EN 3873:2010

(Main)Aerospace series - Test methods for metallic materials - Determination of fatigue crack growth rates using Corner-Cracked (CC) test pieces

Aerospace series - Test methods for metallic materials - Determination of fatigue crack growth rates using Corner-Cracked (CC) test pieces

This standard specifies the requirements for determining fatigue crack growth rates using the corner-crack (CC) test piece. Crack development is measured using a potential-drop system, and the calculated crack depths can be corrected via marker bands created on the fracture surface during the test. Results are expressed in terms of the crack-tip stress-intensity range (K), with crack depths and test stress level noted.

Luft- und Raumfahrt - Prüfverfahren für metallische Werkstoffe - Ermittlung der Rissfortschritts- Geschwindigkeit an Cornercrackproben (Eckanris)

Diese Norm legt die Anforderungen für die Bestimmung der Geschwindigkeit des Ermüdungswachstums unter

Verwendung von Eckanriss-Proben (Corner-Crack, CC) fest. Die Rissentwicklung wird mit einem

Potentialabfallsystem gemessen, und die berechneten Risstiefen können über Markierungsbänder, die im

Verlauf der Prüfung an der Bruchfläche erzeugt wurden, korrigiert werden. Die Ergebnisse werden in Form

der Schwingbreite der Rissspitzen-Spannungsintensität (ΔK) dargestellt, wobei die Risstiefen und das

Prüfspannungsniveau aufgezeichnet werden.

Série aérospatiale - Méthodes d'essais applicables aux matériaux métalliques - Détermination de la vitesse de propagation de fissure en fatigue à l'aide d'éprouvettes avec fissure en coin

Aeronavtika - Preskusne metode za kovinske materiale - Ugotavljanje stopnje rasti razpok, ki nastanejo zaradi utrujenosti, z uporabo preskusnih kosov z razpokami na robovih (CC)

Ta standard določa zahteve za ugotavljanje stopnje rasti razpok, ki nastanejo zaradi utrujenosti, z uporabo preskusnega kosa z razpokami na robovih (CC). Razvoj razpok je merjen z uporabo sistema za potencialni padec, izračunana globina razpoke pa je lahko popravljena z označevalnimi pasovi, narejenimi na razpokani površini med preskusom. Rezultati so izraženi v izrazih za razpon intenzivnosti napetosti konice razpoke (K), z globino razpoke in upoštevano stopnjo preskusne napetosti.

General Information

- Status

- Published

- Publication Date

- 02-Nov-2010

- Withdrawal Date

- 30-May-2011

- Technical Committee

- ASD-STAN - Aerospace

- Drafting Committee

- ASD-STAN/D 4 - Metallic

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 03-Nov-2010

- Completion Date

- 03-Nov-2010

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 3873:2010 (CEN)

EN 3873:2010 is a European aerospace series standard published by CEN that specifies test methods for determining fatigue crack growth rates in metallic materials using Corner‑Cracked (CC) test pieces. The standard prescribes crack monitoring by a direct-current potential‑drop system, correction of crack depths using marker bands on the fracture surface, and reporting of results as a function of the crack‑tip stress‑intensity range (∆K) with associated crack depths and applied stress levels.

Key topics and technical requirements

- Test specimen: Corner‑crack (CC) test piece geometry for square/rectangular cross sections; reference point for crack depth is the original corner (zero‑point offset must be defined when corners are rounded).

- Crack monitoring: Continuous measurement using a potential‑drop technique; optical or post‑test measurements (micrography / SEM) used to correct/calibrate potential measurements via marker bands.

- Data and output: Fatigue crack growth rate da/dN correlated with ∆K (∆K = Kmax − Kmin); normalized crack depth a/W and reporting of R ratio and test stress level.

- Loading and control: Feedback load‑controlled servohydraulic or electromechanical systems capable of smooth start, stopping and restarting without overload; accuracy and recording requirements (force measurement accuracy examples: ±0.5 %; recording accuracy better than 0.25 %).

- Alignment and calibration: Load‑train alignment per ASTM E1012; instruments and thermocouples calibrated regularly (instruments annually; thermocouples commonly every six months).

- Environment and temperature: Temperature measurement with calibrated thermocouples (Type R or K) mounted near the notch; furnace and grip heating for elevated‑temperature tests with recorded tolerances.

- Applicability limits: Intended for materials where the plastic zone at the crack tip remains small relative to section (linear‑elastic behaviour); results can also inform cases where Kmax or other parameters better describe growth.

Applications - who uses EN 3873:2010

- Aerospace materials and structural engineers evaluating fatigue life of components (holes, corners, turbine disk features).

- Fatigue testing laboratories and materials research groups performing da/dN vs ∆K characterization.

- NDT and inspection planners using crack‑growth data to define inspection intervals and detectability requirements.

- OEMs, certification bodies and failure‑investigation teams requiring standardized, reproducible crack‑growth data for metallic alloys and heat treatments.

