IEC 61439-5:2023

(Main)Low-voltage switchgear and controlgear assemblies - Part 5: Assemblies for power distribution in public networks

Low-voltage switchgear and controlgear assemblies - Part 5: Assemblies for power distribution in public networks

IEC 61439-5:2023 defines the specific requirements for public electricity network distribution assemblies (PENDAs). PENDAs have the following criteria:

- used for the distribution of electrical energy in three phase systems for which the rated voltage does not exceed 1 000 V AC (see Figure 101 for a typical distribution network) and DC systems not exceeding 1 500 V DC;

- stationary;

- open type assemblies are not covered by this document;

- suitable for installation in places where only skilled persons have access for their use, however, outdoor types can be installed in situations that are accessible to ordinary persons

- intended for use in energy distribution in public power grids;

- indoor use: assemblies for installation inside of electric power substations;

- outdoor use: assemblies containing an enclosure suitable for open air installation.

This third edition cancels and replaces the second edition published in 2014. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) omission of the requirement to conduct mechanical tests at -25 °C when enclosures are made of a metallic material;

b) addition of assumed loading factors generation supplies and electric vehicle charging applications;

c) additional dielectric tests when a PENDA is used in a distribution substation with separate HV and LV earths;

d) further clarification of representative samples for design verification.

The content of the corrigendum 1 (2025-02) has been included in this copy.

Ensembles d'appareillage à basse tension - Partie 5: Ensembles pour réseaux de distribution publique

L'IEC 61439-5:2023 définit les exigences spécifiques aux ensembles pour réseaux de distribution publique d'électricité (ERD). Les ERD remplissent les critères suivants:

- ils sont utilisés pour la distribution de l'énergie électrique dans des systèmes triphasés pour lesquels la tension assignée ne dépasse pas 1 000 V en courant alternatif (se reporter à la Figure 101 qui représente un réseau de distribution classique) et des systèmes à courant continu qui ne dépassent pas 1 500 V en courant continu;

- ils sont fixes;

- les ensembles ouverts ne sont pas couverts par le présent document;

- ils sont adaptés à une installation dans des emplacements où seules des personnes qualifiées ont accès pour leur utilisation; cependant, les types pour l'extérieur peuvent être installés dans des endroits accessibles à des personnes ordinaires;

- ils sont destinés à être utilisés dans les réseaux de distribution publique;

- à l'intérieur: ensembles installés à l'intérieur de postes d'alimentation électrique;

- à l'extérieur: ensembles avec une enveloppe adaptée à une installation en plein air.

Cette troisième édition annule et remplace la deuxième édition parue en 2014. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) omission de l'exigence de réalisation d'essais mécaniques à -25 °C lorsque les enveloppes sont en matériau métallique;

b) ajout d'application de charge de véhicules électriques et de production d'énergie avec des facteurs de charge présumés;

c) ajout d'essais diélectriques lorsqu'un ERD est utilisé dans un poste avec terres HT et BT séparées;

d) description plus détaillée des échantillons représentatifs pour la vérification de la conception.

Le contenu du corrigendum 1 (2025-02) a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 03-May-2023

- Technical Committee

- SC 121B - Low-voltage switchgear and controlgear assemblies

- Drafting Committee

- MT 7 - TC 121/SC 121B/MT 7

- Current Stage

- PPUB - Publication issued

- Start Date

- 05-May-2023

- Completion Date

- 02-Jun-2023

Relations

- Effective Date

- 10-Jan-2025

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview - IEC 61439-5:2023 (PENDAs)

IEC 61439-5:2023 is the part of the IEC 61439 series that defines specific requirements for public electricity network distribution assemblies (PENDAs) used in low‑voltage power distribution in public networks. It applies to stationary, enclosed assemblies used to distribute electrical energy in three‑phase systems up to 1 000 V AC (and DC systems up to 1 500 V DC). The third edition (2023) replaces the 2014 edition and includes a corrigendum; it is a technical revision that updates test and design requirements for PENDAs used indoors (substations) and outdoors.

Key topics and technical requirements

- Scope and definitions: Clarifies PENDA types - PENDA-I (indoor) and PENDA-O (outdoor). Open types are excluded. Assemblies are intended for installation and maintenance by skilled persons, though some outdoor types may be accessible to ordinary persons.

- Service conditions and constructional requirements: Specifies environmental, mechanical and material considerations for enclosures and internal structures to suit substation and outdoor installations.

- Electrical and dielectric tests: Includes performance verification and additional dielectric tests where PENDAs are used in substations with separate HV and LV earths.

- Mechanical testing and verification: Design verification and routine tests for mechanical strength, impact resistance and resistance to static/torsional loads. Notably, the 2023 edition omits the former requirement for mechanical tests at −25 °C for metallic enclosures.

- Thermal and loading considerations: Guidance on temperature rise verification and assumed loading factors - newly expanded to cover generation supplies and electric vehicle charging applications.

- Design verification & representative samples: Clarifies which sample assemblies and configurations are representative for verification testing.

- Documentation and information: Requirements for information exchange between manufacturer and DSO or end user, including items subject to agreement.

Practical applications and users

Who uses IEC 61439-5:

- Distribution system operators (DSOs) specifying LV distribution panels in transformer substations

- Switchgear and assembly manufacturers designing low‑voltage switchgear for public networks

- Electrical engineers and system integrators implementing public power distribution, including EV charging and distributed generation interconnections

- Test laboratories and certification bodies performing design, dielectric and mechanical verifications

- Spec writers, procurement teams and regulators defining network equipment requirements

Typical applications:

- LV distribution cubicles in public network substations

- Outdoor enclosed distribution cabinets for feeders and customer connections

- Panels integrating monitoring, control and signalling for smart‑grid deployments

Related standards

- IEC 61439-1 (General rules) - normative companion

- IEC 60695-11-10, IEC 62262, ISO 9223, ISO 6506-1 - cited normative references

Keywords: IEC 61439-5, PENDA, low‑voltage switchgear, public networks, PENDA-O, PENDA-I, power distribution, dielectric tests, design verification, EV charging.

