prEN IEC 60865-1:2025

(Main)Short-circuit currents - Calculation of effects - Part 1: Definitions and calculation methods

Short-circuit currents - Calculation of effects - Part 1: Definitions and calculation methods

Kurzschlussströme - Berechnung der Wirkung - Teil 1: Begriffe und Berechnungsverfahren

Courants de court-circuit - Calcul des effects - Partie 1: Définitions et méthodes de calcul

Kratkostični toki - Izračun učinkov - 1. del: Definicije in računski postopki

General Information

- Status

- Not Published

- Publication Date

- 18-Jul-2027

- Technical Committee

- CLC/SR 73 - Short-circuit currents

- Current Stage

- 4020 - Enquiry circulated - Enquiry

- Start Date

- 19-Dec-2025

- Due Date

- 30-Jun-2025

- Completion Date

- 19-Dec-2025

Relations

- Effective Date

- 23-Apr-2024

Overview

prEN IEC 60865-1:2025 - Short-circuit currents - Calculation of effects - Part 1: Definitions and calculation methods - is an essential international standard for the electrical power industry. Developed by the International Electrotechnical Commission (IEC) through CENELEC, this document provides unified definitions and calculation methods for assessing the mechanical and thermal effects of short-circuit currents. It is a key reference for electrical engineers and designers involved with power transmission and distribution systems, focusing on the impact of short-circuits on different types of electrical conductors and related infrastructure.

Key Topics

This standard comprehensively addresses the following core areas:

- Definitions and Symbols: Clear and precise terminology, symbols, and units to ensure consistent communication across the industry.

- Calculation Methods: Procedures for determining the effects of short-circuit currents on rigid and flexible conductors, including stress, force, and thermal impacts.

- Electromagnetic and Thermal Effects: Analysis of electromagnetic forces during single-phase and three-phase short-circuits, as well as the rise in temperature due to high current flow.

- Conductor Arrangements:

- Rigid and flexible conductor systems

- Effects on both horizontal and vertical (dropper) conductors

- Special consideration for bundled and sub-conductors

- Mechanical Loads: Calculations for structural loads imposed on power line supports and connectors during electrical faults.

- Thermal Calculations: Methods to evaluate the temperature rise and short-time current withstand capacity of conductors during a fault event.

- Annex with Equations: Normative annex provides necessary equations for calculation diagrams and practical application.

Applications

The practical value of prEN IEC 60865-1:2025 is evident in several critical areas of the electrical power sector:

- Power Transmission and Distribution:

- Ensures the mechanical stability of overhead lines and busbar systems under fault conditions.

- Assists in the selection and dimensioning of conductors, supports, and insulators.

- Guides structural engineers in evaluating the dynamic loads imposed by short-circuit events.

- Design and Engineering of Switchgear and Substations:

- Supports safe design and installation by predicting forces under fault conditions.

- Helps maintain minimum clearance and insulation requirements to ensure operational safety.

- Network Reliability and Safety:

- Reduces the risk of equipment failure, electrical fires, and outages by enabling effective short-circuit management.

- Ensures compliance with international industry benchmarks and facilitates certification.

- Asset Management and Maintenance Planning:

- Assists asset managers in evaluating the need for upgrades or reinforcements based on short-circuit risk assessments.

Related Standards

For comprehensive short-circuit current analysis and design, this document should be used alongside other key international standards, including:

- IEC 60909: Calculation of short-circuit currents in three-phase a.c. systems (basis for magnitude determination).

- IEC 60949: Calculation of thermally permissible short-circuit currents for cables (applies to specific conductor types).

- IEC 60986: Requirements for the calculation of the current-carrying capability in flexible conductors.

- IEC 61660-2: Electromagnetic and thermal effect calculations for DC auxiliary installations.

Conclusion

prEN IEC 60865-1:2025 is the reference standard for calculating the mechanical and thermal effects of short-circuit currents in a.c. electrical systems. By providing internationally harmonized definitions and calculation methods, it helps ensure the integrity, safety, and reliability of power transmission and distribution infrastructure worldwide. Electrical design professionals, engineers, and asset managers will find this standard critical in delivering compliant and robust electrical networks.

Keywords: Short-circuit currents, calculation methods, mechanical effects, thermal effects, rigid conductors, flexible conductors, power transmission, distribution lines, IEC 60865, electrical safety, conductor stress, electromagnetic forces, conductor temperature, electrical standards.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

prEN IEC 60865-1:2025 is a draft published by CLC. Its full title is "Short-circuit currents - Calculation of effects - Part 1: Definitions and calculation methods". This standard covers: Short-circuit currents - Calculation of effects - Part 1: Definitions and calculation methods

Short-circuit currents - Calculation of effects - Part 1: Definitions and calculation methods

prEN IEC 60865-1:2025 is classified under the following ICS (International Classification for Standards) categories: 17.220.01 - Electricity. Magnetism. General aspects; 29.240.20 - Power transmission and distribution lines. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN IEC 60865-1:2025 has the following relationships with other standards: It is inter standard links to EN 60865-1:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN IEC 60865-1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2026