Related standards (normative references)

- EN 2002‑002 (tensile testing at elevated temperature)

- EN ISO 7500‑1 (verification/calibration of testing machines)

- EN ISO 3785 (specimen axis designation)

- ASTM E647‑2008 (fatigue crack growth rates)

- ASTM E1012‑2005 (alignment verification)

Keywords: EN 3873:2010, corner‑crack, CC test pieces, fatigue crack growth rates, potential‑drop, ∆K, aerospace testing, metallic materials.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 3873:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Aerospace series - Test methods for metallic materials - Determination of fatigue crack growth rates using Corner-Cracked (CC) test pieces". This standard covers: This standard specifies the requirements for determining fatigue crack growth rates using the corner-crack (CC) test piece. Crack development is measured using a potential-drop system, and the calculated crack depths can be corrected via marker bands created on the fracture surface during the test. Results are expressed in terms of the crack-tip stress-intensity range (K), with crack depths and test stress level noted.

This standard specifies the requirements for determining fatigue crack growth rates using the corner-crack (CC) test piece. Crack development is measured using a potential-drop system, and the calculated crack depths can be corrected via marker bands created on the fracture surface during the test. Results are expressed in terms of the crack-tip stress-intensity range (K), with crack depths and test stress level noted.

EN 3873:2010 is classified under the following ICS (International Classification for Standards) categories: 49.025.05 - Ferrous alloys in general; 49.025.15 - Non-ferrous alloys in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 3873:2010 has the following relationships with other standards: It is inter standard links to EN ISO 7500-1:2018, EN 2002-002:2005, EN ISO 3785:2023, EN 4800-001:2010, EN 4800-005:2025, EN 4800-005:2010, EN 4800-001:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 3873:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Aeronavtika - Preskusne metode za kovinske materiale - Ugotavljanje stopnje rasti razpok, ki nastanejo zaradi utrujenosti, z uporabo preskusnih kosov z razpokami na robovih (CC)Luft- und Raumfahrt - Prüfverfahren für metallische Werkstoffe - Ermittlung der Rißfortschritts- Geschwindigkeit an Cornercrackproben (Eckanris)Série aérospatiale - Méthode d'essais applicables aux matériaux métalliques - Détermination de la vitesse de propagation de fissure en fatigue à l'aide d'éprouvettes avec fissure en coinAerospace series - Test methods for metallic materials - Determination of fatigue crack growth rates using Corner-Cracked (CC) test pieces49.025.05Železove zlitine na splošnoFerrous alloys in generalICS:Ta slovenski standard je istoveten z:EN 3873:2010SIST EN 3873:2011en01-maj-2011SIST EN 3873:2011SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 3873

November 2010 ICS 49.025.05; 49.025.15 English Version

Aerospace series - Test methods for metallic materials - Determination of fatigue crack growth rates using Corner-Cracked (CC) test pieces

Série aérospatiale - Méthodes d'essais applicables aux matériaux métalliques - Détermination de la vitesse de propagation de fissure en fatigue à l'aide d'éprouvettes avec fissure en coin

Luft- und Raumfahrt - Prüfverfahren für metallische Werkstoffe - Ermittlung der Rißfortschritts-Geschwindigkeit an Cornercrackproben (Eckanris) This European Standard was approved by CEN on 30 July 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 3873:2010: ESIST EN 3873:2011

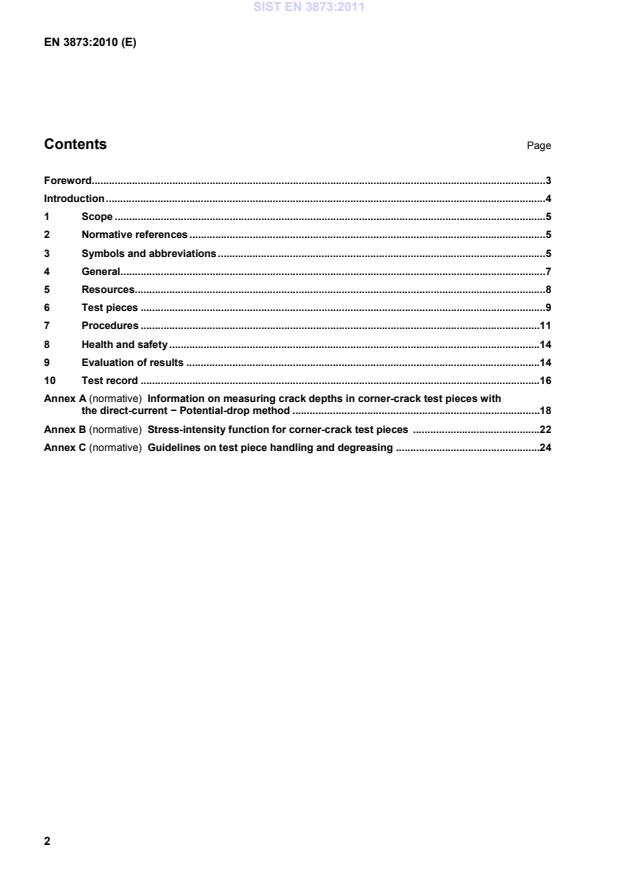

Information on measuring crack depths in corner-crack test pieces with the direct-current − Potential-drop method . 18Annex B (normative)