REDLINE IEC 61439-5:2023 - Low-voltage switchgear and controlgear assemblies - Part 5: Assemblies for power distribution in public networks Released:5/4/2023

IEC 61439-5:2023 - Low-voltage switchgear and controlgear assemblies - Part 5: Assemblies for power distribution in public networks Released:5/4/2023 Isbn:9782832269398

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61439-5:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Low-voltage switchgear and controlgear assemblies - Part 5: Assemblies for power distribution in public networks". This standard covers: IEC 61439-5:2023 defines the specific requirements for public electricity network distribution assemblies (PENDAs). PENDAs have the following criteria: - used for the distribution of electrical energy in three phase systems for which the rated voltage does not exceed 1 000 V AC (see Figure 101 for a typical distribution network) and DC systems not exceeding 1 500 V DC; - stationary; - open type assemblies are not covered by this document; - suitable for installation in places where only skilled persons have access for their use, however, outdoor types can be installed in situations that are accessible to ordinary persons - intended for use in energy distribution in public power grids; - indoor use: assemblies for installation inside of electric power substations; - outdoor use: assemblies containing an enclosure suitable for open air installation. This third edition cancels and replaces the second edition published in 2014. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) omission of the requirement to conduct mechanical tests at -25 °C when enclosures are made of a metallic material; b) addition of assumed loading factors generation supplies and electric vehicle charging applications; c) additional dielectric tests when a PENDA is used in a distribution substation with separate HV and LV earths; d) further clarification of representative samples for design verification. The content of the corrigendum 1 (2025-02) has been included in this copy.

IEC 61439-5:2023 defines the specific requirements for public electricity network distribution assemblies (PENDAs). PENDAs have the following criteria: - used for the distribution of electrical energy in three phase systems for which the rated voltage does not exceed 1 000 V AC (see Figure 101 for a typical distribution network) and DC systems not exceeding 1 500 V DC; - stationary; - open type assemblies are not covered by this document; - suitable for installation in places where only skilled persons have access for their use, however, outdoor types can be installed in situations that are accessible to ordinary persons - intended for use in energy distribution in public power grids; - indoor use: assemblies for installation inside of electric power substations; - outdoor use: assemblies containing an enclosure suitable for open air installation. This third edition cancels and replaces the second edition published in 2014. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) omission of the requirement to conduct mechanical tests at -25 °C when enclosures are made of a metallic material; b) addition of assumed loading factors generation supplies and electric vehicle charging applications; c) additional dielectric tests when a PENDA is used in a distribution substation with separate HV and LV earths; d) further clarification of representative samples for design verification. The content of the corrigendum 1 (2025-02) has been included in this copy.

IEC 61439-5:2023 is classified under the following ICS (International Classification for Standards) categories: 29.130.20 - Low voltage switchgear and controlgear. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61439-5:2023 has the following relationships with other standards: It is inter standard links to IEC 61439-5:2023/COR1:2025, IEC 61439-5:2014/COR1:2015, IEC 61439-5:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61439-5:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61439-5 ®

Edition 3.0 2023-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Low-voltage switchgear and controlgear assemblies –

Part 5: Assemblies for power distribution in public networks

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61439-5 ®

Edition 3.0 2023-05

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Low-voltage switchgear and controlgear assemblies –

Part 5: Assemblies for power distribution in public networks

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.130.20 ISBN 978-2-8322-6987-9

– 2 – IEC 61439-5:2023 RLV © IEC 2023

CONTENTS

FOREWORD . 3

1 Scope . 6

2 Normative references . 7

3 Terms and definitions . 8

4 Symbols and abbreviations . 9

5 Interface characteristics. 9

6 Information . 10

7 Service conditions . 10

8 Constructional requirements . 10

9 Performance requirements. 14

10 Design verification . 14

11 Routine verification . 30

Annexes . 31

Annex O L (informative) Guidance on verification of temperature rise verification . 32

Annex AA (normative) Cross-section of conductors . 33

Annex BB (informative) Items subject to agreement between the assembly

manufacturer and the user . 35

Annex CC (informative) Design verification . 39

Annex DD (informative) List of notes concerning certain countries . 41

Bibliography . 42

Figure 101 – Typical distribution network . 7

Figure 102 – Diagram of test to verify resistance to shock load of a PENDA-O . 18

Figure 103 – Diagram of test to verify impact force withstand of a PENDA-O . 19

Figure 104 – Diagram of test to verify the resistance to static load . 20

Figure 105 – Sandbag for test to verify the resistance to shock load . 21

Figure 106 – Diagram of test to verify resistance to torsional stress of a PENDA-O . 23

Figure 107 – Diagram of test to verify the mechanical strength of doors . 26

Figure 108 – Striker element for test of resistance to mechanical shock impacts

induced by sharp-edged objects . 27

Figure 109 – Typical test arrangement for mechanical strength of base . 28

Table 101 – Values of assumed loading . 9

Table 102 – Axial load to be applied to the inserts . 27

Table AA.1 – Minimum and maximum cross-section of copper and aluminium

conductors, suitable for connection (see 8.8) . 33

Table AA.2 – Standard cross-sections of round copper conductors and approximate

relationship between mm and AWG/kcmil sizes (see 8.8 of IEC 61439‑1:2020) . 34

Table BB.1 – Items subject to agreement between the ASSEMBLY manufacturer

and the user . 35

Table CC.1 – List of design verifications to be performed. 39

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LOW-VOLTAGE SWITCHGEAR AND CONTROLGEAR ASSEMBLIES –

Part 5: Assemblies for power distribution in public networks

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition IEC 61439-5:2014. A vertical bar appears in the margin

wherever a change has been made. Additions are in green text, deletions are in

strikethrough red text.

– 4 – IEC 61439-5:2023 RLV © IEC 2023

IEC 61439-5 has been prepared by subcommittee 121B: Low-voltage switchgear and

controlgear assemblies, of IEC technical committee 121: Switchgear and controlgear and their

assemblies for low voltage. It is an International Standard.

This third edition cancels and replaces the second edition published in 2014. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) omission of the requirement to conduct mechanical tests at -25 °C when enclosures are

made of a metallic material;

b) addition of assumed loading factors generation supplies and electric vehicle charging

applications;

c) additional dielectric tests when a PENDA is used in a distribution substation with separate

HV and LV earths;

d) further clarification of representative samples for design verification.

The text of this International Standard is based on the following documents:

Draft Report on voting

121B/173/FDIS 121B/178/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

This document is to be read in conjunction with IEC 61439-1. The provisions of the general

rules dealt with in IEC 61439-1 are only applicable to this document insofar as they are

specifically cited. When this document states "addition", "modification" or "replacement", the

relevant text in IEC 61439-1:2020 is to be adapted accordingly. Subclauses that are numbered

with a 101 (102, 103 etc.) suffix are additional to the same subclause in IEC 61439‑1:2020.

Tables and figures in IEC 61439-5:2023 that are new are numbered starting with 101.

New annexes in IEC 61439-5:2023 are lettered AA, BB, etc.