Kratkostični toki - Izračun učinkov - 1. del: Definicije in računski postopki

Short-circuit currents - Calculation of effects - Part 1: Definitions and calculation methods

Kurzschlussströme - Berechnung der Wirkung - Teil 1: Begriffe und

Berechnungsverfahren

Courants de court-circuit - Calcul des effects - Partie 1: Définitions et méthodes de calcul

Ta slovenski standard je istoveten z: prEN IEC 60865-1:2025

ICS:

17.220.01 Elektrika. Magnetizem. Electricity. Magnetism.

Splošni vidiki General aspects

29.240.20 Daljnovodi Power transmission and

distribution lines

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

73/239/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 60865-1 ED4

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2025-12-26 2026-03-20

SUPERSEDES DOCUMENTS:

73/214/RR

IEC TC 73 : SHORT-CIRCUIT CURRENTS

SECRETARIAT: SECRETARY:

Norway Mr Lars Jakob Paulsen

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

TC 8,SC 8A,TC 18,TC 88,TC 99

ASPECTS CONCERNED:

Electricity transmission and distribution,Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft

for Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of

which they are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some

Countries” clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is

the final stage for submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Short-circuit currents - Calculation of effects - Part 1: Definitions and calculation methods

PROPOSED STABILITY DATE: 2029

NOTE FROM TC/SC OFFICERS:

Editorial changes from previous version and one other change: The term Dropper has been added to

Clause 3.8 based of feedback from MT1 and thus changed the numbering of the subsequent terms.

electronic file, to make a copy and to print out the content for the sole purpose of preparing National Committee positions.

You may not copy or "mirror" the file or printed version of the document, or any part of it, for any other purpose without

permission in writing from IEC.

IEC 60865-1 IEC:2026

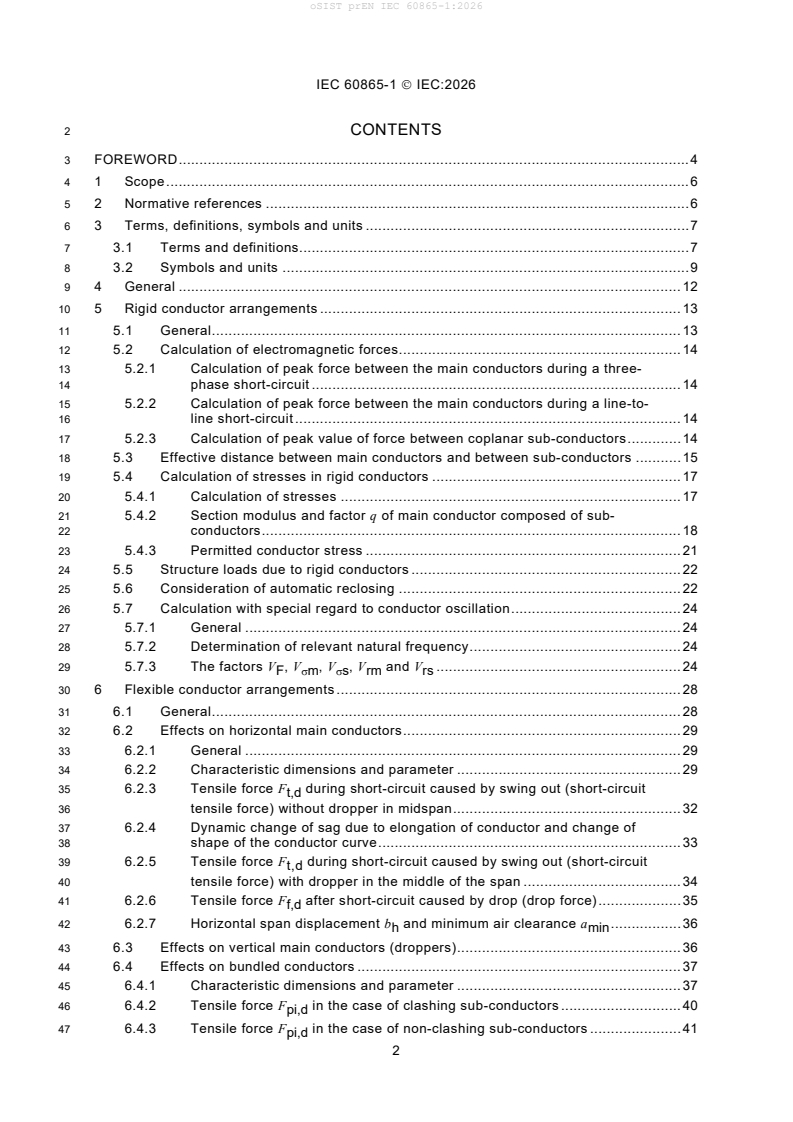

2 CONTENTS

3 FOREWORD . 4

4 1 Scope . 6

5 2 Normative references . 6

6 3 Terms, definitions, symbols and units . 7

7 3.1 Terms and definitions. 7

8 3.2 Symbols and units . 9

9 4 General . 12

10 5 Rigid conductor arrangements . 13

11 5.1 General . 13

12 5.2 Calculation of electromagnetic forces . 14

13 5.2.1 Calculation of peak force between the main conductors during a three-

14 phase short-circuit . 14

15 5.2.2 Calculation of peak force between the main conductors during a line-to-

16 line short-circuit . 14

17 5.2.3 Calculation of peak value of force between coplanar sub-conductors . 14

18 5.3 Effective distance between main conductors and between sub-conductors . 15

