric properties . 95

11.10 Wiring, operational performance and function . 95

Annex A (normative) Minimum and maximum cross-section of copper cables suitable

for connection to terminals for external cables (see 8.8) . 105

Annex B (normative) Method of calculating the cross-sectional area of protective

conductors with regard to thermal stresses due to currents of short duration . 106

Annex C (informative) User information template . 107

Annex D (informative) Design verification . 111

Annex E (informative) Rated diversity factor . 112

E.1 General . 112

E.2 Rated diversity factor for outgoing circuits within an assembly . 112

E.2.1 General . 112

E.2.2 Example of an assembly with an RDF of 0,68 . 115

E.2.3 Example of an assembly with RDF declared for each section . 116

Annex F (normative) Measurement of clearances and creepage distances . 117

F.1 Basic principles . 117

F.2 Use of ribs . 117

Annex G (normative) Correlation between the nominal voltage of the supply system

and the rated impulse withstand voltage of the equipment . 122

Annex H (informative) Operating current and power loss of copper cables . 124

Annex I (informative) Thermal equivalent of an intermittent current . 126

Annex J (normative) Electromagnetic compatibility (EMC). 127

J.1 General . 127

Annex K (normative) Operating current and power loss of bare copper bars . 134

Annex L (informative) Guidance on verification of temperature-rise . 137

L.1 General . 137

L.1.1 Principles . 137

– 6 – IEC 61439-1:2020 © IEC 2020

L.1.2 Current ratings of assemblies . 137

L.2 Temperature-rise limits . 138

L.3 Test . 139

L.3.1 General . 139

L.3.2 Method a) – Verification of the complete assembly (10.10.2.3.5) . 139

L.3.3 Method b) – Verification considering individual functional units

separately and the complete assembly (10.10.2.3.6) . 139

L.3.4 Method c) – Verification considering individual functional units and the

main and distribution busbars separately as well as the complete

assembly (10.10.2.3.7) . 140

L.4 Verification assessment . 140

L.4.1 General . 140

L.4.2 Single compartment assembly with a rated current (I ) not exceeding

nA

630 A . 140

L.4.3 Assembly with rated currents (I ) not exceeding 1 600 A . 140

nA

L.5 Verification by comparison with a reference design . 140

Annex M (normative) Verification of the short-circuit withstand strength of busbar

structures by comparison with a reference design by calculation . 142

M.1 General . 142

M.2 Terms and definitions. 142

M.3 Method of verification . 143

M.4 Conditions for application . 144

M.4.1 General . 144

M.4.2 Peak short-circuit current . 144

M.4.3 Thermal short-circuit strength . 144

M.4.4 Busbar supports . 144

M.4.5 Busbar connections, equipment connections . 144

M.4.6 Angular busbar configurations . 144

M.4.7 Calculations with special regard to conductor oscillation . 145

Annex N (informative) List of notes concerning certain countries . 146

Bibliography . 152

Figure E.1 – Typical assembly . 113

Figure E.2 – Example 1: Table E.1 – Functional unit loading for an assembly with a

rated diversity factor of 0,68 . 115

Figure E.3 – Example 2: Table E.1 – Functional unit loading for an assembly with a

rated diversity factor of 0,6 in Section B and 0,68 in Section C . 116

Figure F.1 – Measurement of clearance and creepage distances . 121

Figure I.1 – Example of average heating effect calculation . 126

Figure J.1 – Examples of ports . 127

Figure L.1 – Verification of temperature-rise . 141

Figure M.1 – Tested busbar structure (TS) . 142

Figure M.2 – Non tested busbar structure (NTS) . 143

Figure M.3 – Angular busbar configuration with supports at the corners . 144

Table 1 – Minimum clearances in air (8.3.2) . 96

Table 2 – Minimum creepage distances (8.3.3) . 97

Table 3 – Cross-sectional area of a copper protective conductor (8.4.3.2.2) . 98

Table 4 – Conductor selection and installation requirements (8.6.4) . 98

Table 5 – Minimum terminal capacity for copper protective conductors (PE) (8.8) . 98

Table 6 – Temperature-rise limits (9.2) . 99

Table 7 – Values for the factor n (9.3.3) . 100

Table 8 – Power-frequency withstand voltage for main circuits (10.9.2) . 100

Table 9 – Power-frequency withstand voltage for auxiliary circuits (10.9.2) . 100

Table 10 – Impulse withstand test voltages (10.9.3) . 100

Table 11 – Copper test conductors for rated currents up to 400 A inclusive (10.10.2.3.2) . 101