The reader’s attention is drawn to the fact that Annex DD lists all of the "in-some-country"

clauses on differing practices of a less permanent nature relating to the subject of this

document.

A list of all parts of the IEC 61439 series, under the general title Low-voltage switchgear and

controlgear assemblies can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 61439-5:2023 RLV © IEC 2023

LOW-VOLTAGE SWITCHGEAR AND CONTROLGEAR ASSEMBLIES –

Part 5: Assemblies for power distribution in public networks

1 Scope

This document defines the specific requirements for public electricity network distribution

assemblies (PENDAs).

PENDAs have the following criteria:

– used for the distribution of electrical energy in three phase systems for which the rated

voltage does not exceed 1 000 V AC (see Figure 101 for a typical distribution network) and

DC systems not exceeding 1 500 V DC;

– stationary;

– open type assemblies are not covered by this document;

– suitable for installation in places where only skilled persons have access for their use,

however, outdoor types may can be installed in situations that are accessible to ordinary

persons

• intended for use in energy distribution in public power grids;

• indoor use: assemblies for installation inside of electric power substations;

• outdoor use: assemblies containing an enclosure suitable for open air installation.

The object of this document is to state the definitions and to specify the service conditions,

construction requirements, technical characteristics and tests for PENDAs. Network parameters

may require Tests at higher performance level can be applicable with some network parameters.

PENDAs may can also include control and or signalling devices associated with the distribution

of electrical energy.

NOTE 1 Control and monitoring devices can be used in smart grid applications or the transmission of smart grid

data.

This document applies to all PENDAs whether they are designed, manufactured on a one-off

basis or fully standardised and manufactured in quantity.

The manufacture and/or assembly may can be carried out other than by the original

manufacturer (see 3.10.1 of IEC 61439-1:20112020).

This document does not apply to individual devices and self-contained components, such as

motor starters, fuse switches, electronic equipment, etc. which comply with the relevant product

standards.

If the substation is owned or operated by a public distribution system operator (DSO), PENDA’s

which are used as LV distribution panels in transformer substations are within the scope of this

document,

This document does not apply to specific types of assemblies covered by other parts of

IEC 61439 series.

Figure 101 – Typical distribution network

NOTE 2 If a PENDA is equipped with additional equipment (for example meters), in such a way that the main

function is changed considerably, then other standards can also apply as agreed between user and manufacturer

(see 8.5 of IEC 61439-1:20112020).

NOTE 3 Where local regulations and practices permit, a PENDA according to this document can be used in other

than public networks.

NOTE 4 DSO’s can define additional requirements for their PENDA’s.

2 Normative references

This clause of IEC 61439-1:2020 applies except as follows.

Addition:

IEC 60695-11-10:2013, Fire hazard testing – Part 11-10: Test flames – 50 W horizontal and

vertical flame test methods

IEC 61439-1:20112020, Low-voltage switchgear and controlgear assemblies – Part 1: General

rules

IEC 62262, Degrees of protection provided by enclosures for electrical equipment against

external mechanical impacts (IK code)

ISO 9223:2012, Corrosion of metals and alloys – Corrosivity of atmospheres – Classification,

determination and estimation

ISO 6506-1:2014, Metallic materials – Brinell hardness test – Part 1: Test method

– 8 – IEC 61439-5:2023 RLV © IEC 2023

3 Terms and definitions

This clause of IEC 61439-1:2020 applies except as follows.

3.1 General terms

Additional terms:

3.1.101

public electricity network distribution assembly

PENDA

assembly, generally for installation in a public electricity network which in use, receives

electrical energy from one or more supplies and distributes that energy through one or more

cables to other equipment

Note 1 to entry: A PENDA is installed, operated and maintained solely by skilled persons.

Note 2 to entry: Some types of a PENDA were previously known as a cable distribution cabinet (CDC).

3.1.101.1

outdoor public electricity network distribution assembly

PENDA-O

cubicle type public electricity network distribution assembly that is suitable for outdoor

installation in places that may can, or may not cannot, be accessible to the public

3.1.101.2

indoor public electricity network distribution assembly

PENDA-I

public electricity network distribution assembly suitable for installation indoors, generally

without an enclosure, but including all structural parts necessary to support busbars, functional

units and other ancillary devices, necessary to complete the assembly

3.1.102

design life

minimum duration for which specified performance characteristics of equipment are expected

when the equipment is operated as intended and regularly maintained by instructed persons in

accordance with the manufacturer’s instructions

[SOURCE: IEC 60050-395:2014, 395-07-93, modified – Note to entry omitted and 'granted'

replaced by 'expected when . instructions'.]

3.3 External design of assemblies

3.3.1

open-type assembly

This term of IEC 61439-1:2020 does not apply.

3.9 Verification

Modifications:

3.9.1

design verification

Delete the note.

3.9.1.2

verification comparison

This term of IEC 61439-1:2020 does not apply.

3.9.1.3

verification assessment

This term of IEC 61439-1:2020 does not apply.

4 Symbols and abbreviations

This clause of IEC 61439-1:2020 applies.

5 Interface characteristics

This clause of IEC 61439-1:2020 applies, except as follows.

5.4 Rated diversity factor (RDF)

Addition:

In the absence of an agreement between the assembly manufacturer and user concerning the

actual load currents, the assumed loading of the outgoing circuits of the assembly or group of

outgoing circuits may can be based on the values given in Table 101.

For distribution and final circuits, it is assumed that the load current is the rated current of the

protective device, I , as required by the user, multiplied with the loading factor of Table 101.

n

Table 101 – Values of assumed loading

Number of main circuits Assumed loading factor

2 and 3 0,9

4 and 5 0,8

6 to 9 inclusive 0,7

10 (and above) 0,6

Application Assumed

loading

factor

Regular distribution grid connections 0,9

2 to 3 circuits

Regular distribution grid connections 0,8

4 to 5 circuits

Regular distribution grid connections 0,7

6 to 9 circuits

Regular distribution grid connections 0,6

≥ 10 circuits

Generation supply (e,g. PV, wind farm, biomass) 1,0

Charging infrastructure for EV 1,0

– 10 – IEC 61439-5:2023 RLV © IEC 2023

6 Information

This clause of IEC 61439-1:2020 applies except as follows.

6.1 Assembly designation marking

Addition to first paragraph:

Designation plates may can be placed inside an enclosure of an assembly provided their

intended place ensures good legibility and visibility when the door(s) is(are) open or the cover

is removed.

Replacement of item dg):

dg) IEC 61439-5.