19 5.4 Calculation of stresses in rigid conductors . 17

20 5.4.1 Calculation of stresses . 17

21 5.4.2 Section modulus and factor q of main conductor composed of sub-

22 conductors . 18

23 5.4.3 Permitted conductor stress . 21

24 5.5 Structure loads due to rigid conductors . 22

25 5.6 Consideration of automatic reclosing . 22

26 5.7 Calculation with special regard to conductor oscillation . 24

27 5.7.1 General . 24

28 5.7.2 Determination of relevant natural frequency . 24

29 5.7.3 The factors V , V , V , V and V . 24

F σm σs rm rs

30 6 Flexible conductor arrangements . 28

31 6.1 General . 28

32 6.2 Effects on horizontal main conductors . 29

33 6.2.1 General . 29

34 6.2.2 Characteristic dimensions and parameter . 29

35 6.2.3 Tensile force F during short-circuit caused by swing out (short-circuit

t,d

36 tensile force) without dropper in midspan . 32

37 6.2.4 Dynamic change of sag due to elongation of conductor and change of

38 shape of the conductor curve . 33

39 6.2.5 Tensile force F during short-circuit caused by swing out (short-circuit

t,d

40 tensile force) with dropper in the middle of the span . 34

41 6.2.6 Tensile force F after short-circuit caused by drop (drop force) . 35

f,d

42 6.2.7 Horizontal span displacement b and minimum air clearance a . 36

h min

43 6.3 Effects on vertical main conductors (droppers) . 36

44 6.4 Effects on bundled conductors . 37

45 6.4.1 Characteristic dimensions and parameter . 37

46 6.4.2 Tensile force F in the case of clashing sub-conductors . 40

pi,d

47 6.4.3 Tensile force F in the case of non-clashing sub-conductors . 41

pi,d

IEC 60865-1 IEC:2026

48 6.5 Structure loads due to flexible conductors . 43

49 6.5.1 Design load for post insulators, their supports and connectors. 43

50 6.5.2 Design load for structures, insulators and connectors with tensile forces

51 transmitted by insulator chains . 43

52 6.5.3 Design load for foundations . 44

53 7 The thermal effect on bare conductors . 44

54 7.1 General . 44

55 7.2 Calculation of thermal equivalent short-circuit current . 44

56 7.3 Calculation of temperature rise and rated short-time withstand current

57 density for conductors . 45

58 7.4 Calculation of thermal short-time strength for different durations of the short-

59 circuit . 47

60 Annex A (normative) Equations for calculation of diagrams . 48

61 Bibliography . 54

63 Figure 1 – Factor k

for calculating the effective conductor distance . 16

1s

64 Figure 2 – Loading direction and bending axis for multiple conductor arrangements . 19

65 Figure 3 – Factor e for the influence of connecting pieces in Equation (17) . 26

66 Figure 4 – Factors V , V and V to be used with the three-phase and line-to-line

F σm σs

67 short-circuits . 27

68 Figure 5 – Factors V and V to be used with three-phase automatic reclosing . 28

rm rs

69 Figure 6 – Maximum swing out angle δ for a given maximum short-circuit duration T . 32

max k1

70 Figure 7 – Factor ψ for tensile force in flexible conductors . 33

71 Figure 8 – Geometry of a dropper . 35

72 Figure 9 – ν as a function of ν . 39

2 1

180°

73 Figure 10 – ν ·sin as a function of a /d . 39

3 s

n

74 Figure 11 – ξ as a function of j and ε . 40

st

75 Figure 12 – η as a function of j and ε . 43

st

76 Figure 13 – Relation between rated short-circuit withstand current density (T = 1 s)

kr

77 and conductor temperature . 46

79 Table 1 – Effective distance a between sub-conductors for rectangular cross-section

s

80 dimensions . 17

81 Table 2 – Maximum possible values of V V , V V , V V . 20

σm rm σs rs F rm

82 Table 3 – Factors α, β, γ for different busbar support arrangements . 21

83 Table 4 – Factor q . 23

84 Table 5 – Section moduli W of main conductors with two or more stiffening elements

m

85 between two adjacent supports. The stiffening elements are black. . 23

86 Table 6 – Recommended highest temperatures for mechanically stressed conductors

87 during a short-circuit . 45

IEC 60865-1 IEC:2026

90 INTERNATIONAL ELECTROTECHNICAL COMMISSION

91 ____________

93 SHORT-CIRCUIT CURRENTS –

94 CALCULATION OF EFFECTS –

96 Part 1: Definitions and calculation methods

98 FOREWORD

99 1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization

100 comprising all national electrotechnical committees (IEC National Committees). The object of IEC is to

101 promote international co-operation on all questions concerning standardization in the electrical and

102 electronic fields. To this end and in addition to other activities, IEC publishes International Standards,

103 Technical Specifications, Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter

104 referred to as “IEC Publication(s)”). Their preparation is entrusted to technical committees; any IEC National

105 Committee interested in the subject dealt with may participate in this preparatory work. International,

106 governmental and non-governmental organizations liaising with the IEC also participate in this preparation.