Stress-intensity function for corner-crack test pieces

............................................ 22Annex C (normative)

Guidelines on test piece handling and degreasing . 24SIST EN 3873:2011

1) Published by: American Society for Testing and Materials (ASTM), http://www.astm.org/. SIST EN 3873:2011

Effective range of K, due to crack closure-induced reduction applied ∆K (in MPa √m) ∆Kth Fatigue crack growth threshold

The asymptotic value of ∆K for which da/dN approaches zero. For most materials the operational threshold is defined as the ∆K corresponding to 10-7 m/cycle. When reporting ∆Kth, the corresponding lowest decade of near threshold data used in its determination must be given C Normalized K-gradient C = (1/K × dK/da). For load-shedding to attain a desired initial ∆K, C defines the fractional rate of change of K with increasing crack depth a.

C = 1/K × dK/da = 1/Kmax. × dKmax./da = 1/Kmin. × dKmin./da = 1/∆K × d∆K /da, (in mm-1) N Number of loading cycles Stress cycle (fatigue cycle, load cycle) is the smallest segment of the loading waveform spectrum which is repeated periodically N'

Number of stress cycles between two marker cycles Nm Number of stress cycles in a marker cycle ∆N Stress cycle difference r Notch radius (expressed in millimetres) Fm Mean force (expressed in kilonewtons) Fmax. Maximum tensile force applied to the test piece during a cycle (expressed in kilonewtons) Fmin. Minimum tensile force (in kilonewtons) ∆F Force range (in kilonewtons), ∆F = Fmax. − Fmin. q Resolution of crack depth measuring system (expressed in millimetres) R Force ratio (= Fmin./Fmax. = Kmin./Kmax.) R*m Ratio Fmin./Fmax. during a marker cycle Rp 0,2 % offset yield strength (Proof Stress Rp0,2) at test temperature (expressed in megapascals) SIST EN 3873:2011

(3) 4.6 The reference point for measuring the crack depth with CC test pieces is the original corner of the test piece, determined by the projections of the sides of the test piece on the fracture surface adjacent to the notch. Possible rounding of the corner during test piece manufacture will result in this reference point being no longer on the fracture surface. This rounding must be determined to obtain a “Zero-point offset” between the reference point and the rounded corner where the measurement wire is welded, which is used in the calibration of the potential-drop measurements. SIST EN 3873:2011

K = 102aWYF×××π (7) where a is the crack depth (expressed in centimetres); W

is the test piece width (expressed in centimetres); F

is the force (expressed in kilonewtons); K

is the stress-intensity (expressed in MPa√m). A check for this calculation may be made with the following input and results:

a

1 mm (0,1 cm);

W

0,8 cm;

F

32 kN. here Y 0,691; K 19,365. 6.3 Test piece size requirements For the results to be valid, the test pieces are to be subjected to a stress within the elasticity range of the material for all values of the applied load.

If hold times at maximum load are used during CGR testing at elevated temperatures, the initial 0,05 mm to 0,1 mm of growth data may be influenced by such transient effects, and should be considered as suspect, especially if a gradual transition to higher rates is evident after switching to a hold time. NOTE If reduction of the frequency from precracking to test conditions allows Fmax. to increase, due to test machine control characteristics, then all frequency changes, including stops and restarts, should be immediately preceded by a precautionary 10 % reduction in Fmax. and Fmin. to avoid Fmax. overshoot, and later increased. d) The potential at this reference crack depth and Fmin. is recorded and, if precracking was performed at RT the test piece is heated, still at Fmin., to the test temperature, if elevated temperature tests are required. If so, the potential at the test temperature is recorded and used to obtain the temperature correction coefficient

Temp.)(Test (RT)VVYooTC= (10) This coefficient may be used to correct the potentials measured, for use in the crack depth equation (see Annex A). Optimally, the test piece should be precracked at the test temperature. The reference potential is taken at RT in the notched condition, or after heating, to obtain YTC. A different potential-drop calibration will be necessary, however, due to differences between potentials for notches and cracks of the same depths. If the desired R-ratio is higher than 0,1, further cycling must now be performed to reach the desired R-ratio, reducing the loading range by 10 % after each 0,1 mm of crack extension by increasing the minimum load. For materials with Rp ~ 1 000 MPa, and for low R-ratios, reductions may be made after each 0,05 mm of extension, permitting the use of higher initial precracking stress-intensities, or enabling the possibility to reach lower stress-intensities for the initial testing con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...