6.3 Device and/or component identification

Additional paragraph:

In the case of removable fuse-carriers which are specific to a fuseway, a label shall be placed

on the fuse carrier as well as on the fuse base, to avoid incorrect interchangeability of the

fuse-carrier.

Additional subclause:

6.101 Circuit identification

It shall be possible to identify each functional unit in a clearly visible manner.

7 Service conditions

This clause of IEC 61439-1:2020 applies except as follows.

7.1 Normal service conditions

7.1.1 Climatic conditions

Addition to the first paragraph:

Unless the user specifies that a PENDA shall be suitable for use in an arctic climate, the lower

limit of ambient air temperature is –25 °C as specified in Table 15 of IEC 61439-1:2020. For an

arctic climate the lower limit of ambient temperature is –50 °C.

7.1.1.2 Ambient air temperature for outdoor installations

Replacement of last paragraph with:

Unless the user specifies a PENDA shall be suitable for use in an arctic climate, the lower limit

of ambient air temperature is –25 °C. For an arctic climate the lower limit of ambient

temperature is –50 °C.

7.1.2 Pollution degree

Replace the first paragraph with the following:

The pollution degree referred to in Annex BB is the macro-environmental condition for which

the assembly is intended.

7.2 Special service conditions

Addition of the following note to item h):

NOTE Exposure to vibration arising from traffic and/or occasional ground excavation is a normal service condition

for PENDAs.

Additional paragraph:

Additional requirements for a PENDA-O, to be installed where heavy snowfalls occur and where

they are adjacent to areas where there is snow clearance by ploughing, are subject to

agreement between manufacturer and user.

8 Constructional requirements

This clause of IEC 61439-1:2020 applies except as follows.

8.1 Strength of materials and parts

8.1.1 General

Change the reference to Annex C to Annex BB in paragraph 5 of 8.1.1 of IEC 61439-1:2020.

Addition:

A PENDA-O shall be arranged for ground mounting, transformer mounting, pole mounting,

surface wall mounting or mounting within a recess within a wall, as agreed between user and

manufacturer.

A PENDA may can be directly coupled to a transformer by means of a flange coupling or it may

can connect to its supply by means of cable or via busbars as agreed between user and

manufacturer. Outgoing circuits shall be suitable for connection by means of cables.

A reliable locking device shall be provided on outdoor enclosures which prevents access by

unauthorized persons. Doors, lids and covers shall be so designed that, after they are locked,

they do not open due to subsequent moderate ground settlement, nor due to exposure to

vibration arising from traffic and/or ground excavation and reinstatement works. The fixings of

any covers etc. which are removable for installation or maintenance operations shall only be

accessible while the door(s) is (are) open.

Any auxiliary equipment, e.g. meters, relays, instruments, circuit breaker trip units,

communications equipment, that can be readily replaced, are excluded from the minimum

design life of a PENDA.

NOTE When applicable, a design life can be agreed between user and manufacturer, assuming it is operated as

intended and regularly maintained by instructed personnel in accordance with the manufacturer’s instructions.

8.1.3.2 Resistance of insulating materials to heat and fire

Additional subclause:

8.1.3.2.101 Verification of category of flammability

The insulating materials used for enclosures, barriers and other insulating parts shall have

flame retardant flammability properties in accordance with 10.2.3.102 of this standard

10.2.3.101.

– 12 – IEC 61439-5:2023 RLV © IEC 2023

8.1.5 Mechanical strength

Additional subclause:

8.1.5.101 Verification of mechanical strength

The mechanical properties of a PENDA-O shall comply with 10.2.101.

Parts of the PENDA-O intended to be embedded in the ground shall withstand the stresses

imposed on them during installation and normal service and comply with 10.2.101.9.

Additional subclause:

8.1.101 Thermal stability

The thermal stability of a PENDA shall be verified according to 10.2.3.101.

8.2 Degree of protection provided by an assembly enclosure

8.2.1 Protection against mechanical impact (IK code)

Subclause 8.2.1 of IEC 61439-1:2020 does not apply.

The mechanical impact tests required by this document are at least equal to IK10 in accordance

with IEC 62262 (see 8.1.5.101).

8.2.2 Protection against contact with live parts, ingress of solid foreign bodies and

water (IP code)

Addition:

Open type assemblies (IP00) are not covered by this document.

When a PENDA-O is intended to be installed in places accessible to the public, its enclosure

shall, when fully-installed in accordance with the manufacturer’s instructions, provide a degree

of protection of at least IP34D according to IEC 60529. In other locations, the minimum level of

protection shall be at least IP33.

PENDA-O’s that are intended to be installed in places accessible to the public shall, unless

otherwise stated by the user, be designed such that when any temporary cables are connected,

the enclosure shall provide a degree of protection of at least IP23C according to IEC 60529.

See 8.8.

8.4 Protection against electric shock

8.4.2.1 General

The third paragraph does not apply.

Additional subclause:

8.4.2.101 Earthing and short-circuiting means

When specified by the user, the outgoing units in an assembly shall be so constructed that they

can be earthed and short-circuited in a secure manner by means of a device(s) recommended

by the manufacturer, which ensures the manufacturer’s indicated required degree of protection

(IP code) is maintained for all parts of the assembly. This requirement is not applicable if it

could cause a safety hazard arising from the system conditions and/or operational practice.

8.4.3.1 Installation conditions

Additional paragraph:

For an assembly that is expected When a user specifies the assembly is to feed overhead cable

lines, outgoing units shall be designed in such a way that an attached cable(s) can be earthed

at the termination(s).

8.8 Terminals for external conductors cables

Replacement of the first three paragraphs with the following:

In the absence of a special agreement between user and manufacturer, terminals shall be

capable of accommodating cables having copper or aluminium conductors from the smallest to

the largest cross-sectional area corresponding to the appropriate rated current (see

Table AA.1).

The terminations for outgoing circuits shall be located so that adequate spacing is provided and

to facilitate terminating the phase conductors of a cable irrespective of their lay.

When specified by the user the phase cable terminals of each outgoing circuit shall be

separated from all other hazardous live parts. When the terminals of an outgoing circuit are

exposed protection shall be provided against accidental contact with other hazardous live parts.

Separation and protection shall be from the normal direction of access and in accordance with

IPXXB of IEC 60529.

Where specified by the user, the incoming circuit shall be suitable for connection by means of

either bare or insulated bars.