107 IEC collaborates closely with the International Organization for Standardization (ISO) in accordance with

108 conditions determined by agreement between the two organizations.

109 2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an

110 international consensus of opinion on the relevant subjects since each technical committee has

111 representation from all interested IEC National Committees.

112 3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

113 Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

114 Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

115 misinterpretation by any end user.

116 4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

117 transparently to the maximum extent possible in their national and regional publications. Any divergence

118 between any IEC Publication and the corresponding national or regional publication shall be clearly

119 indicated in the latter.

120 5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

121 assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

122 services carried out by independent certification bodies.

123 6) All users should ensure that they have the latest edition of this publication.

124 7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts

125 and members of its technical committees and IEC National Committees for any personal injury, property

126 damage or other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal

127 fees) and expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other

128 IEC Publications.

129 8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications

130 is indispensable for the correct application of this publication.

131 9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

132 patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent

133 rights in respect thereof. As of the date of publication of this document, IEC had not received notice of (a)

134 patent(s), which may be required to implement this document. However, implementers are cautioned that

135 this may not represent the latest information, which may be obtained from the patent database available at

136 https://patents.iec.ch. IEC shall not be held responsible for identifying any or all such patent rights.

137 International Standard IEC 60865-1 has been prepared by IEC technical committee 73: Short-circuit

138 currents.

139 IEC 60865-1 has been prepared by MT1: CALCULATION OF SHORT-CIRCUIT CURRENTS,

140 of IEC technical committee 73: SHORT-CIRCUIT CURRENTS. It is an International Standard.

141 This fourth edition cancels and replaces the third edition published in 2011. This edition

142 constitutes an editorial revision.

IEC 60865-1 IEC:2026

143 This edition includes no significant technical changes with respect to the previous edition:

144 a) references to figures and clauses have been corrected a few places,

145 b) other minor editorial corrections to equations and variables,

146 c) the term dropper has been added as a new definition.

147 The text of this standard is based on the following documents:

CDV Report on voting

73/152/CDV 73/153/RVC

149 Full information on the voting for the approval of this standard can be found in the report on

150 voting indicated in the above table.

151 This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

152 A list of all parts of the IEC 60865 series, under the general title, Short-circuit currents –

153 Calculation of effects can be found on the IEC website.

154 The committee has decided that the contents of this publication will remain unchanged until the

155 stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data related to

156 the specific publication. At this date, the publication will be

157 • reconfirmed,

158 • withdrawn,

159 • replaced by a revised edition, or

160 • amended.

IEC 60865-1 IEC:2026

163 SHORT-CIRCUIT CURRENTS –

164 CALCULATION OF EFFECTS –

166 Part 1: Definitions and calculation methods

170 1 Scope

171 This part of IEC 60865 is applicable to the mechanical and thermal effects of short-circuit

172 currents. It contains procedures for the calculation of

173 – the electromagnetic effect on rigid conductors and flexible conductors,

174 – the thermal effect on bare conductors.

175 For cables and insulated conductors, reference is made, for example, to IEC 60949 and

176 IEC 60986. For the electromagnetic and thermal effects in d.c. auxiliary installations of power

177 plants and substations reference is made to IEC 61660-2.

178 Only a.c. systems are dealt with in this standard.

179 The following points should, in particular, be noted:

180 a) The calculation of short-circuit currents should be based on IEC 60909. For the

181 determination of the greatest possible short-circuit current, additional information from other

182 IEC standards may be referred to, e.g. details about the underlying circuitry of the

183 calculation or details about current-limiting devices, if this leads to a reduction of the

184 mechanical stress.

185 b) Short-circuit duration used in this standard depends on the protection concept and should

186 be considered in that sense.

187 c) These standardized procedures are adjusted to practical requirements and contain

188 simplifications which are conservative. Testing or more detailed methods of calculation or

189 both may be used.

190 d) In Clause 5 of this standard, for arrangements with rigid conductors, only the stresses

191 caused by short-circuit currents are calculated. Furthermore, other stresses can exist, e.g.

192 caused by dead-load, wind, ice, operating forces or earthquakes. The combination of these

193 loads with the short-circuit loading should be part of an agreement and/or be given by

194 standards, e.g. erection-codes.

195 The tensile forces in arrangements with flexible conductors include the effects of dead-load.

196 With respect to the combination of other loads the considerations given above are valid.

197 e) The calculated loads are design loads and should be used as exceptional loads without any

198 additional partial safety factor according to installation codes of, for example, IEC 61936-1

199 [1] .

201 2 Normative references

202 The following referenced documents are indispensable for the application of this document. For

203 dated references, only the edition cited applies. For undated references, the latest edition of

204 the referenced document (including any amendments) applies.

—————————

Figures in square brackets refer to the bibliography.