Table 12 – Copper test conductors for rated currents from 400 A to 7 000 A

(10.10.2.3.2) . 102

Table 13 – Short-circuit verification by comparison with reference designs: checklist

(10.5.3.3, 10.11.3 and 10.11.4) . 103

Table 14 – Relationship between prospective fault current and diameter of copper wire . 104

Table 15 – Climatic conditions . 104

Table A.1 – Cross-section of copper cables suitable for connection to terminals for

external cables . 105

Table B.1 – Values of k for insulated protective conductors not incorporated in cables

or bare protective conductors in contact with cable covering . 106

Table C.1 – User information template . 107

Table D.1 – List of design verifications to be performed . 111

Table E.1 – Examples of loading for an assembly . 114

Table F.1 – Minimum width of grooves . 117

Table G.1 – Correspondence between the nominal voltage of the supply system and

the equipment rated impulse withstand voltage . 123

Table H.1 – Operating current and power loss of single-core copper cables with a

permissible conductor temperature of 70 °C (ambient temperature inside the assembly:

55 °C) . 124

Table H.2 – Reduction factor k for cables with a permissible conductor temperature

of 70 °C (extract from IEC 60364-5-52:2009, Table B.52.14). 125

Table J.1 – Tests for EMC immunity for environment A (see J.10.12.2) . 131

Table J.2 – Tests for EMC immunity for environment B (see J.10.12.2) . 132

Table J.3 – Acceptance criteria when electromagnetic disturbances are present . 133

Table K.1 – Operating current and power loss of bare copper bars with rectangular

cross-section, run horizontally and arranged with their largest face vertical, frequency

50 Hz to 60 Hz (ambient air temperature inside the assembly: 55 °C, temperature of

the conductor 70 °C) . 134

Table K.2 – Factor k for different temperatures of the air inside the assembly and/or

for the conductors . 135

– 8 – IEC 61439-1:2020 © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LOW-VOLTAGE SWITCHGEAR AND CONTROLGEAR ASSEMBLIES –

Part 1: General rules

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61439-1 has been prepared by subcommittee 121B: Low-voltage

switchgear and controlgear assemblies, of IEC technical committee 121: Switchgear and

controlgear and their assemblies for low voltage.

This third edition cancels and replaces the second edition published in 2011. It constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) clarification that power electric converter systems, switch mode power supplies,

uninterruptable power supplies and adjustable speed power drive systems are tested to

their particular products standard, but when they are incorporated in assemblies the

incorporation is in accordance with the IEC 61439 series of standards;

b) introduction of a group rated current for circuits within a loaded assembly and the

refocusing of temperature-rise verification on this new characteristic;

c) addition of requirements in respect of DC;

d) introduction of the concept of class I and class II assemblies regarding protection against

electric shock.

The text of this International Standard is based on the following documents:

FDIS Report on voting

121B/99/FDIS 121B/103/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

The reader’s attention is drawn to the fact that Annex N lists all the “in-some-countries”

clauses on differing practices of a less permanent nature regarding this document.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61439 series, under the general title Low-voltage switchgear and

controlgear assemblies, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 10 – IEC 61439-1:2020 © IEC 2020

INTRODUCTION

The purpose of this document is to harmonize as far as practicable all rules and requirements

of a general nature applicable to low-voltage switchgear and controlgear assemblies, in order

to obtain uniformity of requirements and verification for assemblies and to avoid the need for

verification in other standards. All those requirements for the various assembly standards

which can be considered as general have therefore been gathered in this document together

with specific subjects of wide interest and application, e.g. temperature-rise, dielectric

properties, etc.

For each type of low-voltage switchgear and controlgear assembly, only two main standards

are necessary to determine all requirements and the corresponding methods of verification:

– the basic standard, (this document) referred to as “IEC 61439-1” in the specific standards,

covering the various types of low-voltage switchgear and controlgear assemblies;

– the specific assembly standard hereinafter also referred to as the relevant assembly

standard.

For a general rule to apply to a specific assembly standard, it should be explicitly referred to

by quoting this document followed by the relevant clause or subclause number e.g.

“IEC 61439-1:2020, 9.1.3”.

A specific assembly standard may not require, and hence need not call up, a general rule

where it is not applicable, or it can add requirements if the general rule is deemed inadequate

in the particular case, but it may not deviate from it unless there is substantial technical

justification detailed in the specific assembly standa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...