Additional subclauses:

8.101 Marking as an obstacle to snow clearance

When specified by the user, Where a PENDA-O that is intended for use in regions where heavy

snowfalls occur in accordance with 7.2, or alternatively, if required by the user, it shall be

possible to mark it marked as an obstacle to snow clearance. Holders shall be provided,

attached to the PENDA-O, to accommodate marking rods and it shall be possible to install and

make adjustments to the position of the marking rod from outside the PENDA-O. The holders

shall be constructed in a manner which ensures that the holder or marking rod will give way to

a mechanical force before the transmitted force to the PENDA-O’s enclosure reaches the value

which would adversely affect the degree of protection (IP code).

8.102 Ease of operation and maintenance

All parts of the assembly shall, as far as practicable, be readily accessible and replaceable

without excessive dismantling. The conditions for interchangeability of parts of the ASSEMBLY

may be subject to an agreement between the user and the manufacturer.

The design shall be such that the cables can be readily connected from the front.

When a PENDA does not have a means of measurement incorporated, it shall be possible, by

the use of a portable instrument, to readily and safely measure voltages in all phases of

incoming units and on both sides of all current breaking and/or switch devices of outgoing units,

also the current in one phase of all outgoing units. During this operation all live parts of the

PENDA shall be protected sufficiently to retain the required degree of protection in accordance

with 8.2. Instructions concerning the procedure to be adopted shall be provided by the

manufacturer.

– 14 – IEC 61439-5:2023 RLV © IEC 2023

If the assembly is intended to be connected to a live reserve power, for example a standby

generator, the switchgear connecting device shall be designed so that connection can be made

with the live parts having a degree of protection of IP10 IPXXB according to IEC 60529.

Locking arrangements shall be provided on a PENDA to secure the door(s) and prevent

unauthorised access. The fixings of any covers etc. which are removable for installation or

maintenance operations shall only be accessible while the door(s) are open.

9 Performance requirements

This clause of IEC 61439-1:2020 applies.

10 Design verification

This clause of IEC 61439-1:2020 applies except as follows.

10.1 General

th th th th th th

Replace 4 , 5 , and 6 6 , 7 , and 8 paragraph with:

Design verification shall only be achieved by the application of tests in accordance with

Clause 10. The alternatives methods of verification by assessment or comparison with a

reference design shall not be used (see Table CC.1).

It is not necessary to test every arrangement produced. Tests carried out on a representative

sample of the most onerous PENDA are deemed to verify the performance of similar and less

onerous assemblies of the same general construction and rating. For example a temperature

rise test carried out on an 800 A PENDA-O with 5 outgoing circuits is deemed to apply to a

PENDA-O of the same construction (same general design of enclosure, same design of busbars

and same incoming units) with 8 outgoing circuits of the same rating as those included in the

PENDAO that was temperature rise tested. The same approach applies to short-circuit

verification. Examples of tests carried out on most onerous representative sample include:

1) A temperature rise test carried out on 800 A PENDA with 5 outgoing circuits is deemed to

apply to an 800 A PENDA of the same construction (same general enclosure, same design

of busbars and same incoming unit(s)) with 8 outgoing circuits of the same design.

2) Mechanical strength tests carried out on the smallest and largest enclosure in a series are

deemed to apply to all other enclosures in the series, when they have the same number of

doors and when they are of the same general construction.

3) Providing the busbar and connection support arrangements are the same, short-circuit tests

carried out on a design of busbar and connections are deemed to apply to higher current

ratings of busbars and connections.

4) A short circuit test carried out on 800 A PENDA with 8 outgoing circuits is deemed to apply

to an 800 A PENDA of the same construction (same general enclosure, same design of

busbars and same incoming unit(s)) with 5 outgoing circuits of the same design.

5) For a given short circuit rating, a short circuit tests carried out on an incoming or outgoing

circuit is deemed to apply to higher current rating circuits of the same design and

construction

Additional last paragraph:

Where necessary to suit their particular network parameters, users may can specify more

onerous or additional test requirements.

10.2 Strength of materials and parts

10.2.2 Resistance to corrosion

10.2.2.1 Test procedure Verification by test

Replacement of last paragraph with the following:

When the corrosion resistance properties and projected life, as agreed between the

manufacturer and the user, can shall be confirmed by reference to ISO 9223:2012, the tests

detailed herein need not be performed.

In all other cases the corrosion resistance of each design of assembly shall be verified by

severity test A or B, as applicable and as detailed 10.2.2.3 of IEC 61439-1:2020 and 10.2.2.2.

10.2.2.2 Severity test A

Replacement of the test specification (paragraph 2) with the following:

Damp heat cycling test of IEC 60068-2-30:2005: Severity – temperature 55 °C, 6 cycles and

variant 1.

At the end of the test, the specimens are removed from the test chamber.

Compliance is checked by visual inspection. The parts tested shall not show rust, cracking or

other deterioration. However, surface corrosion of the protective coating is allowed.

10.2.2.4 Results to be obtained

This subclause of IEC 61439-1:2020 is not applicable in respect of tests carried out in

accordance with 10.2.2.2.

10.2.3 Properties of insulating materials

Additional subclause:

10.2.3.101 Dry heat test

The complete ASSEMBLY shall be placed in an oven, the internal temperature of which is raised

to (100 ± 2) °C over a period of 2 h to 3 h and maintained at this temperature for 5 h.

Compliance is checked by inspection that there are no visible signs of deterioration.

Deformation of protective covers manufactured from insulating materials is acceptable if they

are more than 6 mm distant from parts which may have a temperature rise in excess of 40 K

and do not support live components.

10.2.3.102101 Verification of category of flammability

Representative specimens of each of the materials of enclosures, barriers and other insulating

parts shall be subjected to a flammability test in accordance with test method A – horizontal

burning test of IEC 60695-11-10:2013.

Compliance is checked by inspection that each set of specimens can be classified to category

HB40 criteria a) or b) in accordance with 8.4.3 of IEC 60695-11-10:2013.

10.2.6 Verification of protection against mechanical impact (IK code)

This subclause of IEC 61439-1:2020 is not applicable to assemblies complying with this

document.

– 16 – IEC 61439-5:2023 RLV © IEC 2023

Additional subclauses:

10.2.101 Verification of mechanical strength

10.2.101.1 General

Where enclosures are manufactured in a series and are of the same design and construction,

only the smallest and largest size of enclosure shall be tested.

The tests shall be carried out at an ambient temperature between 10 °C and 40 °C.

With the exception of the test of 10.2.101.7, a new sample assembly may can be used for each

of the independent tests. If the same sample assembly is used for more than one test of

10.2.101, the compliance check for the second numeral of the degree of protection (IP code)

need only be applied when the tests on that sample have been completed.

All tests shall be carried out with the assembly fixed at its normal service mounting and where

appropriate, added support at normal ground level as indicated in Figure 102a, Figure 102b,

Figure 103a, and Figure 103b.