IEC 60865-1 IEC:2026

205 IEC 60909 (all parts) Short-circuit current calculation in three-phase a.c. systems

206 IEC 60949, Calculation of thermally permissible short-circuit currents, taking into account non-

207 adiabatic heating effects

208 IEC 60986, Short-circuit temperature limits of electric cables with rated voltages from 6 kV

209 (U = 7,2 kV) up to 30 kV (U = 36 kV)

m m

210 IEC 61660-2, Short-circuit currents in d.c. auxiliary installations in power plants and substations

211 – Part 2: Calculation of effects

212 3 Terms, definitions, symbols and units

213 3.1 Terms and definitions

214 For the purposes of this document, the following terms and definitions apply.

215 ISO and IEC maintain terminology databases for use in standardization at the following

216 addresses:

217 • ISO Online browsing platform: available at https://www.iso.org/obp

218 • IEC Electropedia: available at https://www.electropedia.org/

219 3.1.1

220 main conductor

221 conductor or arrangement composed of a number of conductors which carries the total current

222 in one phase

223 3.1.2

224 sub-conductor

225 single conductor which carries a certain part of the total current in one phase and is a part of

226 the main conductor

227 3.1.3

228 fixed support

229 support of a rigid conductor in which moments are imposed in the regarded plane

230 3.1.4

231 simple support

232 support of a rigid conductor in which no moments are imposed in the regarded plane

233 3.1.5

234 connecting piece

235 any additional mass within a span which does not belong to the uniform conductor material,

236 including among others, spacers, stiffening elements, bar overlappings, branchings, etc.

237 3.1.6

238 spacer

239 mechanical element between sub-conductors, rigid or flexible, which, at the point of installation,

240 maintains the clearance between sub-conductors

241 3.1.7

242 stiffening element

243 special spacer intended to reduce the mechanical stress of rigid conductors

IEC 60865-1 IEC:2026

244 3.1.8

245 dropper

246 conductor which is orientated vertically and connected to a horizontal spanned conductor and

247 a lower attachment point, e.g. the connection between overhead busbar and underneath

248 disconnector

249 3.1.9

250 relevant natural frequency

251 f

cm

252 first natural frequency of the free vibration of a single span beam without damping and natural

253 frequency of order ν of beams with ν spans without damping

254 3.1.10

255 short-circuit tensile force

256 F

t,d

257 maximum tensile force (design value) in a flexible main conductor due to swing out reached

258 during the short-circuit

259 3.1.11

260 drop force

261 F

f,d

262 maximum tensile force (design value) in a flexible main conductor which occurs when the span

263 drops down after swing out

264 3.1.12

265 pinch force

266 F

pi,d

267 maximum tensile force (design value) in a bundled flexible conductor during the short-circuit

268 due to the attraction of the sub-conductors in the bundle

269 3.1.13

270 duration of the first short-circuit current flow

271 T

k1

272 time interval between the initiation of the short-circuit and the first breaking of the current

273 3.1.14

274 thermal equivalent short-circuit current

275 I

th

276 r.m.s. value of current having the same thermal effect and the same duration as the actual

277 short-circuit current, which can contain d.c. component and can subside in time

278 3.1.15

279 thermal equivalent short-circuit current density

280 S

th

281 ratio of the thermal equivalent short-circuit current and the cross-section area of the conductor

282 3.1.16

283 rated short-time withstand current density, S , for conductors

thr

284 r.m.s. value of the current density which a conductor is able to withstand for the rated short

285 time

IEC 60865-1 IEC:2026

286 3.1.17

287 duration of short-circuit current

288 T

k

289 sum of the time durations of the short-circuit current flow from the initiation of the first short-

290 circuit to the final breaking of the current in all phases

291 3.1.18

292 rated short-time

293 T

kr

294 time duration for which a conductor can withstand a current density equal to its rated short-time

295 withstand current density

296 3.2 Symbols and units

297 All equations used in this standard are quantity equations in which quantity symbols represent

298 physical quantities possessing both numerical values and dimensions.

299 The symbols used in this standard and the SI-units concerned are given in the following lists.

A Cross-section of one main-conductor

m

A Cross-section of one sub-conductor

m

s

a Centre-line distance between conductors m

a Effective distance between main conductors m

m

a Minimum air clearance m

min

a Effective distance between sub-conductors m

s

a Centre-line distance between sub-conductor 1 and m

1n

sub-conductor n

a Centre-line distance between sub-conductors 1 and m

1s

sub-conductor s

b Maximum horizontal displacement m

h

b Dimension of a main conductor perpendicular to the direction of m

m

the force

b Dimension of a sub-conductor perpendicular to the direction m

s

of the force

C Dilatation factor 1

D

C Form factor 1

F

c Dimension of a main conductor in the direction of the force m

m

c Dimension of a sub-conductor in the direction of the force m

s

4 2

c Material constant

m /(A s)

th

d Outer diameter of a tubular or flexible conductor m

E Young's modulus

N/m

E Actual Young's modulus

N/m

eff

e Factor for the influence of connecting pieces 1

F Force acting between two parallel long conductors during a short- N

circuit

IEC 60865-1 IEC:2026

Characteristic electromagnetic force per unit length on flexible N/m

F′

main conductors

F Force between main conductors during a short-circuit N

m

F Force between main conductors during a line-to-line short-circuit N

m2

F Force on the central main conductor during a balanced three- N

m3

phase short-circuit

F Force on support of rigid conductors (peak value, design value) N

r,d

F Drop force of one main conductor (design value) N

f,d

F Pinch force of one main conductor (design value) N

pi,d

F Force between sub-conductors during a short-circuit N

s

F Static tensile force of one flexible main conductor N

st

F Short-circuit tensile force of one main conductor (design value) N

t,d

F Short-circuit current force between the sub-conductors in a bundle N

ν

f System frequency Hz

f Relevant natural frequency of a main conductor Hz

cm

f Relevant natural frequency of a sub-conductor Hz

cs

f Dynamic conductor sag at midspan m

ed

f Equivalent static conductor sag at midspan m

es

f Static conductor sag at midspan m

st

f Stress corresponding to the yield point

N/m

y

g Conventional value of acceleration of gravity

m/s

h Height of the dropper m

′′ Initial symmetrical three-phase short-circuit current (r.m.s.) A

I

k

Initial line-to-earth short-circuit current (r.m.s.) A

I′′

k1

Initial symmetrical line-to-line short-circuit current (r.m.s.) A

I′′

k2

I Thermal equivalent short-circuit current A

th

i Peak short-circuit current in case of a three-phase short-circuit A

p

i Peak short-circuit current in case of a line-to-line short-circuit A

p2

i , i Instantaneous values of the currents in the conductors A

1 2

J Second moment of main conductor area

m

m

J Second moment of sub-conductor area

m

s

j Parameter determining the bundle configuration during short- 1

circuit current flow

k Number of sets of spacers or stiffening elements 1

k Factor for the effective distance between sub-conductor 1 and 1

1n

sub-conductor n

IEC 60865-1 IEC:2026

k Factor for effective conductor distance between sub-conductor 1 1

1s

and sub-conductor s

l Centre-line distance between supports m

l Cord length of a flexible main conductor in the span m

c

l Length of one insulator chain m

i

l Centre-line distance between connecting pieces or between one m

s

connecting piece and the adjacent support

l Cord length of a dropper m

v

m′ Mass per unit length of main conductor kg/m

m

m′ Mass per unit length of one sub-conductor kg/m

s

m Total mass of one set of connecting pieces kg

z

N Stiffness norm of an installation with flexible conductors 1/N

n Number of sub-conductors of a main conductor 1

q Factor of plasticity 1

r The ratio of electromechanic force on a conductor under short- 1

circuit conditions to gravity

S Resultant spring constant of both supports of one span N/m

S Thermal equivalent short-circuit current density

A/mm

th

S Rated short-time withstand current density

A/mm

thr

T Period of conductor oscillation s

T Duration of short-circuit current s

k

T Duration of short-circuit i at repeating short-circuits s

ki

T Rated short-time s

kr

T Duration of the first short-circuit current flow s

k1

T Resulting period of the conductor oscillation during the short- s

res

circuit current flow

t Wall thickness of tubes m

V Ratio of dynamic and static force on supports 1

F

V Ratio of dynamic stress (forces on the supports, contribution of 1

rm

main conductor bending stress) caused by forces between main

conductors with unsuccessful three-phase automatic reclosing and

dynamic stress with successful three-phase automatic reclosing

V Ratio of contribution of dynamic stress caused by forces between 1

rs

sub-conductors with unsuccessful three-phase automatic reclosing

and contribution of dynamic stress with successful three-phase

automatic reclosing

V Ratio of dynamic and static contribution of main conductor stress 1

σm

V Ratio of dynamic and static contribution of sub-conductor stress 1

σs

W Section modulus of main conductor

m

m

W Section modulus of sub-conductor

m

s

IEC 60865-1 IEC:2026

w Width of dropper m

α Factor for force on support 1

β Factor for main conductor stress 1

Factor for relevant natural frequency estimation 1

γ

degrees

δ Actual maximum swing-out angle due to the limitation of the

swing-out movement by the dropper

δ Swing-out angle at the end of the short-circuit current flow degrees

end

Maximum swing-out angle degrees

δ

max

Angular direction of the force degrees

δ

Elastic expansion 1

ε

ela

ε , ε Strain factor of the bundle contraction 1

pi st

Thermal expansion 1

ε

th

Stress factor of the flexible main conductor 1

ζ

Factor for calculating F in the case of non-clashing sub- 1

η

pi,d

conductors

Conductor temperature of the beginning of a short-circuit °C

ϑ

b

ϑ Conductor temperature at the end of a short-circuit °C

e

Factor for the calculation of the peak short-circuit current 1

κ

µ Magnetic constant, permeability of vacuum H/m

ν Number of spans of a continuous beam 1

Factors for calculating F

ν , ν , ν ,

pi,d

e 1 2

ν , ν ,

3 4

Factor for calculating F in the case of clashing sub-conductors 1

ξ

pi,d

Lowest value of cable stress when Young's modulus becomes

σ N/m

fin

constant

σ Bending stress caused by the forces between main conductors

N/m

m,d

(design value)

σ Bending stress caused by the forces between sub-conductors

N/m

s,d

(design value)

σ Total conductor stress (design value)

N/m

tot,d

Quantity for the maximum swing-out angle 1

χ

Factors for the tensile force in a flexible conductor 1

ϕ, ψ

300 4 General

301 With the calculation methods presented in this standard

302 • stresses in rigid conductors,

303 • tensile forces in flexible conductors,

304 • forces on insulators and substructures, which might expose them to bending, tension and/or

305 compression,

IEC 60865-1 IEC:2026

306 • span displacements of flexible conductors and

307 • heating of conductors

308 can be estimated.