Dimensions in millimetres

Start position

Impact

position

Cabinet

Top edge of base

Base

Support as stated

by the manufacturer

IEC

Figure 102a – Diagram of test to verify the resistance to shock load

of a ground mounted PENDA-O with embedded base

Dimensions in millimetres

Start position

Impact

position

IEC

Figure 102b – Diagram of test to verify resistance to shock load

of a ground mounted PENDA-O without embedded base

1 000

1 000

– 18 – IEC 61439-5:2023 RLV © IEC 2023

Dimensions in millimetres

Figure 102a – Diagram of test to verify the resistance to shock load

of a ground mounted PENDA-O with embedded base

Dimensions in millimetres

Figure 102b – Diagram of test to verify resistance to shock load

of a ground mounted PENDA-O without embedded base

Figure 102 – Diagram of test to verify resistance to shock load of a PENDA-O

Dimensions in millimetres

Figure 103a – Diagram of test to verify impact force withstand

for a ground mounted PENDA-O with embedded base

Dimensions in millimetres

Figure 103b – Diagram of test to verify impact force withstand

for a ground mounted PENDA-O without embedded base

Figure 103 – Diagram of test to verify impact force withstand of a PENDA-O

With the exception of the test of 10.2.101.8, the door(s) of the assembly, if applicable, shall be

locked at the commencement of the test and remain locked for the duration of the test.

10.2.101.2 Verification of resistance to static load

The following tests shall be carried out on all types of PENDA-0:

Test 1 – An evenly distributed load of 8 500 N/m shall be applied for 5 min to the roof of the

enclosure (see Figure 104).

– 20 – IEC 61439-5:2023 RLV © IEC 2023

Test 2 – A force of 1 200 N shall be applied for 5 min in turn to the front and back upper edges

of the roof of the enclosure (see Figure 104).

Figure 104 – Diagram of test to verify the resistance to static load

Compliance is checked by verification after the test that the minimum degree of protection is in

accordance with 8.2.2, and the operation of the door(s) and locking points are not impaired;

also by verification that the electrical clearances have remained satisfactory for the duration of

the tests and in the case of an assembly having metallic enclosure, that no contact between

live parts and the enclosure has occurred caused by permanent or temporary distortion.

10.2.101.3 Verification of resistance to shock load

The test shall apply to all types of PENDA-O.

A bag in accordance with Figure 105 containing dry sand and having a total mass of 15 kg shall

be hung from an overhead support vertically above the surface under test and at least 1 m

above the highest strike point of the assembly.

Dimensions in millimetres

Figure 105 – Sandbag for test to verify the resistance to shock load

Each test shall consist of one blow aimed at the upper part of each of the vertical surfaces of

the assembly which are visible when the assembly is installed in its normal service position.

Separate enclosures may can be used for each of the test blows.

In the case of an enclosure of cylindrical form, the test shall consist of three blows which are

positioned with an angular displacement of 120°.

A test shall consist of raising the lifting eye through a height of 1 m and allowing the sandbag

to fall through a vertical arc to impact the approximate centre of the upper part of the surface

of the assembly under test (see Figure 102a and Figure 102b).

Compliance is checked by verification after the test that the degree of protection remains in

accordance with 8.2.2, and the operation of the door(s) and locking points are not impaired;

also by verification that the electrical clearances have remained satisfactory for the duration of

the tests and, in the case of an assembly having a metallic enclosure, that no contact between

live parts and the enclosure has occurred caused by permanent or temporary distortion. In the

case of an assembly having an insulating enclosure, if the appropriate conditions are satisfied,

then damage such as small dents or small degrees of surface cracking or flaking are

disregarded, provided that there are no associated cracks detrimental to the serviceability of

the assembly.

– 22 – IEC 61439-5:2023 RLV © IEC 2023

10.2.101.4 Verification of resistance to torsional stress

The test only applies to all types of PENDA-O.

The test is carried out using a horizontally rotatable frame constructed from

60 mm × 60 mm × 5 mm angle iron, having vertical locations 100 mm long at the frame arm’s

extremities. The assembly under test is rigidly fixed at its base and the frame closely fitted over

it, so that the end locations of the frame arm are in contact with the roof and walls of the

assembly.

The assembly, with the door(s) closed shall have a torsional force of 2 × 1 000 N applied for

30 s as shown in Figure 106a and Figure 106b. This is comprised two separate tests, first with

the two forces each of 1 000 N applied to twist the PENDA in a clockwise direction and the

second with the two forces each of 1 000 N applied to rotate the PENDA in an anti-clockwise

direction.

Dimensions in millimetres

Figure 106a – Diagram of test to verify the resistance to torsional stress

of a ground mounted PENDA-O with embedded base

Dimensions in millimetres

Figure 106b – Diagram of test to verify resistance to torsional stress

of a ground mounted PENDA-O without embedded base

Figure 106 – Diagram of test to verify resistance to torsional stress of a PENDA-O

Compliance is checked by verifying that the doors(s) remain closed for the duration of the test

and by verification after the test that the degree of protection remains in accordance with 8.2.2.

10.2.101.5 Verification of impact force withstand

10.2.101.5.1 Test applicable to PENDAs PENDA-Os designed for operation at ambient

temperatures of between 40 °C and –25 °C

The test shall be carried o

...

IEC 61439-5 ®

Edition 3.0 2023-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Low-voltage switchgear and controlgear assemblies –

Part 5: Assemblies for power distribution in public networks

Ensembles d'appareillage à basse tension –

Partie 5: Ensembles pour réseaux de distribution publique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur les adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 300 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 19 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61439-5 ®

Edition 3.0 2023-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Low-voltage switchgear and controlgear assemblies –

Part 5: Assemblies for power distribution in public networks

Ensembles d'appareillage à basse tension –

Partie 5: Ensembles pour réseaux de distribution publique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.130.20 ISBN 978-2-8322-6939-8