309 Electromagnetic forces are induced in conductors by the currents flowing through them. Where

310 such electromagnetic forces interact on parallel conductors, they cause stresses that have to

311 be taken into account at the substations. For this reason:

312 • the forces between parallel conductors are set forth in the following clauses;

313 • the electromagnetic force components set up by conductors with bends and/or cross-overs

314 may normally be disregarded.

315 In the case of metal-clad systems, the change of the electromagnetic forces between the

316 conductors due to magnetic shielding can be taken into account. In addition, however, the

317 forces acting between each conductor and its enclosure and between the enclosures shall be

318 considered.

319 When parallel conductors are long compared to the distance between them, the forces will be

320 evenly distributed along the conductors and are given by Equation (1)

µ

l

321 F = ii (1)

2π a

322 where

323 i and i are the instantaneous values of the currents in the conductors;

1 2

324 l is the centre-line distance between the supports;

325 a is the centre-line distance between the conductors.

326 When the currents in the two conductors have the same direction, the forces are attractive.

327 When the directions of the currents are opposite, the forces are repulsive.

328 5 Rigid conductor arrangements

329 5.1 General

330 Rigid conductors can be supported in different ways, either fixed or simple or in a combination

331 of both. Depending on the type of support and the number of supports, the stresses in the

332 conductors and the forces on the supports will be different for the same short-circuit current.

333 The equations given also include the elasticity of the supports.

334 The stresses in the conductors and the forces on the supports also depend on the ratio between

335 the relevant natural frequency of the mechanical system and the electrical system frequency.

336 For example, in the case of resonance or near to resonance, the stresses and forces in the

337 system can be amplified. If f / f < 0,5 the response of the system decreases and the maximum

cm

338 stresses are in the outer phases.

IEC 60865-1 IEC:2026

339 5.2 Calculation of electromagnetic forces

340 5.2.1 Calculation of peak force between the main conductors during a three-phase

341 short-circuit

342 In a three-phase system with the main conductors arranged with the same centre-line distances

343 on the same plane, the maximum force acts on the central main conductor during a three-phase

344 short-circuit and is given by:

µ 3 l

345 Fi= (2)

m3 p

22π a

m

346 where

347 i is the peak value of the short-circuit current in the case of a balanced three-phase short-

p

348 circuit. For the calculation, see the IEC 60909 series;

349 l is the maximum centre-line distance between adjacent supports;

350 a is the effective distance between main conductors in 5.3.

m

351 NOTE Equation (2) can also be used for calculating the resulting peak force when conductors with circular cross-

352 sections are in the corners of an equilateral triangle and where a is the length of the side of the triangle.

m

353 5.2.2 Calculation of peak force between the main conductors during a line-to-line

354 short-circuit

355 The maximum force acting between the conductors carrying the short-circuit current during a

356 line-to-line short-circuit in a three-phase system or in a two-line single-phase-system is given

357 by:

µ l

358 Fi= (3)

m2 p2

2π a

m

359 where

360 i is the peak short-circuit current in the case of a line-to-line short-circuit;

p2

361 l is the maximum centre-line distance between adjacent supports;

362 a is the effective distance between main conductors in 5.3.

m

363 5.2.3 Calculation of peak value of force between coplanar sub-conductors

364 The maximum force acts on the outer sub-conductors and is between two adjacent connecting

365 pieces given by:

i

µ l

p

0s

366 F = (4)

s

2π na

s

367 where

368 n is the number of sub-conductors;

369 l is the maximum existing centre-line distance between two adjacent connecting pieces;

s

370 a is the effective distance between sub-conductors;

s

371 i is equal to i for a three-phase system or to i for a two-line single-phase system.

p p p2

IEC 60865-1 IEC:2026

373 5.3 Effective distance between main conductors and between sub-conductors

374 The forces between conductors carrying short-circuit currents depend on the geometrical

configuration and the profile of the conductors. For this reason the effective distance a

m

376 between main conductors has been introduced in 5.2.1 and 5.2.2 and the effective distance a

s

377 between sub-conductors in 5.2.3. They shall be taken as follows:

378 Effective distance a between coplanar main conductors with the centre-line distance a:

m

379 • Main conductors consisting of single circular cross-sections:

380 a = a (5)

m

381 • Main conductors consisting of single rectangular cross-sections and main conductors

382 composed of sub-conductors with rectangular cross-sections:

a

383 a = (6)

m

k

384 k shall be taken from Figure 1, with a = a, b = b and c = c .