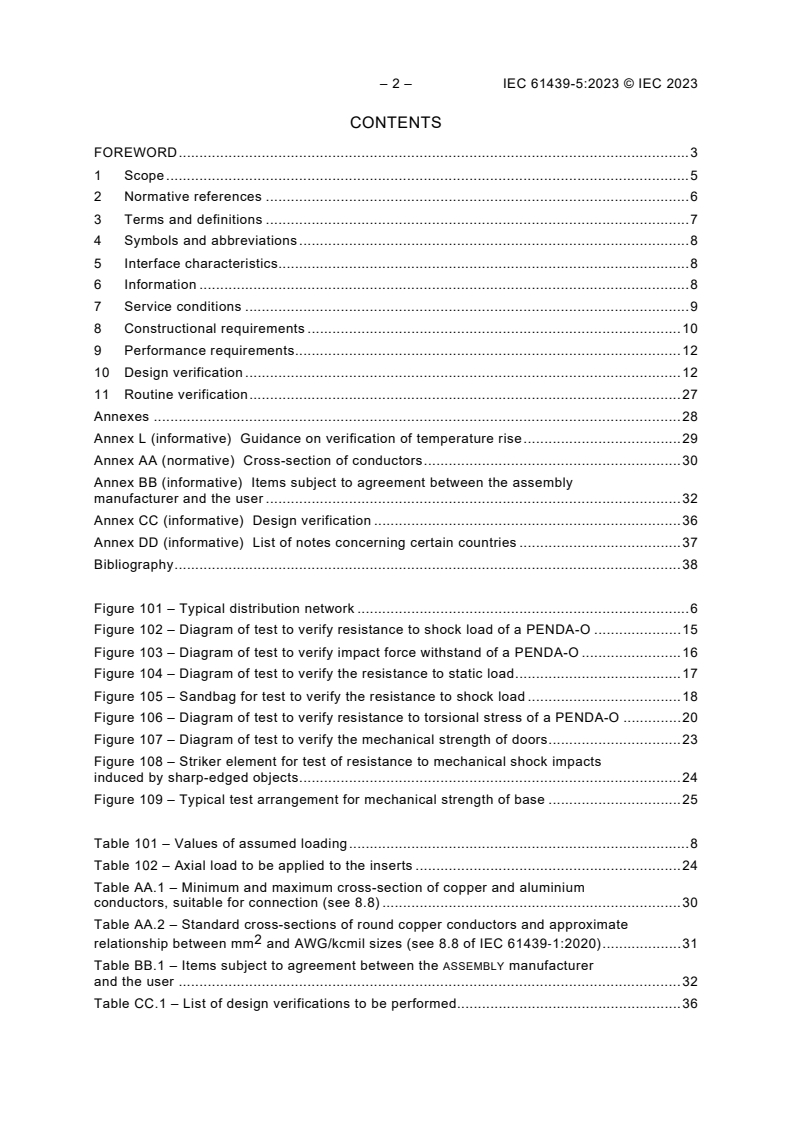

– 2 – IEC 61439-5:2023 © IEC 2023

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 6

3 Terms and definitions . 7

4 Symbols and abbreviations . 8

5 Interface characteristics. 8

6 Information . 8

7 Service conditions . 9

8 Constructional requirements . 10

9 Performance requirements. 12

10 Design verification . 12

11 Routine verification . 27

Annexes . 28

Annex L (informative) Guidance on verification of temperature rise . 29

Annex AA (normative) Cross-section of conductors . 30

Annex BB (informative) Items subject to agreement between the assembly

manufacturer and the user . 32

Annex CC (informative) Design verification . 36

Annex DD (informative) List of notes concerning certain countries . 37

Bibliography . 38

Figure 101 – Typical distribution network . 6

Figure 102 – Diagram of test to verify resistance to shock load of a PENDA-O . 15

Figure 103 – Diagram of test to verify impact force withstand of a PENDA-O . 16

Figure 104 – Diagram of test to verify the resistance to static load . 17

Figure 105 – Sandbag for test to verify the resistance to shock load . 18

Figure 106 – Diagram of test to verify resistance to torsional stress of a PENDA-O . 20

Figure 107 – Diagram of test to verify the mechanical strength of doors . 23

Figure 108 – Striker element for test of resistance to mechanical shock impacts

induced by sharp-edged objects . 24

Figure 109 – Typical test arrangement for mechanical strength of base . 25

Table 101 – Values of assumed loading . 8

Table 102 – Axial load to be applied to the inserts . 24

Table AA.1 – Minimum and maximum cross-section of copper and aluminium

conductors, suitable for connection (see 8.8) . 30

Table AA.2 – Standard cross-sections of round copper conductors and approximate

relationship between mm and AWG/kcmil sizes (see 8.8 of IEC 61439‑1:2020) . 31

Table BB.1 – Items subject to agreement between the ASSEMBLY manufacturer

and the user . 32

Table CC.1 – List of design verifications to be performed. 36

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LOW-VOLTAGE SWITCHGEAR AND CONTROLGEAR ASSEMBLIES –

Part 5: Assemblies for power distribution in public networks

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61439-5 has been prepared by subcommittee 121B: Low-voltage switchgear and

controlgear assemblies, of IEC technical committee 121: Switchgear and controlgear and their

assemblies for low voltage. It is an International Standard.

This third edition cancels and replaces the second edition published in 2014. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) omission of the requirement to conduct mechanical tests at -25 °C when enclosures are

made of a metallic material;

b) addition of assumed loading factors generation supplies and electric vehicle charging

applications;

c) additional dielectric tests when a PENDA is used in a distribution substation with separate

HV and LV earths;

d) further clarification of representative samples for design verification.

– 4 – IEC 61439-5:2023 © IEC 2023

The text of this International Standard is based on the following documents:

Draft Report on voting

121B/173/FDIS 121B/178/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

This document is to be read in conjunction with IEC 61439-1. The provisions of the general

rules dealt with in IEC 61439-1 are only applicable to this document insofar as they are

specifically cited. When this document states "addition", "modification" or "replacement", the

relevant text in IEC 61439-1:2020 is to be adapted accordingly. Subclauses that are numbered

with a 101 (102, 103 etc.) suffix are additional to the same subclause in IEC 61439‑1:2020.

Tables and figures in IEC 61439-5:2023 that are new are numbered starting with 101.

New annexes in IEC 61439-5:2023 are lettered AA, BB, etc.

The reader’s attention is drawn to the fact that Annex DD lists all of the "in-some-country"

clauses on differing practices of a less permanent nature relating to the subject of this

document.

A list of all parts of the IEC 61439 series, under the general title Low-voltage switchgear and

controlgear assemblies can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

LOW-VOLTAGE SWITCHGEAR AND CONTROLGEAR ASSEMBLIES –

Part 5: Assemblies for power distribution in public networks

1 Scope

This document defines the specific requirements for public electricity network distribution

assemblies (PENDAs).