12 1s s m s m

385 Effective distance a between the n coplanar sub-conductors of a main conductor:

s

386 • Sub-conductors with circular cross-sections:

1 1 1 1 1 1

(7)

= + + +⋯ +⋯ +

𝑎𝑎 𝑎𝑎 𝑎𝑎 𝑎𝑎 𝑎𝑎 𝑎𝑎

s 12 13 14 1s 1n

388 • Sub-conductors with rectangular cross-sections:

389 Some values for a are given in Table 1. For other distances and sub-conductor

s

390 dimensions the equation

1 k k k k k

12 13 14 1s 1n

(8)

= + + +⋯ + +⋯ +

𝑎𝑎 𝑎𝑎 𝑎𝑎 𝑎𝑎 𝑎𝑎 𝑎𝑎

s 12 13 14 1s 1n

393 can be used. The values for k ,.k shall be taken from Figure 1.

12 1n

IEC 60865-1 IEC:2026

IEC 2481/11

395 Figure 1 – Factor k for calculating the effective conductor distance

1s

396 For programming, the Equation is given in Clause A.2.

IEC 60865-1 IEC:2026

399 Table 1 – Effective distance a between sub-conductors

s

a

400 for rectangular cross-section dimensions

b

s

Rectangular cross sections 0,04 0,05 0,06 0,08 0,10 0,12 0,16 0,20

c

s

0,005 0,020 0,024 0,027 0,033 0,040 – – –

0,010 0,028 0,031 0,034 0,041 0,047 0,054 0,067 0,080

0,005 – 0,013 0,015 0,018 0,022 – – –

0,010 0,017 0,019 0,020 0,023 0,027 0,030 0,037 0,043

0,005 – – – – – – – –

0,010 0,014 0,015 0,016 0,018 0,020 0,022 0,026 0,031

0,005 – 0,014 0,015 0,018 0,020 – – –

0,010 0,017 0,018 0,020 0,022 0,025 0,027 0,032 –

a

All dimensions are given in metres.

402 5.4 Calculation of stresses in rigid conductors

403 5.4.1 Calculation of stresses

404 Conductors have to be fixed in a way that axial forces can be disregarded. Under this

405 assumption the forces acting are bending forces and the general equation for the bending stress

406 caused by the forces between main conductors is given by:

Fl

m

407 σβ= VV (9)

m,d σm rm

8W

m

408 where

409 F is either the value F of three-phase systems according to Equation (2) or F of two-

m m3 m2

410 line single-phase systems according to Equation (3);

IEC 60865-1 IEC:2026

411 W is the section modulus of the main conductor and shall be calculated with respect to the

m

412 direction of forces between main conductors.

413 The bending stress caused by the forces between sub-conductors is given by:

Fl

ss

414 σ = VV (10)

s,d σs rs

16W

s

415 where

416 F according to Equation (4) shall be used;

s

417 W is the section modulus of the sub-conductor and shall be calculated with respect to the

s

418 direction of forces between sub-conductors.

419 V , V , V and V are factors which take into account the dynamic phenomena, and β is a

σm σs rm rs

420 factor depending on the type and the number of supports. The maximum possible values of

421 V V and V V shall be taken from Table 2 and the factorβ shall be taken from Table 3.

σm rm σs rs

422 NOTE The factor β describes the reduction of the bending stress at the place of its supports, taking into account

423 the plastic deformation of the conductor (see Table 3).

424 Non-uniform spans in continuous beams may be treated, with sufficient degree of accuracy by

425 assuming the maximum span applied throughout. This means that

426 • the end supports are not subjected to greater stress than the inner ones,

427 • span lengths less than 20 % of the adjacent ones shall be avoided. If that does not prove to

428 be possible, the conductors shall be decoupled using flexible joints at the supports. If there

429 is a flexible joint within a span, the length of this span should be less than 70 % of the

430 lengths of the adjacent spans.

431 If it is not evident whether a beam is supported or fixed, the worst case shall be taken into

432 account.

433 For further consideration, see 5.7

434 5.4.2 Section modulus and factor q of main conductor composed of sub-conductors

435 The bending stress and, consequently, the mechanical withstand of the conductor, depends on

436 the section modulus.

437 If the stress occurs in accordance with Figure 2a, the section modulus W is independent of

m

438 the number of connecting pieces and is equal to the sum of the section moduli W of the sub-

s

439 conductors (W with respect to the axis x-x). The factor q has then the value 1,5 for rectangular

s

440 cross-sections and 1,19 for U and I sections.

441 If the stress occurs in accordance with Figure 2b and in the case there is only one or no

442 stiffening element within a supported distance, the section modulus W is equal to the sum of

m

443 the section moduli W of the sub-conductors (W with respect to the axis y-y). The factor q has

s s

444 then the value 1,5 for rectangular cross-sections and 1,83 for U and I sections.

445 When, within a supported distance, there are two or more stiffening elements, higher values of

446 section moduli may be used:

IEC 60865-1 IEC:2026

447 • for main conductors composed of sub-conductors of rectangular cross-sections with a space

448 between the bars equal to the bar thickness, the section moduli are given in

449 Table 5;

450 • for conductor groups having U and I cross-sections, 50 % of the section moduli with respect

451 to the axis 0-0 should be used.

452 The factor q then has a value of 1,5 for rectangular cross-section and 1,83 for U and I sections.

IEC 24

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...