PENDAs have the following criteria:

– used for the distribution of electrical energy in three phase systems for which the rated

voltage does not exceed 1 000 V AC (see Figure 101 for a typical distribution network) and

DC systems not exceeding 1 500 V DC;

– stationary;

– open type assemblies are not covered by this document;

– suitable for installation in places where only skilled persons have access for their use,

however, outdoor types can be installed in situations that are accessible to ordinary persons

• intended for use in energy distribution in public power grids;

• indoor use: assemblies for installation inside of electric power substations;

• outdoor use: assemblies containing an enclosure suitable for open air installation.

The object of this document is to state the definitions and to specify the service conditions,

construction requirements, technical characteristics and tests for PENDAs. Tests at higher

performance level can be applicable with some network parameters.

PENDAs can also include control and or signalling devices associated with the distribution of

electrical energy.

NOTE 1 Control and monitoring devices can be used in smart grid applications or the transmission of smart grid

data.

This document applies to all PENDAs whether they are designed, manufactured on a one-off

basis or fully standardised and manufactured in quantity.

The manufacture and/or assembly can be carried out other than by the original manufacturer

(see 3.10.1 of IEC 61439-1:2020).

This document does not apply to individual devices and self-contained components, such as

motor starters, fuse switches, electronic equipment, etc. which comply with the relevant product

standards.

If the substation is owned or operated by a public distribution system operator (DSO), PENDA’s

which are used as LV distribution panels in transformer substations are within the scope of this

document,

This document does not apply to specific types of assemblies covered by other parts of

IEC 61439 series.

– 6 – IEC 61439-5:2023 © IEC 2023

Figure 101 – Typical distribution network

NOTE 2 If a PENDA is equipped with additional equipment (for example meters), in such a way that the main

function is changed considerably, then other standards can also apply as agreed between user and manufacturer

(see 8.5 of IEC 61439-1:2020).

NOTE 3 Where local regulations and practices permit, a PENDA according to this document can be used in other

than public networks.

NOTE 4 DSO’s can define additional requirements for their PENDA’s.

2 Normative references

This clause of IEC 61439-1:2020 applies except as follows.

Addition:

IEC 60695-11-10:2013, Fire hazard testing – Part 11-10: Test flames – 50 W horizontal and

vertical flame test methods

IEC 61439-1:2020, Low-voltage switchgear and controlgear assemblies – Part 1: General rules

IEC 62262, Degrees of protection provided by enclosures for electrical equipment against

external mechanical impacts (IK code)

ISO 9223:2012, Corrosion of metals and alloys – Corrosivity of atmospheres – Classification,

determination and estimation

ISO 6506-1:2014, Metallic materials – Brinell hardness test – Part 1: Test method

3 Terms and definitions

This clause of IEC 61439-1:2020 applies except as follows.

3.1 General terms

Additional terms:

3.1.101

public electricity network distribution assembly

PENDA

assembly, generally for installation in a public electricity network which in use, receives

electrical energy from one or more supplies and distributes that energy through one or more

cables to other equipment

Note 1 to entry: A PENDA is installed, operated and maintained solely by skilled persons.

Note 2 to entry: Some types of a PENDA were previously known as a cable distribution cabinet (CDC).

3.1.101.1

outdoor public electricity network distribution assembly

PENDA-O

cubicle type public electricity network distribution assembly that is suitable for outdoor

installation in places that can, or cannot, be accessible to the public

3.1.101.2

indoor public electricity network distribution assembly

PENDA-I

public electricity network distribution assembly suitable for installation indoors, generally

without an enclosure, but including all structural parts necessary to support busbars, functional

units and other ancillary devices, necessary to complete the assembly

3.1.102

design life

minimum duration for which specified performance characteristics of equipment are expected

when the equipment is operated as intended and regularly maintained by instructed persons in

accordance with the manufacturer’s instructions

[SOURCE: IEC 60050-395:2014, 395-07-93, modified – Note to entry omitted and 'granted'

replaced by 'expected when . instructions'.]

3.3 External design of assemblies

3.3.1

open-type assembly

This term of IEC 61439-1:2020 does not apply.

3.9 Verification

Modifications:

3.9.1

design verification

Delete the note.

3.9.1.2

verification comparison

This term of IEC 61439-1:2020 does not apply.

– 8 – IEC 61439-5:2023 © IEC 2023

3.9.1.3

verification assessment

This term of IEC 61439-1:2020 does not apply.

4 Symbols and abbreviations

This clause of IEC 61439-1:2020 applies.

5 Interface characteristics

This clause of IEC 61439-1:2020 applies, except as follows.

5.4 Rated diversity factor (RDF)

Addition:

In the absence of an agreement between the assembly manufacturer and user concerning the

actual load currents, the assumed loading of the outgoing circuits of the assembly or group of

outgoing circuits can be based on the values given in Table 101.

For distribution and final circuits, it is assumed that the load current is the rated current of the

protective device, I , as required by the user, multiplied with the loading factor of Table 101.

n

Table 101 – Values of assumed loading

Application Assumed

loading

factor

Regular distribution grid connections 0,9

2 to 3 circuits

Regular distribution grid connections 0,8

4 to 5 circuits

Regular distribution grid connections 0,7

6 to 9 circuits

Regular distribution grid connections 0,6

≥ 10 circuits

Generation supply (e,g. PV, wind farm, biomass) 1,0

Charging infrastructure for EV 1,0

6 Information

This clause of IEC 61439-1:2020 applies except as follows.

6.1 Assembly designation marking

Addition to first paragraph:

Designation plates can be placed inside an enclosure of an assembly provided their intended

place ensures good legibility and visibility when the door(s) is(are) open or the cover is

removed.

Replacement of item g):

g) IEC 61439-5.

6.3 Device and/or component identification

Additional paragraph:

In the case of removable fuse-carriers which are specific to a fuseway, a label shall be placed

on the fuse carrier as well as on the fuse base, to avoid incorrect interchangeability of the

fuse-carrier.

Additional subclause:

6.101 Circuit identification

It shall be possible to identify each functional unit in a clearly visible manner.

7 Service conditions

This clause of IEC 61439-1:2020 applies except as follows.

7.1 Normal service conditions

7.1.1 Climatic conditions

Addition to the first paragraph:

Unless the user specifies that a PENDA shall be suitable for use in an arctic climate, the lower

limit of ambient air temperature is –25 °C as specified in Table 15 of IEC 61439-1:2020. For an

arctic climate the lower limit of ambient temperature is –50 °C.

7.1.2 Pollution degree

Replace the first paragraph with the following:

The pollution degree referred to in Annex BB is the macro-environmental condition for which

the assembly is intended.

7.2 Special service conditions

Additional paragraph:

Additional requirements for a PENDA-O, to be installed where heavy snowfalls occur and where

they are adjacent to areas where there is snow clearance by ploughing, are subject to